Coffeepot stirrer material and preparation method thereof

A technology for agitators and coffee pots, applied in the field of materials, can solve the problems of easy adsorption and difficult removal of coffee stains, and achieve the effects of satisfying complex structures, preventing organic matter from adhering, and enhancing surface rigidity and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

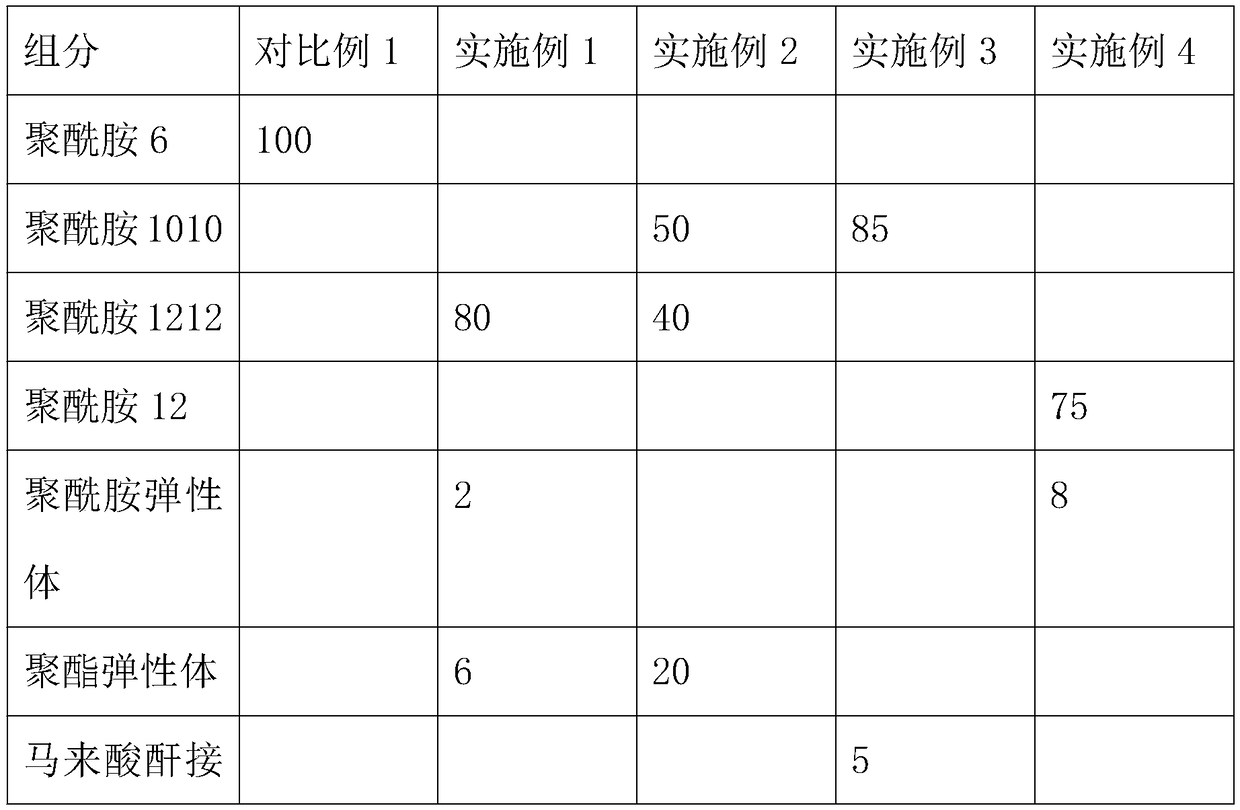

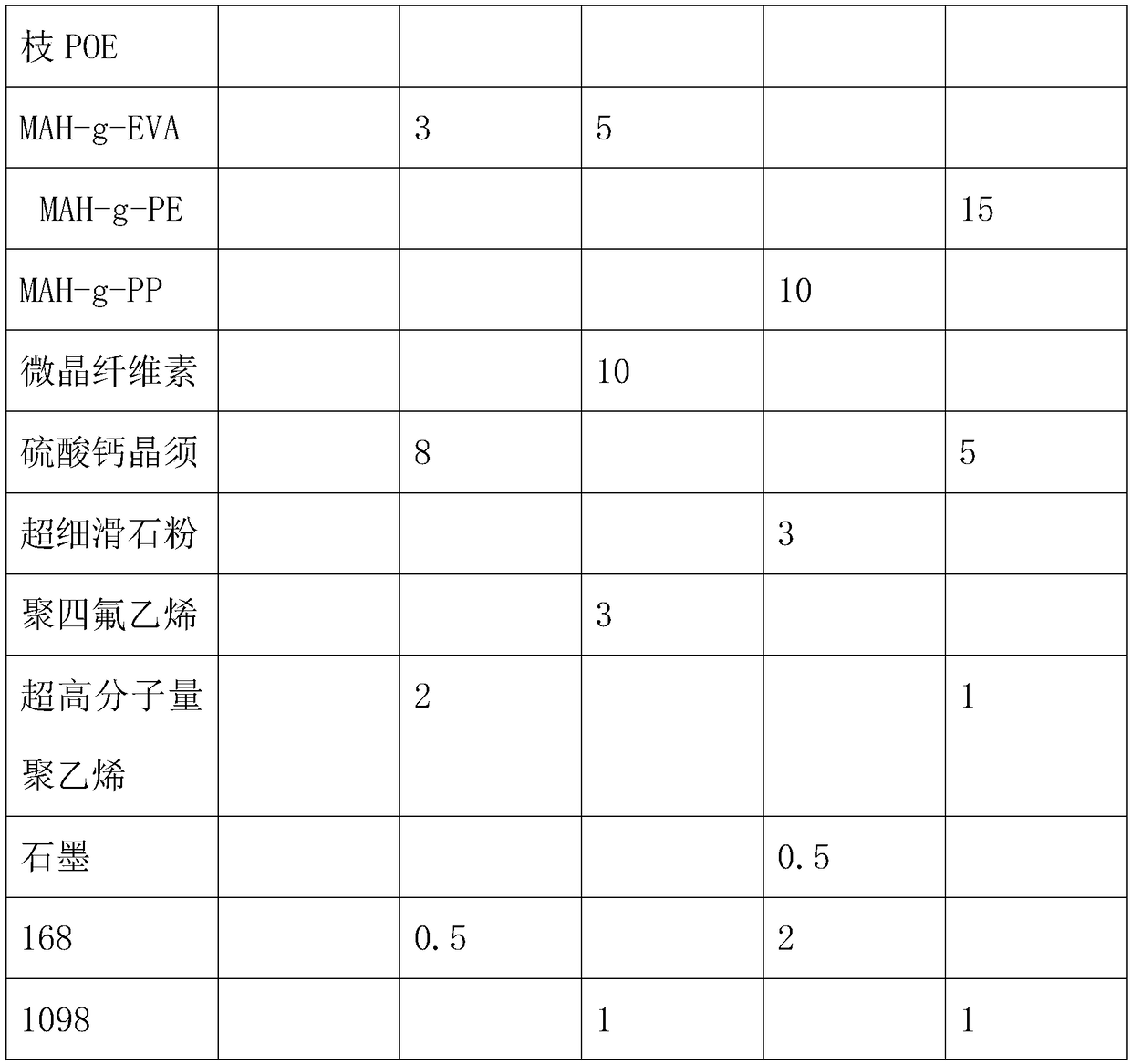

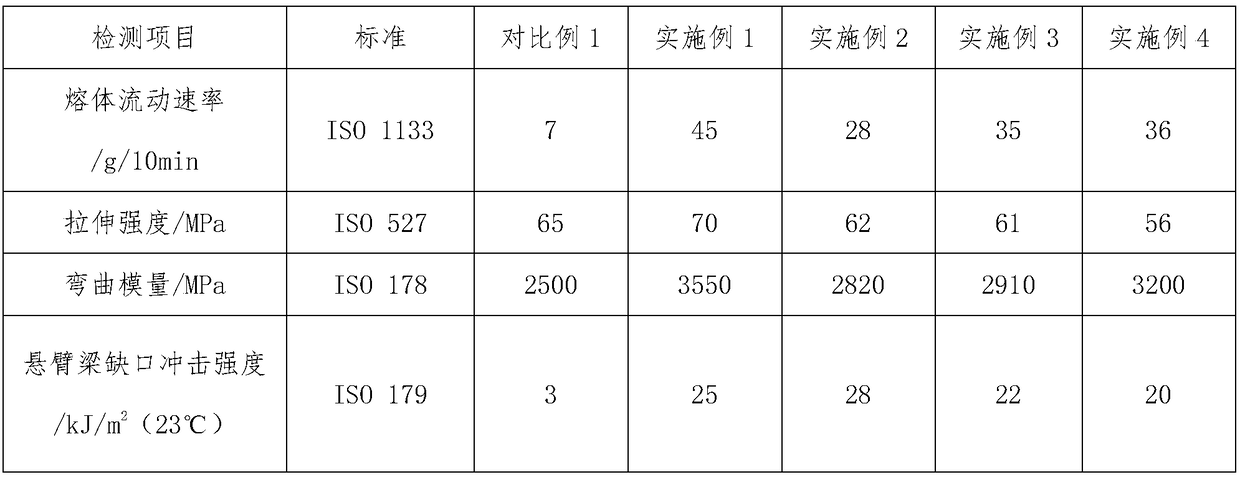

[0029] A coffee pot stirrer material, comprising the following steps and materials:

[0030] (1) 80 parts of polyamide 1212, 2 parts of functional elastomer polyamide elastomer, 6 parts of polyester elastomer, 3 parts of MAH-g-EVA, 2 parts of wear-resistant additive ultra-high molecular weight polyethylene, Add 0.5 parts of other additives, antioxidant 168, into the mixer, and pre-mix for 1 minute to obtain a mixture.

[0031] (2) The mixture obtained in the above step (1) is added in the twin-screw extruder through a hopper, and 8 parts of filler calcium sulfate whiskers are accurately weighed by a weight loss scale and introduced into the extruder by a side feeder, Engaging plasticizing, mixing, extruding, drawing, air-drying, and granulating to obtain polyamide composite materials that can be used in coffee pot stirrers; among them, the temperature of the extruder is set from one zone to the machine head: 220-235-265-280 -265-255°C.

[0032] (3) Pass the mixture obtained ...

Embodiment 2

[0035] A coffee pot stirrer material, comprising the following steps and materials:

[0036] (1) 50 parts of polyamide 1010 and 40 parts of polyamide 1212, 20 parts of functional elastomer polyester elastomer, 5 parts of MAH-g-EVA, 3 parts of wear-resistant additive polytetrafluoroethylene, and other additives 1 part of antioxidant 1098 was added to the mixer, and pre-mixed for 2 minutes to obtain a mixture.

[0037] (2) Add the mixture obtained in the above step (1) into the twin-screw extruder through the hopper, and accurately weigh 10 parts of the filler microcrystalline cellulose through a weight loss scale and introduce it into the extruder through a side feeder. Engaging plasticizing, mixing, extruding, drawing, air-drying, and granulating to obtain polyamide composite materials that can be used in coffee pot stirrers; among them, the temperature of the extruder is set from one zone to the machine head: 220-240-270-280 -270-250°C.

[0038] (3) Pass the mixture obtaine...

Embodiment 3

[0041] A coffee pot stirrer material, comprising the following steps and materials:

[0042] (1) 85 parts of polyamide 1010, 5 parts of functional elastomer maleic anhydride grafted POE, 10 parts of MAH-g-PP, 0.5 parts of wear-resistant additive graphite, and 168 parts of other additives and antioxidants 2 parts were added to the mixer, and pre-mixed for 3 minutes to obtain a mixture.

[0043] (2) Add the mixture obtained in the above step (1) into the twin-screw extruder through the hopper, and accurately weigh 3 parts of the filler superfine talcum powder through a weight loss scale and introduce it into the extruder through a side feeder. Engaging plasticizing, mixing, extruding, drawing, air-drying, and granulating to obtain polyamide composite materials that can be used in coffee pot stirrers; among them, the temperature of the extruder is set from one zone to the machine head: 220-230-280-280 -260-250°C.

[0044] (3) Pass the mixture obtained in the step (2) through an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com