Culture net cage door welding device and cage door welding method

A technology for welding devices and breeding nets, applied to online nets, other household appliances, household appliances, etc., can solve problems such as low work efficiency, high labor intensity, and poor welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The structure and operating principle of the farming net cage door welding device and the cage door welding method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

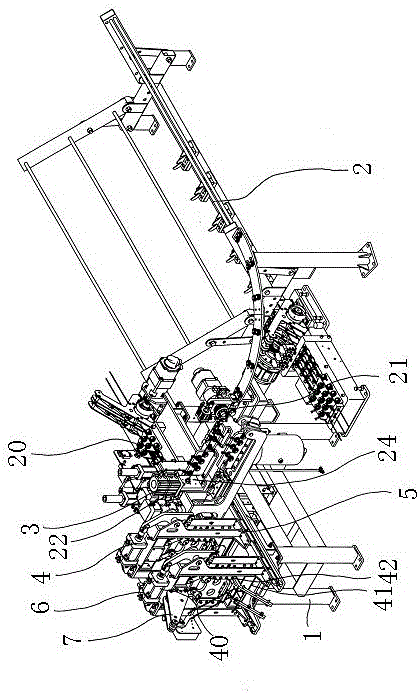

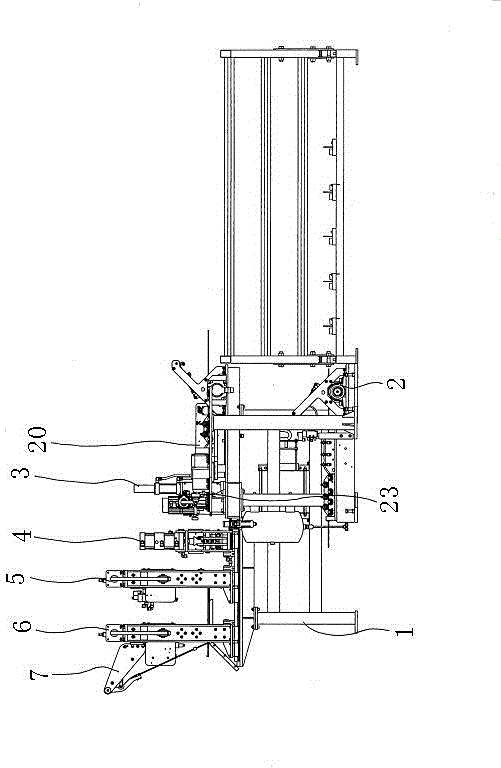

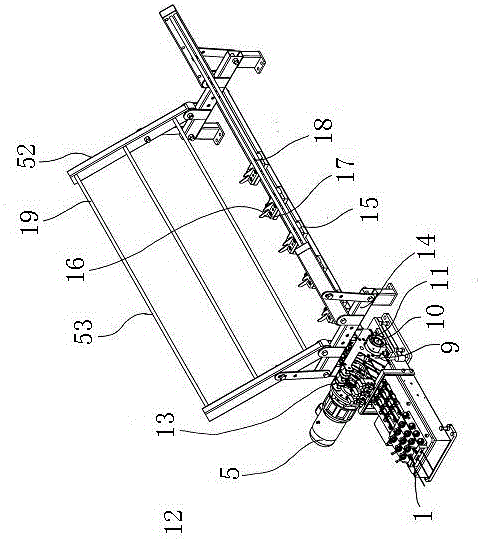

[0057] Such as figure 1 with figure 2 As shown, the structural representation of the welding device for the breeding net cage door of the present invention, the welding device for the breeding net cage door of the present invention comprises a frame 1, a material feeding slowing frame 2, a cage door frame welding mechanism 3, a strengthening horizontal wire welding mechanism 4, a longitudinal wire Cutting mechanism 5, longitudinal wire bending mechanism 6, cage door blanking mechanism 7, such as image 3 with Figure 4 As shown, the feeding buffer frame 2 includes a first straightening mechanism 8, and a wire gripping mechanism 9 is arranged behind the first straightening mechanism 8, and the wire gripping mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com