Production method of wheel-mounted brake disc and wheel-mounted brake disc prepared by applying the method

A production method and technology of brake discs, applied in the directions of brake discs, brake components, brake types, etc., can solve the problems of poor cooling of the heat dissipation surface, different shrinkage rates, uneven cooling, etc., and improve the dynamic balance detection of products. The effect of passing rate, avoiding warpage deformation, and uniform shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

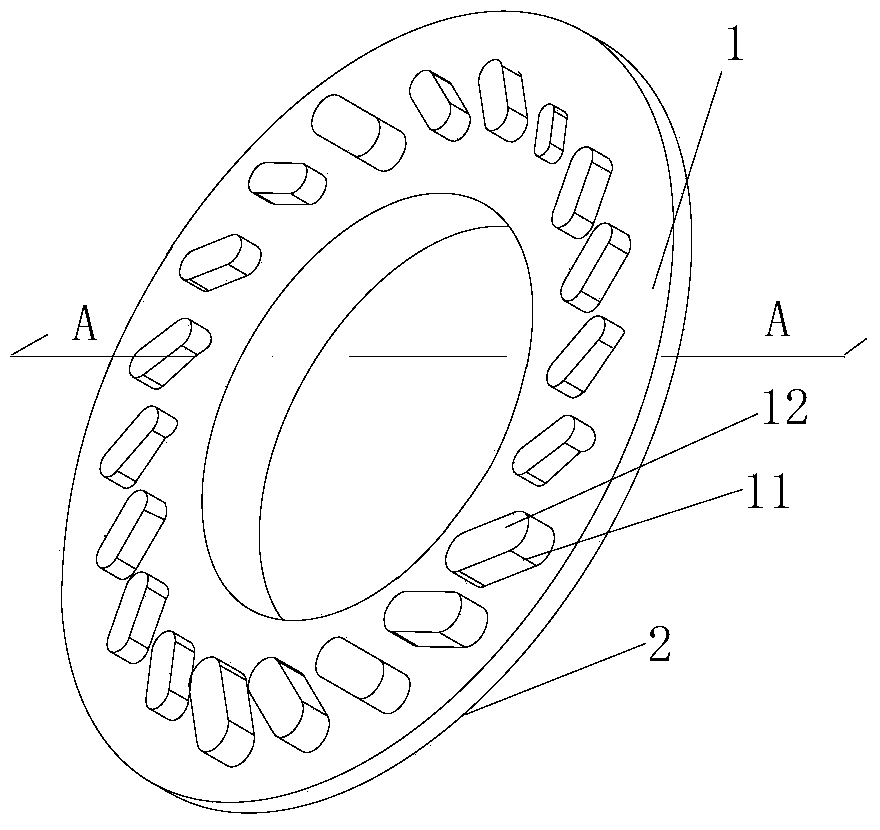

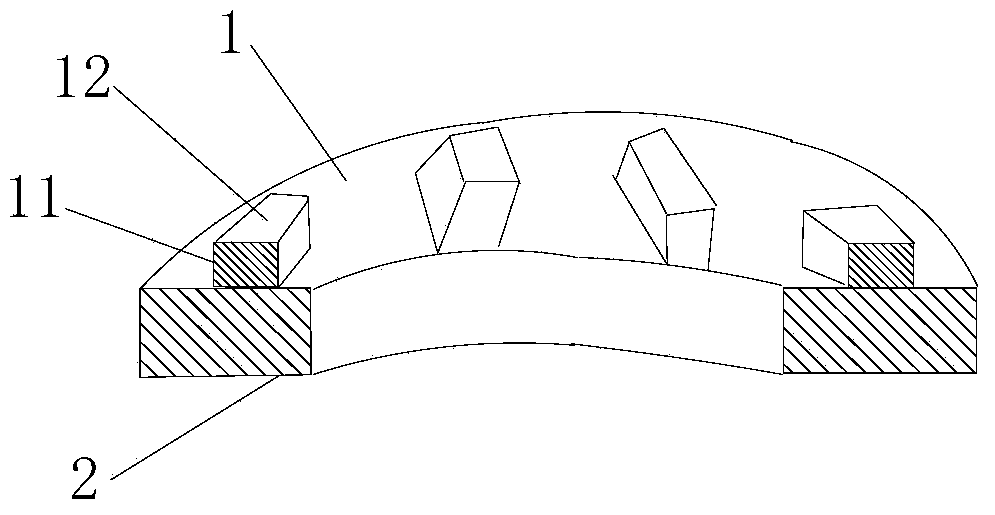

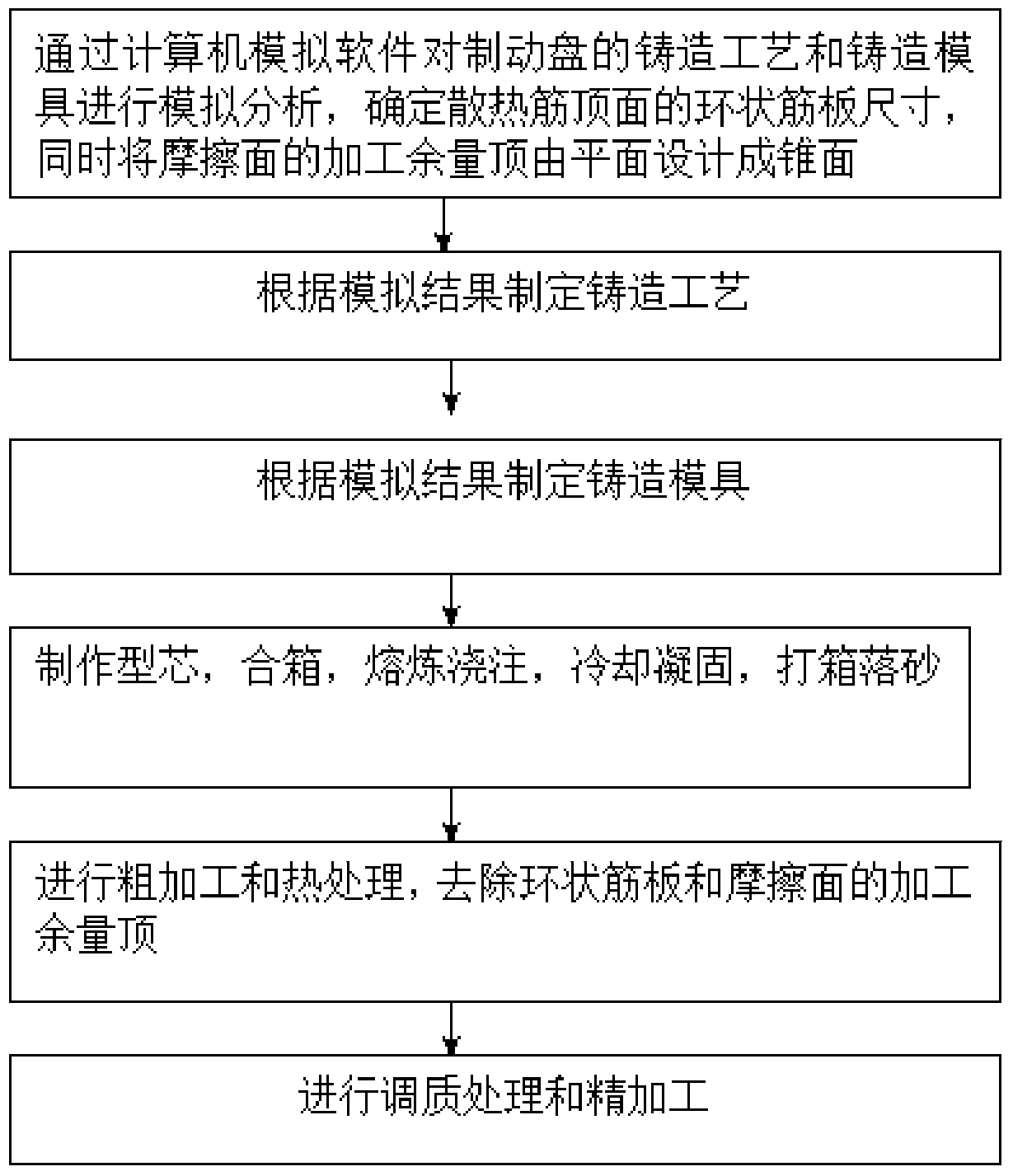

[0027] Taking a high-speed train with a speed of 250km / h as an example, the cast steel wheel-mounted brake disc (with an outer diameter of 620mm and an inner diameter of 260mm) as an example, the process flow of the casting method is as follows: image 3 As shown, it includes the following steps in sequence:

[0028] A. The casting process and casting mold of the brake disc are simulated and analyzed by computer simulation software, and the thickness of the annular rib plate on the top surface of the heat dissipation rib is determined to be 10mm (in the remaining embodiments, it can be 5mm, 6mm, 7mm, 8mm , 9mm, etc.), and at the same time, the machining allowance of the friction surface of the brake disc is designed as a conical surface, and the machining allowance is 10mm, so that the cross-section changes from a rectangle to a triangle, which increases the resistance of the casting deformation and keeps the casting shrinking steadily. , to prevent deformation.

[0029] B. F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com