Protection device for copper bar connection

A protection device and copper bar technology, applied in the direction of connection insulation, etc., can solve the problems of affecting the insulation effect and easy damage, and achieve the effects of avoiding partial discharge, reasonable price, and large modification space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

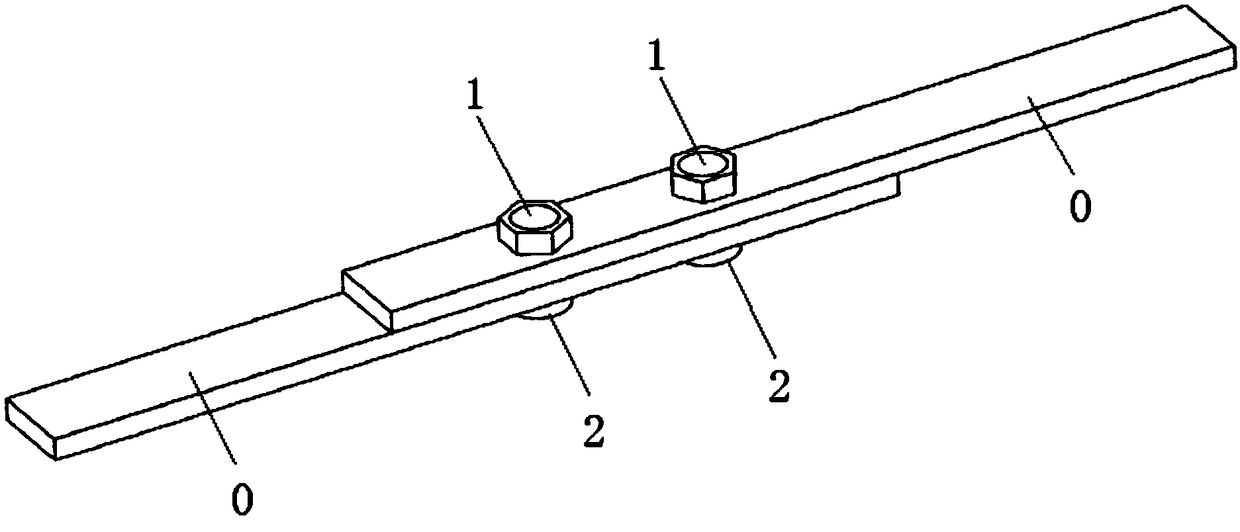

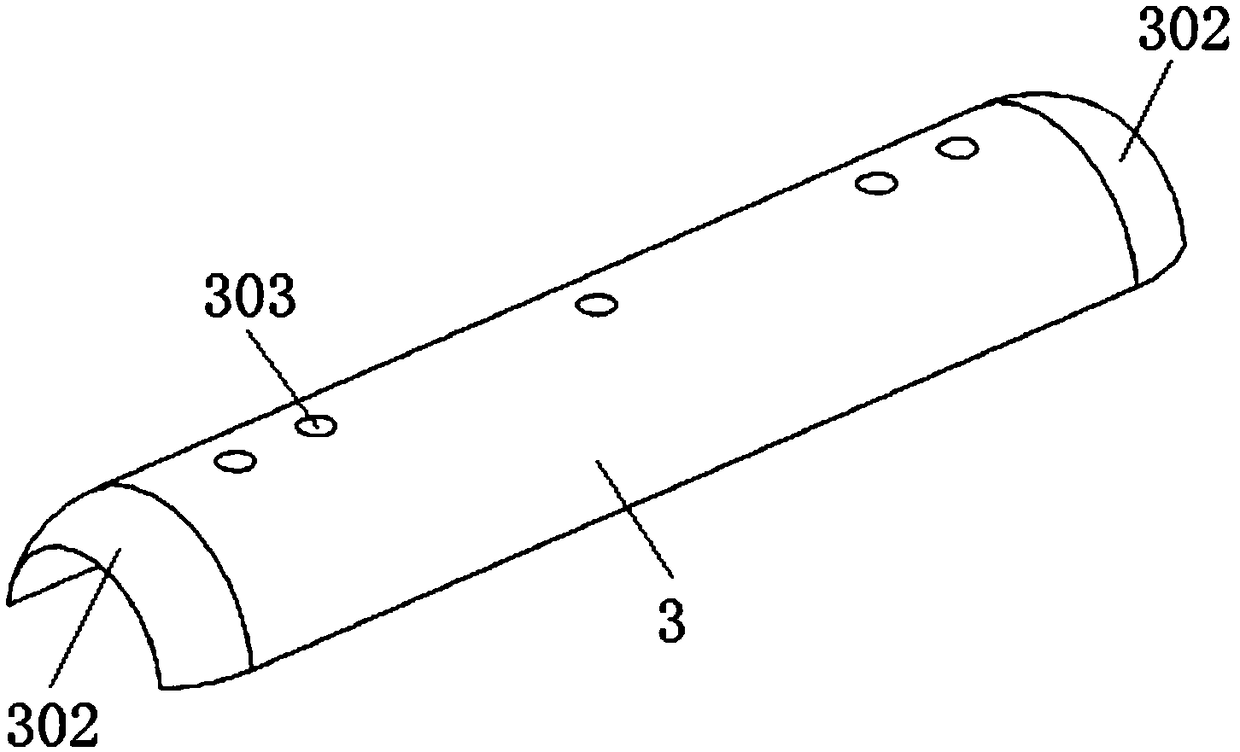

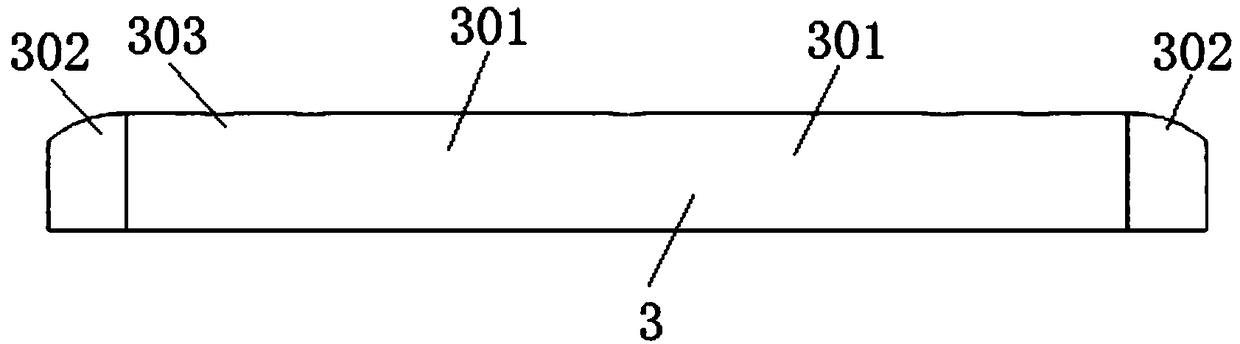

[0028] Such as figure 1 As shown, a protective device for connecting copper bars includes fastening bolts 1 and fastening nuts 2 for connecting copper bars 0 of the same phase, and the connecting ends of copper bars 0 of the same phase are aligned and connected up and down; as Figure 6 As shown, the upper and lower sides of the connection ends of the two copper bars 0 are symmetrically provided with protective sleeves 3; Figure 2-5 As shown, the inner wall of the protective cover 3 is provided with a bolt groove 301 corresponding to the fastening bolt 1, and the bolt groove 301 accommodates the protruding part of the fastening bolt 1, which effectively avoids shrinking the sleeve after heat generation. The excessive shrinkage of the tube caused by the tip of the fastening bolt 1 to damage the phenomenon also avoids the occurrence of adverse condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com