Heating magnetically orientable pigment in a printing process

A kind of printing equipment and viscous technology, which is applied in the direction of magnetic coating, printing, printing machines, etc., can solve the problems of low satisfaction of thin sheets, high-viscosity paste ink arrangement cannot be implemented, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

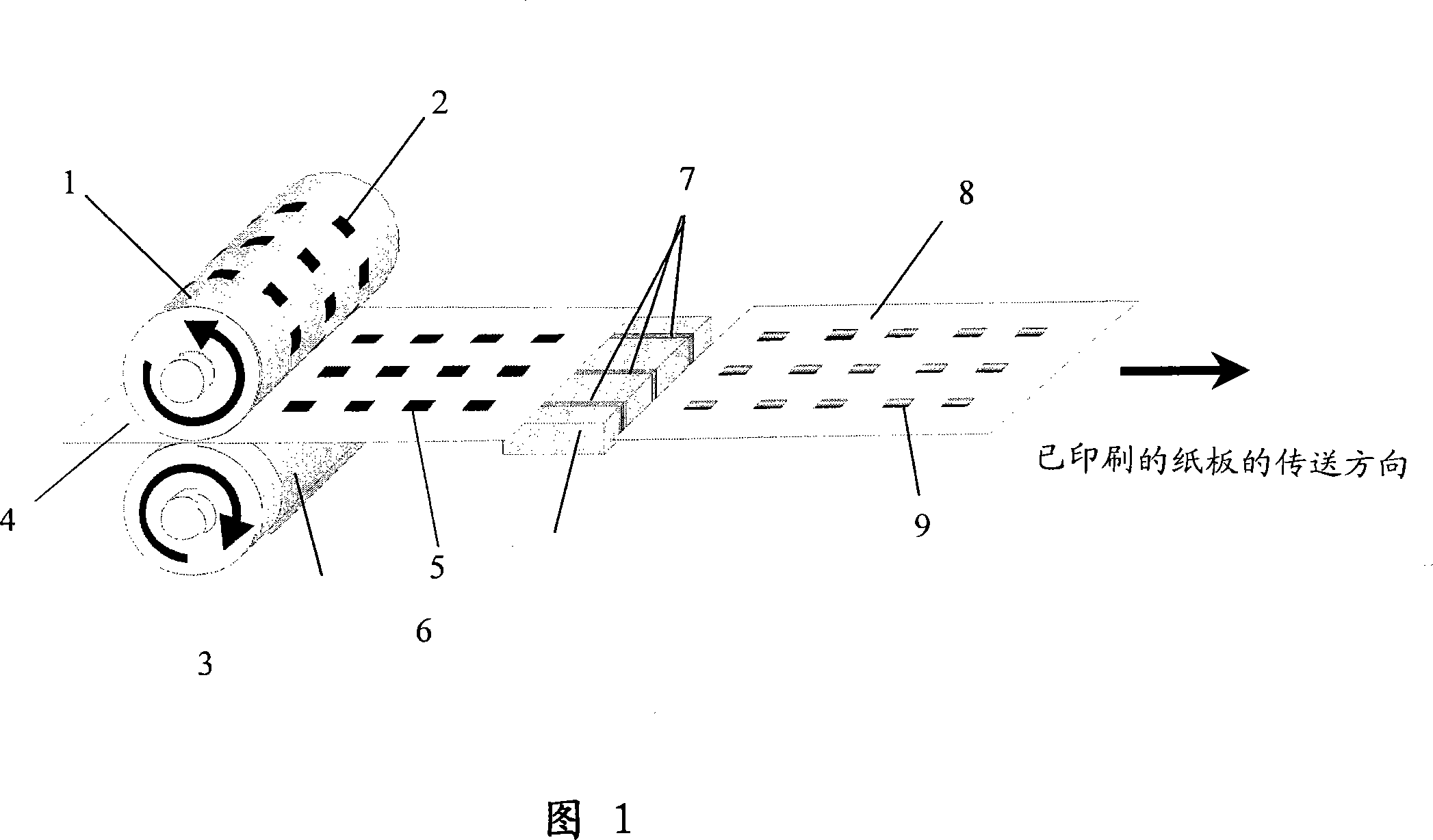

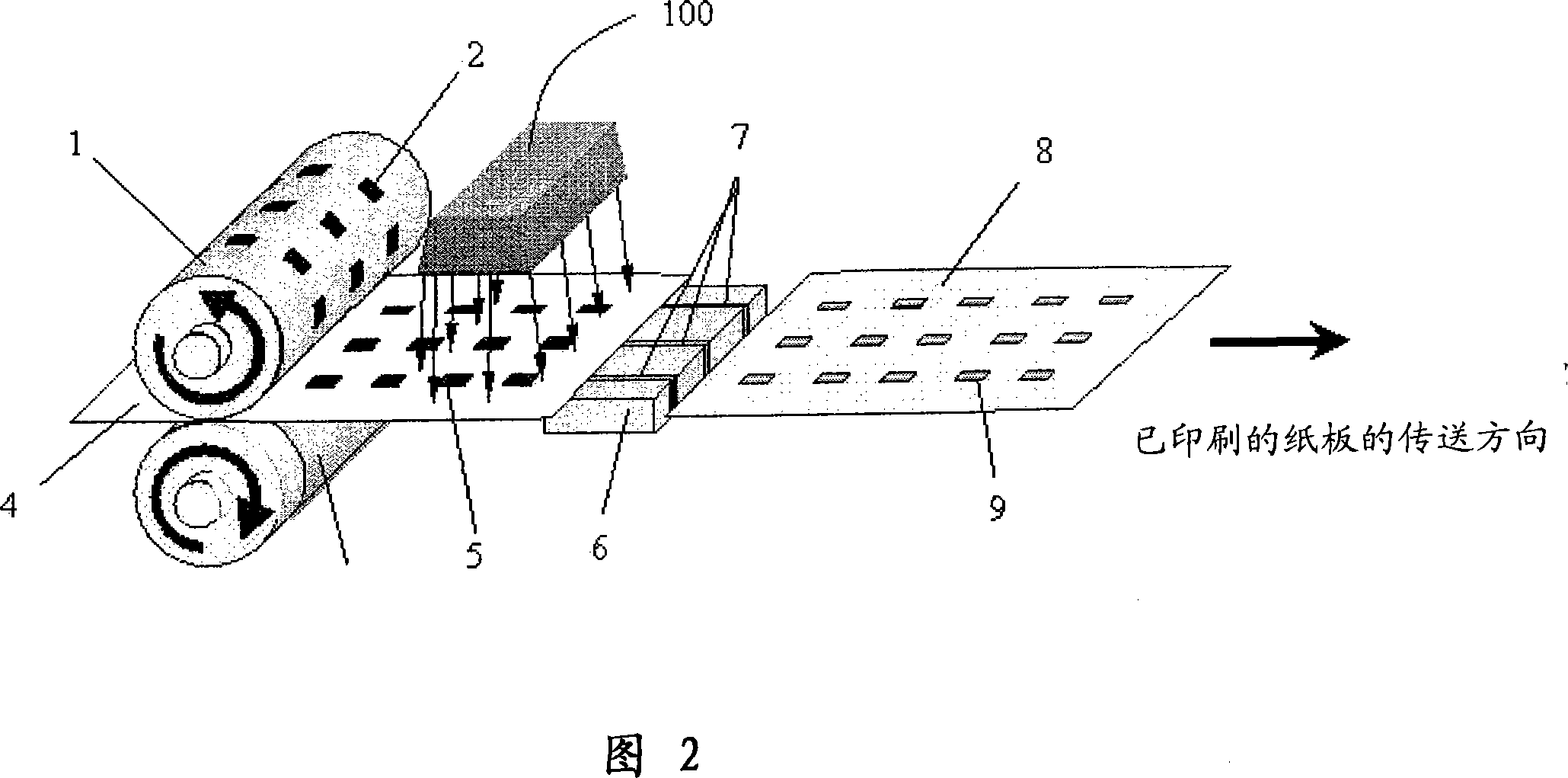

[0036] [28] A new process is provided for the printing of security and high value documents which allows a paste-like ink with magnetic flakes or flakes dispersed therein to be oriented in a magnetic field. The pasty viscous ink preferably comprises optical interference pigment flakes, or reflective pigment flakes, or single or multilayer diffractive pigment flakes with magnetic properties. The invention is equally applicable in any alignment method in which the flakes can be aligned in a preferred direction using any applicable force. For example, particles that move in an electric or magnetic field that can force special effect flakes in a desired direction can be used in the present invention where paste-like printing inks with flakes can temporarily reduce tack during alignment.

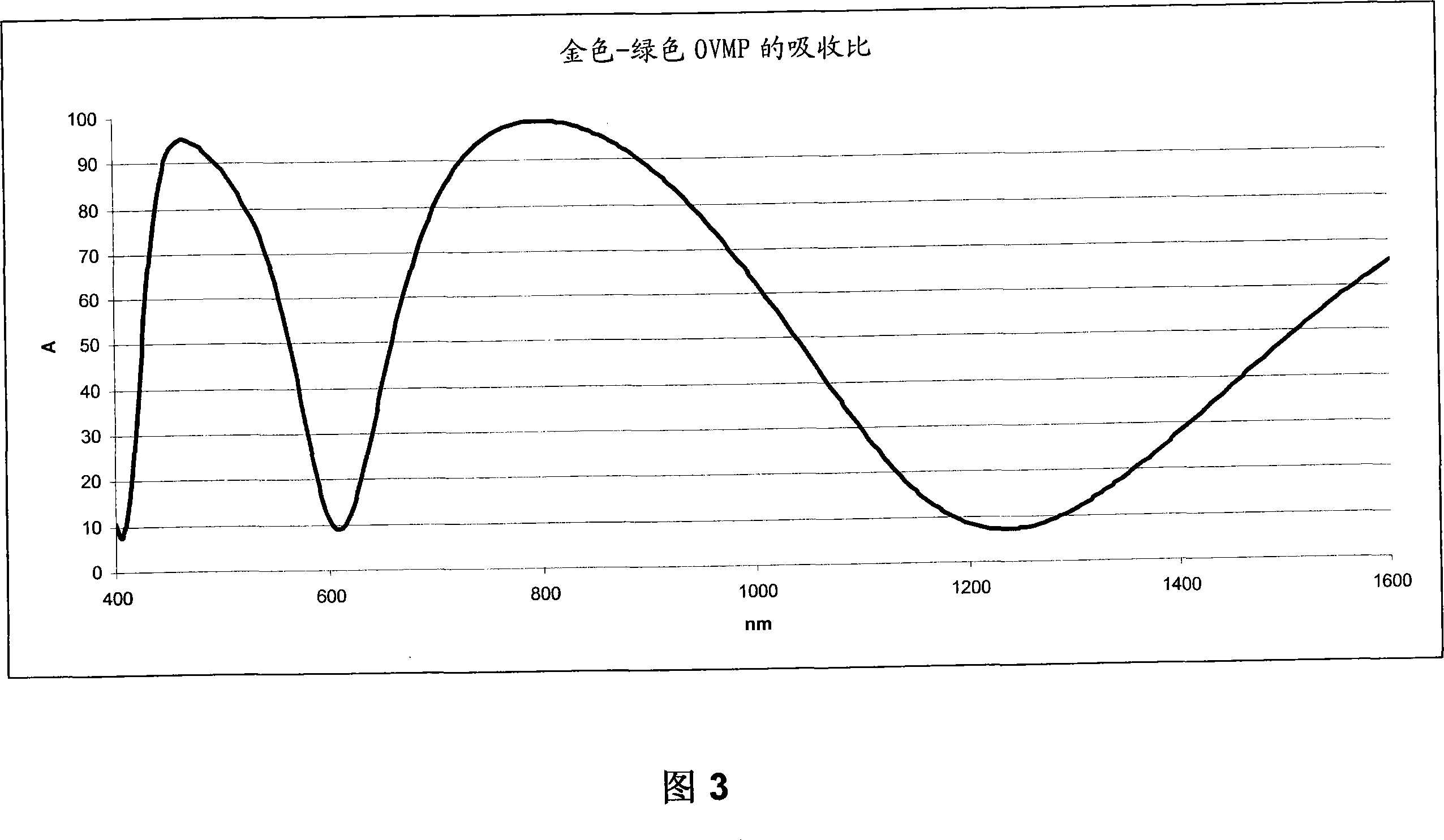

[0037] [29] In one example, the interference pigment is an optically variable pigment comprising a thin layer of the aforementioned magnetic material. The pigments are dispersed in a highly visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com