Atmospheric pressure induced air dielectric barrier discharge (DBD) low temperature plasma generation device

A low-temperature plasma and air medium technology, applied in the direction of plasma, electrical components, etc., can solve the problems of high plasma airflow temperature, low surface treatment efficiency, difficult industrial application, etc., and achieve the effect of reducing electric field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

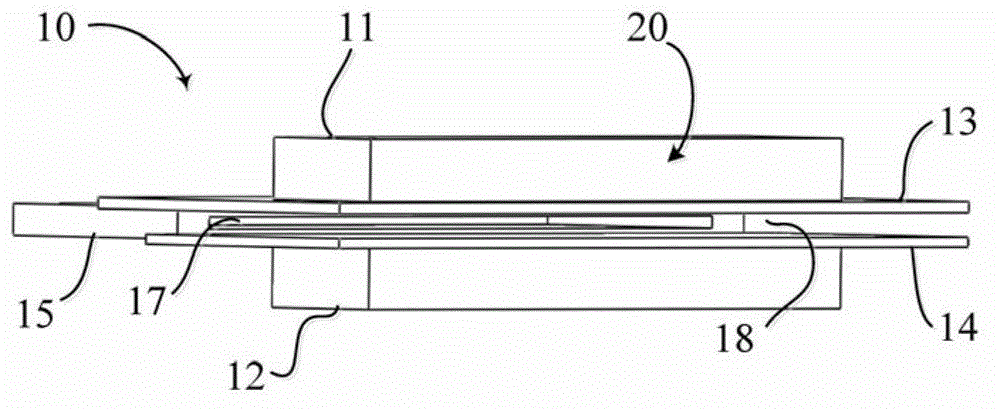

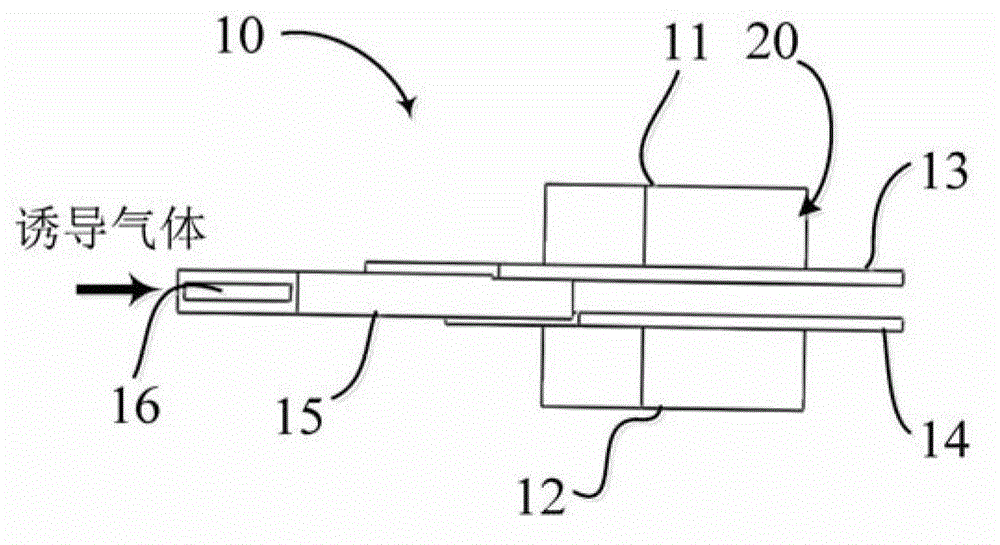

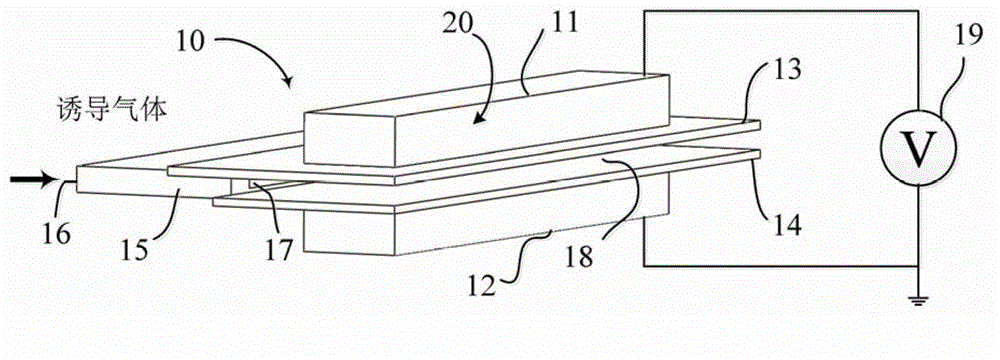

[0034]The atmospheric-pressure low-temperature plasma generating device provided by the present invention is composed of a discharge unit with a dielectric barrier discharge electrode structure, a slit cavity and a power supply device. The discharge unit includes two plate electrodes, namely a high-voltage electrode and a ground electrode. The electrodes are made of heat-resistant metal materials, such as aluminum, copper, tungsten, nickel, tantalum, platinum and alloys of these metals, but not limited to the above materials; It also includes an insulating dielectric layer (flat plate) covering the surface of the high-voltage electrode. The insulating dielectric layer can limit the magnitude of the discharge current between the two electrodes and prevent the glow-like discharge from turning into an arc or spark discharge. The insulating medium layer is made of insulating materials such as fiber, plastic, rubber, mica, glass, ceramics or polytetrafluoroethylene. The slit cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Voltage amplitude | aaaaa | aaaaa |

| Discharge current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com