Patents

Literature

208results about How to "Increase arc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

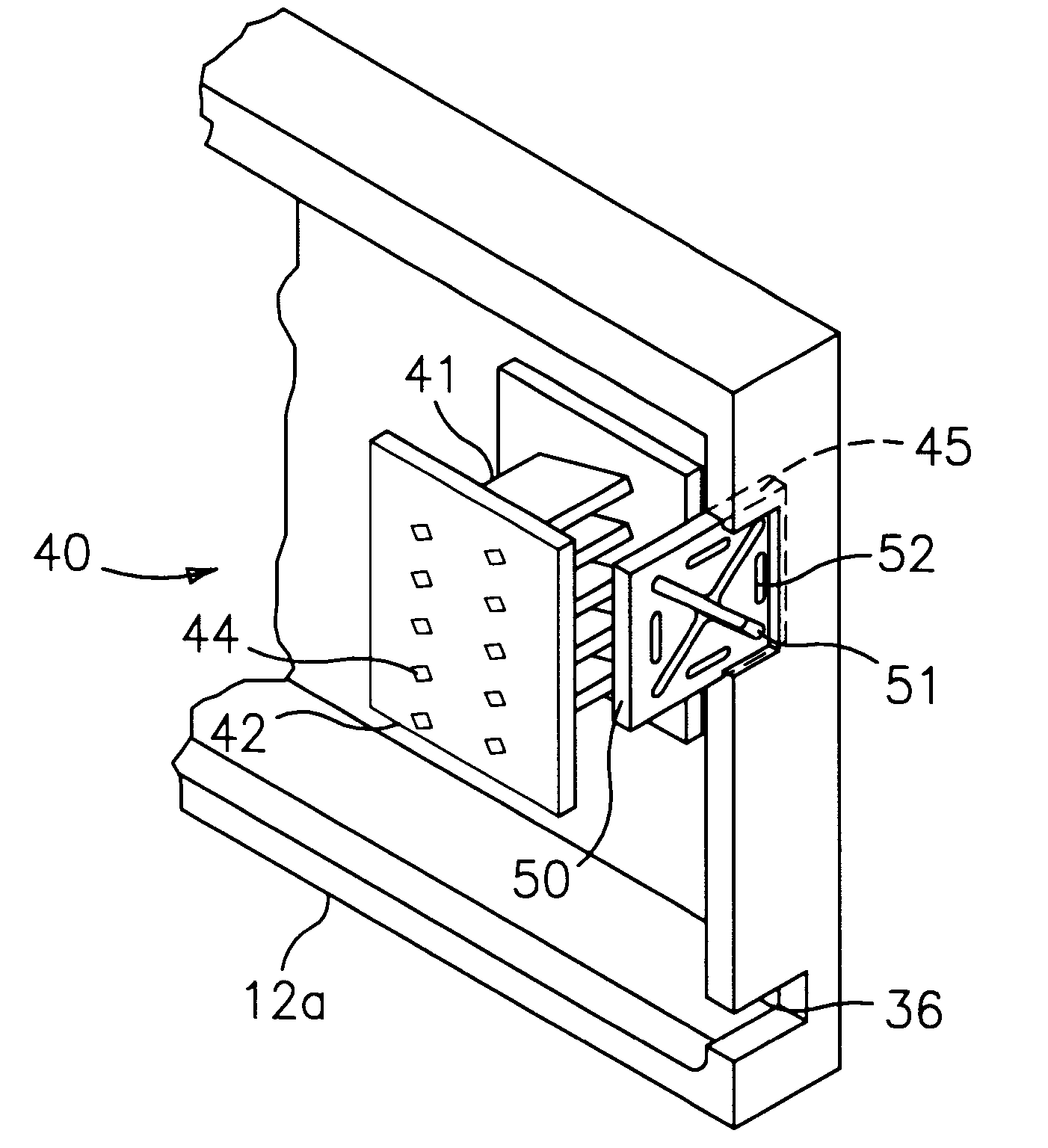

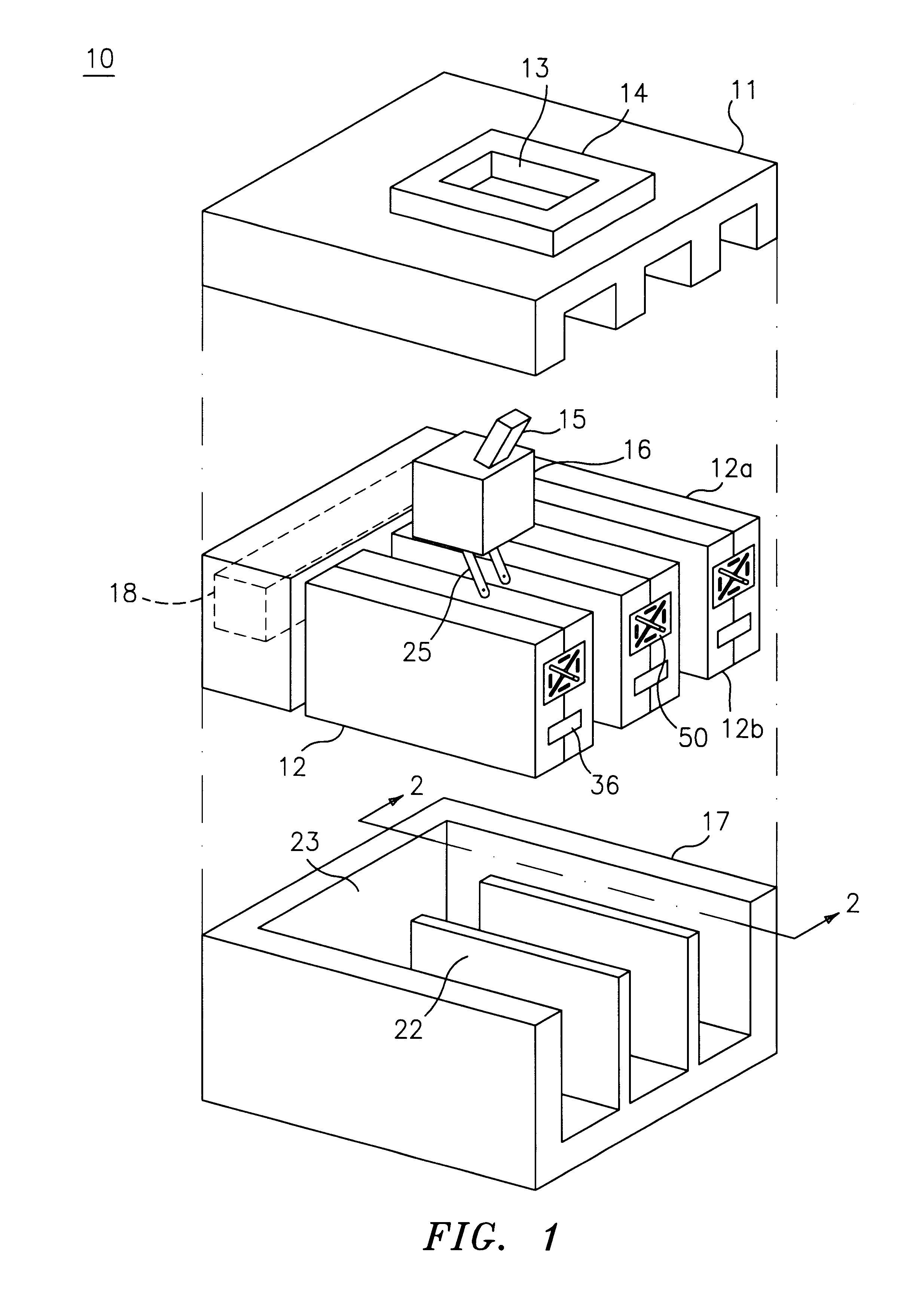

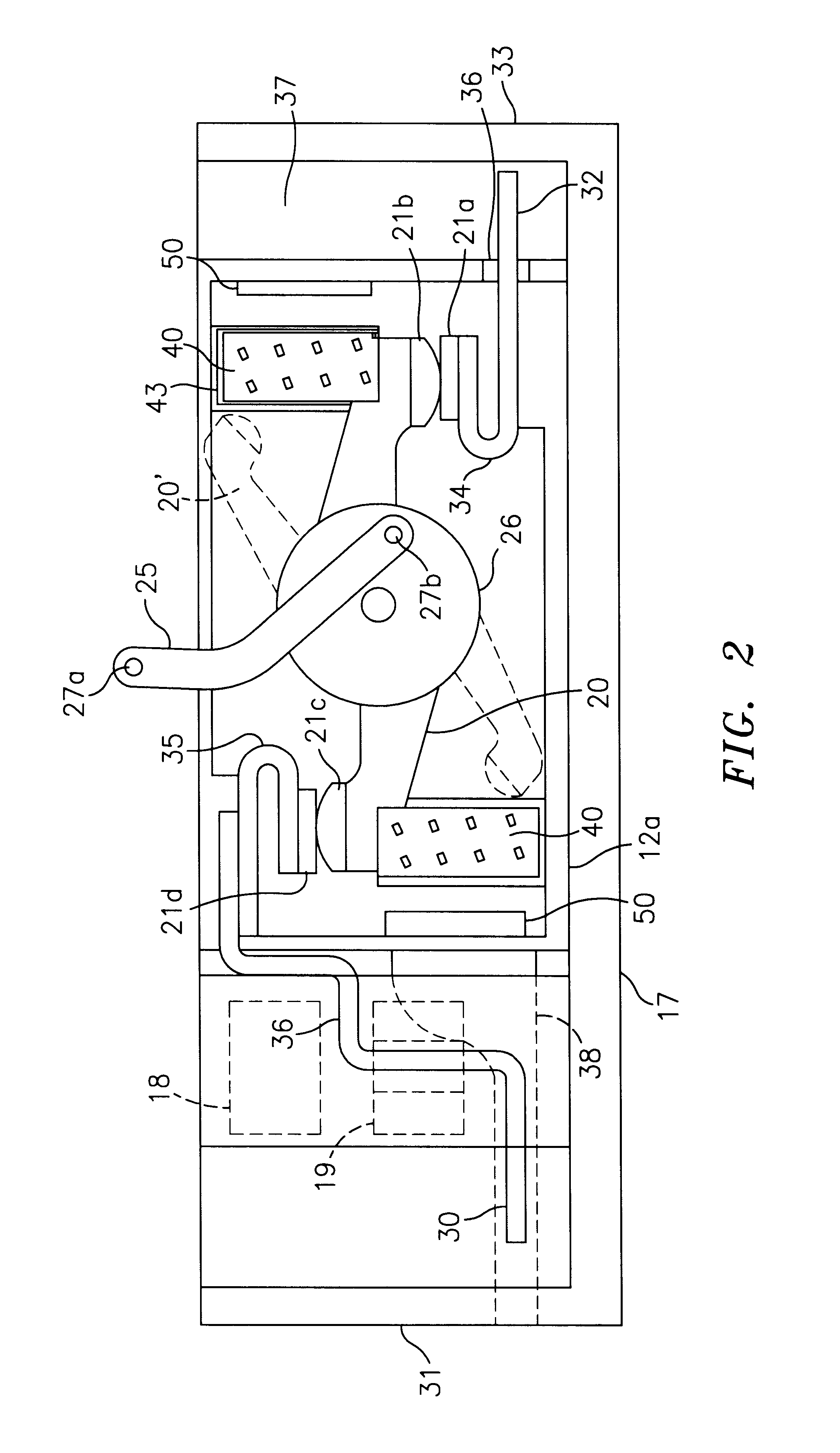

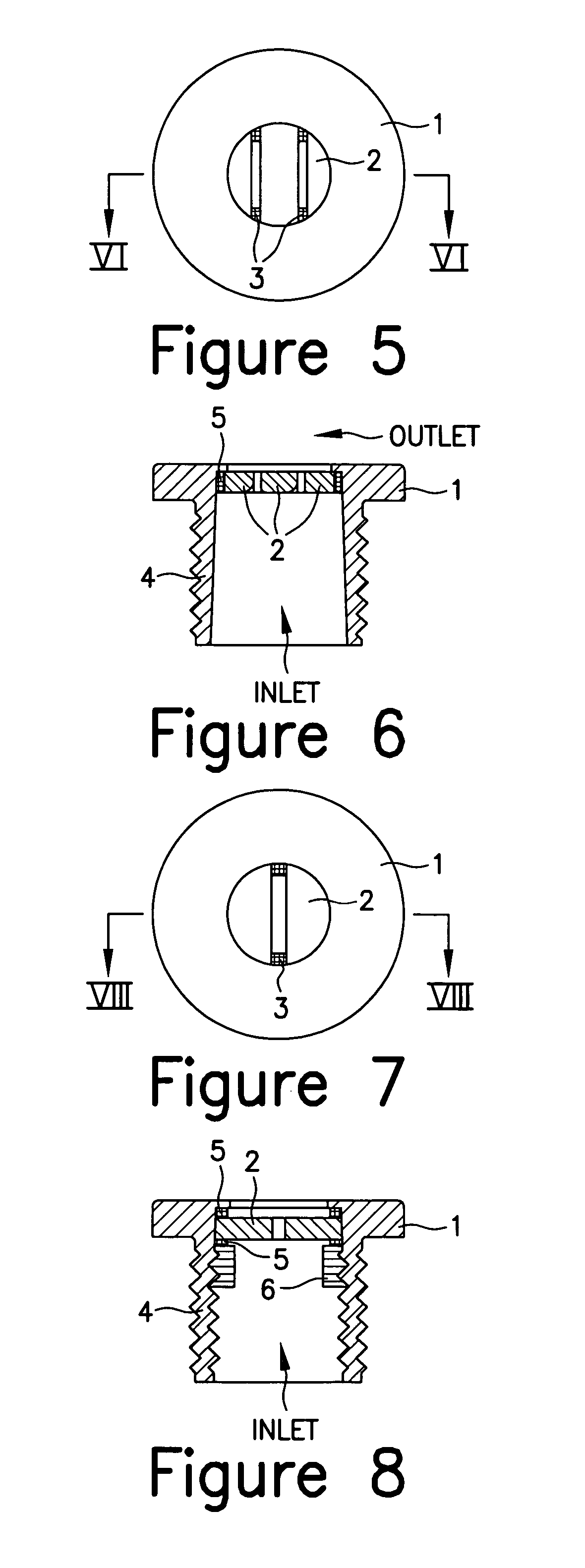

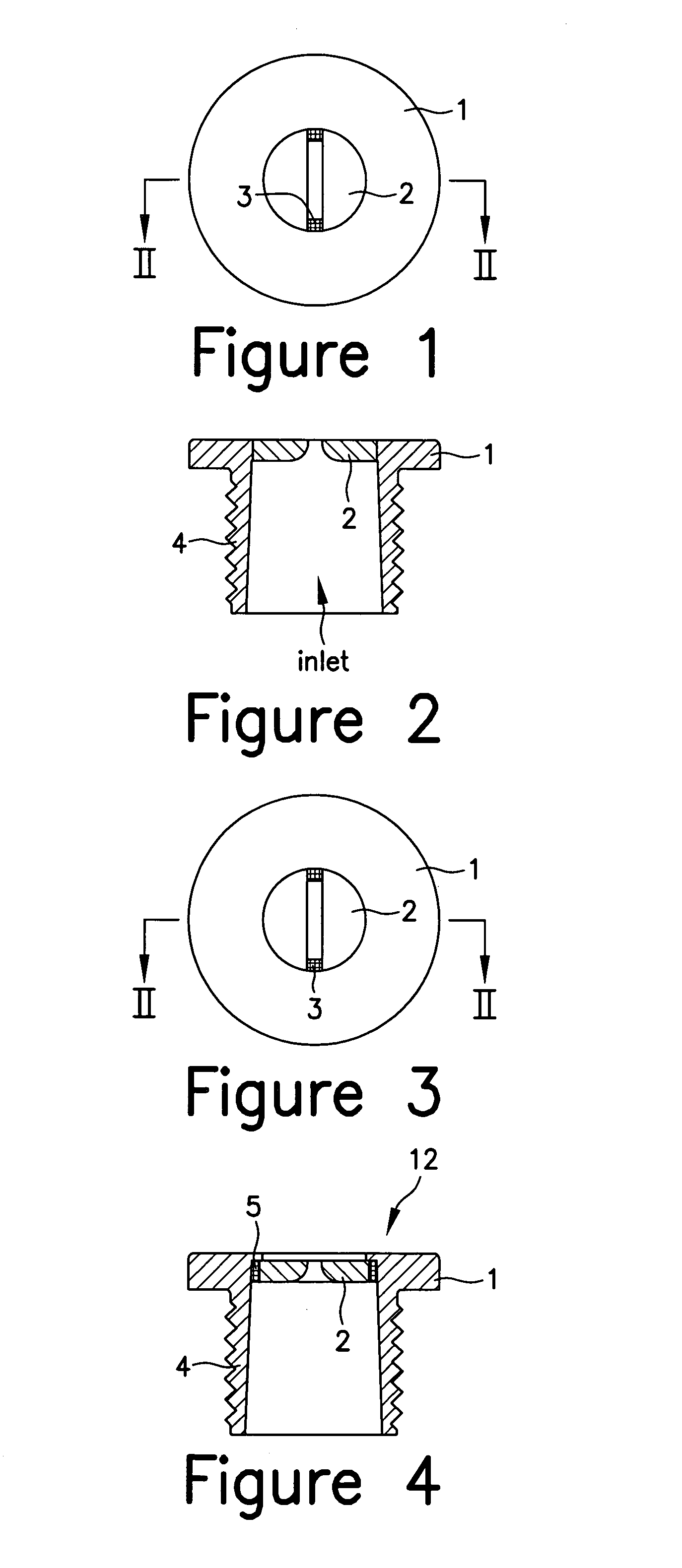

Circuit breaker arc exhaust baffle with variable aperture

InactiveUS6222147B1Reduce stressIncrease pressureProtective switch detailsHigh-tension/heavy-dress switchesCircuit breakerCircuit protection

An improved exhaust baffle for a circuit protective device such as a circuit breaker utilizes material having elastomeric characteristics to provide for variable apertures where the cross-sectional opening of the apertures is dependent on the pressure gradient across the exhaust baffle, thereby effectively controlling arc pressure and arc effluent during short circuit interruption. Fabrication of the exhaust baffle with geometric symmetry about one or more axes or planes also facilitates assembly during product construction.

Owner:ABB (SCHWEIZ) AG

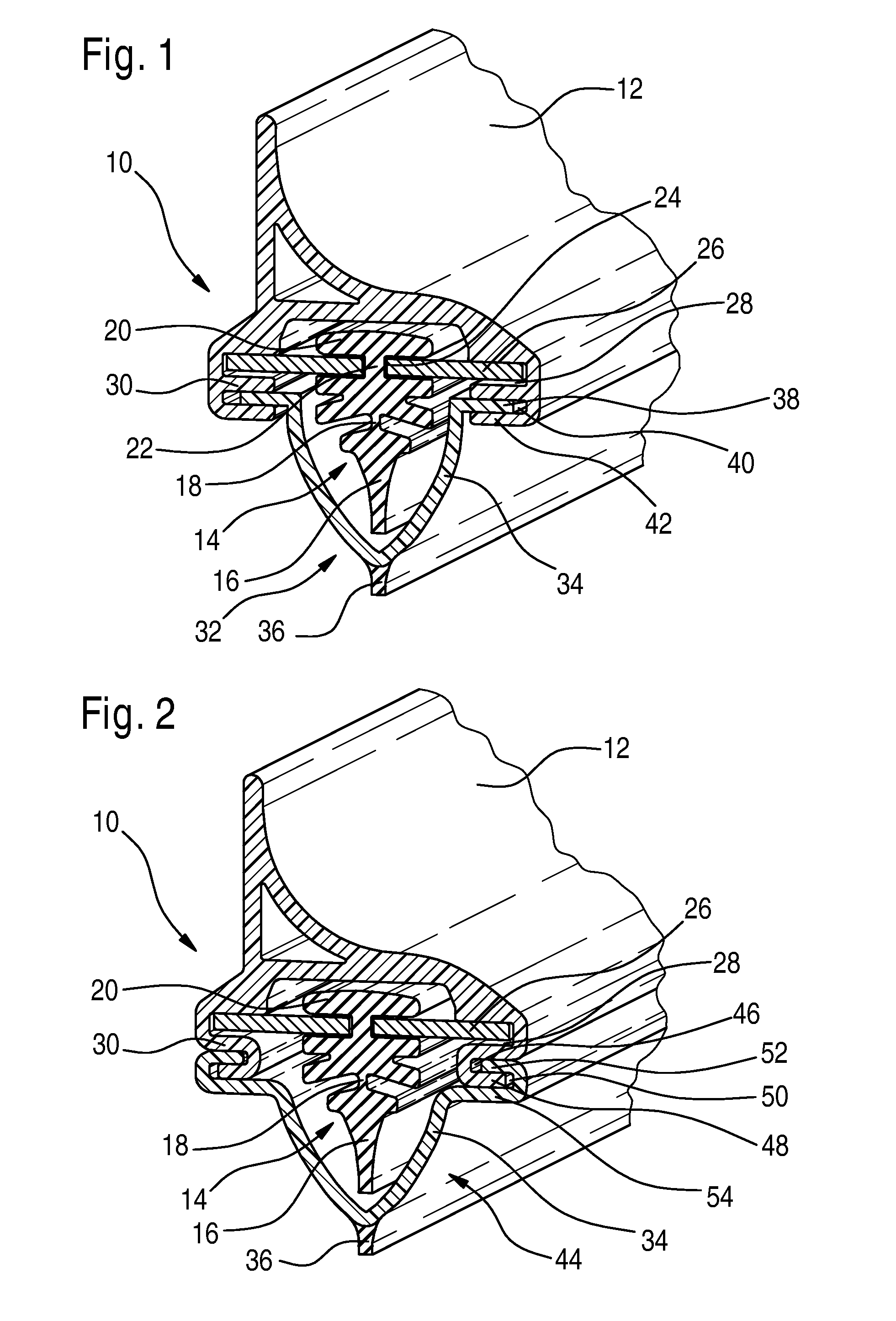

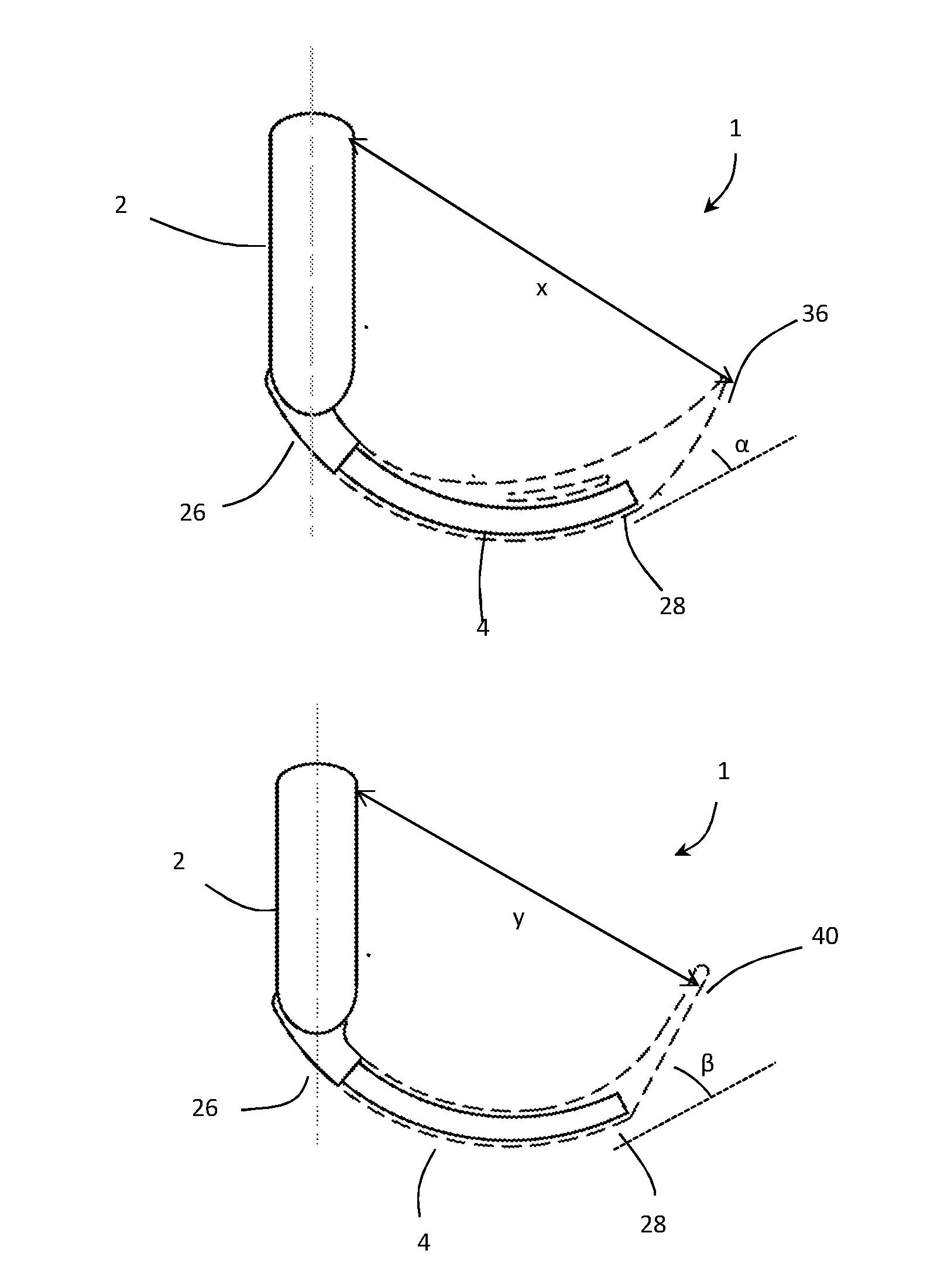

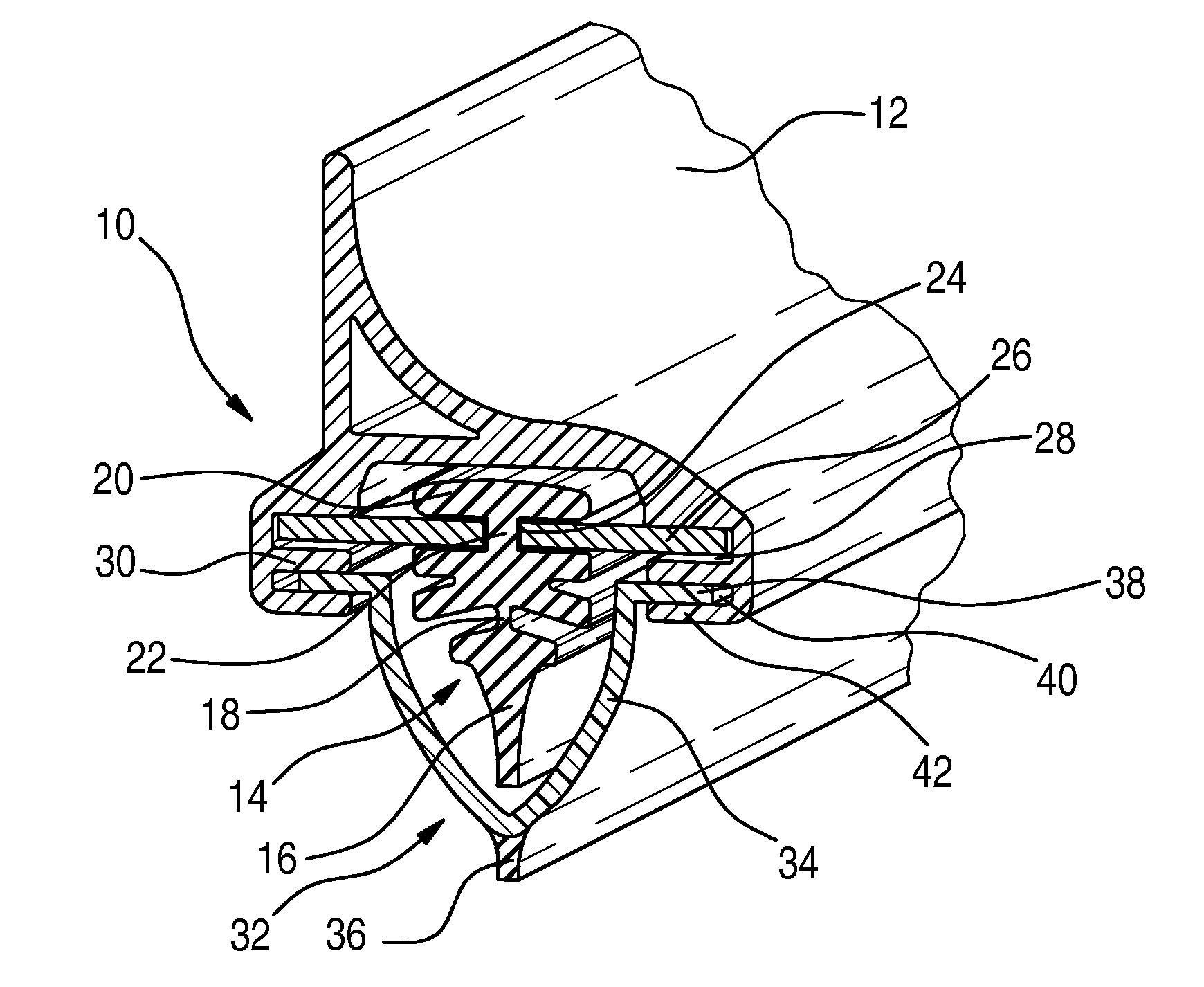

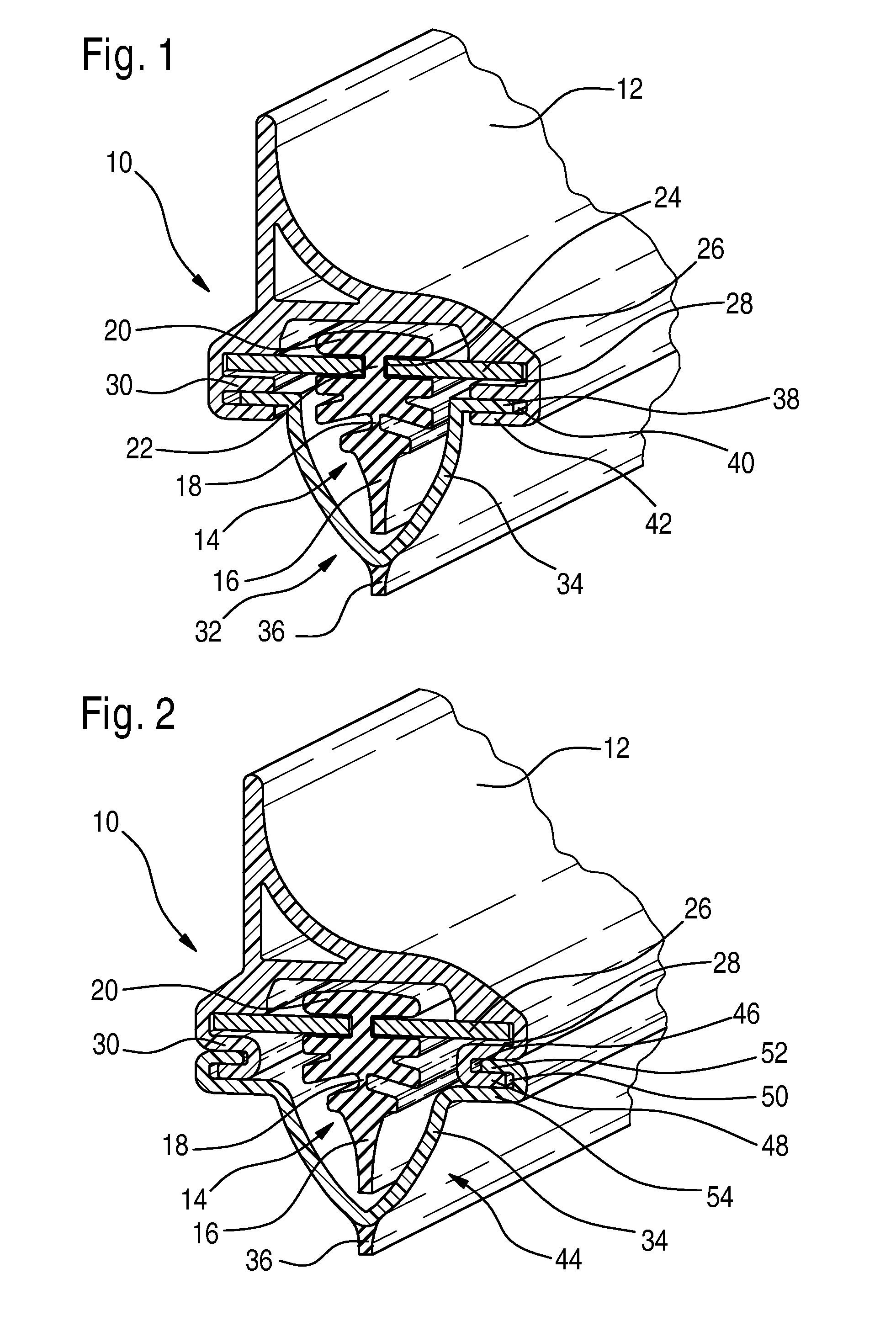

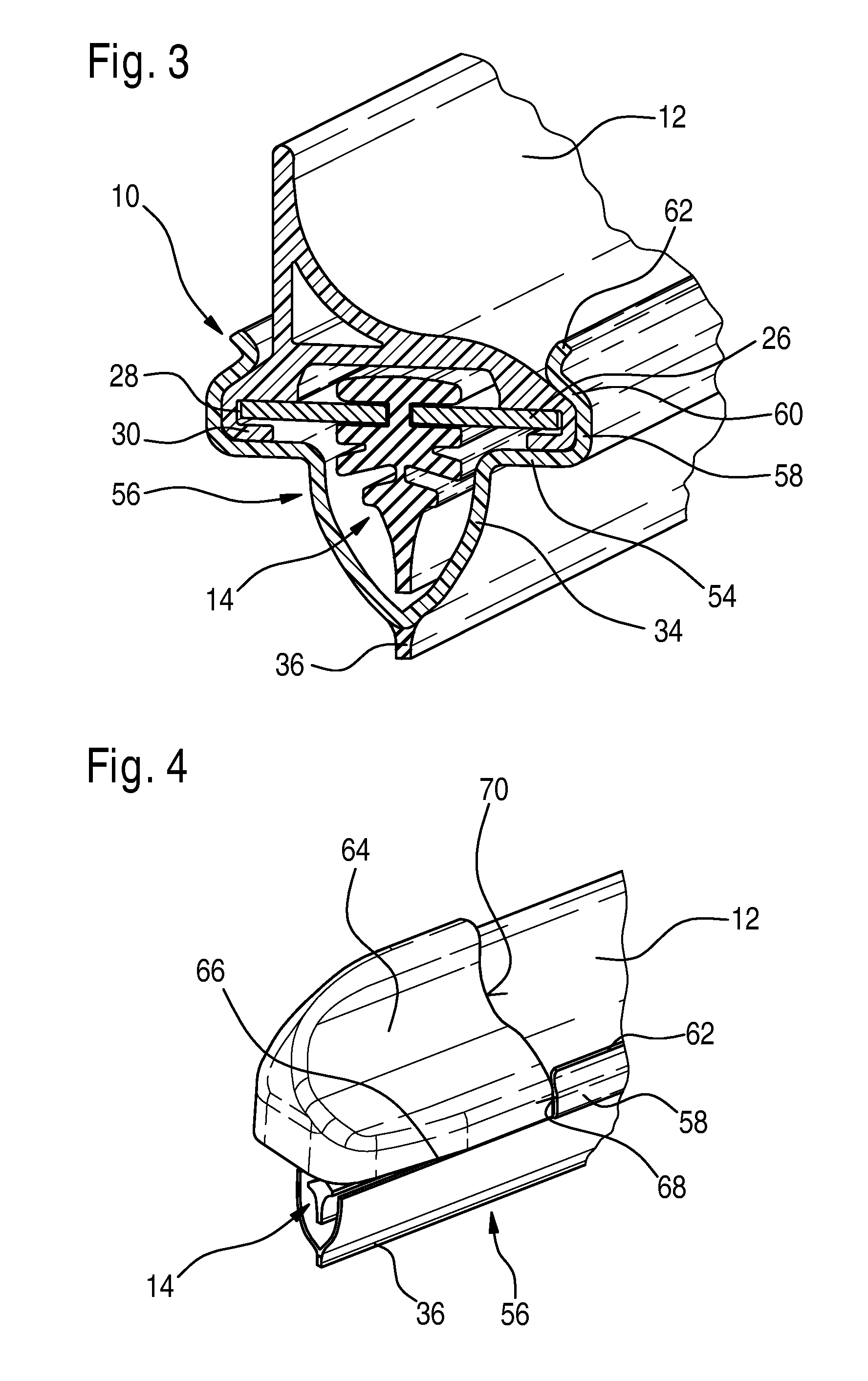

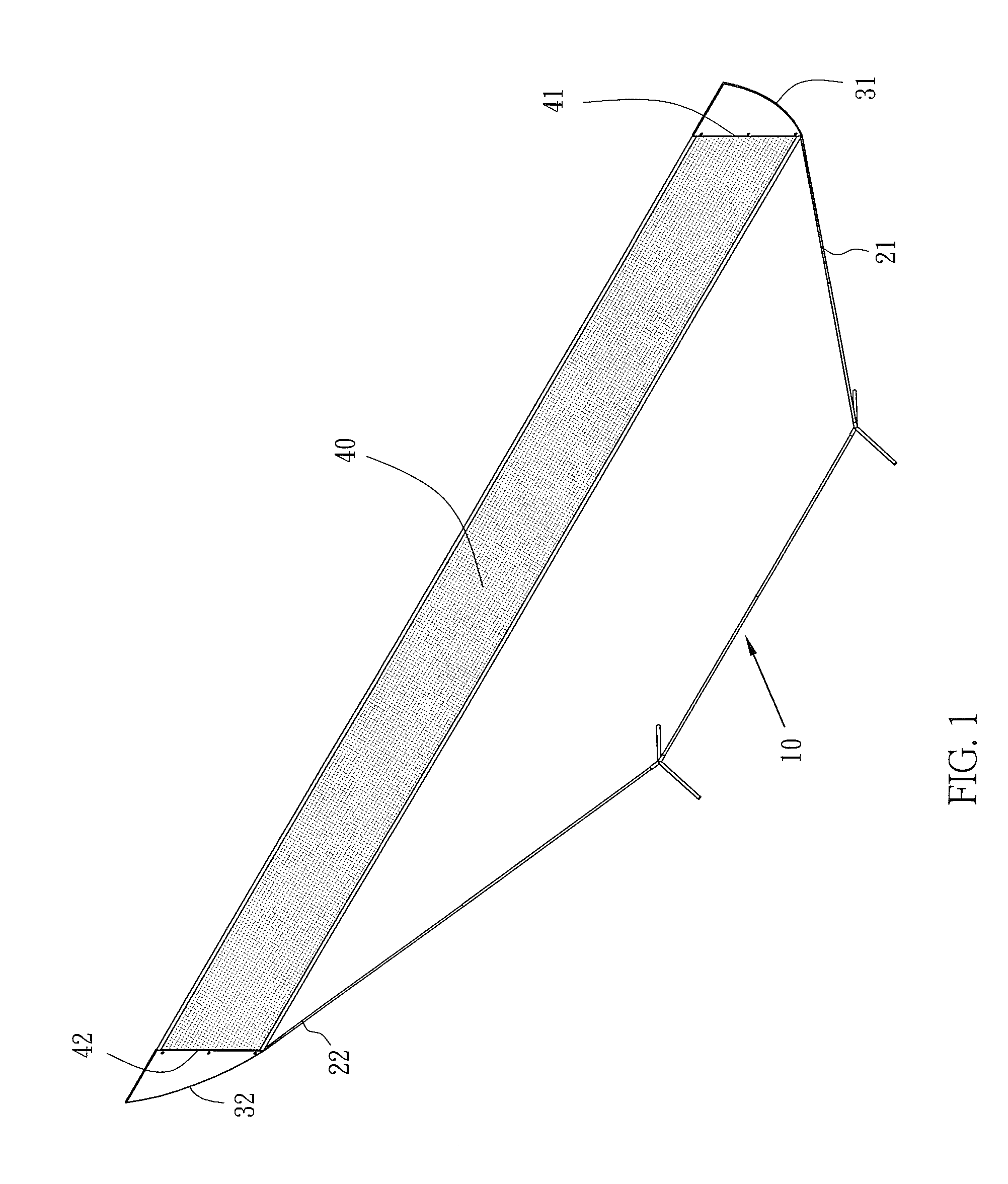

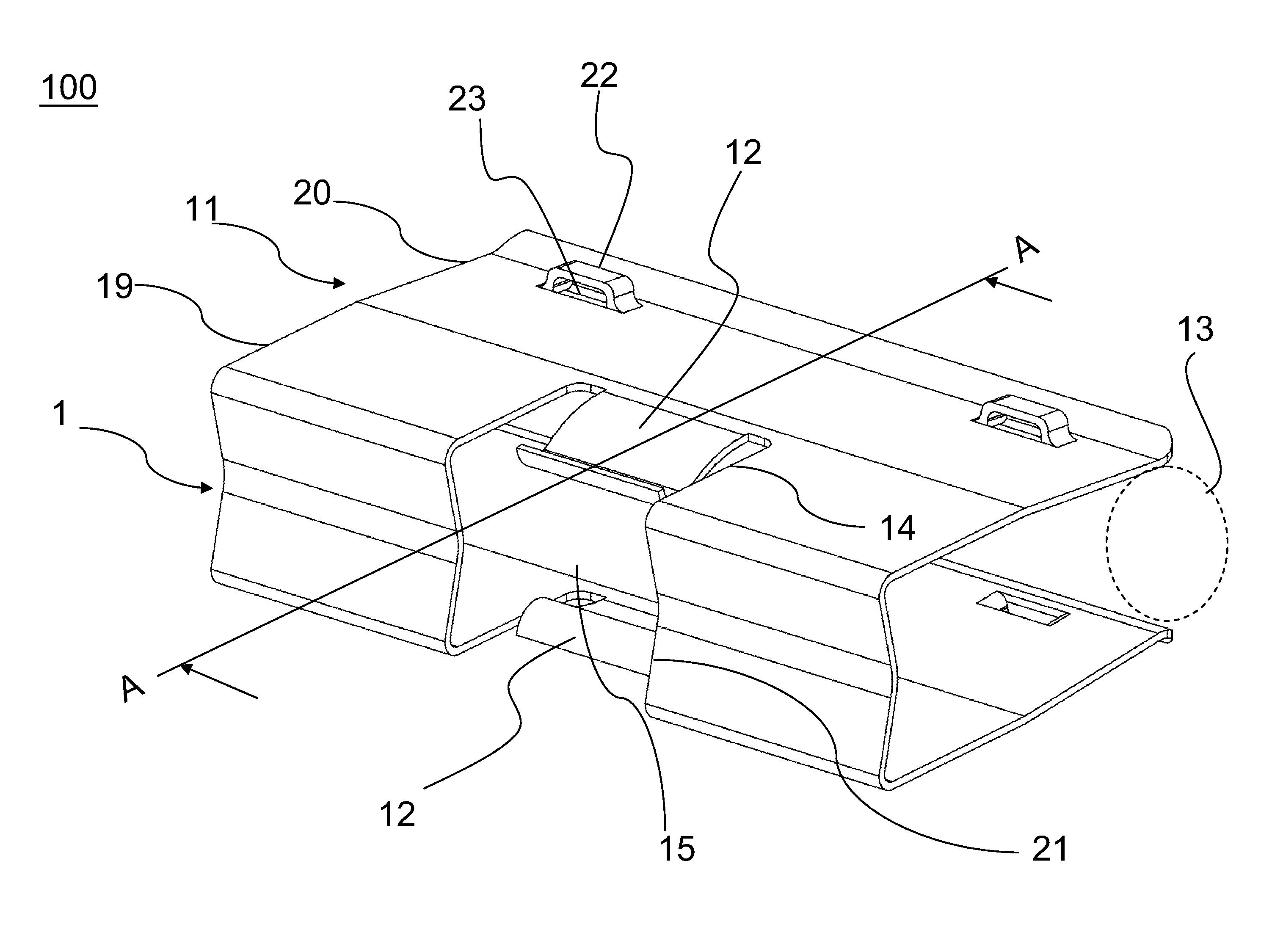

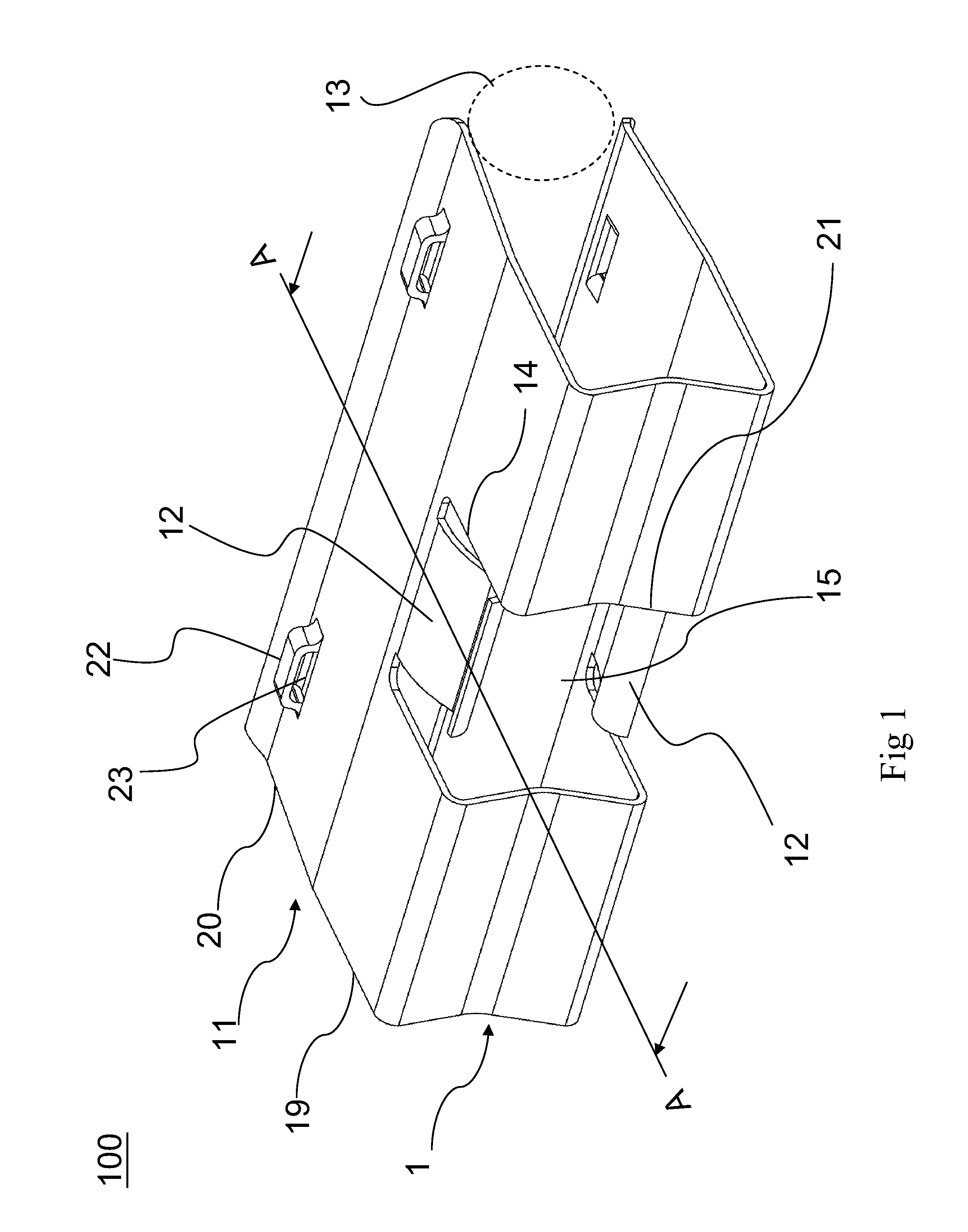

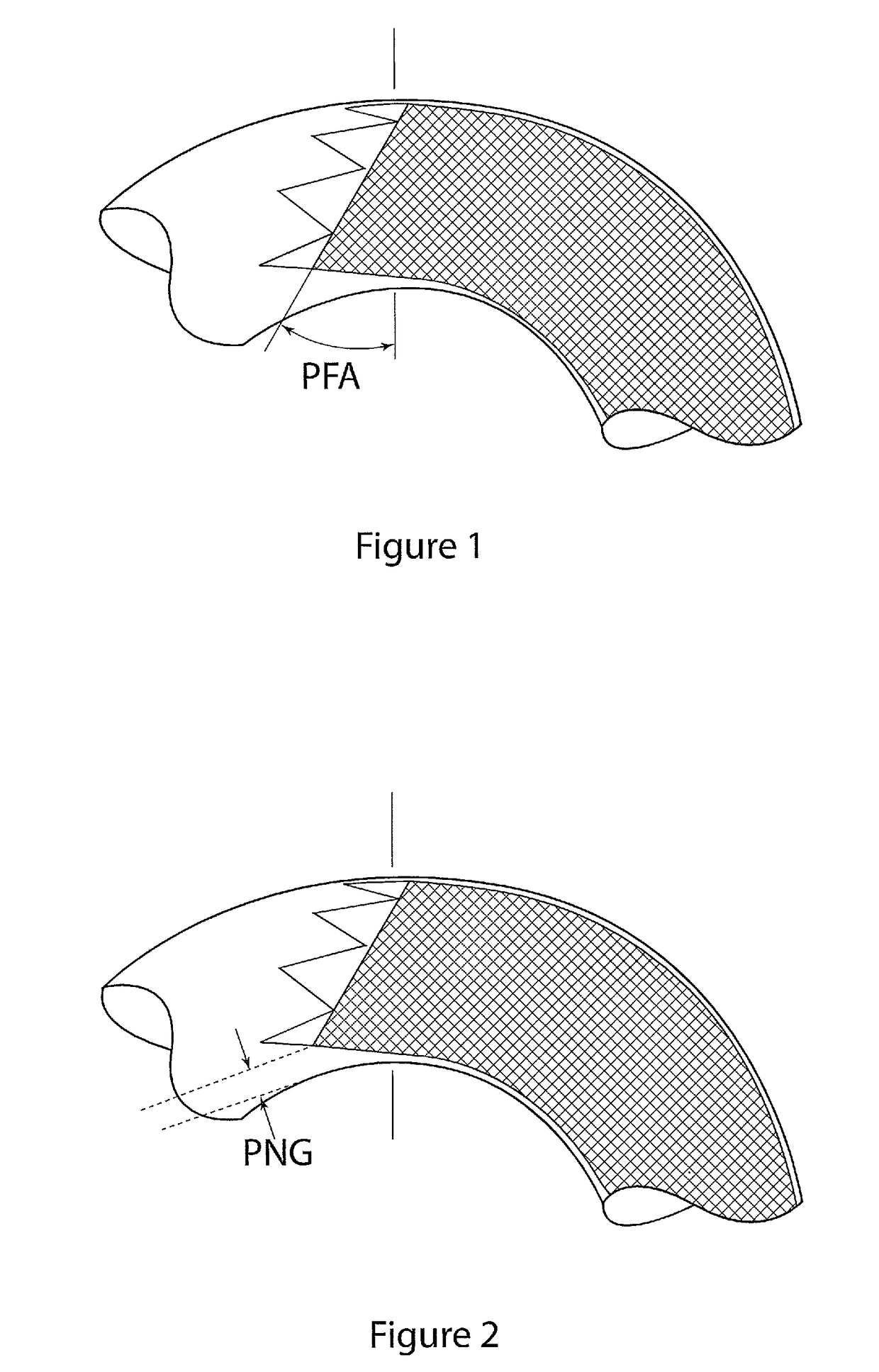

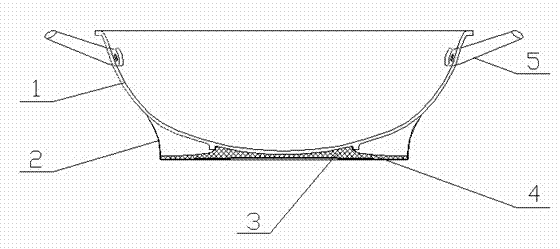

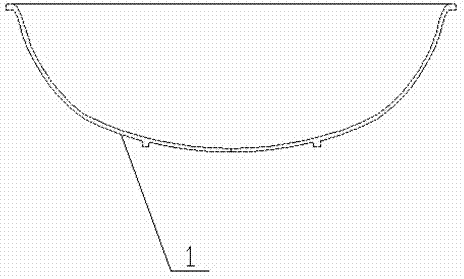

Wiper blade of a windscreen wiper, provided with a protective rail

The invention relates to a wiper blade (10) of a windshield wiper provided with a protective rail (32, 44, 56, 72, 88), comprising a base body (34) that has an essentially V-shaped cross section and a wiper lip (36) of the wiper blade (10) and that is detachably fixed to the wiper blade (10) with the aid of fixing elements (38, 52, 58, 78, 90). It is proposed that the wiper blade (10) consist of a wiper strip (14) with at least one flat, bar-type, elastic support element (26) and a spoiler (12), wherein the protective rail (32, 44, 56, 72, 88) rests on the support element (26) or spoiler (12).

Owner:ROBERT BOSCH GMBH +1

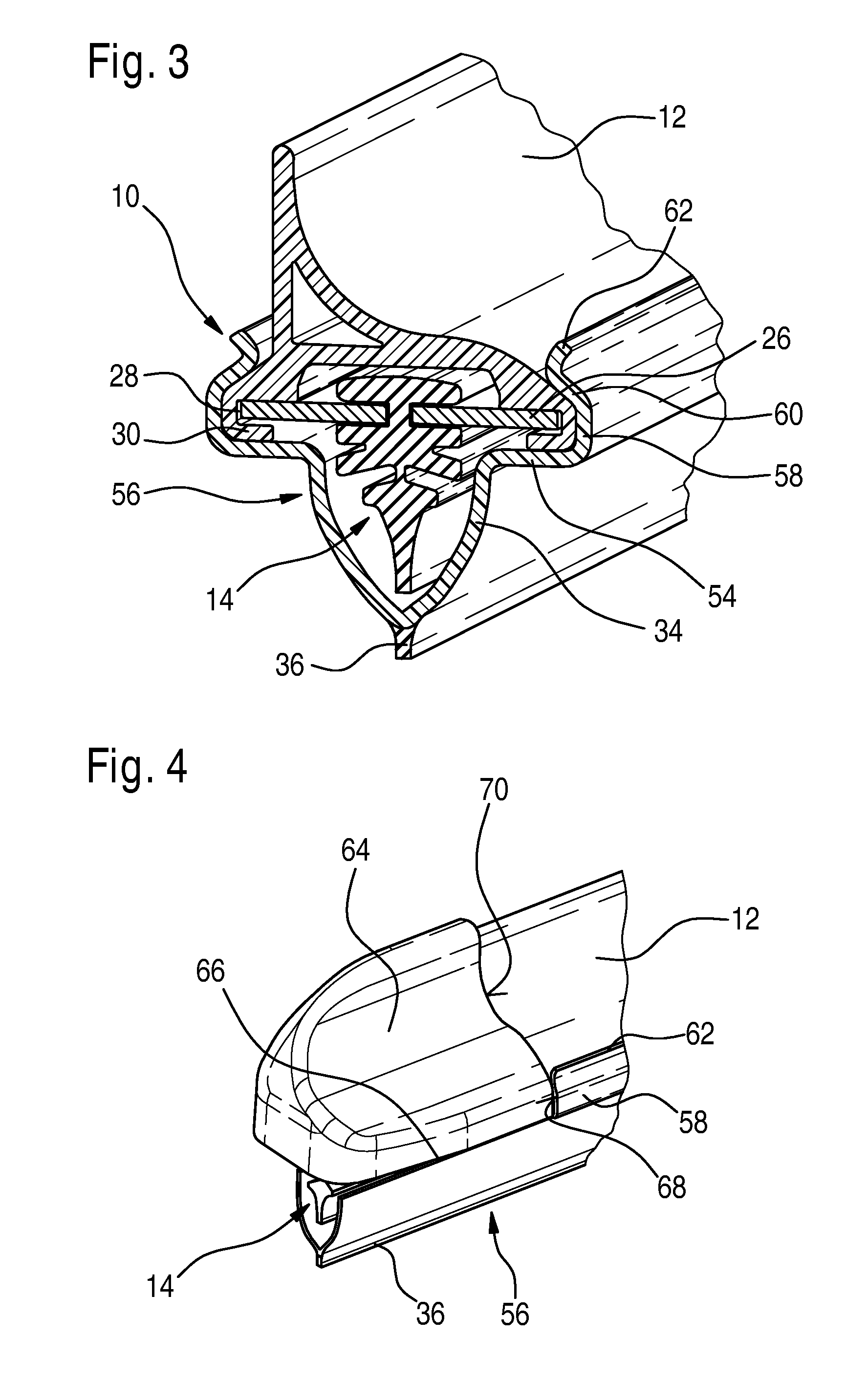

Stereoscopic image arc-shooting rail apparatus and its shooting method

InactiveCN101464615ASimple structureEasy to carryStands/trestlesStereoscopic photographyStereo cameraShooting method

The invention discloses an arc shooting track device for stereo images and a shooting method thereof. A slider is installed on the arc shooting track; a camera is installed on the slider; the control of the camera shutter and the control of the slider share a duplex control switch; and when the duplex switch of the camera shutter and the slider on the arc shooting track is open, the camera and the slider work synchronously. Through the control of the duplex switch, a continuous mode function of the camera can be utilized to cause the camera to move on the track and simultaneously conduct momentary continuous shooting in the arc direction, so as to achieve the shooting of the stereo images, and reach and surpass the stereo image effect shot by a multi-lens stereo camera.

Owner:SHANGHAI YIYING DIGITAL TECH

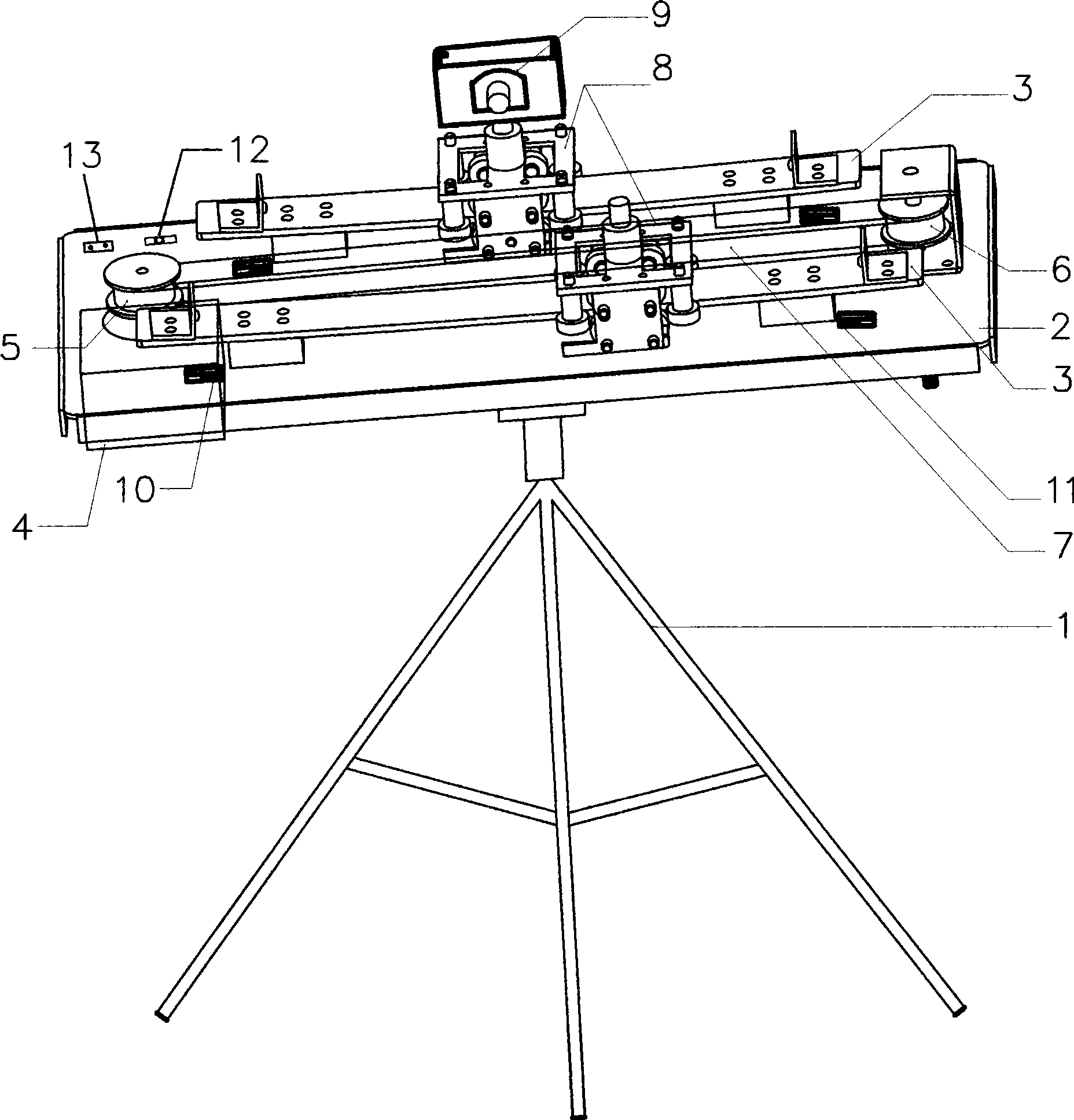

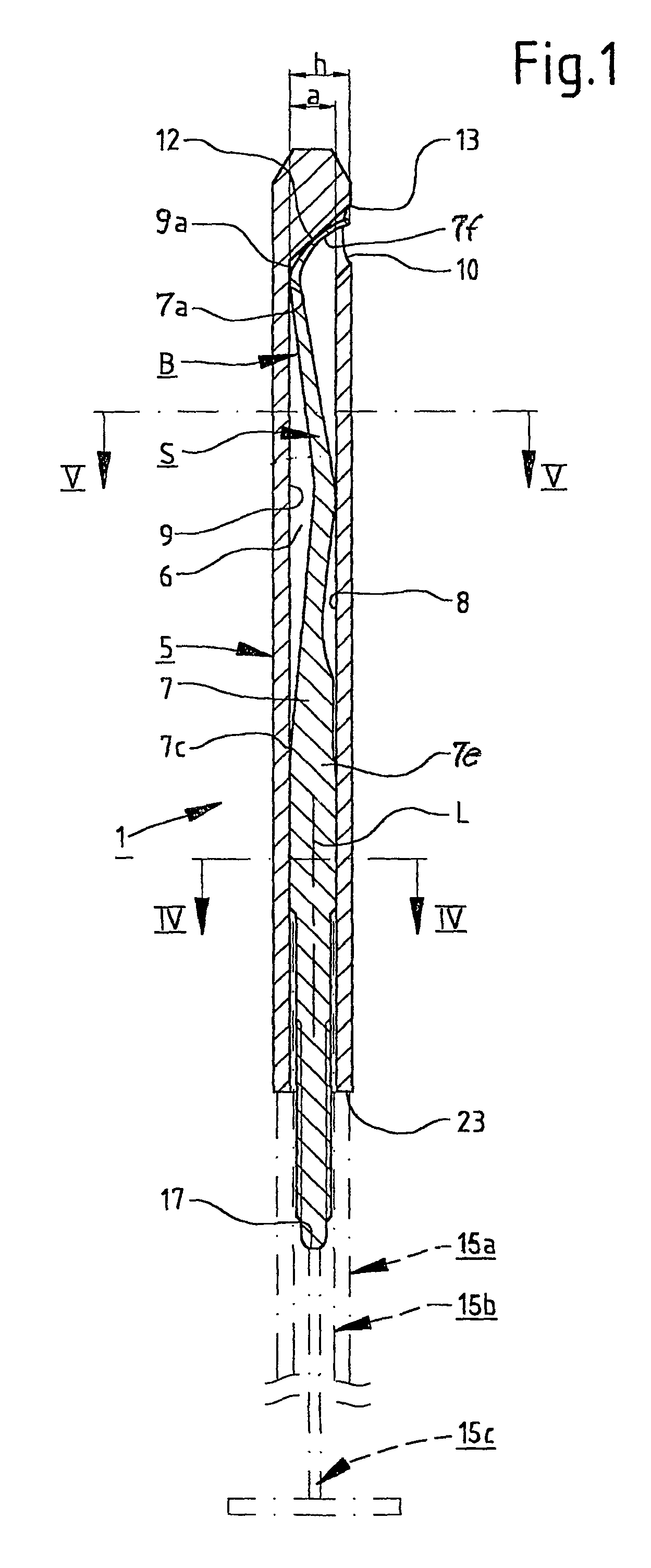

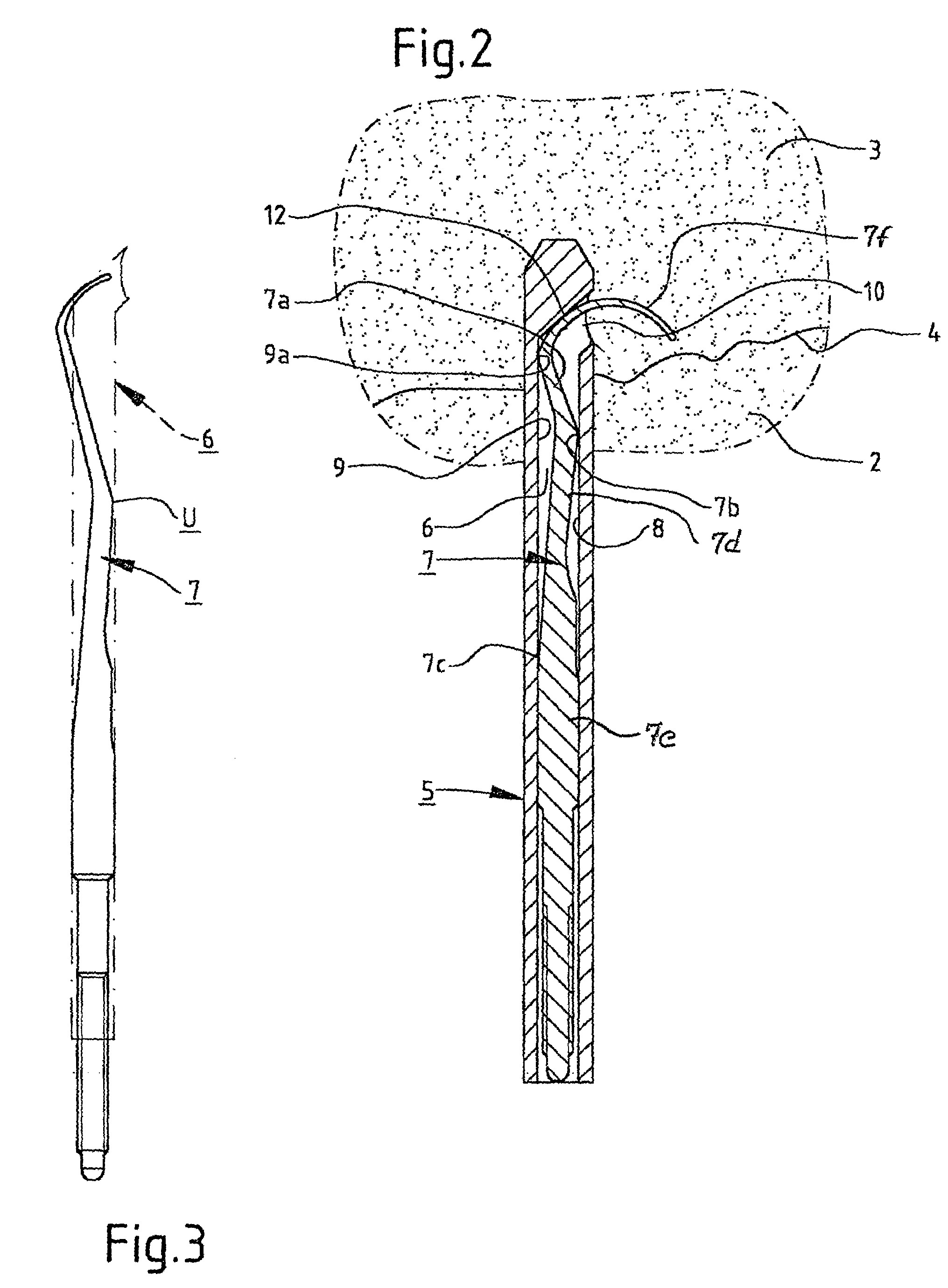

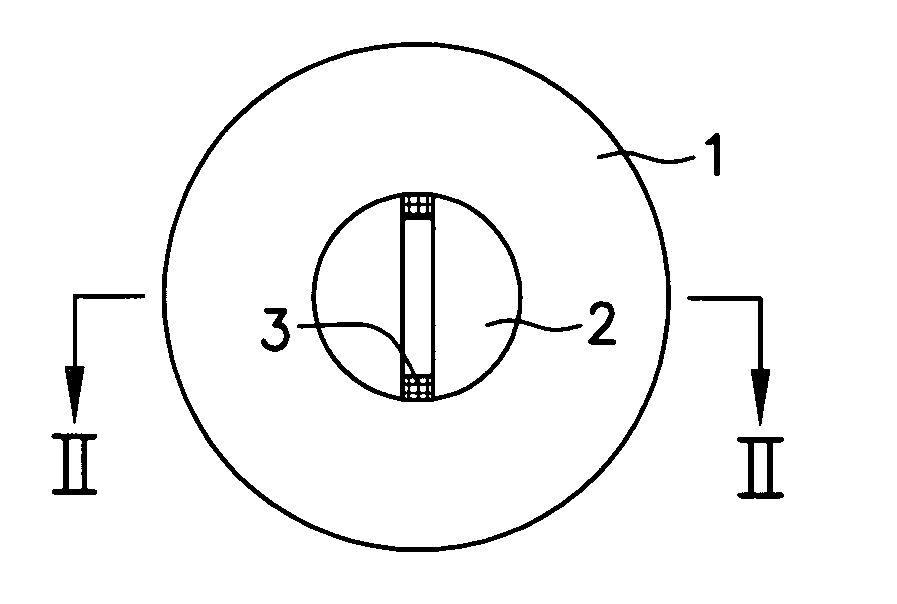

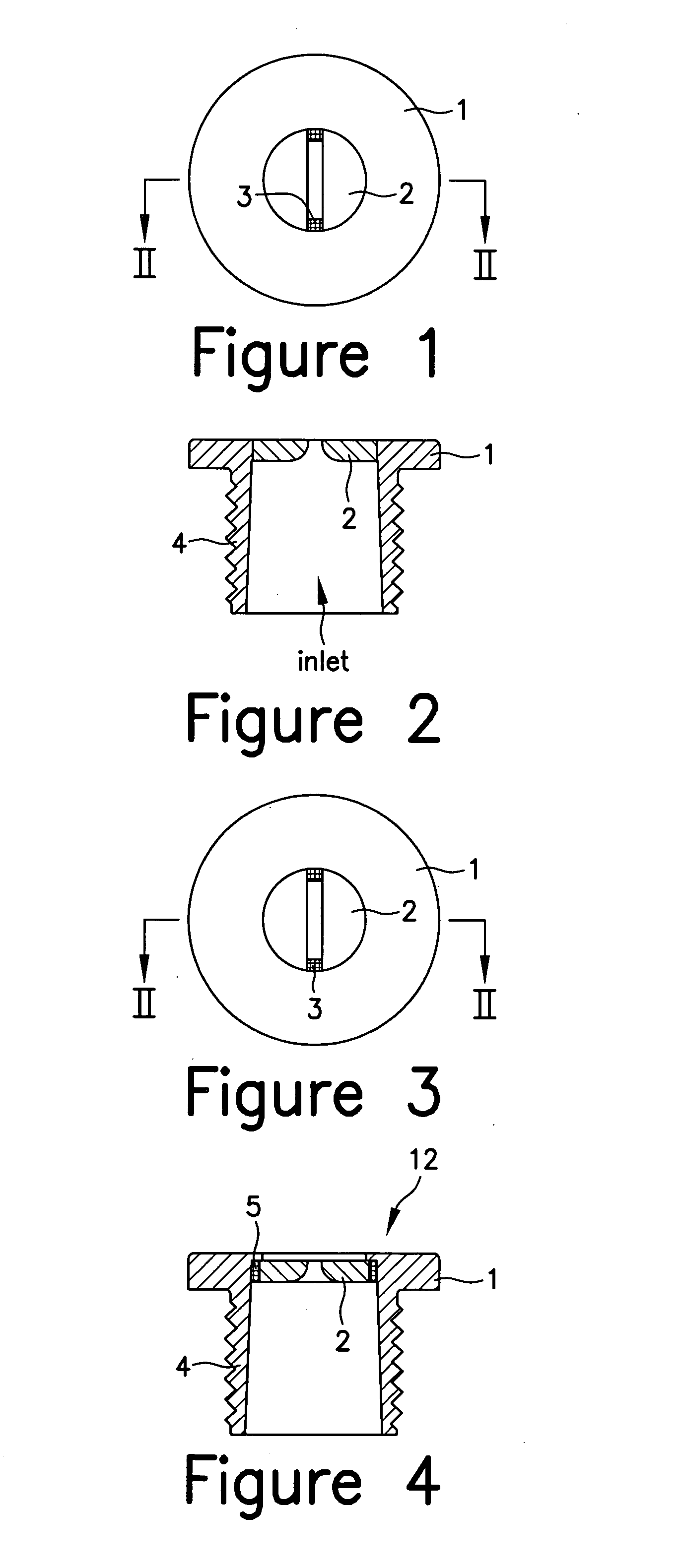

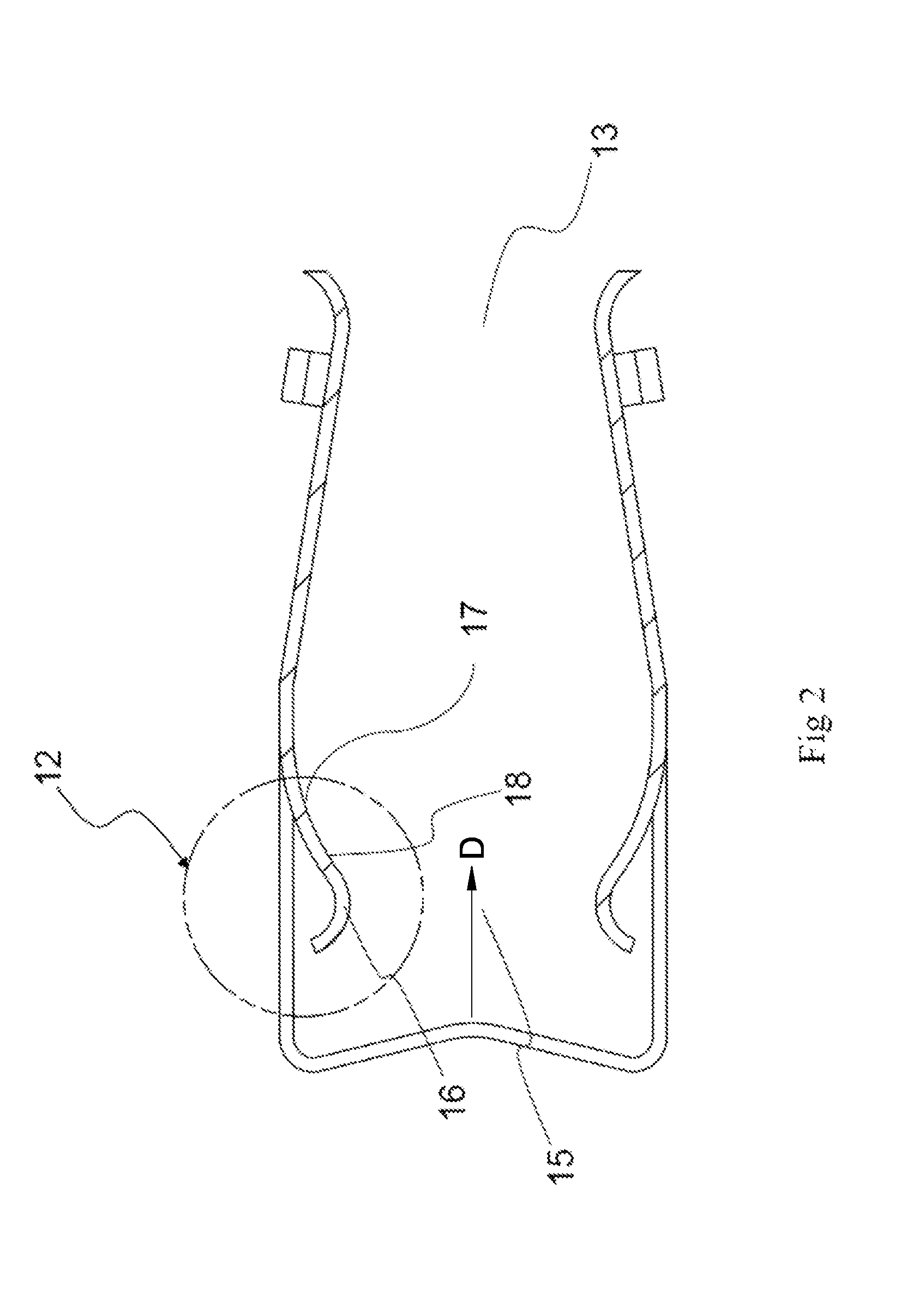

Device at fixing means for fixation of bone fragments at bone fractures

InactiveUS7029476B2Easy to fixReduce the possibilitySuture equipmentsInternal osteosythesisThighBone splinters

The present invention relates to a device at fixing means for fixation of bone fragments at bone fractures, wherein the fixing means (1) preferably is a spike for thigh-bone necks for fixation of bone fragments (2.3) at fractures (4) of the thigh-bone neck. The fixing means (1) comprises a sleeve (5) and a pin (7) provided therein. The pin (7) includes a front part (7a) which is directed obliquely forward relative to a rear part (7e) thereof and towards front parts (9a) of a second wall surface (9) close to a guide surface (12) of the sleeve (5) when the pin (7) is located in a ready position (B) in said sleeve (5).

Owner:HANSSON HENRIK

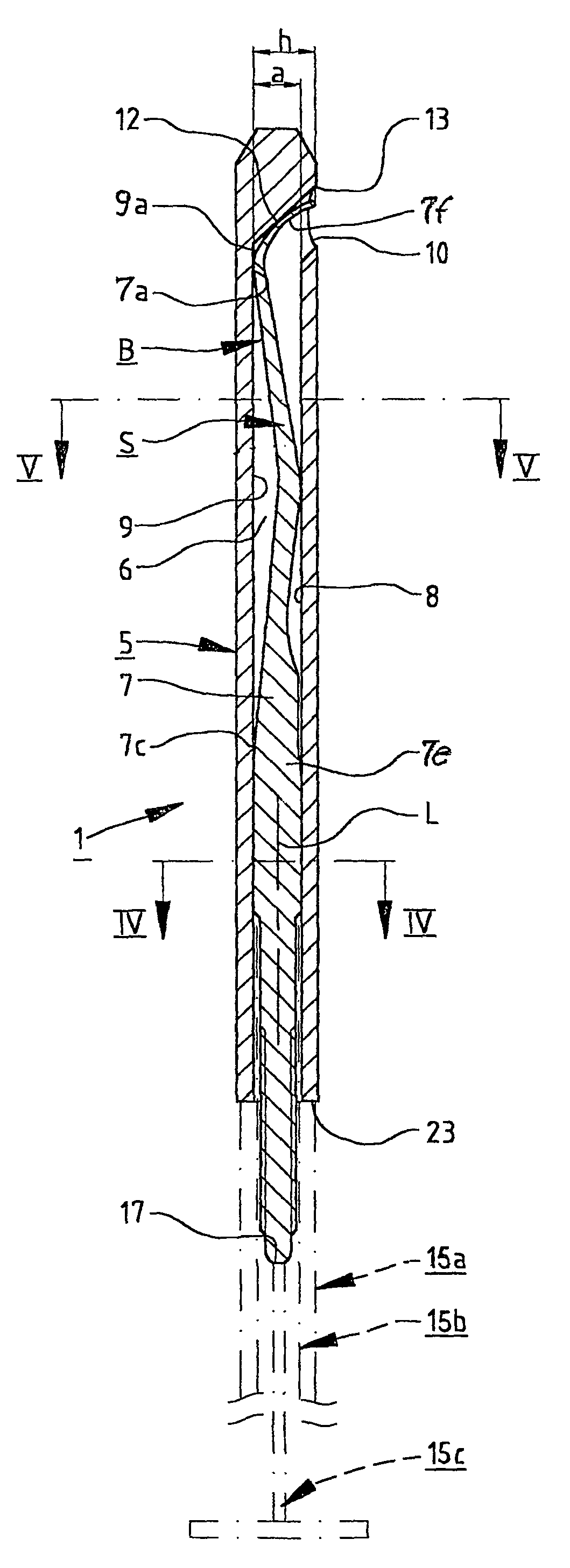

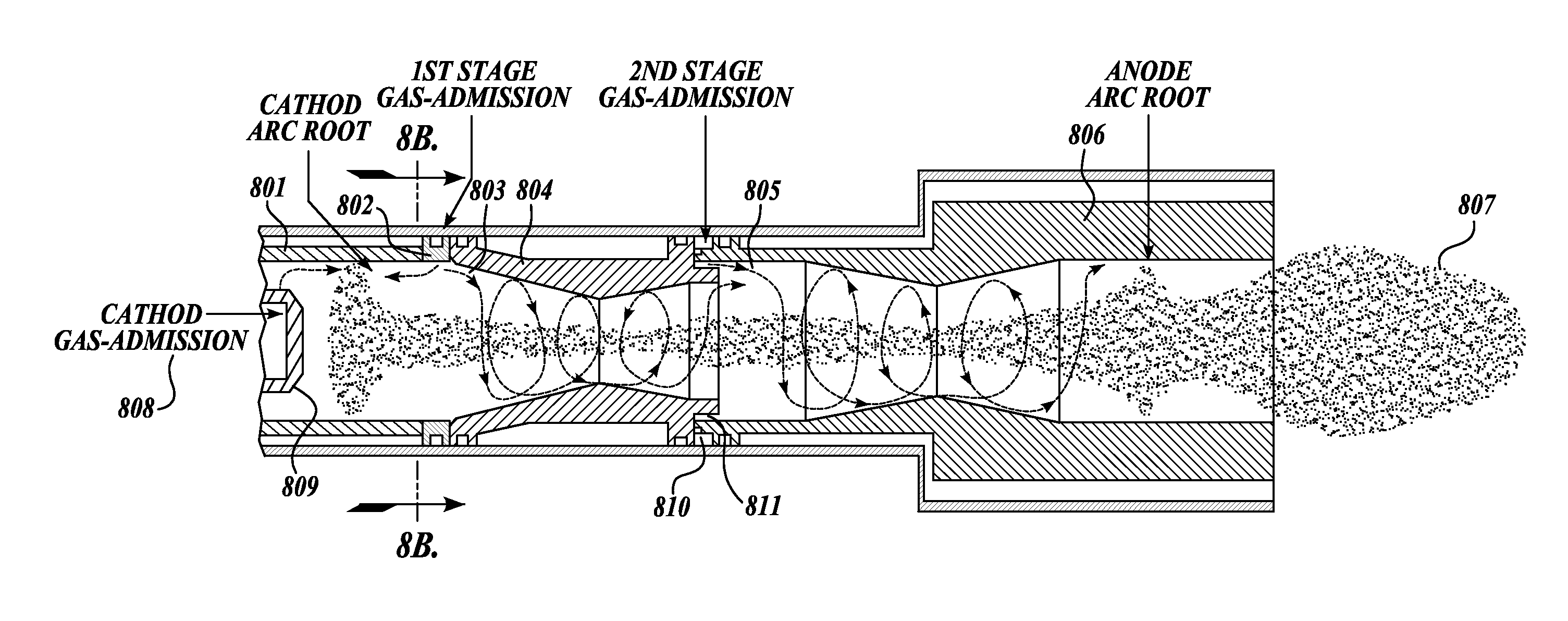

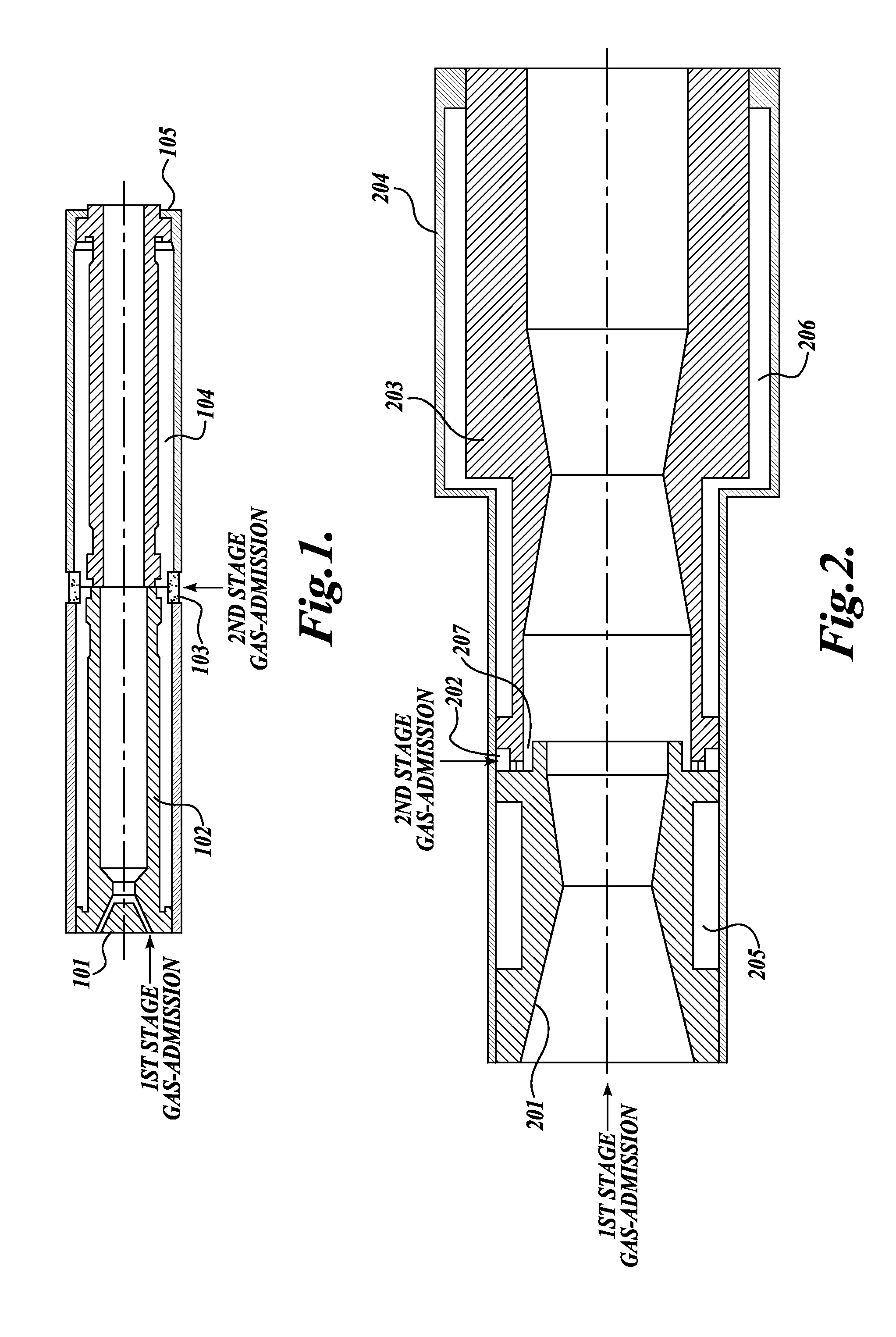

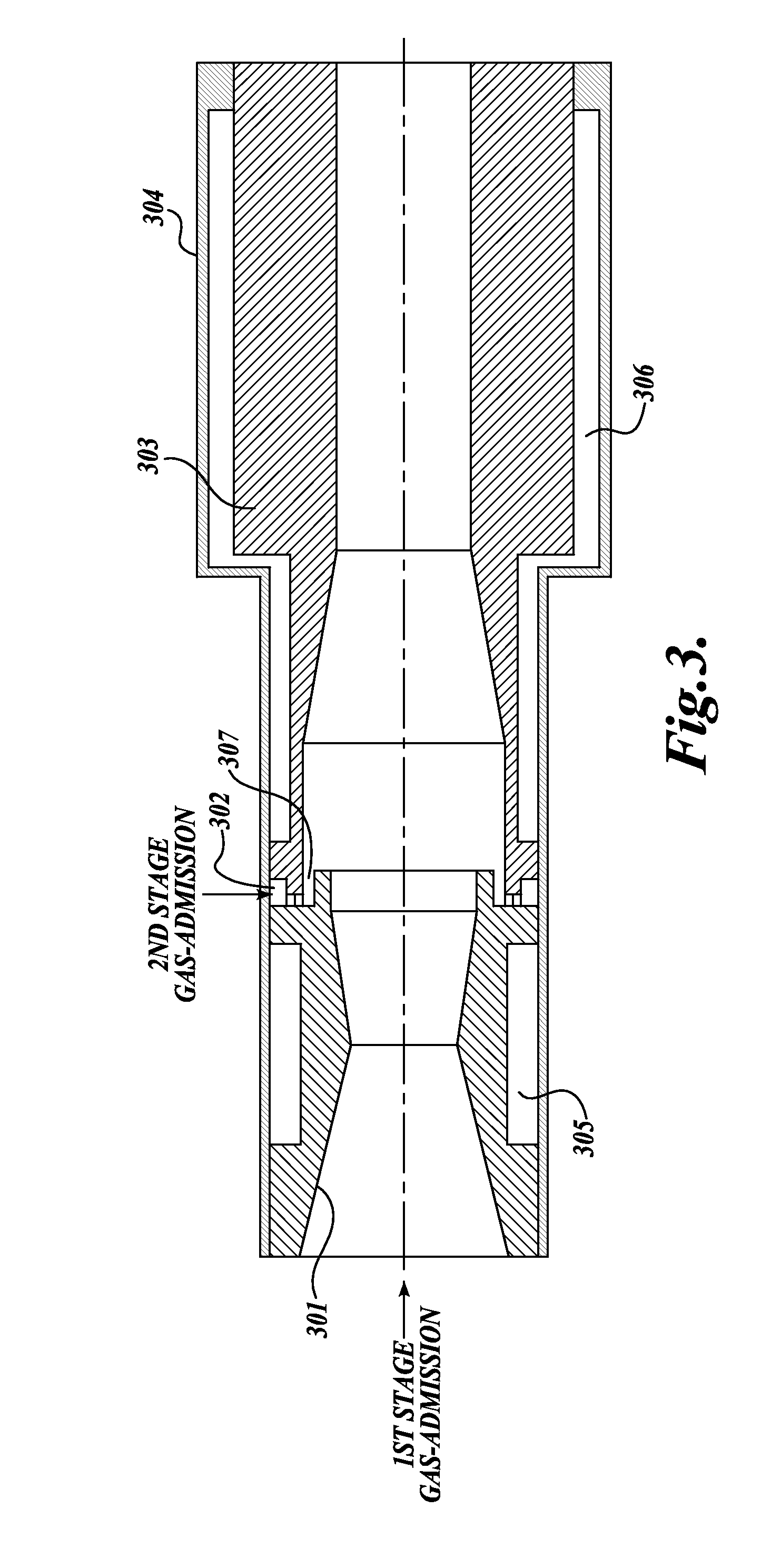

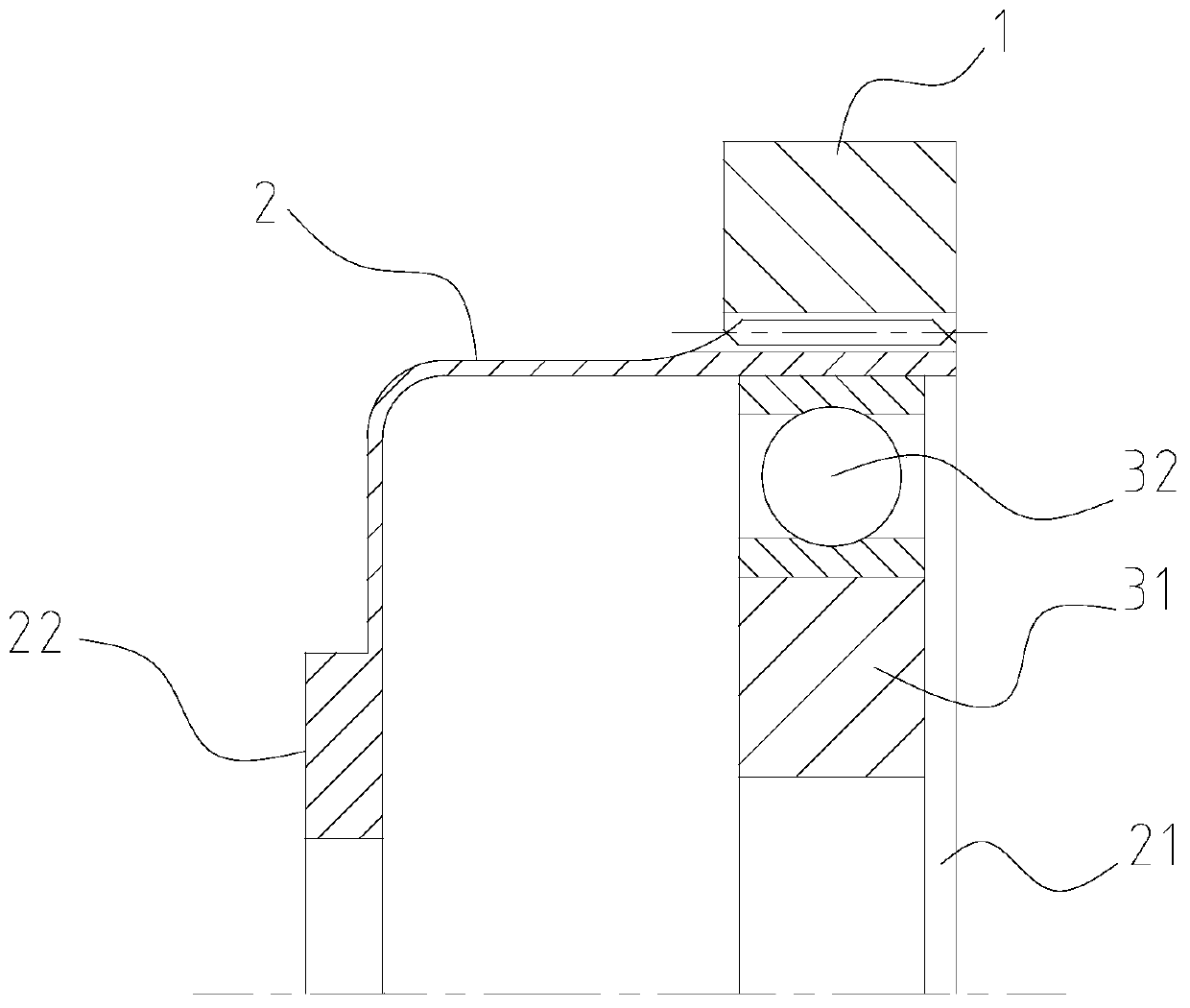

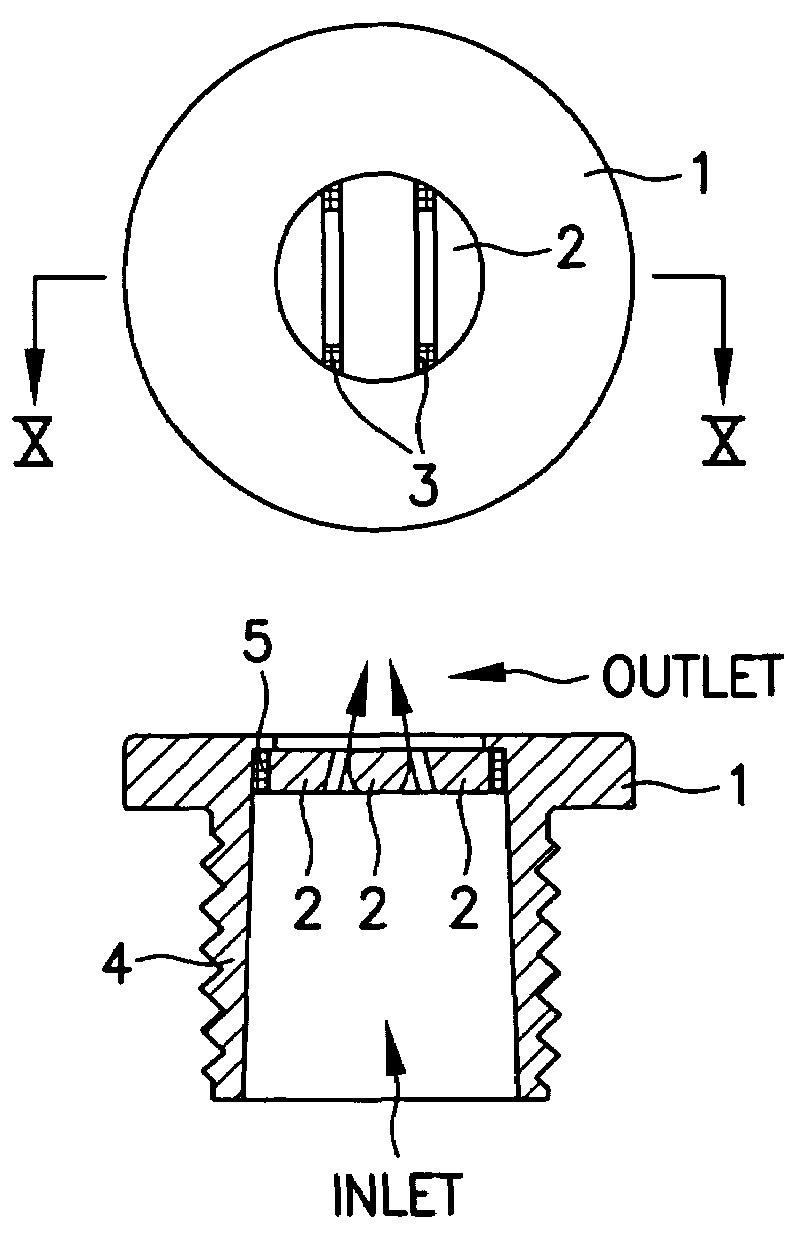

Anode of an arc plasma generator and the arc plasma generator

ActiveUS20120025693A1Increased voltageIncrease arcLamp incadescent bodiesDischarge tube solid anodesElectric arcAnode

An anode of an arc plasma generator and the arc plasma generator are disclosed. The plasma generator is a multi-stage gas admission type arc plasma generator, and the plasma generator includes a cathode and an anode. The anode comprises at least two portions (201, 203), wherein any two adjacent portions of the anode are connected electrically with one another.

Owner:YANTAI LONGYUAN POWER TECH

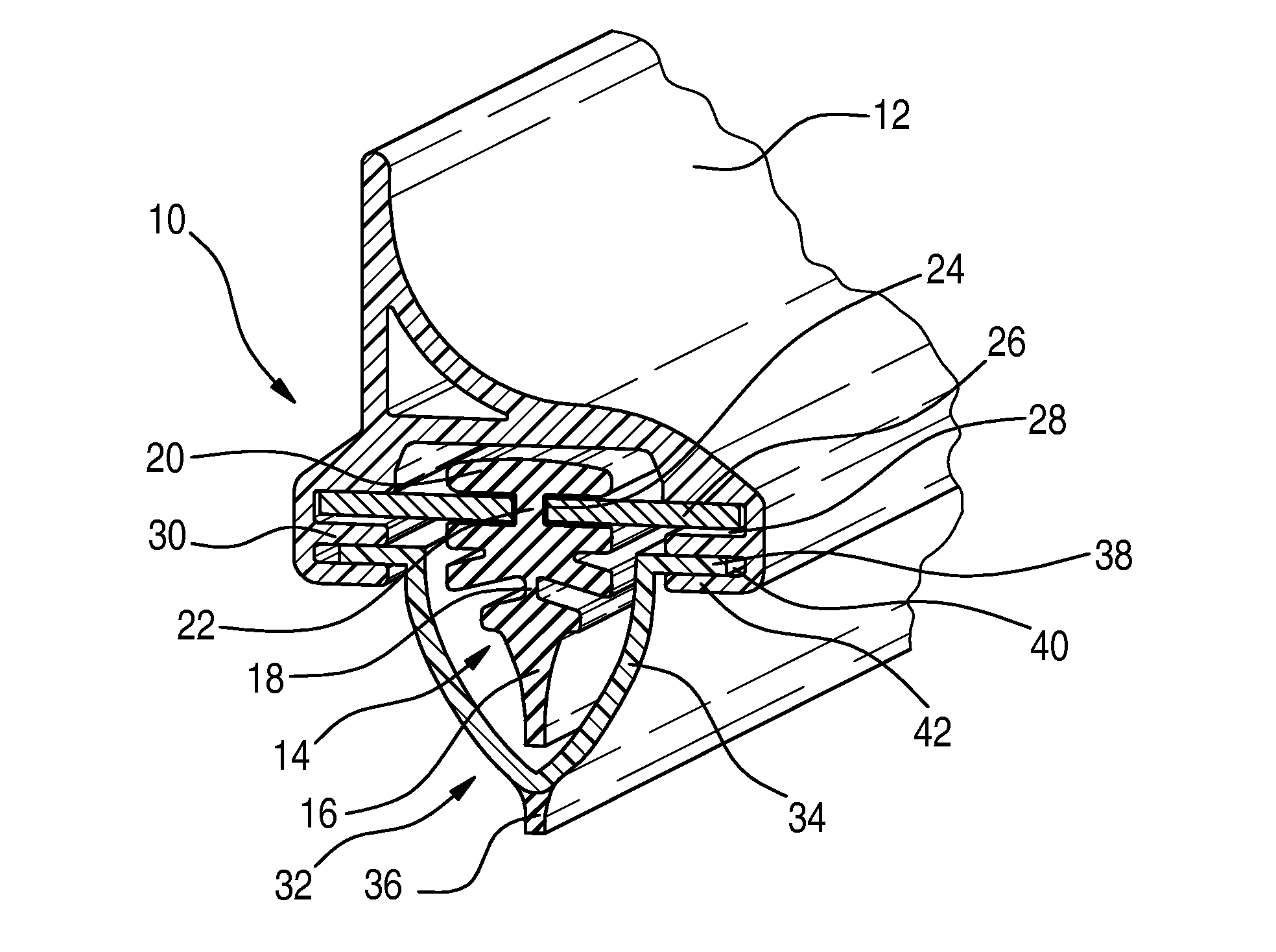

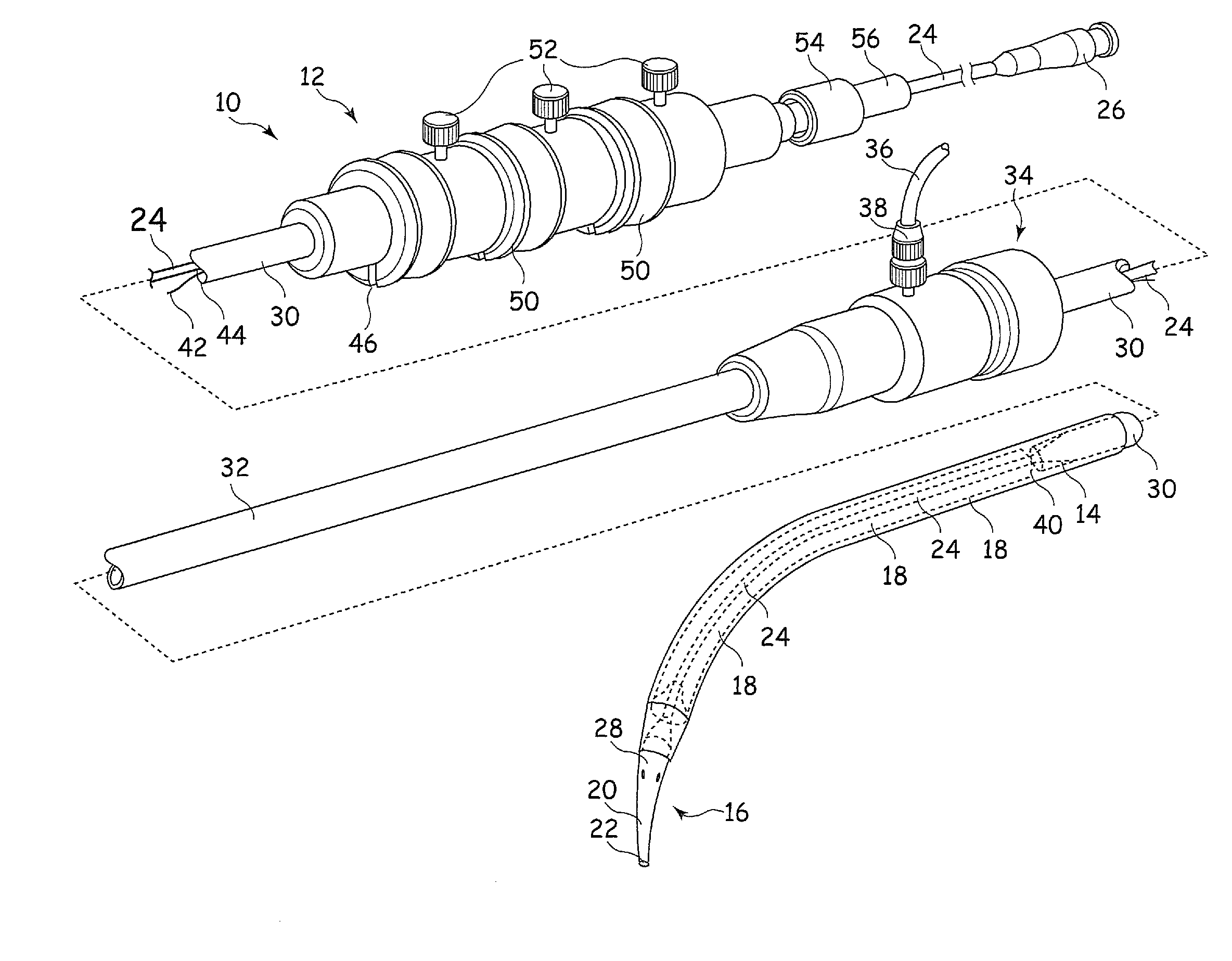

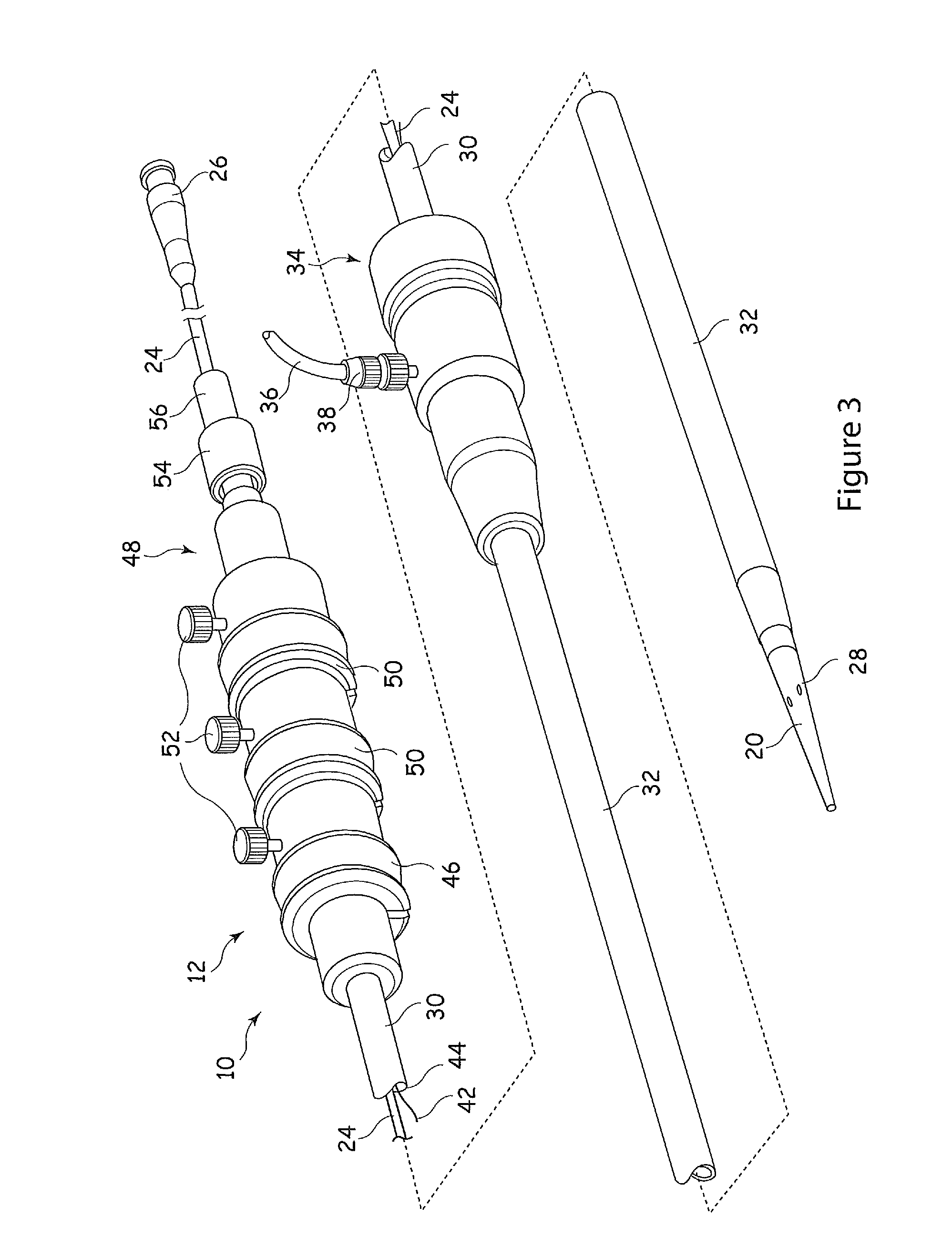

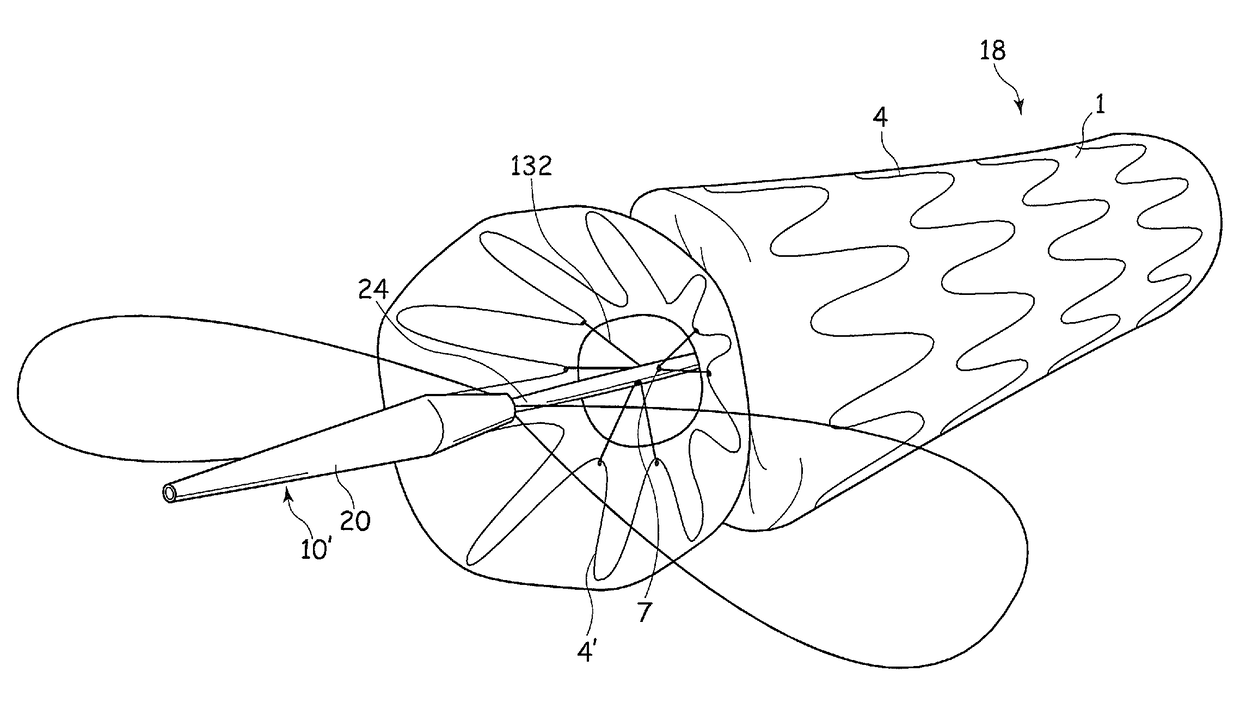

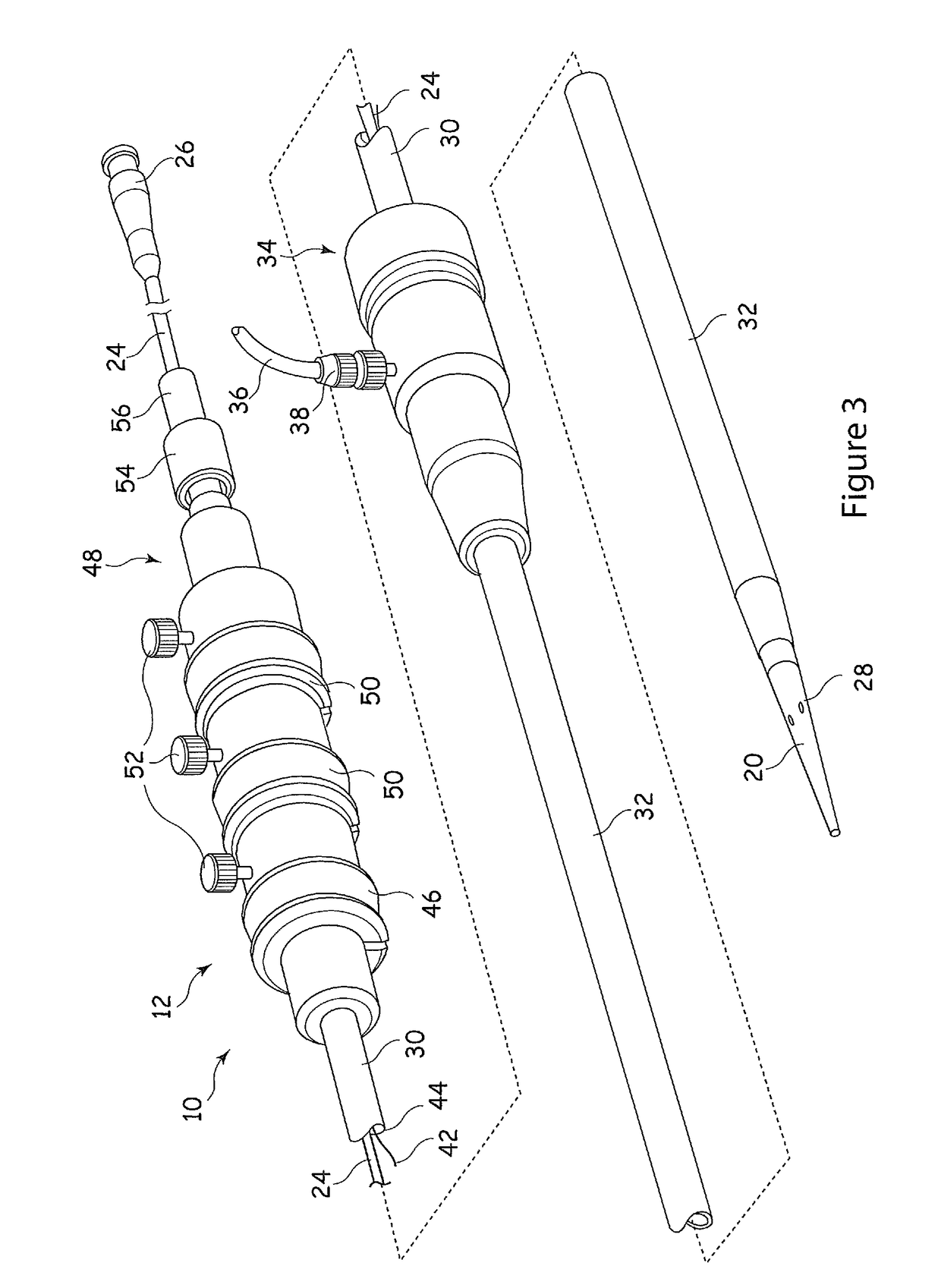

Introducer for Deploying a Stent Graft in a Curved Lumen and Stent Graft Therefor

A stent graft (18) for deployment in a curved lumen such as the aortic or thoracic arch (130) comprises a constraining mechanism at its proximal end. A stent (4′) provided at the proximal end of the stent graft (18) includes loops of material (11) that co-operate with restraining wires (42) that extend between a central guide wire carrier (24) and a restraining wire cannula (8). The constraining mechanism acts to maintain the proximal stent (4′) constrained at three points around its circumference at both the proximal and distal ends of the proximal stent (4′). The proximal stent (4′) is thus allowed to expand after expansion of the remainder of the stent graft (18) during deployment. In an embodiment, the constraining mechanism acts to constrain two adjacent struts of the proximal stent (4′) at three points radially therearound, at the proximal end of the stent (4′) and at the distal end of the stent (4′). The proximal stent (4′) may then overlap with the interior of an adjacent stent at an inner part (31) of a curved vessel.

Owner:COOK MEDICAL TECH LLC

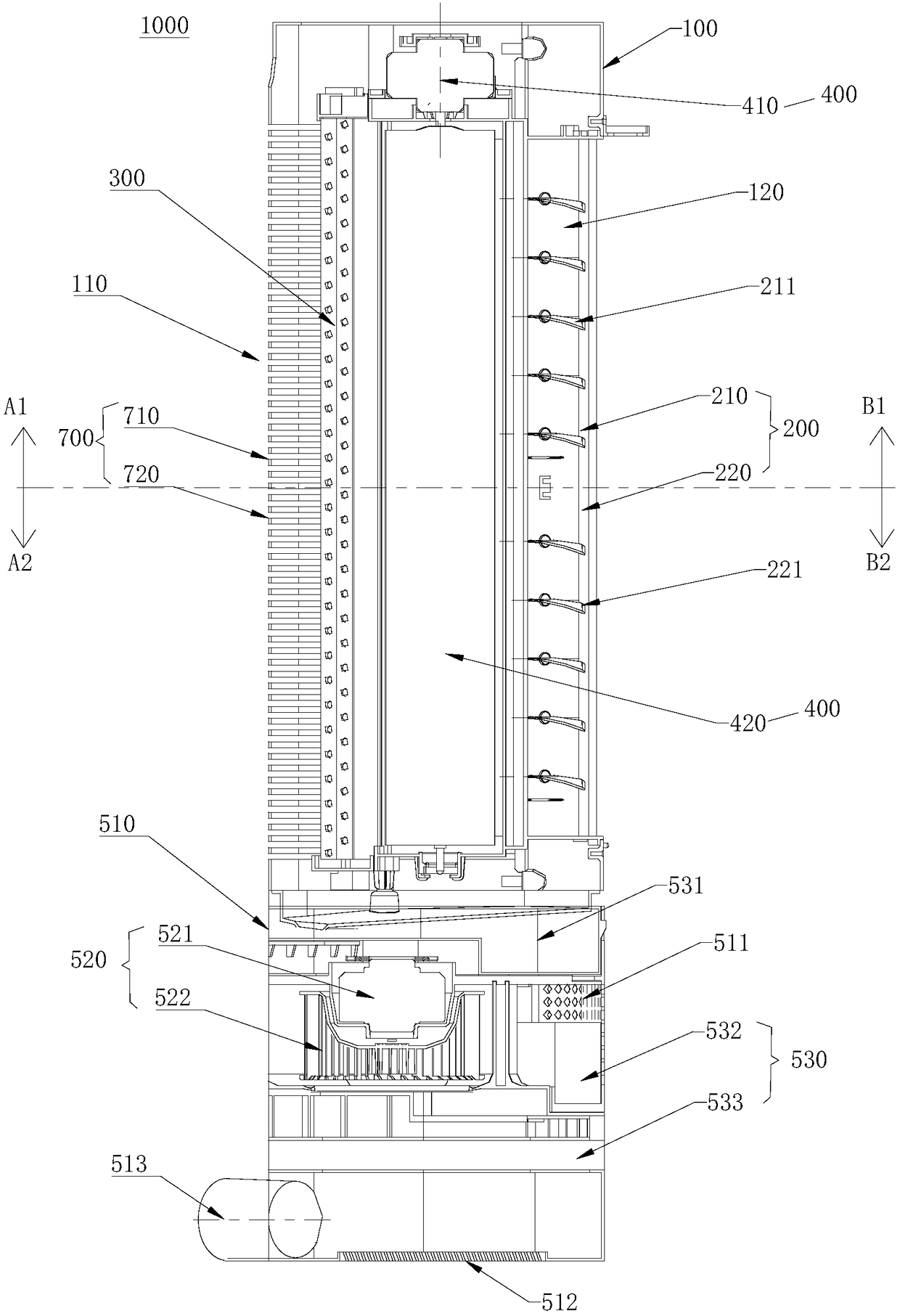

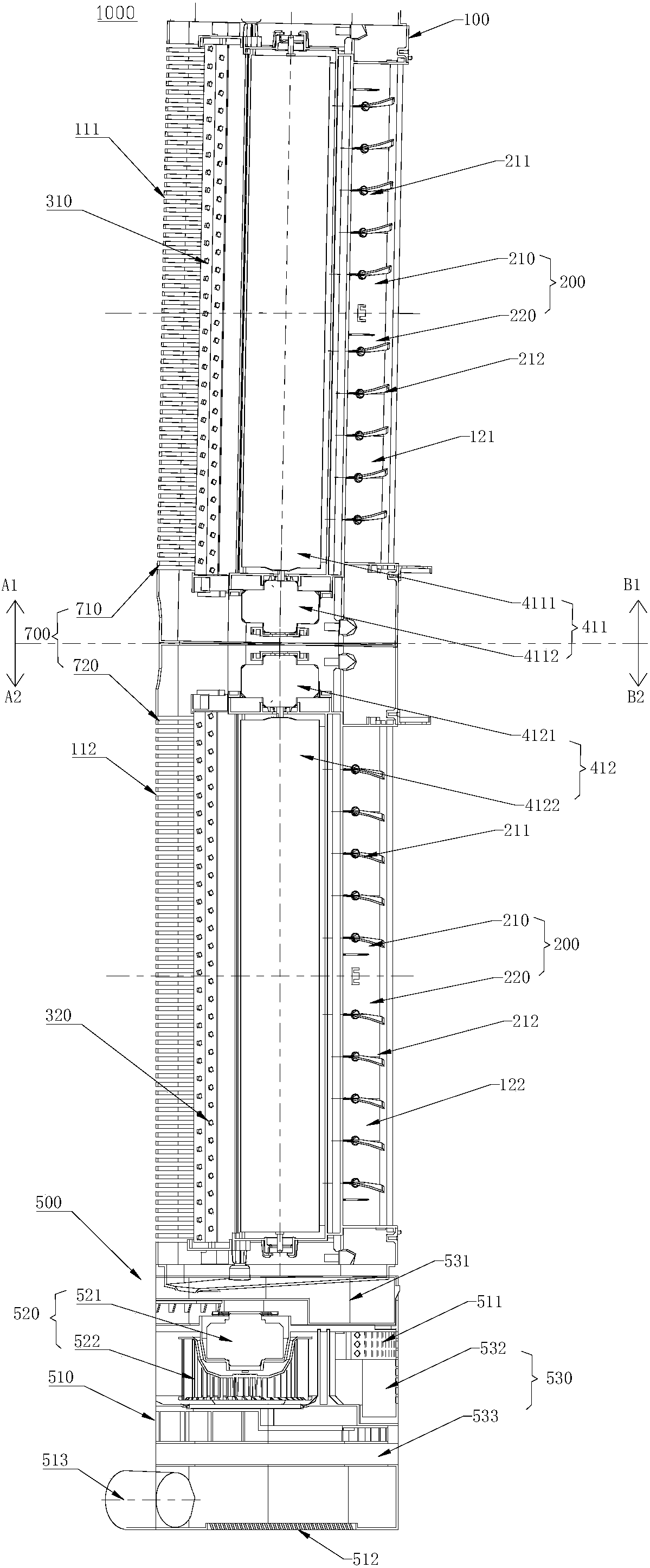

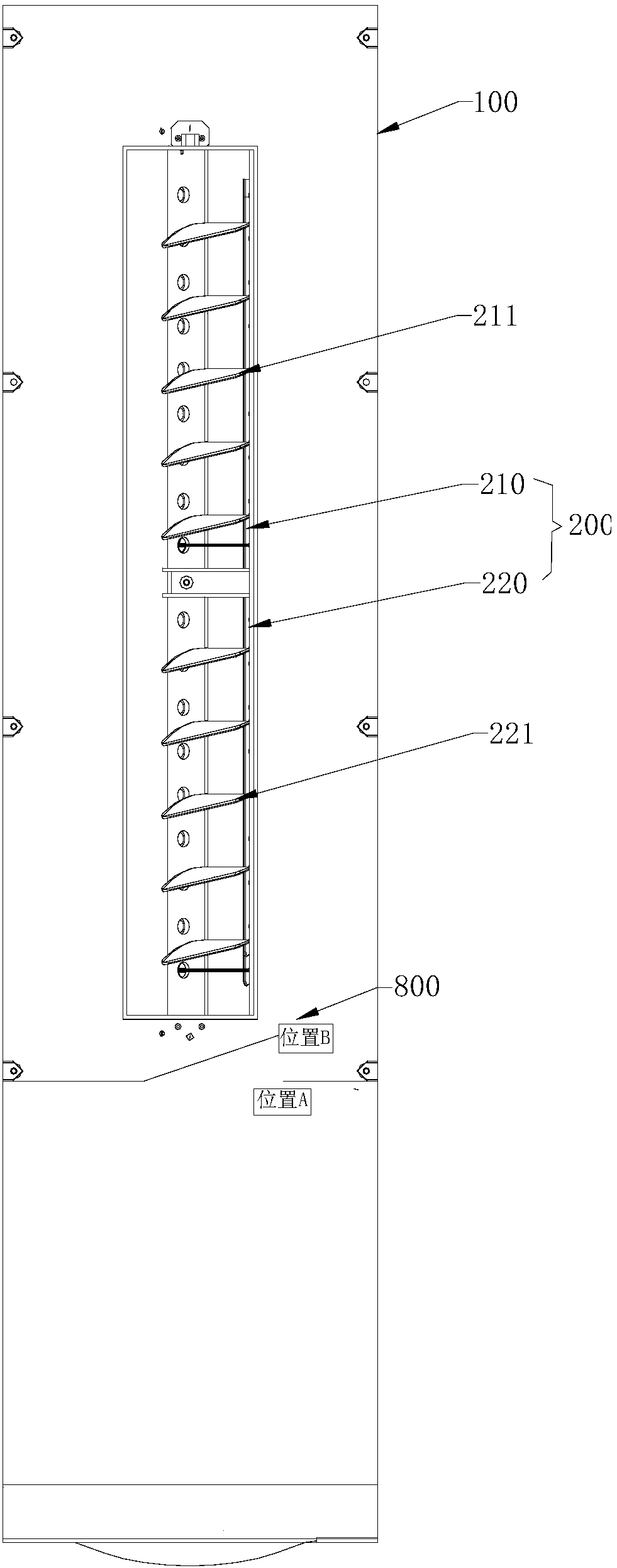

Air conditioner and control method and device of air conditioner

ActiveCN108488920AReduce working noiseDoes not affect appearanceDucting arrangementsMechanical apparatusThermal comfortFresh air

The invention discloses an air conditioner and a control method and device of the air conditioner. The air conditioner comprises an indoor unit. The indoor unit comprises a machine shell, an air handling module, multiple sets of air inlet adjusting assemblies and a switching valve. An air conditioning air flue is defined in the machine shell, and an air inlet is arranged on the machine shell. An upper air inlet area and a lower air inlet area are formed by the air inlet. The air handling module comprises a shell. A fresh air flue is defined in the shell. The method comprises the following steps that when the air conditioner operates by starting a heating mode, the air inlet is adjusted to be in the maximum air inlet state through the multiple sets of air inlet adjusting assemblies; the airinlet temperatures of the upper air inlet area and the lower air inlet area are acquired, and the temperature difference value is acquired; when the operation time reaches the first preset time, thetemperature difference value is judged; and if the temperature difference value is larger than the first preset temperature difference, the switching valve is controlled so as to control the air conditioning air flue to communicate with the fresh air flue, so that the indoor vertical temperature difference is reduced. The indoor heating power lamination phenomenon during heating operation of the air conditioner is effectively relieved, and therefore the indoor heat comfort is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

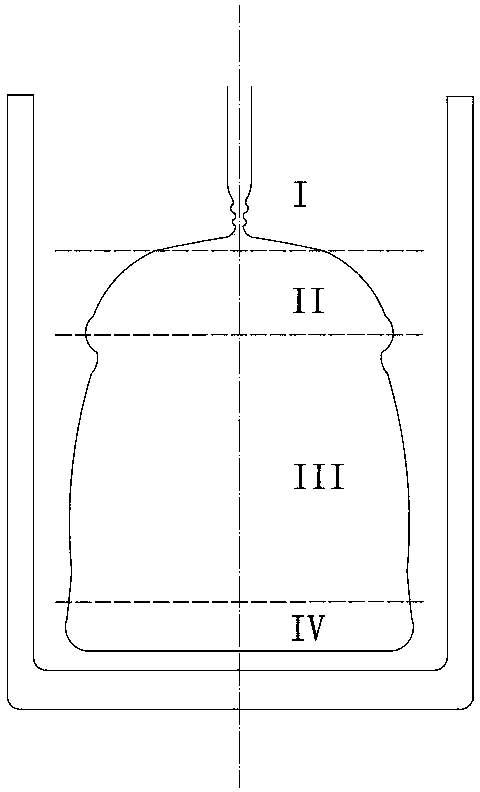

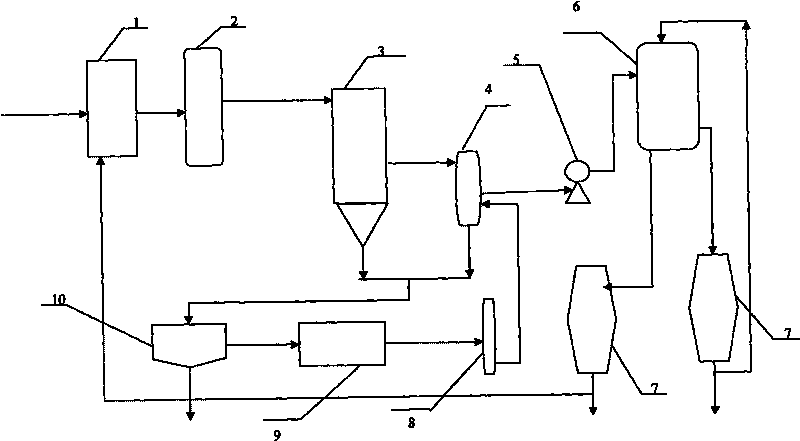

Growth method for preparing sapphire single crystal with Kyropoulos method

ActiveCN103966661APull speed decreaseEasy to liftPolycrystalline material growthUsing seed in meltGrowth phaseVoltage regulation

The invention provides a growth method for preparing a sapphire single crystal with a Kyropoulos method. The growth method mainly comprises the following control phases: a shouldering phase, an equal-diameter growth phase and an ending phase, wherein the shouldering phase is performed after seeding ending and comprises an initial shouldering stage and a later shouldering stage, the cooling speed is controlled by adjusting the voltage and matched with the crystal pulling speed to achieve stable growth at the initial shouldering stage, the crystal grows to about 1.5 kg after 20-25 h growth, and the crystal enters the later shouldering stage, the voltage adjusting quantity is smaller than that in the initial shouldering stage, the pulling speed is increased at the later shouldering stage and cooling is performed gradually, growth is performed for 45-52 h, and the crystal grows to about 4 kg and enters the equal-diameter growth phase; the crystal pulling speed is decreased at the equal-diameter growth phase, cooling is accelerated simultaneously, growth is performed for 75 h, and the crystal grows to about 28 kg-32 kg and enters the ending phase; and the cooling speed is further decreased and fast pulling is performed at the ending phase, and automatic draw-off is achieved. The growth method for preparing the sapphire single crystal with the Kyropoulos method can solve the problem that more bubbles exist in the sapphire single crystal grown with the conventional Kyropoulos method.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

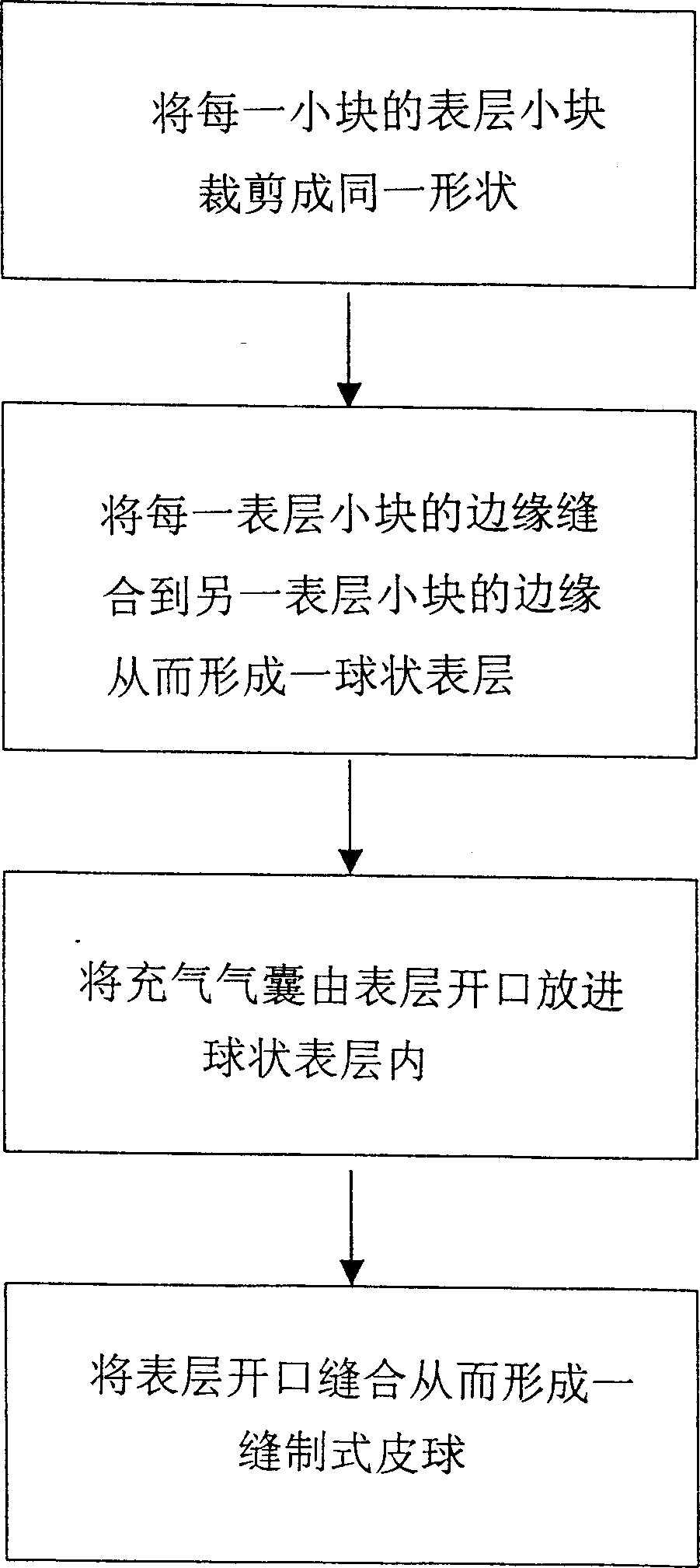

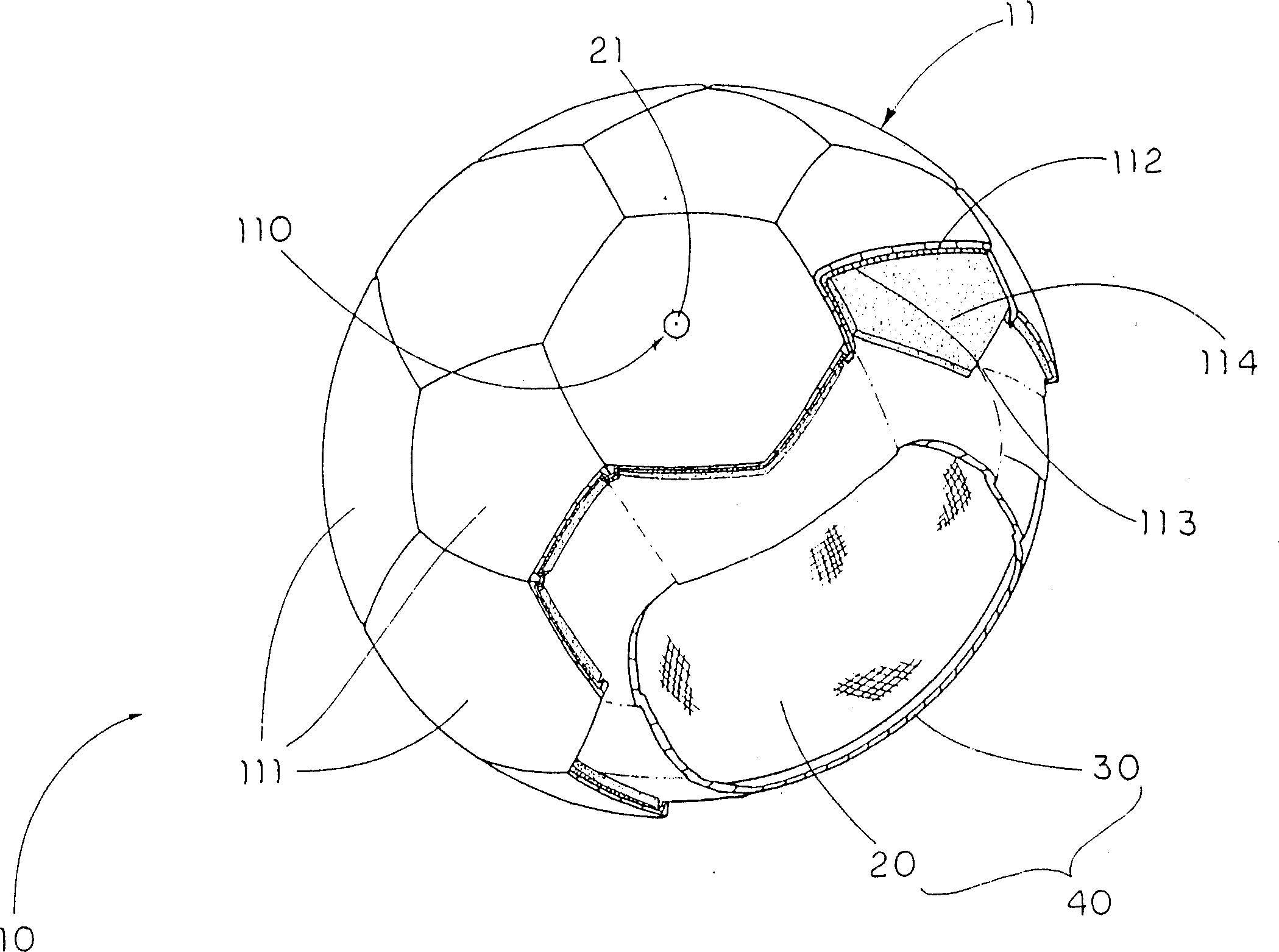

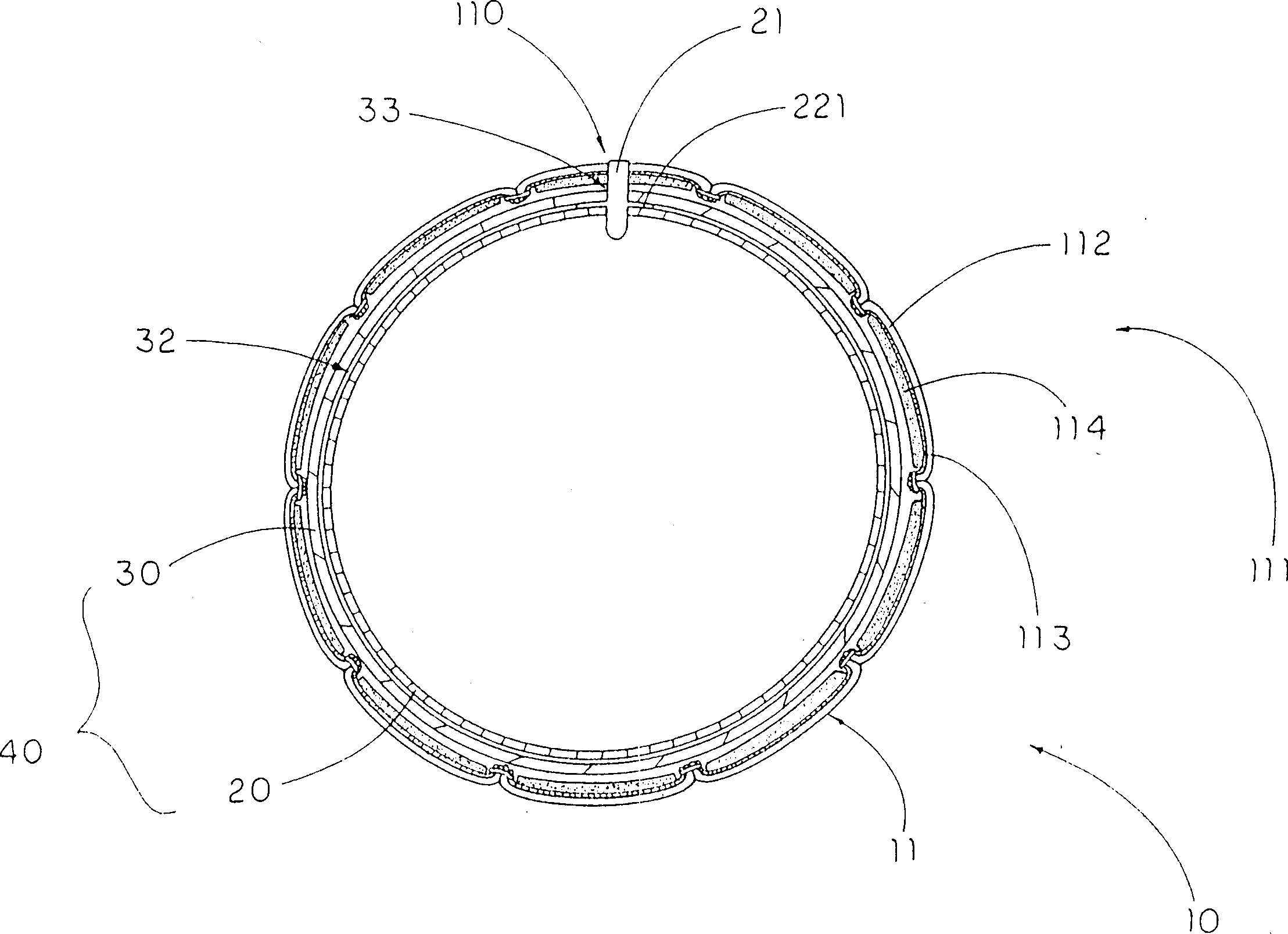

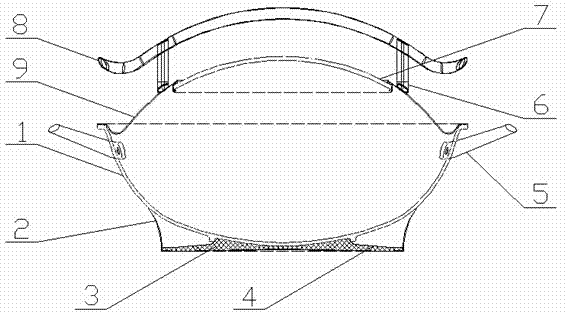

Ball bag built-in sewn ball

The present invention relates to a sewed ball with built-in ball bag. Said ball is formed from a ball surface layer and a ball bag internal bladder placed in the interior of ball surface layer. Said ball bag internal bladder includes an inflatable air bag with an inflatable hole, a built-in ball bag which has a receiving space for receiving said inflatable air bag and a movable air hole from which the inflatable hole can be passed through and extended outward. Said ball surface layer can be used for receiving said ball bag internal bladder, after said ball bag internal bladder is inflated, said ball surface layer can be expanded and formed into a ball with a certain radian and flexibility. Said invention also provides its sewing method.

Owner:欧陈丽卿

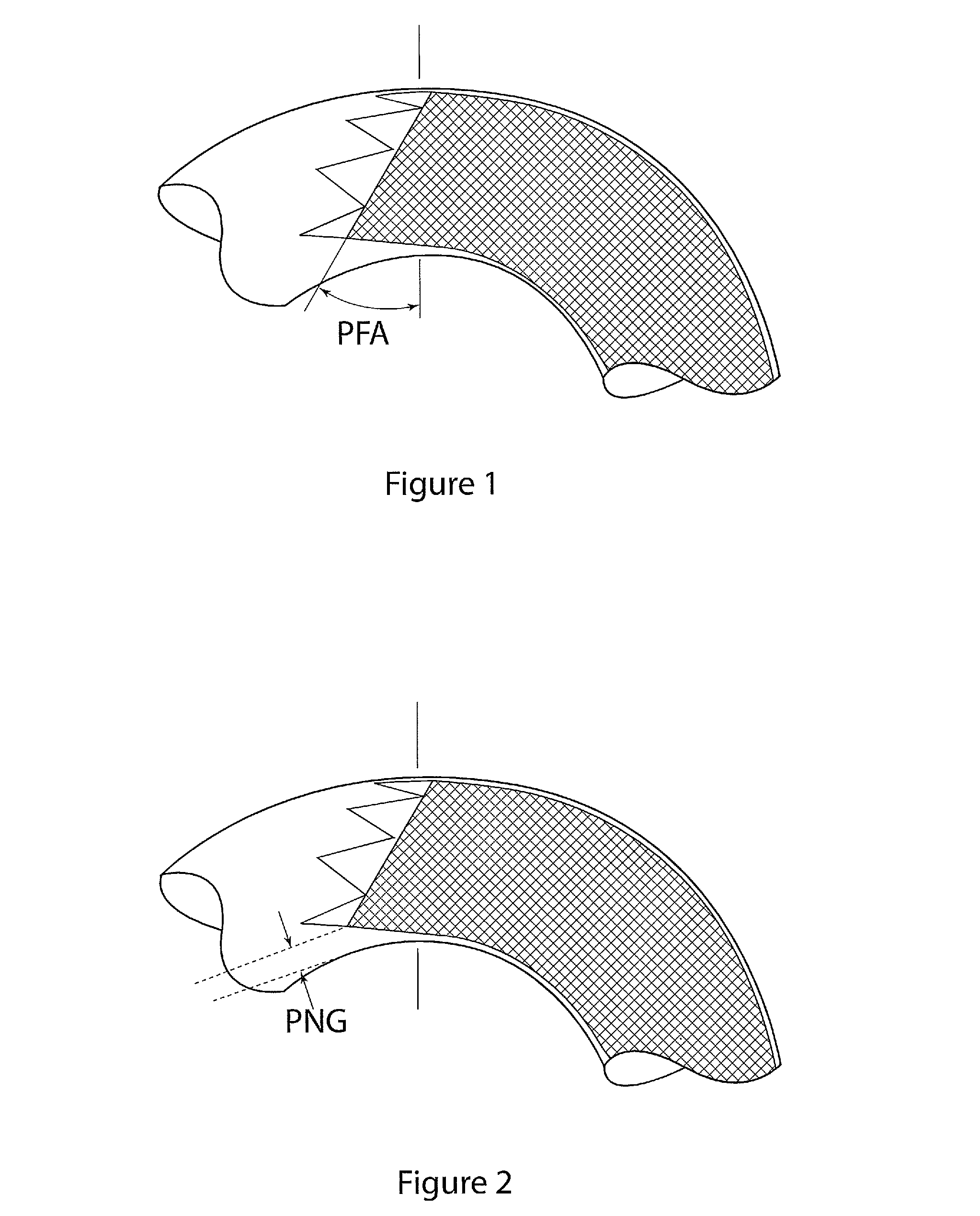

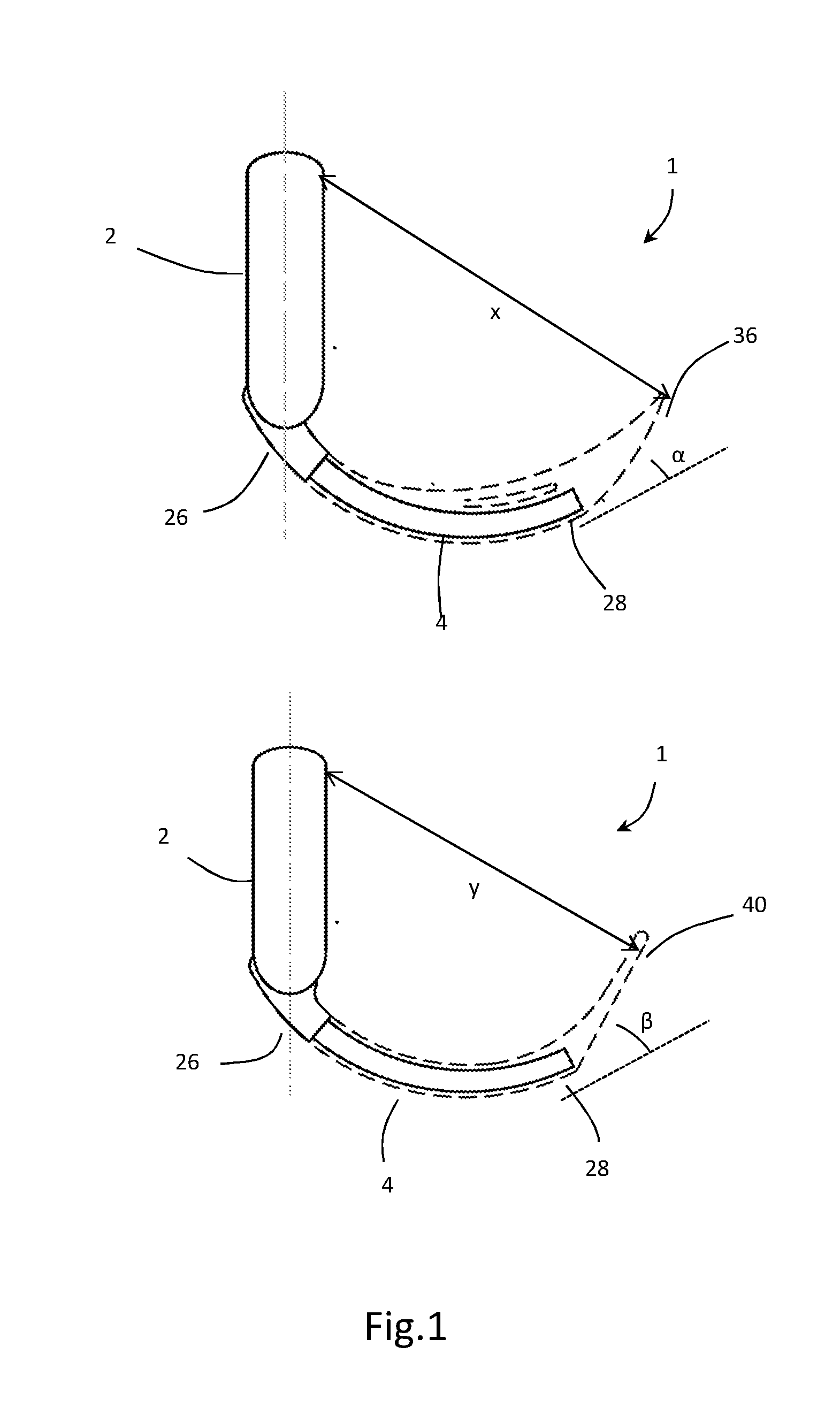

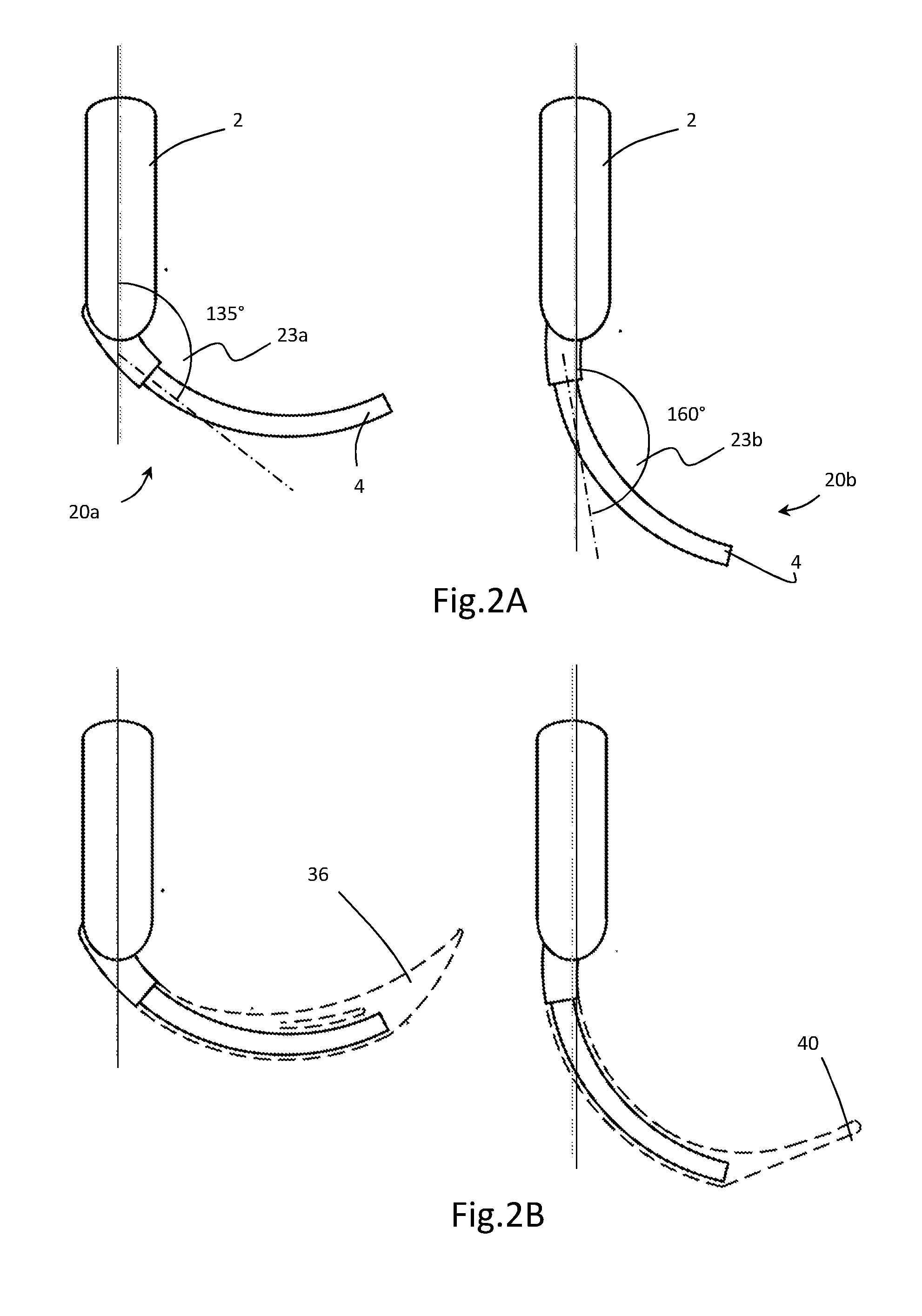

Laryngoscope and laryngoscope blades

InactiveUS20140296645A1Faster and moreIncrease arcBronchoscopesLaryngoscopesEngineeringLaryngoscope blade

A laryngoscope body for use with laryngoscope blades is presented having an elongate handle and a blade retaining member configured to retain a blade such that the blade extends away from the elongate handle; wherein the blade retaining member is fixable at a plurality of positions to allow a blade to be retained on the blade retaining member at a plurality of—angles relative to the elongate handle. There is also disclosed a kit of parts comprising a laryngoscope body and a plurality of blades, as well as a method of use for the said laryngoscope body with a suitable laryngoscope blade.

Owner:COVIDIEN AG

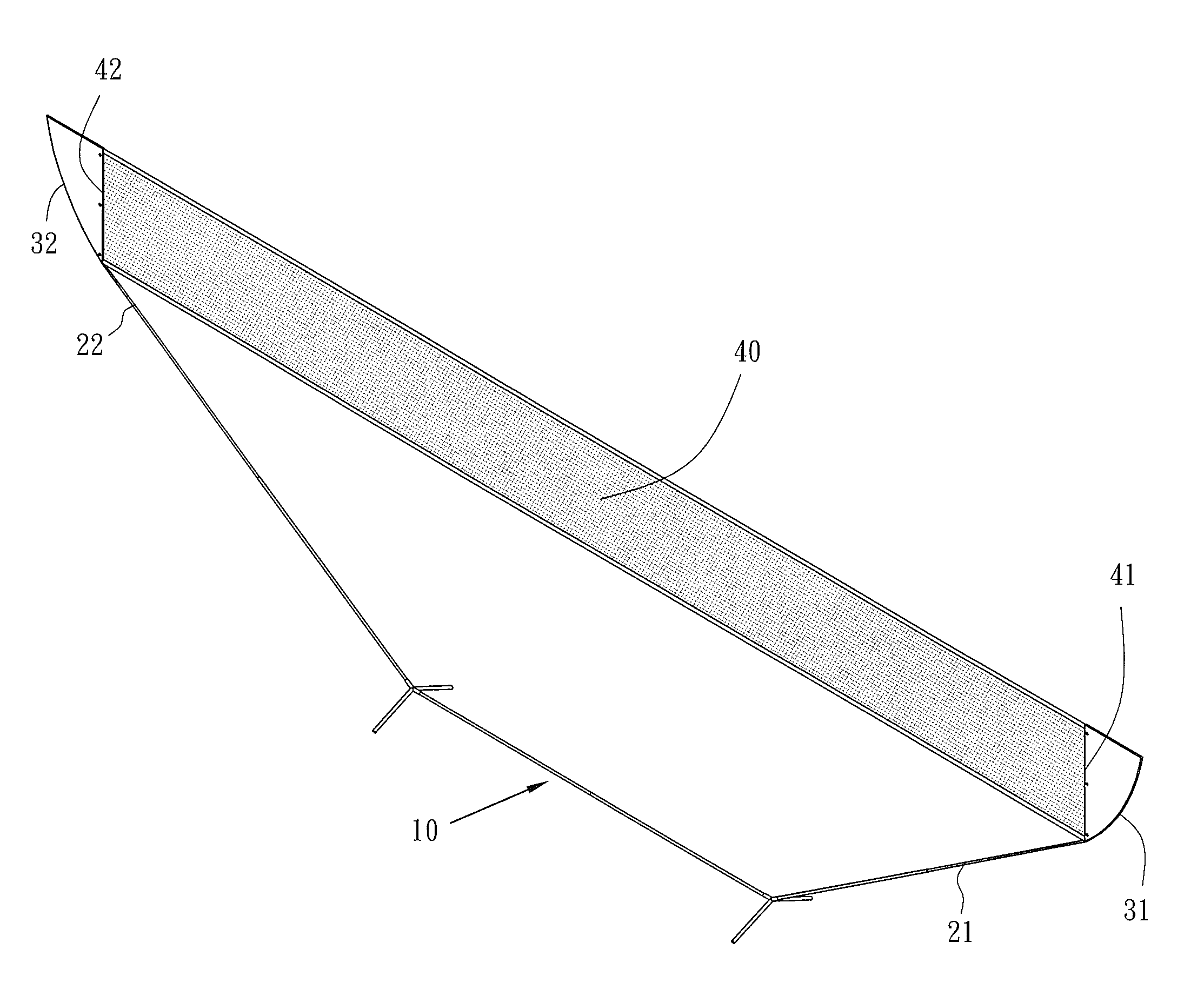

Wiper blade of a windscreen wiper, provided with a protective rail

InactiveUS20090025174A1More flexibleIncrease arcWindow cleanersVehicle cleaningWindscreen wiperEngineering

The invention relates to a wiper blade (10) of a windshield wiper provided with a protective rail (32, 44, 56, 72, 88), comprising a base body (34) that has an essentially V-shaped cross section and a wiper lip (36) of the wiper blade (10) and that is detachably fixed to the wiper blade (10) with the aid of fixing elements (38, 52, 58, 78, 90). It is proposed that the wiper blade (10) consist of a wiper strip (14) with at least one flat, bar-type, elastic support element (26) and a spoiler (12), wherein the protective rail (32, 44, 56, 72, 88) rests on the support element (26) or spoiler (12).

Owner:ROBERT BOSCH GMBH +1

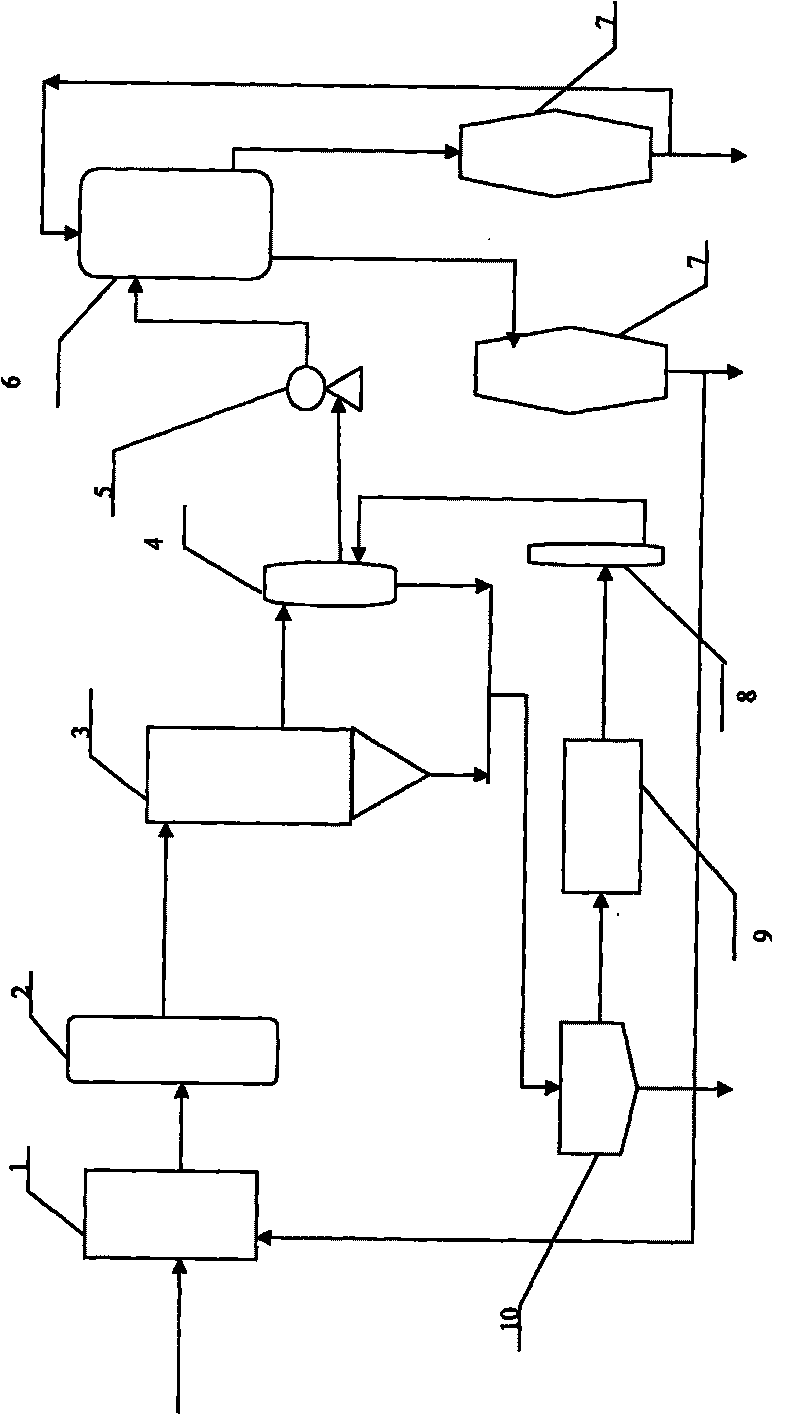

Device and method for producing acetylene by hydrogen direct current arc plasma cracking coal

ActiveCN101734995AThorough treatmentNo pollution in the processHydrocarbonsHydrocarbon preparationCoal dustProcess design

The invention relates to a device and a method for producing acetylene by hydrogen direct current arc plasma cracking coal. The method comprises the following steps: the hydrogen coal dust is fed into a plasma reactor, enters a quenching machine for quenching after the reaction, then enters a cyclone separator for preseparation between gas and solid; the gas part enters a rinsing dust removing tower for dedusting, is sent to a compressor for compression by a booster fan, then enters a pressure swing adsorption tower for adsorption and concentration, and simultaneously, the gas out of the pressure swing adsorption tower enters the compressor again and is sent to an adsorption tower for extracting hydrogen; the solid dust separated by the cyclone separator and the rinsing dust removing tower forms solution with water; a ceramic membrane device is utilized to carry out liquid and solid separation; the solid dust is sent to a power plant to be served as raw materials; and water enters therinsing tower for recycling. The invention has reasonable process design and high economic efficiency, can be used in combination or separately, and can be directly used in the processes for producing hydrogen chloride, acetylene ethane derivative, methanol and the derivatives and the like.

Owner:XINJIANG TIANYE GRP

Anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and preparation method thereof

ActiveCN105002748AReduce creasesIncrease softnessLamination ancillary operationsSynthetic resin layered productsFiberWrinkle skin

The invention discloses anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and a preparation method thereof. The preparation method comprises the steps that fiber screen laying and needling are carried out on a spunlaced non-woven fabric surface, and a anti-wrinkle non-woven base is formed; after dipping carried out in a polyurethane dipping sizing agent is finished, condensing and ironing are carried out in a DMF aqueous solution; after coating is carried out by a polyurethane coating, the condensing, washing and drying are sequentially carried out; a post-processing grinding machine is used for carrying out orientated grinding on the surface of a semi-finished product; one layer of a thermoplastic polyurethane resin dry coating sizing agent is coated on release paper, after drying is conducted, one layer of a thermoplastic polyurethane dry bonding layer sizing agent is coated on the release paper, then drying is carried out in a drying oven until the release paper is half-dried, and a dry synthetic leather semi-finished product is obtained; the dry synthetic leather semi-finished product is attached to the wet synthetic leather semi-finished product, and after drying and ripening are conducted, the non-woven fabric polyurethane synthetic leather is obtained. The non-woven fabric polyurethane synthetic leather has the advantages that wrinkles cannot be generated, the physical mechanical strength is high, meanwhile sizing of shoemaking is good, and the durability is good; processing and performance requirements for children shoes, sport leisure shoes and the like are completely met.

Owner:ANHUI ANLI MATERIAL TECH

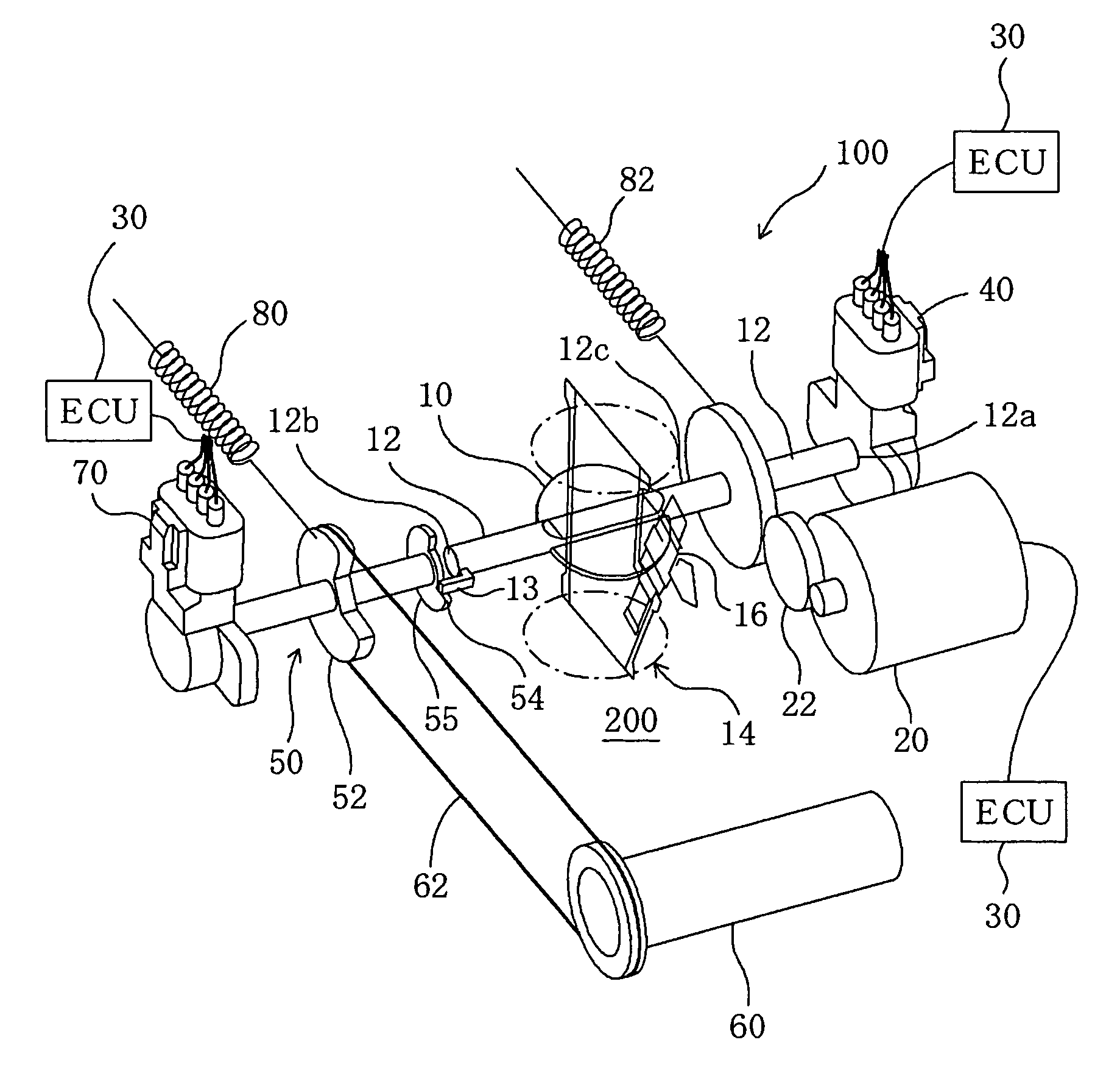

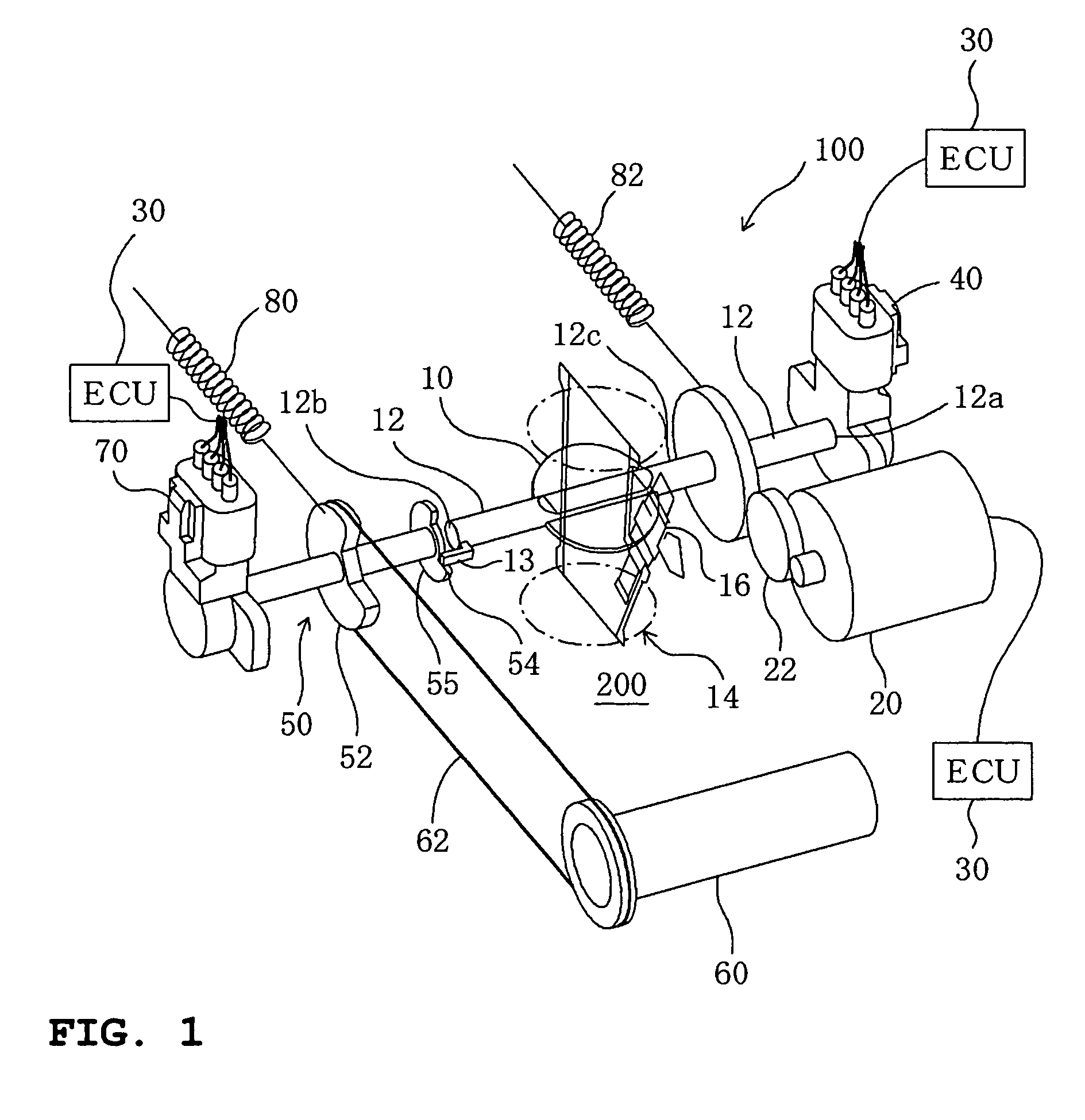

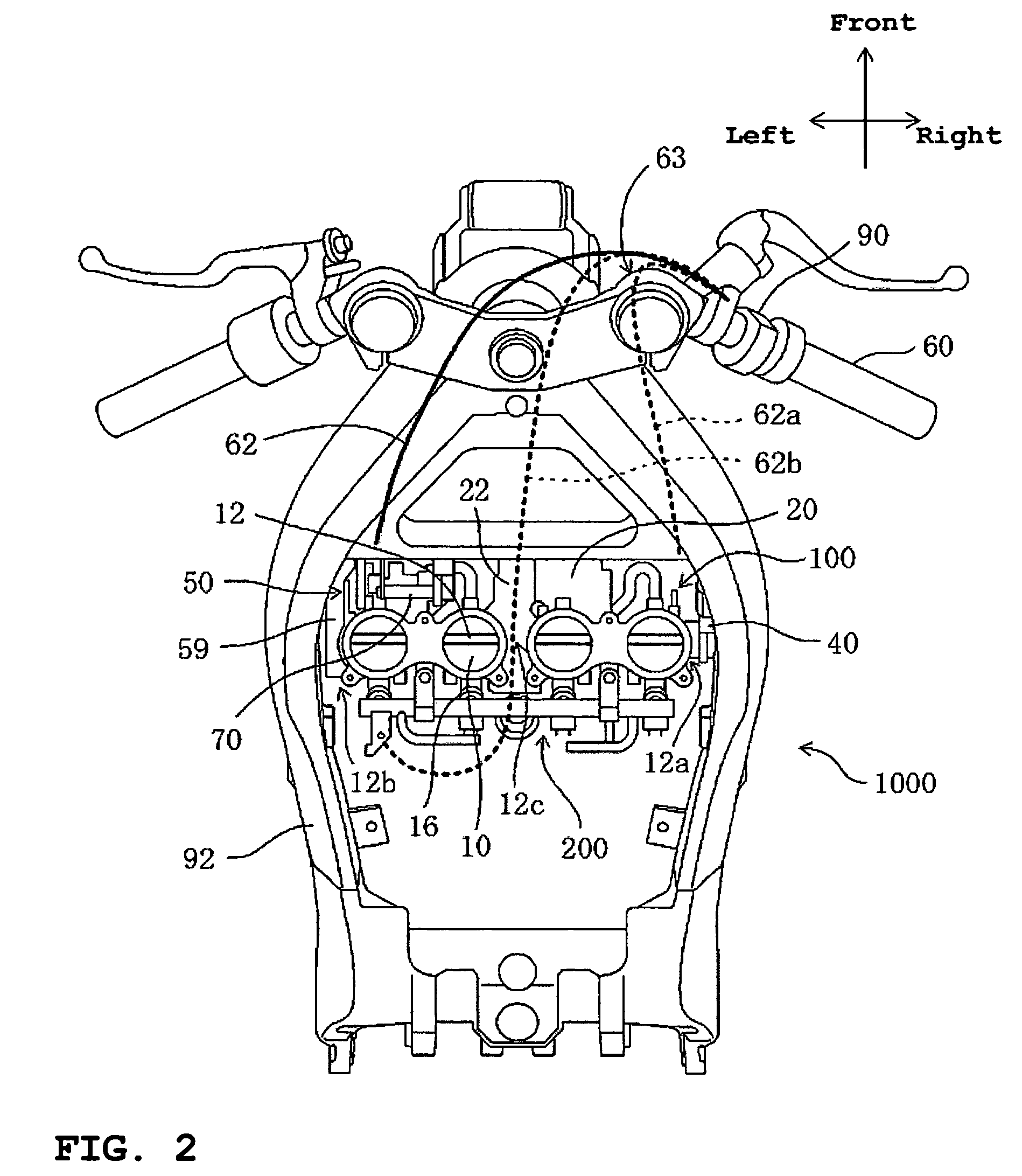

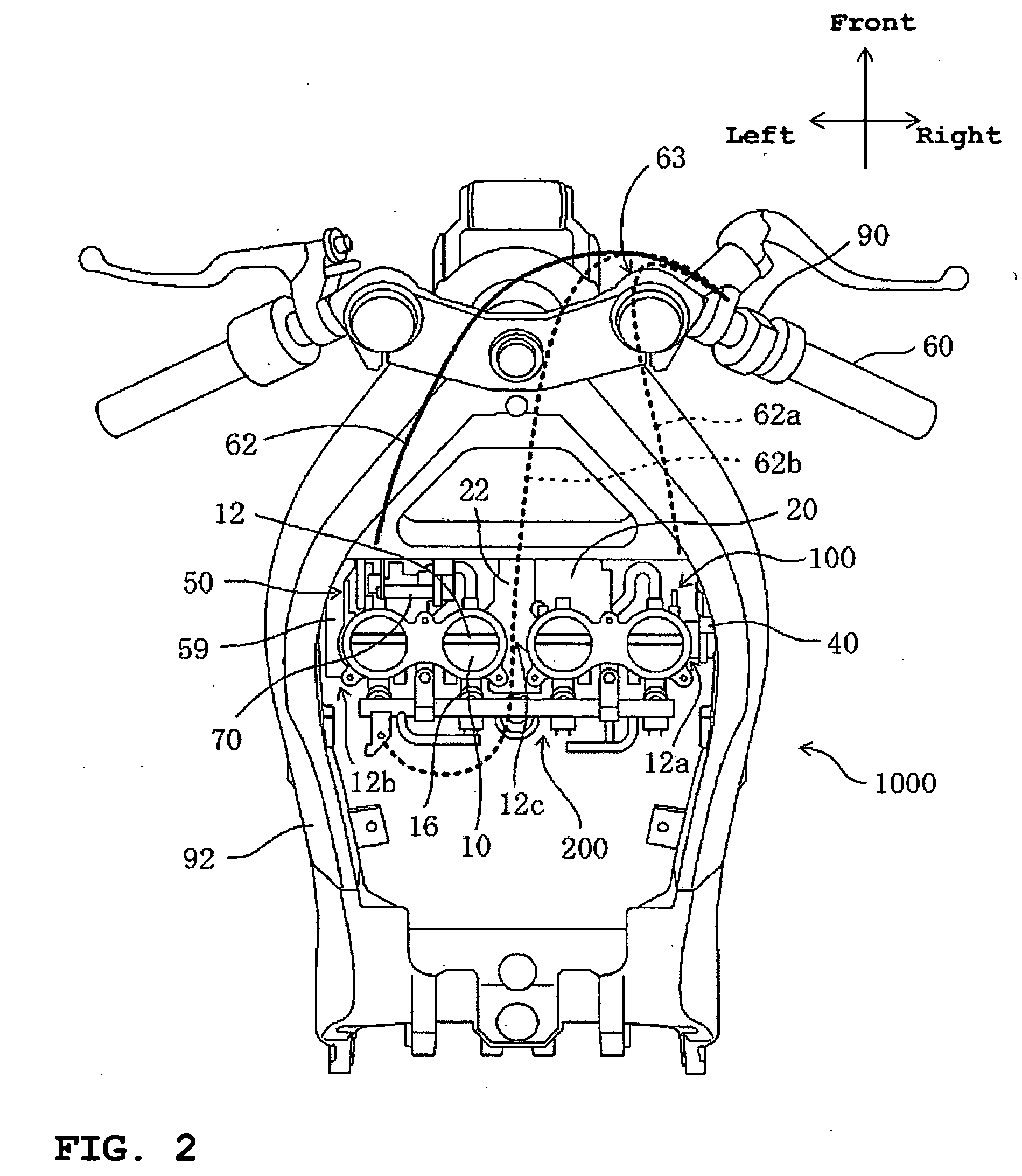

Straddle type vehicle having an electronic throttle valve system

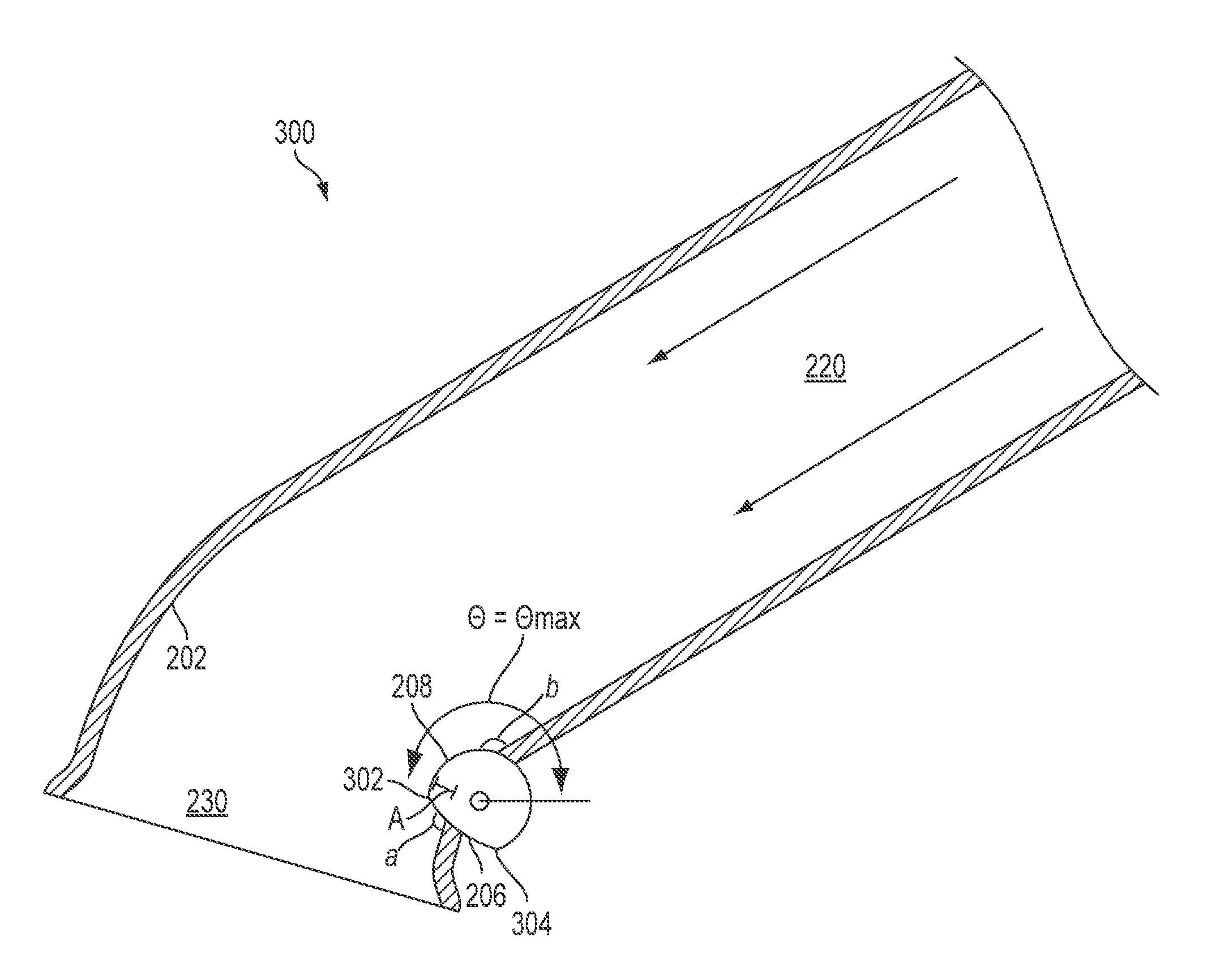

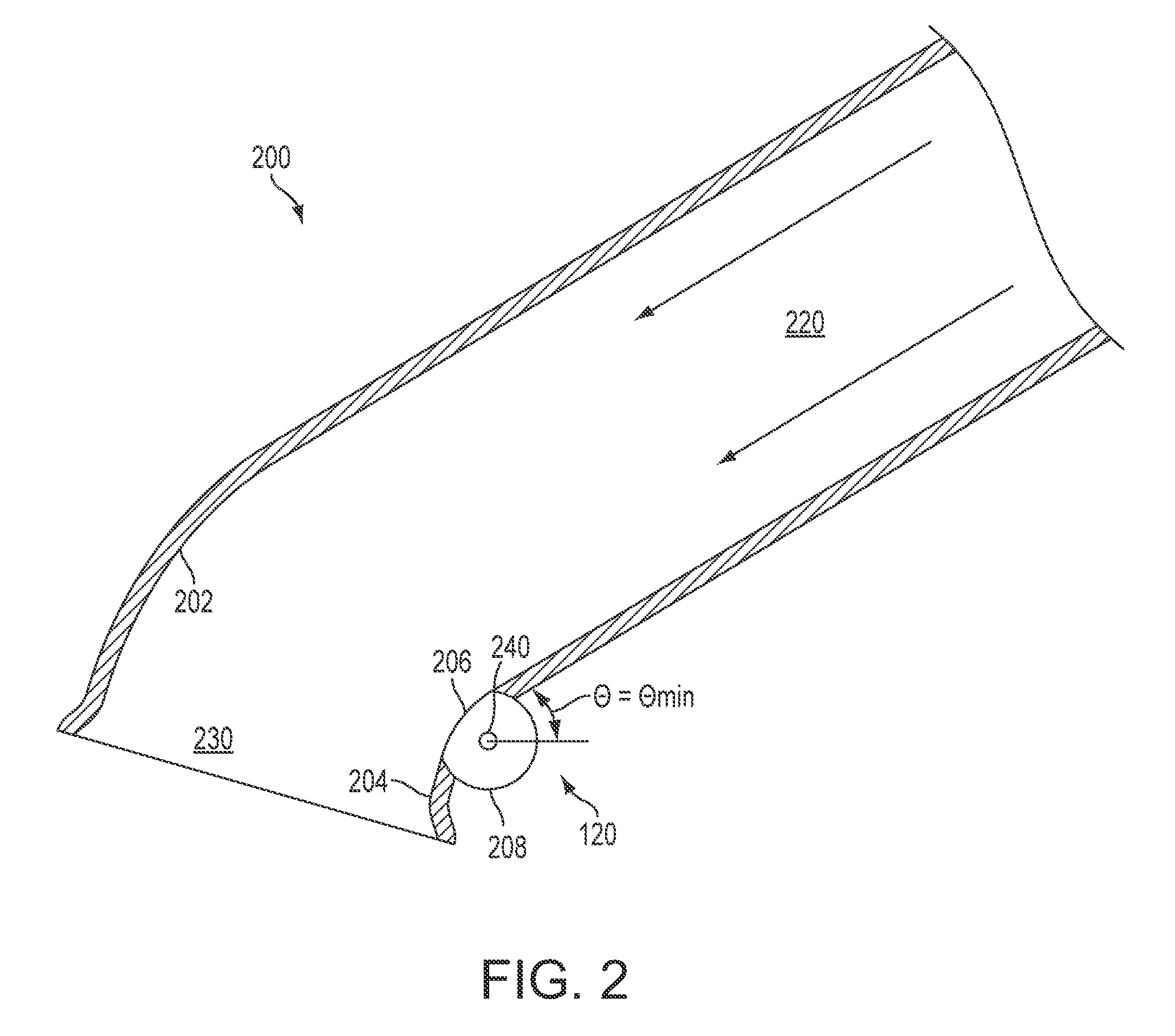

ActiveUS7311082B2Increase arcSuitable for useElectrical controlMachines/enginesExternal combustion engineElectronic throttle

Owner:YAMAHA MOTOR CO LTD

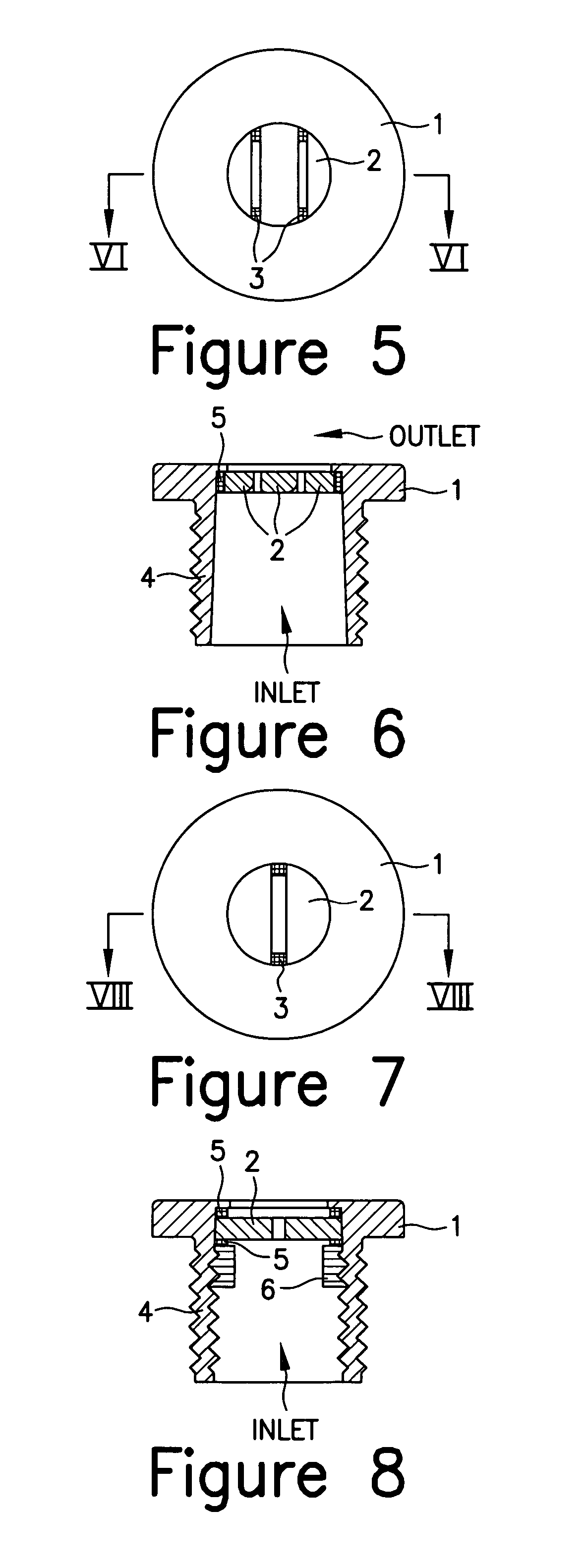

Method for fluid jet formation and apparatus for the same

A nozzle having a housing and an assembly including at least two conjugated parts separated by a spacer seal. The assembly is arranged in the housing so as to form a nozzle outlet. At least one of he housing, the parts, and the spacer seal are deformable so as to define a geometry of the nozzle outlet and seal surfaces between the parts and the spacer seal and between the parts and the housing.

Owner:GESKIN ERNEST +2

Yarn guiding device for textile machinery yarn

ActiveCN109693971ASmooth and smooth entryEasy to handleFilament handlingFibre cleaning/openingYarnFixed frame

The invention discloses a yarn guiding device for textile machinery yarn. The yarn guiding device comprises a fixed frame and a yarn guiding frame; the yarn guiding frame comprises an arc-shaped rotating plate and an arc-shaped fixed plate; an upper pressure roller is arranged at the right end of the arc-shaped rotating plate, and the left end of the arc-shaped rotating plate is connected with anadjusting air cylinder; a lower pressure roller is arranged at the right end of the arc-shaped fixed plate, and a yarn arranging wheel is arranged on the arc-shaped fixed plate; and a first yarn guiding roller is arranged between the yarn arranging wheel and a yarn leading roller, and a second yarn guiding roller is arranged between the yarn arranging wheel and the lower pressure roller. The yarntransferred from different angles can be led, the yarn is prevented from being broken in the transferring process, burrs and impurities on the surface of the yarn can be removed in the yarn leading process through the design of the yarn arranging wheel, thus the surface of the yarn is smoother and flatter, and the quality of the yarn is improved; and meanwhile, electrostatic friction generated inthe yarn transferring process can be removed through a electrostatic eliminating assembly, and the problems of yarn fault increasing, yarn breaking and flying are reduced.

Owner:绍兴华清化纤纺织有限公司

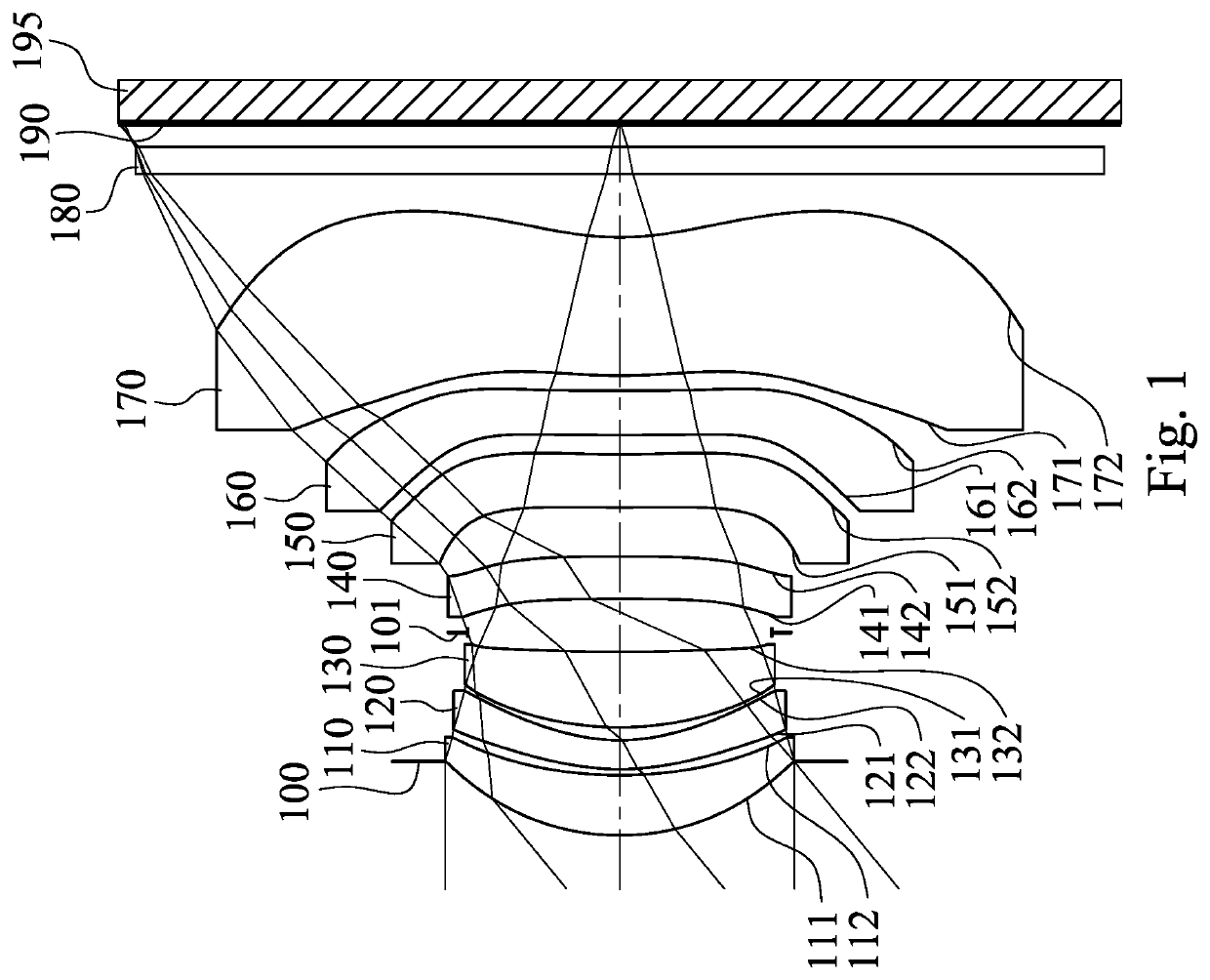

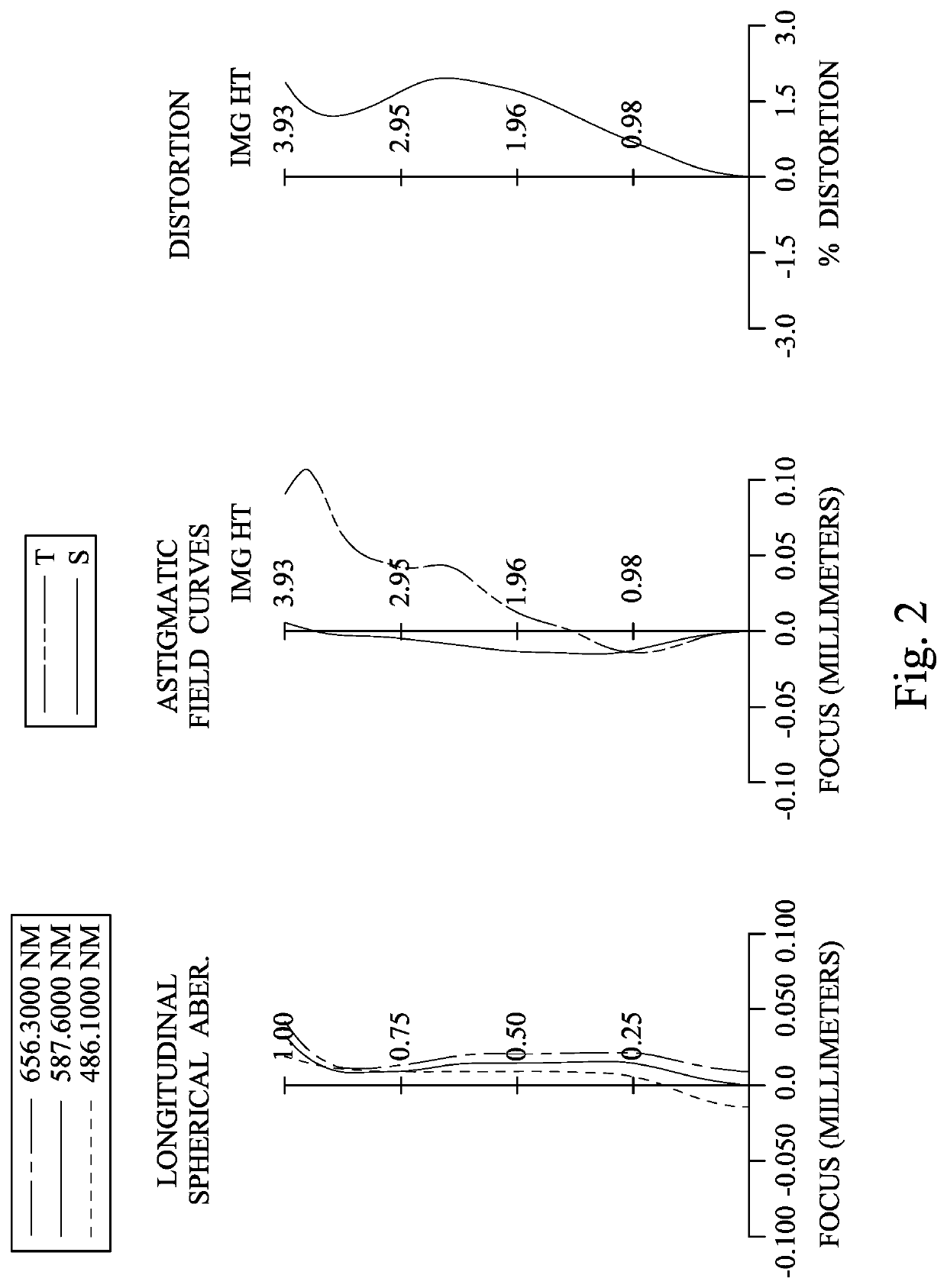

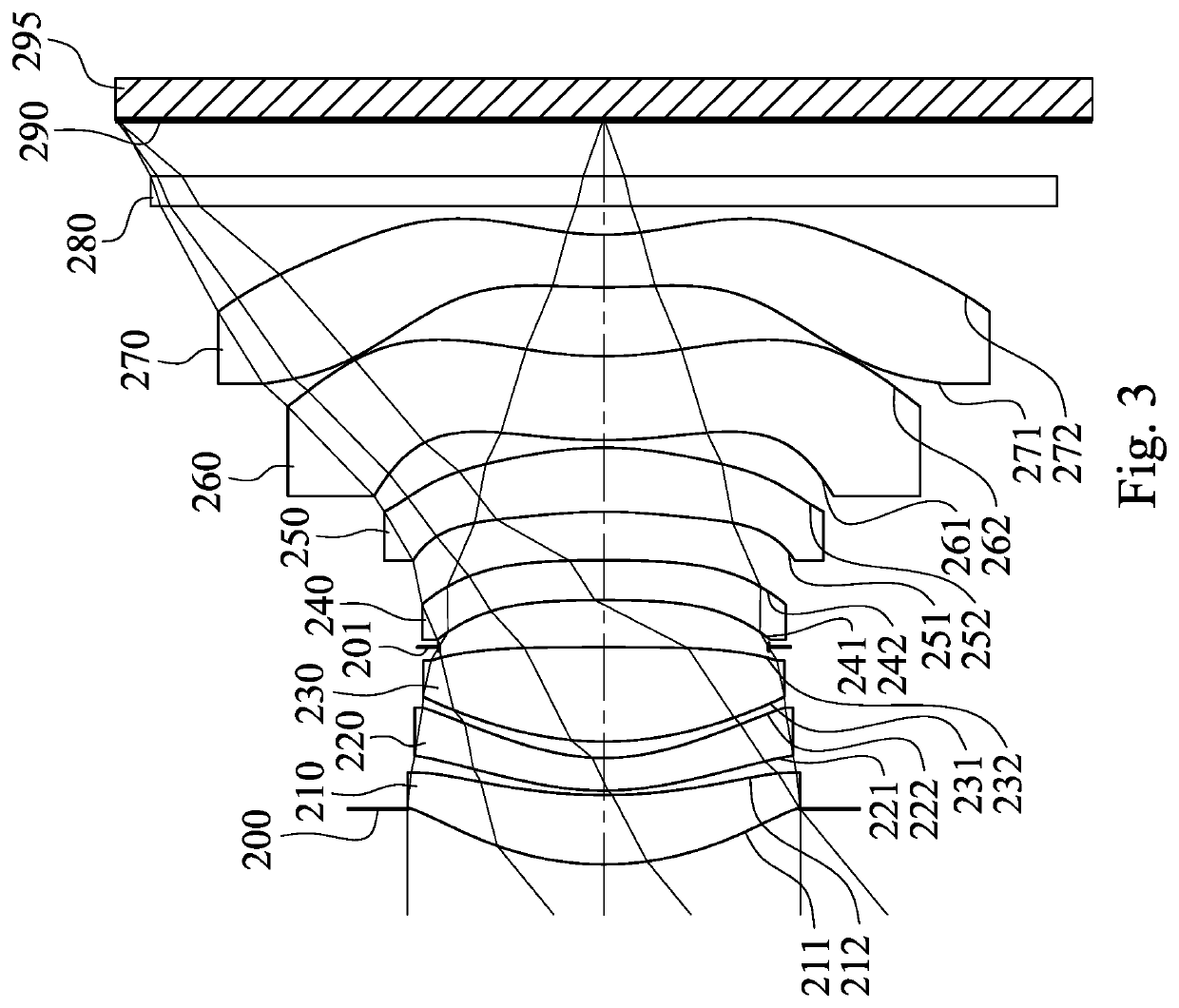

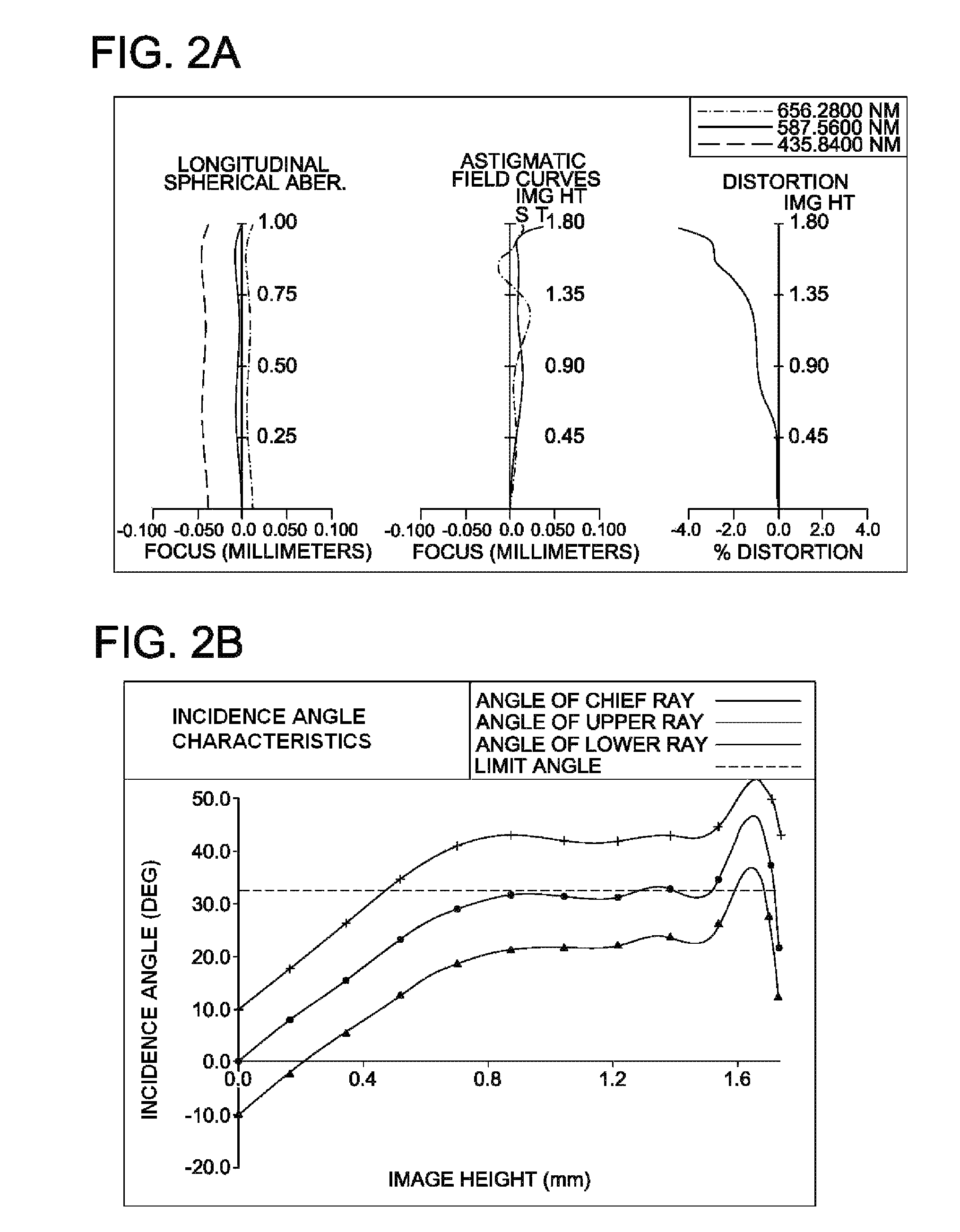

Photographing optical lens assembly, imaging apparatus and electronic device

ActiveUS20190353874A1Add light refraction effectAberration correctionOptical elementsElectronElectronic equipment

A photographing optical lens assembly includes seven lens elements, the seven lens elements being, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, a sixth lens element and a seventh lens element. Each of the seven lens elements includes an object-side surface facing towards the object side and an image-side surface facing towards the image side. The image-side surface of the seventh lens element is concave in a paraxial region thereof and includes at least one inflection point in an off-axis region thereof.

Owner:LARGAN PRECISION

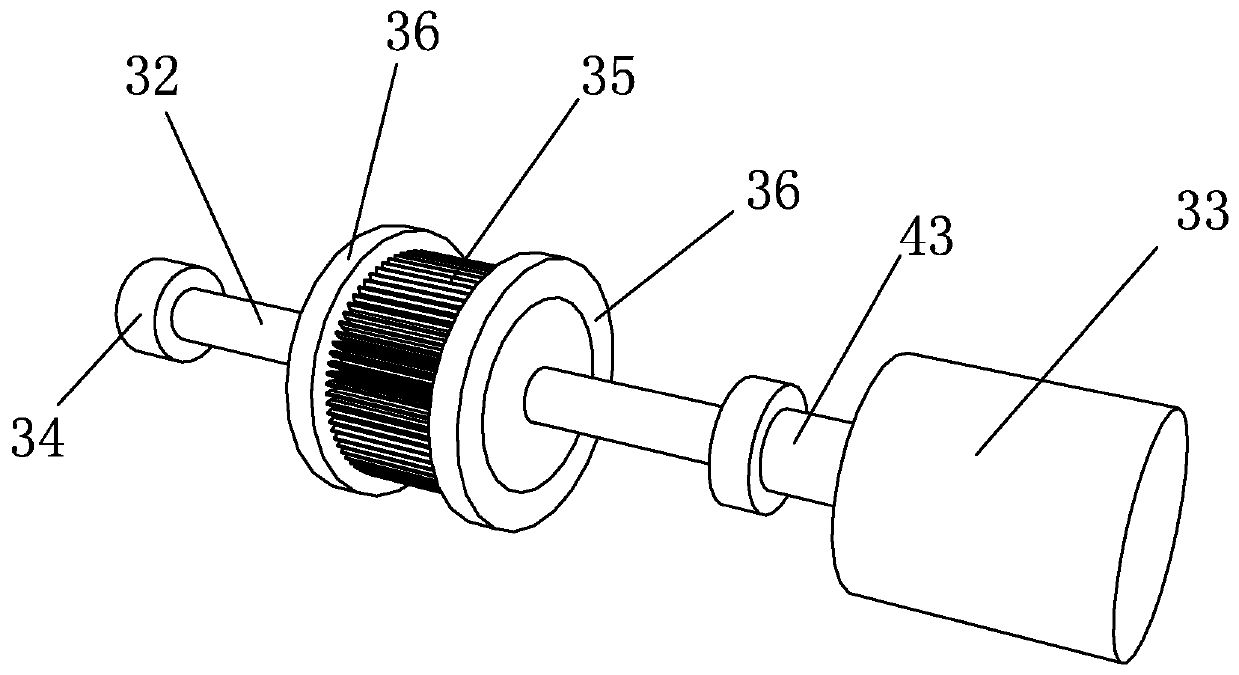

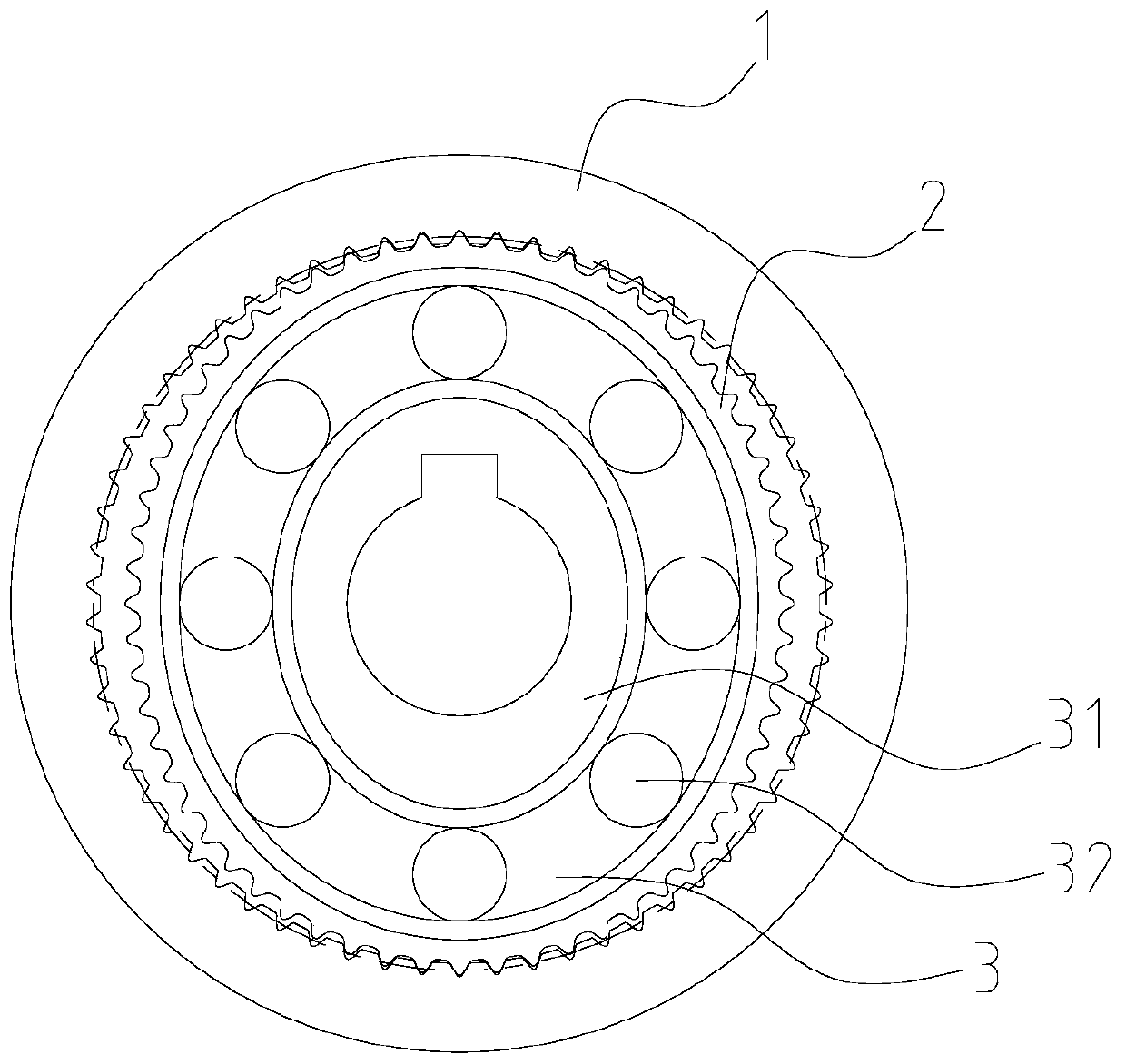

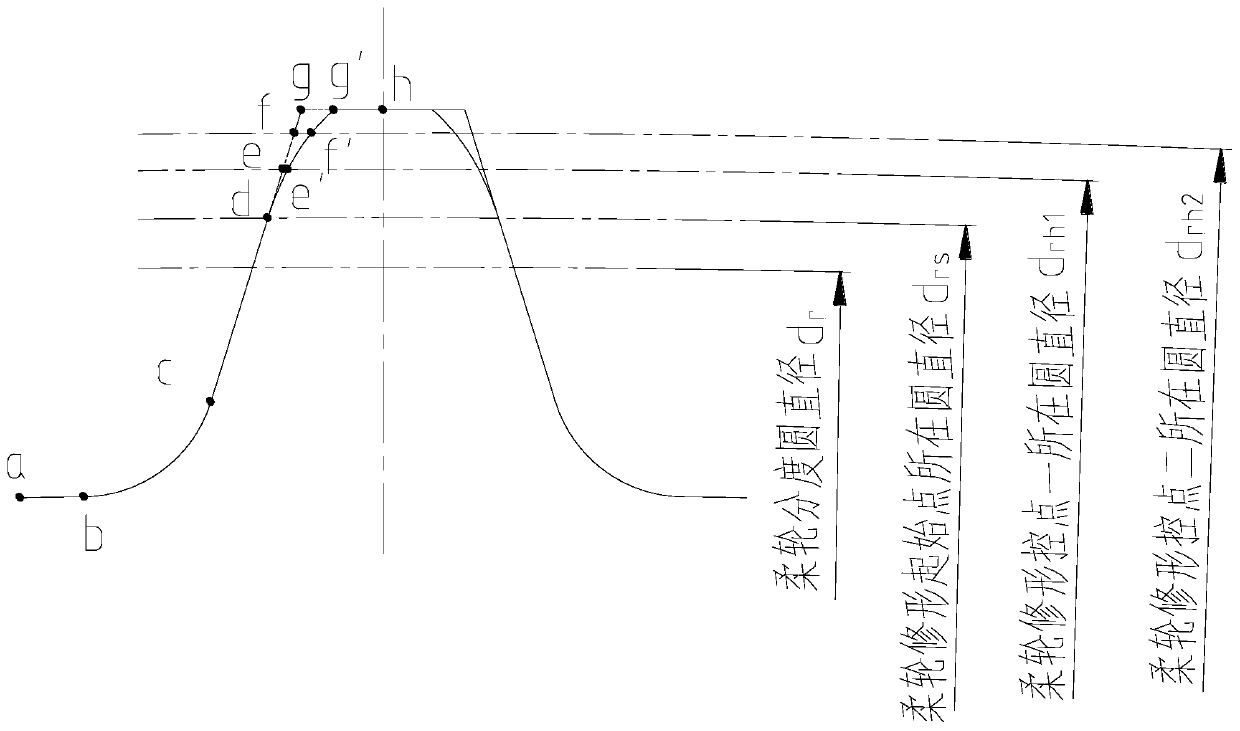

Involute harmonic gear shaping method and harmonic reducer

The invention discloses an involute harmonic gear shaping method, and comprises the following shaping steps that A) a flexible gear shaping step: (1) calculating the gear modulus of the flexible gearthrough a formula; (2) obtaining the tooth profile basic elements of the flexible gear according to the calculation, and drawing the original involute tooth profile of the flexible gear; (3) obtaininga left tooth surface involute tooth profile curve before the flexible gear is not modified according to the tooth profile basic element parameters of the flexible gear, and calculating the shape corrected parameters of the tooth profile of the flexible gear, shaping the tooth top part of the original involute tooth profile of the flexible gear so as to form a smooth curve; and (4) determining a tooth direction correcting parameter according to the tooth width of the flexible gear and the constraint condition that the flexible gear is engaged in or out of the meshing moment and does not generate tooth top interference, correcting the tooth shape in the tooth direction, and completing the final design of the tooth shape. The invention further discloses a harmonic reducer. The harmonic reducer comprises a flexible gear, a rigid gear and a wave generator; and the machining and manufacturing parameters are obtained through calculation according to the shaping method. According to the method and the device, the motion performance of the harmonic gear can be improved, and the manufacturing cost is low.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

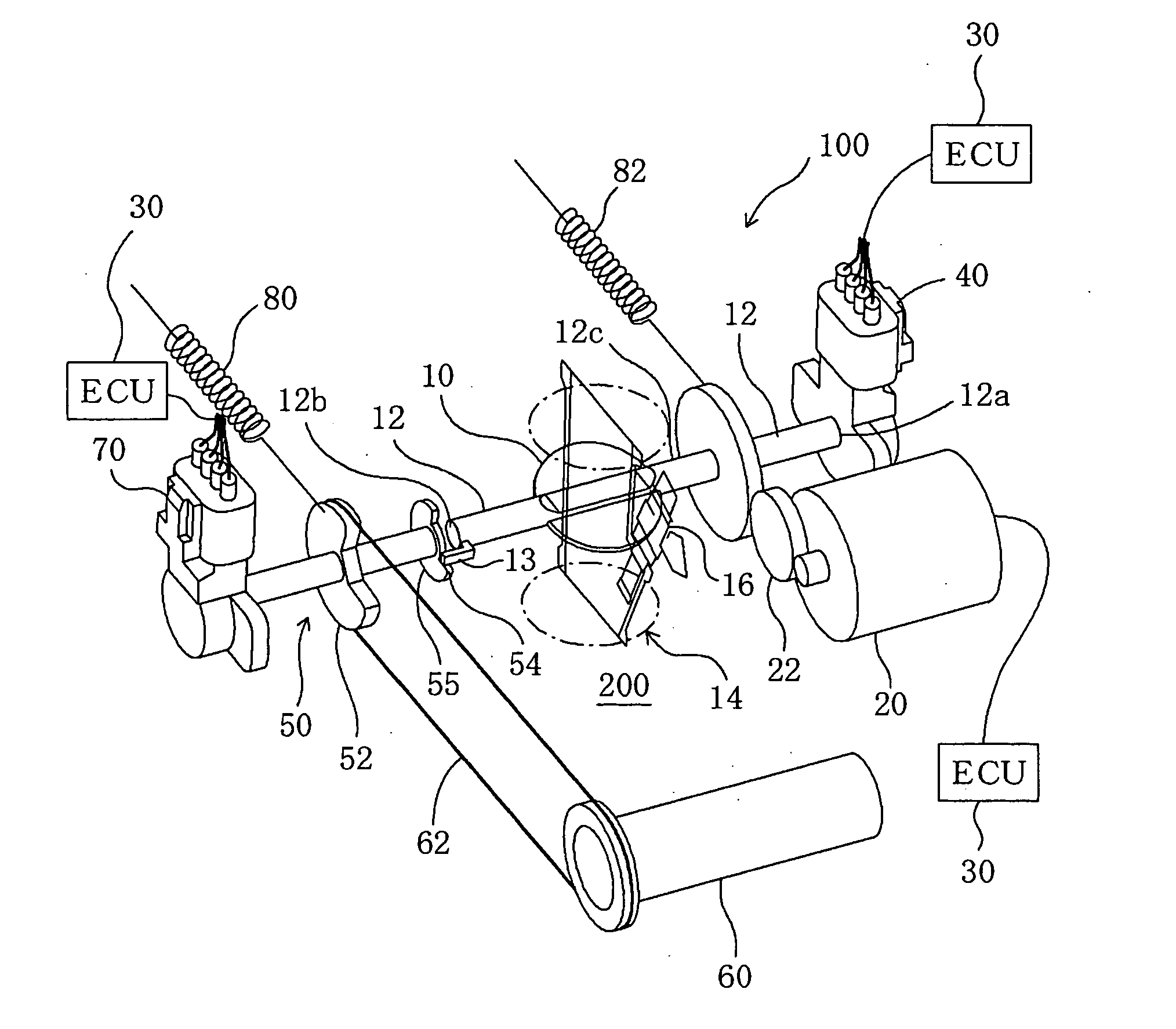

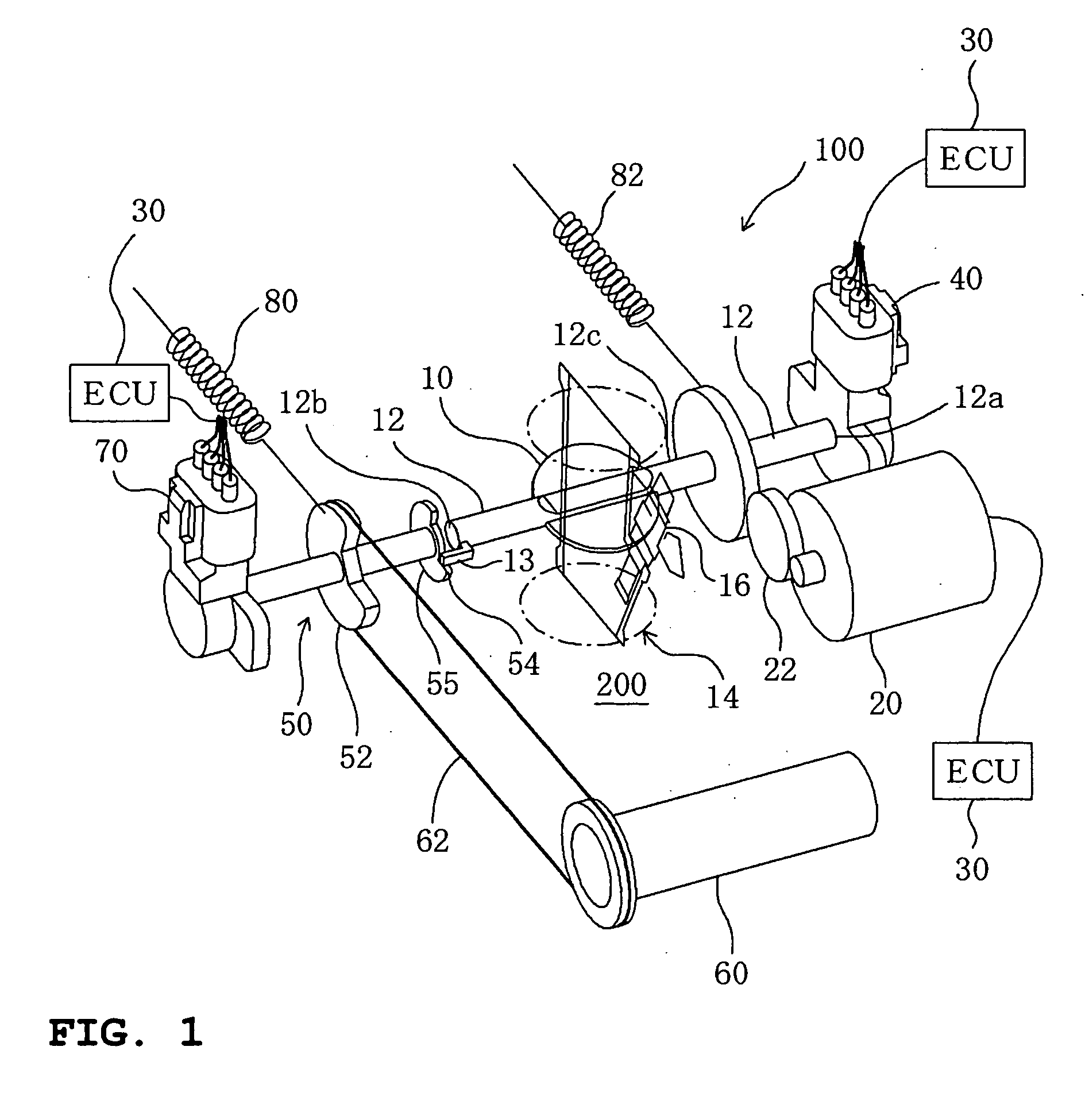

Straddle type vehicle having an electronic throttle valve system

ActiveUS20060243246A1Suitable for useIncrease arcEngine controllersMachines/enginesInternal combustion engineVALVE PORT

An electronic throttle valve system more suitable for use in straddle type vehicles. A straddle type vehicle has an electronic throttle valve system for adjusting the amount of intake air to an internal combustion engine. The electronic throttle valve system includes a throttle valve for adjusting the amount of intake air to the internal combustion engine, an electric motor for actuating the throttle valve, and a control unit for controlling the electric motor. The throttle valve is fixed to a valve shaft. The electric motor is connected to the valve shaft. The valve shaft is provided with a throttle opening sensor on the right end, and a mechanical, throttle valve actuating mechanism on the left end. A throttle cable is engaged with the mechanism, while being coupled to a throttle grip (acceleration controller) provided on a right one of a pair of handlebars.

Owner:YAMAHA MOTOR CO LTD

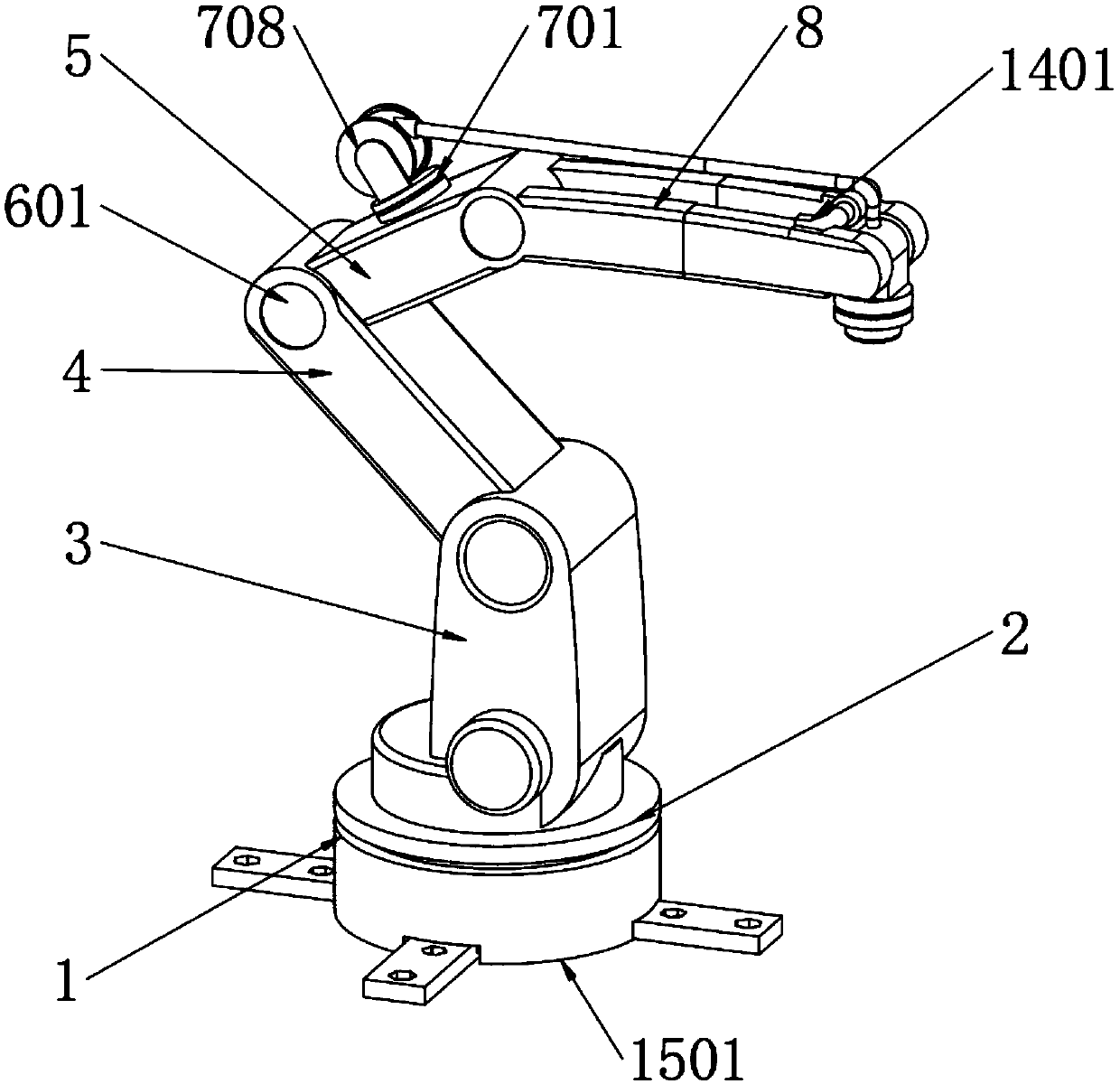

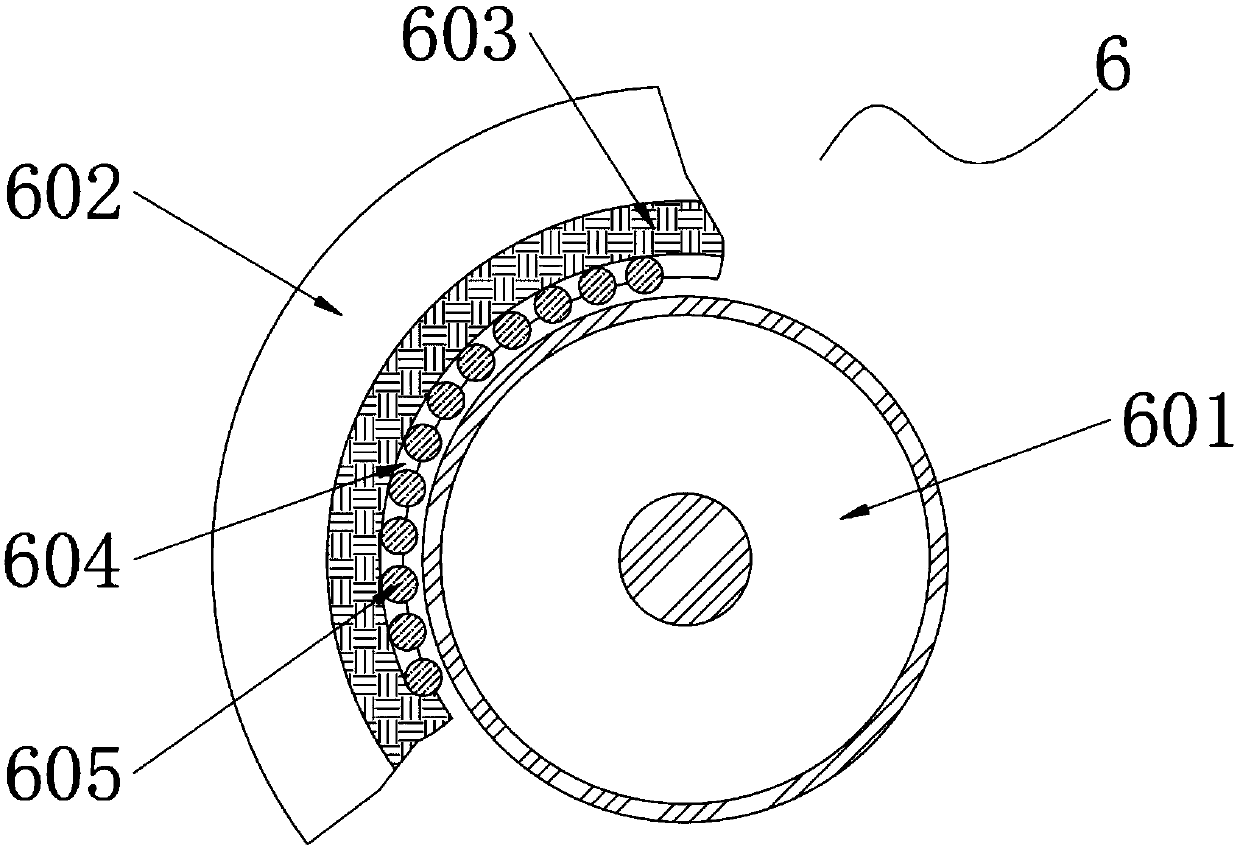

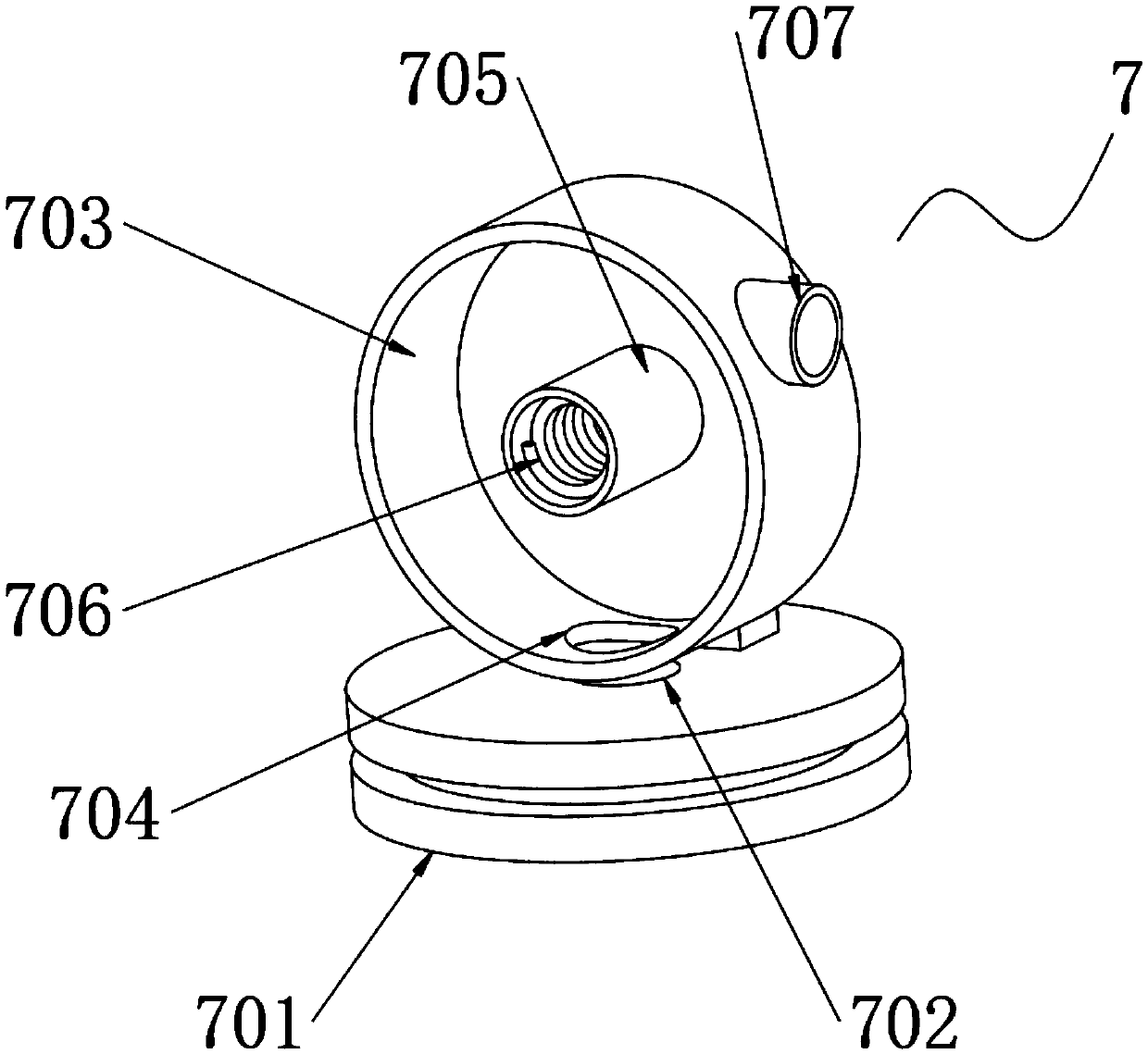

Improved mechanical arm device

ActiveCN109605334AScientific and reasonable structureEasy to useProgramme-controlled manipulatorJointsEngineeringMechanical engineering

The improved mechanical arm device. The improved mechanical arm device comprises a base, wherein a first connecting arm is arranged at the top end of the base, one end of the first connecting arm is provided with a rotating shaft assembly, one side of the rotating shaft assembly is connected with a second connecting arm, and a take-up assembly is arranged at the top end of the second connecting arm. According to the improved mechanical arm device, the structure is scientific and reasonable, the use is safe and convenient, the take-up assembly is arranged, and the functions of a take-up box, atake-up wheel and a spring are achieved so that the mechanical arm connecting line coils can be conveniently wound into the take-up box to be hidden, abrasion caused by the fact that connecting linesare exposed to be wound or in contact with an external object is avoided; due to the elastic action of the spring, the connecting lines can be automatically tightened; and the rotating shaft assemblyis arranged, through the action of an elastic plate and balls, the balls can be conveniently in contact with a rotating shaft through the rotation of the rotating shaft so that the balls can roll andextrude a sponge layer, lubricating oil inside the sponge layer is guided to the surface of the rotating shaft, the rotating shaft is lubricated, the structure is simple, and the use is convenient andfast.

Owner:久智光电子材料科技有限公司

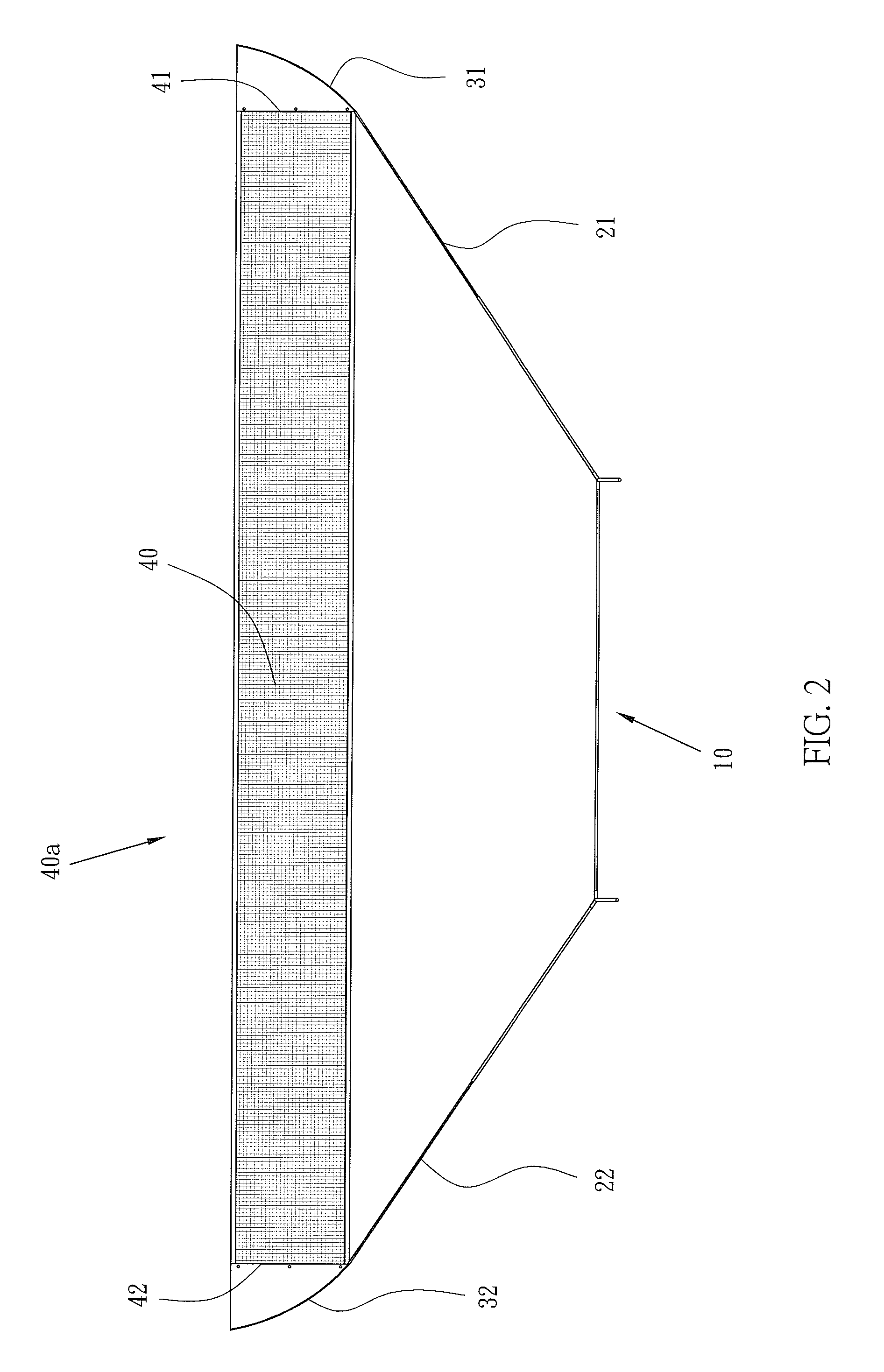

Ball Net Structure

InactiveUS20150057109A1Uniform stress distributionExtended service lifeTennisBall sportsPull forceEngineering

Owner:CHEN BENJAMIN

Method for fluid jet formation and apparatus for the same

A nozzle having a housing and an assembly including at least two conjugated parts separated by a spacer seal. The assembly is arranged in the housing so as to form a nozzle outlet. At least one of he housing, the parts, and the spacer seal are deformable so as to define a geometry of the nozzle outlet and seal surfaces between the parts and the spacer seal and between the parts and the housing.

Owner:GESKIN ERNEST +2

Imaging lens, imaging device, and mobile terminal

Owner:KONICA MINOLTA OPTO

Clamp structure

ActiveUS8701254B2Improve yieldFirmly connectedSnap fastenersSolar heating energyJunction boxEngineering

A clamp structure includes a base plate, a pair of first jaws, and a pair of second jaws. The first jaws extend respectively from two sides of the base plate in a face-to-face manner and form a first jaw opening at their ends. The first jaws are also formed with a pair of cutouts that face each other. The second jaws extend respectively from the pair of cutouts towards the base plate and form a second jaw opening at their ends. Each second jaw has a hook-shaped configuration composed of a first arc near the second jaw opening and a second arc away from the base plate, wherein the first arc has a greater curvature than the second arc. A junction box and a solar panel which are bonded together can be inserted into and thus clamped by the clamp structure so as to be secured against lateral shifting.

Owner:KS TERMINALS INC

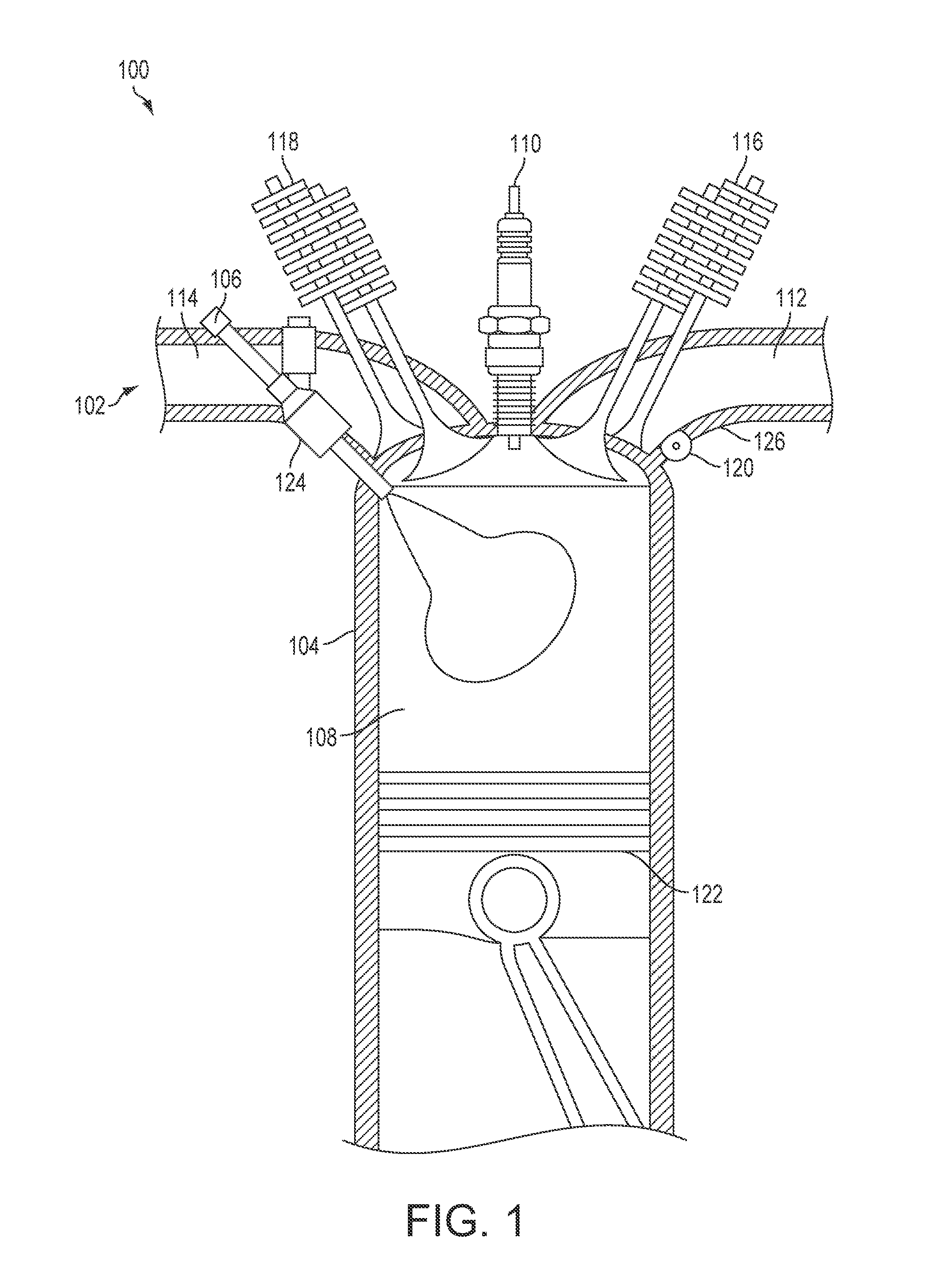

Rotatable valve in a cylinder intake duct

ActiveUS8430074B2Increase burn rateImprove combustion stabilityInternal combustion piston enginesCylinder headsEngineeringOperant conditioning

A spark ignition direct injection fuel cylinder for an engine includes a rotatable valve at a curved wall of an intake duct. The rotatable valve provides a variable step in to adjust the degree of tumble airflow while reducing flow restriction to improve engine performance across operating conditions.

Owner:FORD GLOBAL TECH LLC

Introducer for deploying a stent graft in a curved lumen and stent graft therefor

A stent graft (18) for deployment in a curved lumen such as the aortic or thoracic arch (130) comprises a constraining mechanism at its proximal end. A stent (4′) provided at the proximal end of the stent graft (18) includes loops of material (11) that co-operate with restraining wires (42) that extend between a central guide wire carrier (24) and a restraining wire cannula (8). The constraining mechanism acts to maintain the proximal stent (4′) constrained at three points around its circumference at both the proximal and distal ends of the proximal stent (4′). The proximal stent (4′) is thus allowed to expand after expansion of the remainder of the stent graft (18) during deployment. In an embodiment, the constraining mechanism acts to constrain two adjacent struts of the proximal stent (4′) at three points radially therearound, at the proximal end of the stent (4′) and at the distal end of the stent (4′). The proximal stent (4′) may then overlap with the interior of an adjacent stent at an inner part (31) of a curved vessel.

Owner:COOK MEDICAL TECH LLC

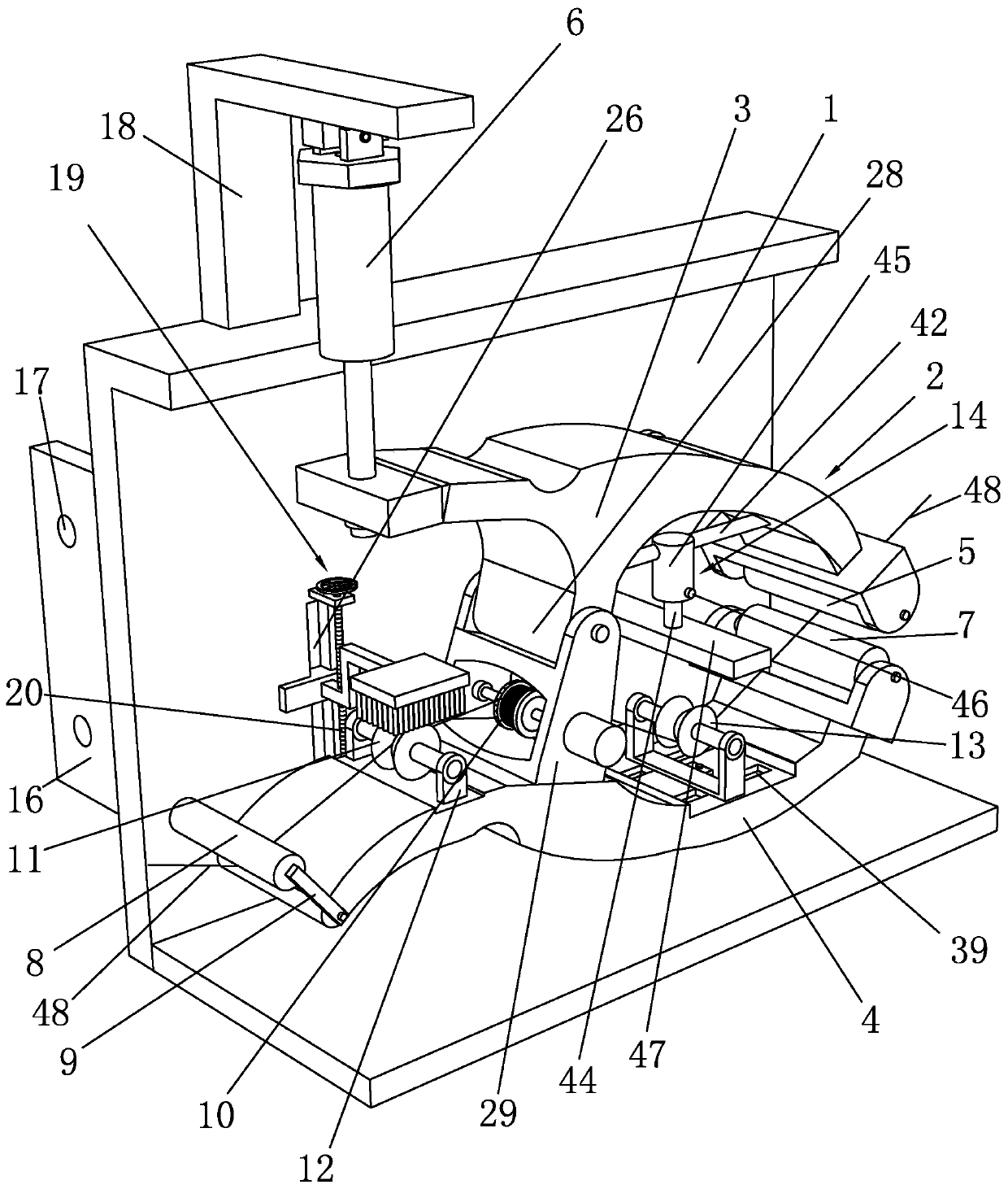

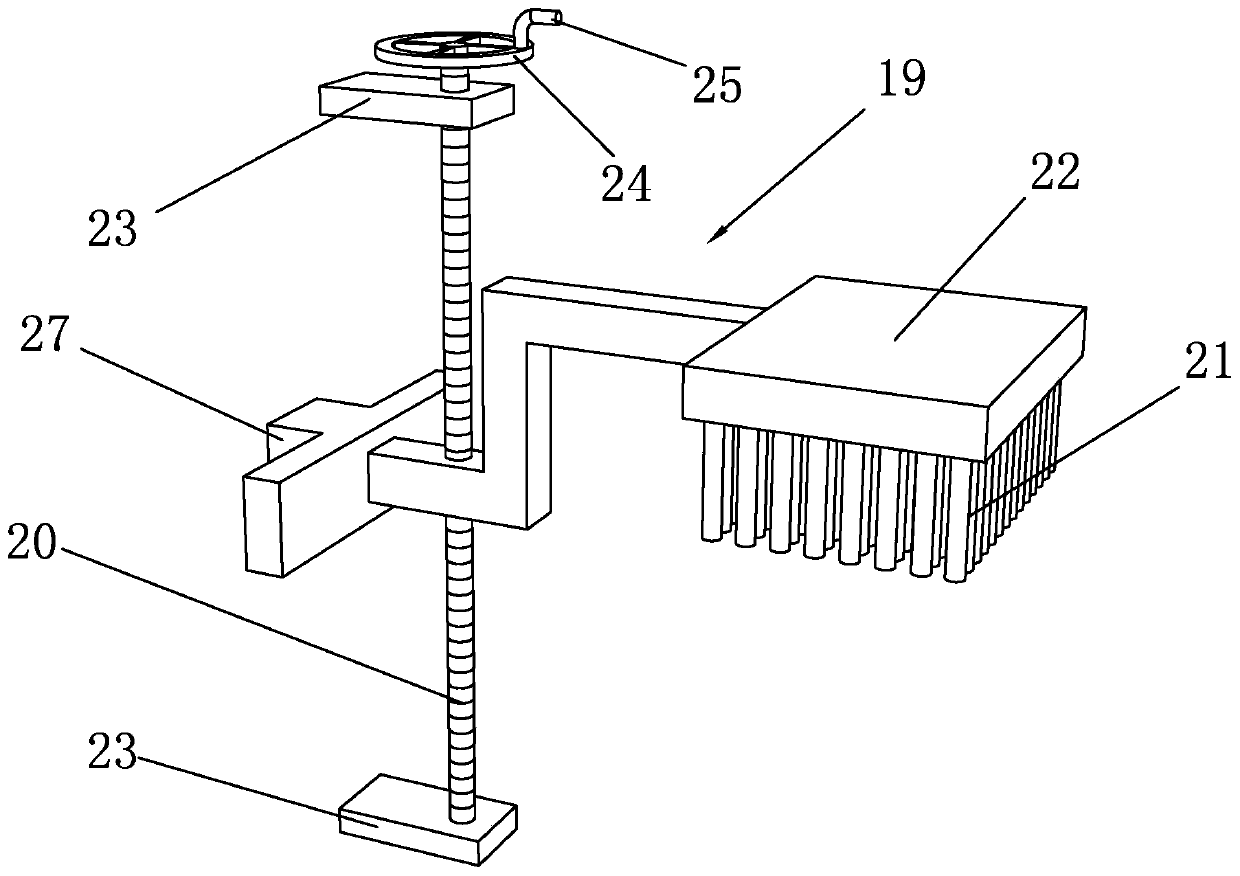

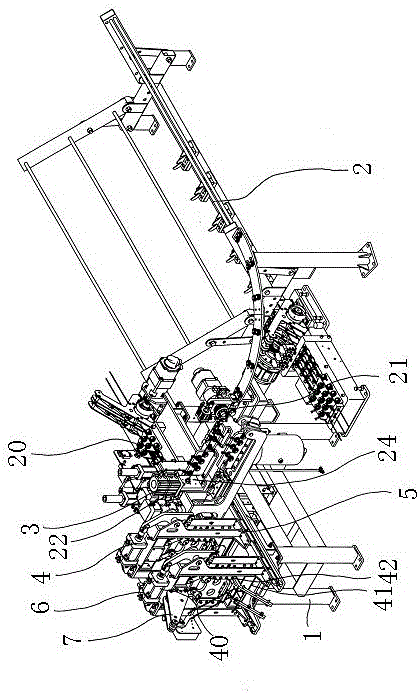

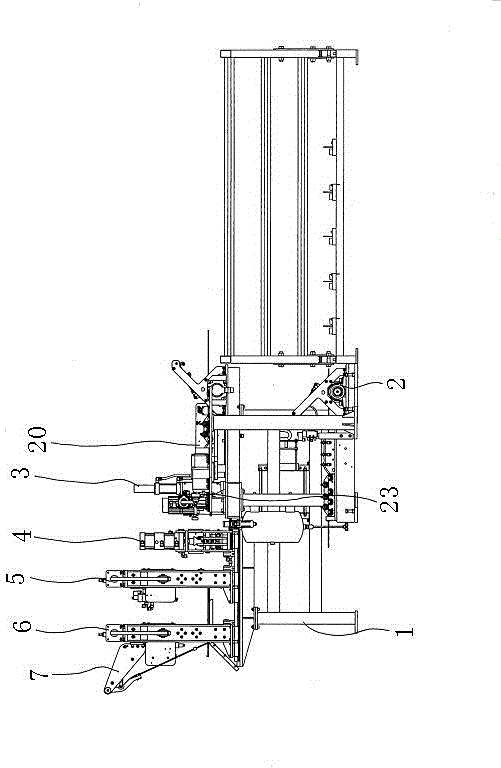

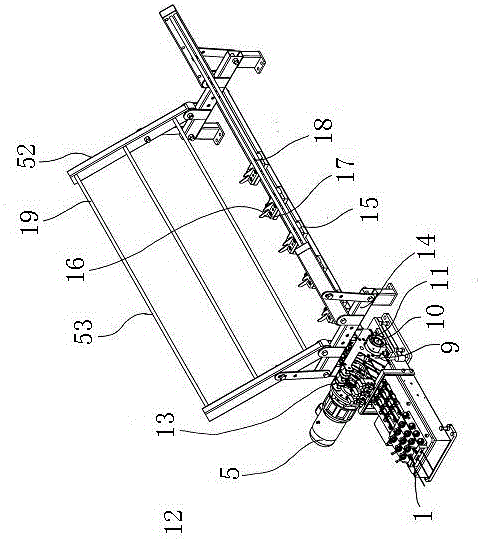

Culture net cage door welding device and cage door welding method

The invention belongs to the technical field of welding machines and discloses a culture net cage door welding device and a cage door welding method. The culture net cage door welding device has main technical characteristics that the culture net cage door welding device comprises a rack, a feeding and buffering frame, a cage door frame welding mechanism, a reinforced transverse wire welding mechanism, a longitudinal wire cutting mechanism, a longitudinal wire bending mechanism and a cage door blanking mechanism, wherein the longitudinal wire cutting mechanism is located in front of the longitudinal wire bending mechanism. The feeding and buffering frame can be used for automatically finishing paying-off work and a motor does not need to be frequently started; the service life of the motor is long and the tension of metal wires is consistent, so that a welded wire net has high quality; the end face of a reinforced transverse wire end is arc-shaped, is tightly fitted to the side face of a cage door frame longitudinal wire and is not trimmed so that a hanging head is not formed and a procedure of trimming again is saved; the wire is slightly pressed and then is cut off, and the longitudinal wire is finally bent; and with the adoption of the structure and the method, the stretching of a front metal wire, caused by a cage door, is avoided.

Owner:河北骄阳焊工有限公司

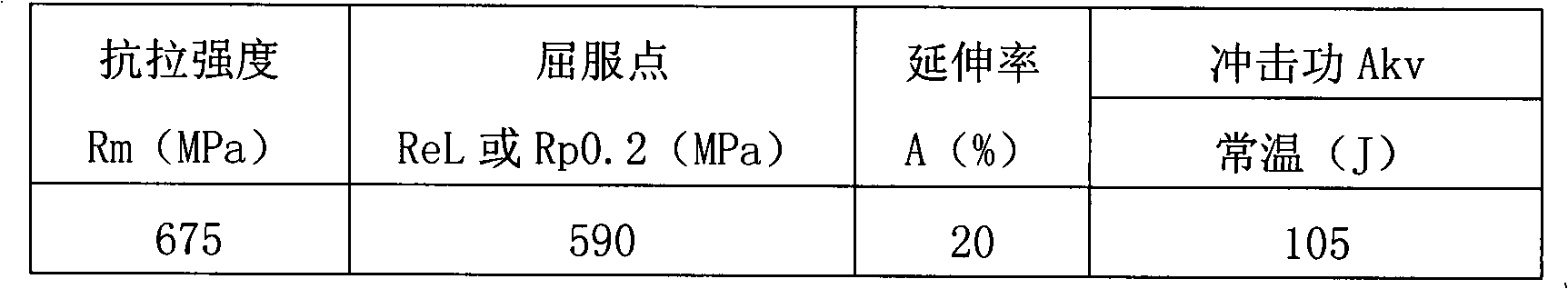

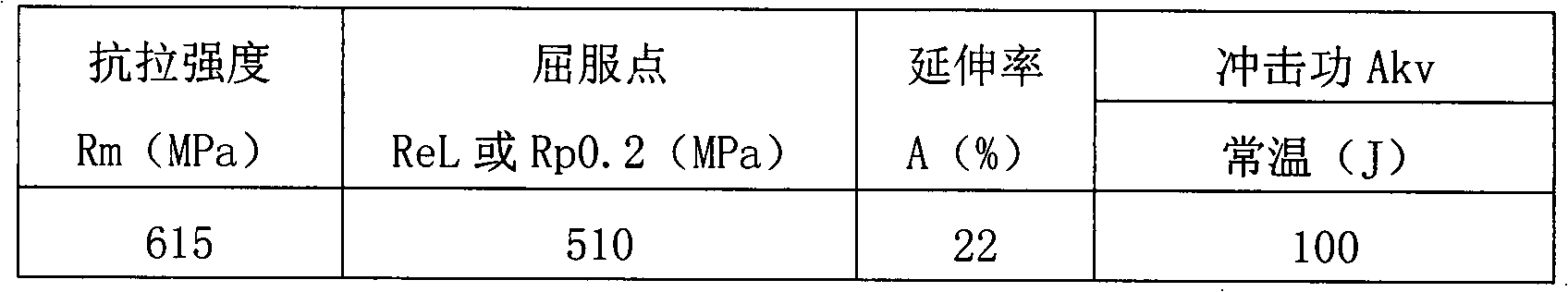

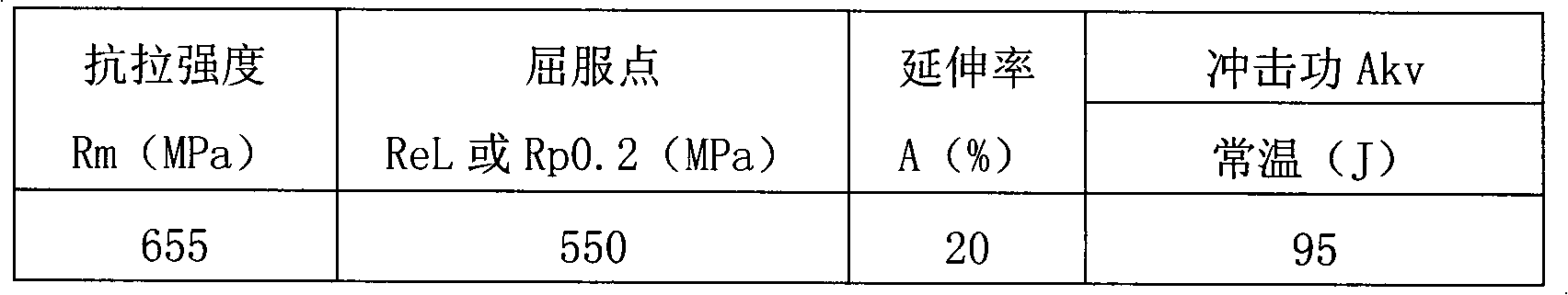

Gas protective welding flux cored wire for welding heat resistant steel

ActiveCN102489901ALow diffusible hydrogen contentImprove performanceWelding/cutting media/materialsSoldering mediaFerrosiliconMolten slag

The invention belongs to a gas protective welding flux cored wire for welding heat resistant steel. The gas protective welding flux cored wire comprises low-carbon steel metal skin and a flux core, wherein the low-carbon steel metal skin comprises the following components in percentage by weight: 0.01 to 0.1 percent of C, 0.1 to 0.4 percent of Mn, 0.01 to 0.03 percent of Si, 0.005 to 0.015 percent of S, 0.005 to 0.015 percent of P and the balance of iron; the flux core accounts for 14 to 25 percent of the total weight of the welding wire and comprises the following components in percentage by weight: 1.2 to 3.0 percent of medium-carbon ferromanganese, 0.20 to 2.0 percent of ferrosilicon powder, 0.05 to 0.5 percent of magnesium powder, 1.5 to 2.0 percent of metal chromium powder, 0.2 to 2.0 percent of ferromolybdenum powder, 0.05 to 0.2 percent of electrically fused magnesia, 0.01 to 0.3 percent of fluoride and 7 to 15 percent of iron powder; and the components are mixed uniformly, the mixture is coiled on a thin steel strip made of low-carbon steel to form strips, and the strips are drawn to form wires. The gas protective welding flux cored wire has the characteristics of no molten slag on deposited metal after welding, capability of performing continuous multi-layer welding without slag removal, high welding process property, stable electric arcs, small splatter, attractive appearance of weld joints and the like, the welding efficiency is improved by 20 to 40 percent, and vertical downward welding can be realized by short circuiting transfer.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

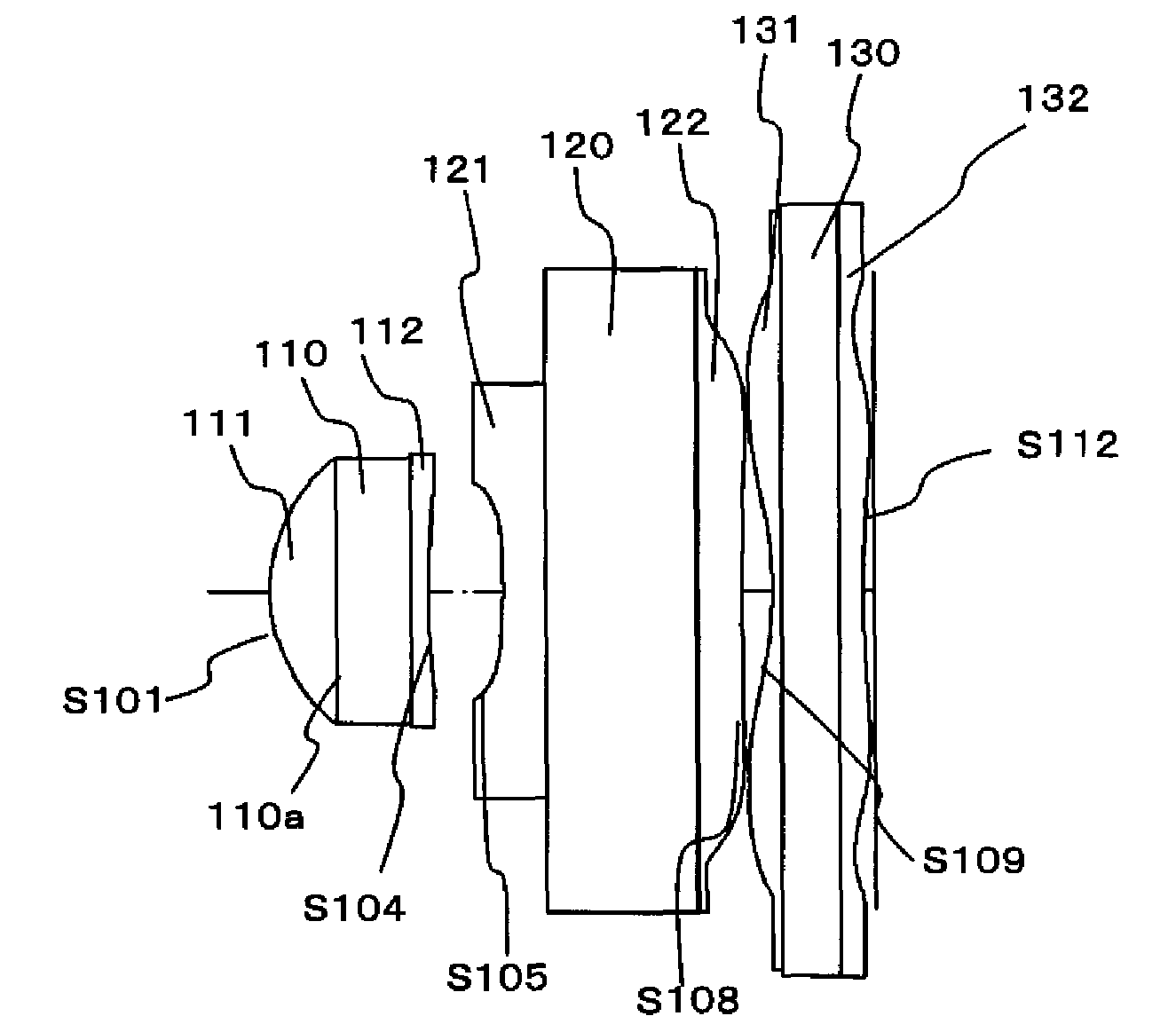

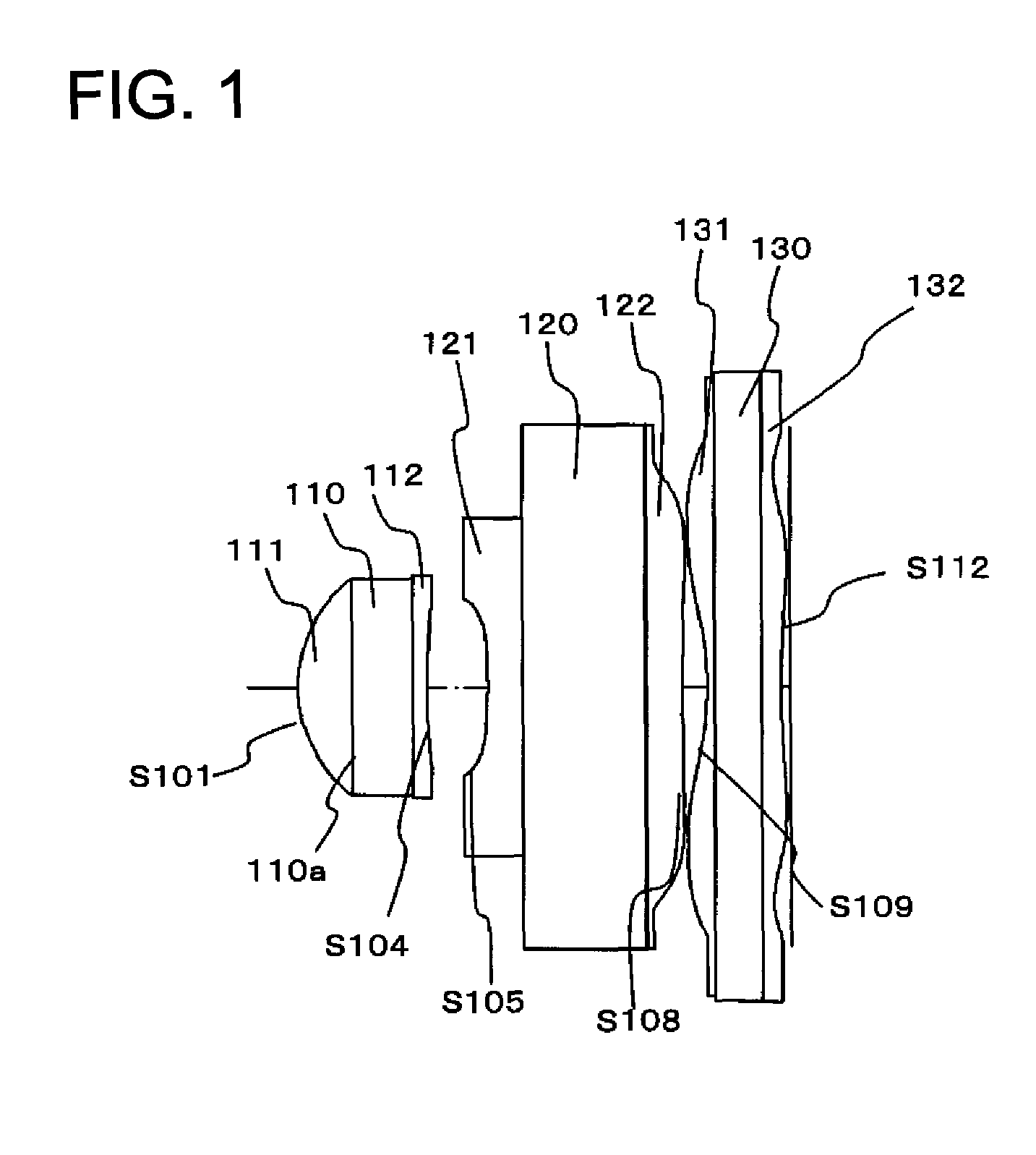

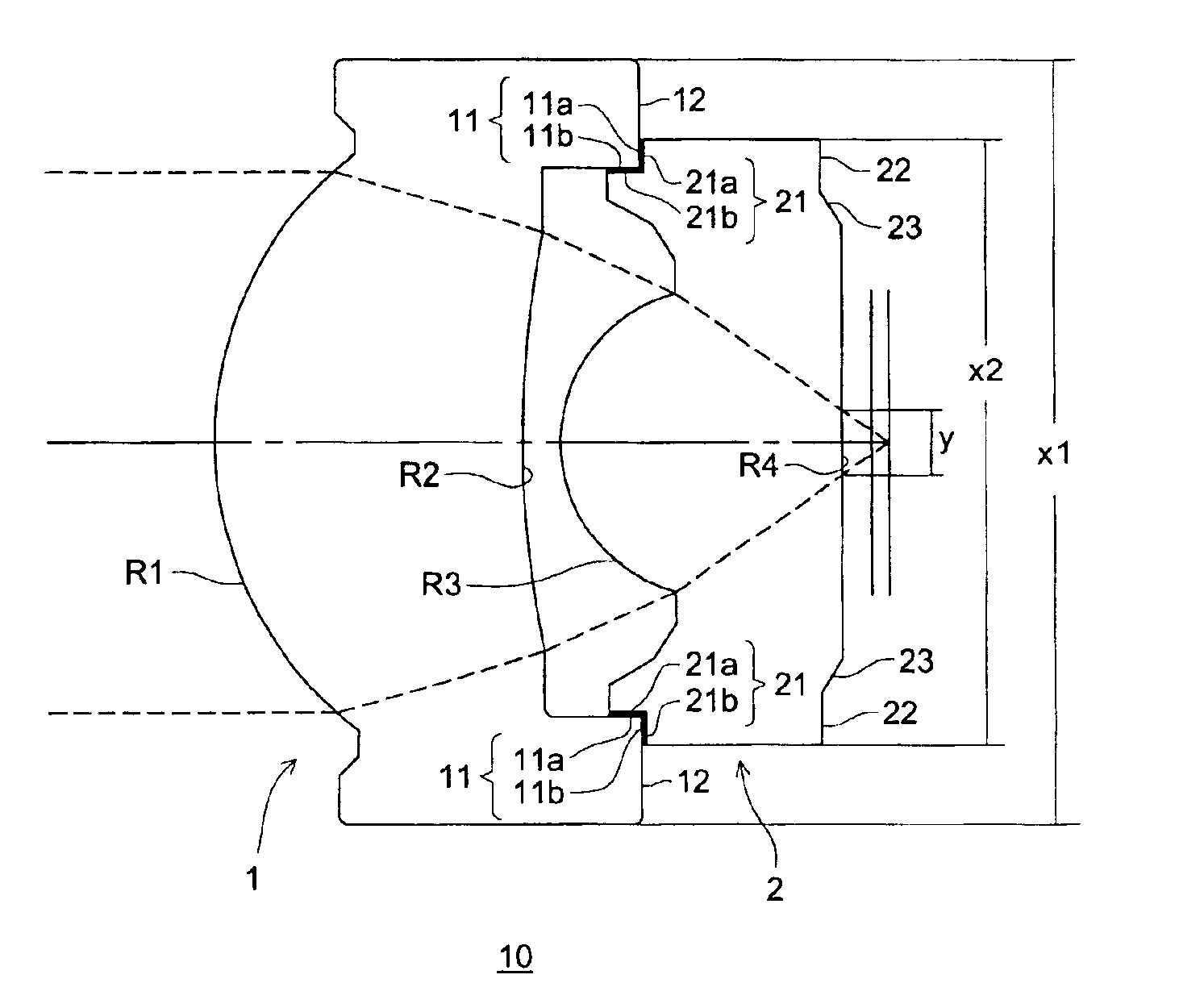

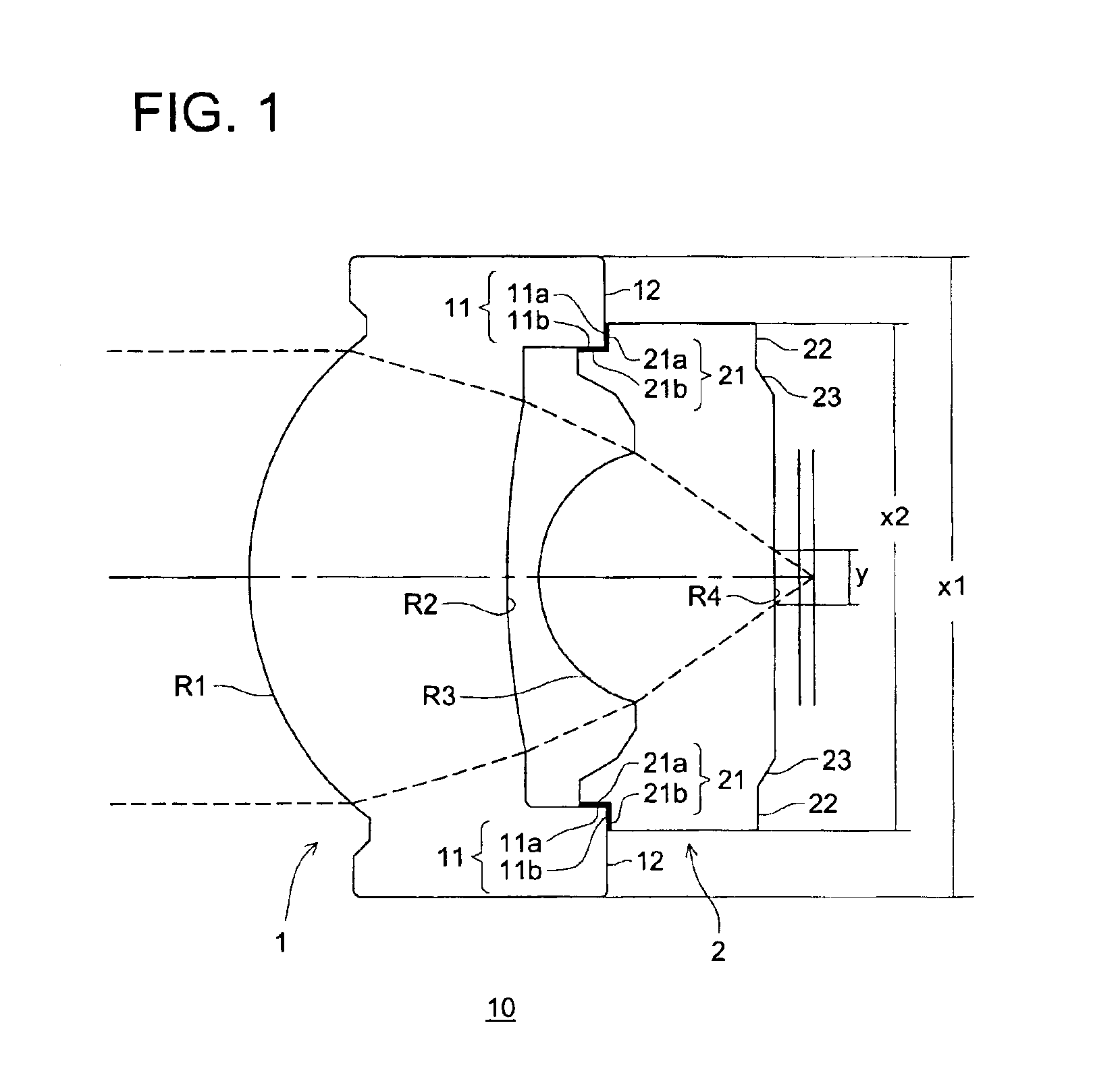

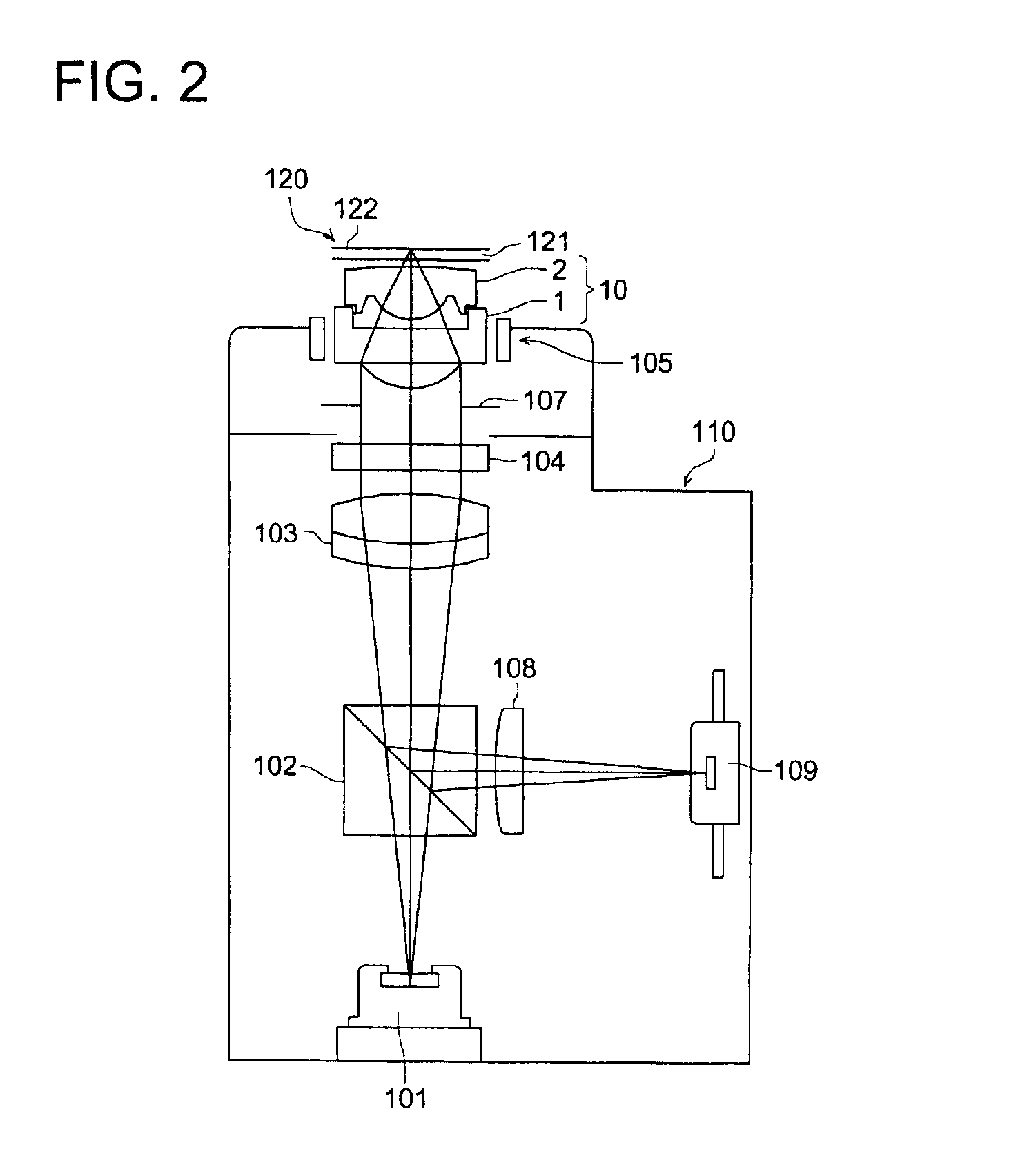

Objective lens for use in optical pickup apparatus and optical pickup apparatus

InactiveUS6919996B2Small apertureEasy to produceRecord information storageOptical beam guiding meansOptical pickupEngineering

An objective lens for use in an optical pickup apparatus, comprises a first lens molded with a plastic and having an optically functional section, flange section provided around the periphery of the optically functional section, and a first contacting section provided on the flange section; and a second lens molded with a plastic, located opposite to the first lens and having an optically functional section, a flange section provided around the periphery of the optically functional section, and a second contacting section provided on the flange section. The first lens and the second lens are joined in such a way that the first contacting section and the second contacting section are brought in contact with each other.

Owner:KONICA CORP

Cooking fume-free energy-gathering frying pan and water vapor circulating pot cover matched with same

ActiveCN104840086AComply with structural requirementsKeep it authenticCooking-vessel lids/coversFree energiesEngineering

The invention discloses a cooking fume-free energy-gathering frying pan and a water vapor circulating pot cover matched with the same. The cooking fume-free energy-gathering frying pan comprises a pan body, a wrapped bottom sheet, a cover sheet and a pan handle, wherein the cover sheet, an aluminum sheet and the wrapped bottom sheet are welded together by adopting a pressure welding method; one surface of the formed cooking fume-free energy-gathering frying pan is a flat surface, one surface is the concave combined wrapped bottom sheet, the flat part is made of stainless iron, the concave part is made of aluminum, and the aluminum concave surface of the combined wrapped bottom sheet is closely welded on the bottom of the pan body. The pot cover mainly comprises a glass sheet, a steel cover handle and a steel cover, wherein the glass sheet is riveted at a middle circular hole of the steel cover by virtue of hot curved tempering. The water vapor circulating pot cover matched with the cooking fume-free energy-gathering frying pan can be used for making fried dishes complete in color, aroma and taste, accords with effects of modern health maintenance, health care, low oil, and low pollution; meanwhile, the pot cover can bidirectionally stand on a desk top without collapse, so that the space is saved, clean and sanitary effects are achieved, and the pan and the cover are novel invention of a cooking tool in a kitchen, and are novel products of new revolution of the cooking tool.

Owner:江门市晶美玻璃制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com