High-toughness hybrid 3D printing light-cured resin and preparation method thereof

A light-curing resin, 3D printing technology, applied in the field of 3D printing, can solve the problems of easy breaking, not resistant to falling, not resistant to impact, etc., to prevent color damage, improve the anti-fall performance, and reduce shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

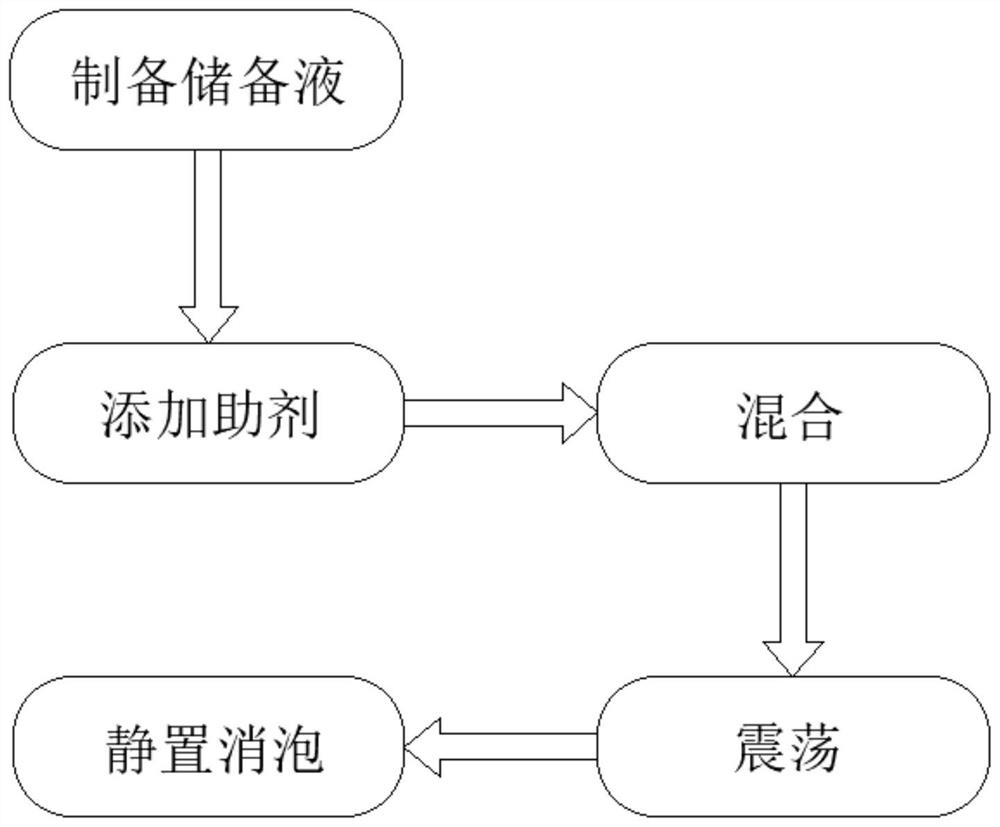

[0031] refer to figure 1 , a high-toughness hybrid 3D printing photocurable resin, its formula includes: 46 parts of monofunctional acrylate, 19 parts of difunctional reactive diluent, 11 parts of rigid polysiloxane, 1.4 parts of photoinitiator, organic dye 2.8 parts, 0.9 parts of additives.

[0032] Monofunctional acrylates in the present invention include hydroxypropyl acrylate, hydroxybutyl acrylate, isobornyl acrylate, isobornyl methacrylate, acryloyl morpholine, N,N-dimethylacrylamide, cyclotrimethylol 2-Acrylic acid (2-ethyl-2-methyl-1,3- Two or more of dioxan-4-yl) methyl esters, the monofunctional acrylate is a combination of acryloylmorpholine and cyclotrimethylolpropane methylal acrylate with a mass ratio of 1:4 The mixture, the structure in the monofunctional acrylate can reinforce or increase the cohesion of the resin, so that the resin has a certain strength and flexibility after curing. The cured material after resin curing has high mechanical properties, makin...

Embodiment 2

[0041] refer to figure 1 , a high-toughness hybrid 3D printing photocurable resin, its formula includes: 60 parts of monofunctional acrylate, 30 parts of bifunctional reactive diluent, 15 parts of rigid polysiloxane, 2.5 parts of photoinitiator, organic dye 3 parts, 2 parts of additives.

[0042] Monofunctional acrylates in the present invention include hydroxypropyl acrylate, hydroxybutyl acrylate, isobornyl acrylate, isobornyl methacrylate, acryloyl morpholine, N,N-dimethylacrylamide, cyclotrimethylol 2-Acrylic acid (2-ethyl-2-methyl-1,3- Two or more of dioxan-4-yl) methyl esters, the monofunctional acrylate is a combination of acryloylmorpholine and cyclotrimethylolpropane methylal acrylate with a mass ratio of 1:4 The mixture, the structure in the monofunctional acrylate can reinforce or increase the cohesion of the resin, so that the resin has a certain strength and flexibility after curing. The cured material after resin curing has high mechanical properties, making up...

Embodiment 3

[0051] refer to figure 1 , a high-toughness hybrid 3D printing photocurable resin, its formula includes: 70 parts of monofunctional acrylate, 40 parts of difunctional reactive diluent, 16 parts of rigid polysiloxane, 5 parts of photoinitiator, organic dye 4 parts, 3 parts of additives.

[0052] Monofunctional acrylates in the present invention include hydroxypropyl acrylate, hydroxybutyl acrylate, isobornyl acrylate, isobornyl methacrylate, acryloyl morpholine, N,N-dimethylacrylamide, cyclotrimethylol 2-Acrylic acid (2-ethyl-2-methyl-1,3- Two or more of dioxan-4-yl) methyl esters, the monofunctional acrylate is a combination of acryloylmorpholine and cyclotrimethylolpropane methylal acrylate with a mass ratio of 1:4 The mixture, the structure in the monofunctional acrylate can reinforce or increase the cohesion of the resin, so that the resin has a certain strength and flexibility after curing. The cured material after resin curing has high mechanical properties, making up f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com