Patents

Literature

44results about How to "Uniform shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

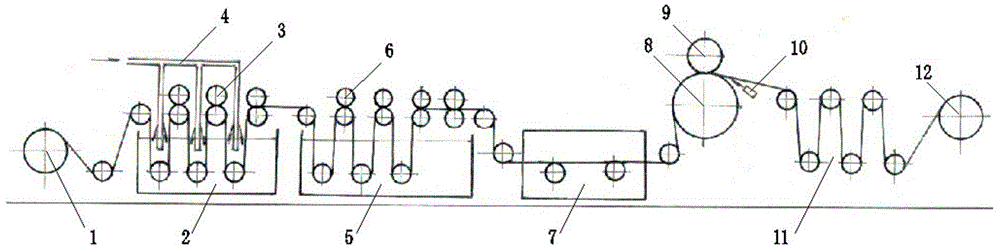

Terylene half speed blended spinning-type ammonia-substituted fiber blended spinning method and its apparatus

InactiveCN101265627AMeet the target requirementsStable Intrinsic IndexFilament/thread formingHeating/cooling textile fabricsYarnSingle stage

The invention designs a blending method and a device for terylene medium-speed blended ammoniac fibers, and includes section transporting and screening, section drying, screw extrusion, melting and spinning, and air blast cooling. The invention is characterized by the following steps: respectively enter POY spinning and FDY spinning after cooling, entering a nozzle for oiling after POY spinning, and then entering a pre-network; entering a tanker for oiling after FDY spinning, entering the pre-network, entering hot-rolling and drafting, enabling POY filaments and FDY filaments to enter into a guiding flute-type draw-off godet for combining and compounding, entering a go-between after compounding, hot-rolling and sizing, and winding and forming after entering a primary network. The blending method for the terylene medium-speed blended ammoniac fibers can produce FDY and POY composite network yarn by the single-stage process, the combined network yarn ITY product produced by the method has stable inner index and quality, little influencing factor, uniform waster-water shrinkage rate, stable chromaticity, and great economic benefit.

Owner:TONGKUN GRP

Method for joint coating on pipeline by heat-shrinkable tape

ActiveCN101709821AEffective combinationUniform shrinkageCorrosion preventionPipe elementsProduct gasBond strength

The invention discloses a method for joint coating on pipeline by heat-shrinkable tape, which comprises the following process flows of: polarization treatment on the heat-shrinkable tape, blasting treatment on a surface of the joint coating, gas treatment on the surface of the joint coating, preservative treatment on the surface of the joint coating, wrapping the heat-shrinkable tape on the surface of the joint coating and other procedures. The method has the advantages of simple process, simple and convenient operation, strong bond strength, high anti-corrosive property, long service life, wide adaptive temperature range, and convenient construction, and is beneficial to popularization and application.

Owner:北京双元油通工程技术有限公司

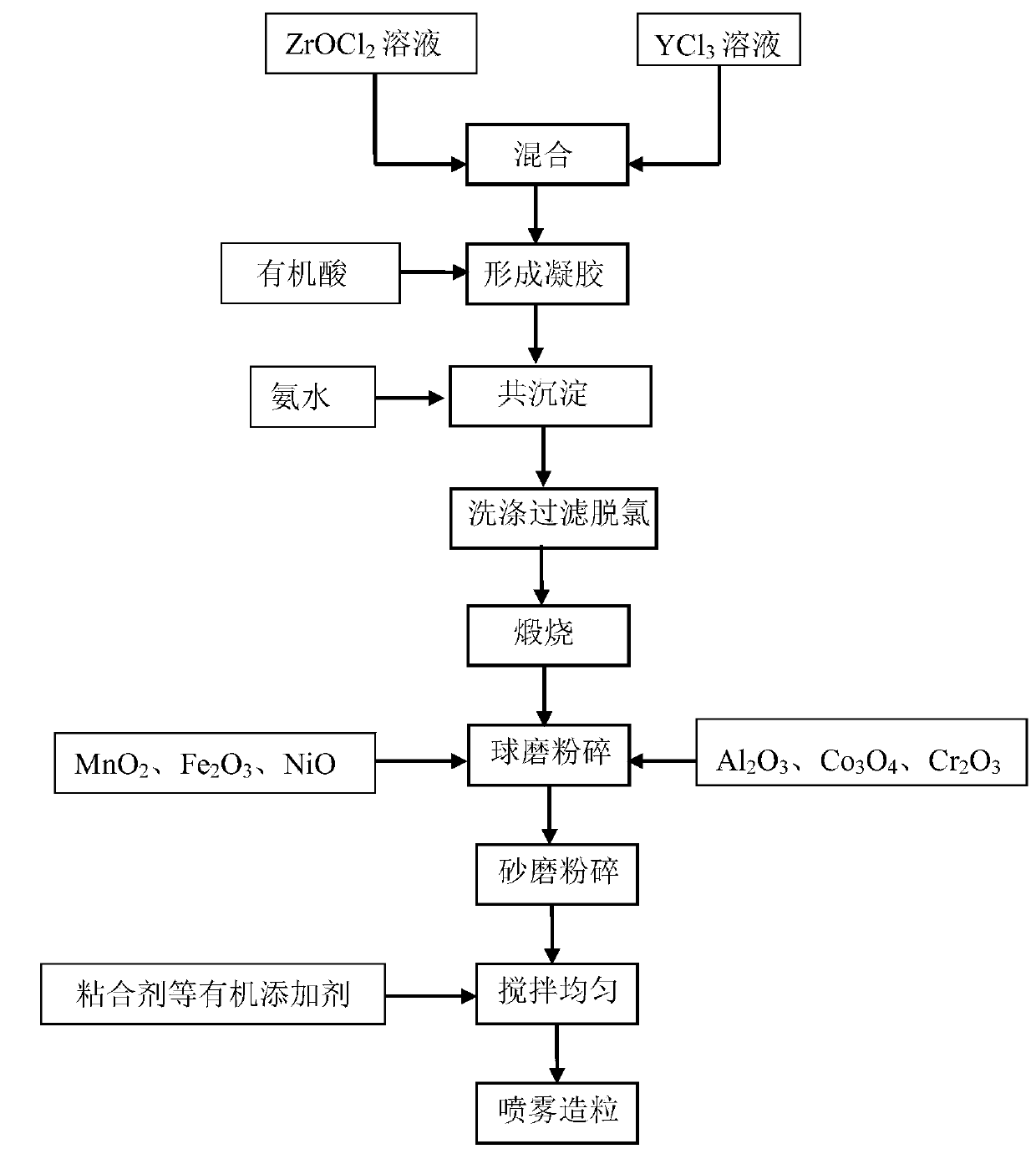

Preparation method of black yttrium-stabilized zirconium oxide powder

ActiveCN111204802AImprove stabilityUniform particle size distributionZirconium oxidesAdhesiveZirconium oxychloride

The invention belongs to the technical field of inorganic new materials, and particularly relates to a preparation method of black yttrium-stabilized zirconium oxide powder. The preparation method comprises the steps: mixing a zirconium oxychloride solution and a yttrium trichloride solution in a proportion; adding an organic acid to generate a gel, adding an ammonia water solution to neutralize and precipitate, washing, filtering and dechlorinating, calcining an obtained filter cake to obtain a precursor powder, adding a coloring agent and a binding agent, ball-milling, sanding and crushing,adding an adhesive and a release agent, uniformly mixing, spraying, granulating and drying to obtain the yttrium-stabilized zirconium oxide powder. The invention relates to the preparation method of black yttrium-stabilized zirconium oxide powder. The process is simple, the yield is high, the produced powder is good in stability, uniform in particle size distribution, good in flowability and stable in shrinkage rate; the sintering temperature is 1350 DEG C, which is 100 DEG C lower than the temperature of common zirconium oxide ceramic production, moulding is convenient, the blank strength ishigh, the processability is good, and black ceramic products prepared from the powder has the advantages of high strength, good toughness, good stability and the like.

Owner:长裕控股集团股份有限公司

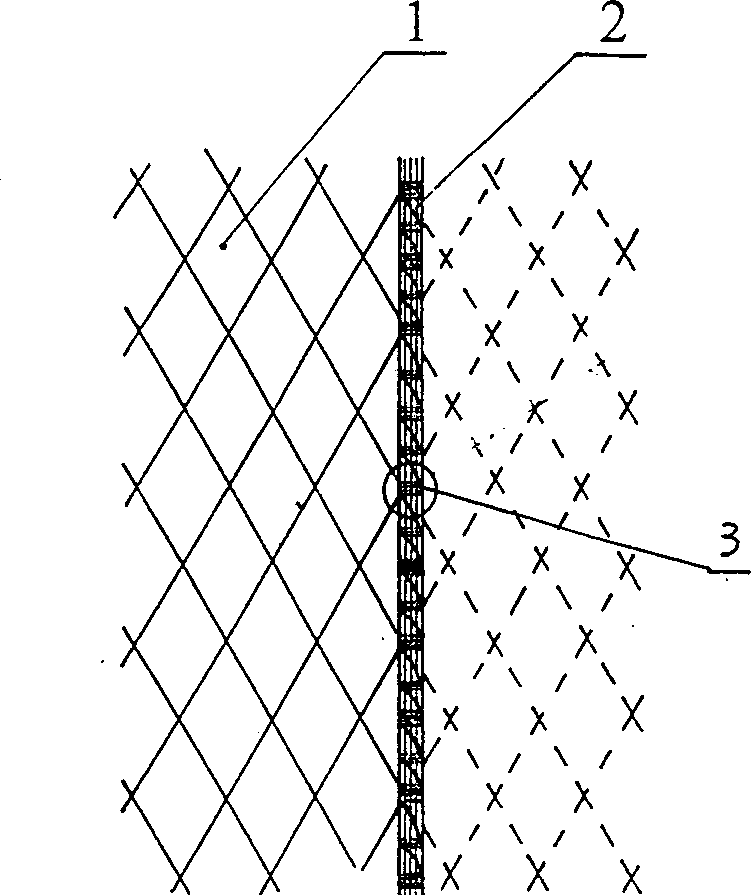

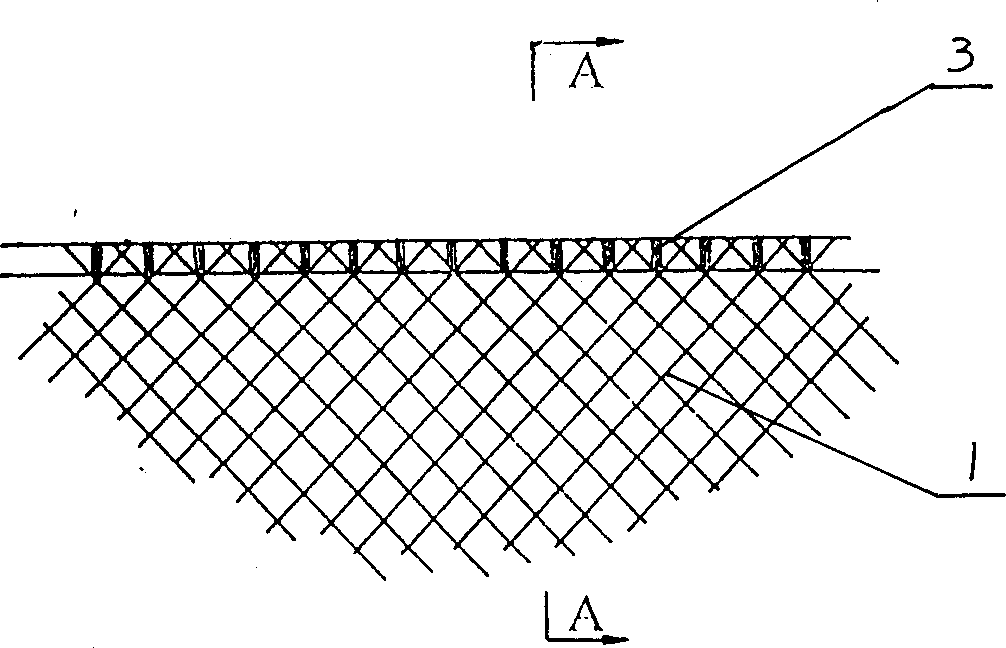

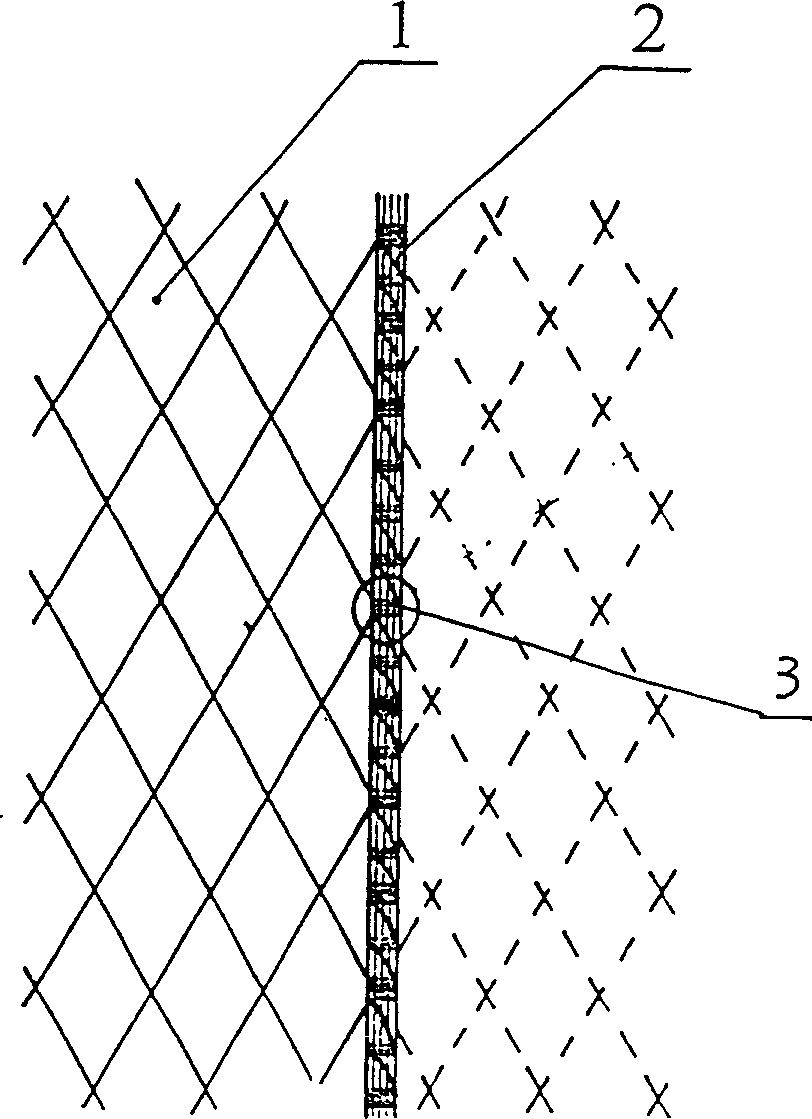

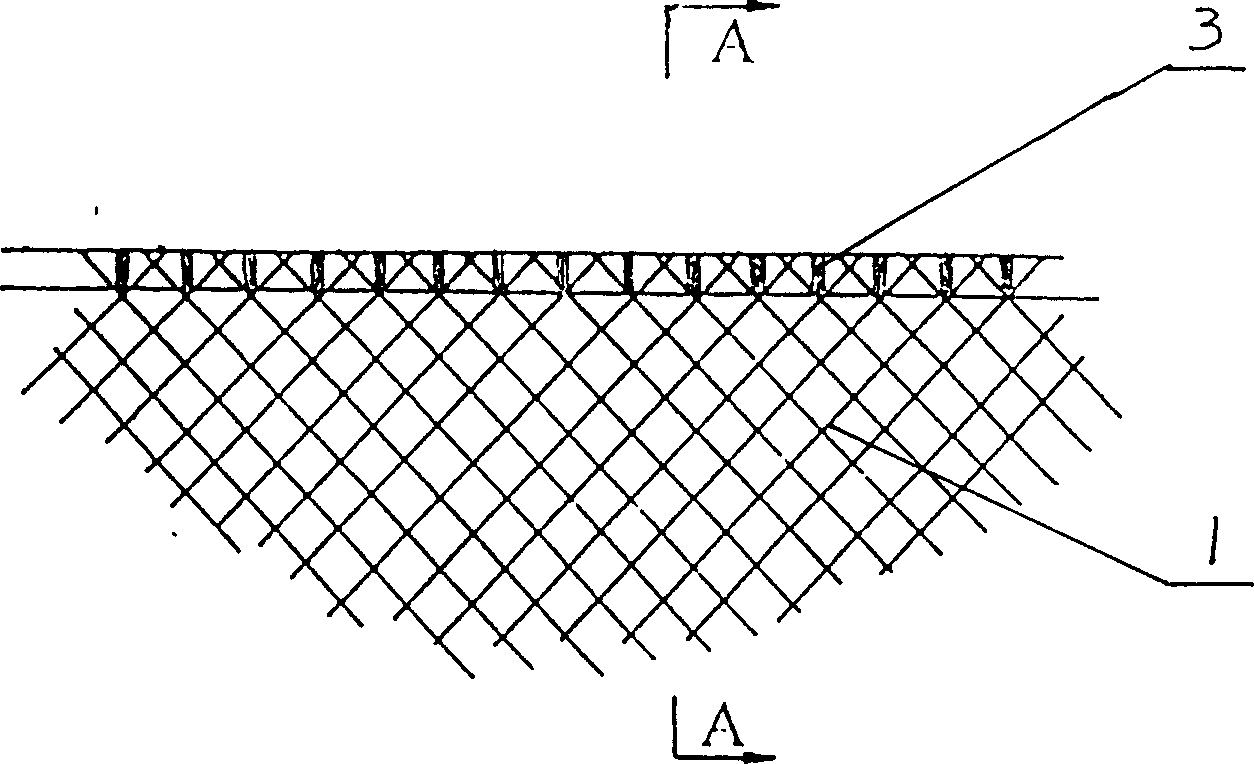

Technology for binding fish-culturing net or netted appliance

InactiveCN1354976AImprove the forceAvoid breakingClimate change adaptationKnottingEngineeringUltimate tensile strength

A technology for binding the netted appliance for culturing fish in deep sea includes such steps as cutting the netted fabric to needed shapes and sizes, sewing and binding with ropes, and features its additional edge-binding step. Its advantages include high strength, uniform stress, and not deforming or not being damaged by waves easily.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

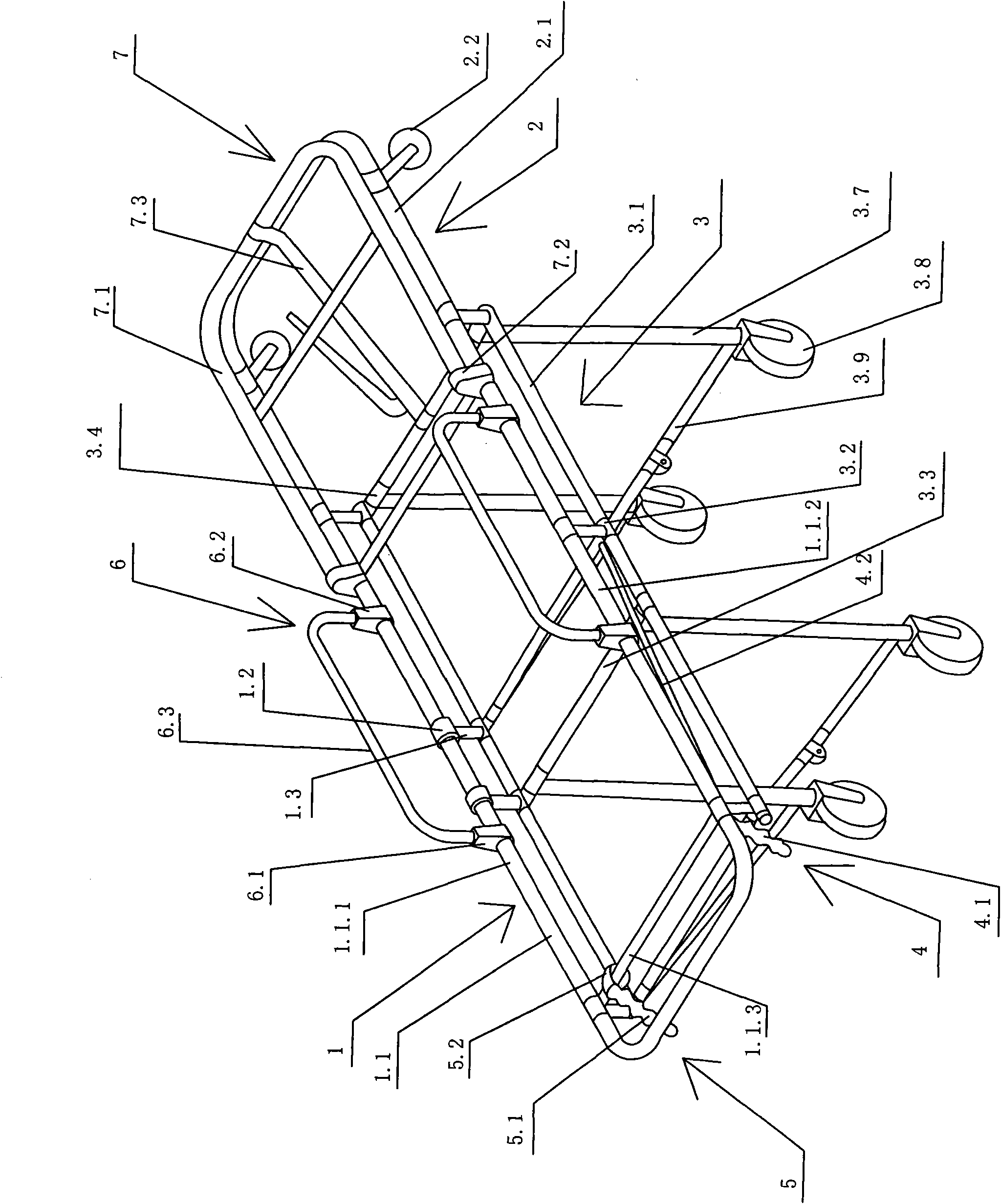

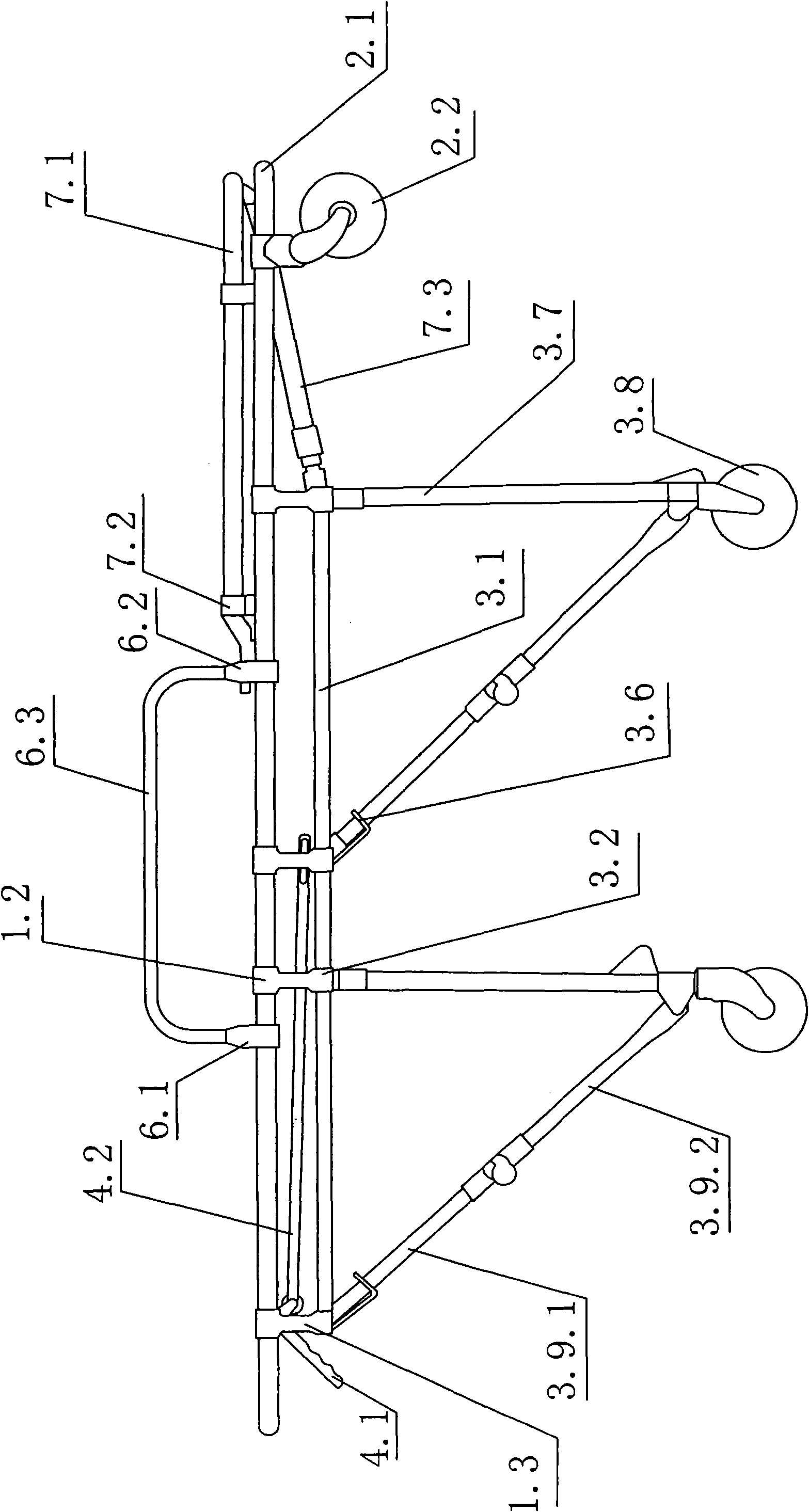

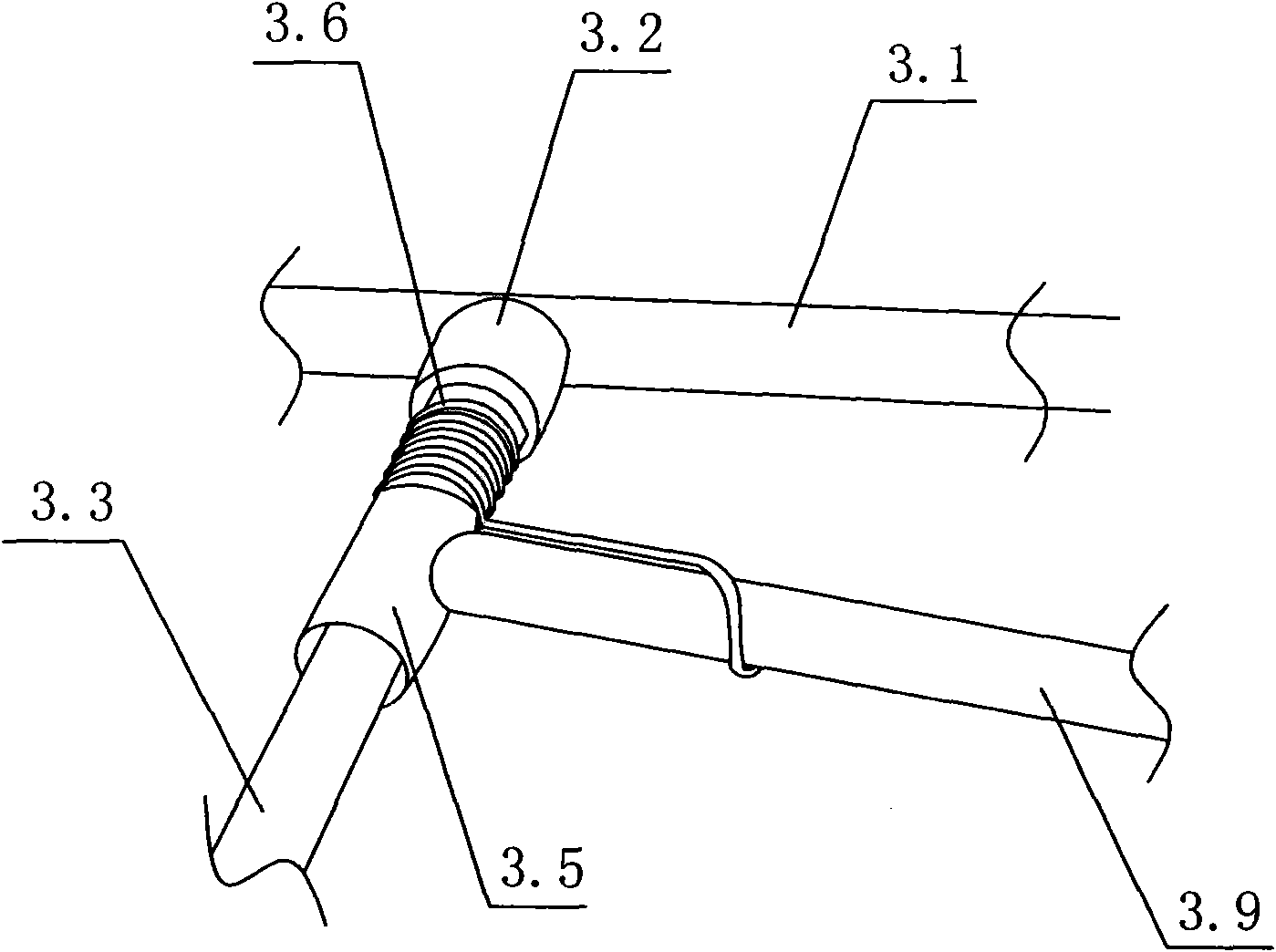

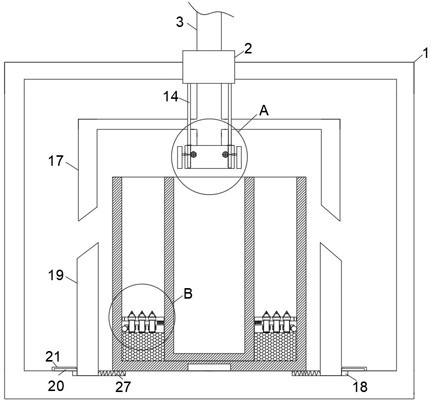

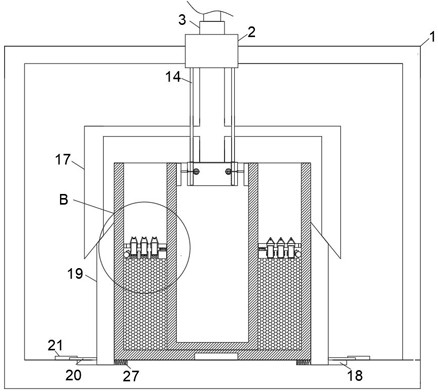

Boarding stretcher

The invention relates to a stretcher, in particular to a boarding stretcher which is mainly used for carrying an injured person on an ambulance, belonging to the technical field of medical appliance and equipment. A lug (3.5.1) is arranged on a movable plastic sleeve (3.5); a slotted hole (4.2.1) is arranged on a control rod (4.2); a bolt (3.5.1.1) on the lug (3.5.1) passes through the slotted hole (4.2.1) and is clamped on the slotted hole (4.2.1); a stop block (3.5.2) is arranged on the movable plastic sleeve (3.5); a shifting block (5.2) is arranged on a left handle (5.1); and the shifting block (5.2) is matched with the stop block (3.5.2). In the boarding stretcher, supporting legs are controlled to be folded by pulling the handle, so that the supporting legs can be uniformly retracted, thereby reducing the impact to the stretcher when the stretcher is carried on the ambulance, and reducing the pain of the injured person; and simultaneously the simple and convenient control mode also improves the efficiency of rescuing the injured person.

Owner:江阴万事兴医疗器械股份有限公司

High-performance uniform-shrinkage-rate PET composite material and preparation method thereof

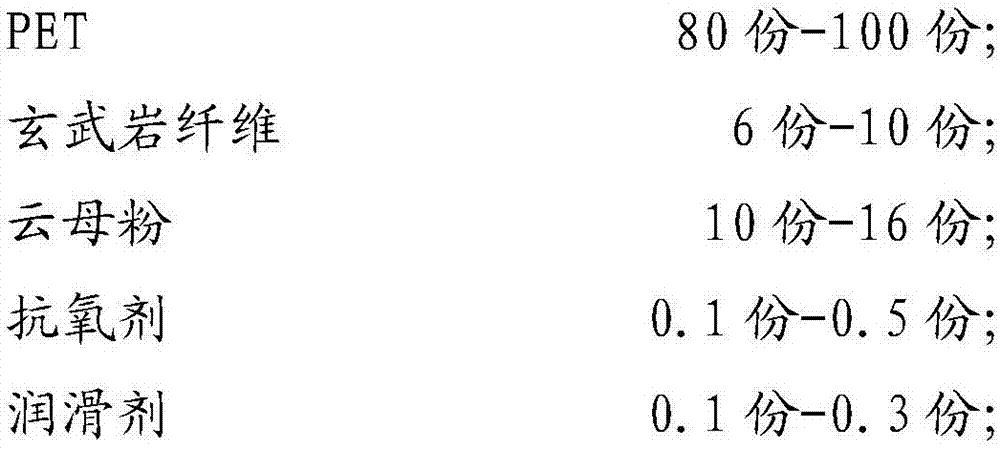

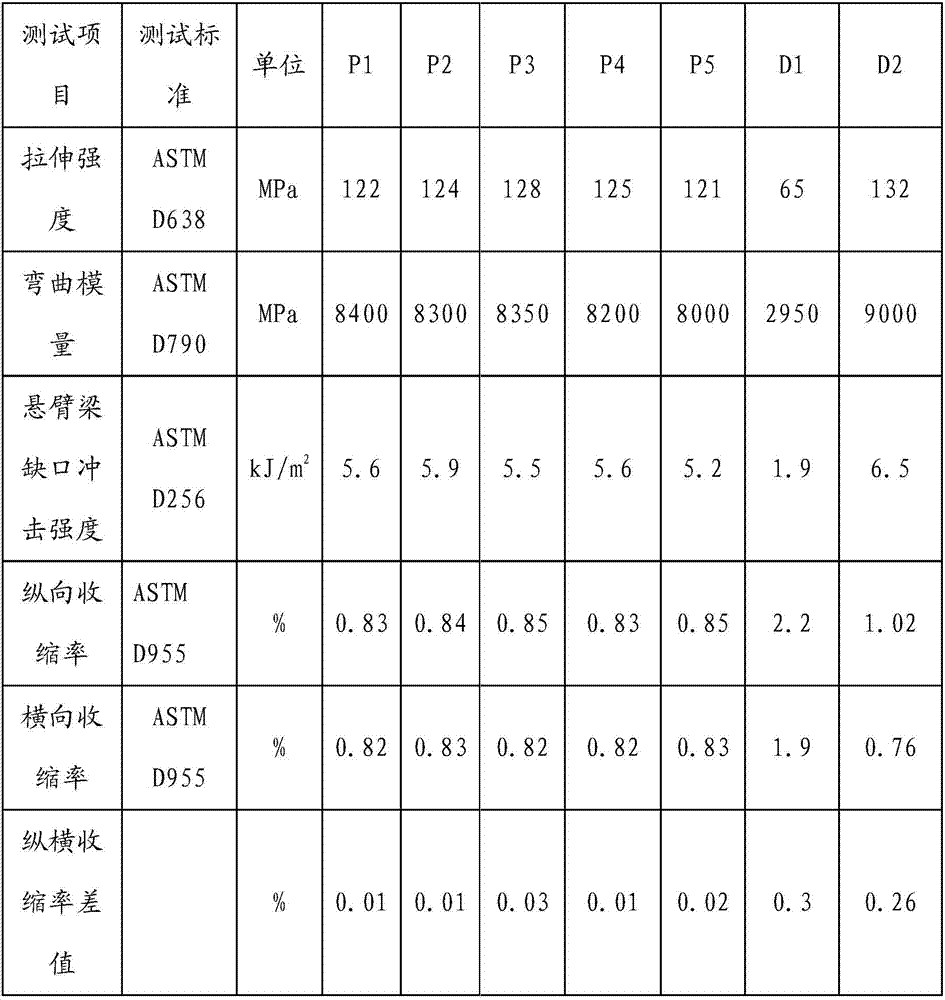

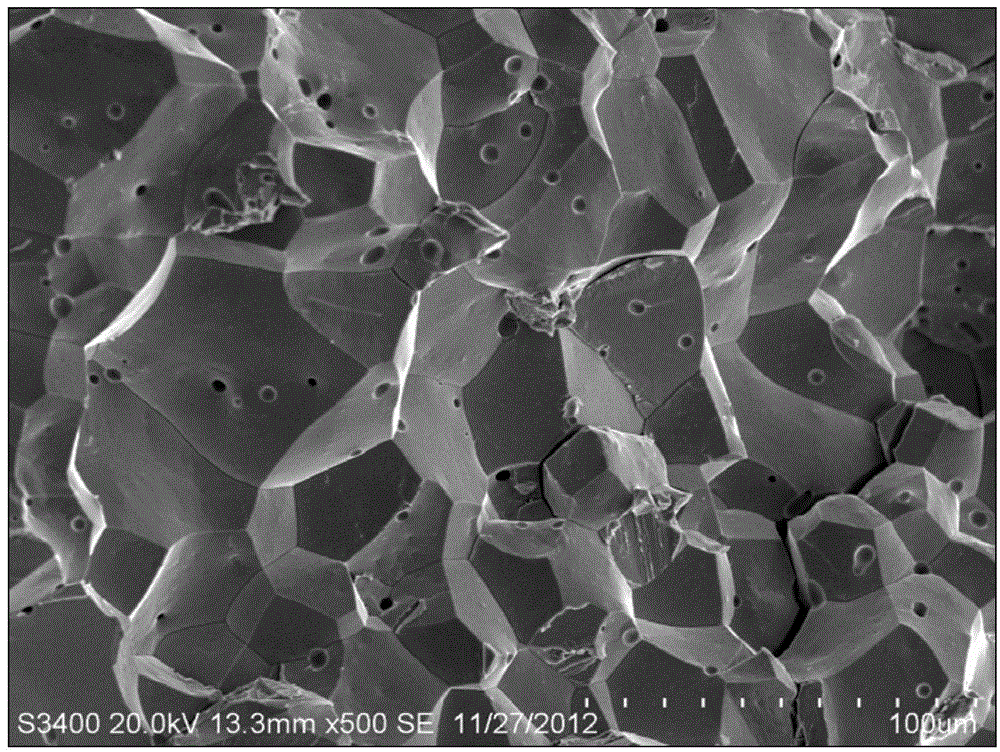

The invention relates to a high-performance uniform-shrinkage-rate PET composite material and a preparation method thereof. The PET composite material consists of the following components in parts by weigh as follows: 80-100 parts of PET, 6-10 parts of basalt fibers, 10-16 parts of mica powder, 0.1-0.5 part of an antioxidant and 0.1-0.3 part of a lubricant. According to the invention, the prepared PET composite material has excellent mechanical properties and uniform lateral and longitudinal shrinkage rates, ameliorates the problems that the impact property of PET composite materials is low and the shrinkage rate of the PET composite materials is not uniform. positive nitrogen ions N<+> are introduced to the surfaces of the basalt glass fibers through plasma processing, so that the active sites of the surfaces are increased, and the surface polarity is improved, and accordingly the attractive force and adhesive ability of the glass fiber surfaces are increased and the compatibility of the glass fibers and PET matrix is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Fine denier light terylene short fine with luminous function

InactiveCN101195936AGood glossUniform shrinkageMonocomponent polyesters artificial filamentArtifical filament manufactureFluorescencePolyester

The invention aims to provide fine denier (1 to 33 dtex) bright polyester staple fiber with luminescence function. The invention adopts the technical proposal that the supper bright PET sliced sheet is adopted as the spinning raw material; before the sliced sheet being transmitted, the fluorescence luminescence agent with the mass percentage concentration of 0.15% is added and mixed with the sliced sheet; the high temperature tension hot-setting technology condition is adopted to reduce the boiling water shrinkage ratio (or the dry heat shrinkage ratio) of the fiber. The product of the invention has the function of emitting fluorescence under normal conditions, the function can not be lost after coloring, and on the contrary, can realize the function of foiling essential color. Simultaneously, because the supper bright PET sliced sheet is adopted during the production, the glossiness of the product itself is good. The unique technical conditions ensure the product shrinkage to be concordant and uniform, the yarn weaved by utilizing the fiber has the advantages that the shrinkage is small and the dimensional stability is good. The invention can be commonly used for producing the computer metallic yarn and the sewing thread.

Owner:SHENGHONG GRP CO LTD

Tubular molybdenum target material preparation method

ActiveCN103978345ANo obvious sintering deformation phenomenonUniform and good surface qualityVacuum evaporation coatingSputtering coatingMaterials preparationMetal

The invention provides a tubular molybdenum target material preparation method. The method comprises the following steps: 1, molybdenum powder is compressed into a molybdenum tube blank; 2, a two-stage sintering process is adopted, and the molybdenum tube blank is subjected to sintering processing; 3, the molybdenum tube blank which is subjected to sintering processing is heated, and then is extruded and processed, and a tubular molybdenum target material is obtained after turning processing. According to the preparation method, cuttings are fewer, the production efficiency is high, the length of a molybdenum tube is adjustable, and the cost advantage is obvious; the production technological process is short, the metal loss is little, the comprehensive finished product rate is high, and the tubular molybdenum target material used for sputtering is conveniently, rapidly and largely produced.

Owner:JINDUICHENG MOLYBDENUM CO LTD

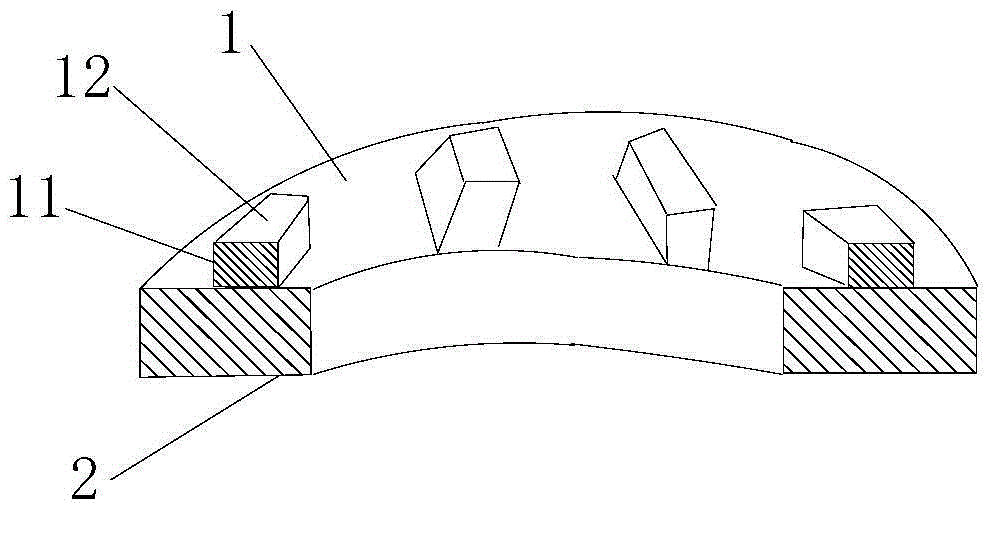

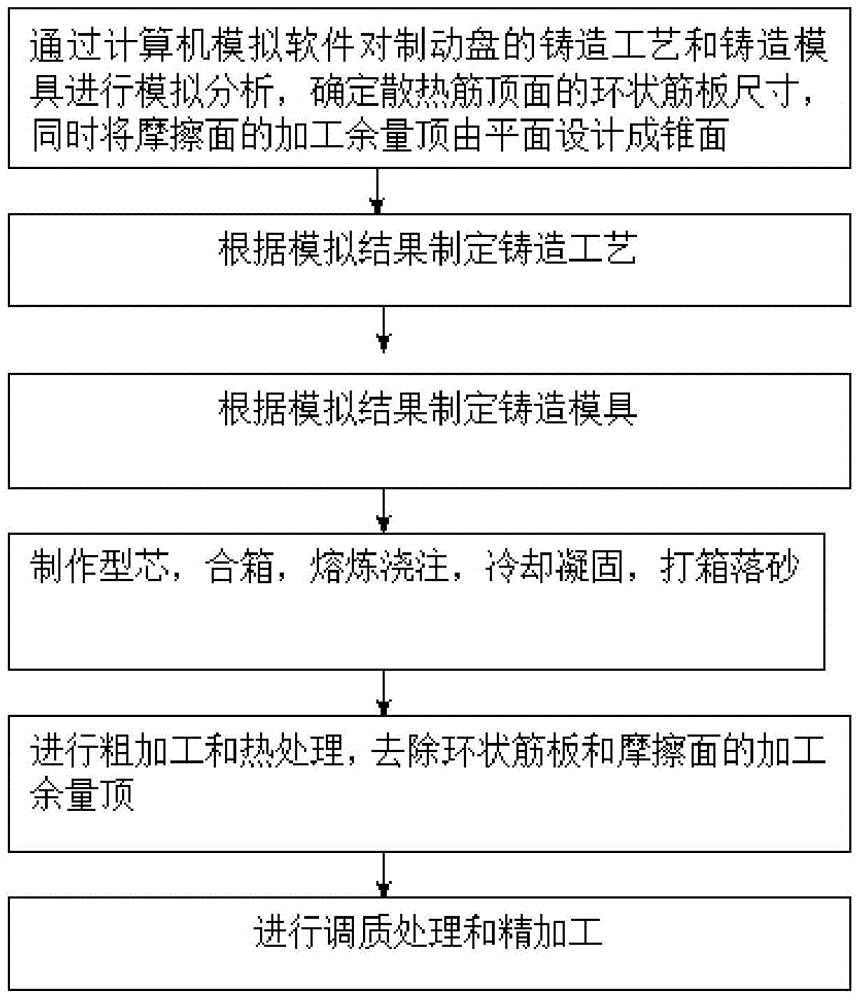

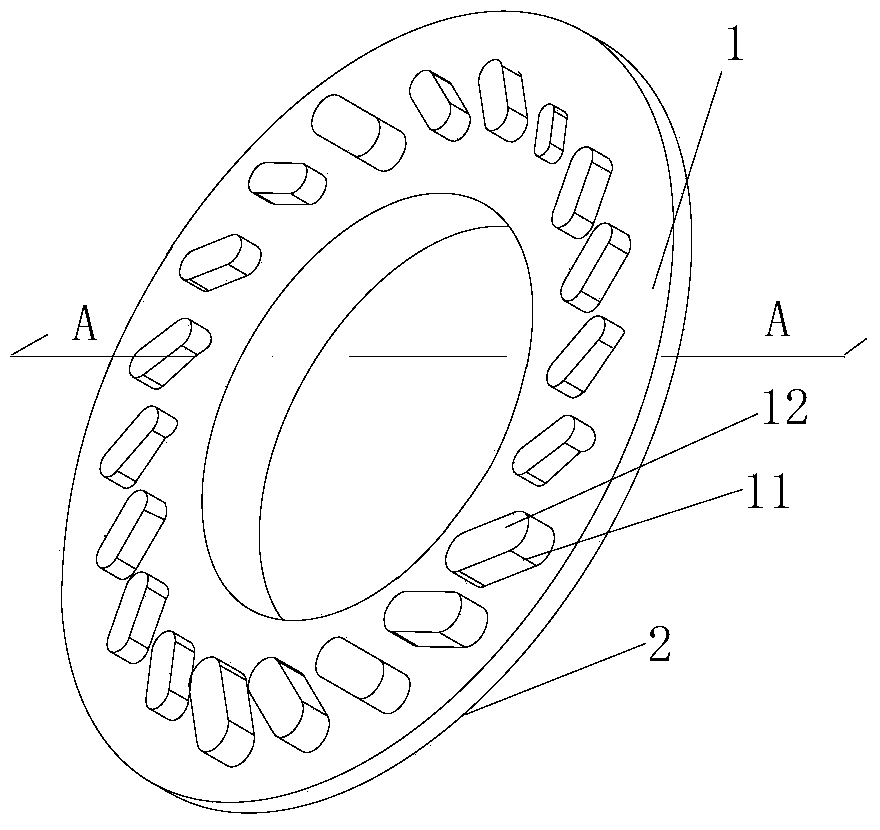

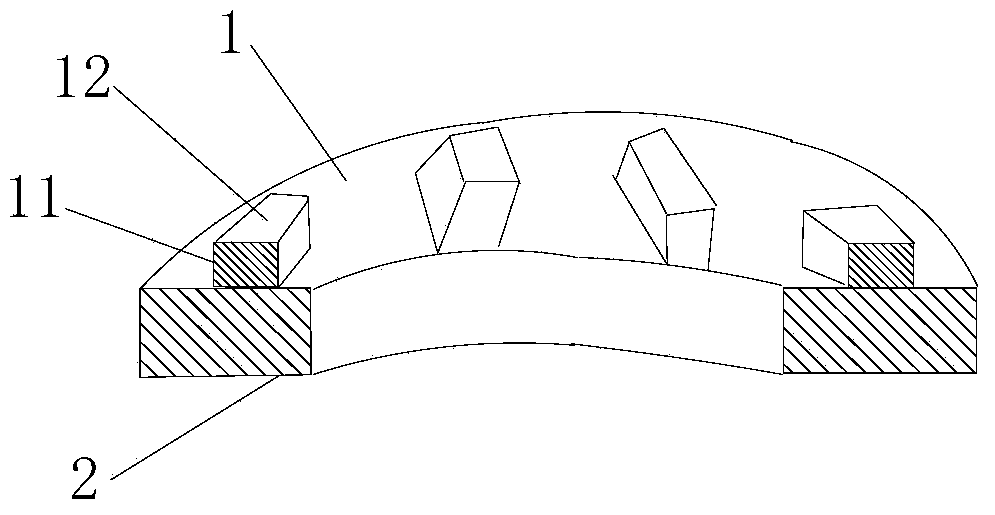

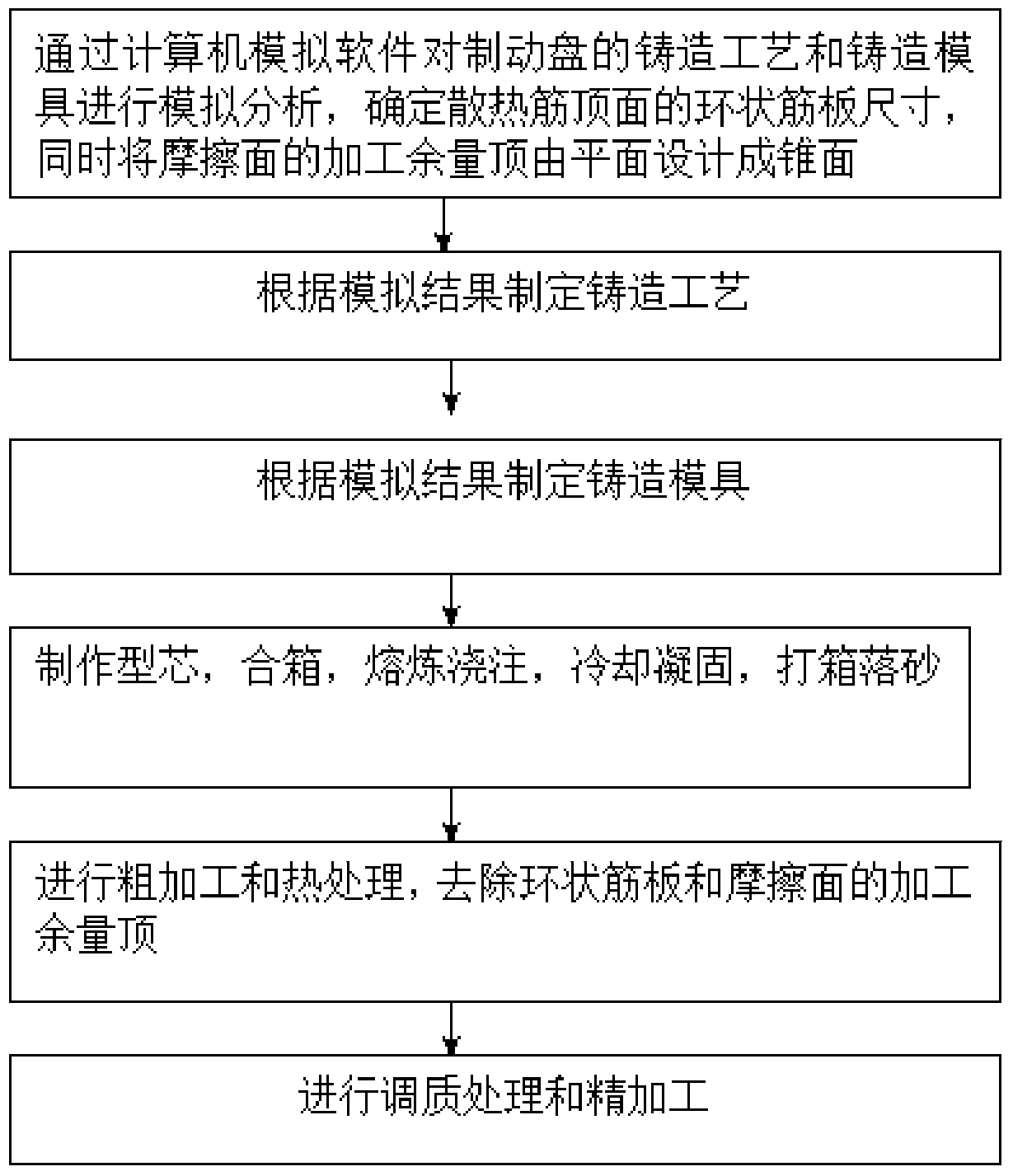

Wheel-like braking disc production method and wheel-like braking disc produced by using wheel-like braking disc production method

ActiveCN106392016ASolve warping deformationSolve defects that form wavy surfacesBraking discsFoundry mouldsDynamic balanceEngineering

The present invention relates to a wheel-like braking disc production method and a wheel-like braking disc produced by using the wheel-like braking disc production method. According to the present invention, during the wheel-like braking disc casting process, an integral and annular rib plate is additionally arranged on the heat dissipation rib top surface of the heat dissipation surface of a braking disc, the annular rib plate and the braking disc are subjected to one casting molding, and the heat dissipation rib top surfaces are connected one by one to form a stable annular frame structure with double rings arranged on the upper surface and the lower surface; during the cooling solidification process after the casting, the annular rib plate on the heat dissipation rib top surface is firstly solidified so as to fix a heat dissipation rib, such that the shrinkage is significantly uniform when the cast is cooled, and the warping deformation generated due to the asymmetric geometrical size of the cast can be avoided; the machining allowance top surface of the friction surface of the braking disc is designed into to a tapered surface so as to increase the cast deformation resistance and make the cast maintain the stabilized shrinkage; and after the cooling molding, the annular rib plate is removed through the machining and the machining allowance top surface of the friction surface is processed into the plane, such that the cast structure shape is not affected, and the product dynamic balance detection qualification rate is substantially improved.

Owner:JIANGSU DINGTAI ENG MATERIAL

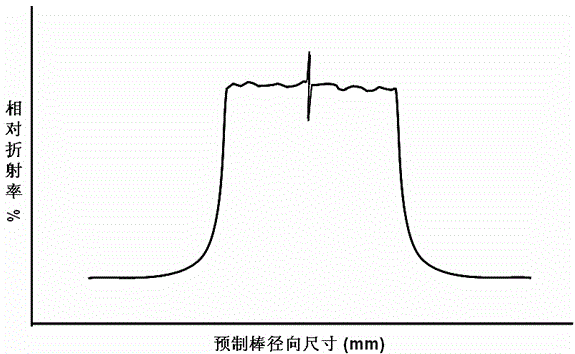

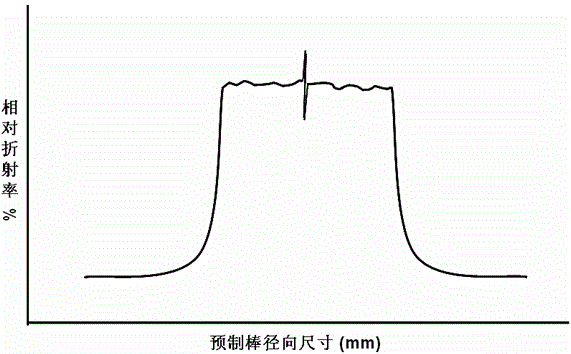

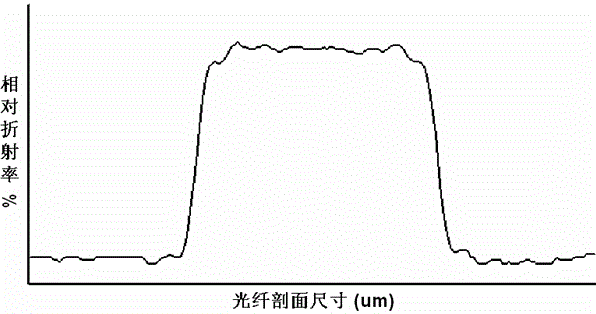

Fusion shrinkage preparation method of core rod of optical fiber preform rod

InactiveCN104086079ARefractive index dip avoidanceHighly corrosiveGlass making apparatusRefractive indexHeating furnace

The invention relates to a fusion shrinkage preparation method for preparing a core rod of an optical fiber preform rod through fusion shrinkage of a doped quartz liner tube. According to the fusion shrinkage preparation method of the core rod of the optical fiber preform rod, the deposited doped quartz liner tube is mounted on a fusion shrinkage lathe. The fusion shrinkage preparation method of the core rod of the optical fiber preform rod is characterized by comprising the following steps: enabling the doped quartz liner tube to rotate at a rotation speed being 15-30rad / min, supplying a heat source for fusion shrinkage by taking a heating furnace sleeve as a heating device, heating at the temperature of 1900 to 2250 DEG C, enabling the heating furnace sleeve to move forth and back from one end to the other end of an axial liner tube of the doped quartz liner tube, carrying out gradual fusion shrinkage on the doped quartz liner tube and finally firing; and sealing two ends of the doped quartz liner tube and introducing mixed gas for corroding the inner wall of the liner tube in the fusion shrinkage process. By virtue of the fusion shrinkage preparation method of the core rod of the optical fiber preform rod, an F-containing compound high in reactivity is taken as the lining corrosion gas; the fusion shrinkage and corrosion are carried out synchronously, so that the reduction of a refractive index of a core layer can be effectively avoided, the time for producing the core rod of the preform rod can be greatly reduced, the processing efficiency and the efficiency of using the device can be improved, the production cost of the optical fiber preform rod can be reduced, and the stability of the optical fiber water peak can be guaranteed, therefore the quality of the optical fiber processing is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

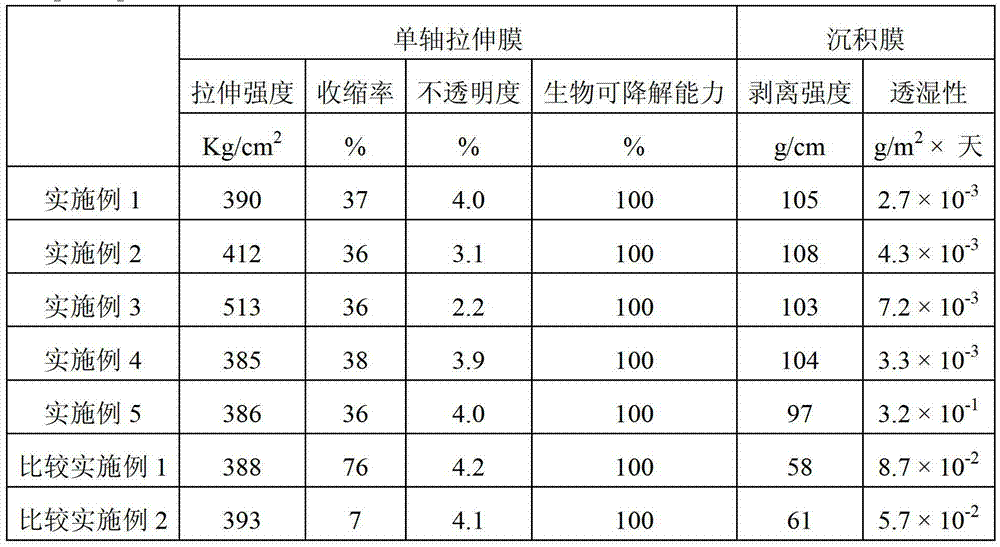

Shrinkable film and method for manufacturing same

ActiveCN103097128AUniform shrinkageUniform transparencySynthetic resin layered productsVacuum evaporation coatingFood packagingEngineering

The present invention relates to a film for packaging food and to a method for manufacturing same. More particularly, the present invention relates to a film for packaging food and to a method for manufacturing same, wherein the film has superior flexibility, transparency, and biodegradability, and has excellent adhesion to a metal coating layer to achieve improved moisture barrier properties.

Owner:KOLON IND INC

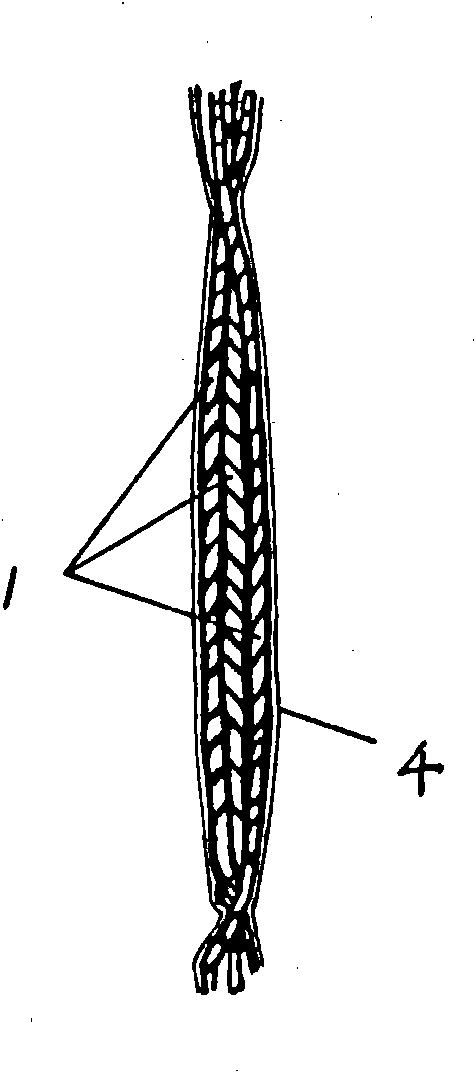

Coupling wire of FRP (Fiber Reinforced Plastics) and PTFE (Polytetrafluoroethylene) fiber

InactiveCN102051723AImprove mechanical propertiesImprove chemical performanceFibre treatmentYarnGlass fiberCoupling

The invention relates to a coupling wire of FRP (Fiber Reinforced Plastics) and PTFE (Polytetrafluoroethylene) fiber, comprising a wire body. The coupling wire of FRP PTFE fiber is characterized in that the wire body is formed by twisting and entwisting fascicule made from multiple bundles of FRP and PTFE fiber, the fascicule made from multiple bundles of FRP and PTFE fiber comprises at least two FRP filaments and at least one PTFE fiber, the wire body is formed by twisting and entwisting at least three bundles of fascicule made from the FRP and the PTFE fiber, and a PTFE film formed by dipping PTFE latex is arranged outside the wire body. Compared with FRP wires, the invention has remarkably improved comprehensive mechanical and chemical performance, is hardly broken and has strong clinging power. The invention can be used for processing and making products in the shapes of strands, bundles, felt, fabrics, and the like.

Owner:SHANGHAI JINYOU FLUORINE MATERIALS

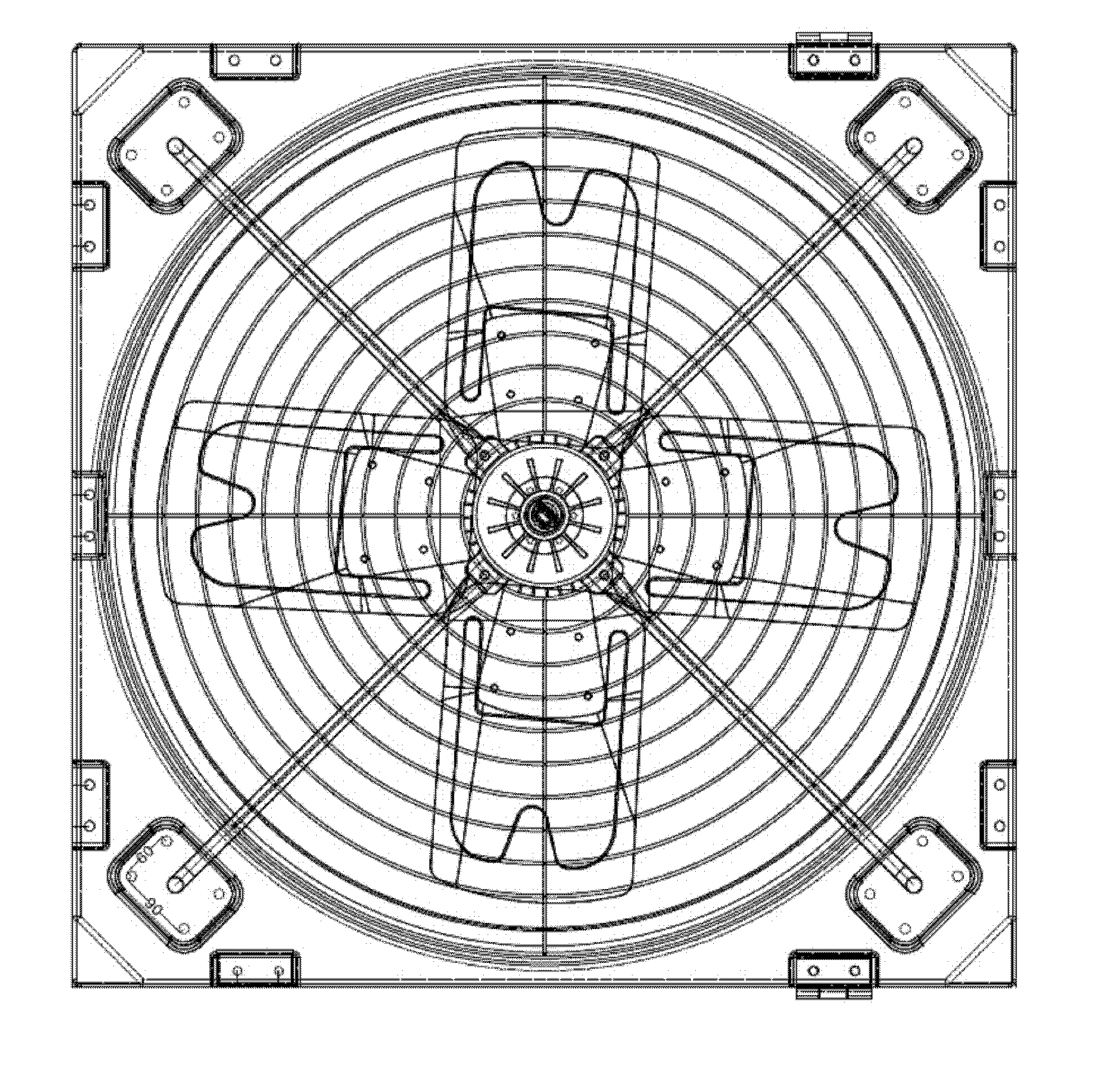

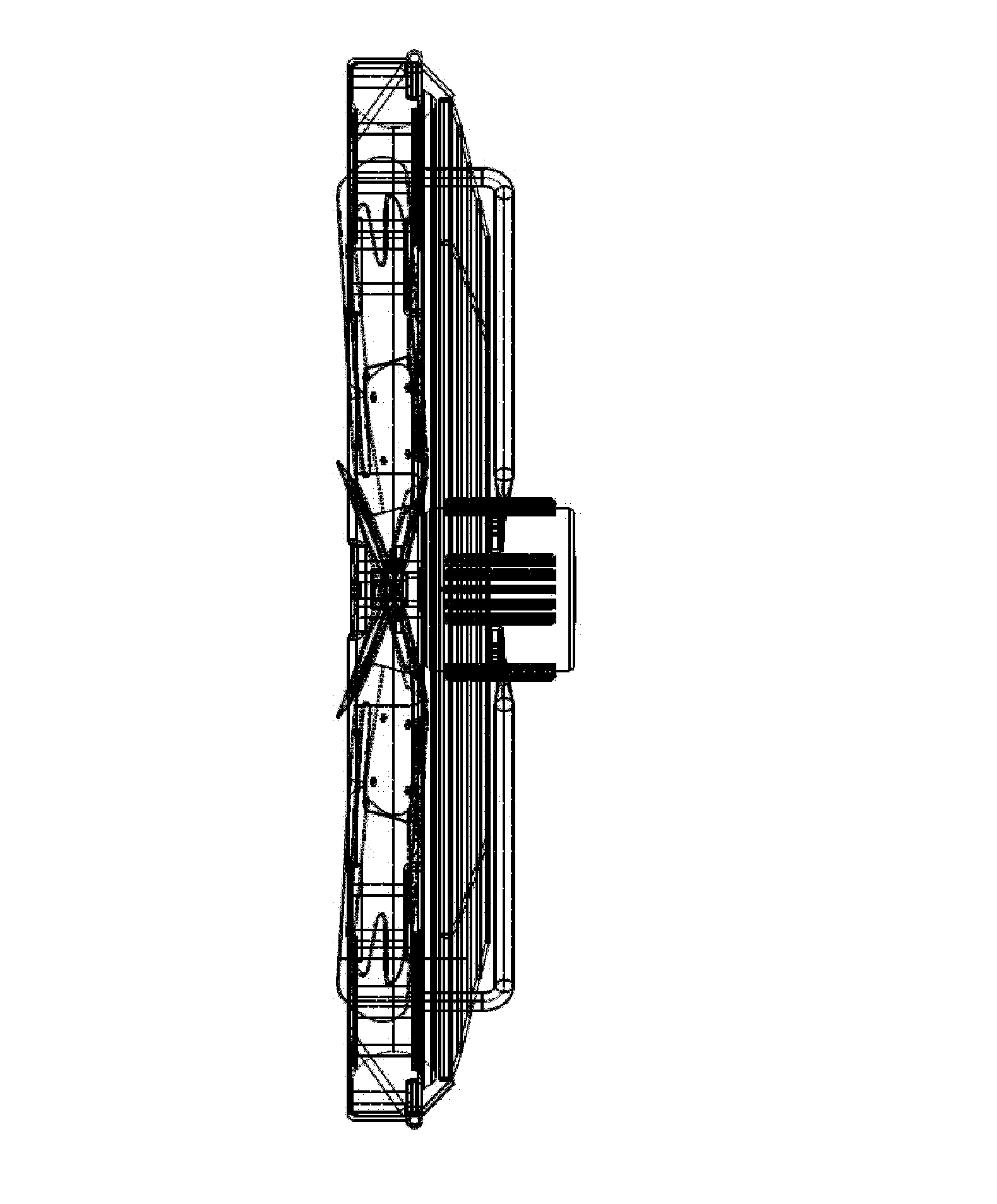

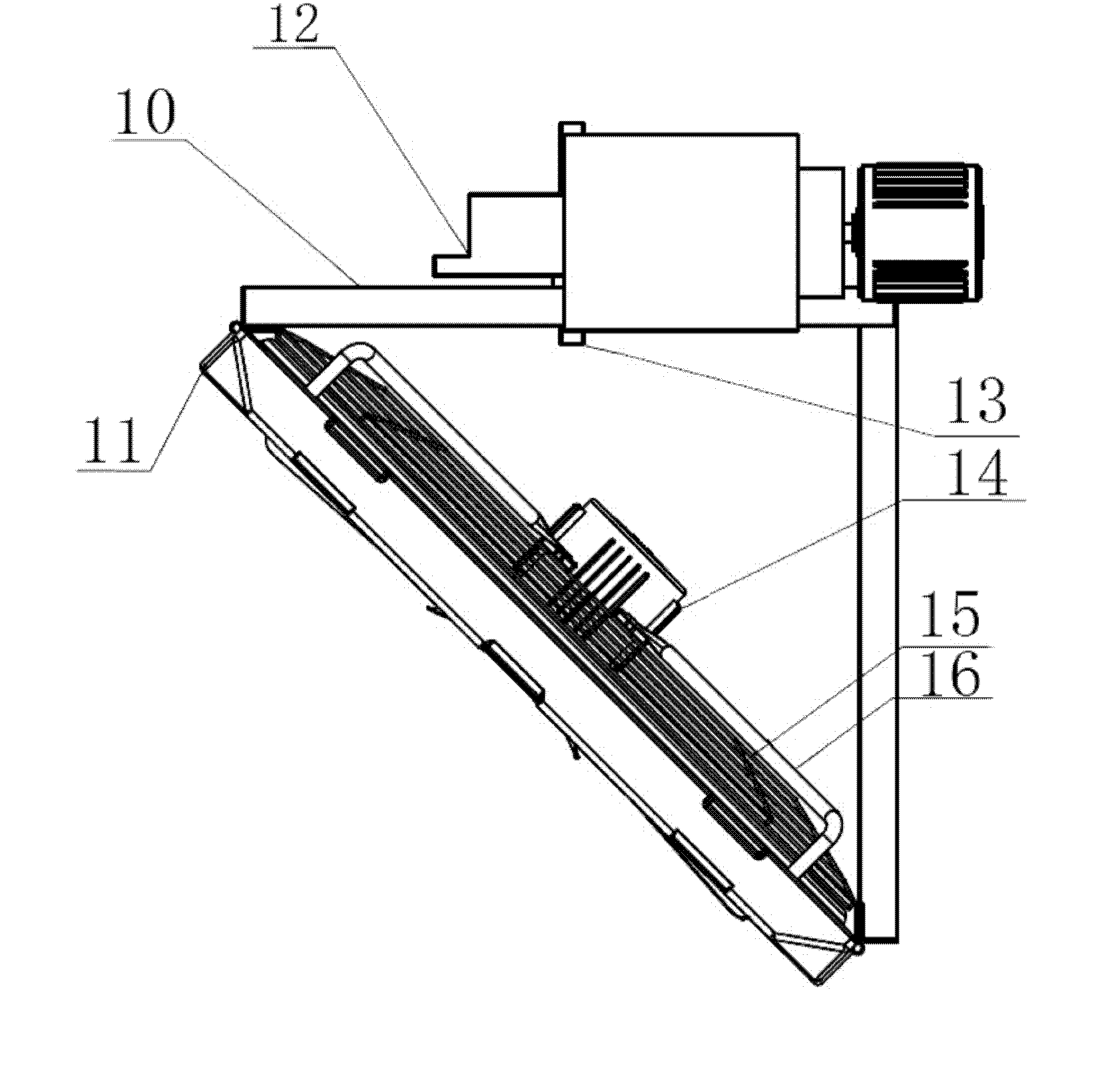

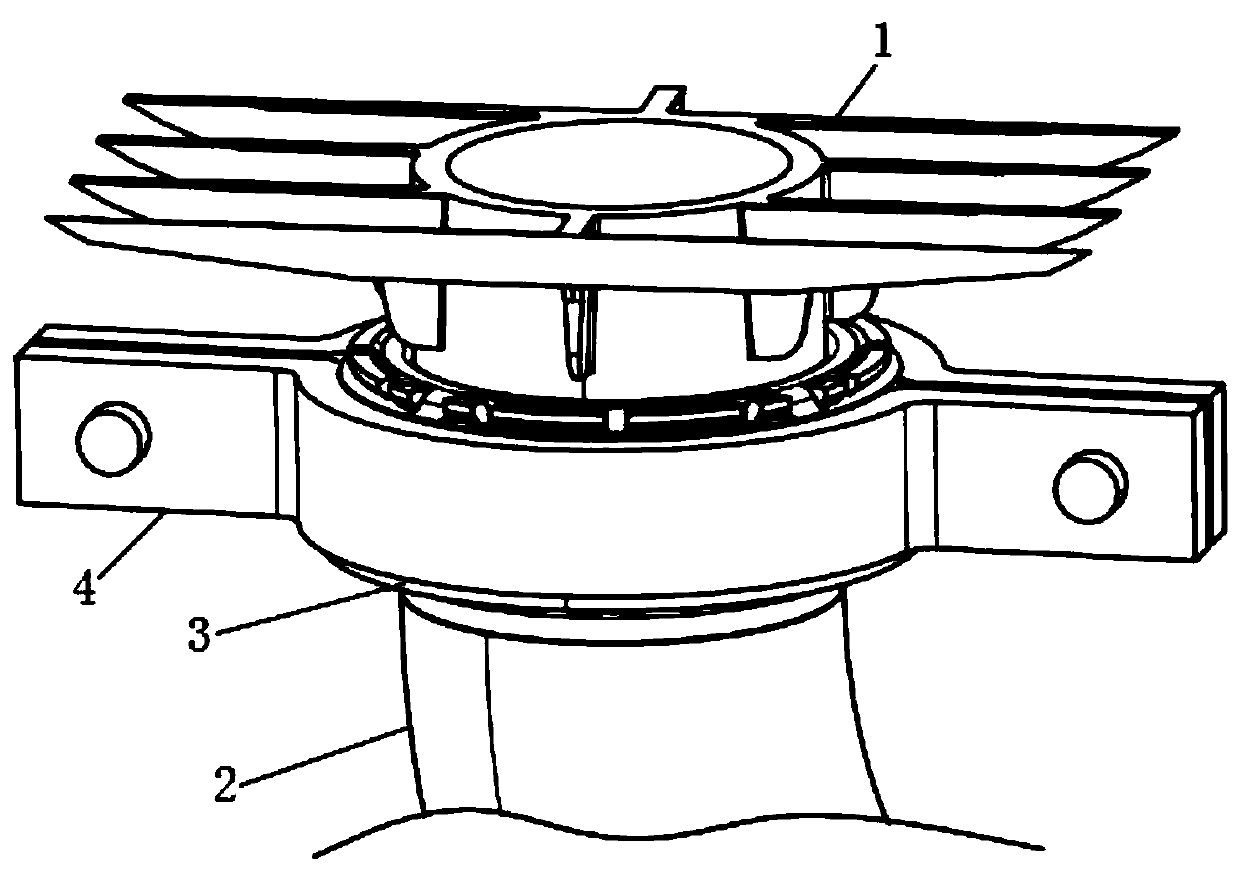

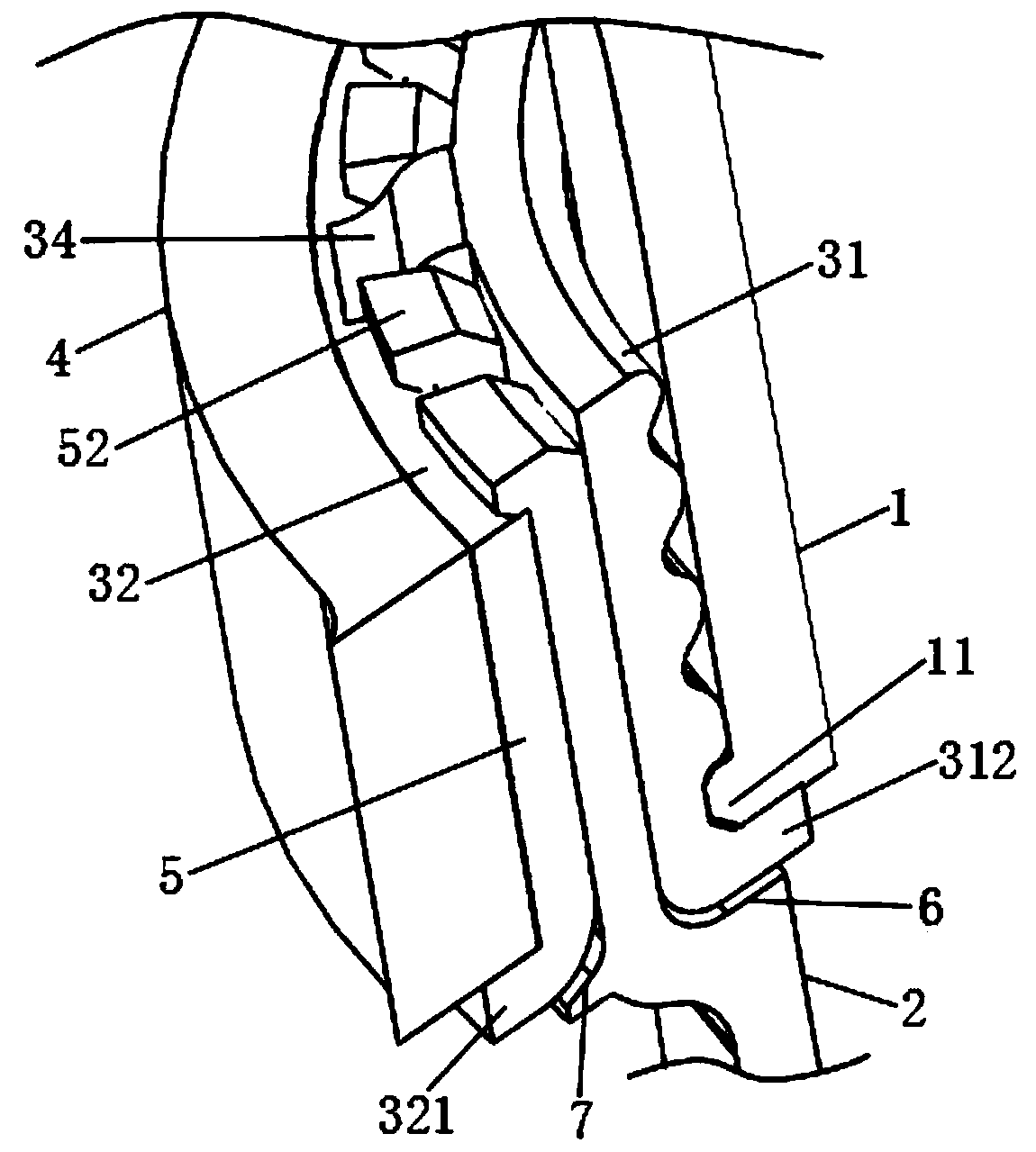

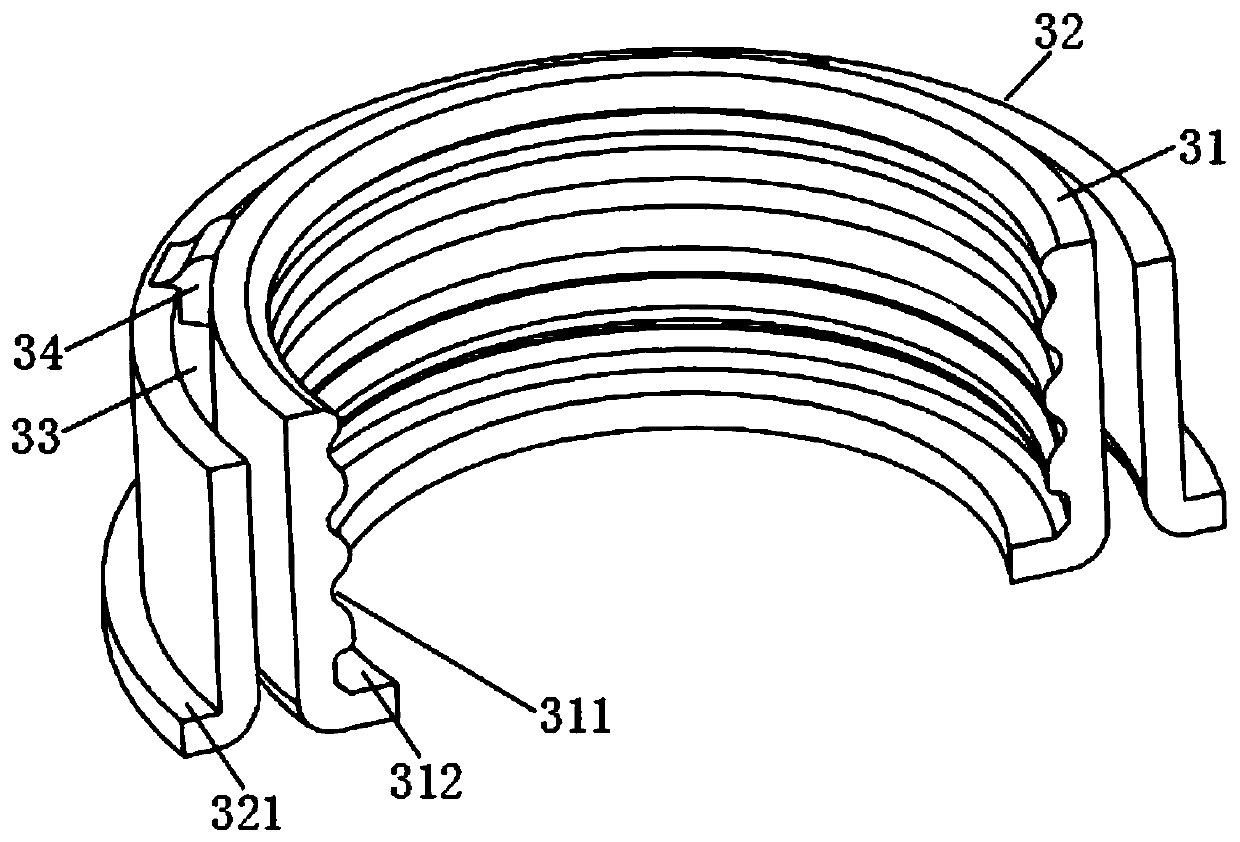

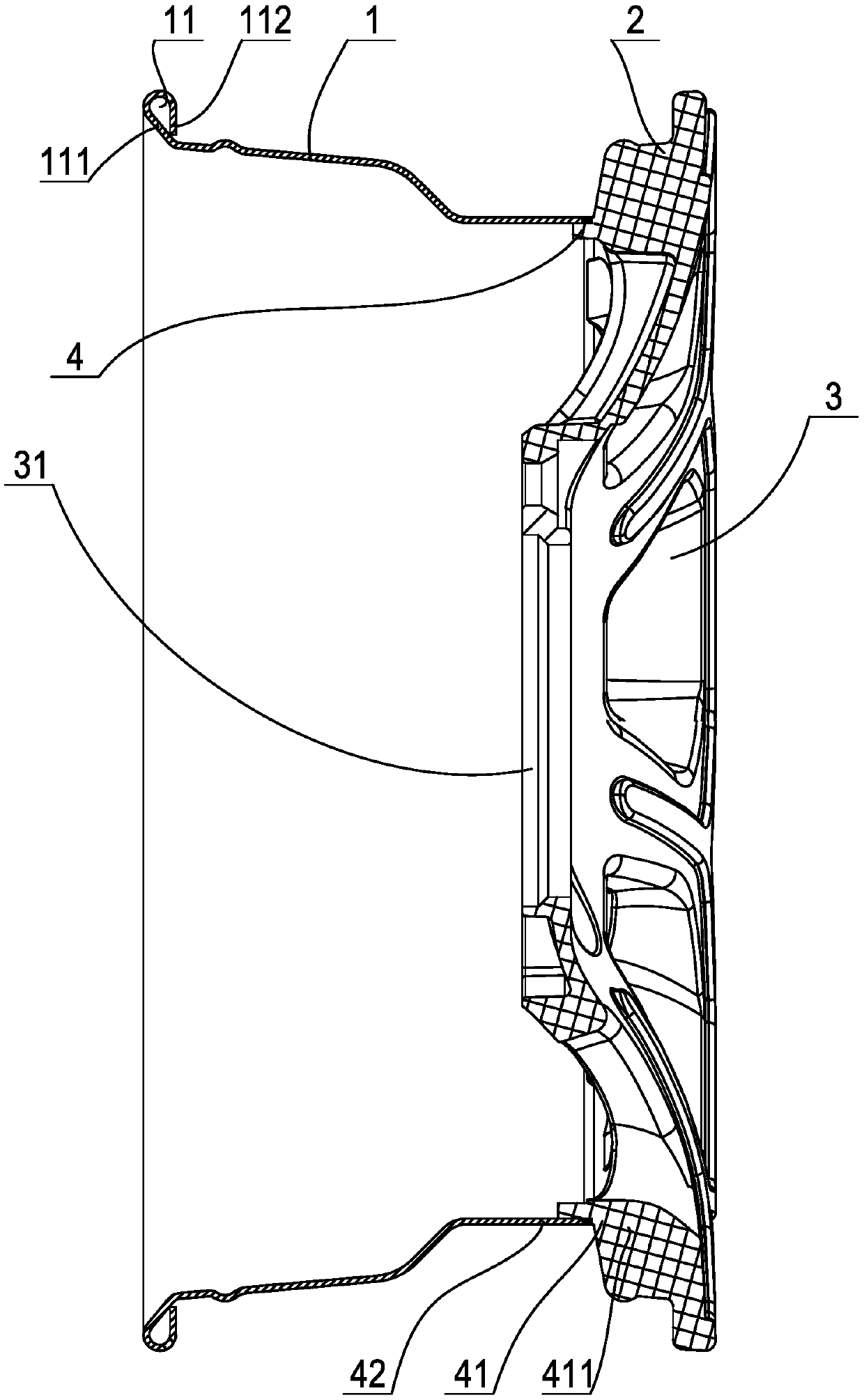

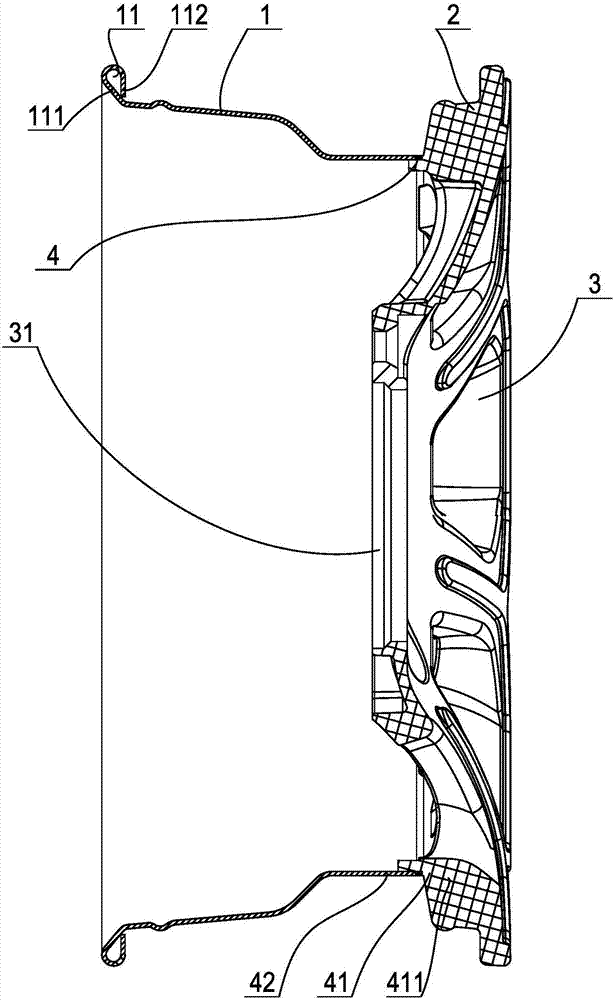

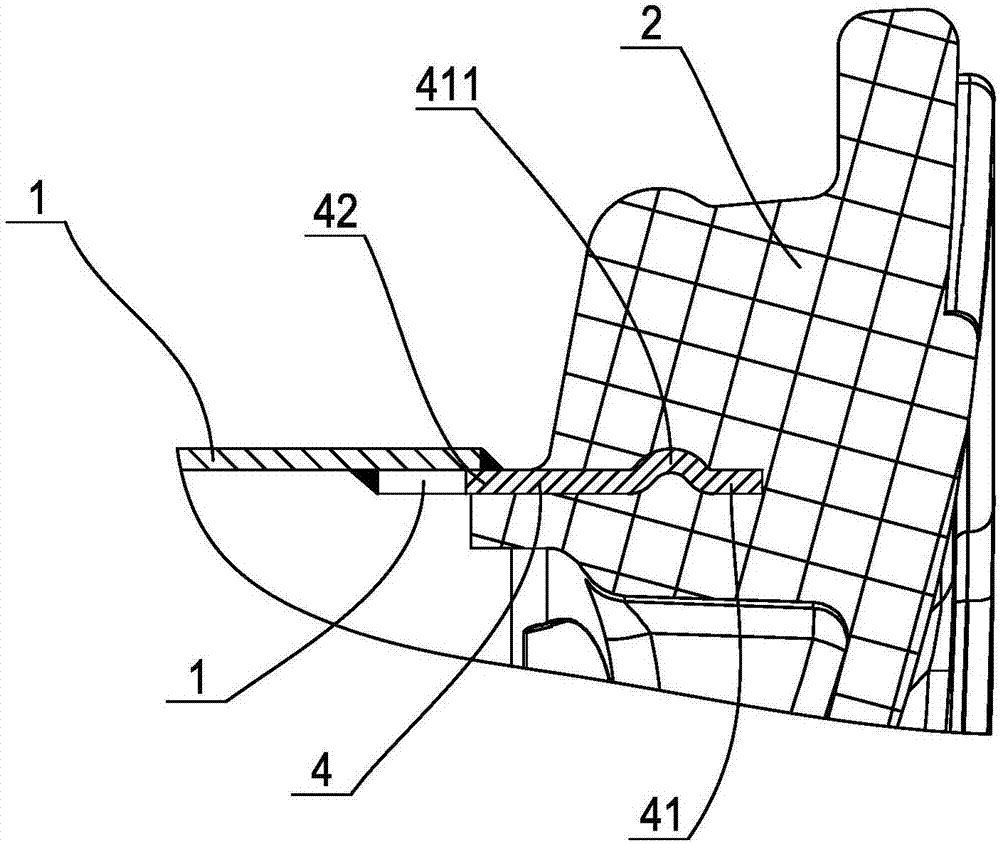

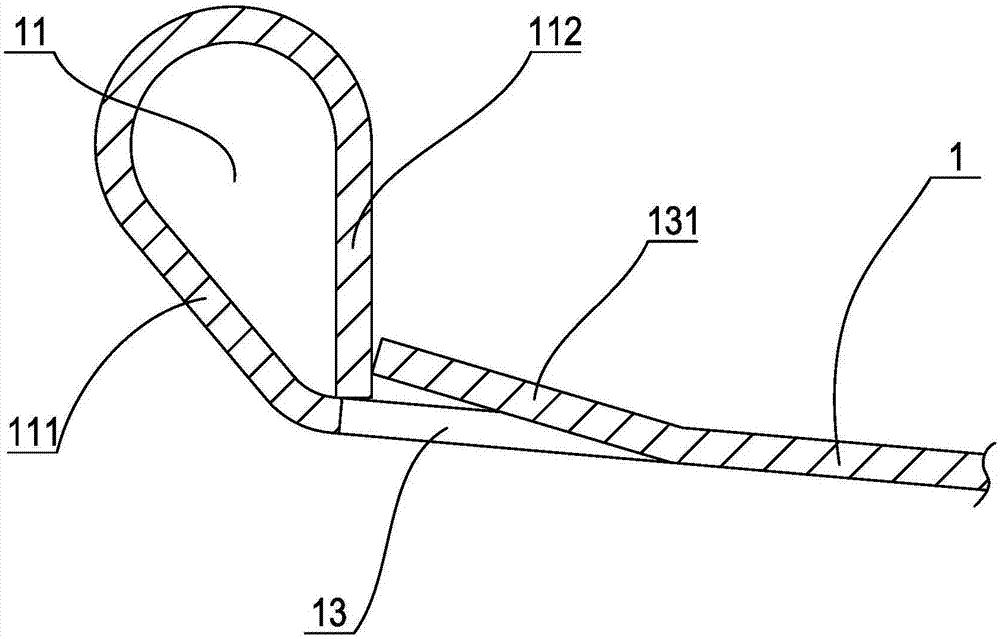

Fan used for animal husbandry and production method of fan

The invention relates to the technical field of heat dissipation of colony houses for livestock, in particular to a fan used for animal husbandry and a production method of the fan. The fan comprises a fan body and a support, a power source is connected with an electric control box and a motor, the support consists of a rotating system, a power system and an electric control system, a reducer with an oblique gear and a turbine is arranged on a motor shaft of the rotating system, a transmission shaft and the electric control box are disposed on the reducer, a plurality of rotating shafts are disposed on the transmission shaft, couplers are equidistantly disposed on the transmission shaft on the left sides and the right sides of the rotating shafts, a bearing is arranged in an inner cavity of each rotating shaft, the bearings are connected with plane bearings, a gear is disposed outside each rotating shaft, the gears drive the turbine, a fan angle adjusting support is disposed on the lower portions of the plane bearings of the rotating shafts and provided with a fan shell, the fan shell is a square hollow frame structure made of plastics in a rotational moulding forming manner, and a circular inner cavity which rotates along blades of the fan is arranged in the middle of the square frame structure. The fan is durable, reduces cost and is safe and reliable.

Owner:上海特瑞机械设备盐城大丰有限公司

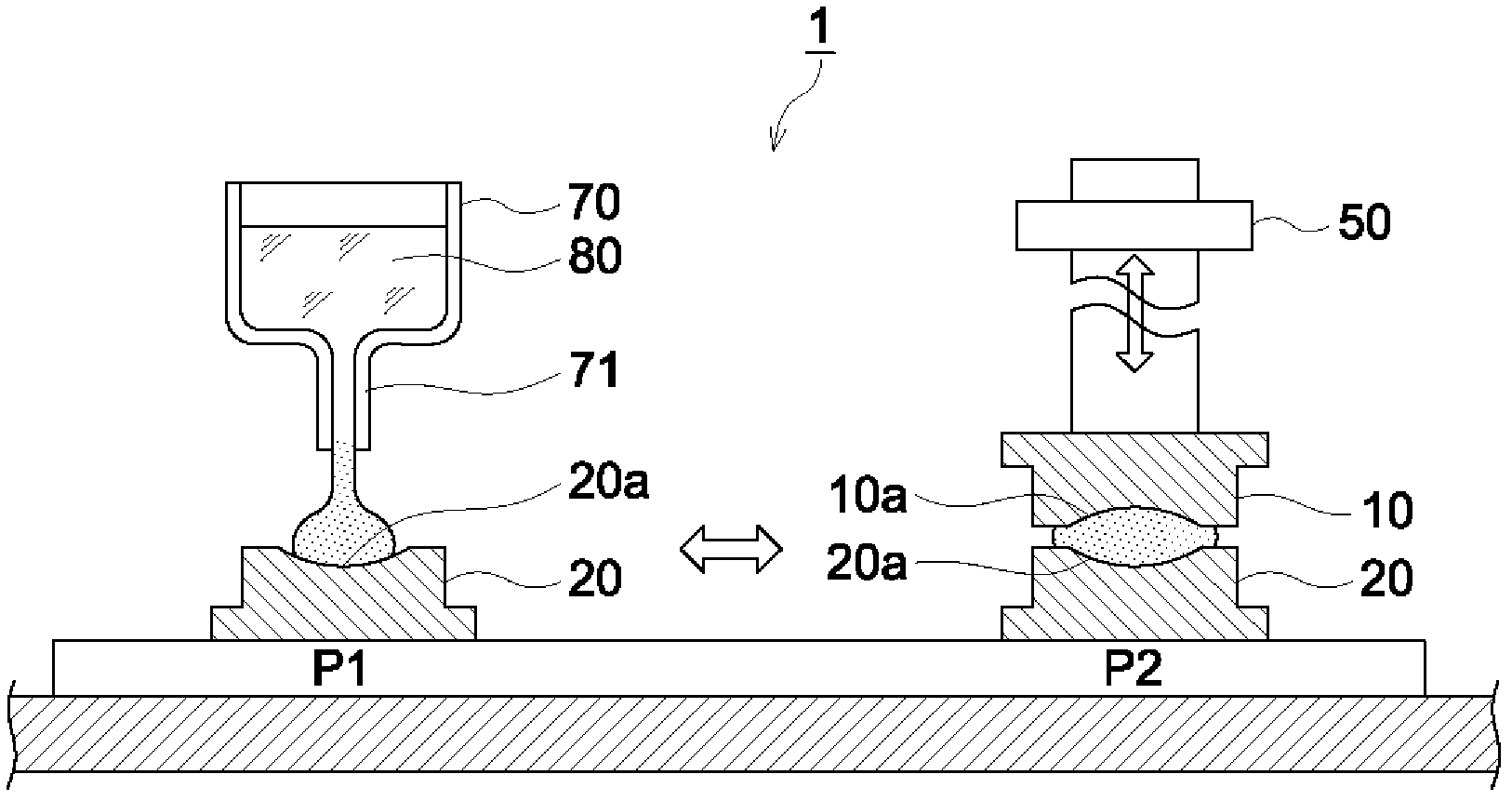

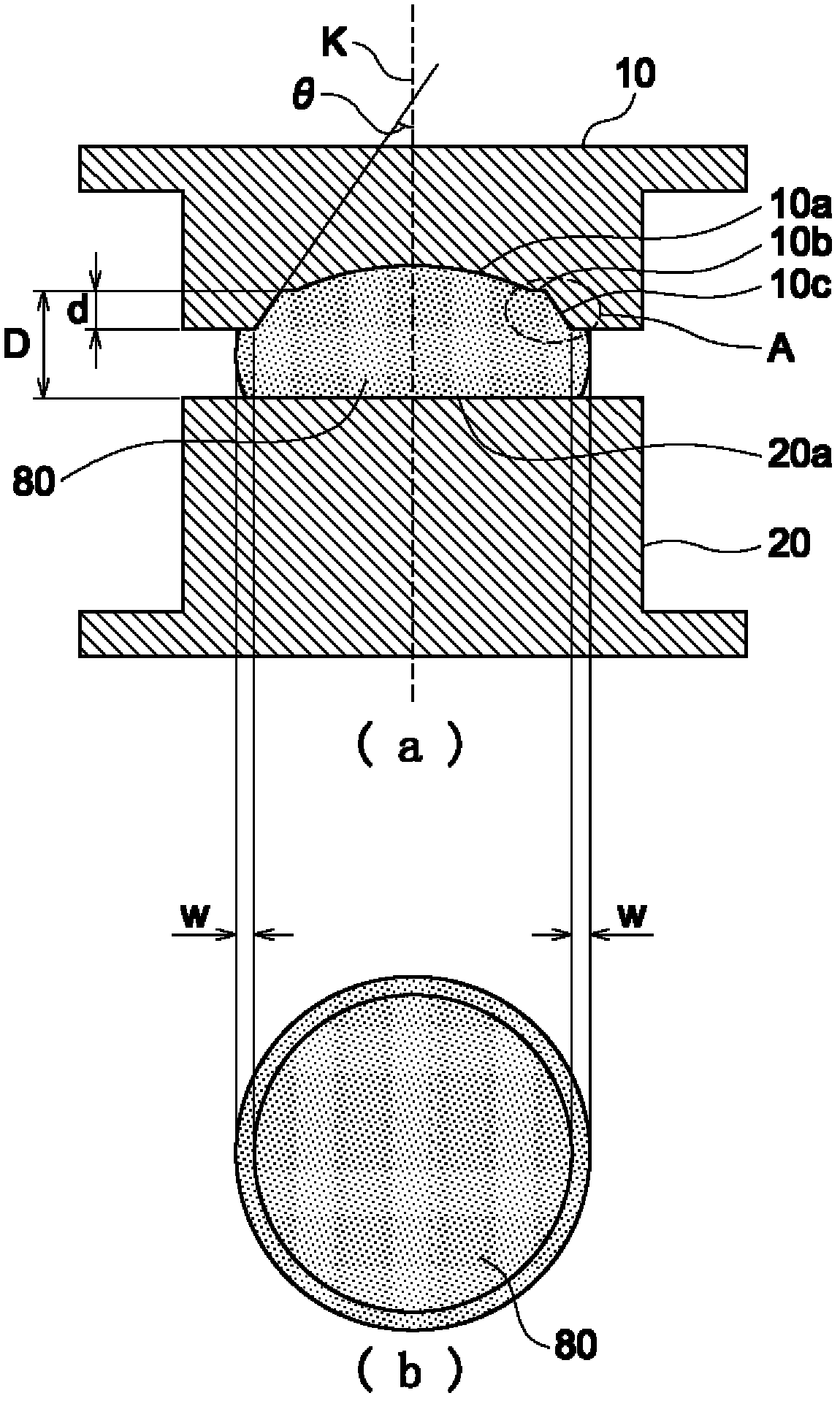

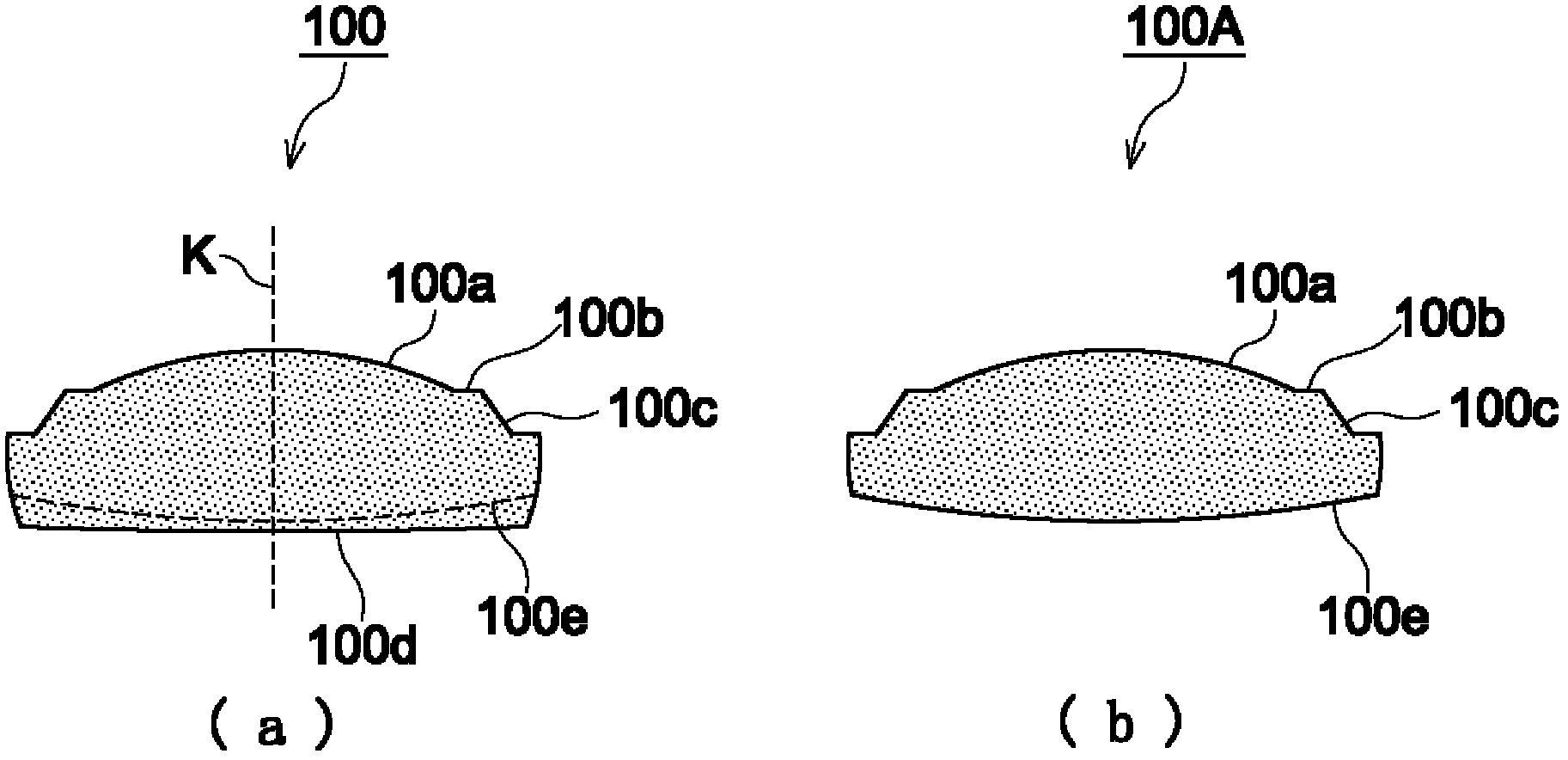

Apparatus for manufacturing glass molding

InactiveCN102405195ASuppression of different cooling rate differencesSuppression of cooling rate differencesGlass pressing apparatusLensOptical surfaceMaterials science

Provided is an apparatus for manufacturing a glass molding which can manufacture a glass molding having a high precision optical surface. An apparatus for manufacturing a glass molding has a lower die which receives molten glass, and an upper die which pressure molds the molten glass supplied to the lower die in conjunction therewith, wherein the upper die has a first molding surface which transfers the optical surface, a second flat molding surface provided around the periphery of the first molding surface, and a third molding surface provided around the periphery of the second molding surface and tilting relative to the central axis of the upper die passing through the center of the first molding surface to spread in the direction of the lower die.

Owner:KONICA MINOLTA OPTO

Preparation method and manufacturing die of ITO tubular target material with large length-diameter ratio

ActiveCN114394818AEliminates drastic changes in shrinkage rateReduce sintering shrinkageVacuum evaporation coatingSputtering coatingIndiumBall (bearing)

The invention discloses a preparation method and a manufacturing mold of an ITO tubular target material with a large length-diameter ratio, and relates to the technical field of preparation methods of ITO tubular target materials, and the preparation method comprises the following steps: step 1, uniformly mixing indium oxide powder and tin oxide powder according to a weight percentage of 90: 10; step 2, roasting the mixed powder to form ITO (Indium Tin Oxide) mixed powder; through the steel inner core with taper, the inner diameters of the upper end and the lower end of the ITO tubular biscuit have natural taper, so that the inner diameter deviation of the upper end and the lower end caused by inconsistent shrinkage rates from the lower end to the upper end due to friction between the ITO tubular biscuit and the burning bearing plate in the sintering process can be reduced; meanwhile, the high-roundness zirconium oxide balls which do not react with the ITO tubular biscuit are used as the burning bearing plate, the shrinkage resistance generated when the ITO tubular biscuit is sintered from bottom to top can be reduced through relative free sliding or dislocation of the zirconium oxide balls, and uniform and consistent shrinkage of the inner diameter of the upper end and the inner diameter of the lower end of the large-length-diameter-ratio tube target is achieved.

Owner:江苏东玖光电科技有限公司

Production method of wheel-mounted brake disc and wheel-mounted brake disc prepared by applying the method

ActiveCN106392016BSolve warping deformationUniform thicknessFoundry mouldsBraking discsDynamic balanceEngineering

Owner:JIANGSU DINGTAI ENG MATERIAL

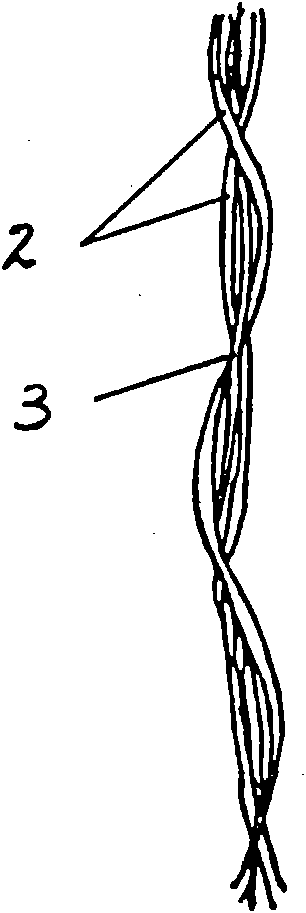

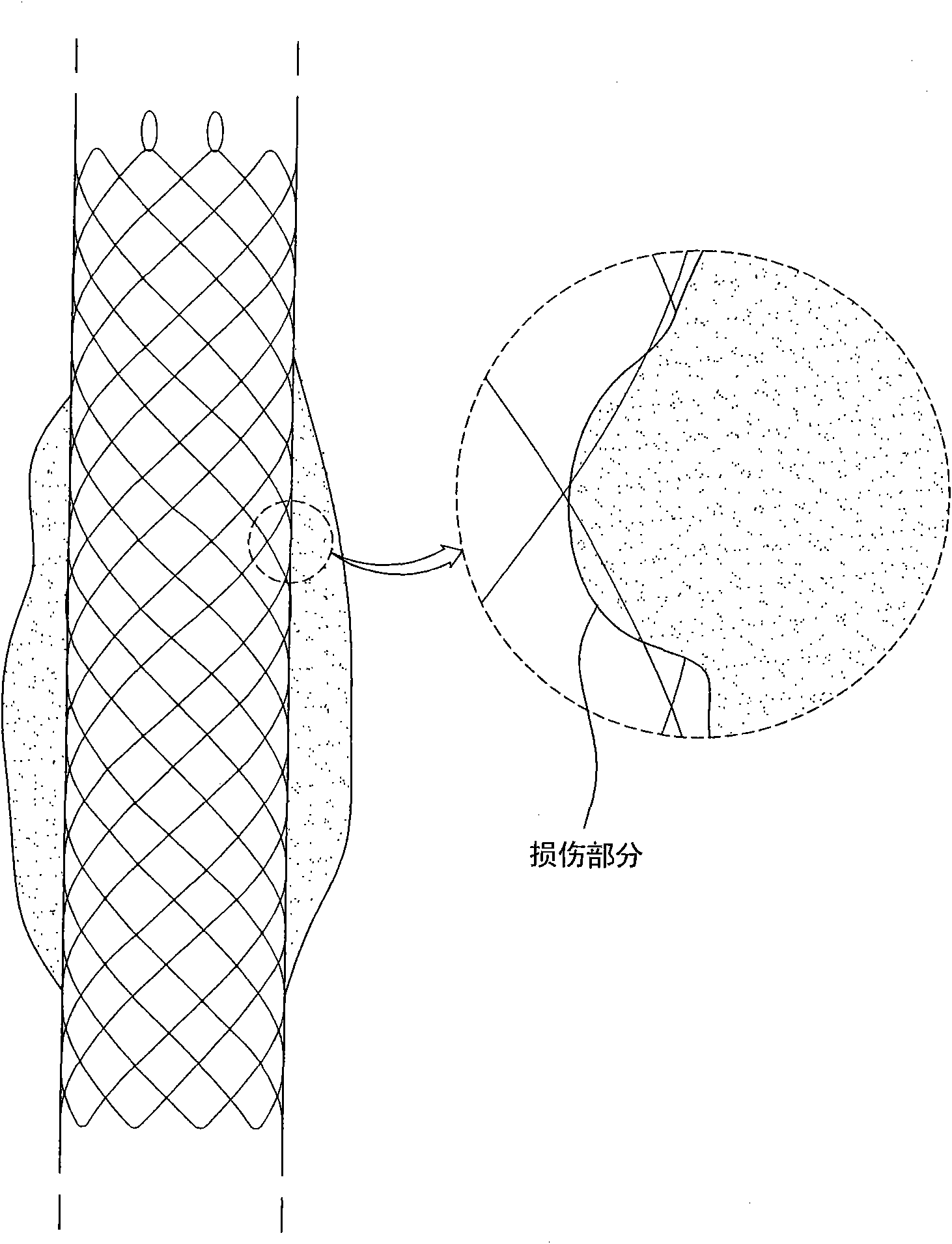

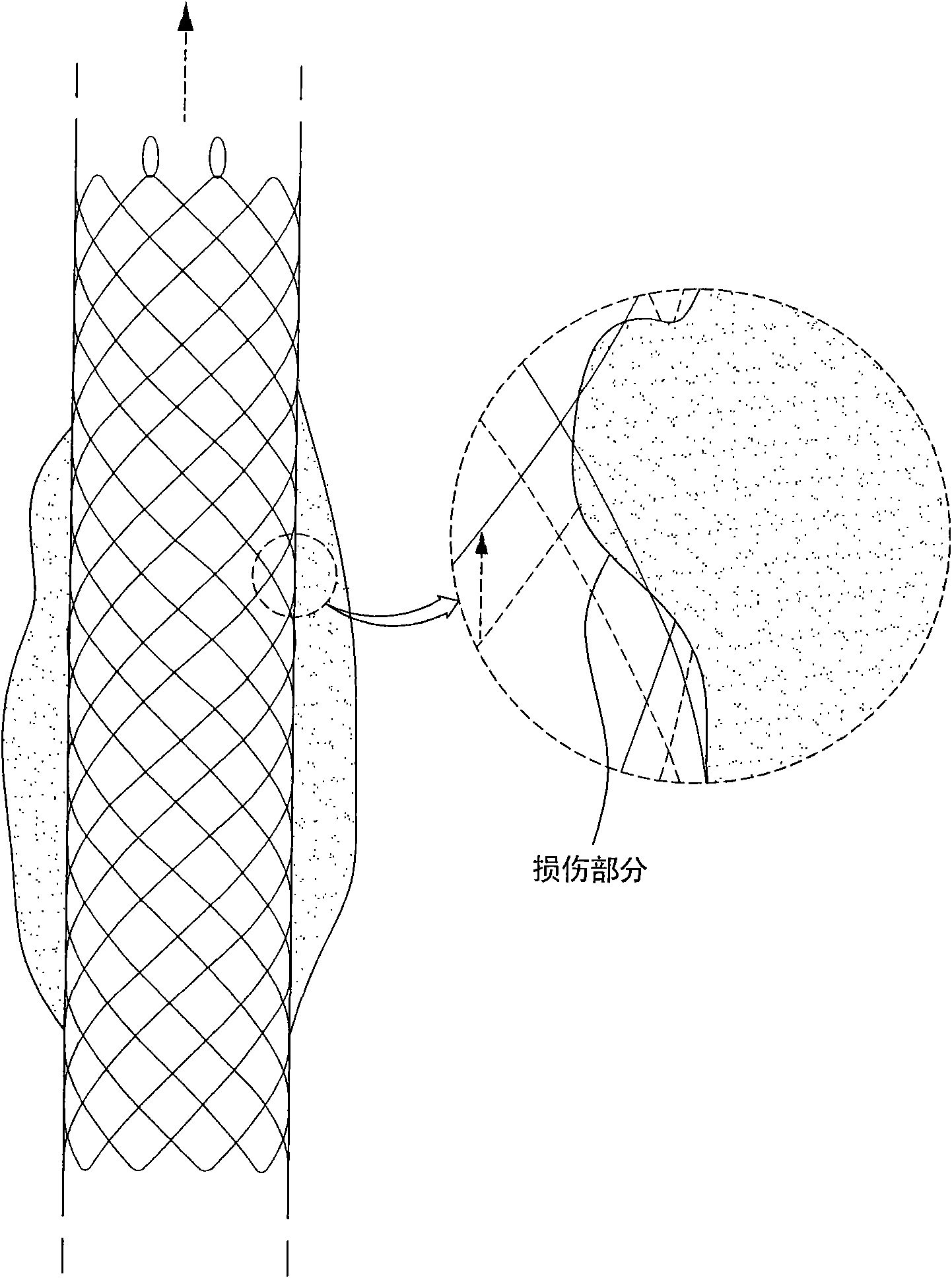

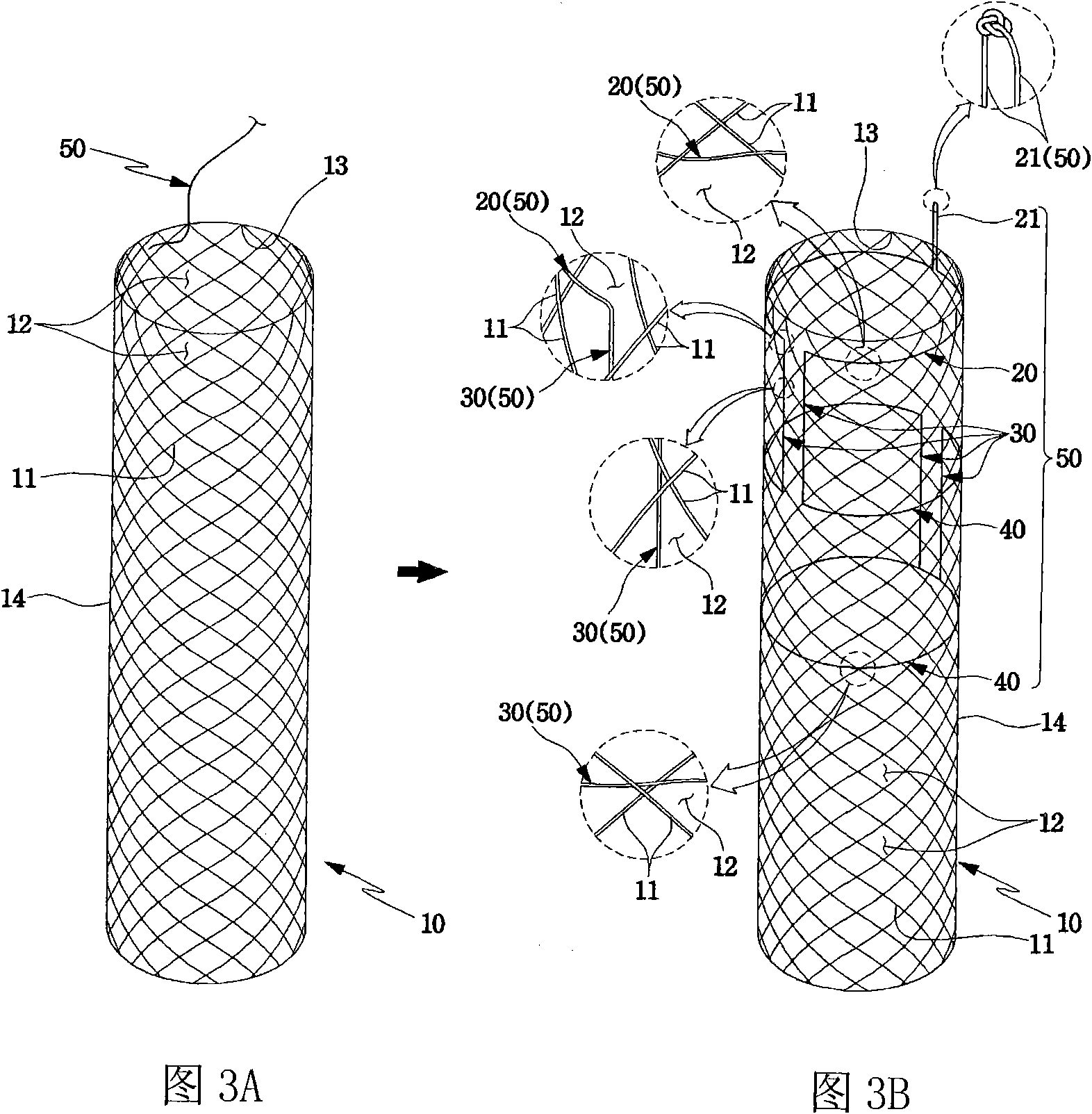

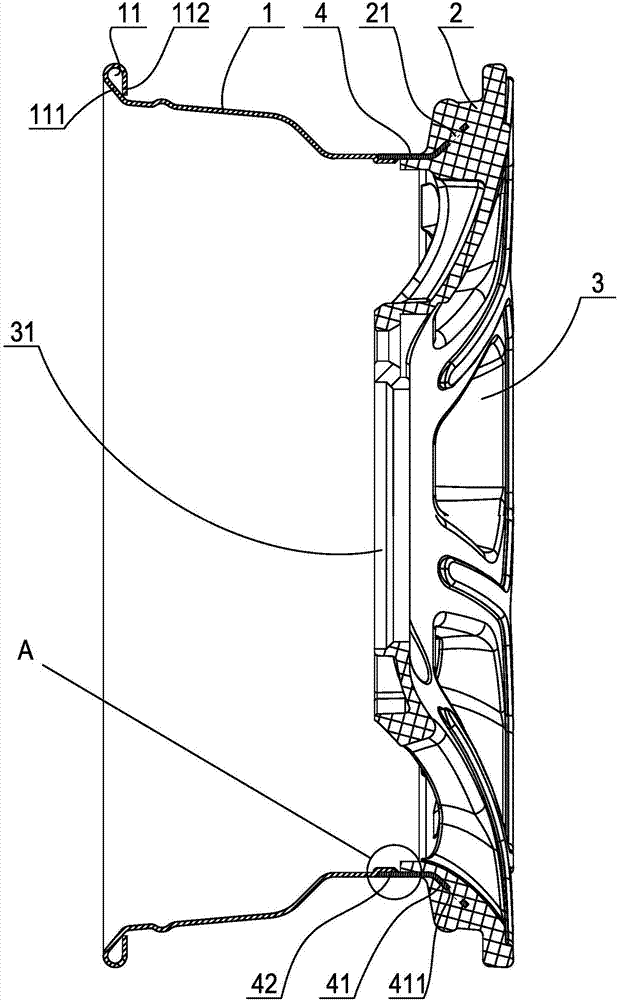

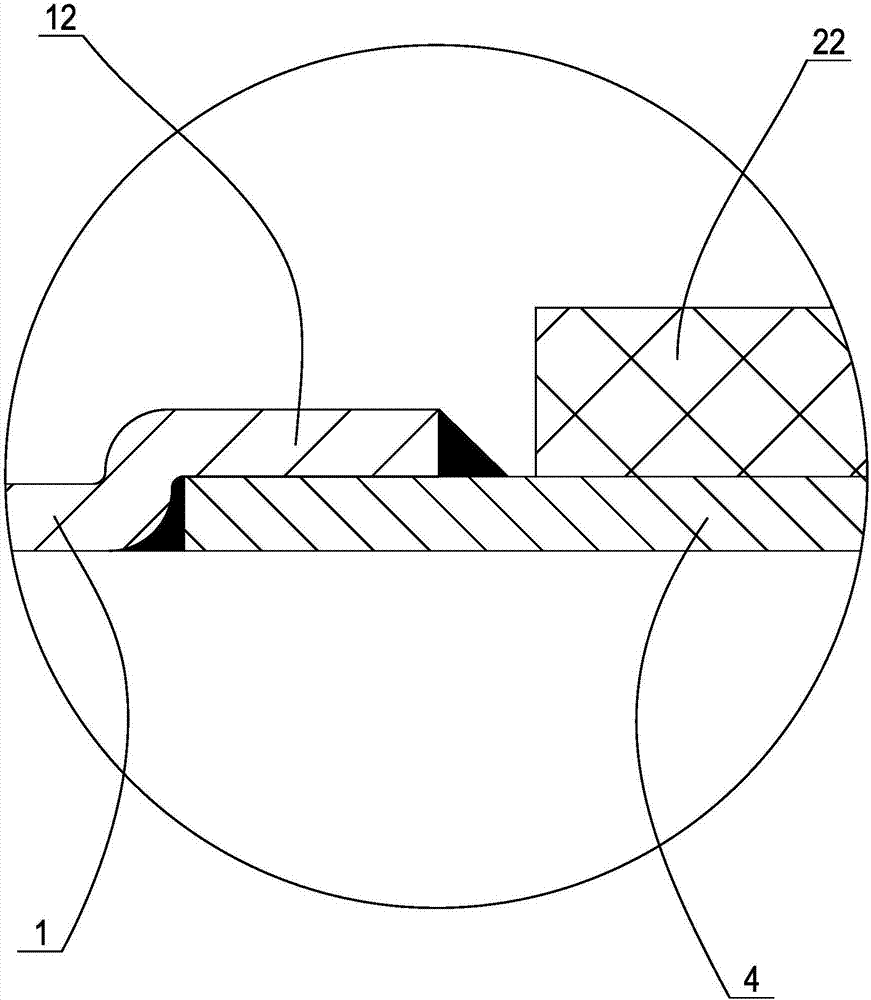

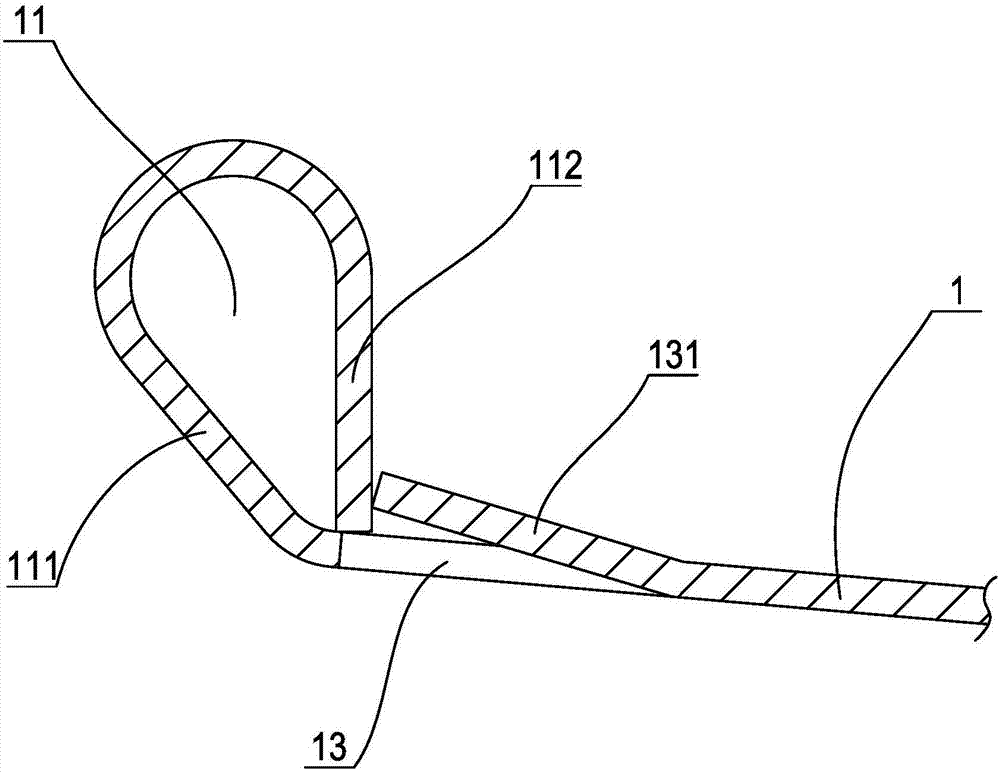

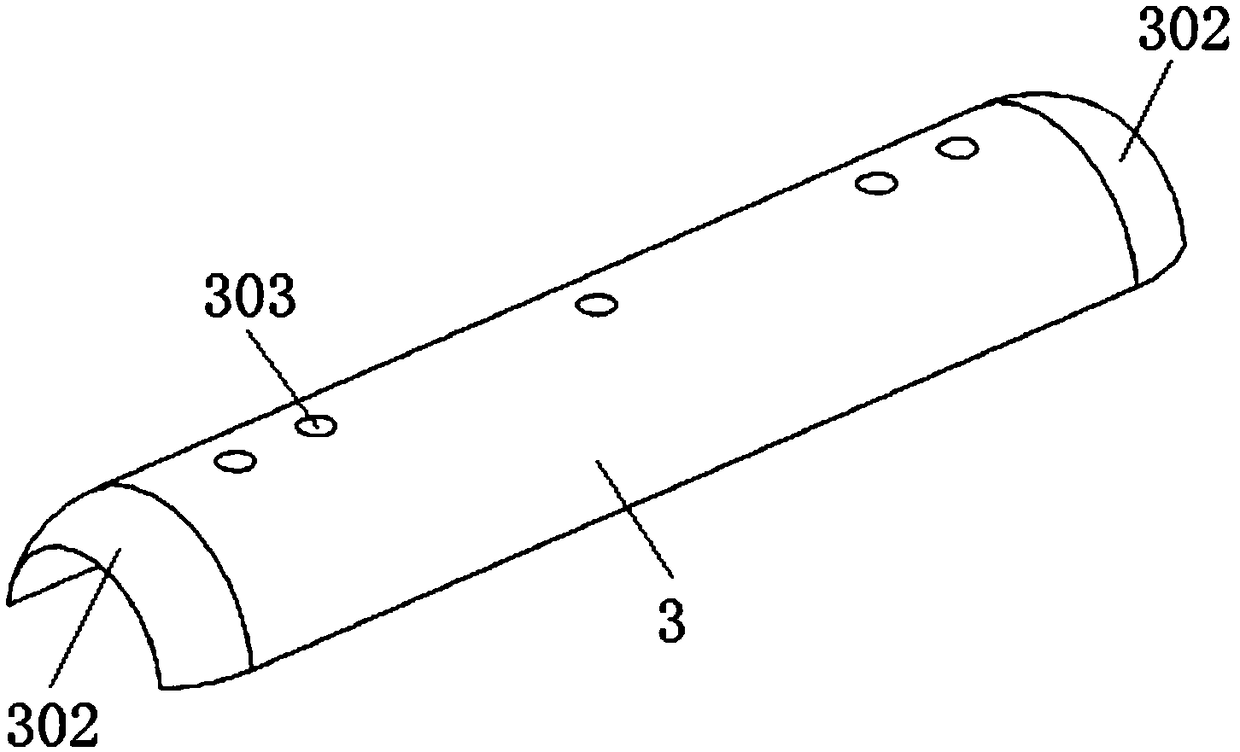

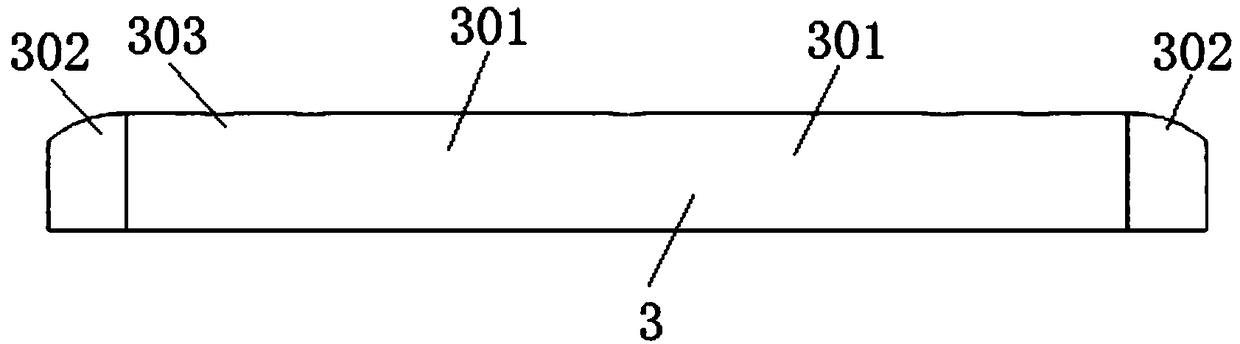

Drawstring for removal of stent

Disclosed herein is a drawstring for removal of a stent. The drawstring includes an end string, a longitudinal string and a circumferential string. The end string is formed in an end of the stent body in an annular shape in such a way that the end string passes, in a zigzag manner, through mesh arranged in a circumferential direction of the stent body. A hook loop is formed by tying opposite endsof the end string to each other. The longitudinal string extends at a first end thereof from the end string in the longitudinal direction of the stent body. The circumferential string extends from a second end of the longitudinal string and is formed in an annular shape in such a way that the circumferential string passes, in a zigzag manner, through mesh arranged in the circumferential directionof the stent body.

Owner:TAEWOONG MEDICAL CO LTD +1

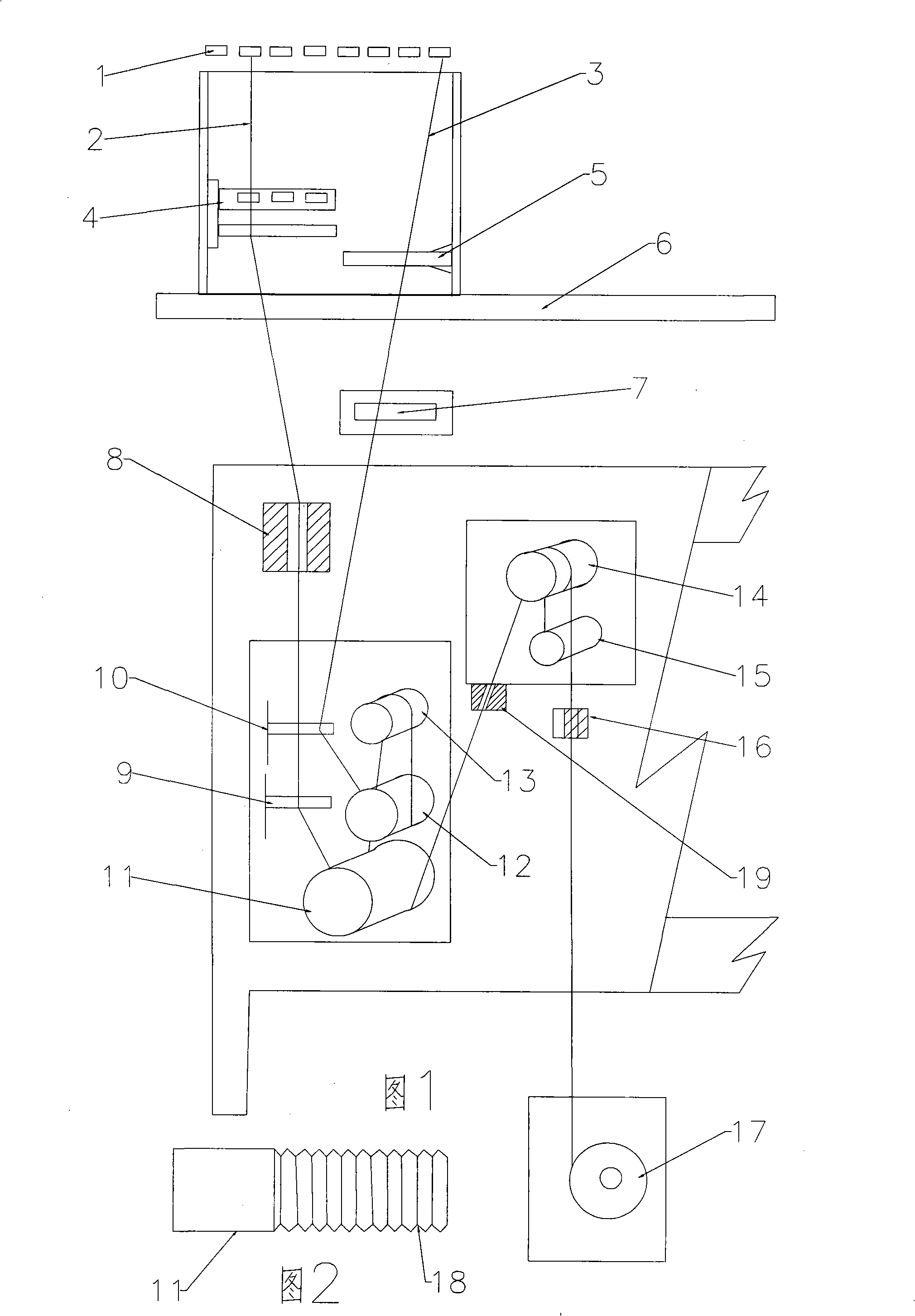

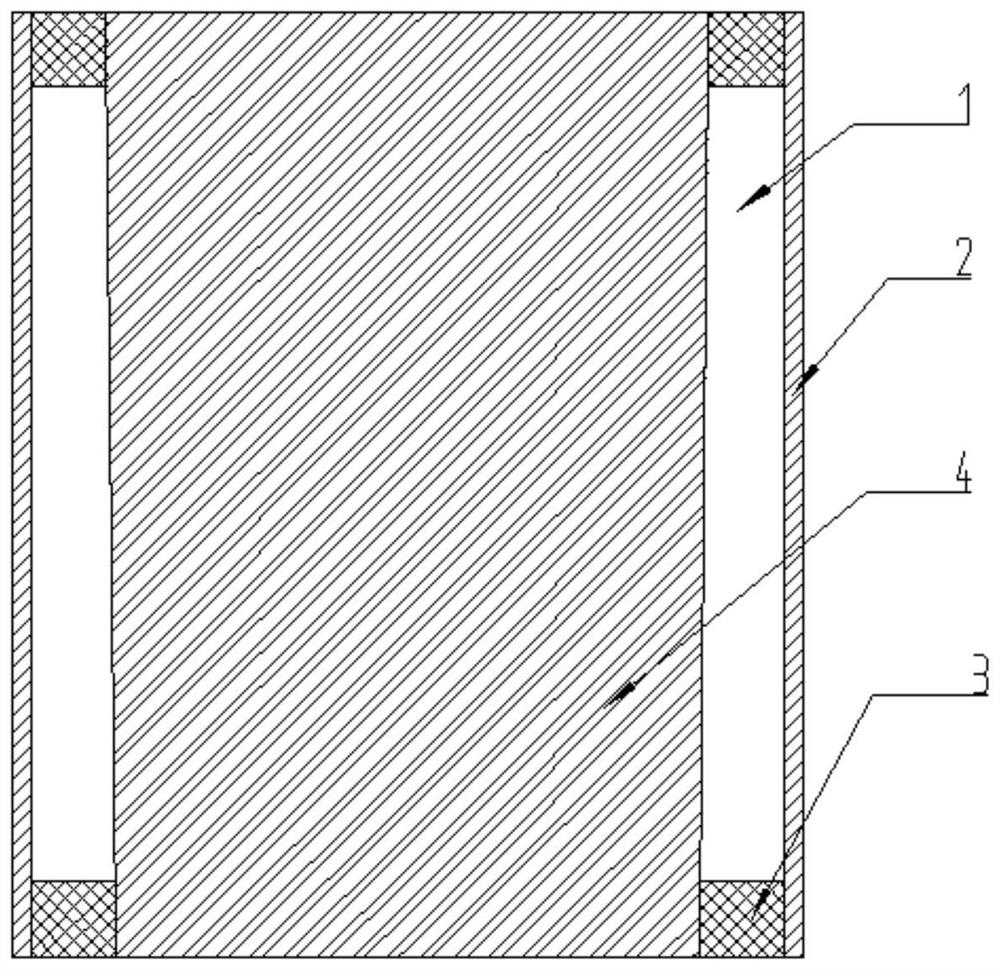

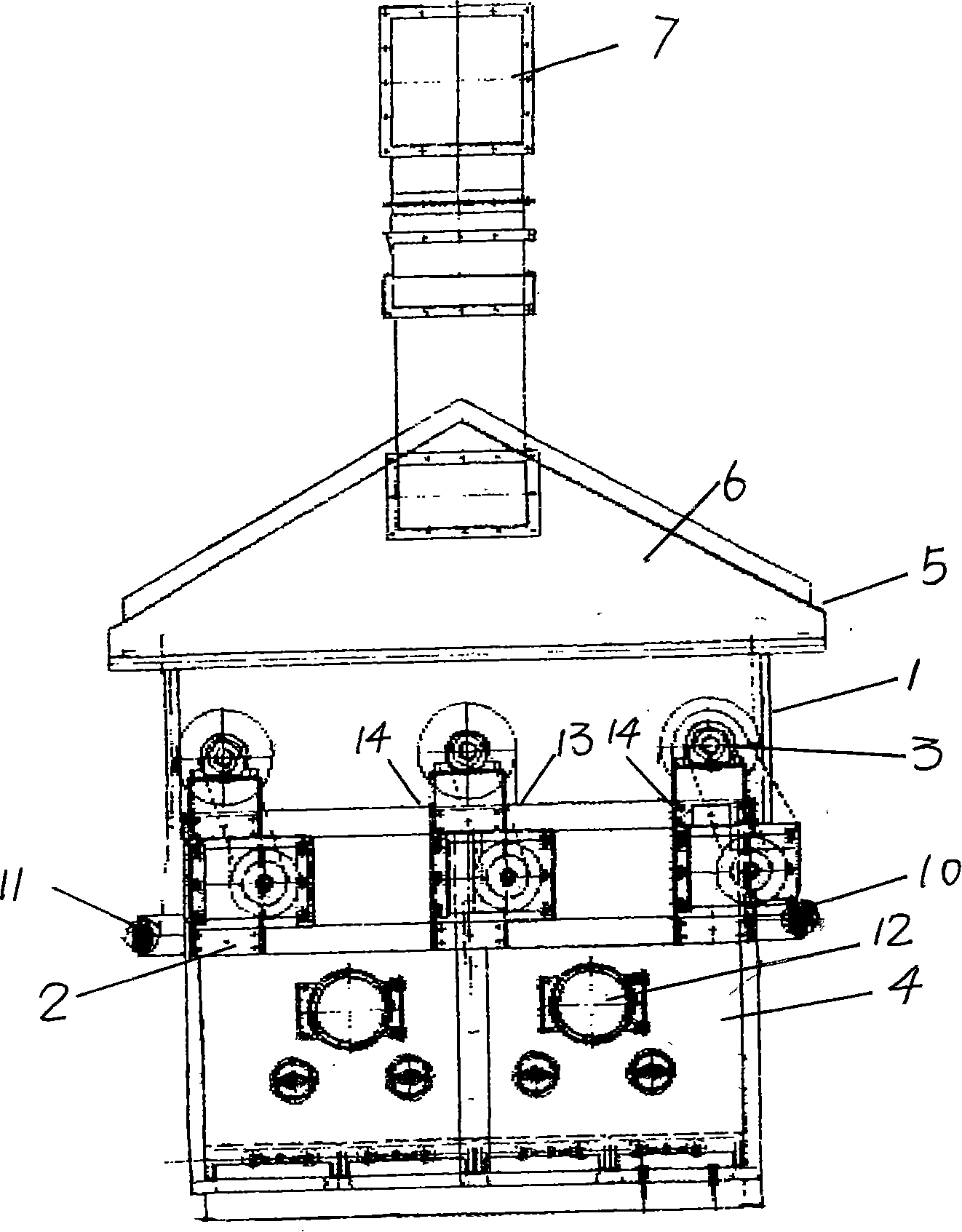

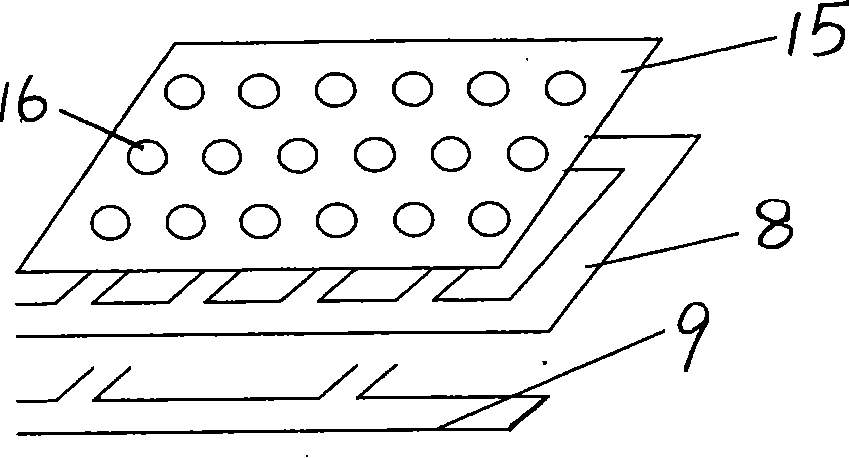

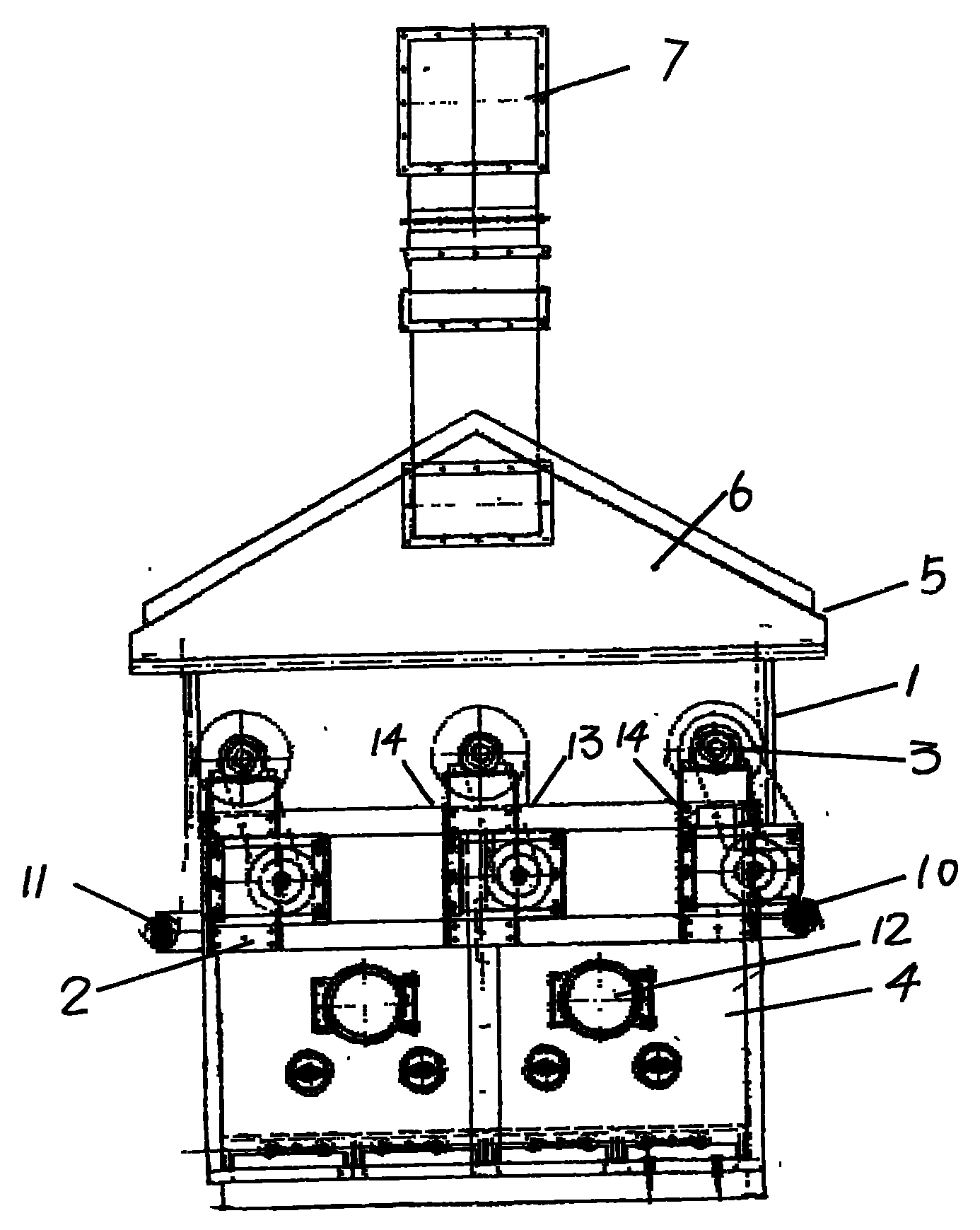

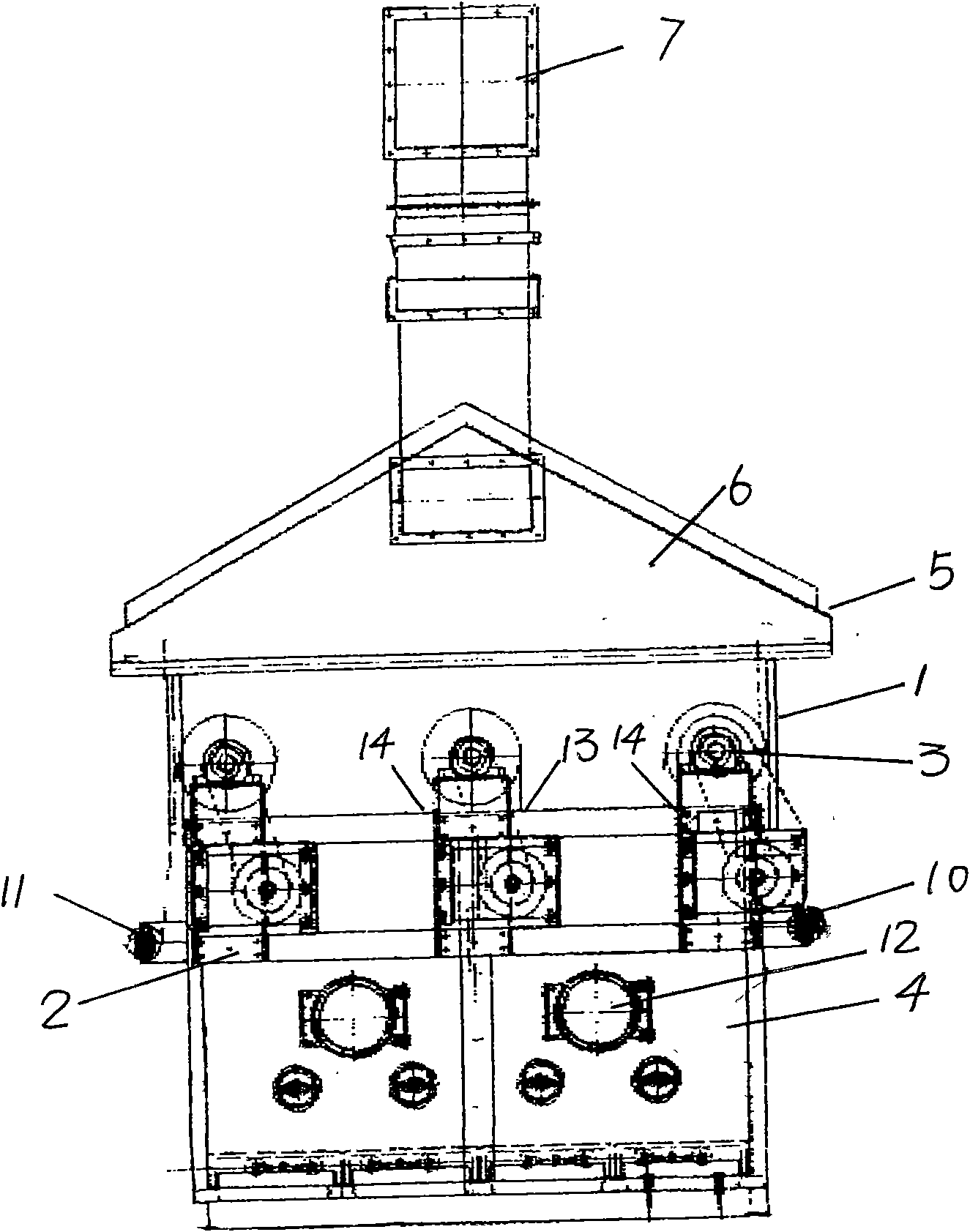

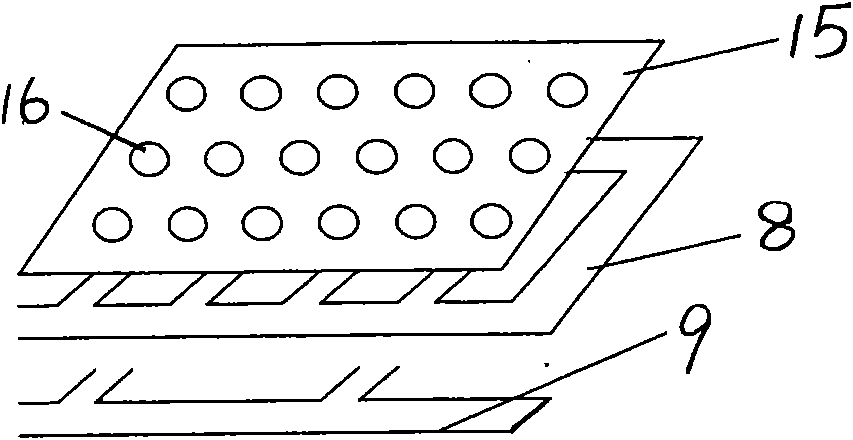

Preshrinking device for warp-beam preshrinking coiler

ActiveCN101619529BProduce pollutionEvenly heatedShrinkingHeating/cooling textile fabricsEngineeringSteel plates

The invention relates to a preshrinking device for a warp-beam preshrinking coiler, which is characterized in that: a stander is provided with three sets of preshrinking rollers arranged in parallel; a heating cabin is arranged below the preshrinking rollers; an air sucking and exhausting device is arranged above the preshrinking rollers; a driving rod matched with the preshrinking rollers are arranged in the heating cabin; a steel plate is arranged on the bottom of the heating cabin; and an oil heating pipe and a steam pipe are paved below the steel plate. The preshrinking device preshrinks fabrics through the heat released by the oil heating pipe and the steam released by the steam pipe. Under the linkage action of the preshrinking rollers and the driving rod, the fabrics are slowly moved along a preset route and are uniformly heated, humidified and preshrunk in the heating cabin. Because oil in the oil heating pipe can be repeatedly heated to use, and the heat and steam released from the heating cabin can be finally exhausted from a workshop through the air sucking and exhausting device, the whole preshrinking device cannot pollute the environment, and has low energy consumption and greatly-improved production efficiency.

Owner:SHANGHAI TIANQIANG TEXTILE

Preshrinking device for warp-beam preshrinking coiler

ActiveCN101619529AProduce pollutionEvenly heatedShrinkingHeating/cooling textile fabricsSheet steelEngineering

The invention relates to a preshrinking device for a warp-beam preshrinking coiler, which is characterized in that: a stander is provided with three sets of preshrinking rollers arranged in parallel; a heating cabin is arranged below the preshrinking rollers; an air sucking and exhausting device is arranged above the preshrinking rollers; a driving rod matched with the preshrinking rollers are arranged in the heating cabin; a steel plate is arranged on the bottom of the heating cabin; and an oil heating pipe and a steam pipe are paved below the steel plate. The preshrinking device preshrinks fabrics through the heat released by the oil heating pipe and the steam released by the steam pipe. Under the linkage action of the preshrinking rollers and the driving rod, the fabrics are slowly moved along a preset route and are uniformly heated, humidified and preshrunk in the heating cabin. Because oil in the oil heating pipe can be repeatedly heated to use, and the heat and steam released from the heating cabin can be finally exhausted from a workshop through the air sucking and exhausting device, the whole preshrinking device cannot pollute the environment, and has low energy consumption and greatly-improved production efficiency.

Owner:SHANGHAI TIANQIANG TEXTILE

A kind of precision casting wax and its preparation method and application

ActiveCN105175851BNo wire drawingImprove the effect of precision machiningFoundry moulding apparatusWaxPolystyrene

The invention relates to precision casting wax. The precision casting wax comprises the following ingredients, by weight, 80-90% of PE wax, 4-10% of polystyrene, 4-10% of eleaostearic acid and 0.2-0.4% of white carbon black, and the mass percent sum of the precision casting wax is 100wt%. During the CAD precise processing of the precision casting wax, re-fusion and wire drawing phenomena in a small-sized scope are reduced obviously, and the effects of the precision casting wax with PE wax as base wax and used for CAD precise processing are improved obviously. The internal components of the precision casting wax are uniform, the shrinkage of each part is uniform, and the wax block quality is raised.

Owner:上海沪亮生物医药科技有限公司

A fabric treatment device with melting treatment

ActiveCN103911778BStable fabric structureRealize industrial productionHeating/cooling textile fabricsTextile treatment machine arrangementsShrinkage rateHot melt

Owner:SUZHOU VOCATIONAL UNIV

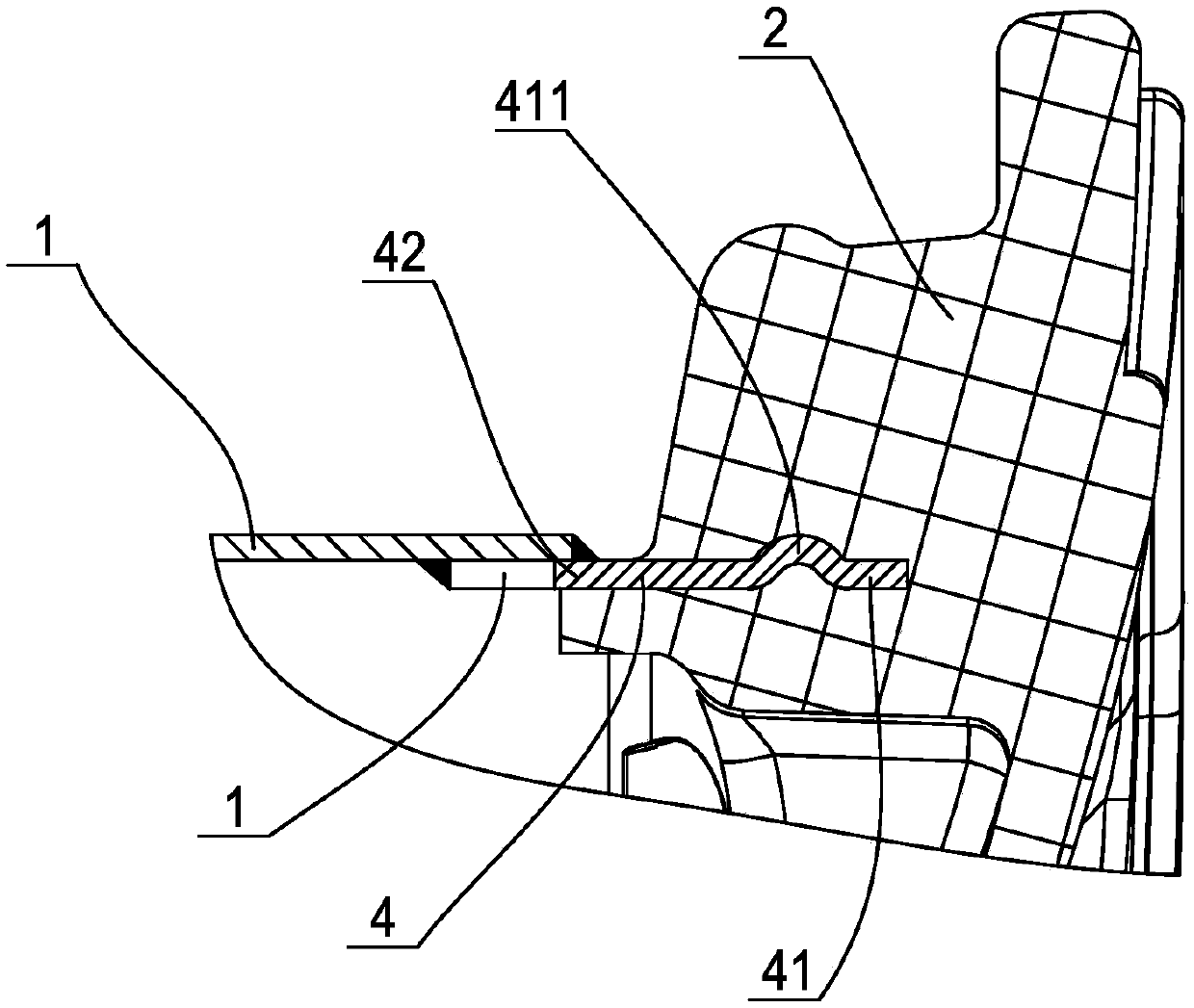

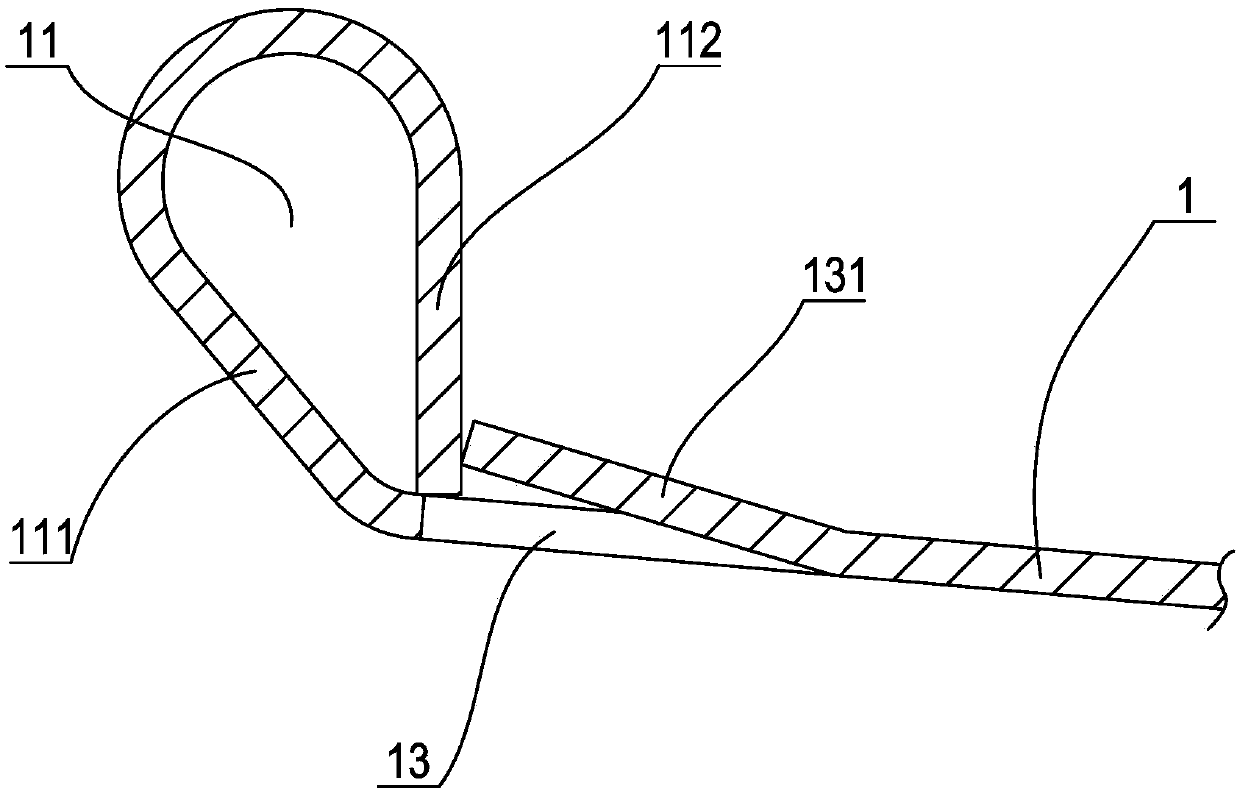

Connecting structure for short joint and used for fuel cell system

PendingCN110985779ALocking pressure equalizationImprove the tightnessSleeve/socket jointsReactant parameters controlAdhesive glueStructural engineering

The invention discloses a connecting structure for a short joint and used for a fuel cell system, relates to the technical field of sealed connecting structures of vehicle fuel cell systems, and solves the problems of low fastening degree and poor durability in the prior art. The connecting structure comprises a first connector and a second connector, and further comprises a sealing connector, thesealing connector comprises an inner sleeve and an outer sleeve, a plug-in slot is formed between the inner sleeve and the outer sleeve, the first connector is in inserted connection within the innersleeve, the second connector is in inserted connection within the plug-in slot, and a locking piece is arranged on the outer side of the sealing connector. The connecting structure is reasonable in structure and reliable in connection, the two joints can be firmly connected, the fastening degree is high, the durability and the sealing performance are high, and the possible aging problem of glue after using of the glue is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

Composite aluminum rim and manufacturing method

ActiveCN107309607BShaping without addingEasy to processRimsWheel manufactureManufacturing cost reductionDie casting

The invention discloses a composite aluminum rim and a manufacturing method thereof. The composite aluminum rim comprises a left ring body molded by punching, a right ring body molded by die casting and a web plate; a connecting part molded by rolling is arranged in the right ring body; each of the two abutting ends of the connecting part is provided with a plurality of rectangular notches, and rectangular convex blocks adapted to the corresponding rectangular notches; a rectangular sawtooth is formed between every two adjacent rectangular notches; a rectangular groove is formed between every two adjacent rectangular convex blocks; the connecting part comprises an embedded section connected with the right ring body, and a welding section welded with the left ring body; when the right ring body and the web plate are subjected to die-casting molding, the connecting part is connected with a mould core of a die-casting molding mould in a sleeving manner, so that an adjustment gap is formed between the end of each rectangular convex block and the bottom of one corresponding rectangular notch, and an adjustment gap is formed between the end of each rectangular sawtooth and the bottom of one corresponding rectangular groove; and reinforced connecting blocks are formed in the adjustment gaps. With the adoption of the scheme, the intensity of the composite aluminum rim can be guaranteed, the production efficiency can be improved and thus the manufacturing cost is reduced, the quality grade of the composite aluminum rim can be raised effectively, and the composite aluminum rim meets the requirements of a high-quality vehicle.

Owner:台州市风驰车轮有限公司

Technology for binding fish-culturing net

InactiveCN1162067CImprove the forceAvoid breakingClimate change adaptationKnottingEngineeringUltimate tensile strength

A technology for binding the netted appliance for culturing fish in deep sea includes such steps as cutting the netted fabric to needed shapes and sizes, sewing and binding with ropes, and features its additional edge-binding step. Its advantages include high strength, uniform stress, and not deforming or not being damaged by waves easily.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Iron-aluminum composite steel ring and manufacturing method thereof

ActiveCN107214270AHigh strengthUniform strengthMetal-working apparatusCompression moldingManufacturing cost reduction

The invention discloses an iron-aluminum composite steel ring and a manufacturing method thereof. The iron-aluminum composite steel ring comprises a left ring body, a right ring body and a center plate. The left ring body is produced by press forming process, the right ring body and the center plate are produced by aluminum alloy compression molding process, the right ring body is internally provided with a transition ring body; the transition ring body comprises an embedding section and a welding section, wherein the embedding section is connected with the right ring body, and the welding section extends out of the right ring body; when the right ring body and the center plate are produced by compression molding, the transition ring body is served as an embedding piece of a compression molding mold, so that the embedding section located at the right end of the transition ring body is embedded in the right ring body; a shaft sleeve is connected with the right end of the left ring body and the welding section extended out of the right ring body of the transition ring body, and the left ring body and the welding section of the transition ring body are connected and integrated through a welding process; a roll rim is arranged on the edge of the left end of the left ring body, wherein the roll rim turns and rolls towards the circumferential surface of the outer side of the left ring body. According to the iron-aluminum composite steel ring and the manufacturing method thereof, not only can strength of a vehicle rim be guaranteed, and is production efficiency significantly improved to reduce the manufacturing cost, but also the quality grade can be effectively improved to adapt the requirement of high-quality vehicle.

Owner:ZHEJIANG FENGCHI MECHANICAL

Composite aluminum rim and manufacturing method thereof

ActiveCN107309607AShaping without addingEasy to processRimsWheel manufactureManufacturing cost reductionDie casting

The invention discloses a composite aluminum rim and a manufacturing method thereof. The composite aluminum rim comprises a left ring body molded by punching, a right ring body molded by die casting and a web plate; a connecting part molded by rolling is arranged in the right ring body; each of the two abutting ends of the connecting part is provided with a plurality of rectangular notches, and rectangular convex blocks adapted to the corresponding rectangular notches; a rectangular sawtooth is formed between every two adjacent rectangular notches; a rectangular groove is formed between every two adjacent rectangular convex blocks; the connecting part comprises an embedded section connected with the right ring body, and a welding section welded with the left ring body; when the right ring body and the web plate are subjected to die-casting molding, the connecting part is connected with a mould core of a die-casting molding mould in a sleeving manner, so that an adjustment gap is formed between the end of each rectangular convex block and the bottom of one corresponding rectangular notch, and an adjustment gap is formed between the end of each rectangular sawtooth and the bottom of one corresponding rectangular groove; and reinforced connecting blocks are formed in the adjustment gaps. With the adoption of the scheme, the intensity of the composite aluminum rim can be guaranteed, the production efficiency can be improved and thus the manufacturing cost is reduced, the quality grade of the composite aluminum rim can be raised effectively, and the composite aluminum rim meets the requirements of a high-quality vehicle.

Owner:台州市风驰车轮有限公司

PA6 composite material as well as preparation method and application thereof

The invention relates to a PA6 composite material and a preparation method and application thereof, the PA6 composite material comprises the following components in parts by weight: 80-100 parts of PA6, 8-12 parts of a modified composite filler, 16-20 parts of modified basalt fiber and 0.1-0.5 part of an antioxidant, and the modified composite filler is a composite filler of modified talcum powder and glass beads. The PA6 composite material provided by the invention has excellent physical properties and uniform longitudinal and transverse shrinkage.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

Protection device for copper bar connection

InactiveCN108400453AExtended service lifeAvoid partial dischargeConnection insulationPartial dischargeEngineering

The invention discloses protection device for copper bar connection. The protection device comprises a fastening bolt and a fastening nut, wherein the fastening bolt and the fastening nut connect thesame-phase copper bars, connection ends of the same-phase copper bars are vertically aligned and connected, protection sleeves are symmetrically arranged above and below two copper bar connection ends, a bolt groove is formed in an inner wall surface of each protection sleeve and is corresponding to the fastening bolt, and thermal shrinkage sleeves sleeve outer wall surfaces of the protection sleeves and the copper bars. In the protection device for copper bar connection, the thermal shrinkage sleeves are heated after the protection sleeves are arranged at the fastening bolt connected with thecopper bar, so that the service lifetime of the thermal shrinkage sleeves is prolonged by the protection sleeves, the phenomenon that the thermal shrinkage sleeves are excessively contracted and arepunctured by a tip of the fastening bolt after heat generation is effectively prevented, and unfavorable condition such as local discharging is also prevented.

Owner:YIHE ELECTRIC GRP

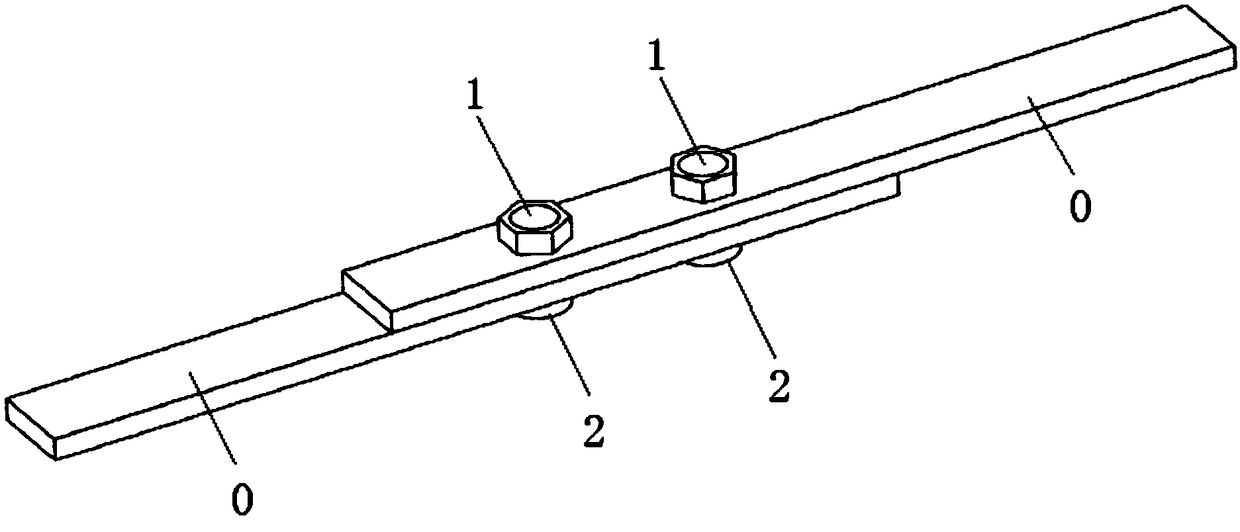

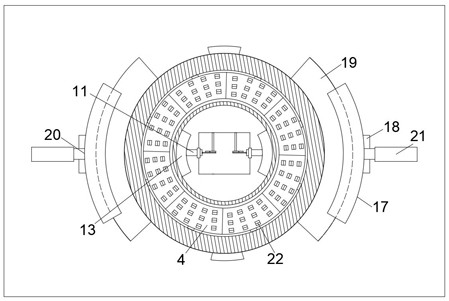

Concentric fixing device for solar shell and inner container interlayer

InactiveCN114674085AEasy to fixQuick pick and placeSolar heating energySolar thermal energy generationHeat conductingEngineering

The invention discloses a concentric fixing device for a solar shell and an inner container interlayer, which comprises an inner container fixing structure, the inner container fixing structure comprises a fixing frame, a sliding sleeve is arranged on the fixing frame, a first sliding rod is inserted into the sliding sleeve, and a second sliding rod is inserted into the sliding sleeve; the lower end of the first sliding rod is connected with a contraction fastener used for fixing the solar inner container. The shell fixing structure comprises a fixing seat connected with the fixing frame, and a clamping structure used for fixing the solar shell is arranged on the fixing seat; the balance adjusting structure comprises a first heat conducting disc and a second heat conducting disc which are sequentially arranged between the solar shell and the inner container interlayer. Through the combined action of the inner container fixing structure, the shell fixing structure and the balance adjusting structure, dynamic balance adjusting and static fixing are combined, concentric fixing of the solar shell and the inner container is achieved, and it is guaranteed that the deformation quantity of the solar shell and the deformation quantity of the inner container are low in the concentric fixing process of the solar shell and the inner container.

Owner:江苏大威新能源科技有限公司

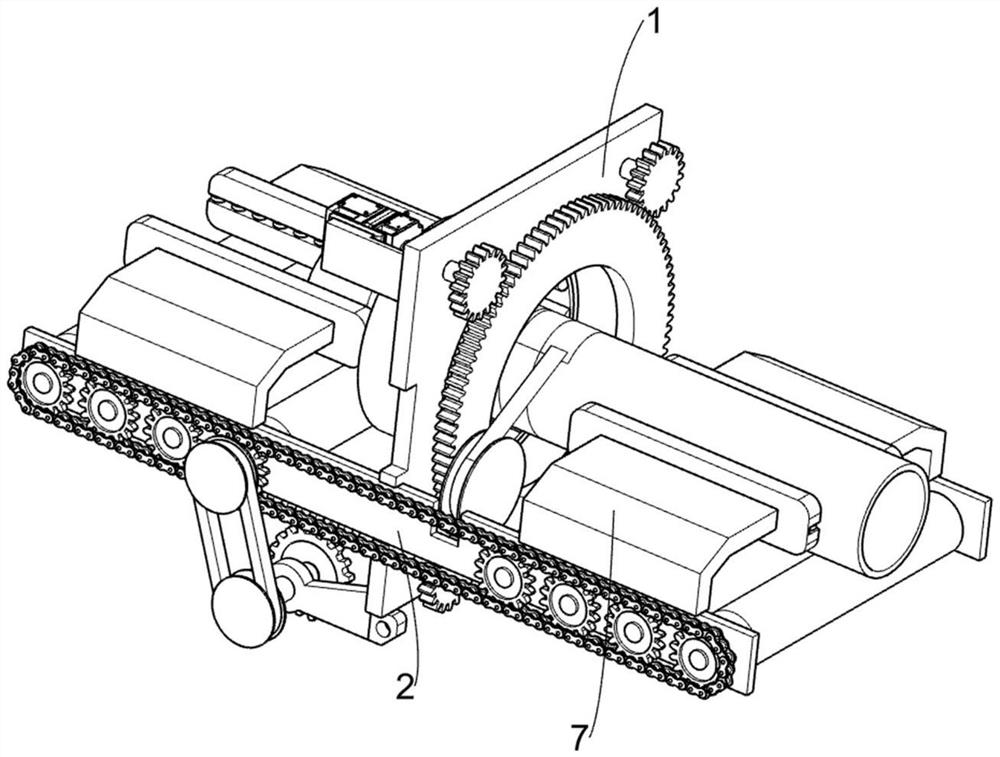

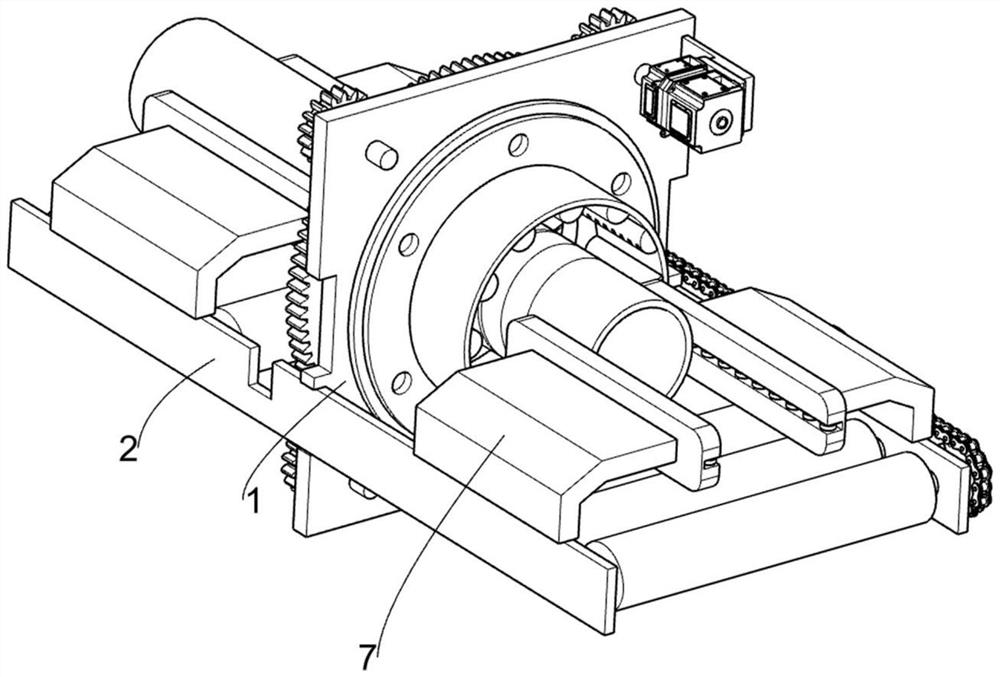

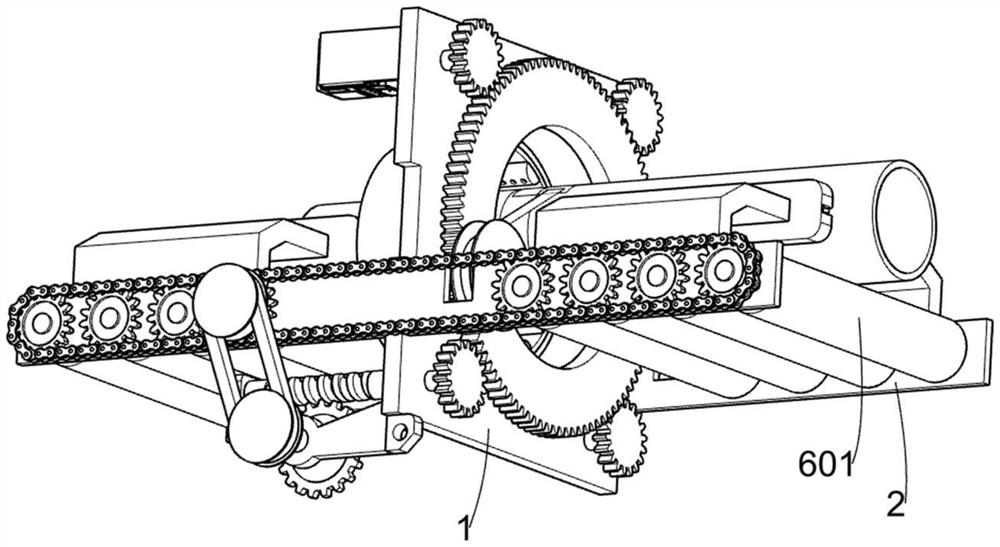

Equipment capable of tightly pasting polyethylene film to anti-corrosion pipeline

The invention relates to equipment for pasting a polyethylene film, in particular to equipment capable of tightly pasting a polyethylene film to an anti-corrosion pipeline. The equipment comprises a square mounting plate, long plates, a polyethylene film pasting mechanism, a polyethylene film ironing and shrinking mechanism and the like. The long plates are symmetrically mounted on the two sides of the square mounting plate, the polyethylene film pasting mechanism is arranged on the square mounting plate, and the polyethylene film ironing and shrinking mechanism is mounted on one side of the square mounting plate. A high-temperature heating strip releases heat to heat the polyethylene film, a gear ring drives a rotary supporting sleeve and a device on the rotary supporting sleeve to rotate through a rotary sleeve, so that the high-temperature heating strip rotates along with the rotary supporting sleeve, the surface of the polyethylene film pasted to the anti-corrosion pipeline is evenly ironed and shrunk, the gear ring rotating anticlockwise at a high speed cooperates with a rotary driving roller rotating slowly, and the polyethylene film can be effectively and fully pasted to the anti-corrosion pipeline.

Owner:济宁市华奕工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com