Spiral blade type small-size air bubble separation device

A bubble separation, rotary vane technology, applied in separation methods, liquid degassing, climate sustainability, etc., can solve the problem of inability to achieve complete gas separation, difficult to meet molten salt reactor degassing and safety requirements, unfavorable separation, etc. problems, to achieve the effect of low cost, recovery of part of the pressure energy, and reduction of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

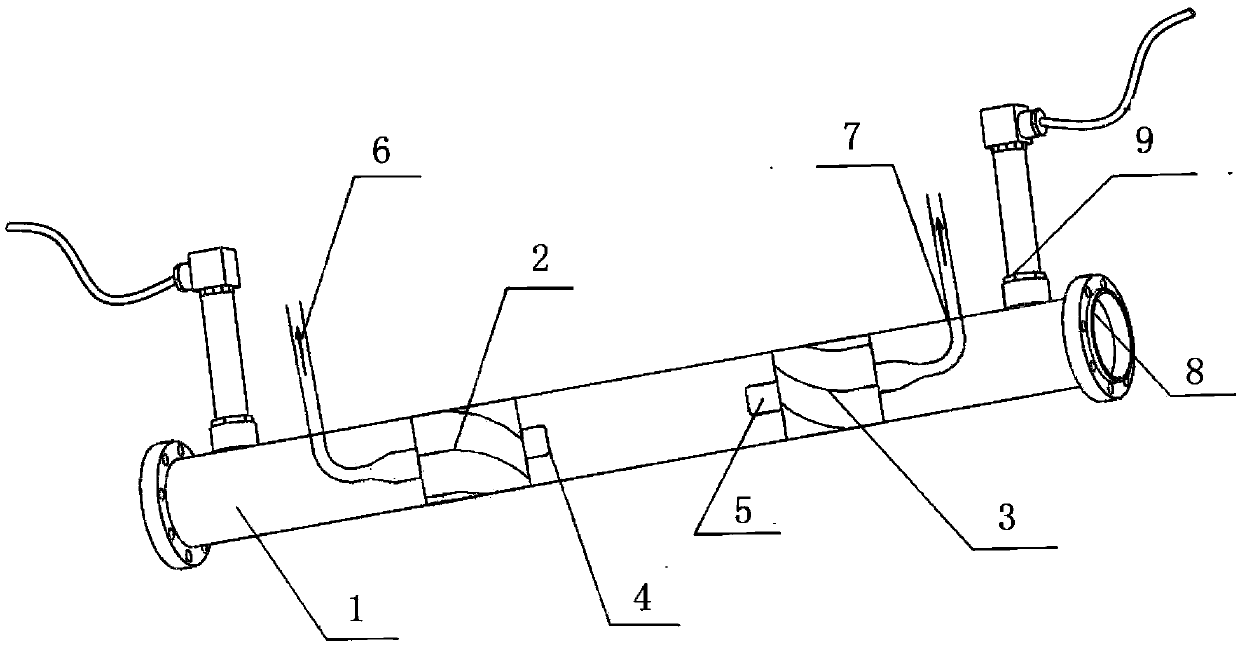

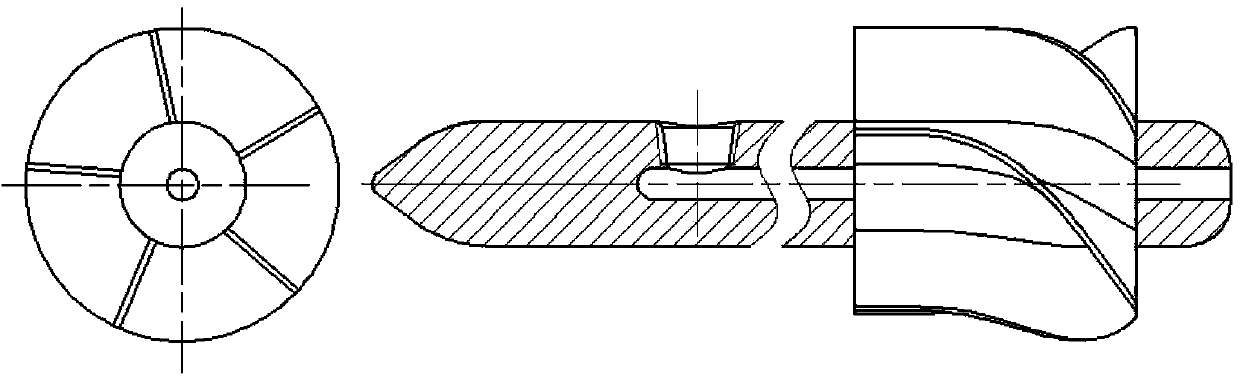

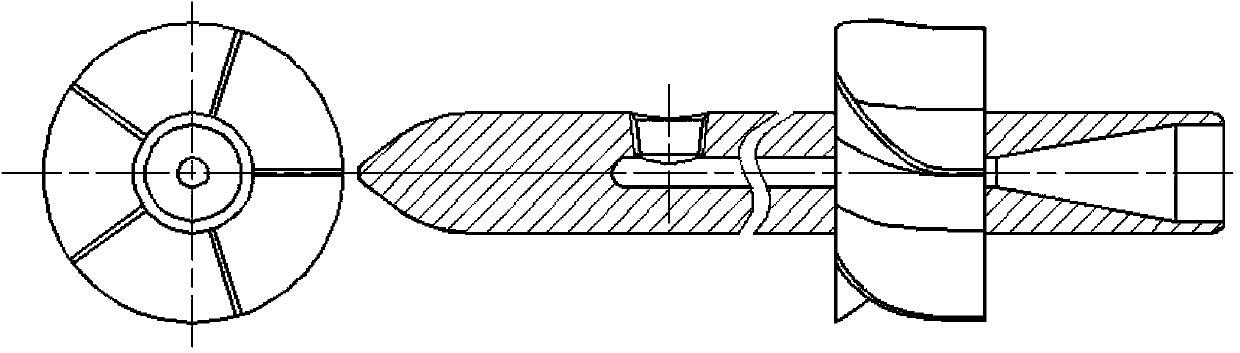

[0024] combine Figure 1~4 , the present invention comprises: cylindrical shell 1, muddy blade 2, recovery blade 3, muddy impeller shaft 4, recovery impeller shaft 5, front air outlet pipe 6; rear air outlet pipe 7, flange plate 8 for connecting with pipeline and pressure sensor9. The mixing blade 2 and the mixing impeller shaft 4 in the center form the mixing impeller, which is located at the front end of the cylinder 1. The center of the mixing impeller shaft 4 has a hole and is connected with the front outlet pipe 6 for leading out the separated gas; the recovery blade 3 and its center The recovery impeller wheel shaft 5 forms the recovery impeller, which is located at the rear end of the cylinder body 1. The center of the recovery impeller wheel shaft 5 is opened and connected with the rear air outlet pipe 7, which is also used for deriving the separated gas;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com