Method for manufacturing mounting device and semiconductor device

A packaging device and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric heating devices, etc., can solve problems such as difficulty in properly heating semiconductor chips, and achieve the effects of heat input suppression and heat transfer suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

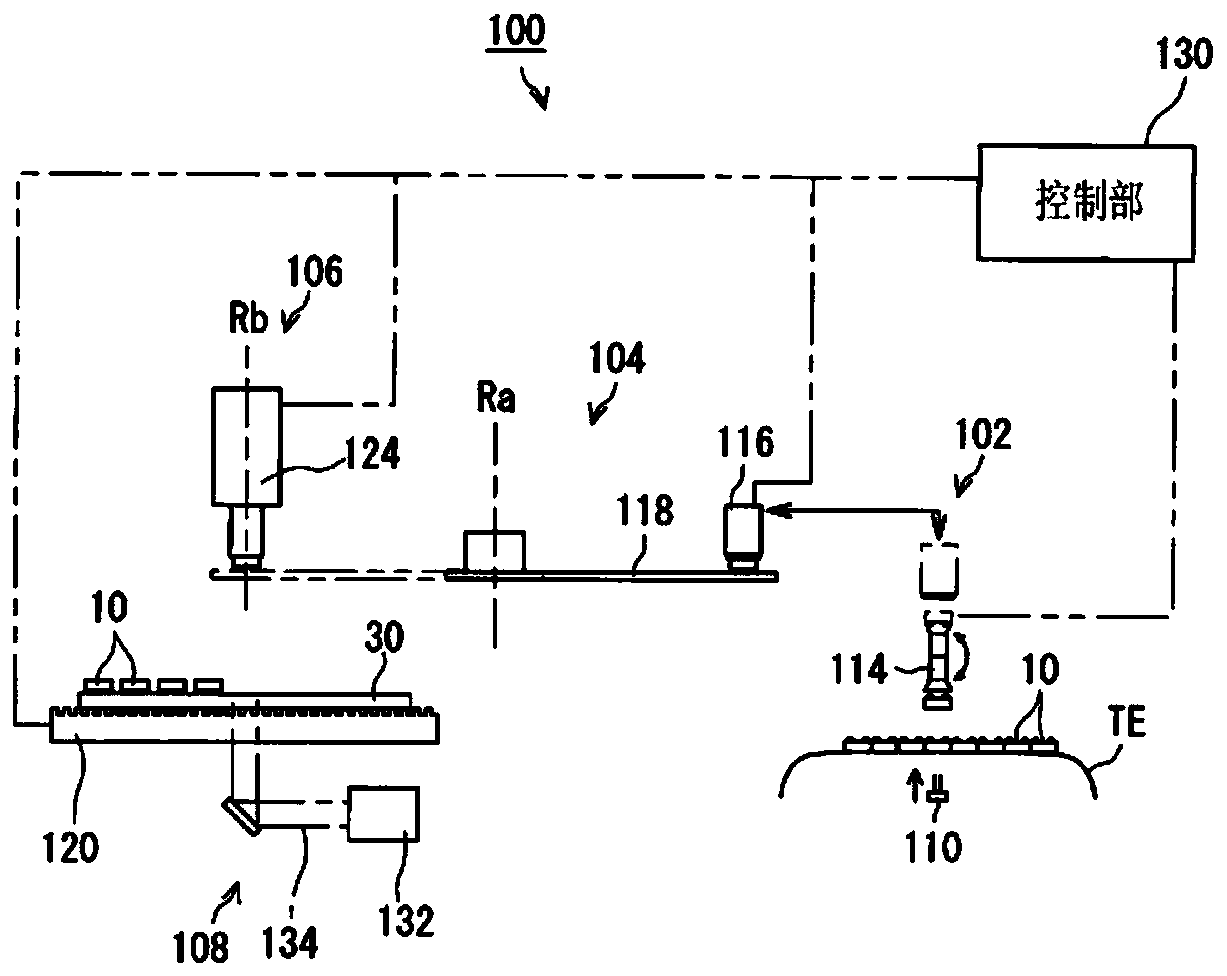

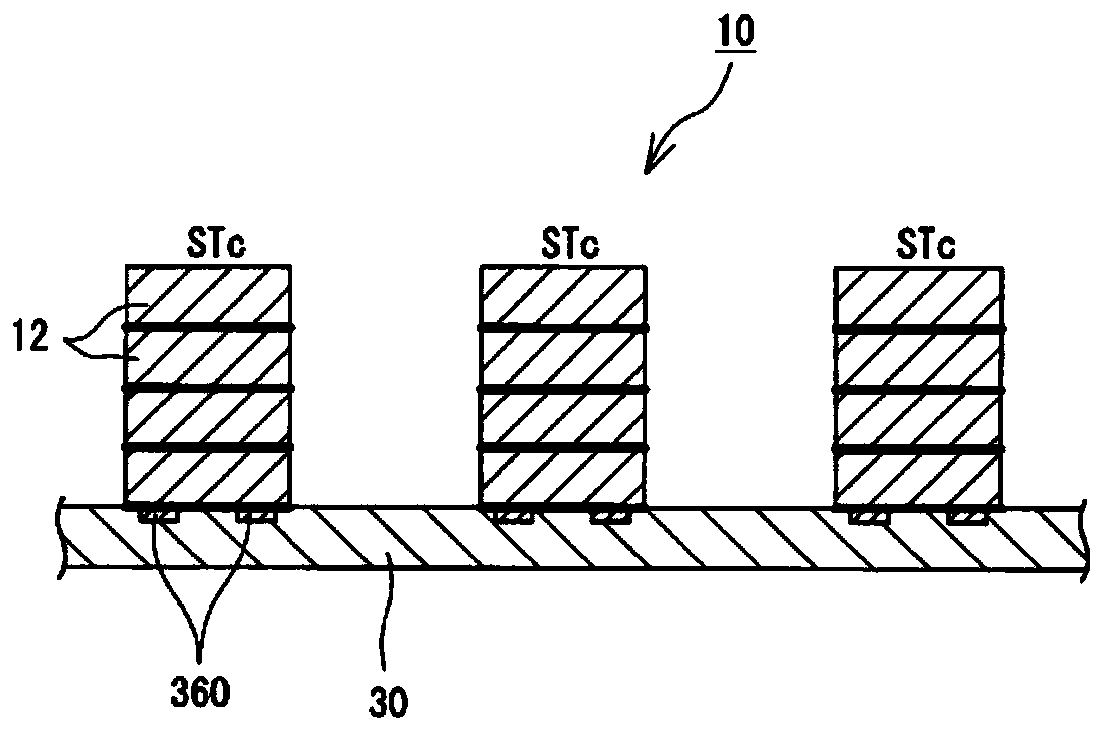

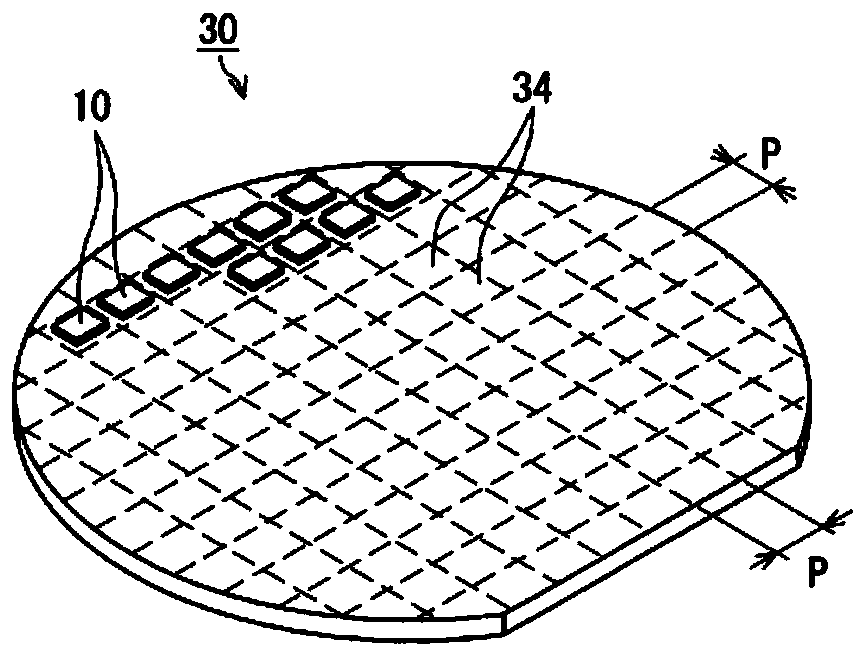

[0036] Hereinafter, a method of manufacturing a semiconductor device and the packaging device 100 will be described with reference to the drawings. figure 1 It is a figure which shows the structure of the packaging apparatus 100. The packaging device 100 is a device for packaging the semiconductor chip 12 on the substrate 30 . The above-mentioned packaging device 100 is a particularly preferable configuration when a plurality of semiconductor chips 12 are stacked and packaged. In addition, in the following description, among the laminated bodies in which a plurality of semiconductor chips 12 are stacked, a laminated body in which a plurality of semiconductor chips 12 constituting the laminated body is in a temporarily pressure-bonded state is referred to as a "temporary laminated body STt", The stacked body in which the plurality of semiconductor chips 12 are in the final pressure-bonded state is called "chip stacked body STc" for distinction.

[0037] The packaging apparatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com