Ball bag built-in sewn ball

A center-mounted, sewing-type technology, applied in the direction of balls, inflatable hollow balls, sports accessories, etc., can solve the problems of lack of curvature, easy collapse of the ball, lack of softness, etc., to achieve uniform softness and broad market Foreground, the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

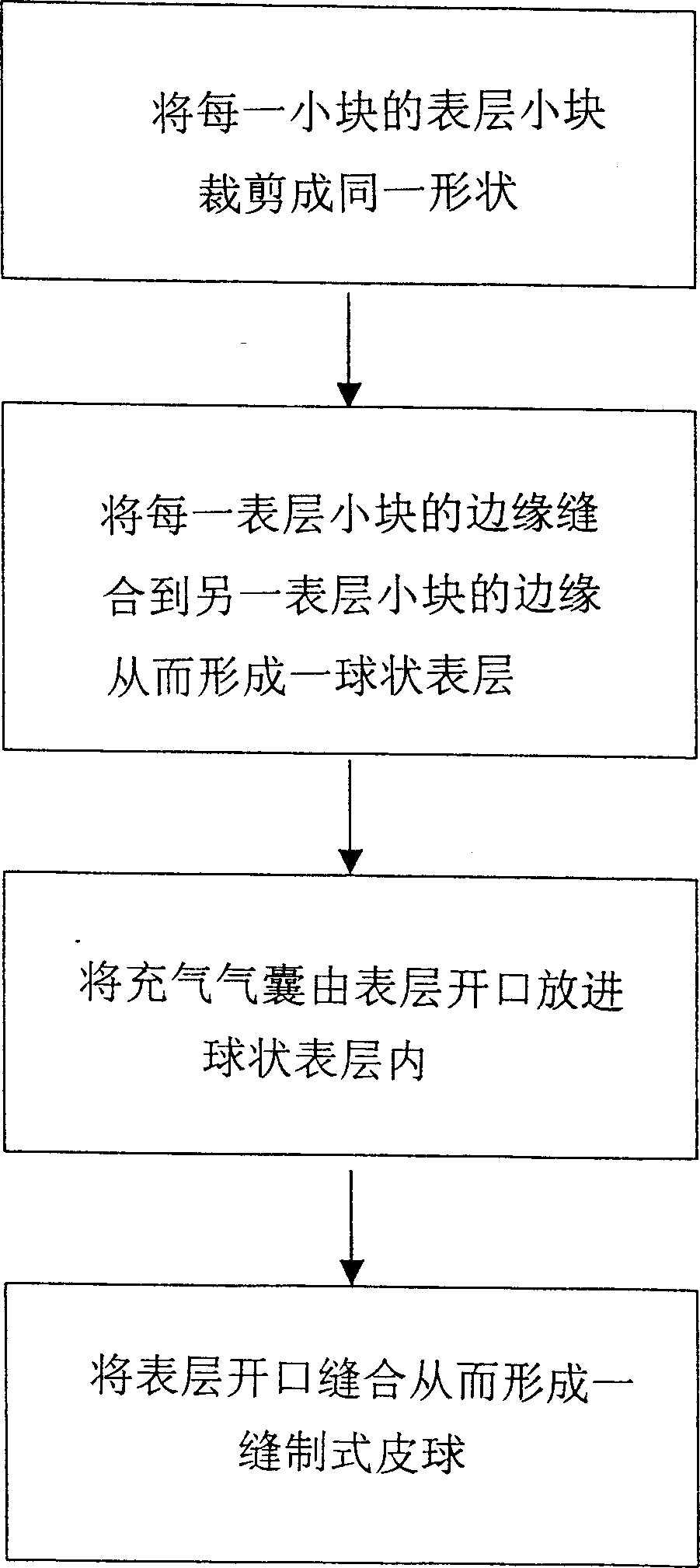

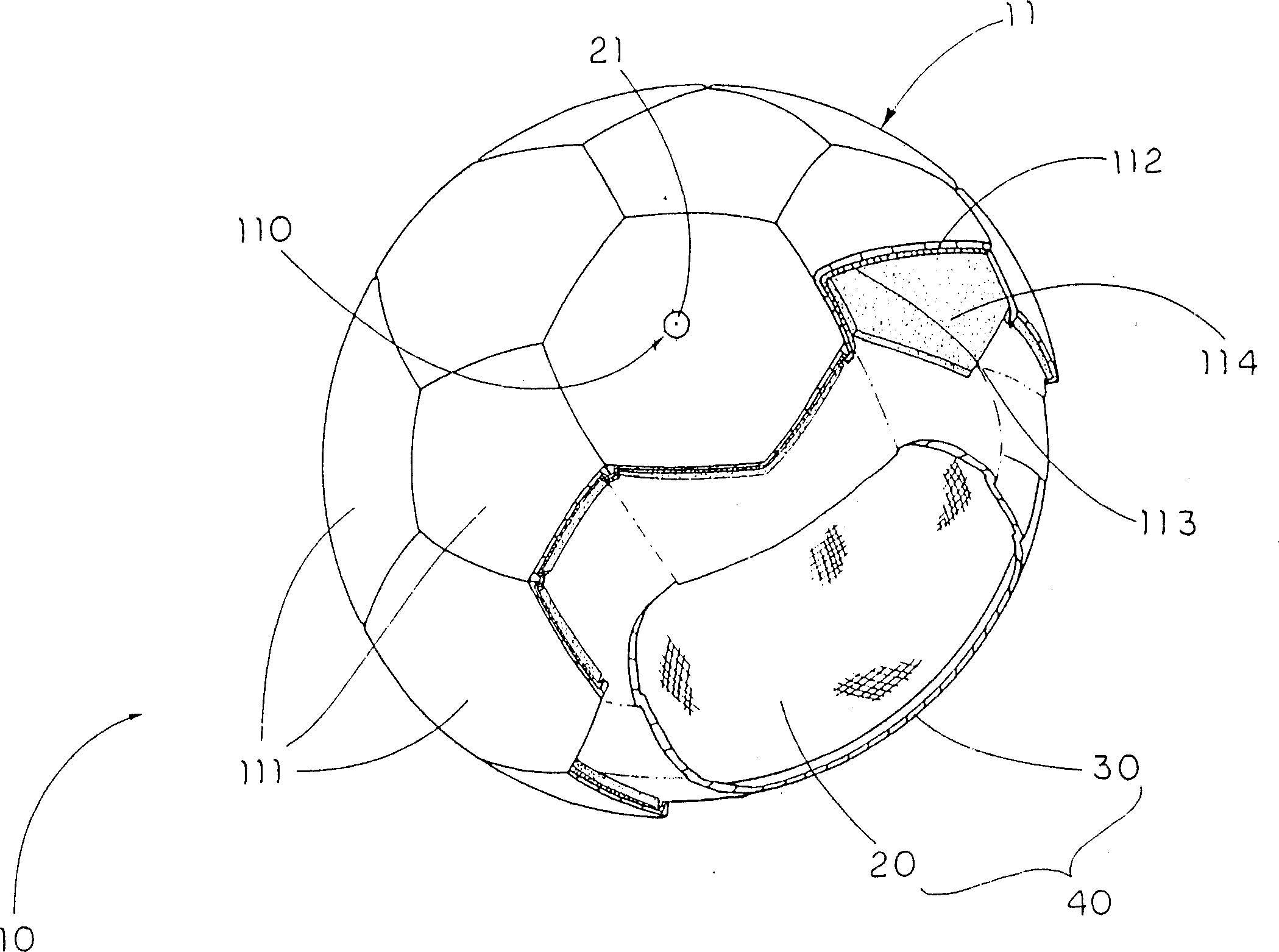

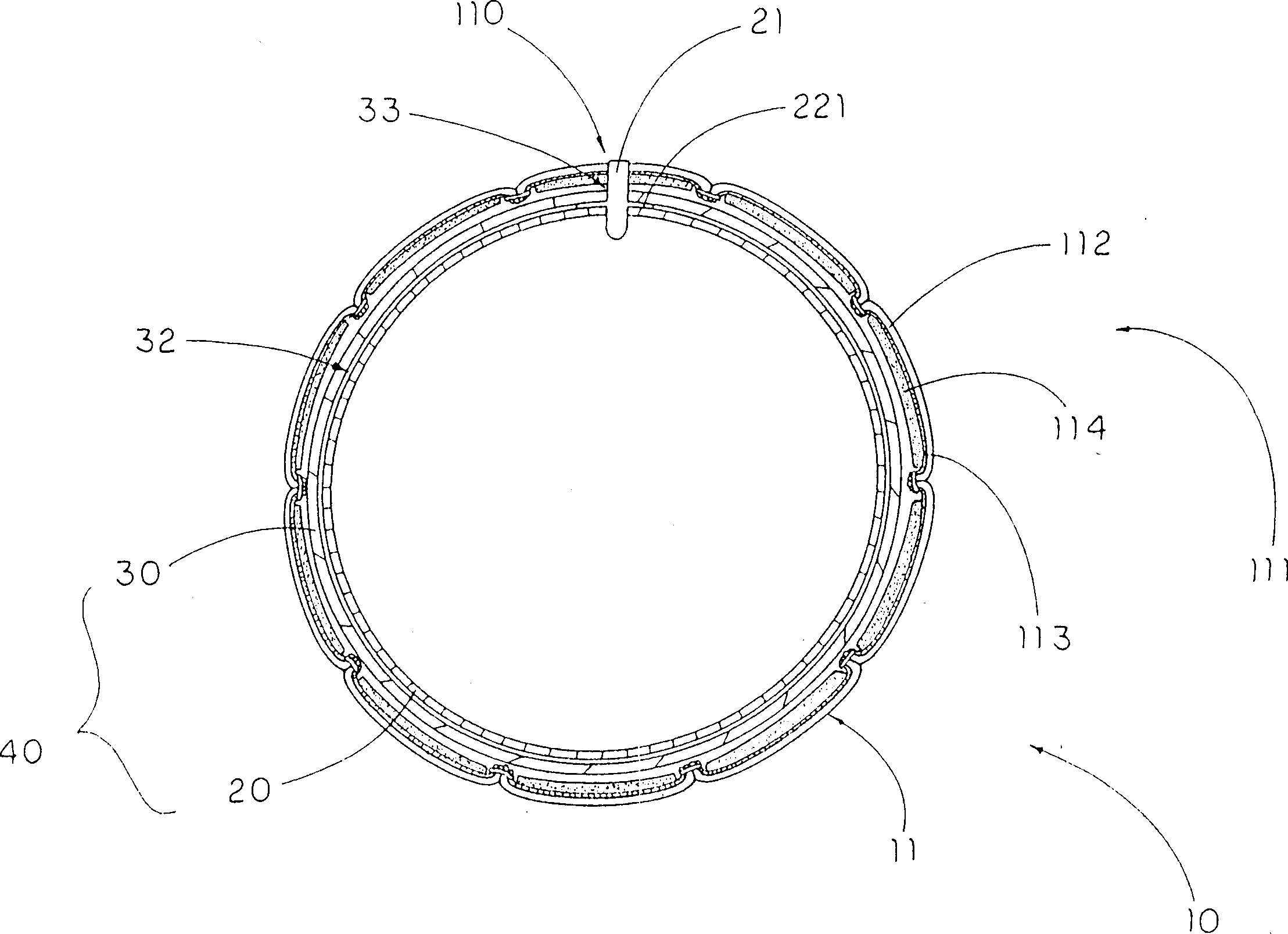

[0069] see figure 2 and image 3 According to the first preferred embodiment of the present invention, the sewn-on ball 10 of the present invention, for example, a basketball, a volleyball or a football, comprises a spherical surface 11 and an inflatable airbag 20 . The spherical surface layer is formed by sewing a plurality of small surface layer pieces edge-to-edge, wherein an air-filling hole 110 is provided on one surface layer small piece. An inflatable airbag 20 is located inside the spherical surface 11, and the inflatable airbag 20 is further provided with an inflation port 21 extending therefrom to an inflation hole 110 of the spherical surface.

[0070] The sewn-on ball 10 of the present invention further includes a middle bag 30 . The central ball bag 30 is located within the spherical surface layer 11 and surrounds the inflatable airbag 20 to maintain the spherical curvature of the inflatable airbag 20 after inflation. The central ball bag 30 and the inflatable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com