Patents

Literature

49results about How to "Uniform surface treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

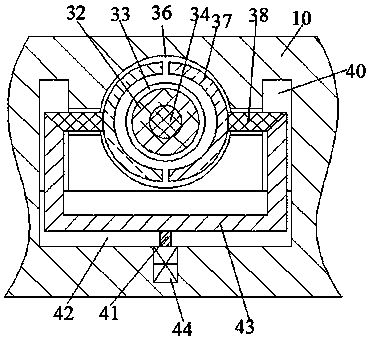

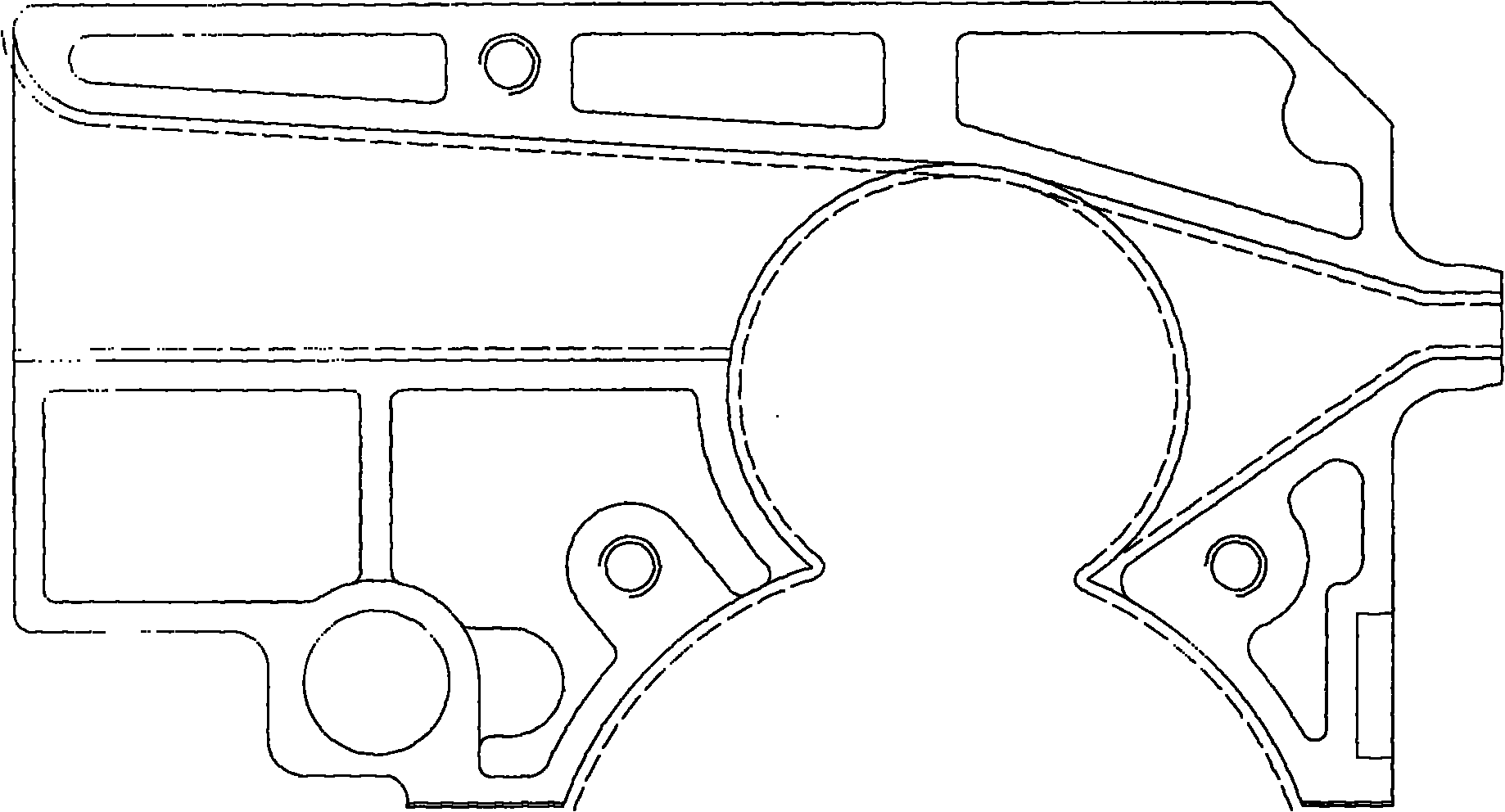

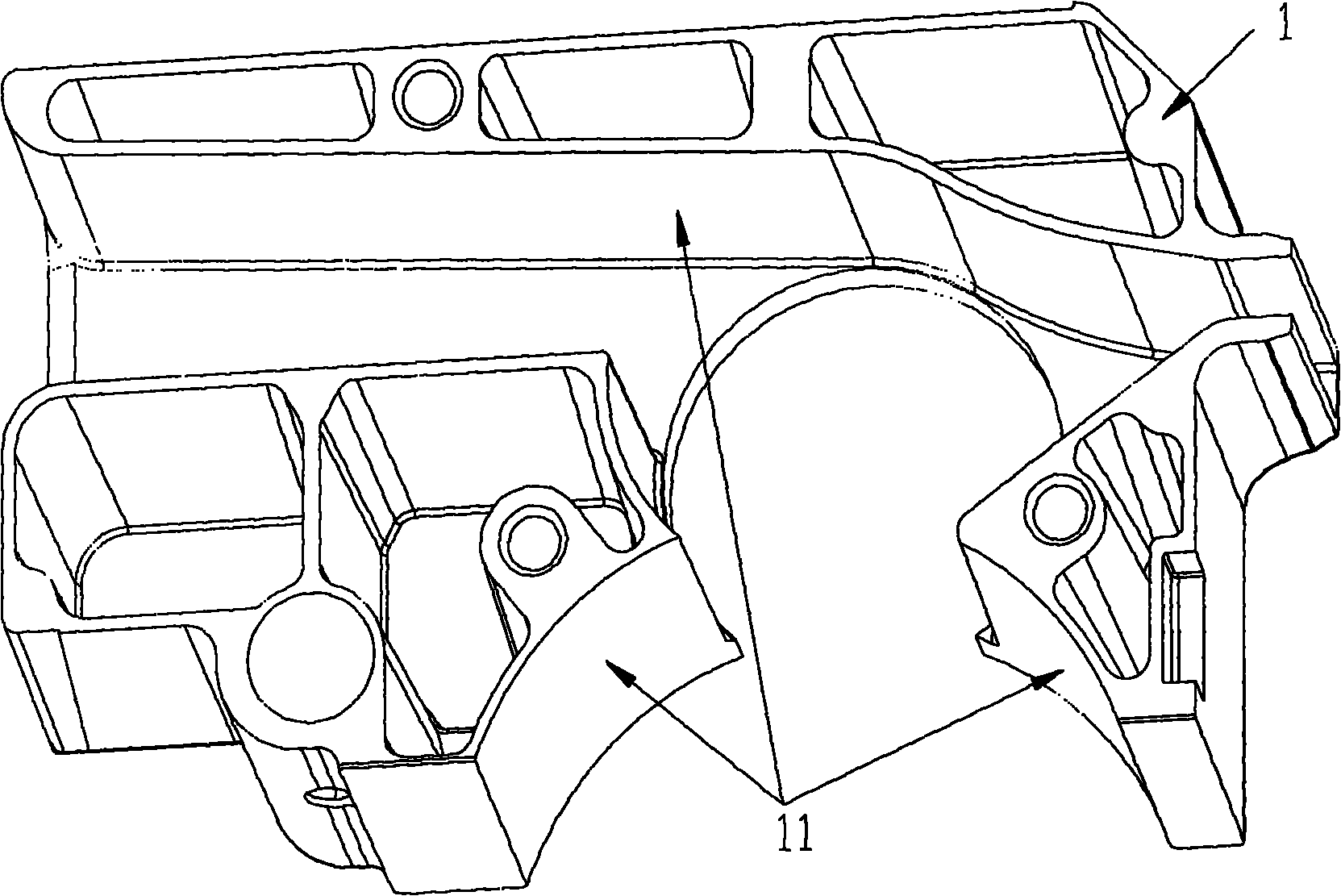

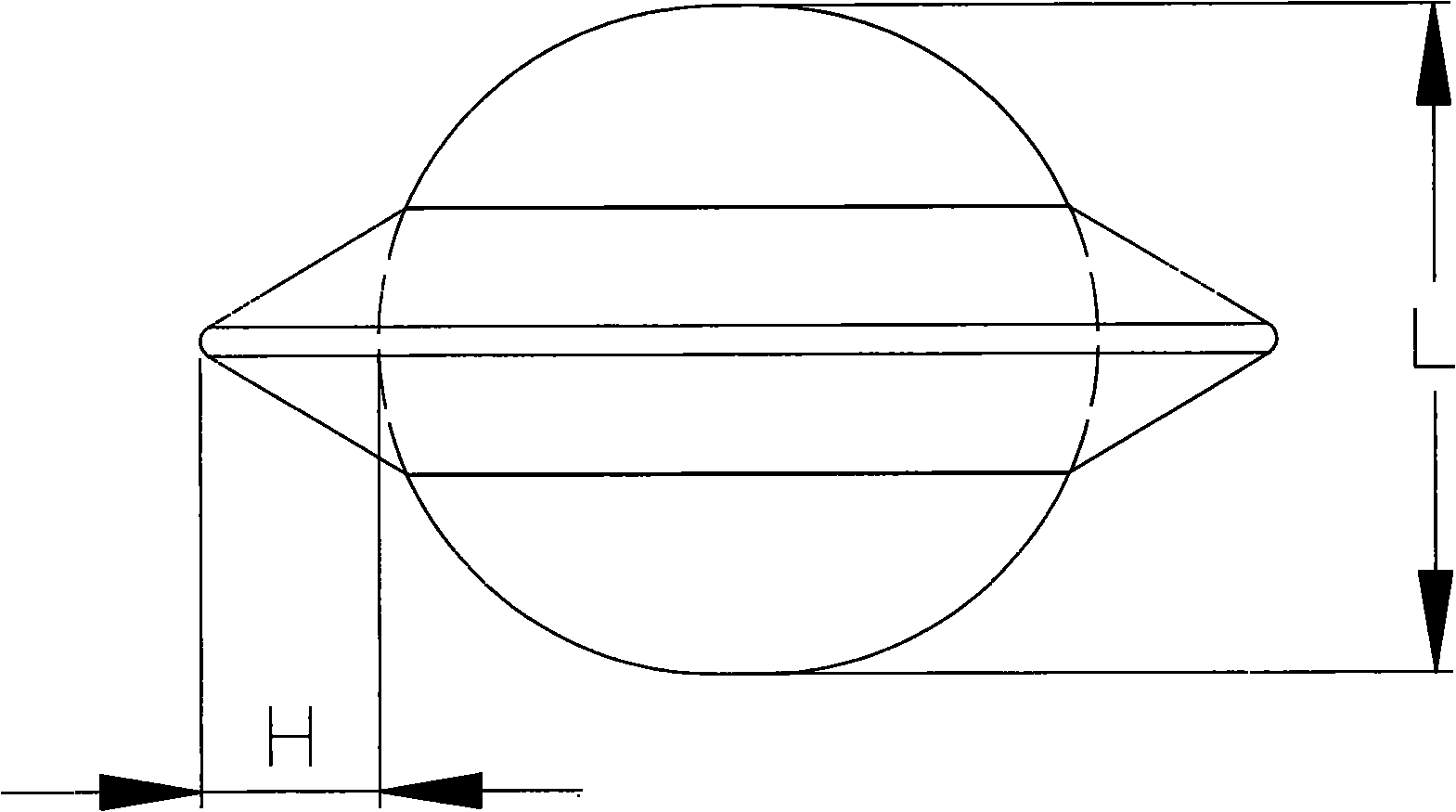

Battery cover member

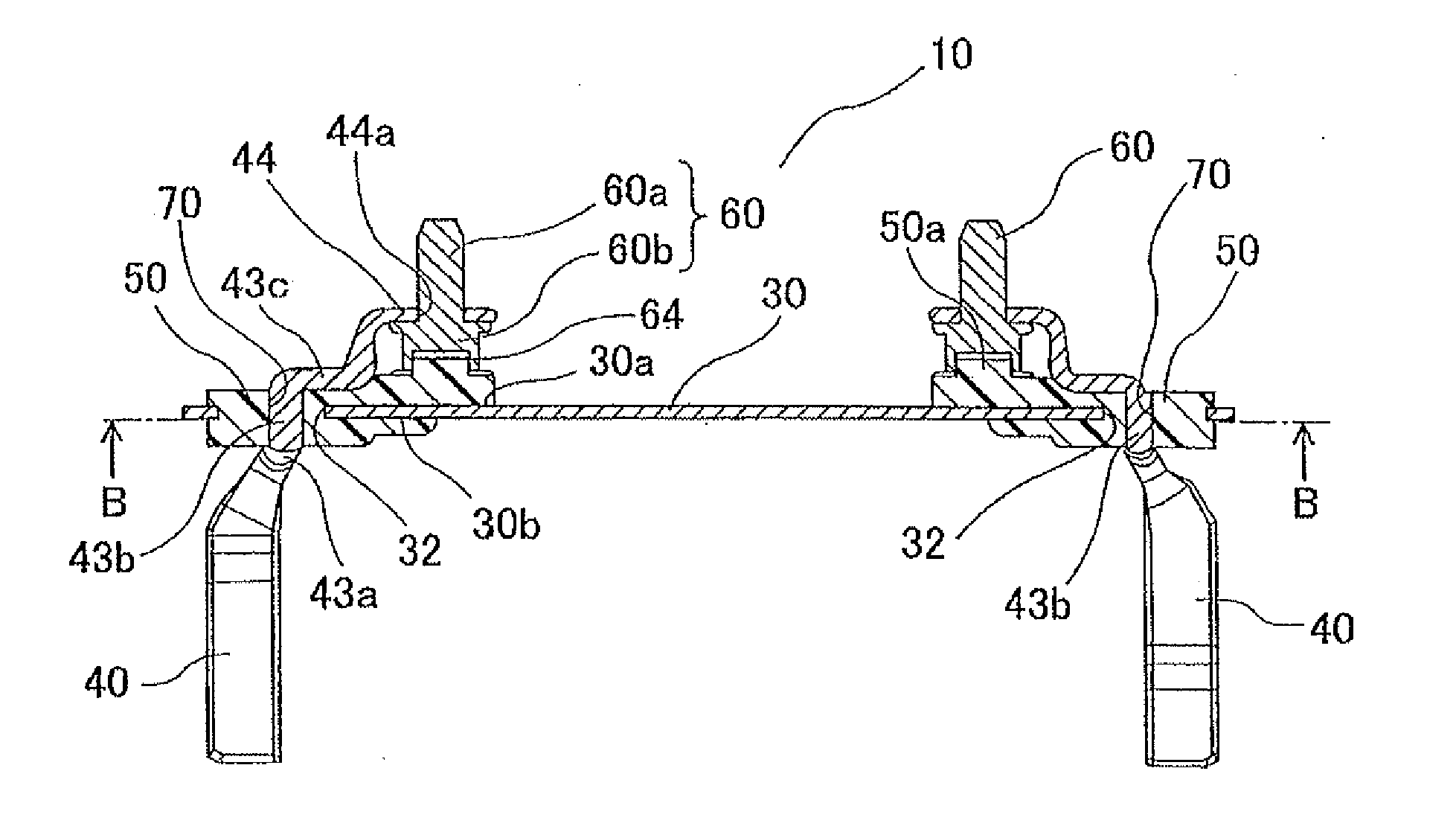

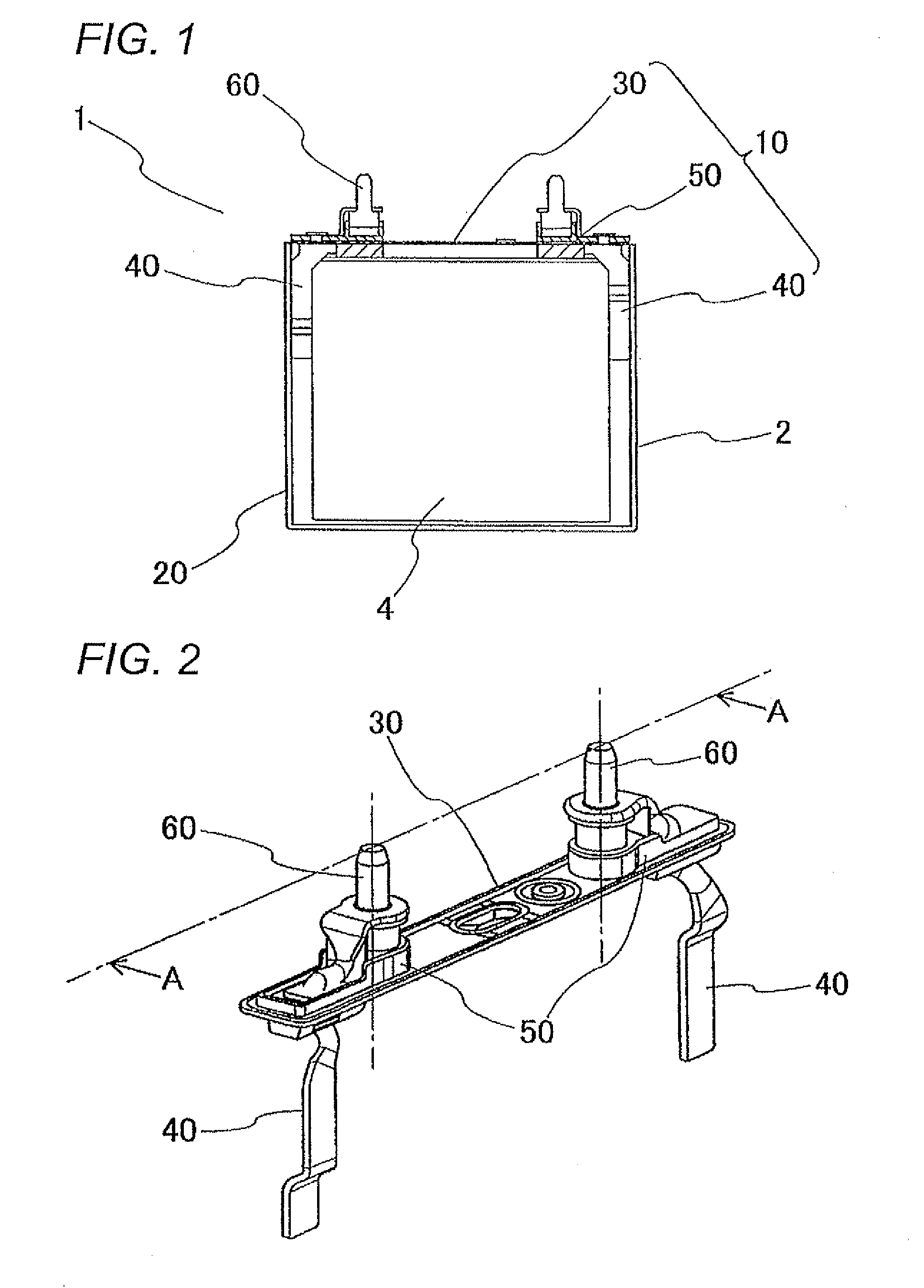

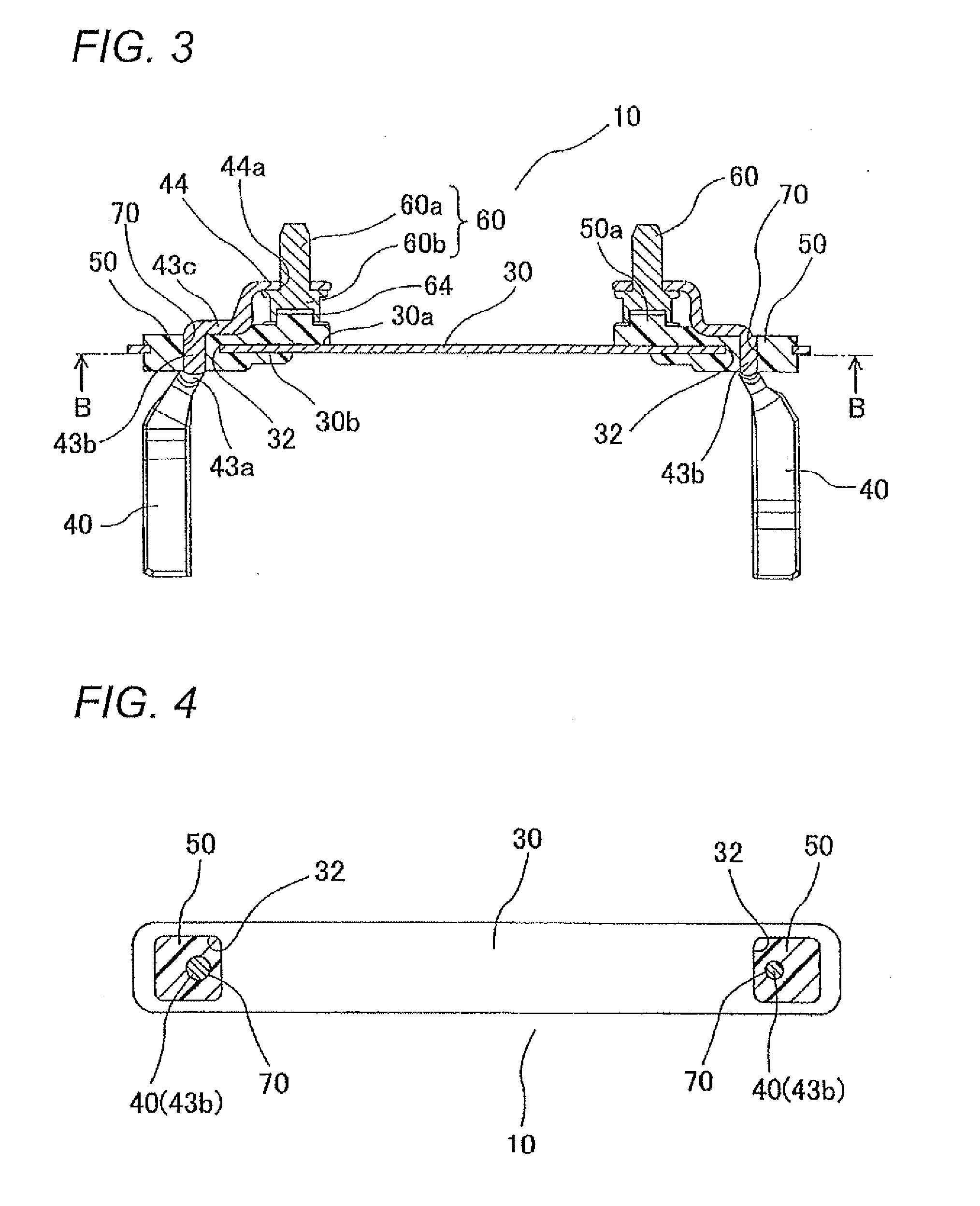

InactiveUS20110076553A1Improve sealing propertiesUniform surface treatmentSmall-sized cells cases/jacketsSecondary cellsMetallic electrodeEngineering

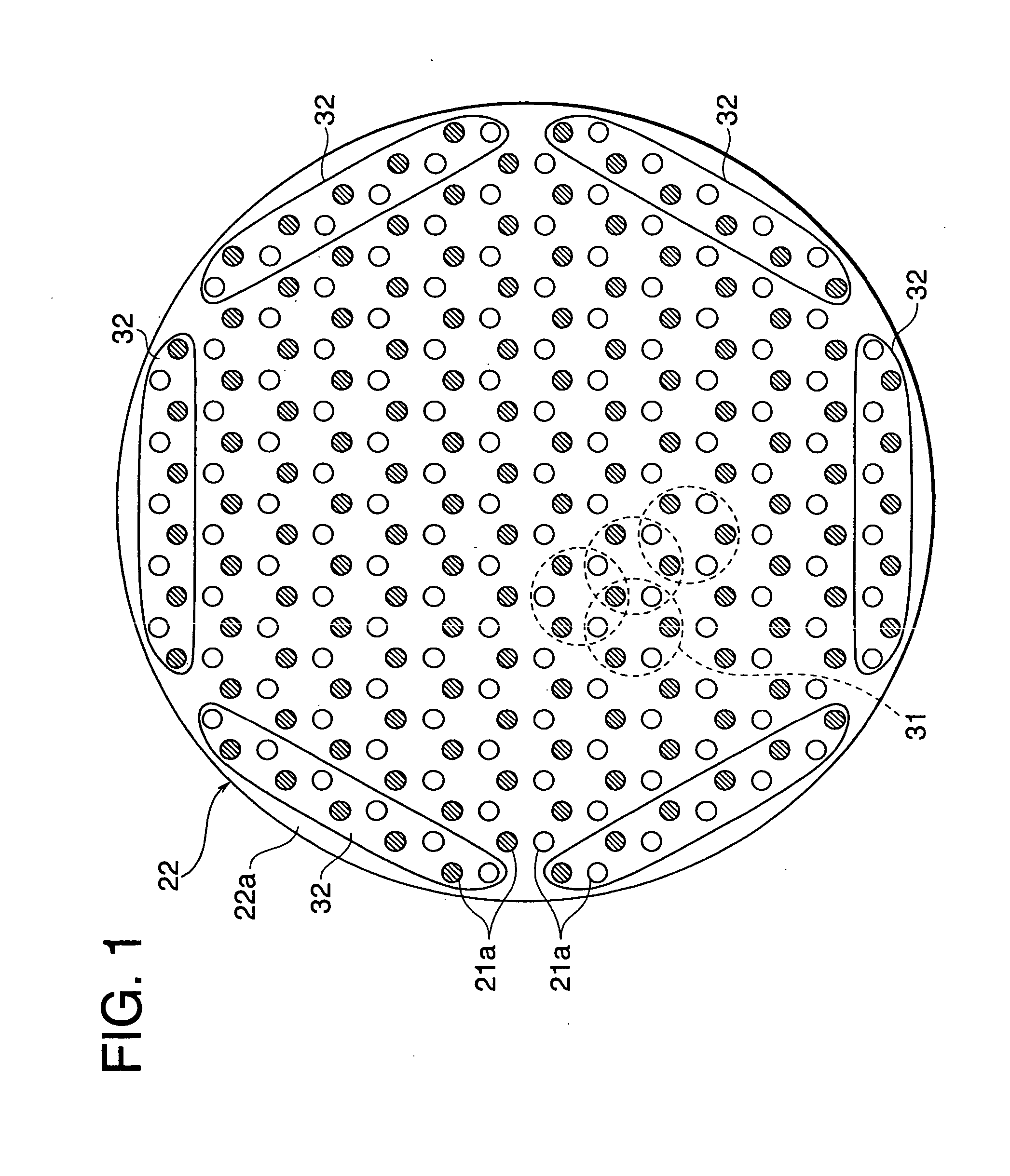

A battery cover member (10) of the present invention includes a metallic electrode terminal (40), a metallic cover member (30) having through holes (32), and an insulating resin member (50), in which the electrode terminals inserted into the through hole and the cover member are integrally bonded together by the insulating member, wherein at least a sealing area (70) of the electrode terminal that adheres to the insulating member is formed as a columnar shape or an elliptically columnar shape.

Owner:TOYODA GOSEI CO LTD

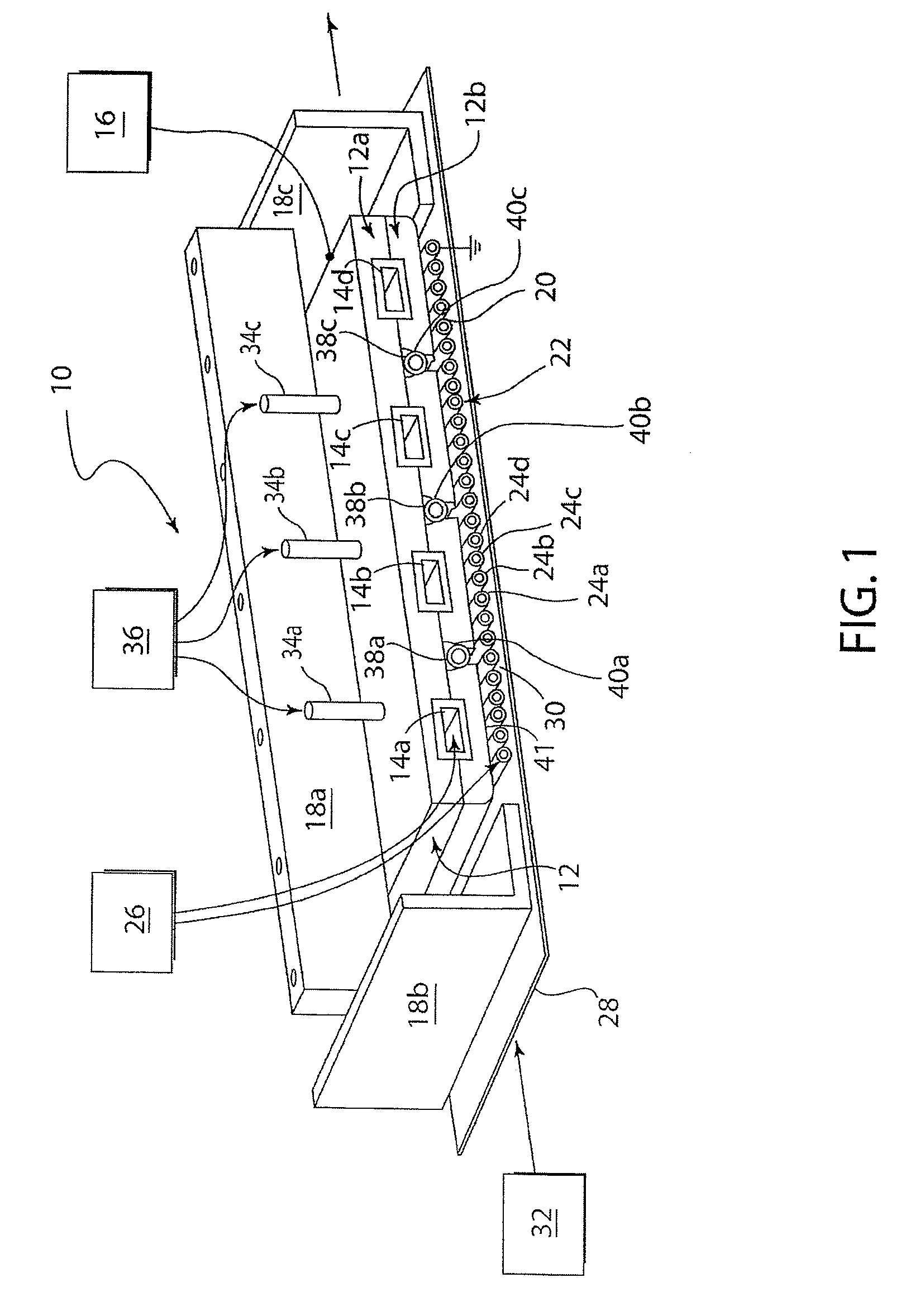

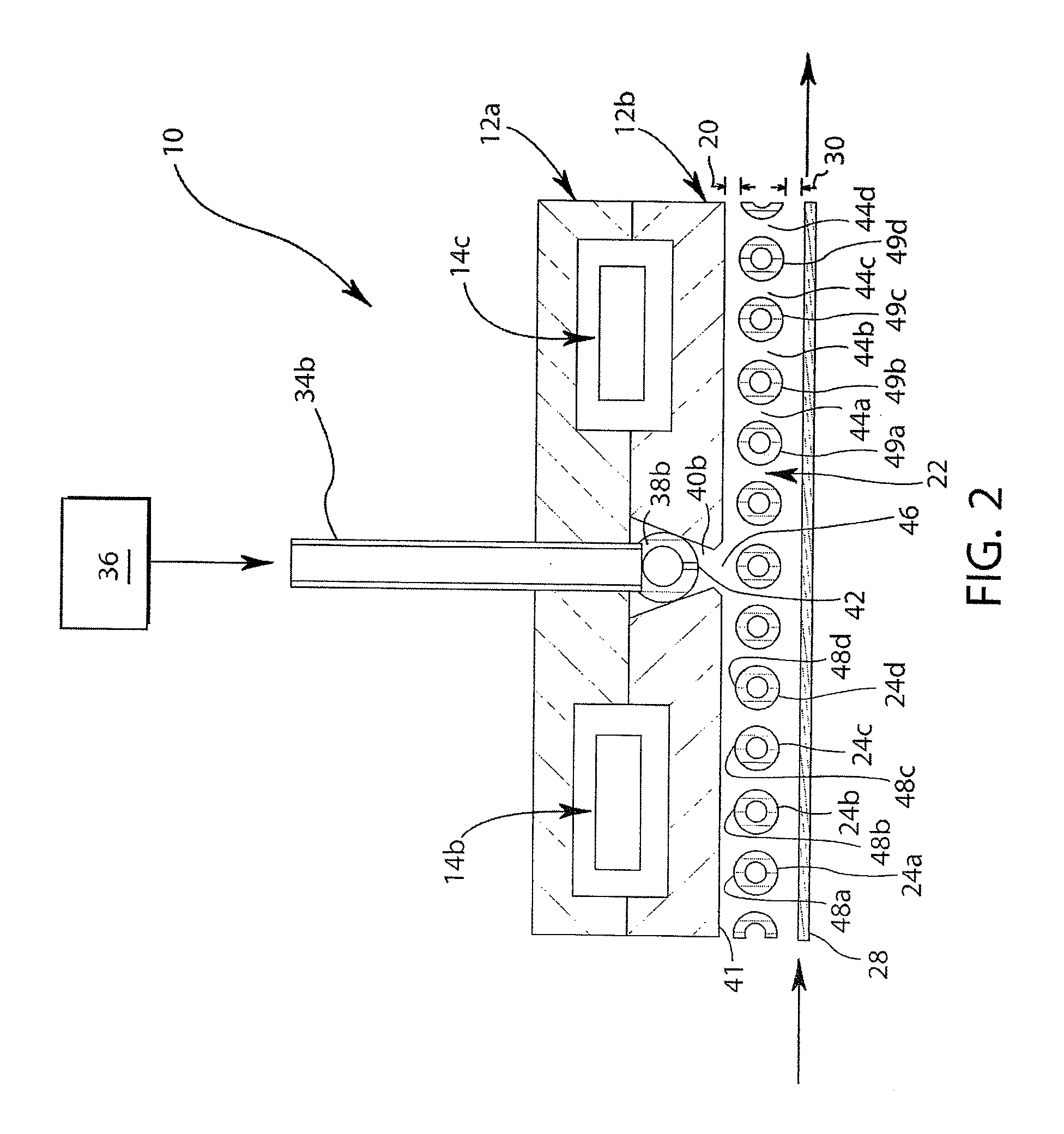

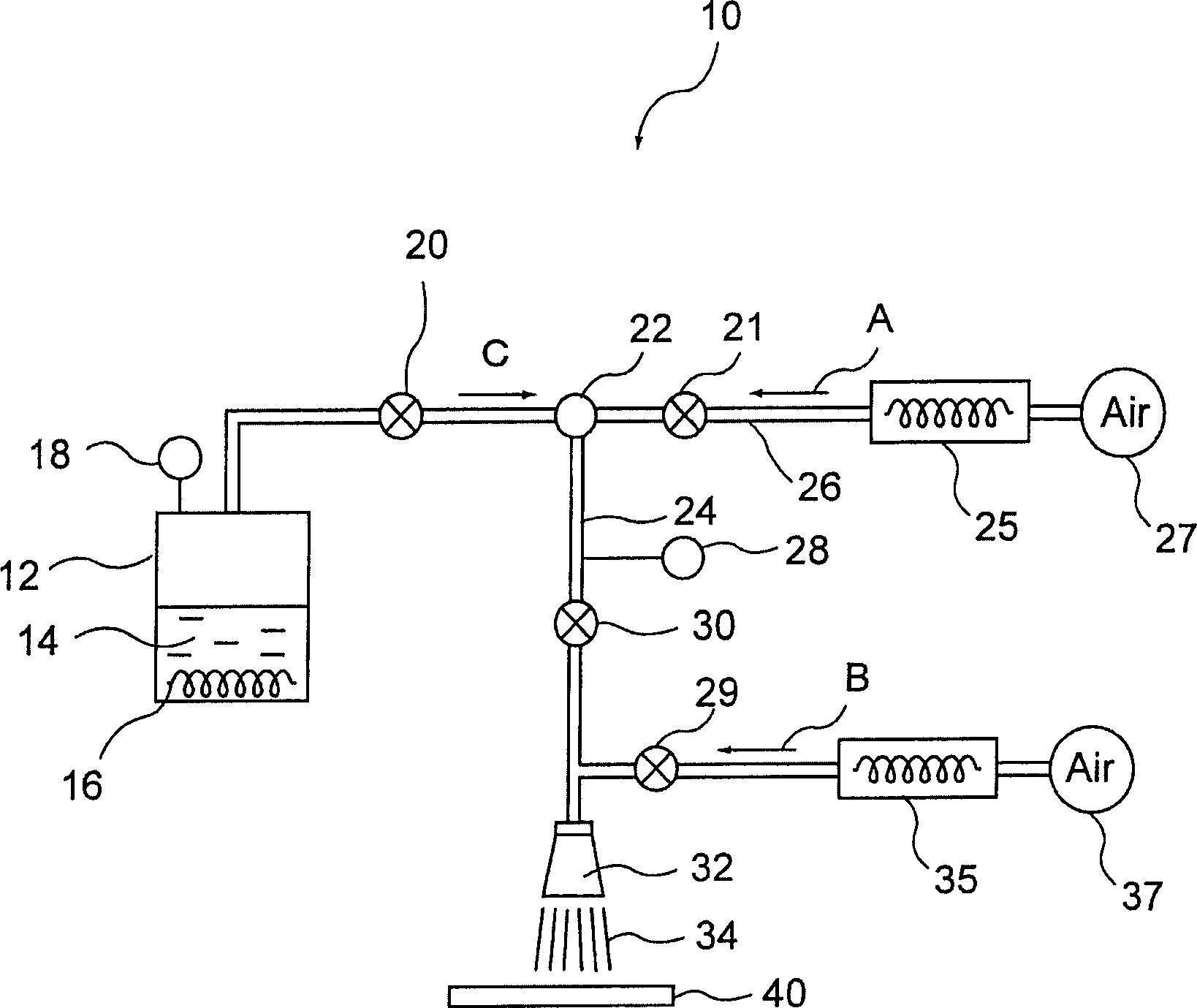

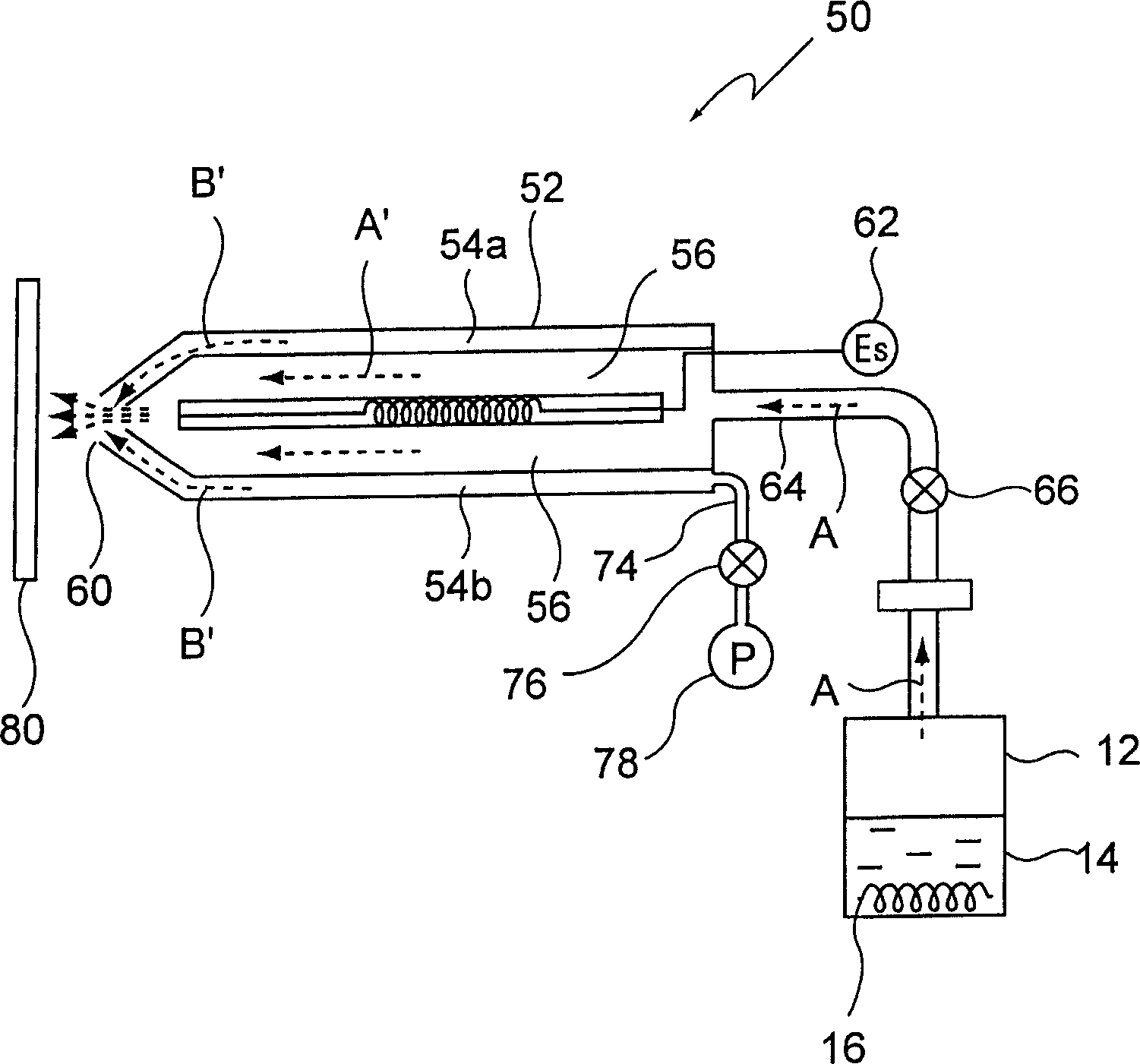

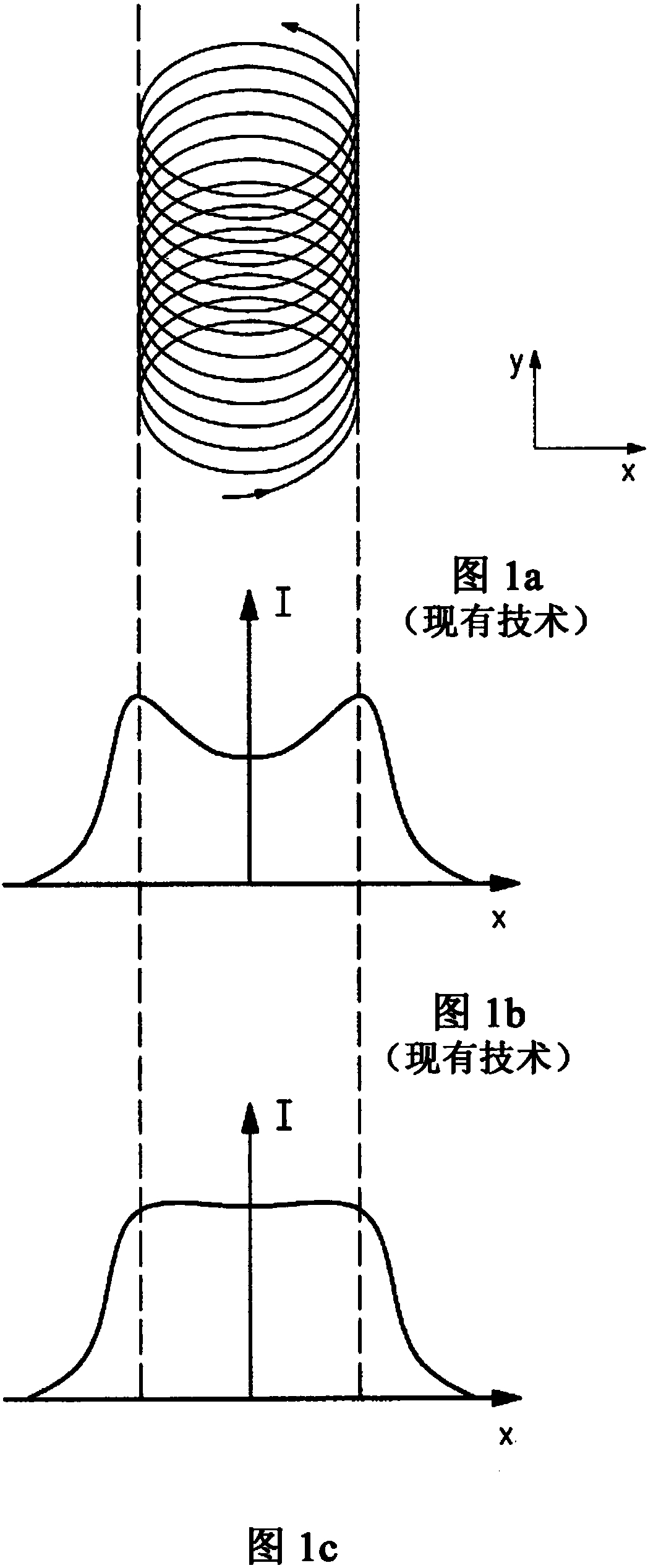

Large area, atmospheric pressure plasma for downstream processing

InactiveUS8361276B2Minimal deactivationEasy to processElectric discharge tubesElectric arc lampsEtchingDownstream processing

An arcless, atmospheric-pressure plasma generating apparatus capable of producing a large-area, temperature-controlled, stable discharge at power densities between about 0.1 W / cm3 and about 200 W / cm3, while having an operating gas temperature of less than 50° C., for processing materials outside of the discharge, is described. The apparatus produces active chemical species, including gaseous metastables and radicals which may be used for polymerization (either free radical-induced or through dehydrogenation-based polymerization), surface cleaning and modification, etching, adhesion promotion, and sterilization, as examples. The invention may include either a cooled rf-driven electrode or a cooled ground electrode, or two cooled electrodes, wherein active components of the plasma may be directed out of the plasma and onto an external workpiece without simultaneously exposing a material to the electrical influence or ionic components of the plasma.

Owner:APJET INC

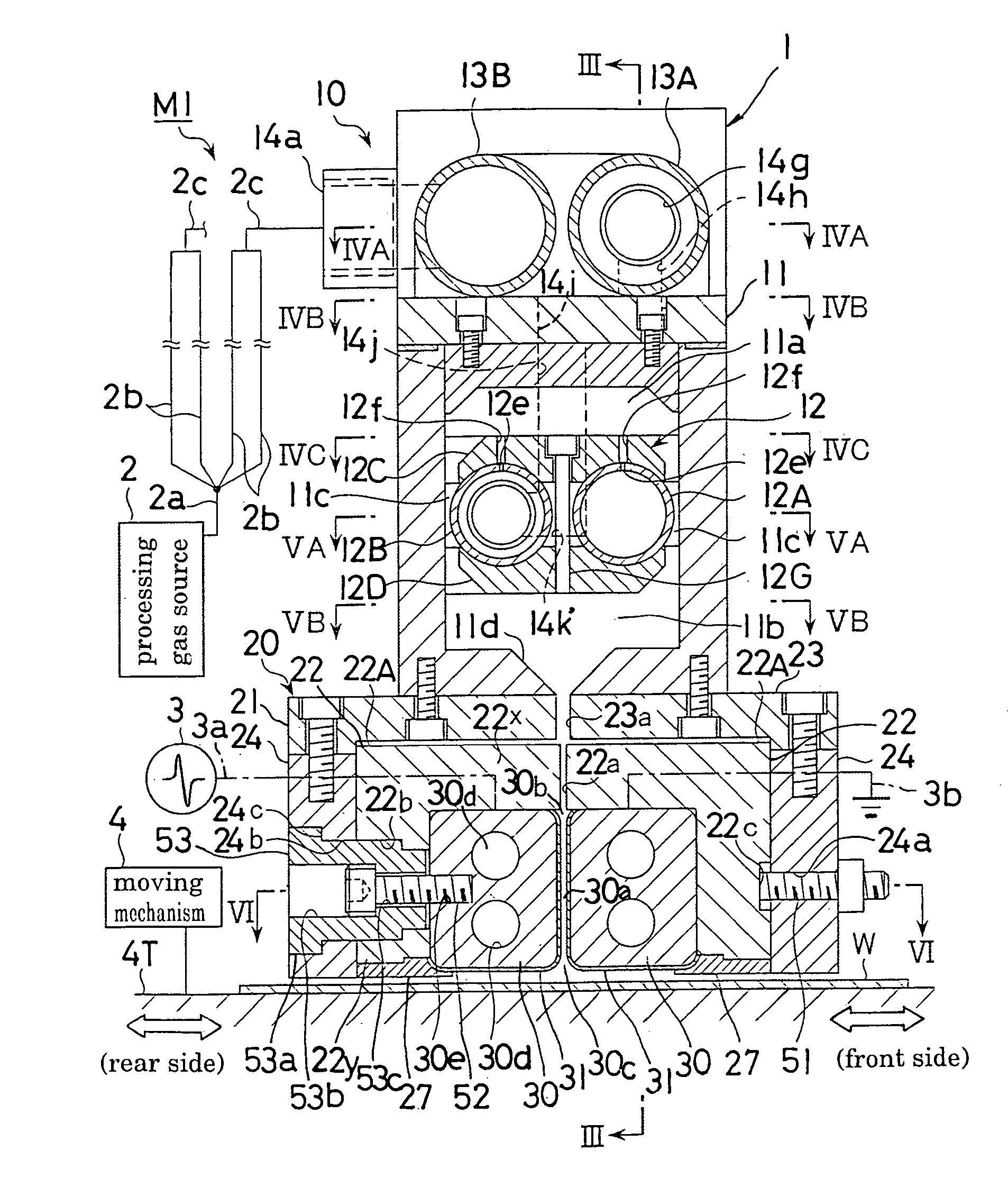

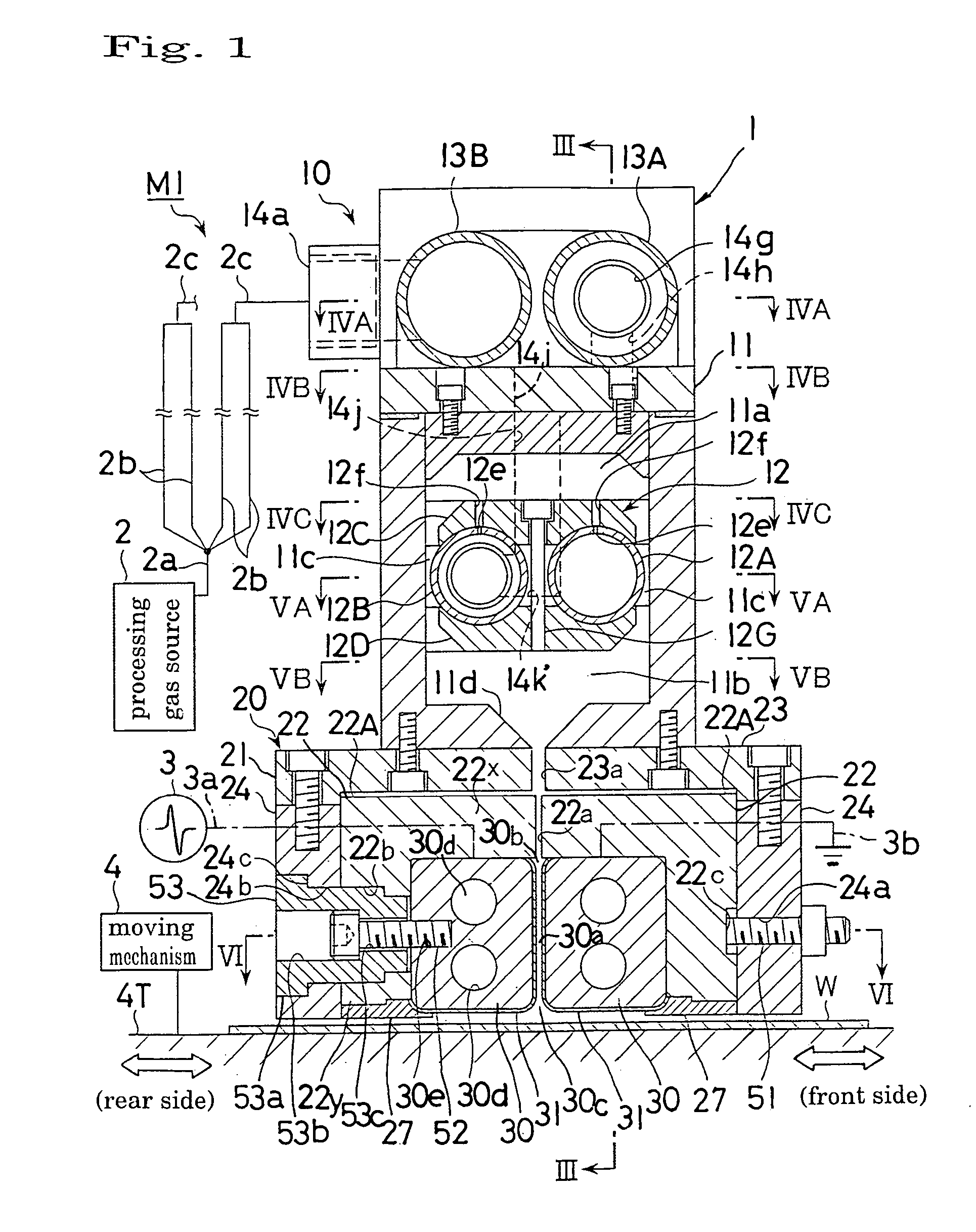

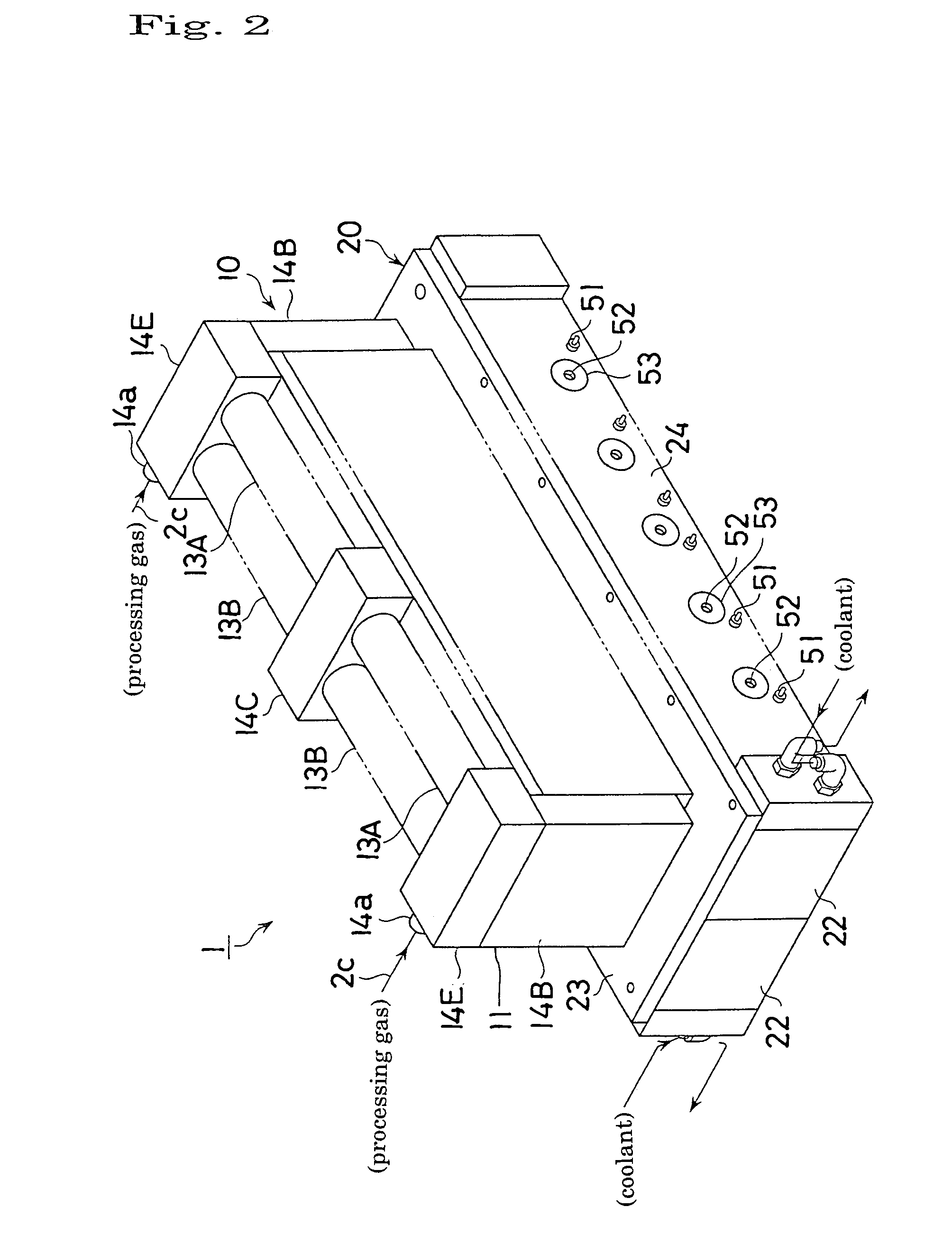

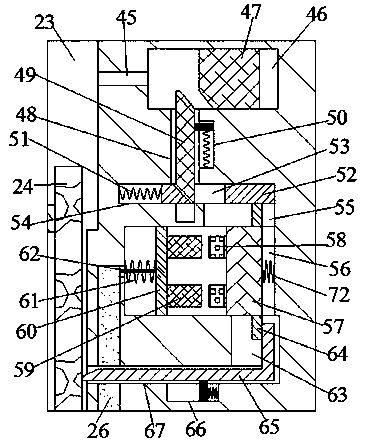

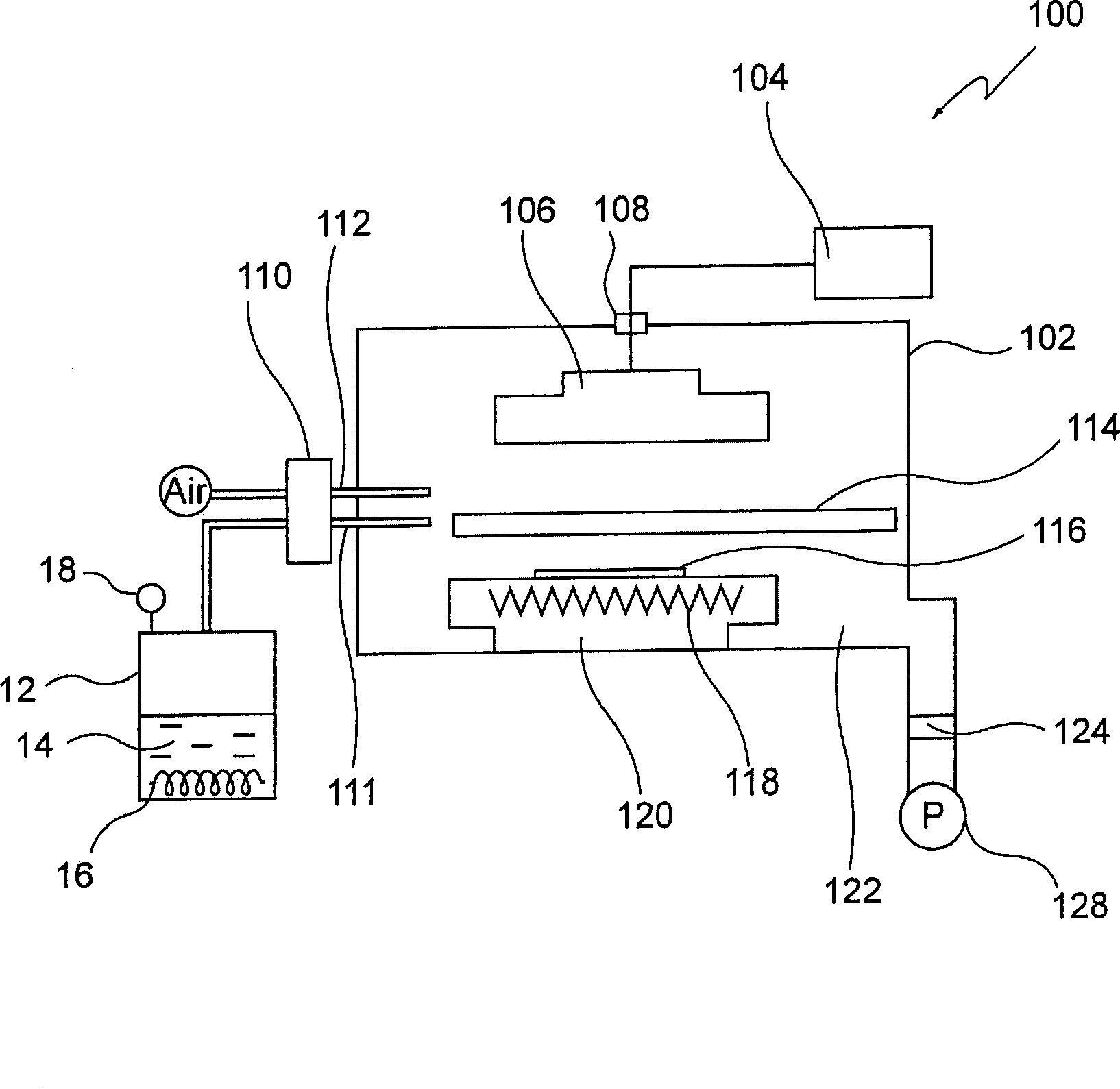

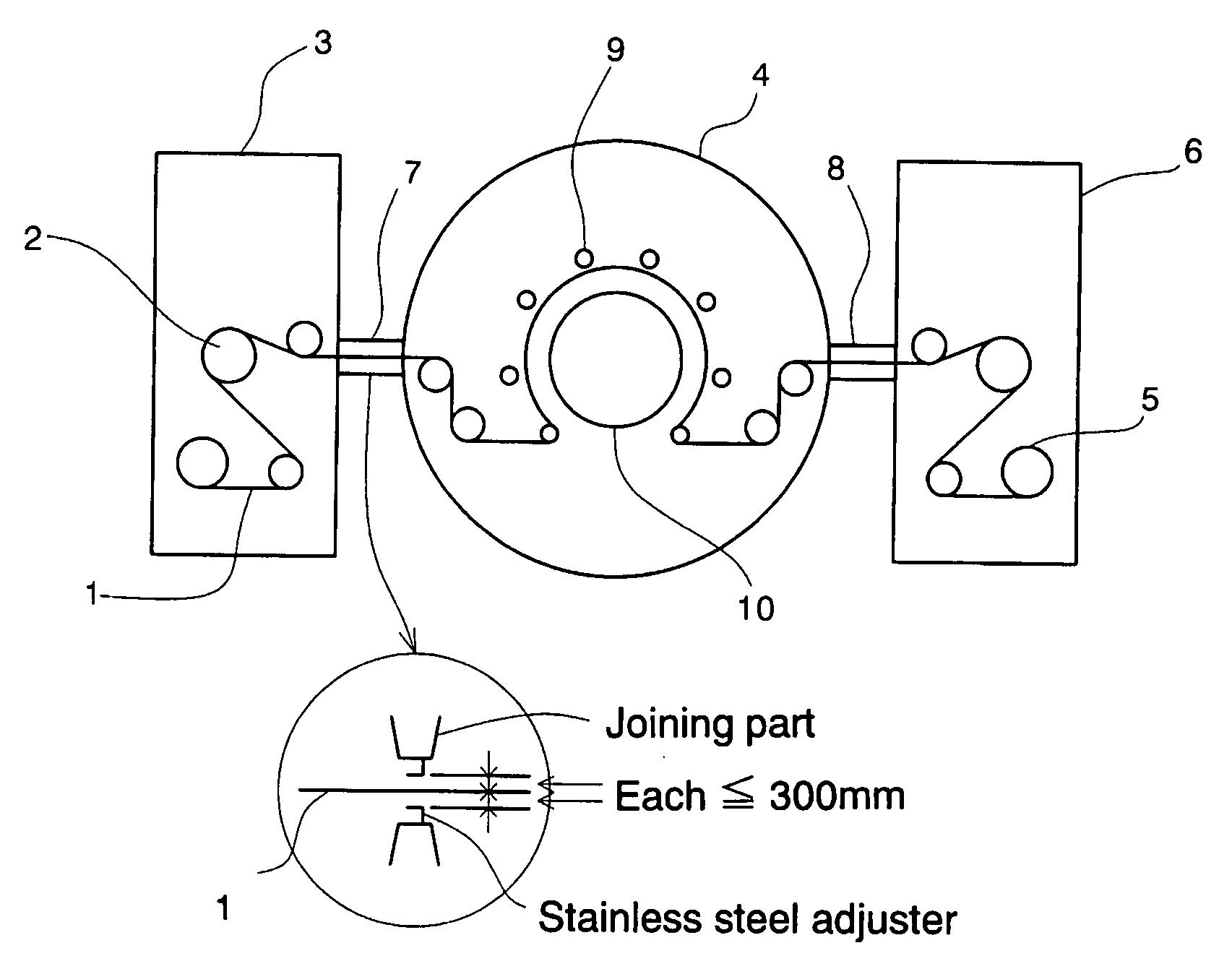

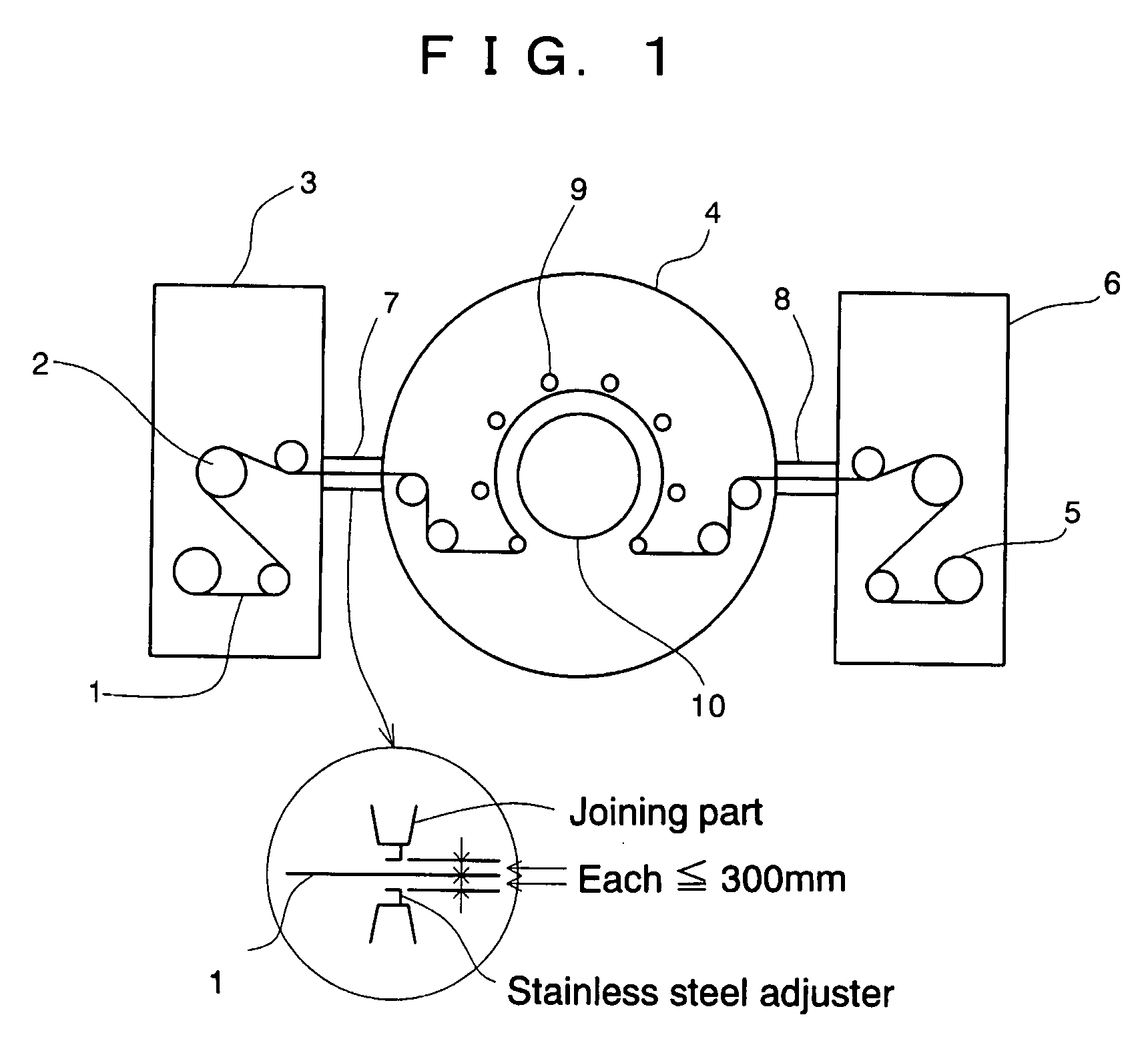

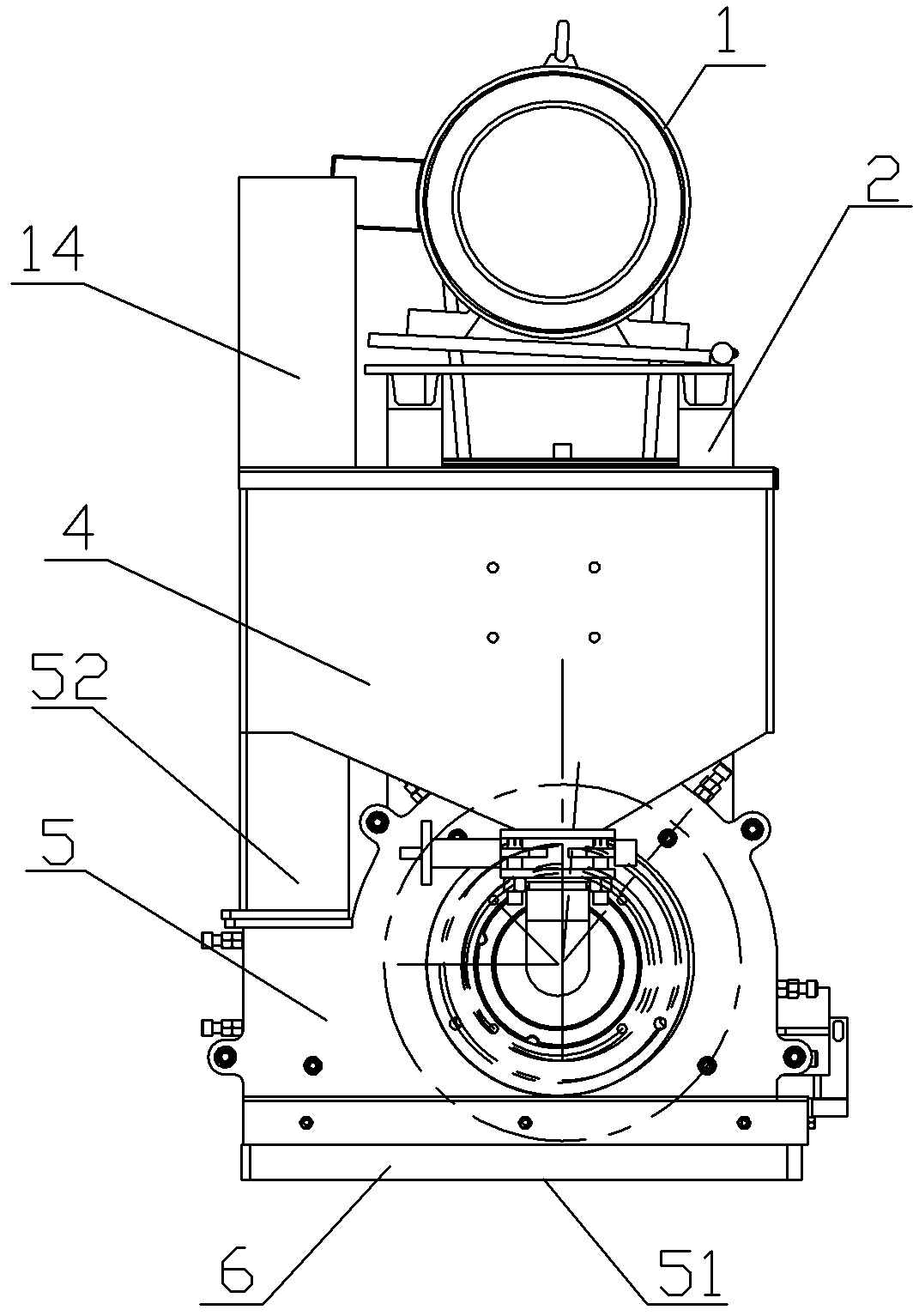

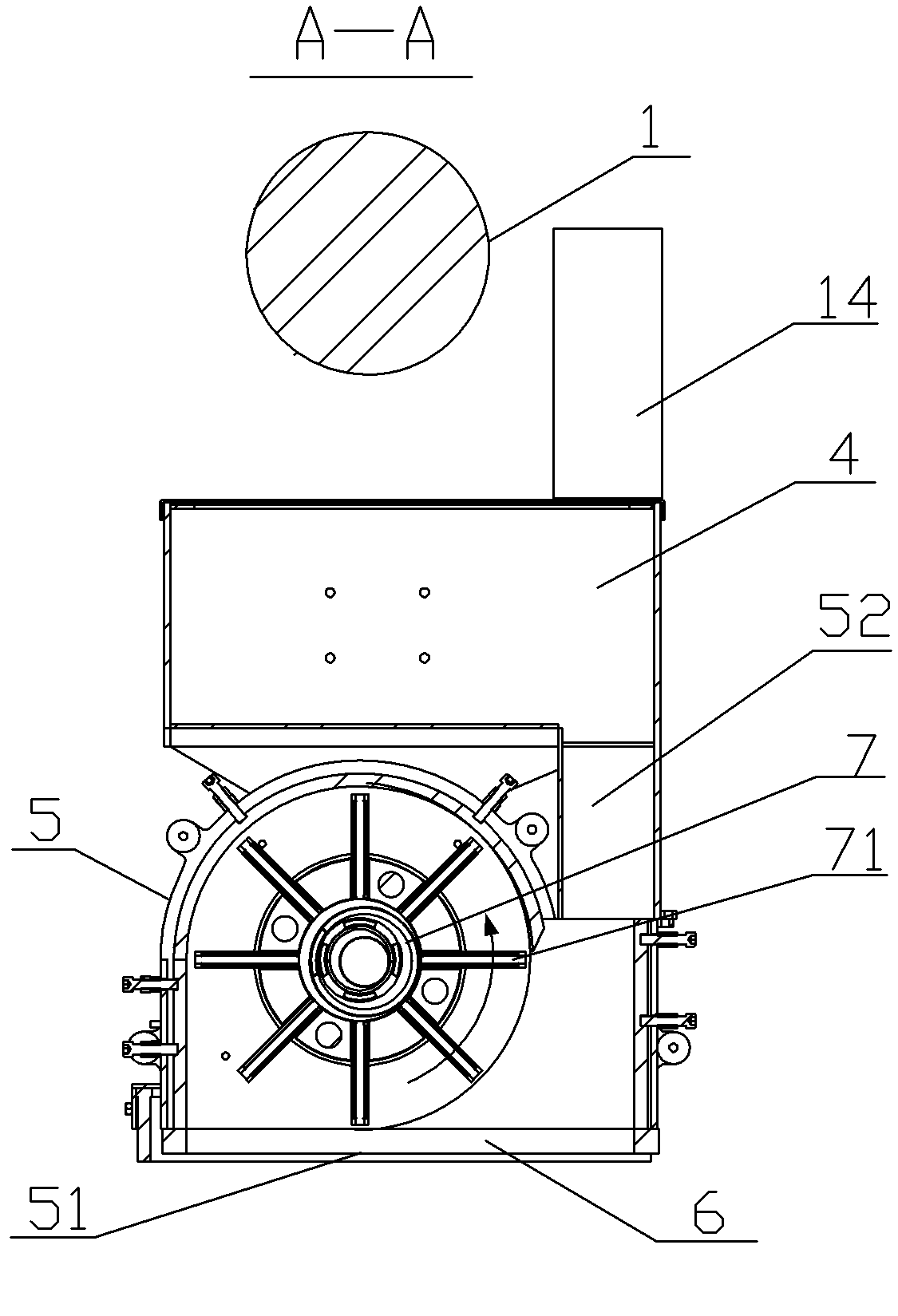

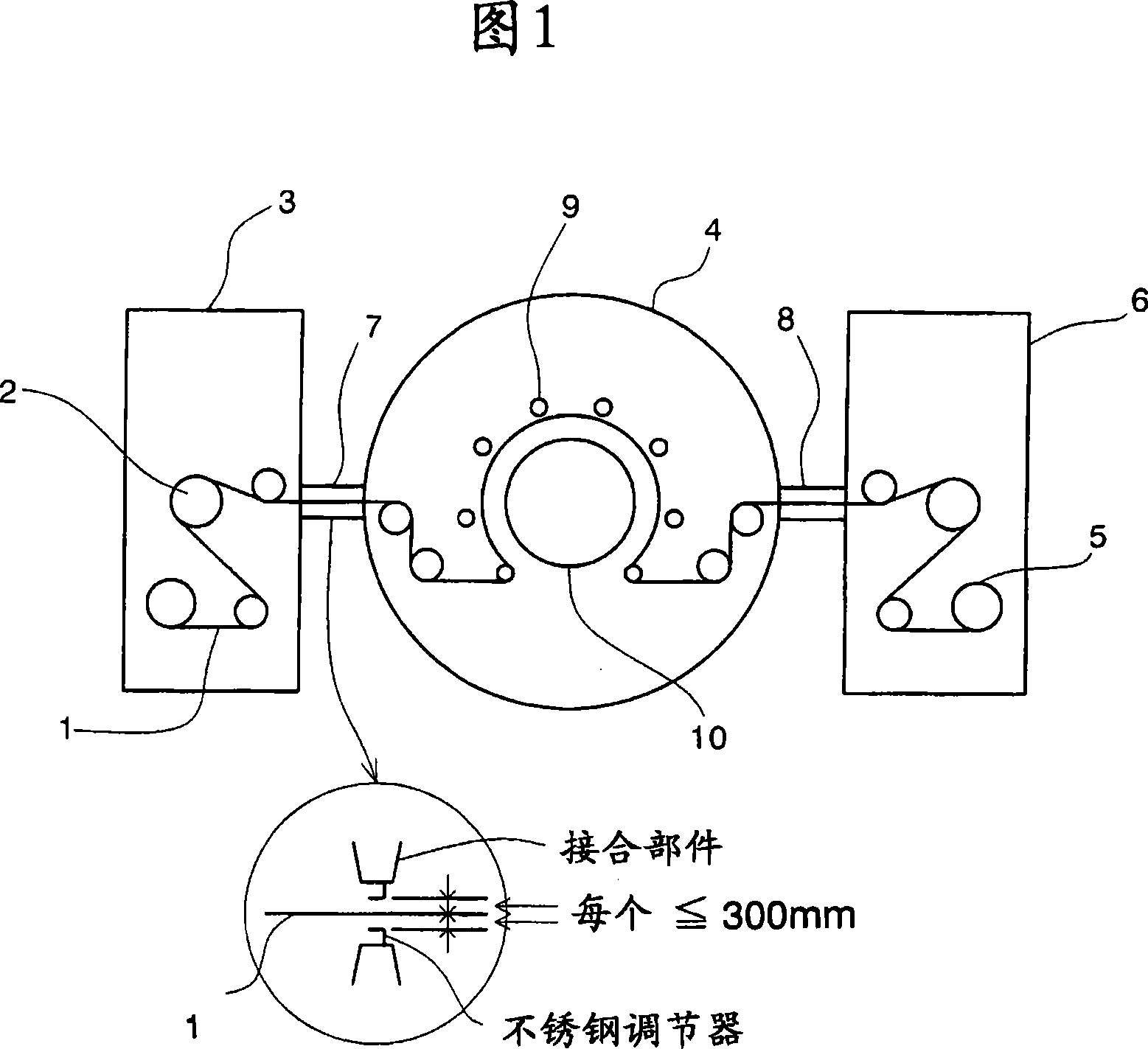

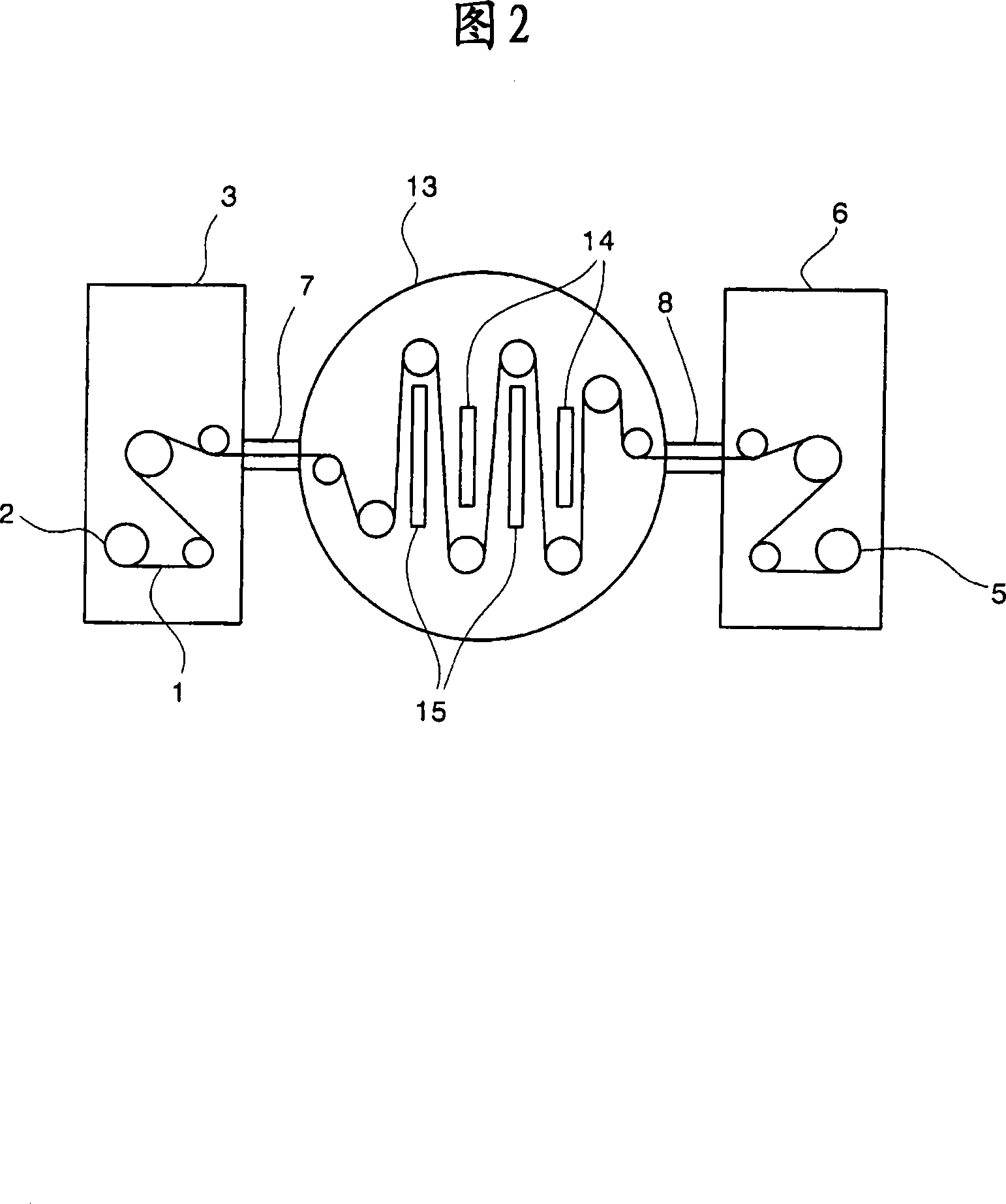

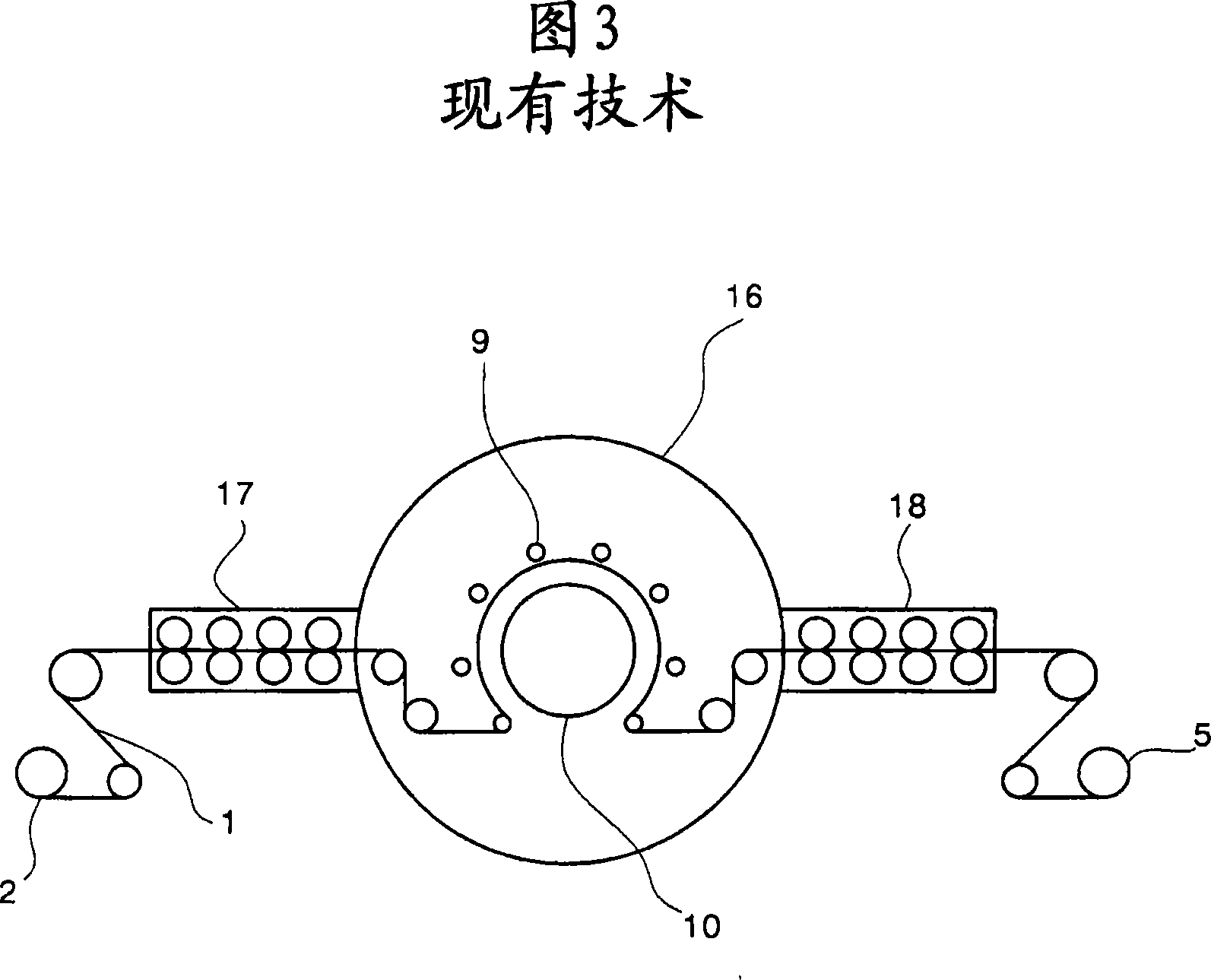

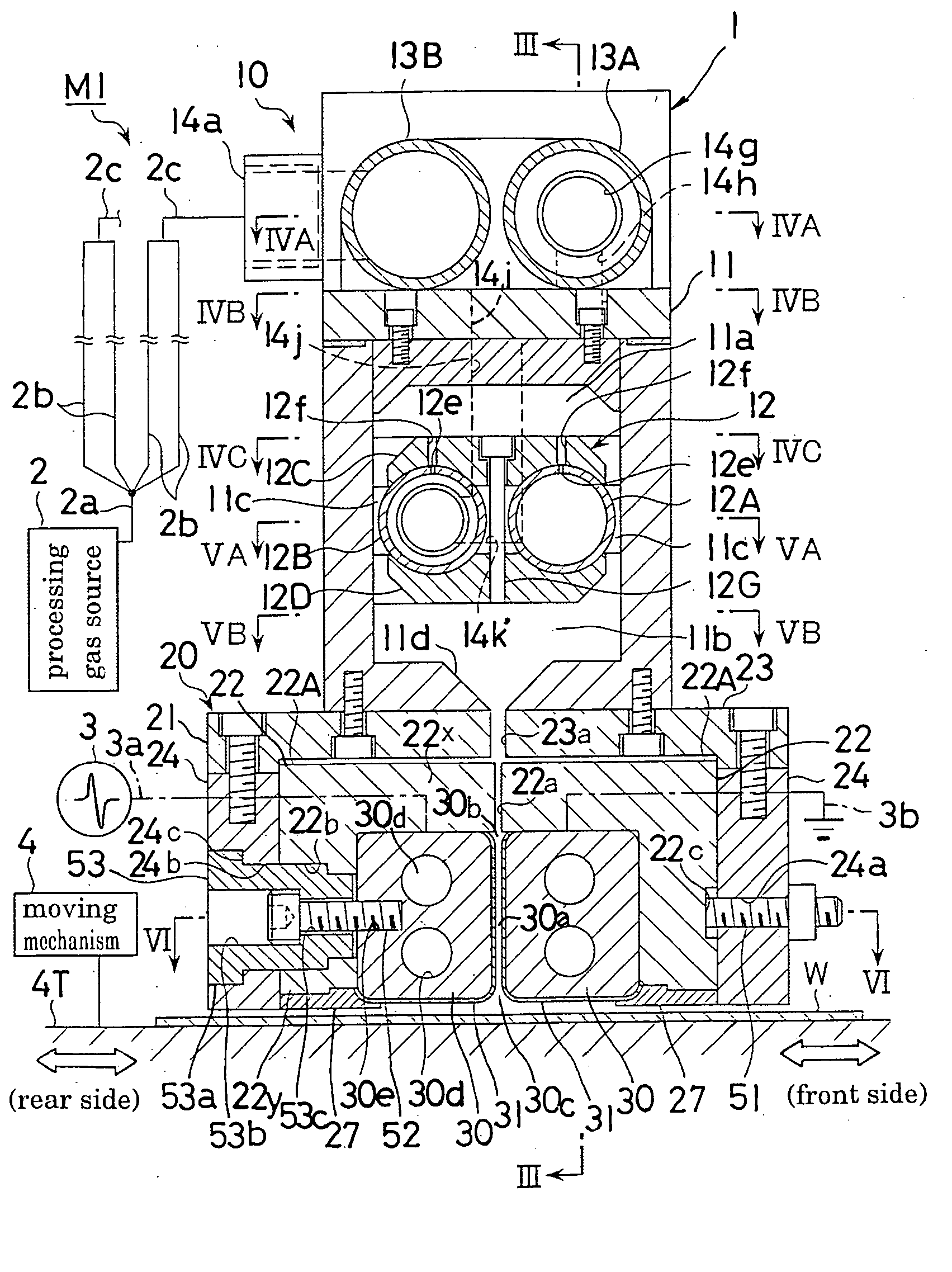

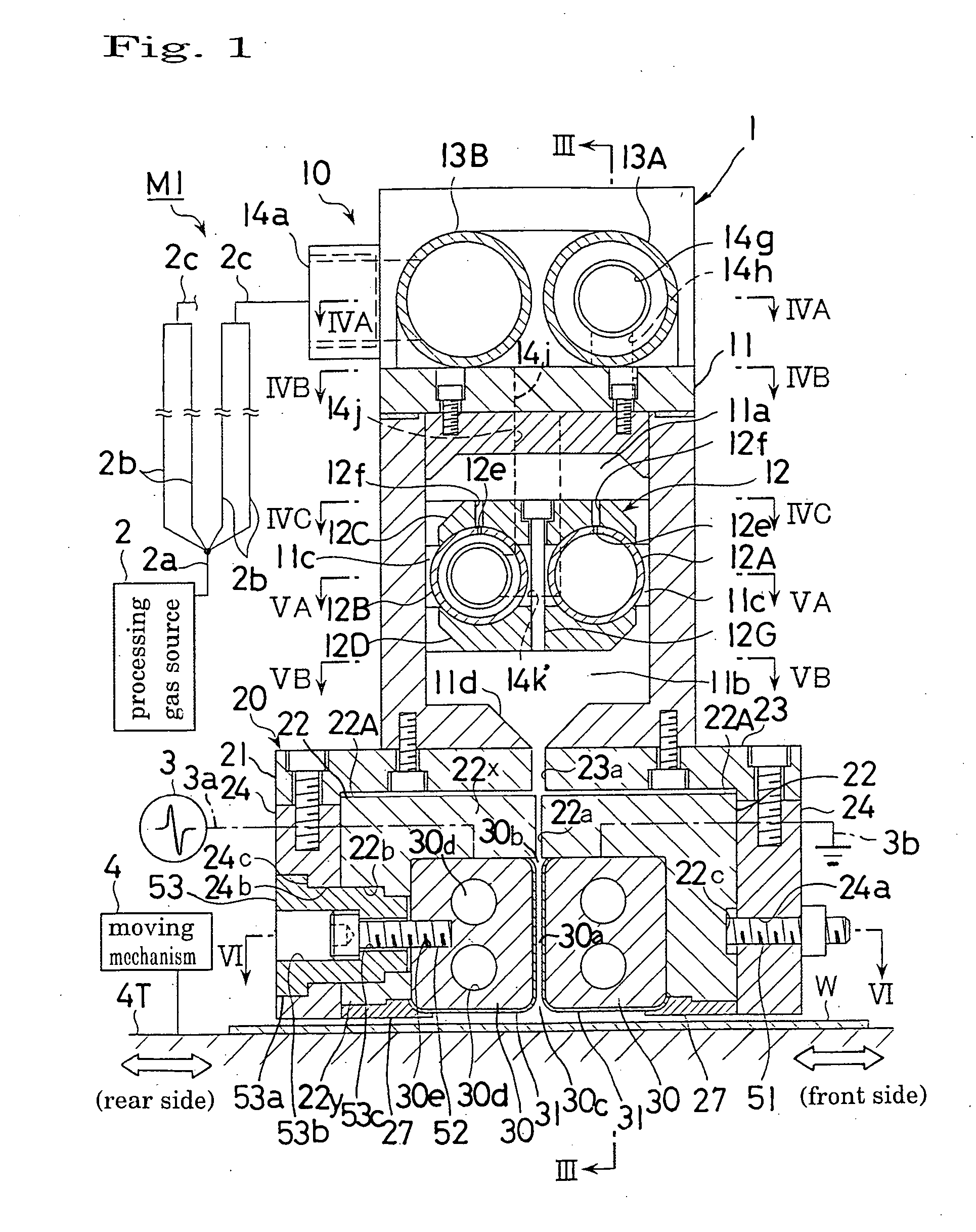

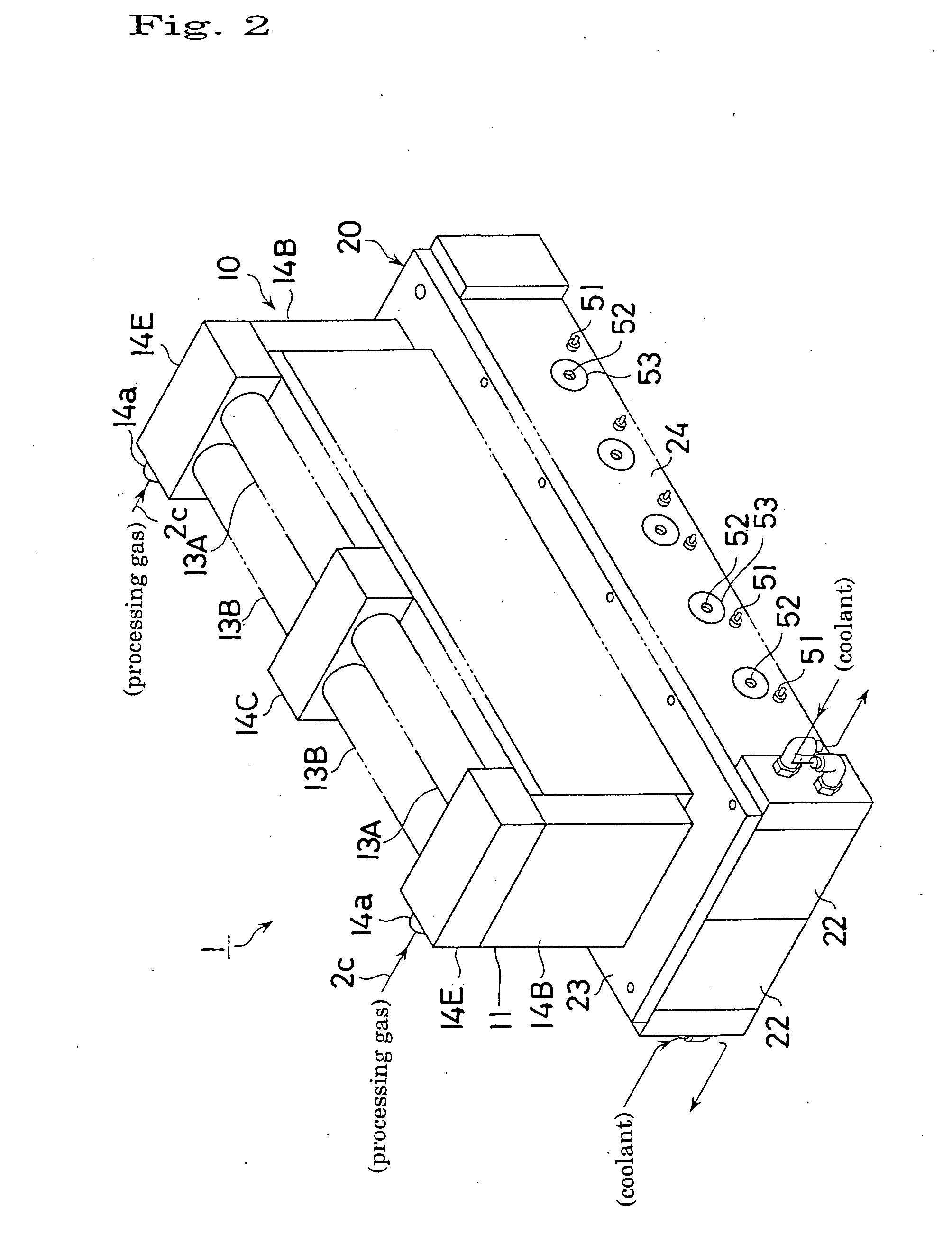

Plasma processing system

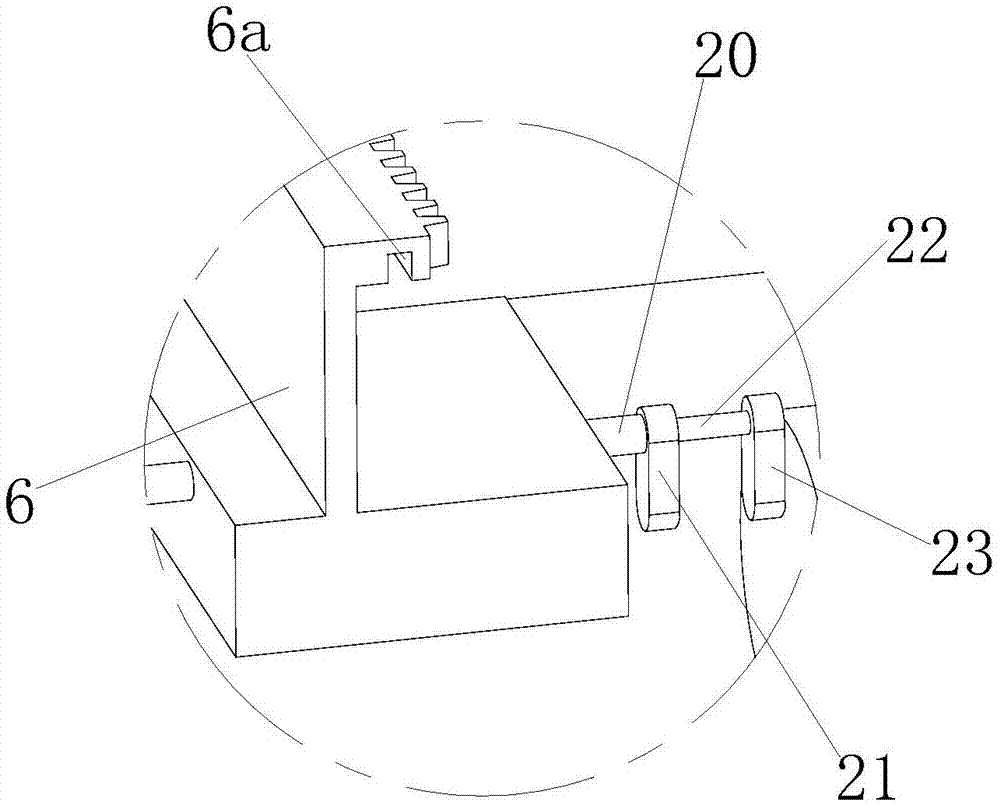

InactiveUS7322313B2Uniform surface treatmentAvoid deformationElectric discharge tubesElectric arc lampsEngineeringPlasma processing

A plasma processing apparatus M1 is provided with a processing part 20 for supporting a pair of elongate electrodes 30. The processing part 20 is provided with a plurality of pull bolts 52 (approach-deforming preventers) mutually spacedly arranged in the longitudinal direction of the electrode 30. A head part of each pull bolt 52 is hooked on a rigid plate 33 through a bolt holder 53, and a leg part thereof is screwed in the electrode 30. Owing to this arrangement, the electrodes 30 can be prevented from being deformed by Coulomb's force.

Owner:SEKISUI CHEM CO LTD

Method for joint coating on pipeline by heat-shrinkable tape

ActiveCN101709821AEffective combinationUniform shrinkageCorrosion preventionPipe elementsProduct gasBond strength

The invention discloses a method for joint coating on pipeline by heat-shrinkable tape, which comprises the following process flows of: polarization treatment on the heat-shrinkable tape, blasting treatment on a surface of the joint coating, gas treatment on the surface of the joint coating, preservative treatment on the surface of the joint coating, wrapping the heat-shrinkable tape on the surface of the joint coating and other procedures. The method has the advantages of simple process, simple and convenient operation, strong bond strength, high anti-corrosive property, long service life, wide adaptive temperature range, and convenient construction, and is beneficial to popularization and application.

Owner:北京双元油通工程技术有限公司

High molecular material surface modification method and its product and application

ActiveCN107189096AAchieve covalently grafted loadingAchieve biomimetic surface modificationAfter treatmentCompound (substance)

The invention discloses a high molecular material surface modification method and its product and application. The surface modification method particularly relates to a biomedical polymer material surface treated on the basis of plasma immersion ion injection and a surface covalent grafting bioactive molecule after treatment so as to realize its bionic modification; the method particularly includes steps of 1), treating the high molecular material through gas plasma immersed ion injection; 2), incubating the treated high molecular material in the solution containing biological molecules. The high molecular material with modified gas plasma immersion ion injection surface has good stability; the grafting ability still cannot be significantly declined even though the high molecular material is stored in the air for a long time, and the high molecular material does not use chemical crosslinking agent; the whole surface modification technique is simple in process, low in cost, and suitable for batch and industrial production. The method and its product have wide application prospects in medical implant materials, functional materials, bioactive materials and other domain.

Owner:SHENZHEN INST OF ADVANCED TECH

Injection molding grade natural straw plastic and its preparation method and application

The invention provides an injection molding grade natural straw plastic and its preparation method and application. The injection molding grade natural straw plastic is prepared from, by weight, 25-65parts of nature straw, 0-12 parts of filling agent, 25-63 parts of macromolecular resin, and 4-5 parts of macromolecular assistant. The preparation method includes steps of mixing nature straw with granularity of 250-350 meshes with diatomite, macromolecular resin and macromolecular assistant to form a raw material; extruding and pelleting by a dual-screw mixing extruder to obtain the injection molding grade natural straw plastic. The injection molding grade natural straw plastic can replace the application of a traditional thermal plastic resin on daily goods; the injection molding grade natural straw plastic passes through the national food hygienic index and can directly contact food. The injection molding grade natural straw plastic has straw smell, and its smell is durable, fragrantand nature; the product is easy to shape and has straw texture; the injection molding grade natural straw plastic can be applied to food packaging, and is wide in application and not easy to wet and go mouldy.

Owner:JIANGSU JINHE HI TECH

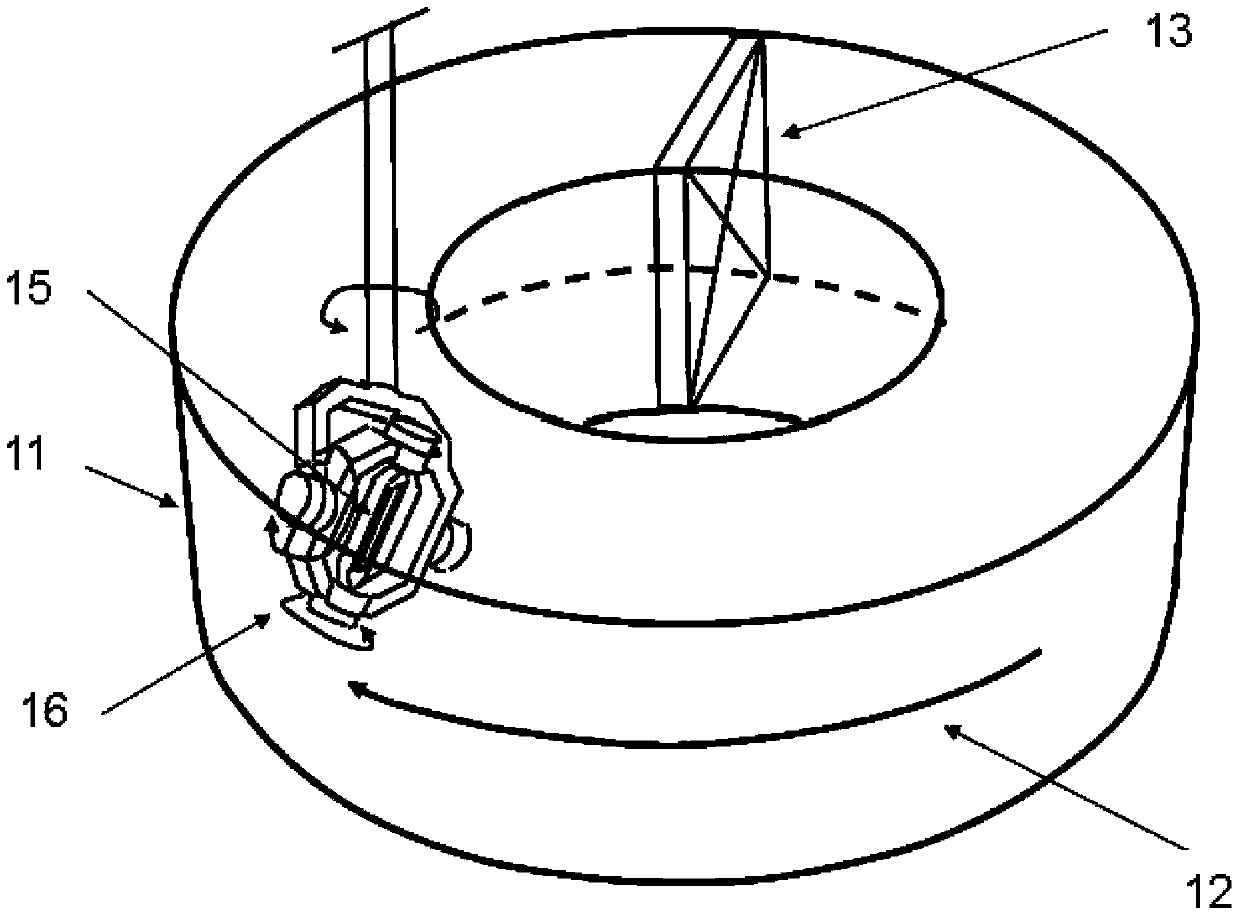

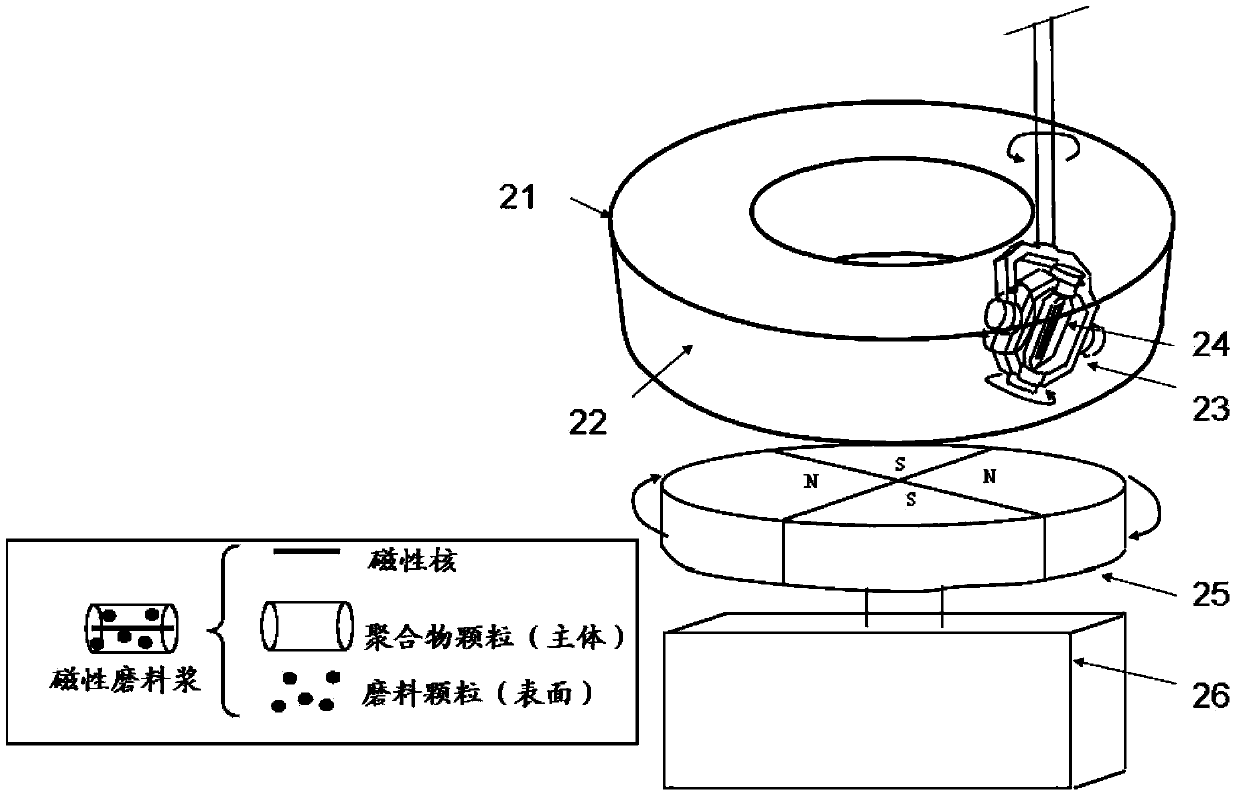

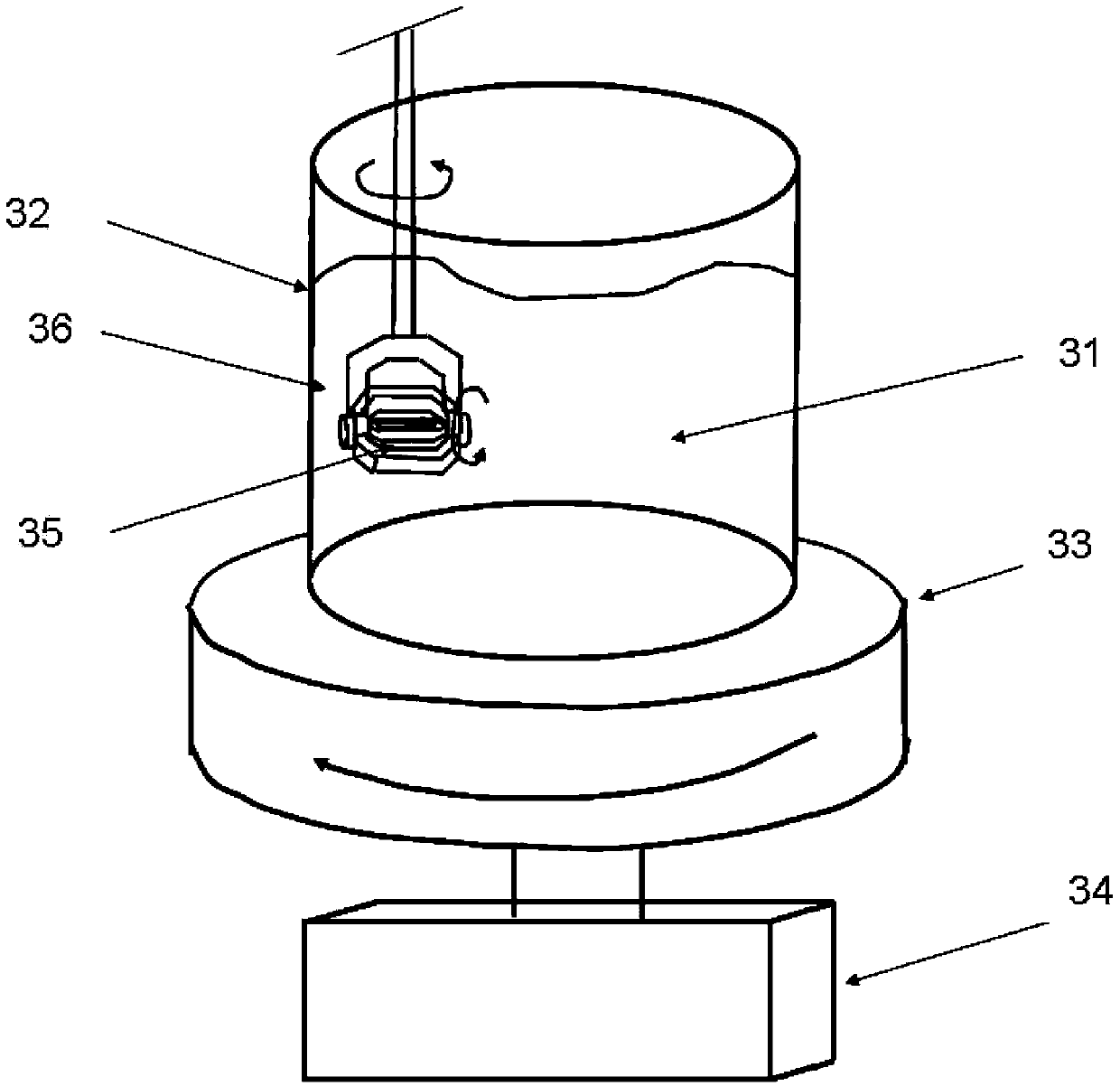

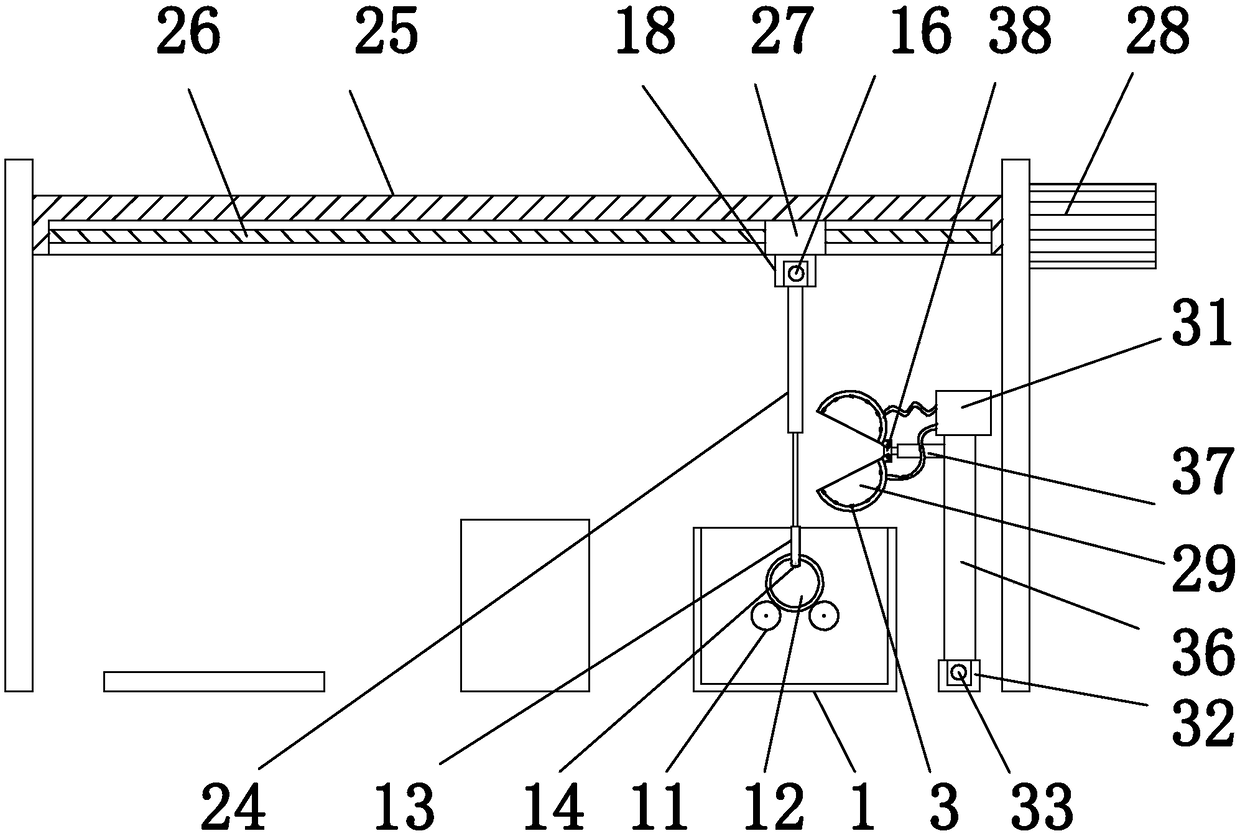

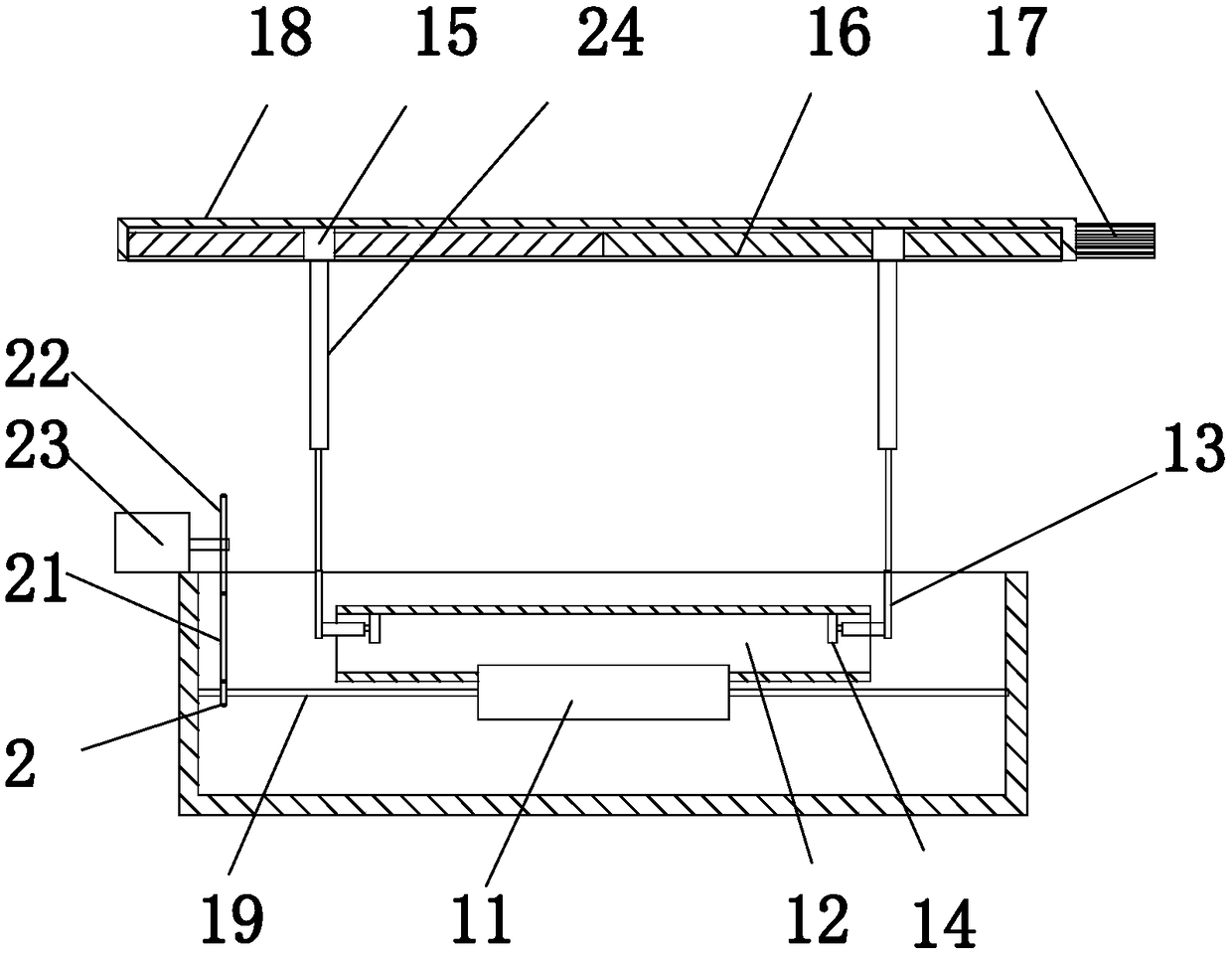

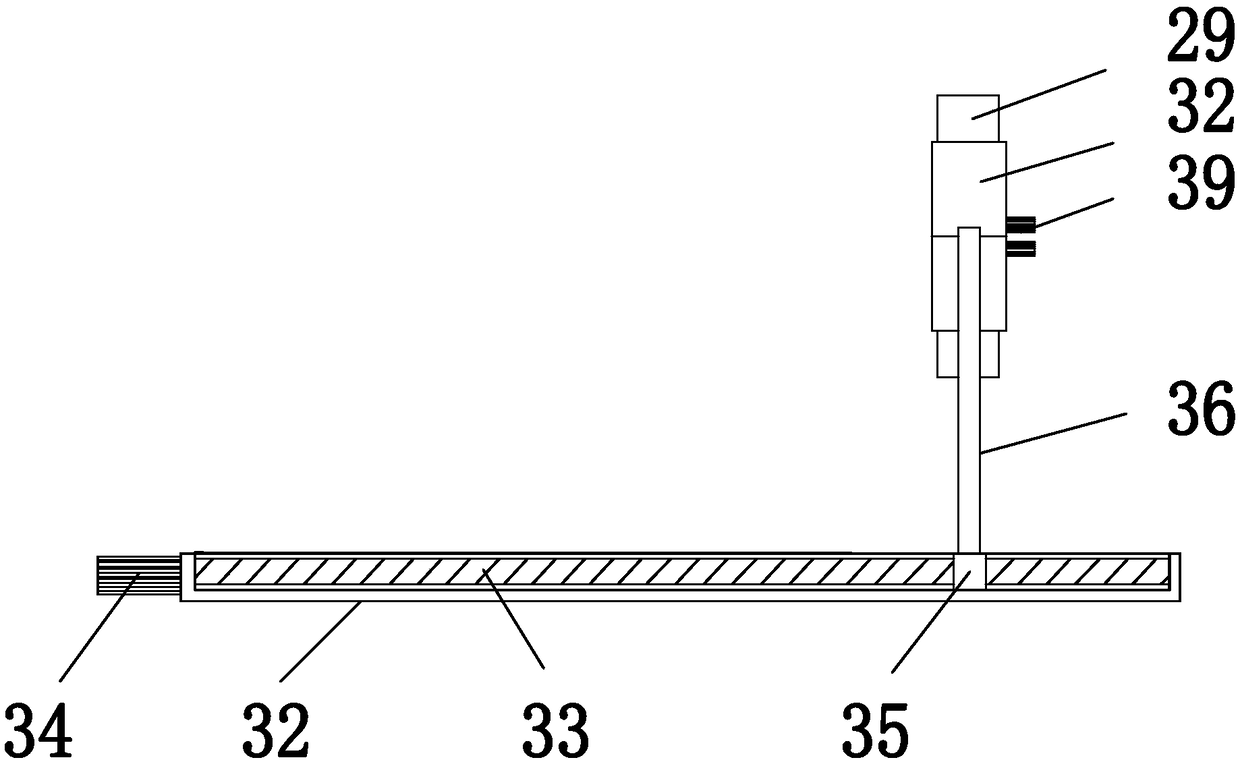

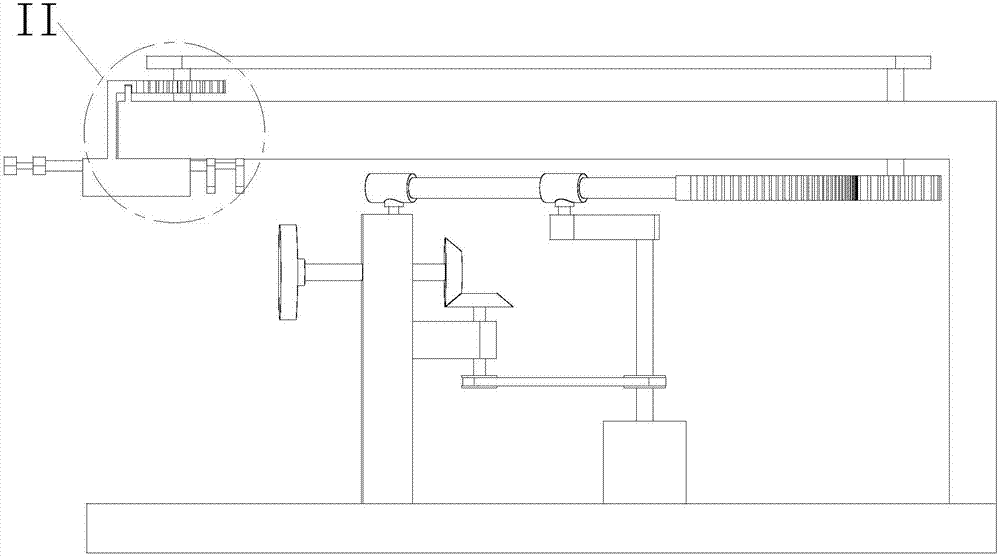

Automatic polishing device for surface finishing of complex-curved-profile parts

InactiveCN103372806AUniform surface treatmentLow costEdge grinding machinesPolishing machinesPolishingEngineering

The present invention discloses an automatic polishing device and the method of using the device for the surface finishing of a workpiece such as complex-curved-profile parts. Automatic polishing is performed by mounting the workpiece on an apparatus which enables different orientations along multiple axes and immerging the workpiece in a controlled flow of abrasive slurry. The device of the present invention provides a uniform finish on free form surface. It is also precise, low cost, non-destructive, and non-polluting.

Owner:NANO & ADVANCED MATERIALS INST

Steel pipe hot galvanizing device

PendingCN109355607AAvoid bumps andDry as soon as possibleHot-dipping/immersion processesEngineeringMechanical engineering

The invention discloses a steel pipe hot galvanizing device which comprises a hot galvanizing box. Opposite rollers are horizontally arranged in the hot galvanizing box. Each roller is rotationally connected with the hot galvanizing box through a power input mechanism. The inner diameters of the two ends of a to-be-galvanized steel pipe are connected with a horizontal movement mechanism through aclamping mechanism, wherein the horizontal movement mechanism is arranged on the outer side of the hot galvanizing box. The clamping mechanism comprises oppositely-arranged vertical plates, and rolling wheels are oppositely arranged on the opposite faces of the vertical plates. Each vertical plate is upwards connected with a height adjusting mechanism. One end of each height adjusting mechanism isconnected with a first nut. The first nuts are rotationally connected to a first lead screw. The first lead screw is arranged to be opposite towards the two ends from the center line. The first leadscrew is connected with the horizontal movement mechanism through a mounting plate. A zinc blowing mechanism is arranged on one side of the hot galvanizing box and is in sliding connection to a zinc blowing movement mechanism. The steel pipe hot galvanizing device has the advantages that uniform hot galvanizing and surface treatment after galvanizing are achieved, and the structure is simple.

Owner:重庆佰鸿机械设备有限公司

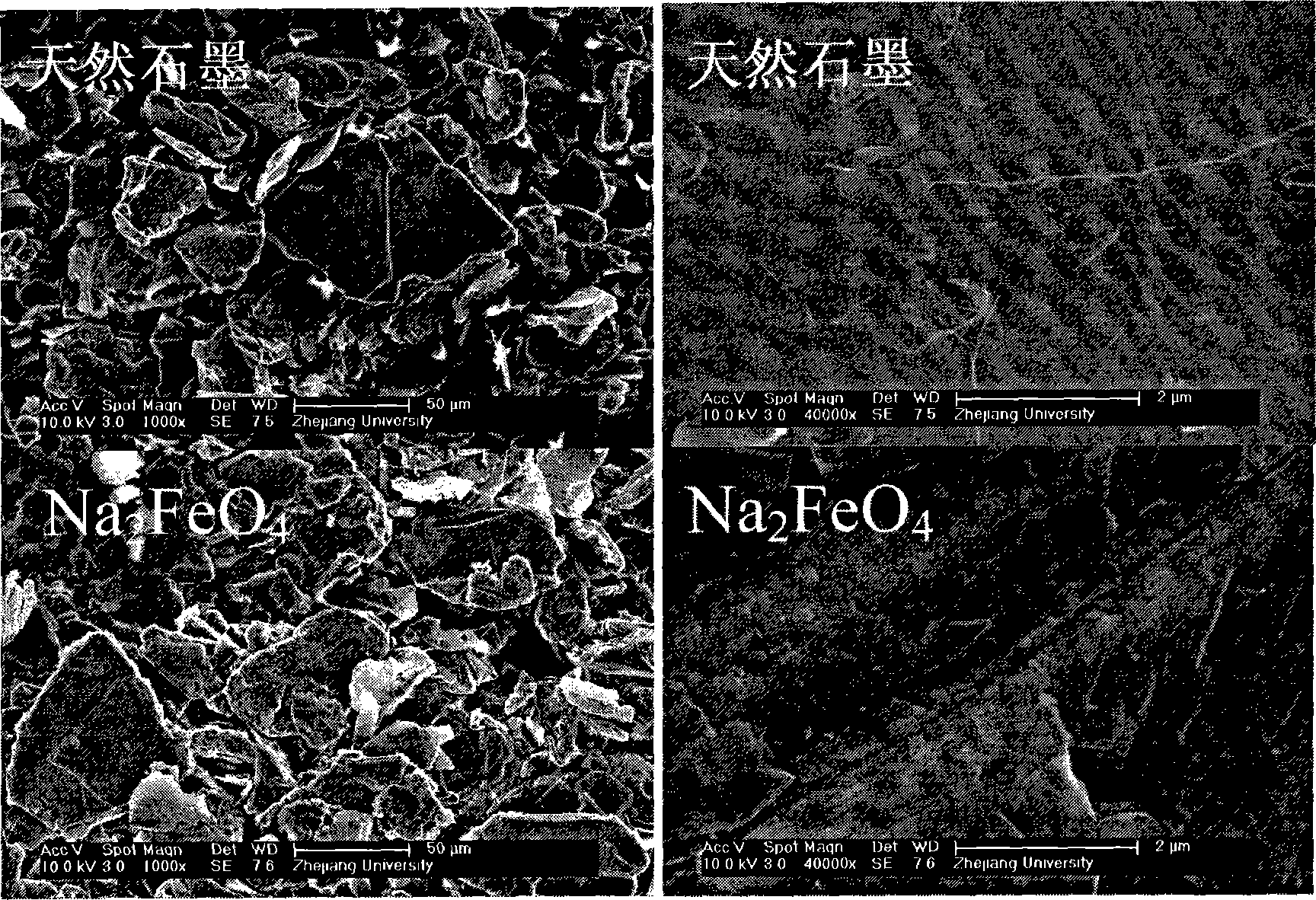

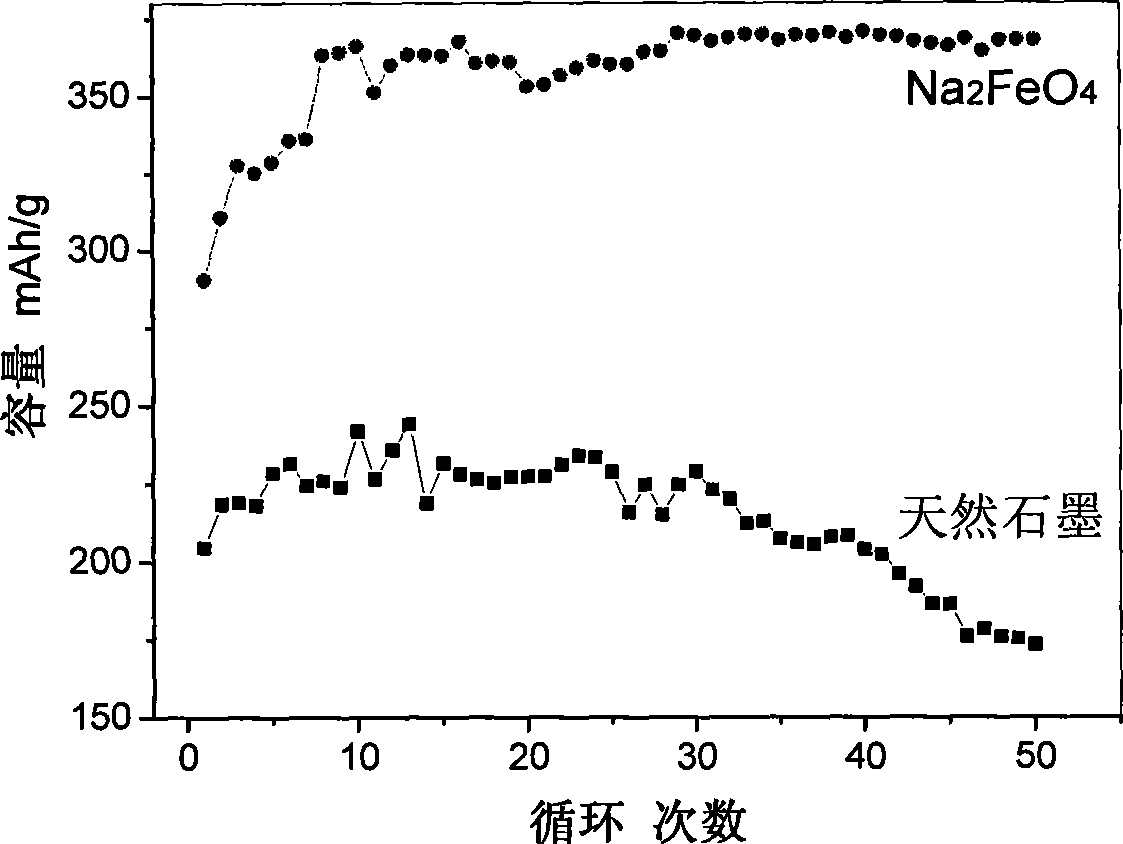

Preparation of modified graphite cathode material of lithium ion secondary battery

InactiveCN101246962AHigh reversible capacityReduce energy consumptionElectrode manufacturing processesEnergy consumptionMaterials science

The present invention discloses a method for producing modified graphite anode material of lithium ion secondary battery which is obtained by liquid phase oxidation natural graphite by ferrate. The present invention employs liquid phase oxidation of natural graphite, has merits of low energy consumption, mid preparation conditions, easy control, uniform surface process. The ferrate oxidant is environment protection and cheap, the preparation condition is mid and easy to control. After oxidation treatment of ferrate, the reversible capacity of modified graphite is improved greatly and can reach to 300-440mAh / g, and good circle capability is shown, after 50 circulations, the capacity is stable yet.

Owner:ZHEJIANG UNIV

Graphene/nano-silica/polystyrene hybrid material as well as preparation method and application thereof

The invention relates to a graphene / nano-silica / polystyrene hybrid material as well as a preparation method and application thereof. Graphene is dispersed into graphene dispersion liquid; then, a coupling agent and nano-silica are added; next, refined styrene is added; the mixture is emulsified and dispersed by a compound emulsifying agent water solution; after the ultrasonic dispersion, stable emulsified liquid is formed; next, the styrene is initiated by a water-soluble initiator to perform in-situ emulsion polymerization; a graphene / nano-silica / polystyrene emulsion is prepared, and is directly used for a water-soluble adhesive or a polymer emulsion system; or after the demulsification, the graphene / nano-silica / polystyrene hybrid material is prepared, i.e., styrene / SiO2 gel is used for adsorbing graphene; prepared graphene modified organic rigid particles are used as nanometer powder; the problem of difficult graphene dispersion is solved.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

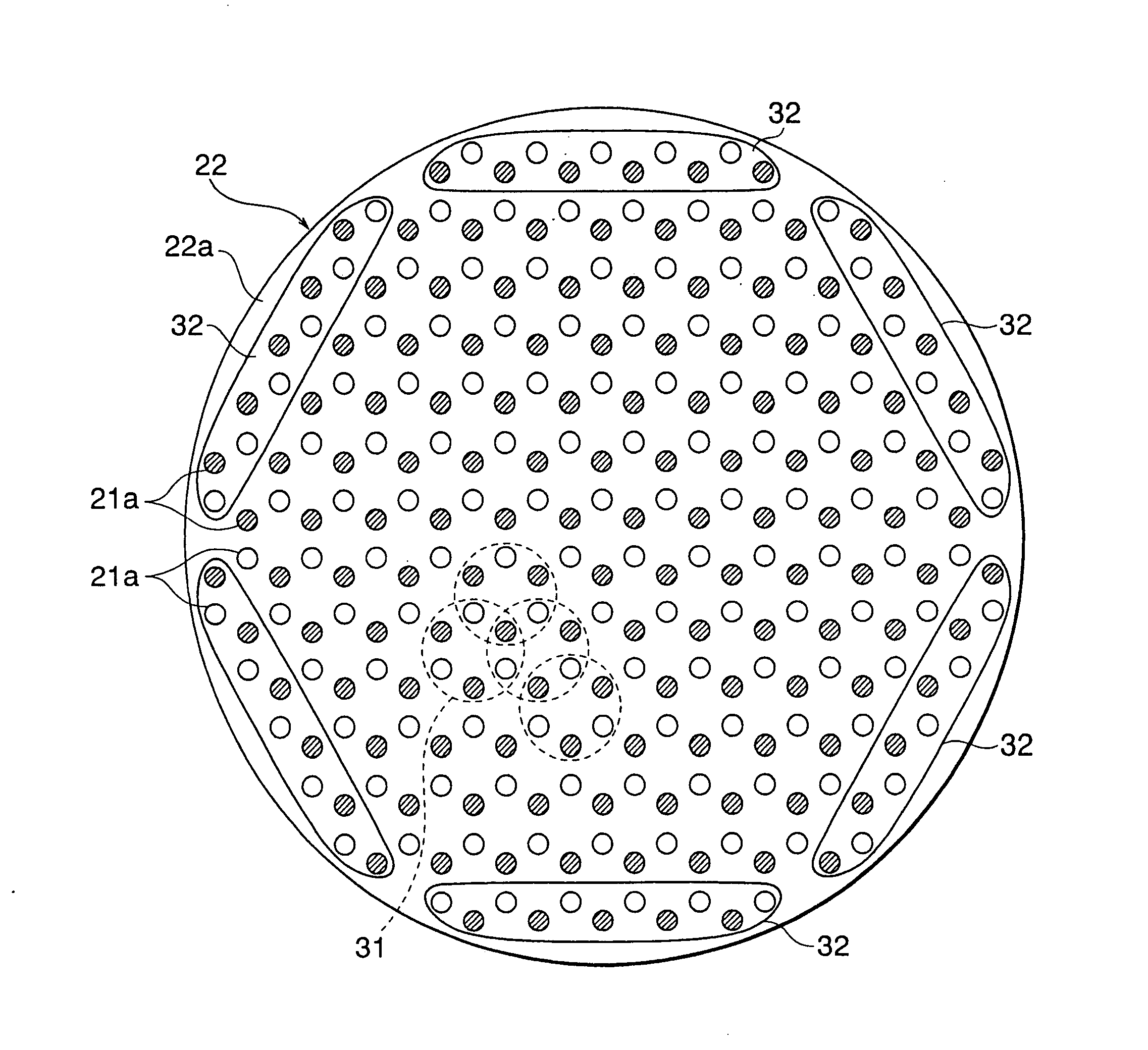

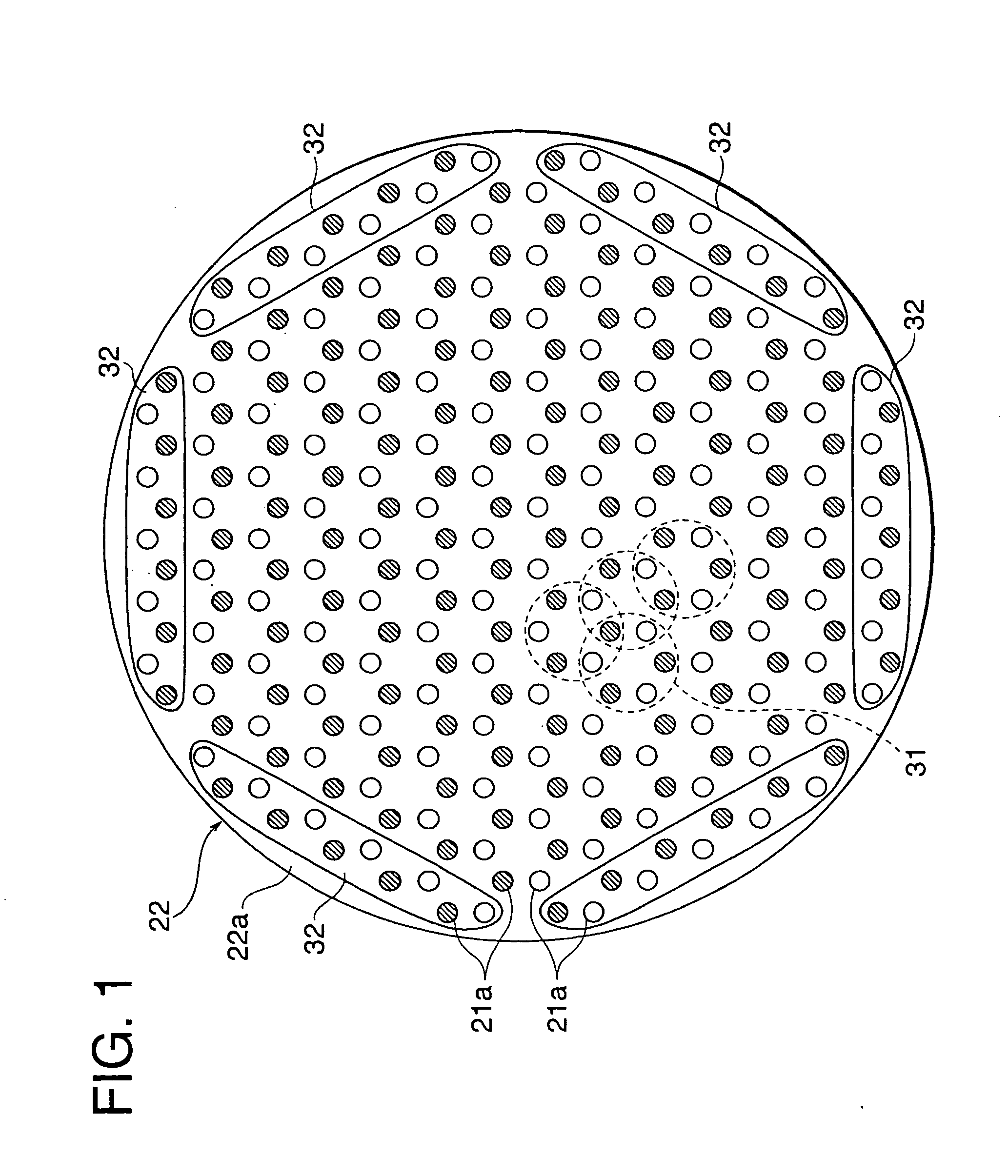

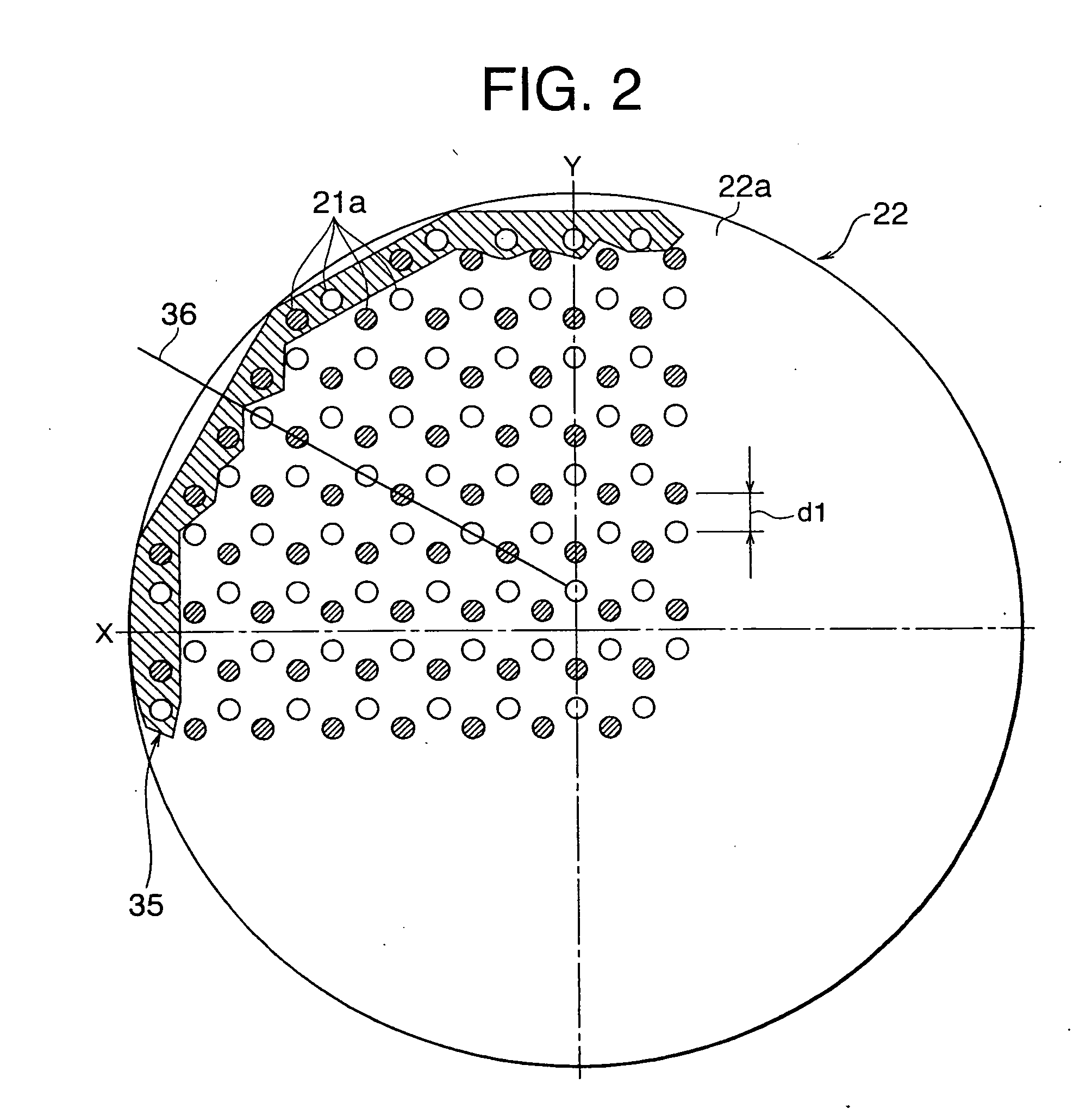

Surface processing apparatus

InactiveUS20080113149A1Shorten the lengthForce of magnet is reducedElectric discharge tubesLayered productsElectrical polarityHoneycomb

This surface processing apparatus has a reactor in which plasma is generated and a substrate whose surface is to be processed by the plasma is arranged, and a magnet plate for creating a point-cusp magnetic field distributed in an inner space of the reactor, in which the plasma is generated. The magnet plate has a plurality of magnets. These magnets are arranged by a honeycomb lattice structure in a circular plane facing in parallel a surface of the substrate. One magnetic pole end face of each of magnets is arranged at a position of each of the lattice points forming hexagonal shapes on the circular plane. The polarities of the magnetic pole end faces of two adjoining magnets are arranged to become opposite alternately. The magnet plate may be provided with a plurality of magnets arranged by a lattice structure forming a square and the magnetic force (coercive force) of some of the magnets arranged at the outermost region is reduced. Thereby, the periodicity of the point-cusp magnetic field in the inside space is maintained as much as possible even at the peripheral edge and the asymmetry of the distribution of the magnetic field at the region where the periodicity is disturbed at the peripheral edge is reduced.

Owner:ANELVA CORP

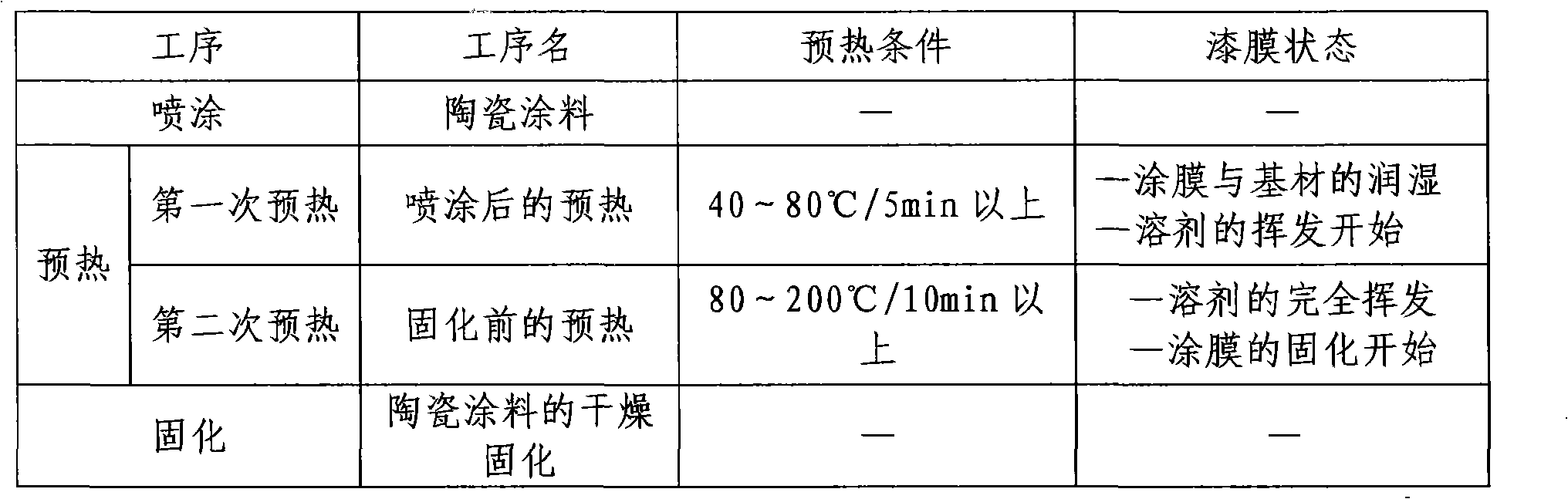

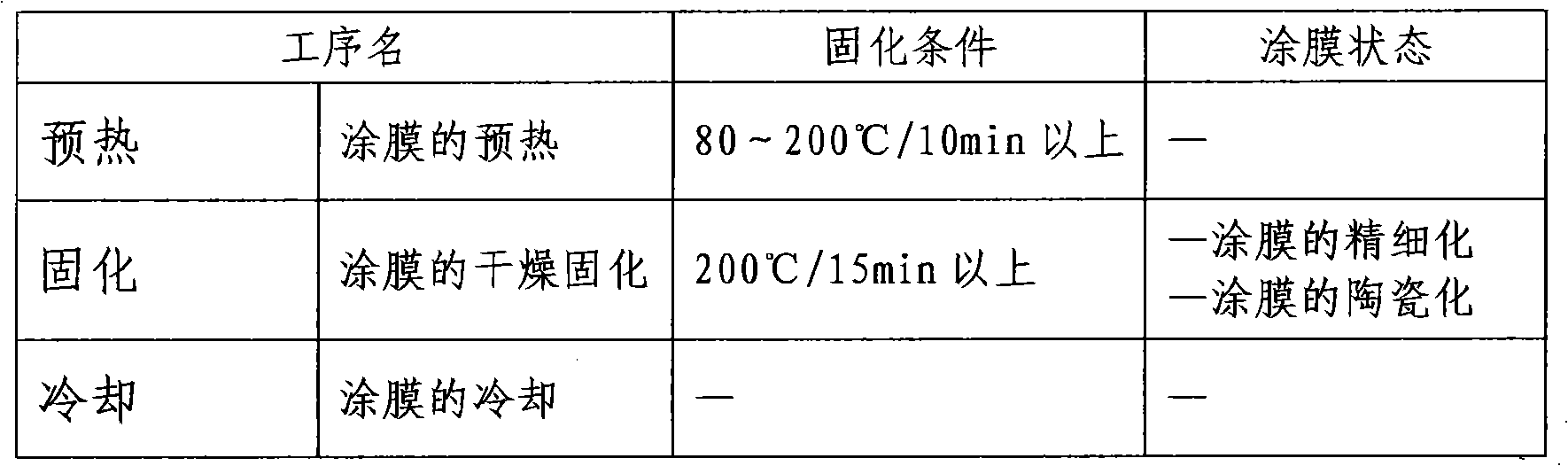

Surface treating method of electric iron metal base plate

InactiveCN101288867AIncrease profitNot easy to decolorizePretreated surfacesCoatingsMachining processImpurity

The invention provides a surface disposal method for an electric iron metal soleplate, comprising the steps as follows: 1) substrate disposal: the surface of the substrate of the soleplate is treated, so as to comply with the basic requirement of spraying; 2) coating aging: the coating is sufficiently and uniformly dispersed; meanwhile, the impurities in the coating are filtrated; 3) spraying procedure: the coating is uniformly sprayed and coated on the surface of the substrate; 4) drying and cooling: the sprayed product is dried and cooled. The method of the invention effectively reduces the times of surface spraying in the production process, reduces the consumption in the practical production process, greatly reduces the complexity of the process in the whole machining process, thus improving the utilization ratio of the whole resource and improving the production efficiency and the comprehensive performance of the products. The method has uniform surface spraying, high temperature resistance and wearability of the oxide film and difficult decoloration, and contains no heavy metals, thus having simple technical process, low fabrication expense and low loss in the machining process.

Owner:MIDEA GRP CO LTD

Gun-barrel surface treatment process

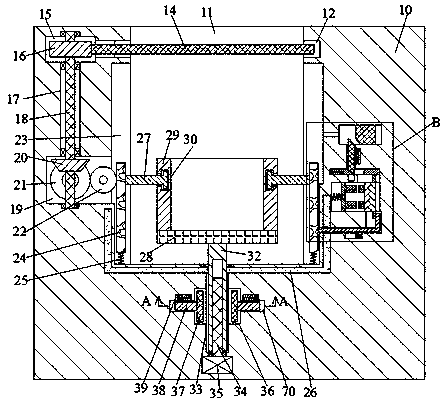

InactiveCN109280915AUniform temperatureSimple structureMetallic material coating processesPneumatic cylinderSurface finishing

The invention discloses a gun-barrel surface treatment process. A device used by the method comprises a device body, the device body is internally provided with a bluing processing cavity with an upward opening, an arc-shaped empty groove with an opening facing the processing cavity is formed in the periphery of the processing cavity in a communicating manner, a closing cover is arranged in the empty groove, the left side of the empty groove is provided with a rotating groove in a communicating manner, a rotating wheel is rotationally arranged in the rotating groove, and the right end of the rotating wheel and the left end of the closing cover are fixedly connected. The gun-barrel surface treatment process is simple in structure and convenient to operate; a threaded block is controlled bya pneumatic cylinder to move to be used for selecting a spline sleeve to perform rotation and rotation lifting operation, the closing cover is opened or closed through a linkage device, the automationdegree is high, and energy conservation and environmental protection are achieved; and treatment liquid is continuously at a suitable normal temperature through a temperature control device, and therotation of a filter net plate enables surface treatment to be uniform and cooling to be even, the precision of the device for gun-barrel surface treatment is improved, and the overall device is compact in structure, fully automatic and easy to operate.

Owner:金华瑞慈科技有限公司

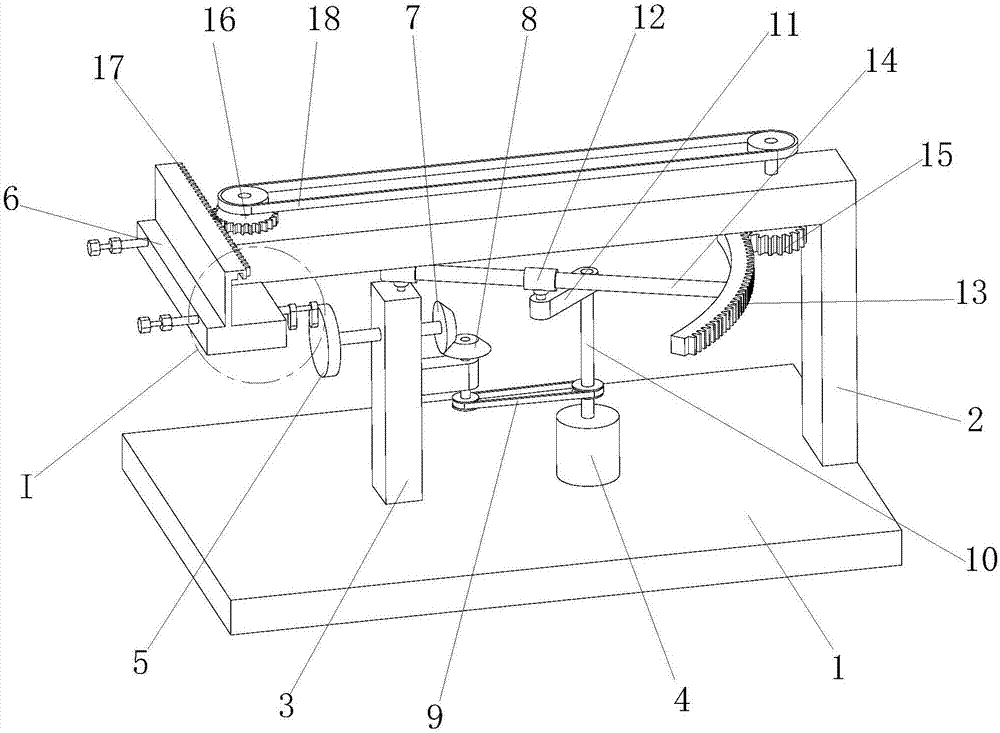

Simple type plate rust removal device

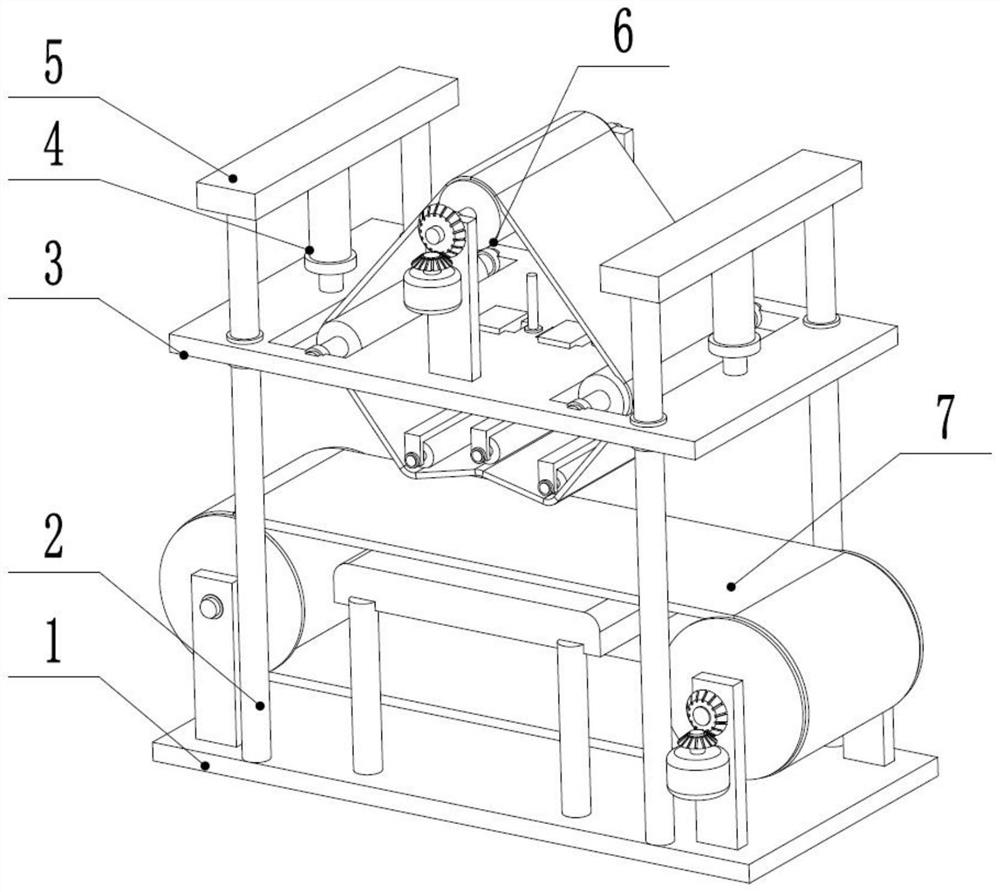

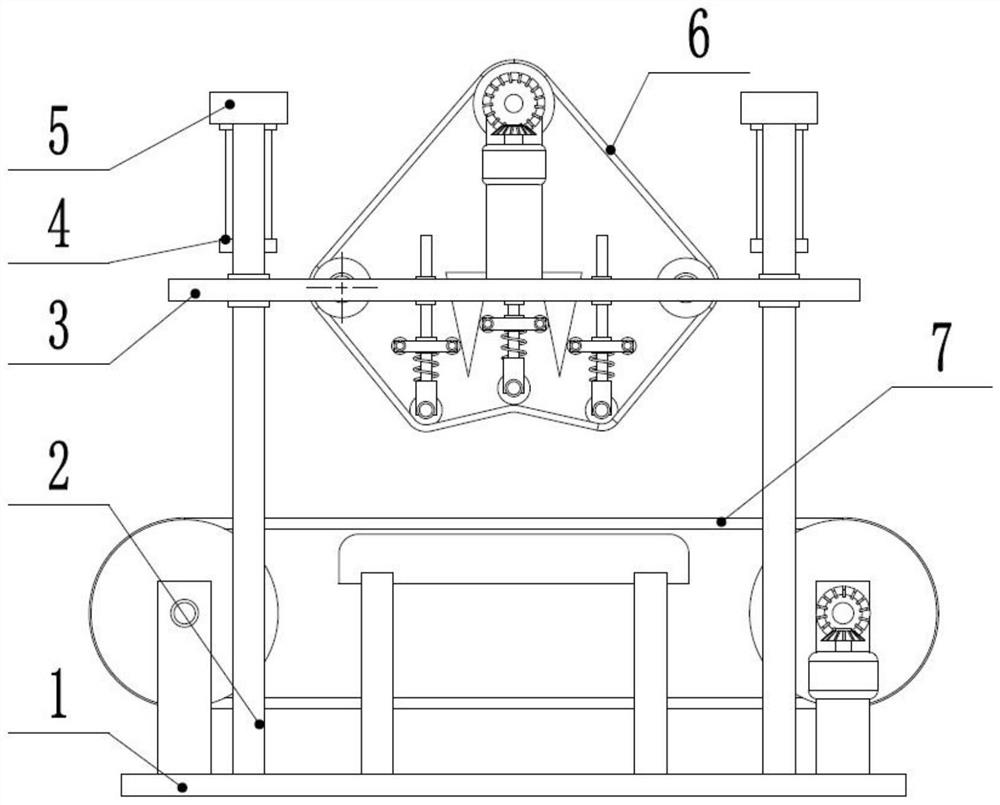

InactiveCN107097135AUniform surface treatmentIngenious structural designGrinding carriagesGrinding drivesReciprocating motionDrive motor

The invention relates to a simple type plate rust removal device. The simple type plate rust removal device comprises a bottom plate, an L-type supporting plate connected with the bottom plate, a mounting column fixed to the bottom plate, and a drive motor fixed to the bottom plate; the mounting column is provided with a grinding wheel; a transmission device is connected between the grinding wheel and the motor; the free end of the L-type supporting plate is provided with a fixing table which conducts horizontal reciprocating movement; a reciprocating swing mechanism is arranged between the fixing table and the motor; a clamping mechanism is arranged on the fixing table; the transmission device comprises a first bevel gear, a second bevel gear and a first transmission mechanism; the reciprocating swing mechanism comprises a long shaft, a swing rod, a slide sleeve, a long rod, a first gear, a second gear, a rack and a second transmission mechanism; and the clamping mechanism comprises a first threaded rod, a first clamping block, a second threaded rod and a second clamping block. By adoption of the device, the surfaces of plates can be completely ground and subjected to rust removal, the rust removal blind areas are eliminated, the whole device is driven by one drive motor, energy consumption is low, and stability of the device is good.

Owner:安徽鑫久亚光电科技有限公司

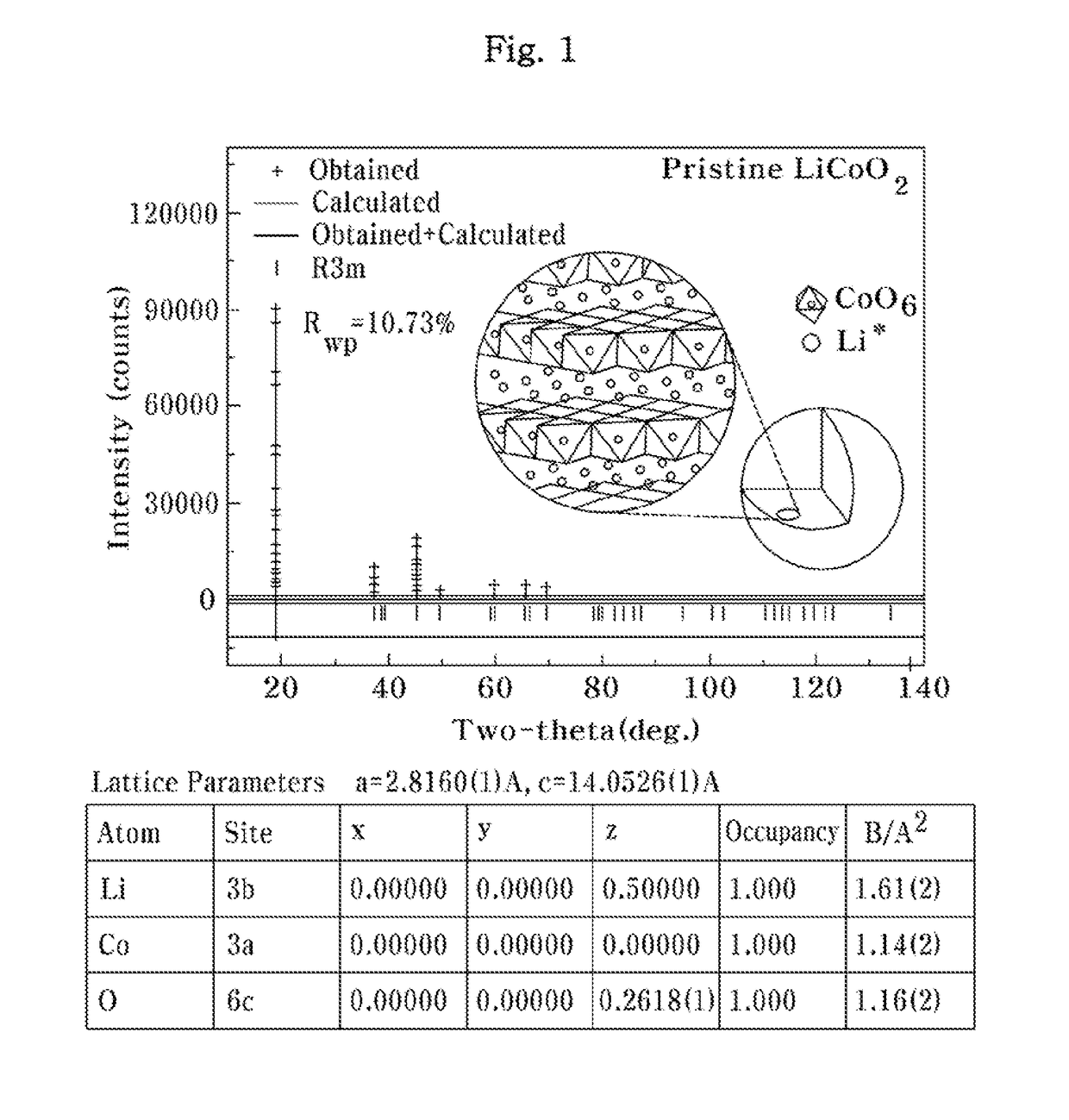

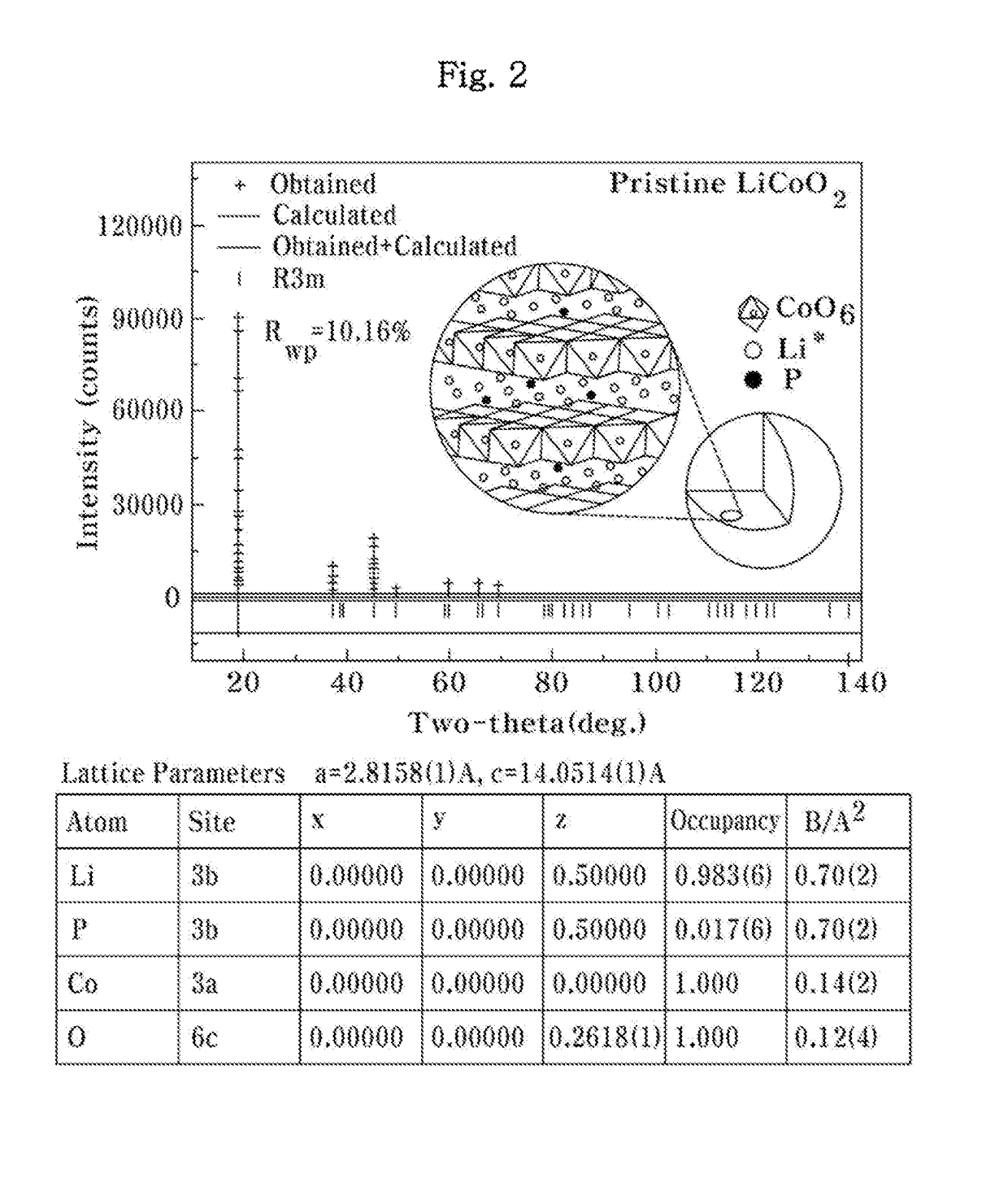

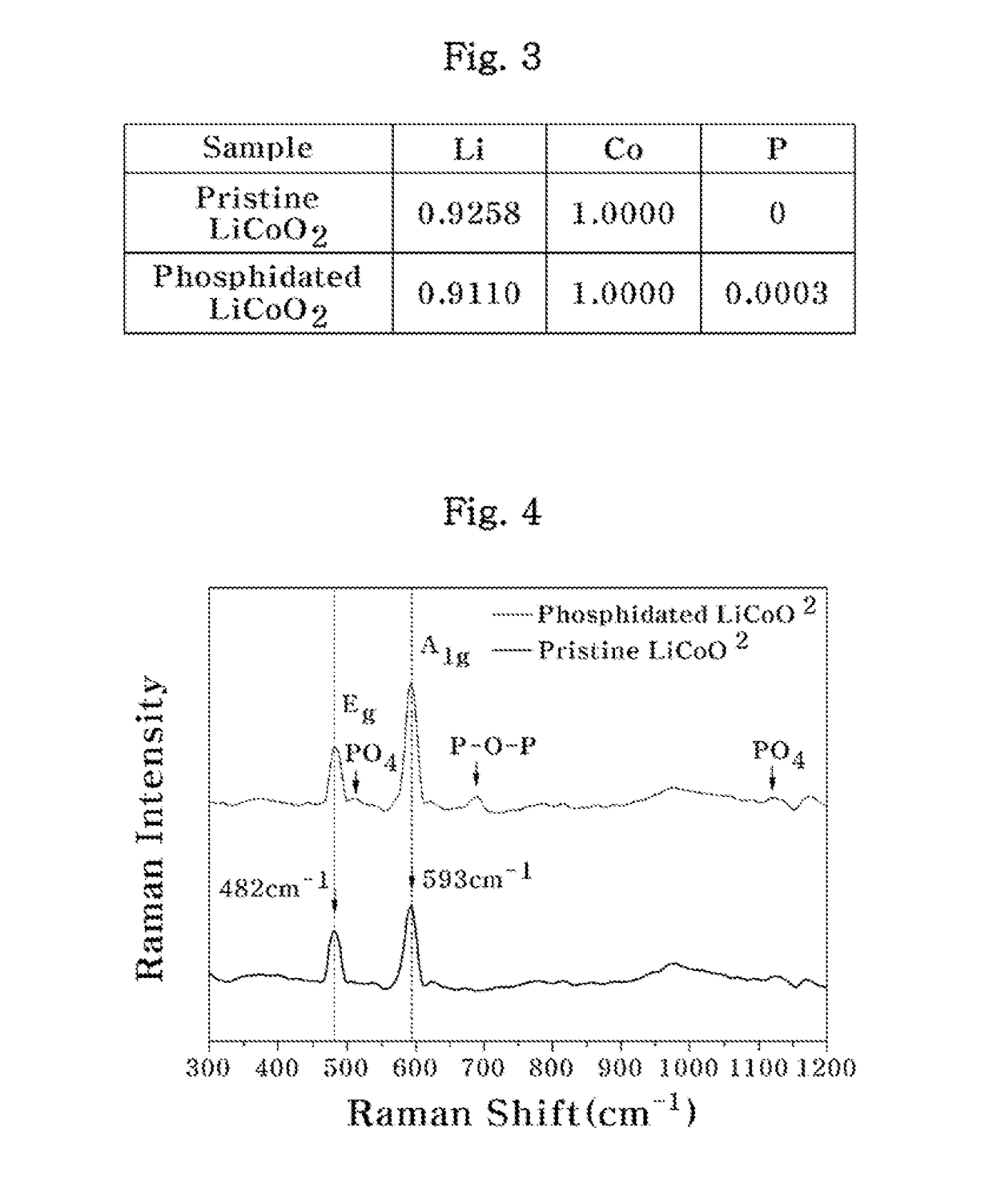

Surface treatment method for lithium cobalt oxide, and lithium secondary battery comprising same

ActiveUS20180123128A1Good reproducibilityImprove structural stabilityCell electrodesSecondary cellsLithiumO-Phosphoric Acid

The present invention relates to a surface treatment method for lithium cobalt oxide, comprising the steps of: (S1) mixing lithium cobalt oxide and an organic phosphoric acid compound; and (S2) heat treating and calcining the mixture prepared in step (S1). The surface treatment method of the present invention is simpler and has higher reproducibility than a conventional surface coating and doping technique, and can improve electrochemical characteristics by reinforcing the structural stability of lithium cobalt oxide. In addition, LiCoO2 prepared by the surface treatment method of the present invention is structurally stable during charging / discharging and does not cause unnecessary phase transition, and thus has excellent lifetime characteristics.

Owner:DONGGUK UNIV IND ACADEMIC COOPERATION FOUND

Method of modifying solid surface and product obtained

InactiveCN1629211AEasy to thermally decomposeUniform surface treatmentLayered productsPretreated surfacesSolid surfaceMaterials science

Provided are a method of modifying the surface of a solid substance that is difficult to bond to an adhesive solid substance without directly using a flame, and a solid substance that has undergone such surface modification. In this method, a gaseous substance containing a modifier compound having at least a silane atom, a titanium atom, or an aluminum atom is sprayed on a solid substance by a heat source at a temperature of 400° C. or higher, or, the modifier compound containing the After the gaseous substance is sprayed on the solid substance, it is heated to 400°C or higher by a heat source, or they are further combined for surface modification.

Owner:森泰浩

Apparatus for low-temperature plasma treatment

InactiveUS20070272153A1Maintaining dimensional stability without causing damage to the filmUniform surface treatmentElectric discharge tubesChemical vapor deposition coatingEngineeringPlastic film

An apparatus for low-temperature plasma treatment of a continuous length plastic film which can work for surface modifying processing for a film using low-temperature plasma while maintaining the dimensional stability without causing damage to the film. The apparatus for performing surface modifying processing for a film comprises: a first vacuum chamber equipped with an unrolling unit for unrolling a rolled plastic film; a second vacuum chamber in which the unrolled plastic film is subjected to a low-temperature plasma treatment on the surface; and a third vacuum chamber equipped with a winding unit for winding the plasma-treated plastic film into a roll, the vacuum chambers being connected together in series along the running direction of the plastic film under treatment.

Owner:SHIN ETSU CHEM IND CO LTD

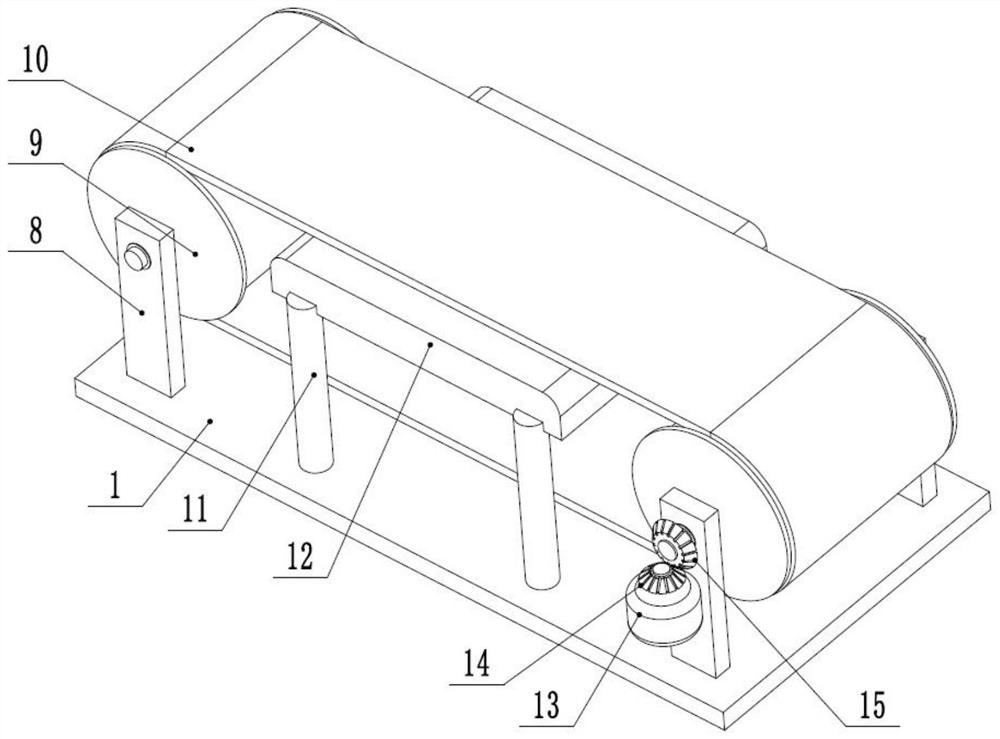

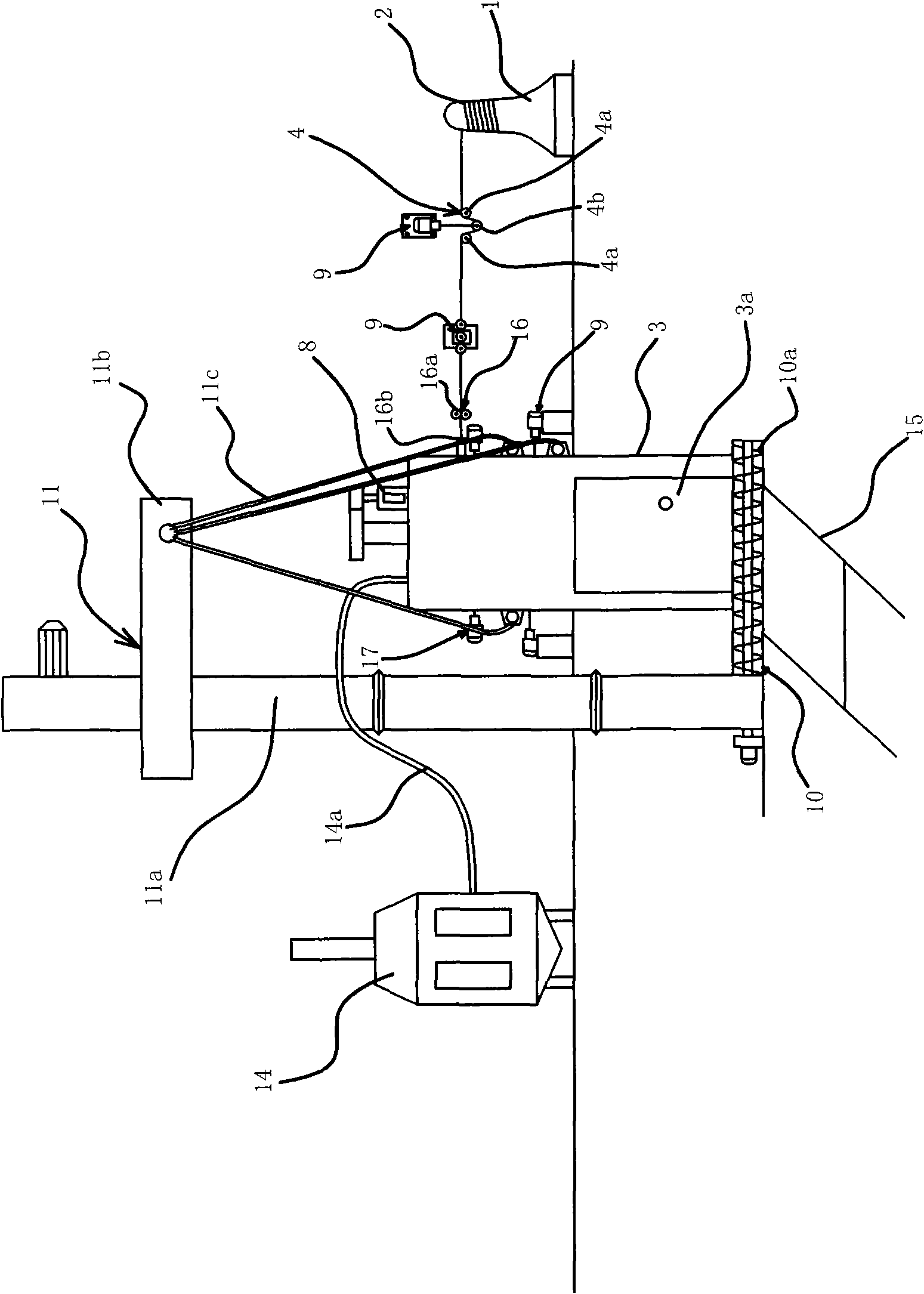

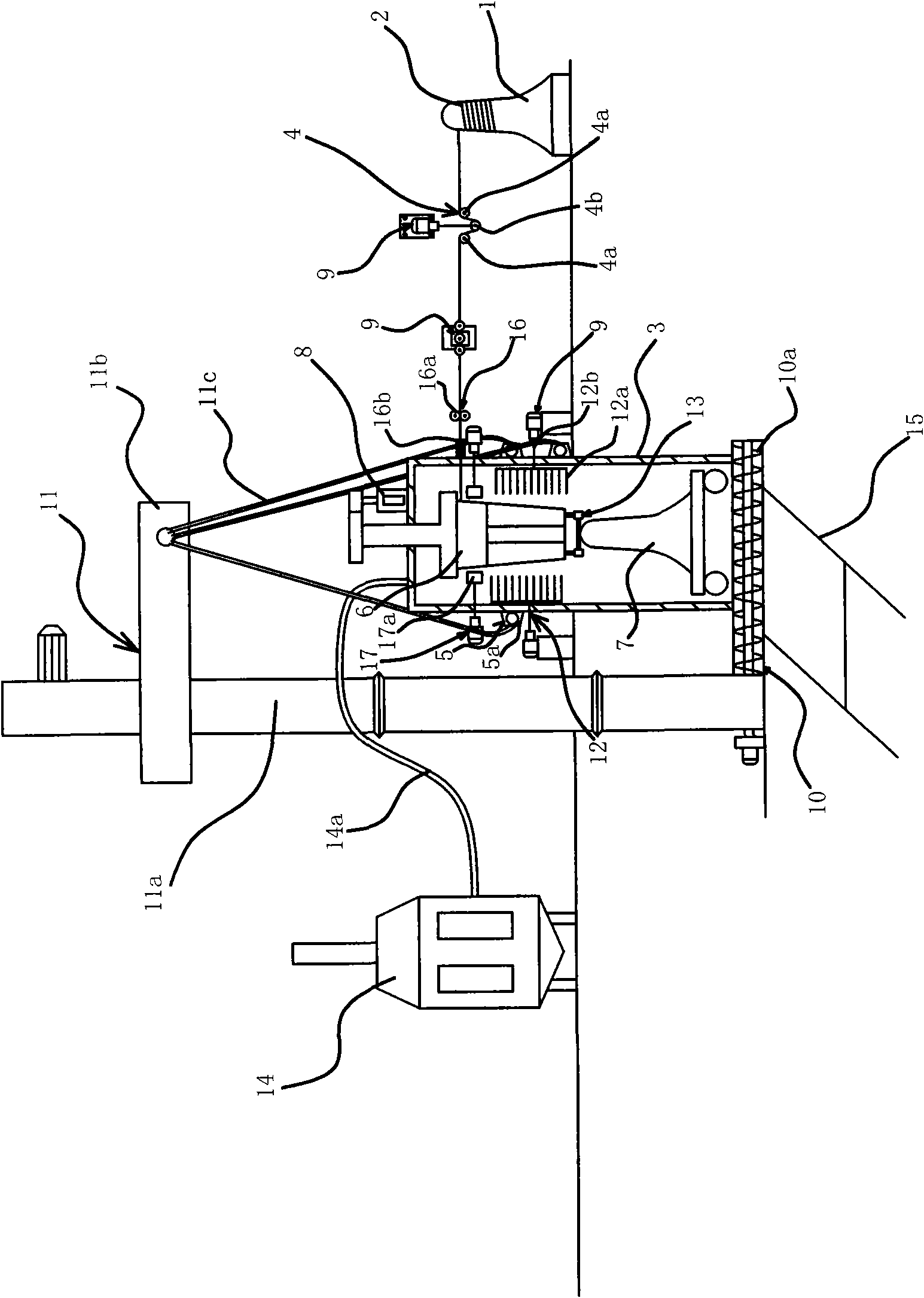

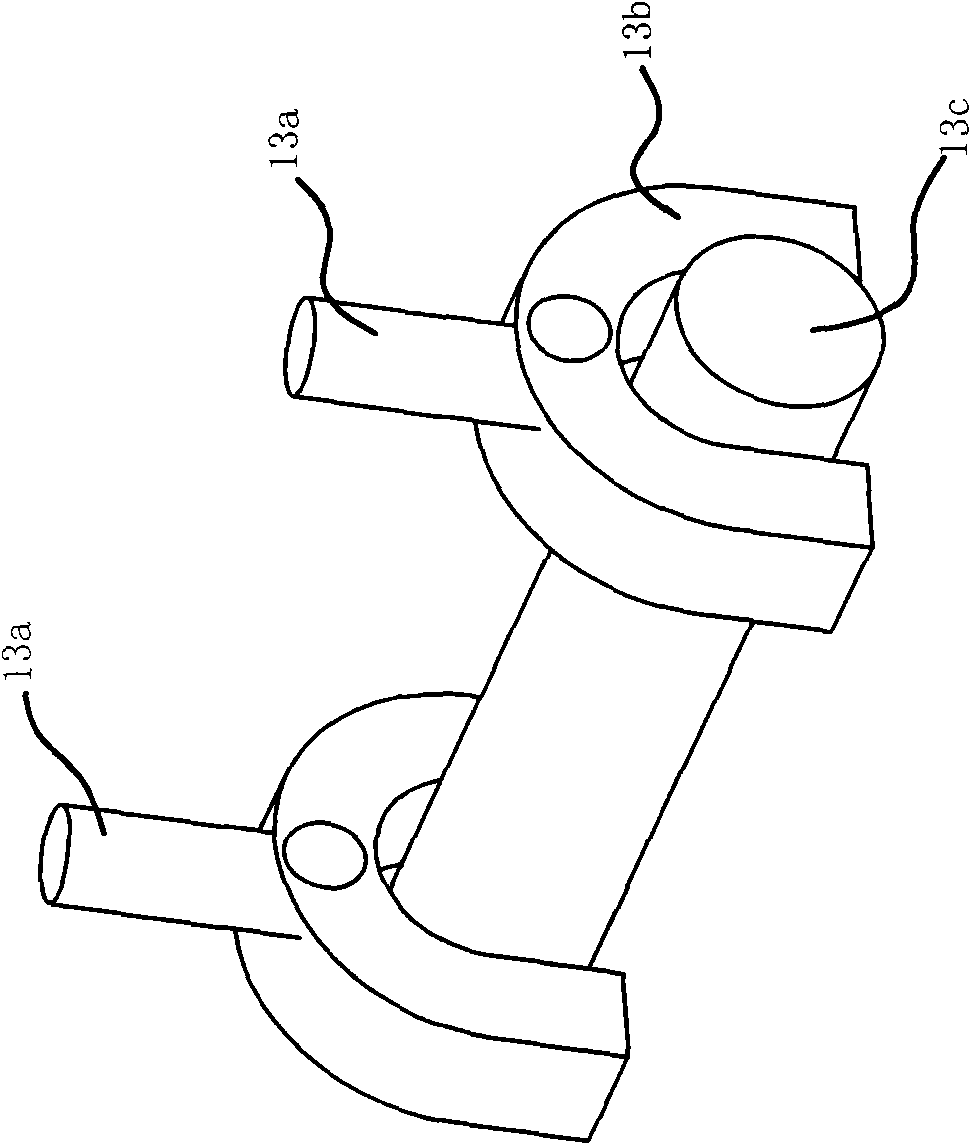

Shot-blasting device for automatically recycling steel shots and metal surface processor using same

InactiveCN102350665ANo pollution in the processRealize automatic recyclingAbrasive machine appurtenancesAbrasive blasting machinesImpellerDrive wheel

The invention relates to a shot-blasting device for automatically recycling steel shots and a metal surface processor using the same. The shot-blasting device is characterized by comprising a shot-blasting impeller and a semicircular top-sealed box which encloses the shot-blasting impeller, wherein the side wall of the box is an upright wall; a shot-blasting window is arranged at the bottom of the box; a shot-returning channel which is connected to a feeding hopper is arranged on the upper part on one side of the box corresponding to an upward rotating direction of the shot-blasting impeller; the feeding hopper is connected to the feeding port of the box through a shot-supplying valve; and the connecting port of a dust catcher is arranged on the feeding hopper. The metal surface processor is characterized in that a control box is arranged on the basis of the shot-blasting device; a dust catcher, a driving wheel, a driven wheel, a shot-blasting impeller driving motor, a walking motor for the driving motor and a dust-removing fan are all connected to the control box; and the driving wheel and the driven wheel are controlled by a height adjusting mechanism. The shot-blasting device and the metal surface processor provided by the invention have the advantages that the steel shots are automatically recycled in a closed loop during a process of processing the inner surface of a tank, thereby achieving the purposes of increasing the processing quality, promoting the production efficiency, reducing the cost, purifying environment and protecting health of operating personnel.

Owner:天津圣弘业环保科技有限公司

Apparatus for low-temperature plasma treatment

InactiveCN101077629AAvoid damageAvoid pollutionElectric discharge tubesEngineeringLow temperature plasma

An apparatus for low-temperature plasma treatment of a continuous length plastic film which can work for surface modifying processing for a film using low-temperature plasma while maintaining the dimensional stability without causing damage to the film. The apparatus for performing surface modifying processing for a film comprises: a first vacuum chamber equipped with an unrolling unit for unrolling a rolled plastic film; a second vacuum chamber in which the unrolled plastic film is subjected to a low-temperature plasma treatment on the surface; and a third vacuum chamber equipped with a winding unit for winding the plasma-treated plastic film into a roll, the vacuum chambers being connected together in series along the running direction of the plastic film under treatment.

Owner:SHIN ETSU CHEM IND CO LTD

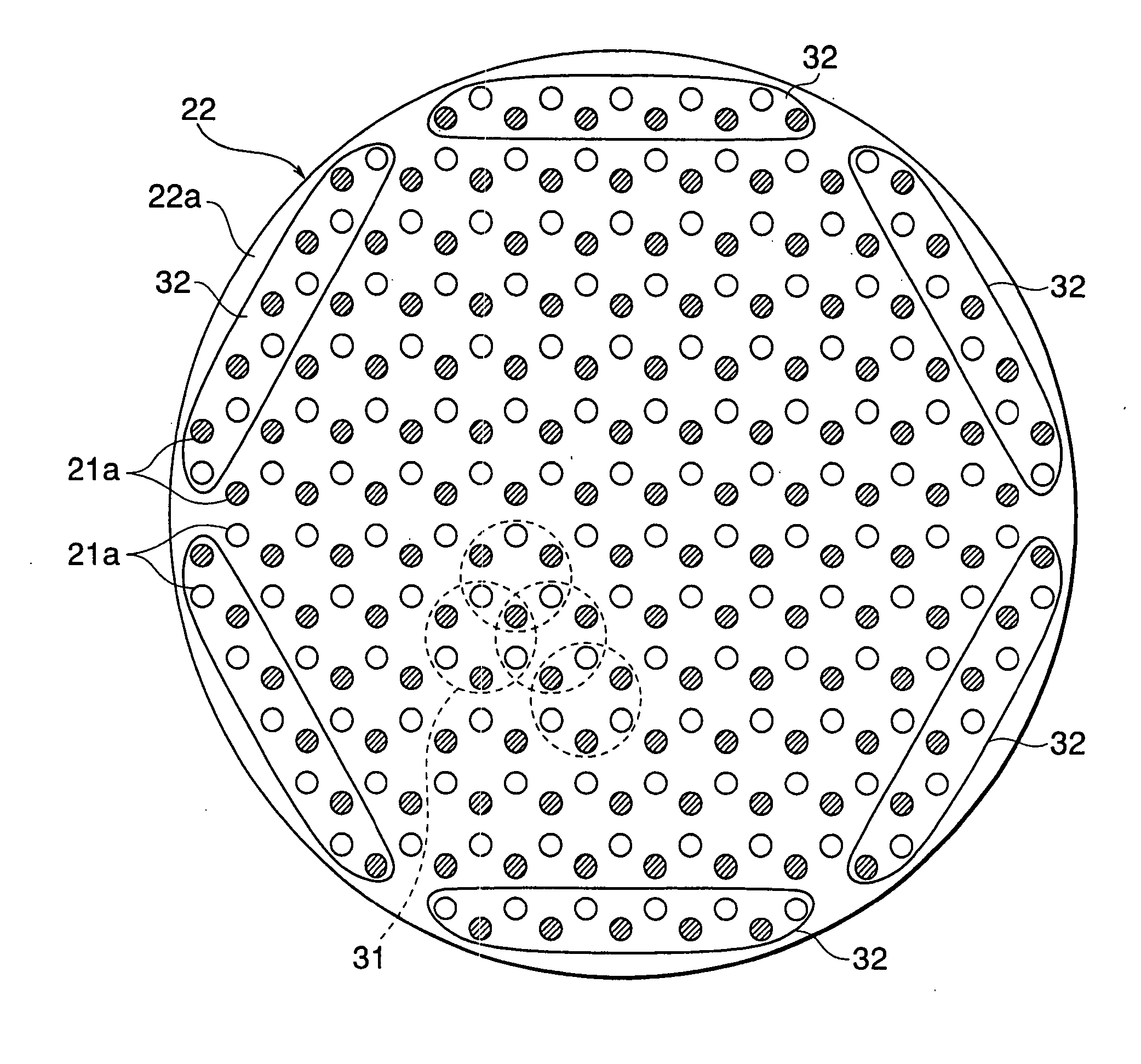

Surface processing apparatus

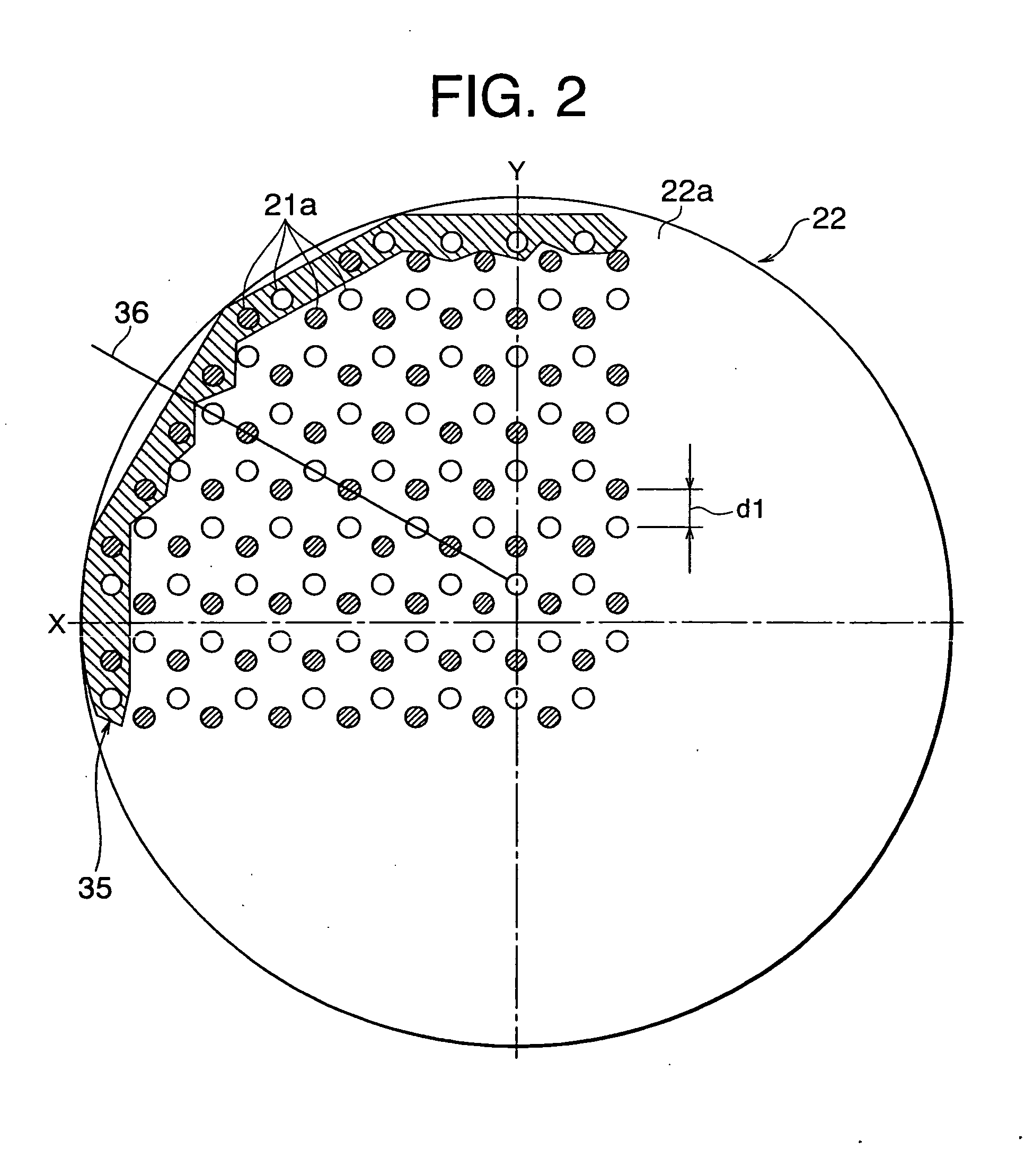

InactiveUS20110174221A1Reduce allocationUniform surface treatmentElectric discharge tubesSemiconductor/solid-state device manufacturingInterior spaceHoneycomb

This surface processing apparatus has a reactor in which plasma is generated and a substrate whose surface is to be processed by the plasma is arranged, and a magnet plate for creating a point-cusp magnetic field distributed in an inner space of the reactor, in which the plasma is generated. The magnet plate has a plurality of magnets. These magnets are arranged by a honeycomb lattice structure in a circular plane facing in parallel a surface of the substrate. One magnetic pole end face of each of magnets is arranged at a position of each of the lattice points forming hexagonal shapes on the circular plane. The polarities of the magnetic pole end faces of two adjoining magnets are arranged to become opposite alternately. The magnet plate may be provided with a plurality of magnets arranged by a lattice structure forming a square and the magnetic force (coercive force) of some of the magnets arranged at the outermost region is reduced. Thereby, the periodicity of the point-cusp magnetic field in the inside space is maintained as much as possible even at the peripheral edge and the asymmetry of the distribution of the magnetic field at the region where the periodicity is disturbed at the peripheral edge is reduced.

Owner:CANON ANELVA CORP

Curved surface polishing equipment for case accessory machining

PendingCN114102373AUniform surface treatmentImprove polishing effectGrinding carriagesGrinding drivesMachine partsPolishing

The invention relates to the technical field of machining, and discloses curved surface polishing equipment for case accessory machining, which comprises a bottom plate, guide columns are arranged on two sides of the bottom plate, a lifting plate is slidably connected to the middle parts of the guide columns, and the curved surface polishing equipment further comprises a polishing mechanism and a supporting mechanism; the supporting mechanism is arranged at the two ends of the bottom plate and comprises a first supporting plate fixedly connected with the bottom plate, the end, away from the ground, of the first supporting plate is rotationally connected with a first driving roller, and the outer side of the first driving roller is sleeved with a conveying belt; the polishing mechanism comprises a second supporting plate fixedly connected with the lifting plate, and the end, away from the ground, of the second supporting plate is rotationally connected with a second driving roller. According to the curved surface polishing equipment for case accessory machining, the triangular force transmission blocks and the top wheels are arranged in the curved surface polishing equipment, so that the pressures of different pressing rollers on a machined part are the same, the surface treatment of a grinding belt on the machined part is more uniform, and the whole grinding and polishing effect is better.

Owner:周梅

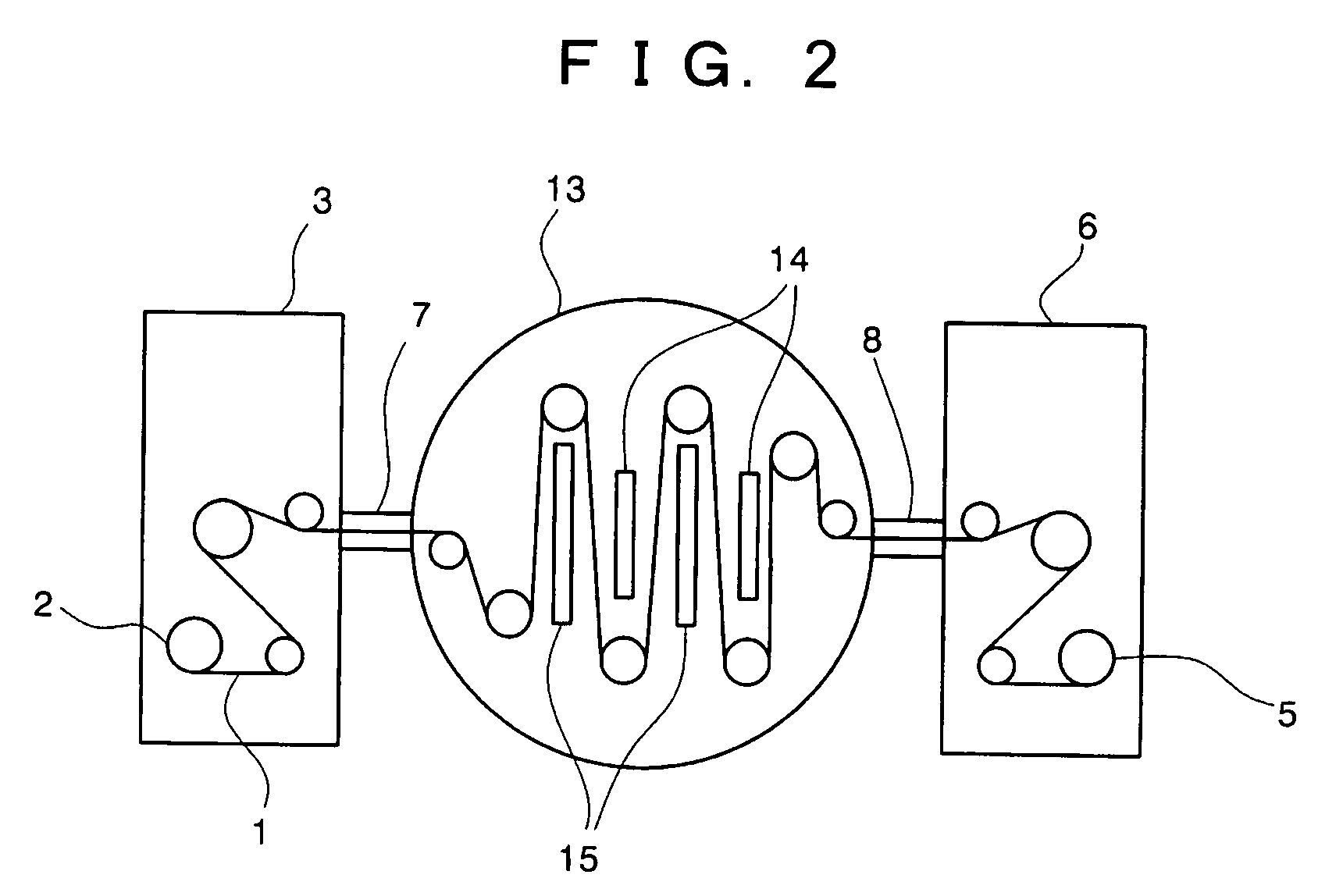

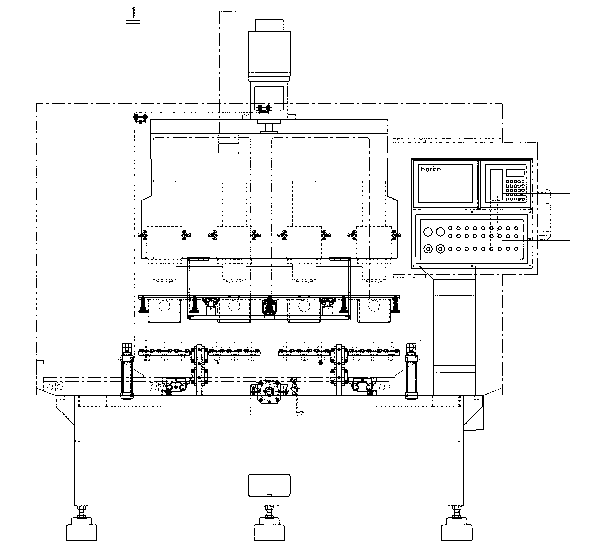

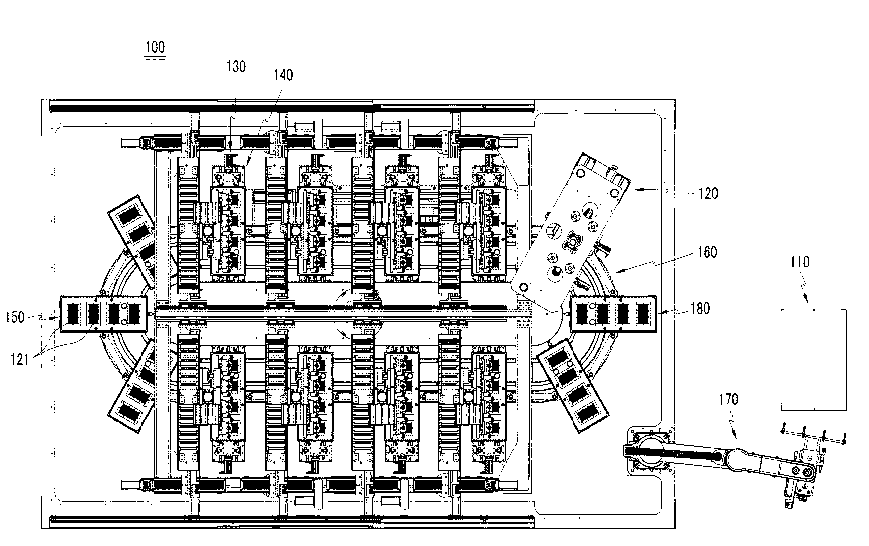

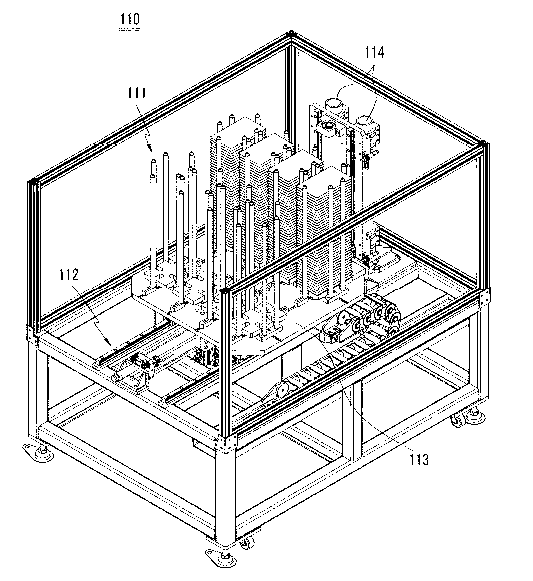

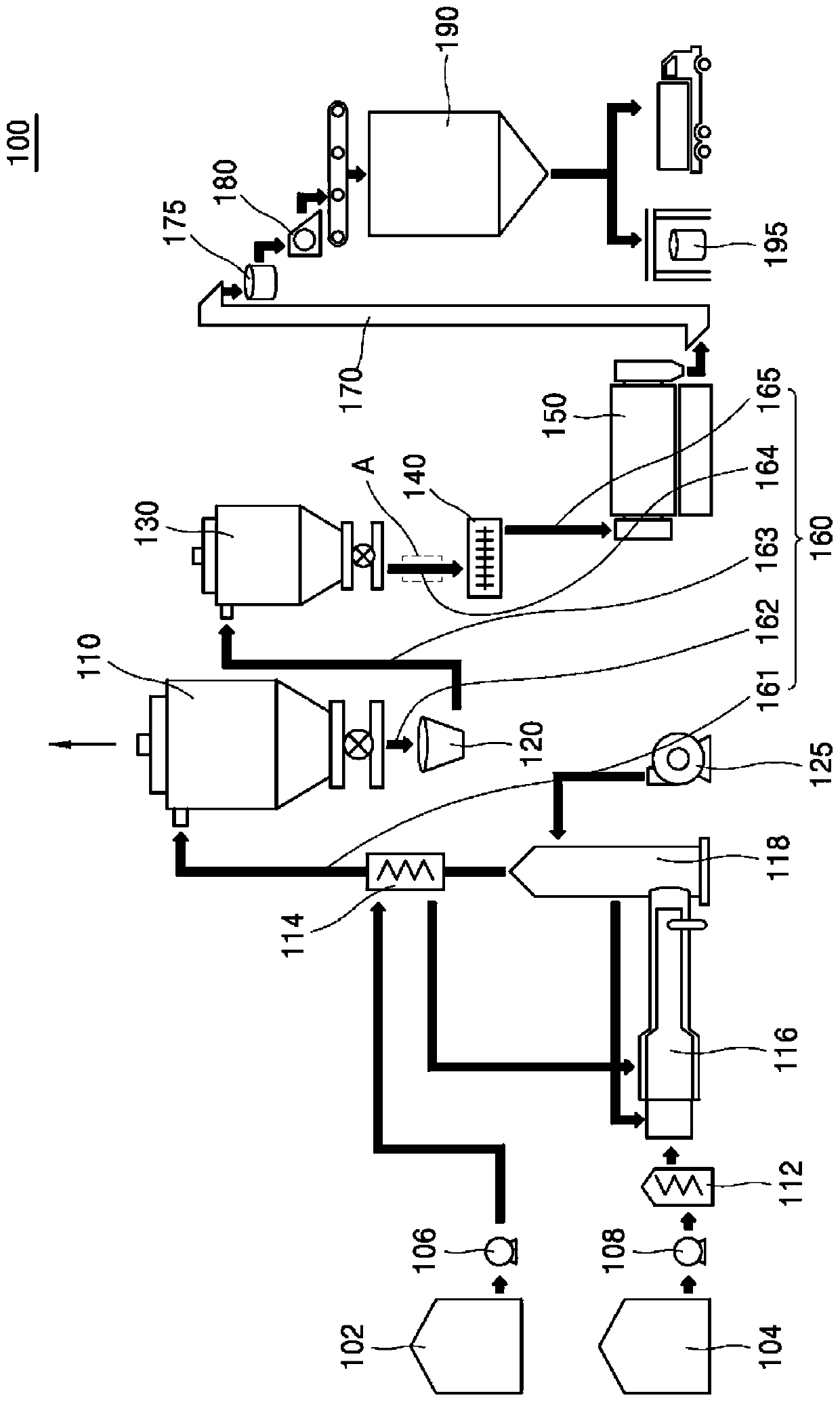

A method of manufacturing a chemically tempered thin glass using a full automated thin glass grinding machine with separated multi spindles and an apparatus for the same

InactiveCN102922385AFast processingIncrease production capacityGrinding drivesGrinding feedersEngineeringThin glass

An automatic machining device with multiple separated spindles for a thin sheet glass and a manufacturing method of a tempered glass using the same are provided to minimize non-uniform chipping, stress, and fine cracks caused by the deterioration of glass. CONSTITUTION: An automatic machining device(100) with multiple separated spindles for a thin sheet glass comprises a multi-shape supply unit(110), a multi-shape positioning unit(120), a horizontally moving and automatically aligning unit(130), and a multi-spindle grinding unit(140). The multi-shape supply unit supplies glasses to the multi-shape positioning unit. The multi-shape positioning unit determines the position of the supplied glasses. The horizontally moving and automatically aligning unit automatically aligns pallets(150) in which the glasses are positioned. The multi-spindle grinding unit is composed of multiple machining spindle assemblies for machining the glasses.

Owner:GLASONIC

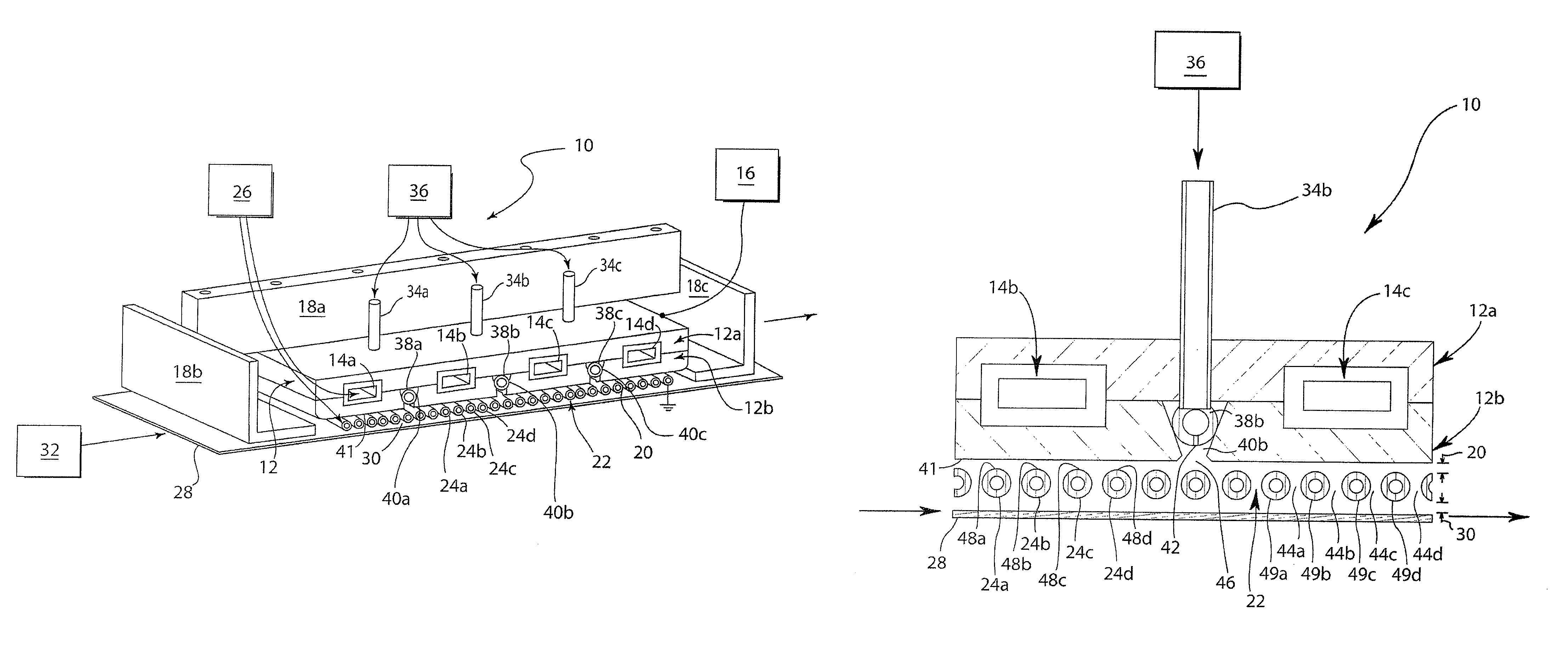

Plasma processing system

InactiveUS20050161317A1Uniform surface treatmentAvoid deformationElectric discharge tubesElectric arc lampsPlasma processingEngineering

A plasma processing apparatus M1 is provided with a processing part 20 for supporting a pair of elongate electrodes 30. The processing part 20 is provided with a plurality of pull bolts 52 (approach-deforming preventers) mutually spacedly arranged in the longitudinal direction of the electrode 30. A head part of each pull bolt 52 is hooked on a rigid plate 33 through a bolt holder 53, and a leg part thereof is screwed in the electrode 30. Owing to this arrangement, the electrodes 30 can be prevented from being deformed by Coulomb's force.

Owner:SEKISUI CHEM CO LTD

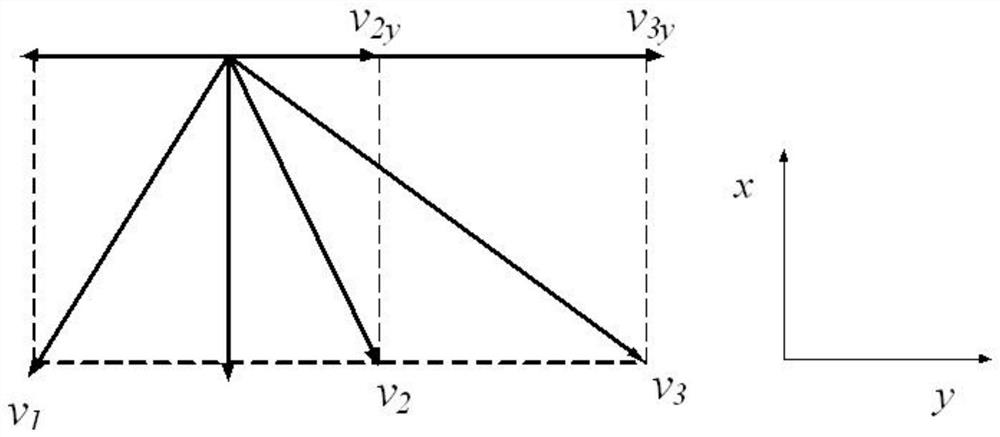

A system and application method for efficient and uniform processing of various profiles by ultrasonic shot peening

ActiveCN109249317BAvoid sharp anglesUniform surface treatmentAbrasive feedersAbrasive machine appurtenancesVibration amplitudePiezoelectric actuators

The invention discloses an ultrasonic shot blasting efficient and uniform processing system for various molded surfaces. The system comprises a workpiece clamping mechanism, a working table and a first connecting member arranged on the working table, a first vibration amplitude transformer, a mixer, a shot blast filling device, a jet mechanism, a driving mechanism, and a control system; a pair ofoppositely positioned first piezoelectric actuators are arranged at the first vibration amplitude transformer; the mixer is located above the first vibration amplitude transformer, and is used for mixing the compressed gas and the shot blast, the shot blast is sprayed to the end surface of the first vibration amplitude transformer, and the shot blast is accelerated by end surface rebounding to process a workpiece at a lower part; The workpiece clamping mechanism includes a second connecting member, a second vibration amplitude transformer, the second vibration amplitude transformer is mountedwith a second piezoelectric actuator, and is capable of generating axial-bending-torsional coupling vibration. The system can improve the speed of shot blast processing, under the action of the vibration of the second vibration amplitude transformer, the workpiece is uniformly processed at a high speed, and efficient processing of the workpiece is realized.

Owner:CENT SOUTH UNIV

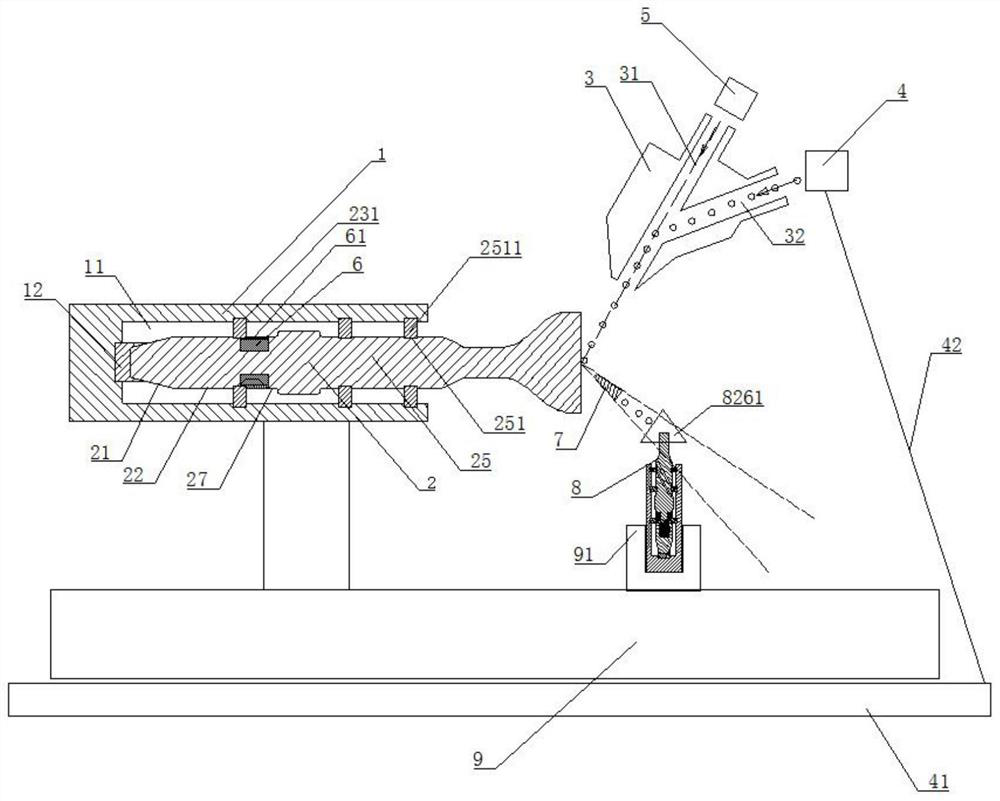

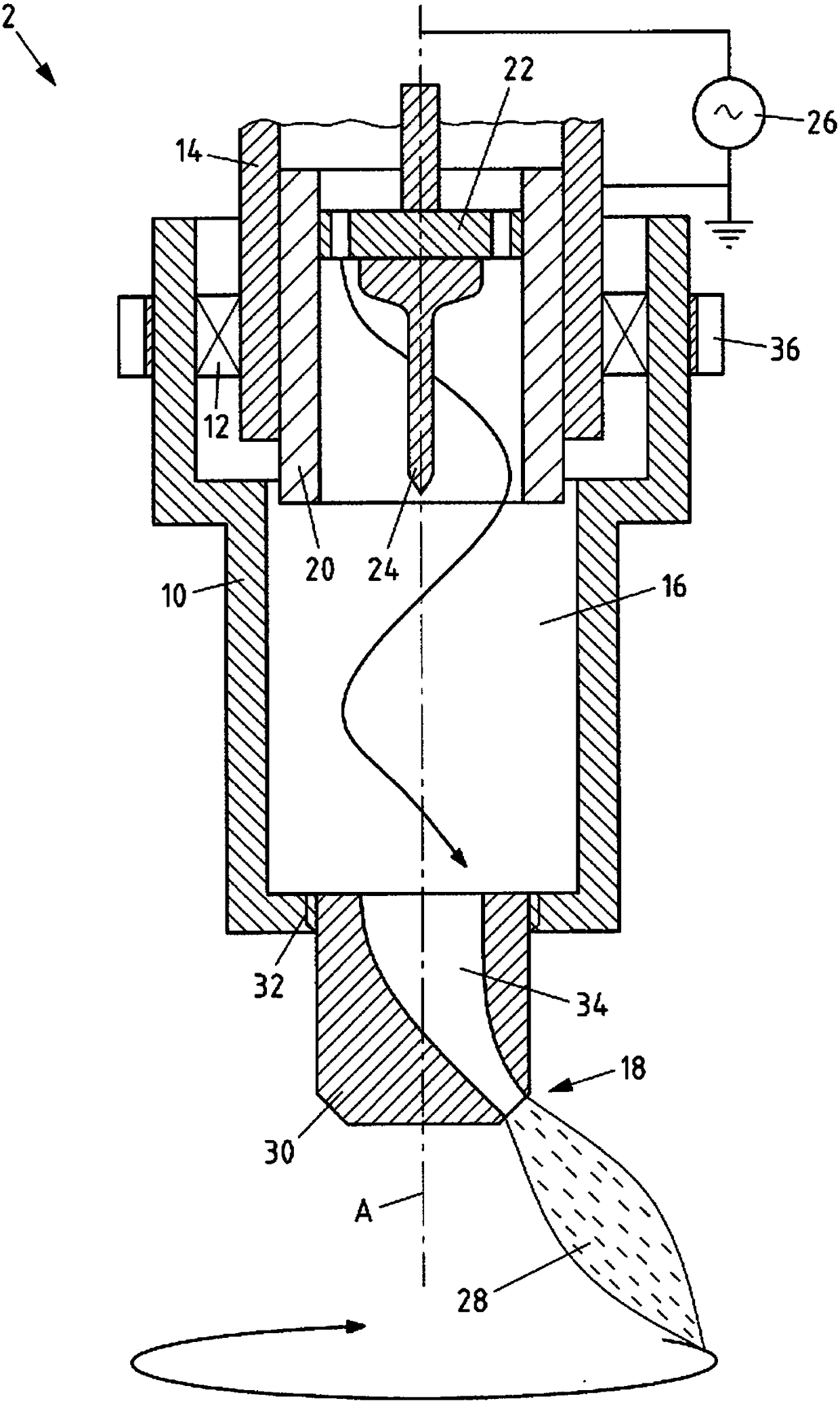

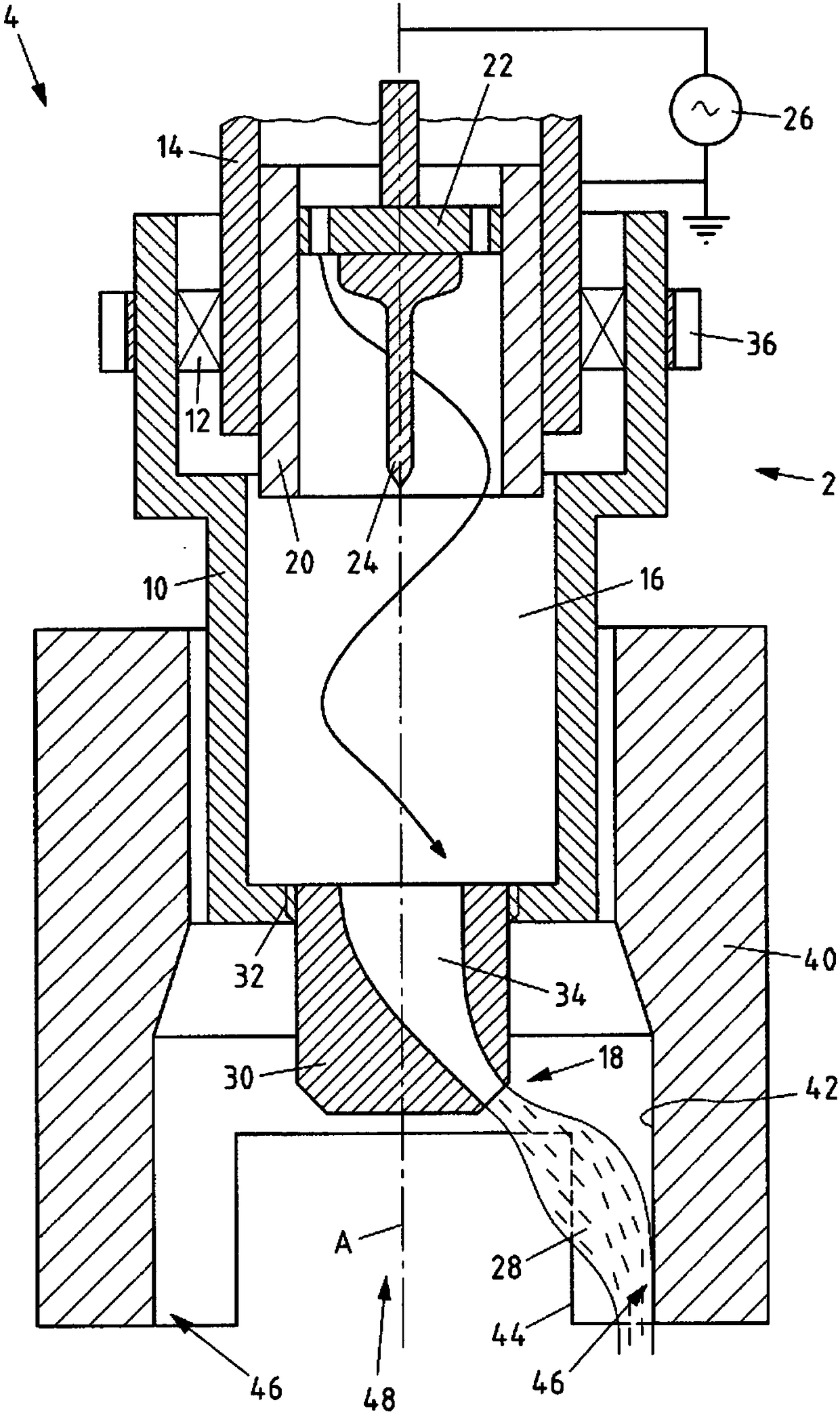

Device for generating atmospheric plasma beam, and method for treating surface of workpiece

The invention relates to a device for generating an atmospheric plasma beam for treating the surface of a workpiece, comprising a tubular housing (10) which has an axis (A), an inner electrode (24) arranged within the housing (10), and a nozzle assembly (30) which has a nozzle opening (18) for discharging a plasma beam to be generated in the housing (10). The direction of the nozzle opening (18) runs at an angle relative to the axis (A), and the nozzle assembly (30) can be rotated about the axis (A). The aim of the invention is to develop the aforementioned device, system, and method for treating the surface of a workpiece such that the aforementioned disadvantages are at least partly eliminated and a uniform treatment of the surface is achieved. This is achieved in that a shield (40) surrounds the nozzle assembly (30), and the shield (40) is designed to change the intensity of the interaction of the plasma beam to be generated with the surface of the workpiece depending on the rotational angle of the nozzle assembly (30) relative to the axis (A). The invention also relates to a method for treating the surface of a workpiece.

Owner:PLASMATREAT GMBH

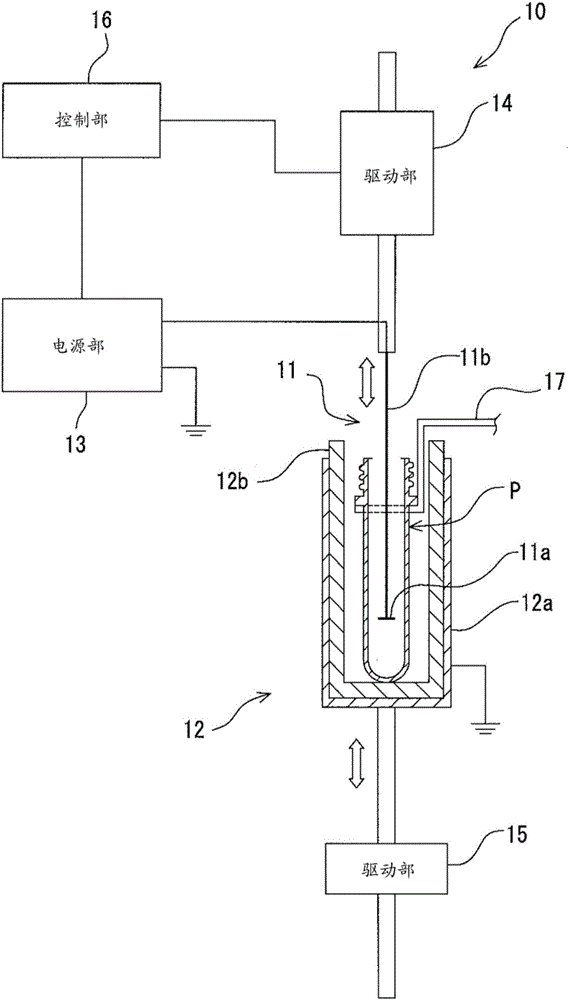

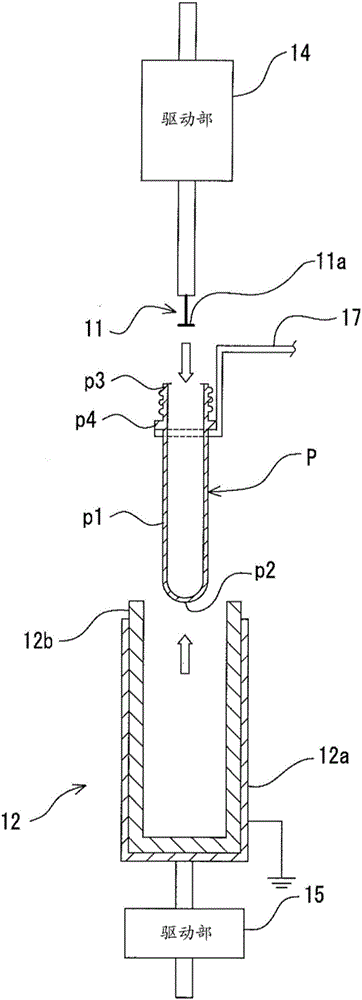

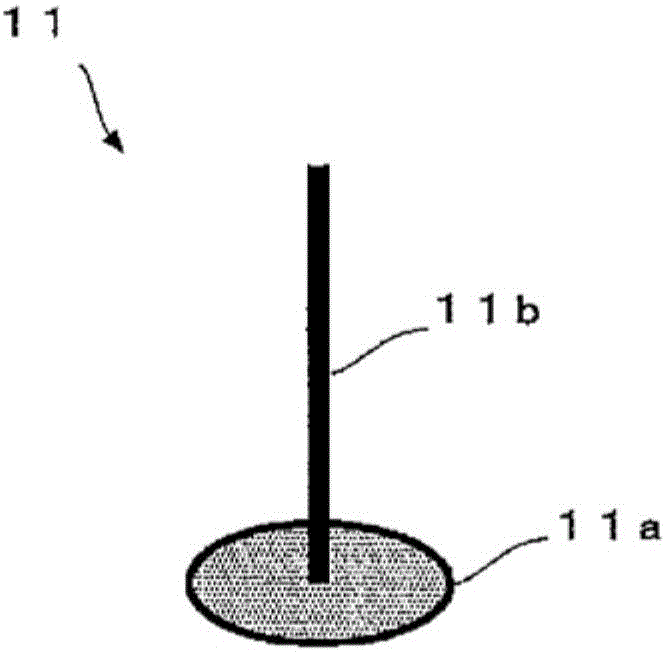

Method for sterilizing preform and resin container

ActiveCN106470905AEfficient modificationGood modification effectPackage sterilisationPackaging under special atmospheric conditionsPolyethylene terephthalatePolyethylene terephthalate glycol

A method for sterilizing preform and resin container increases the sterilizing effect of hydrogen peroxide on a preform or a resin container. The present invention subjects the inner surface of a preform or a resin container to a corona discharge treatment including: a voltage application step for applying a voltage produced by a corona discharge to an electrode capable of passing through the opening in a preform or resin container comprising a material having polyethylene terephthalate as a principal component thereof; an insertion step for inserting the electrode to which the voltage has been applied into the preform or resin container through the opening; and a floor section treatment step for treating the inner surface of the floor section of the preform or resin container by bringing the electrode close to the floor section thereof, until the state of corona discharge from the electrode changes. Thereafter, the present invention subjects the preform or resin container to a sterilization treatment including a hydrogen peroxide supply step for spraying a hydrogen peroxide mist or gas or mixture thereof into the preform or resin container.

Owner:DAI NIPPON PRINTING CO LTD

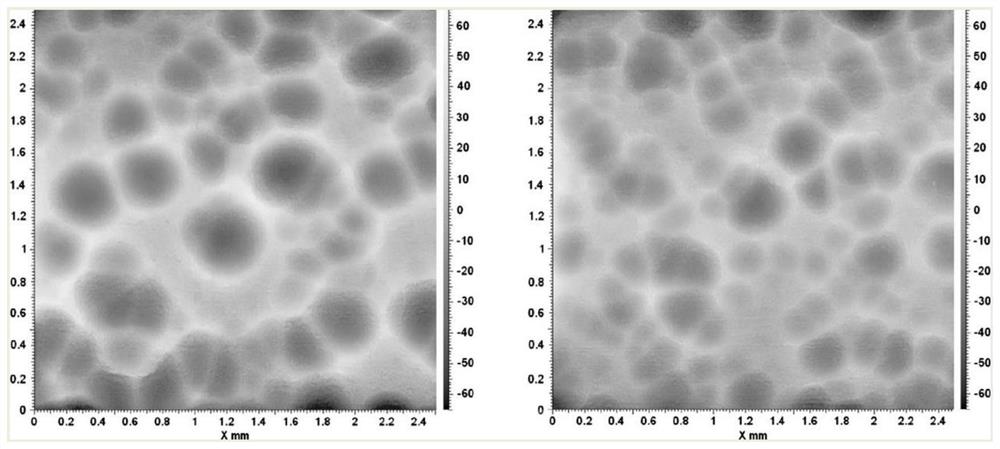

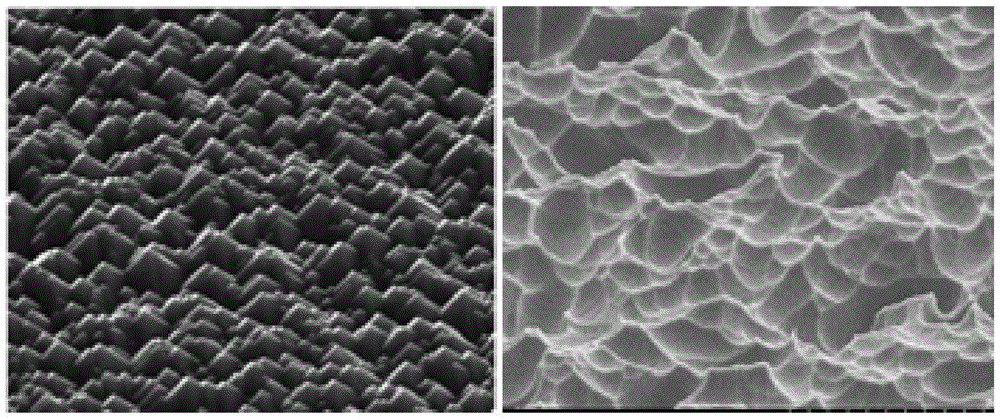

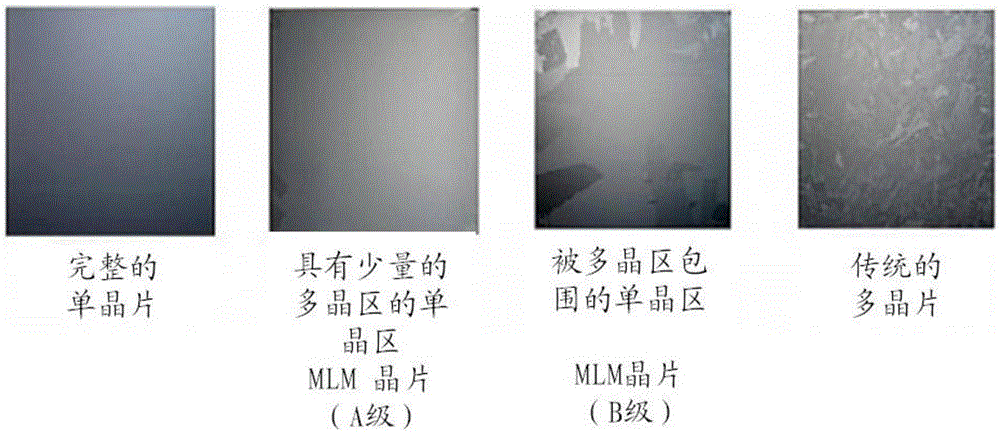

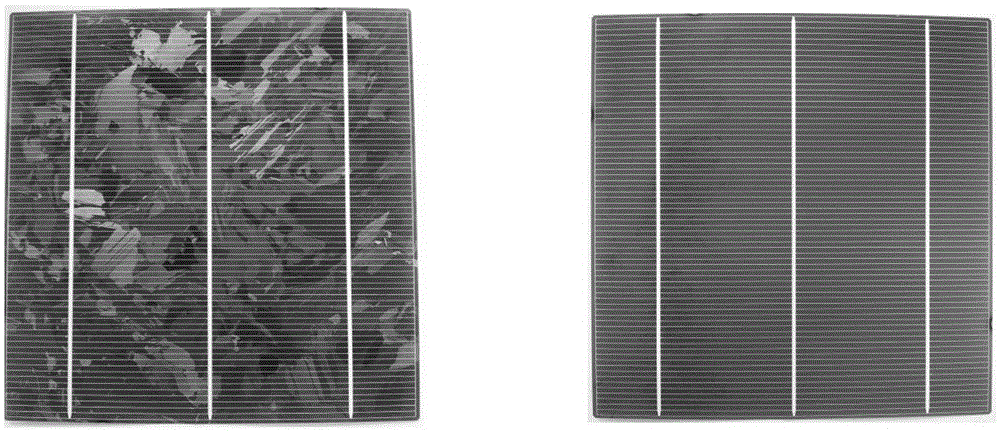

Surface treatment method of substrate for solar cell

InactiveCN103849937BUniform surface treatmentSimple processAfter-treatment detailsFinal product manufactureSingle crystal substrateSingle crystal

PROBLEM TO BE SOLVED: To provide a method of performing surface treatment of a substrate for solar cell, especially of a pseudo single crystal substrate, effectively regardless of the type and directivity of crystal.SOLUTION: In a method of performing surface treatment of a substrate for solar cell, a pyramid structure is formed on the surface of a substrate by performing a first wet etching step, a reactive ion etching step, and a second wet etching step. Such a pyramid structure contributes to enhancement of light absorption efficiency of a solar cell, by lowering the optical reflectance. Efficiency of a solar cell can be enhanced by performing surface treatment of a pseudo single crystal substrate effectively, regardless of the type and directivity of crystal.

Owner:HANWHA CHEMICAL CORPORATION

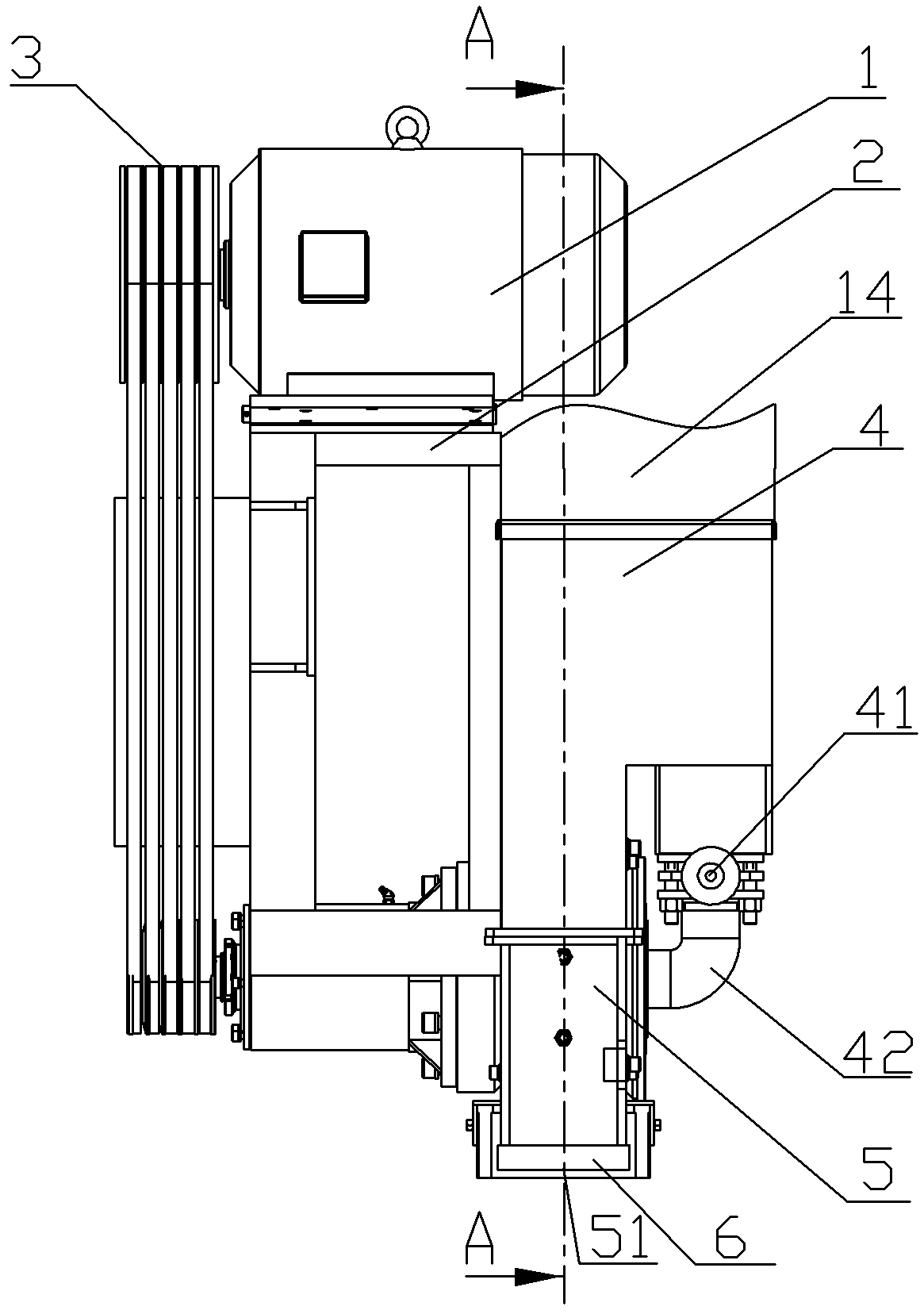

Wire rod rolled product surface processing device

InactiveCN101607383AUniform surface treatmentGood effectAbrasive machine appurtenancesAbrasive blasting machinesSurface finishingMetal

The invention provides a wire rod rolled product surface processing device, belonging to the technical field of metal surface processing. The invention solves the technical problems of small output, low efficiency, increased operation cost, unfavourable effect and the like of the existing wire rod rolled product surface processing device. The wire rod rolled product surface processing device of the invention comprises a material discharging rotary drum on which the wire rod rolled product is arranged, a casing and a material discharging door which is arranged on the lower part of the casing, wherein, the material discharging rotary drum can rotate, the upper part of the inner cavity of the casing is provided with a vertical rotary drum driven to rotate by a motor, and the outer side of the vertical rotary drum is provided with a rust removal mechanism; the inlet end of the wire rod rolled product passes through the casing to enter the inner cavity of the casing, the inlet end of the wire rod rolled product is coiled on the vertical rotary drum by a pressing mechanism, the lower part of the inner cavity of the casing is provided with a rotatable material receiving rotary drum, and the vertical rotary drum is connected with the material receiving rotary drum by a connection structure. The invention has the advantages of high efficiency, favourable descaling effect and rust removal effect and the like.

Owner:刘传玲

Surface treatment method of cleaning air inlet

ActiveCN102211310ASatisfy batch processing tasksLower requirementSuperfinishing machinesAfter treatmentSurface roughness

The invention provides a surface treatment method of a cleaning air inlet. The method has the advantages of uniformity in surface treatment and high efficiency, the surface roughness after treatment is within Ra0.6, and the surface roughness of an internal channel is within Ra0.4. The method comprises the steps of: placing a cleaning air inlet in a vibrating finishing machine, and grinding the surface of the cleaning air inlet by using a grinding medium, wherein the vibrating frequency of the finishing machine is 35-40Hz, the vertical amplitude is 6.0-6.25mm, and the horizontal amplitude is 6.75-7.0mm.

Owner:苏州利达铸造有限公司

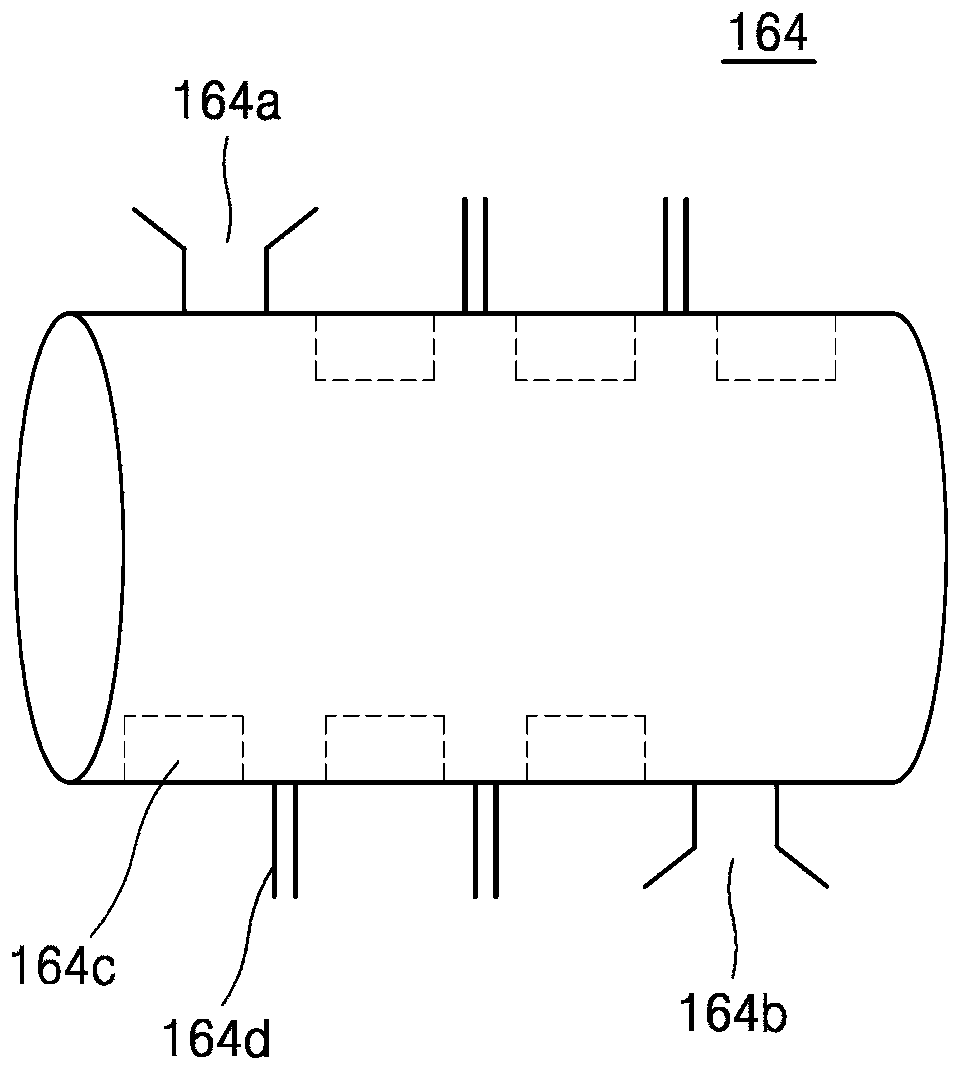

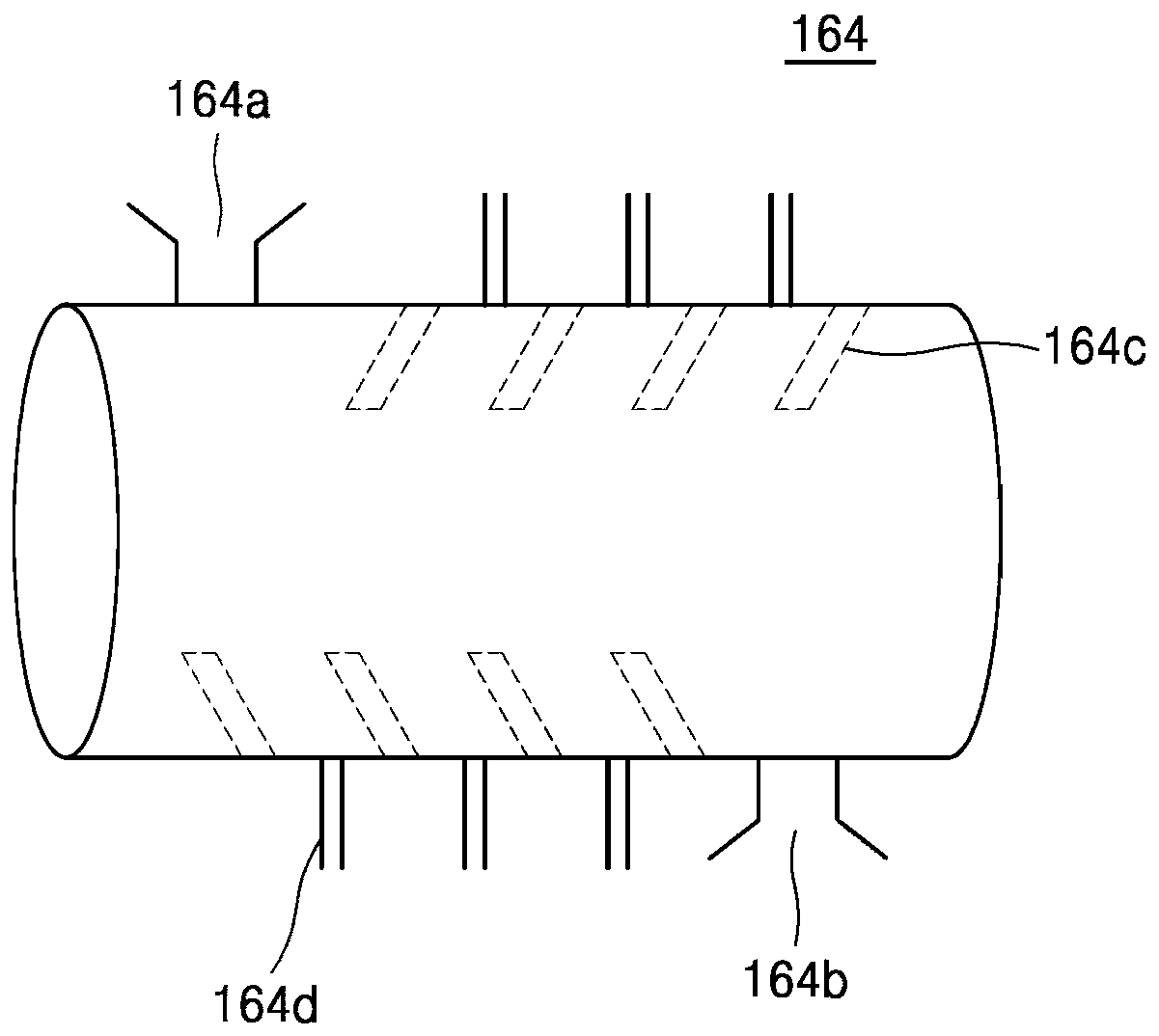

Carbon black production apparatus

ActiveCN109971218AImprove stabilityImprove efficiencyPigment physical treatmentMaterials scienceRaw material

The present invention relates to a carbon black production apparatus which is provided with a reactor capable of uniformly oxidizing carbon black, thereby continuously surface-treating carbon black while producing raw material carbon black.

Owner:OCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com