Patents

Literature

134results about How to "Low diffusible hydrogen content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon steel covered electrode for nuclear power carbon steel welding and preparation method

ActiveCN103551760ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaSlag (welding)Adhesive

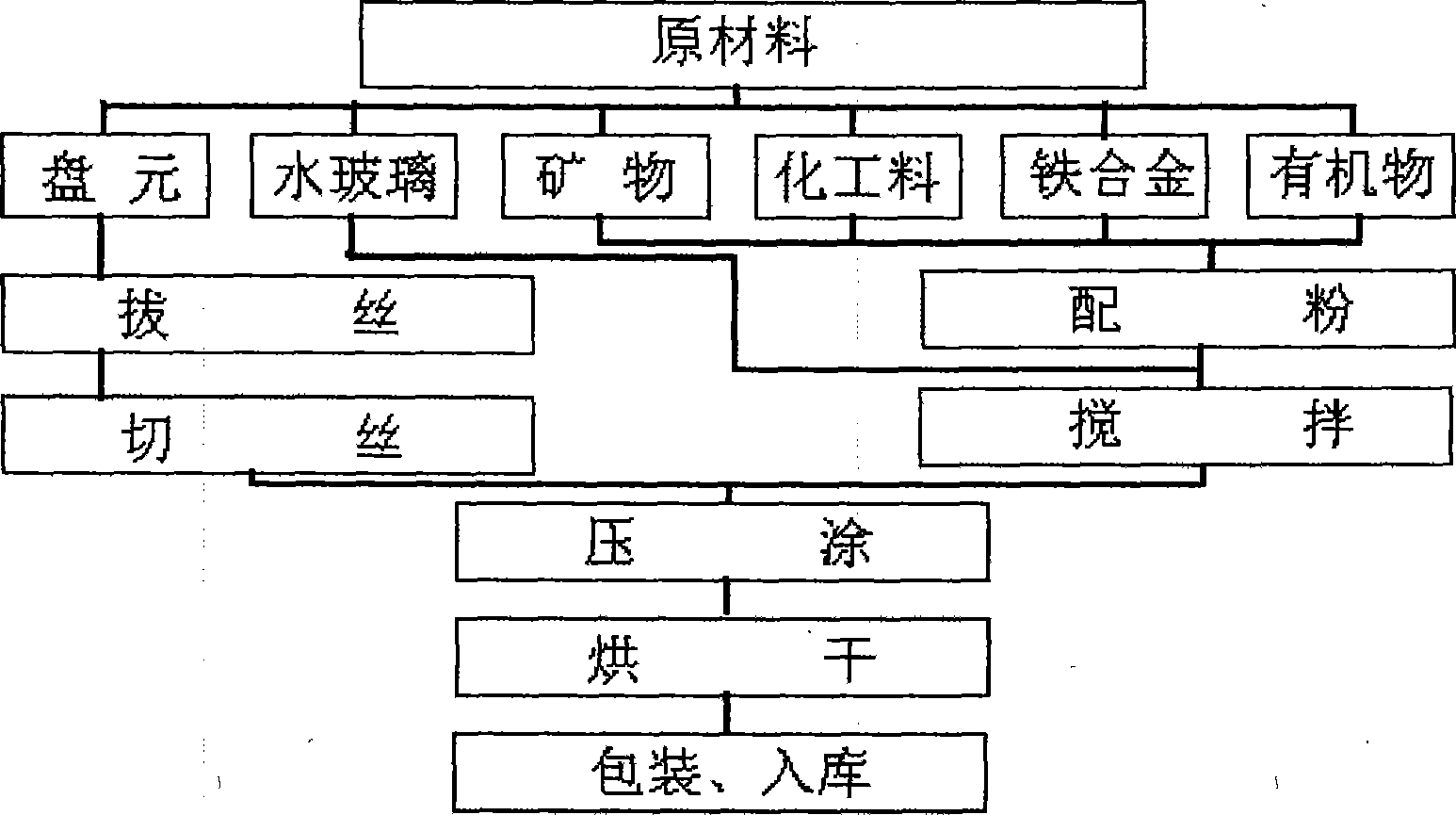

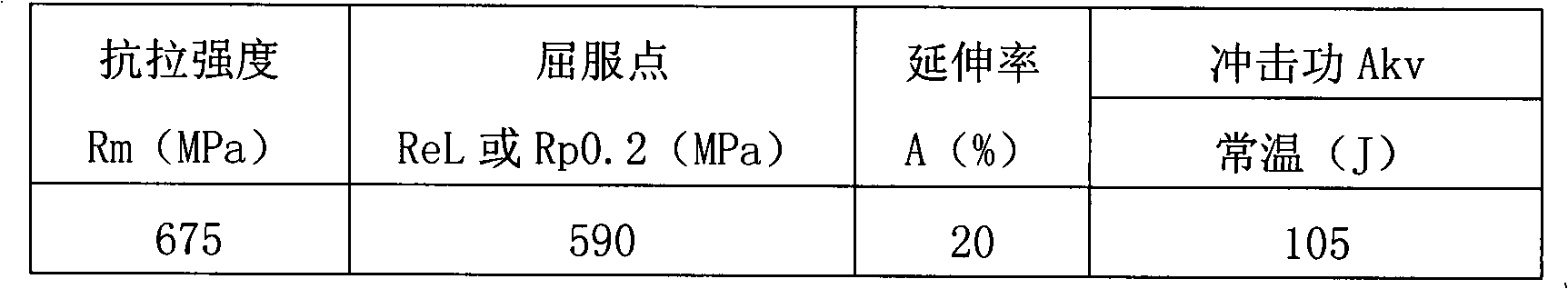

The invention belongs to the technical field of a welding material and particularly relates to a carbon steel covered electrode for the third-generation nuclear power technical welding and a preparation method. The carbon steel covered electrode is characterized by comprising a core wire, a cover and an adhesive, wherein the mass ratio of powder to the covered electrode is (25 to 27):100 and the mass ratio of the powder to the adhesive is 100:(15 to 20). In the welding process of the covered electrode in the invention, electric arcs are stable and splashing is little; slag detachability is good; a postwelding slag crust in the flat welding process can be automatically upwarped; the covered electrode is well formed and has good whole-position operability; after welded deposited metal is subjected to heat preservation for 1h, 16h and 40h at a temperature of 595 to 625 DEG C, mechanical property in the three thermal treatment states meets the technical indexes and has high stability.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +2

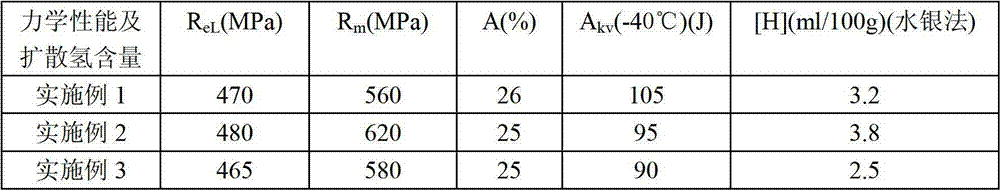

High tenacity and low hydrogen type agglomerated flux for ocean engineering and preparation method thereof

ActiveCN105081615AGood crack resistanceLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaImpact energyMetal

The invention provides high tenacity and low hydrogen type agglomerated flux for ocean engineering. The high tenacity and low hydrogen type agglomerated flux is composed of, by weight, 18%-23% of MgO, 28%-32% of CaF2, 18%-22% of Al2O3, 1%-5% of TiO2, 18%-22% of SiO2, 3%-7% of CaO, 2%-5% of Na3AIF6, 2%-6% of MnO, 0-0.015% of S and 0-0.025% of P. By means of the high tenacity and low hydrogen type agglomerated flux, weld metal has good welding process properties such as sediment separation and pore resistance and a good anti-cracking property; the Charpy impact energy is relatively high at the temperature of -40 DEG C and the content of diffusible hydrogen meets the requirement of ultra-low-hydrogen.

Owner:武汉铁锚焊接材料股份有限公司

Novel electric welding rod

InactiveCN101362258AGuaranteed welding strengthLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaFerrosiliconMetallic Nickel

The invention provides an electric welding rod with ultra low hydrogen and high toughness. The electric welding rod comprises core welding-wires and electrode coating composition. The electrode coating composition comprises the following components (weight percentage): 38-42 percent of marble, 21-28 percent of fluorspar, 1-3 percent of white titanium pigment, 6-10 percent of ferrotitanium, 0.5-1.5 percent of low-carbon ferromanganese, 3-7 percent of ferrosilicon, 3-6 percent of manganese metal, 2-4 percent of metallic chromium, 1-3 percent of mica, 1-3 percent of ferromolybdenum, 1.5-3.5 percent of ferrovanadium, 1-4 percent of nickel powder and 2-4 percent of rare earth metal. H08A is adopted as the core welding-wires, and water glass is used as the cementing agent. The electric welding rod fills the blank of electric welding rod needed for an ultra-thin large diameter circular saw blade, and simultaneously the electric welding rod can also be used for the welding of products in structures of carbon tool steel, alloy tool steel and spring steel material. The electric welding rod has good welding processing property and crack resistance, and simultaneously has very high welding strength, rigidity, plasticity and toughness, and the color of the welding seam is identical with the color of the base material.

Owner:HARBIN INST OF TECH

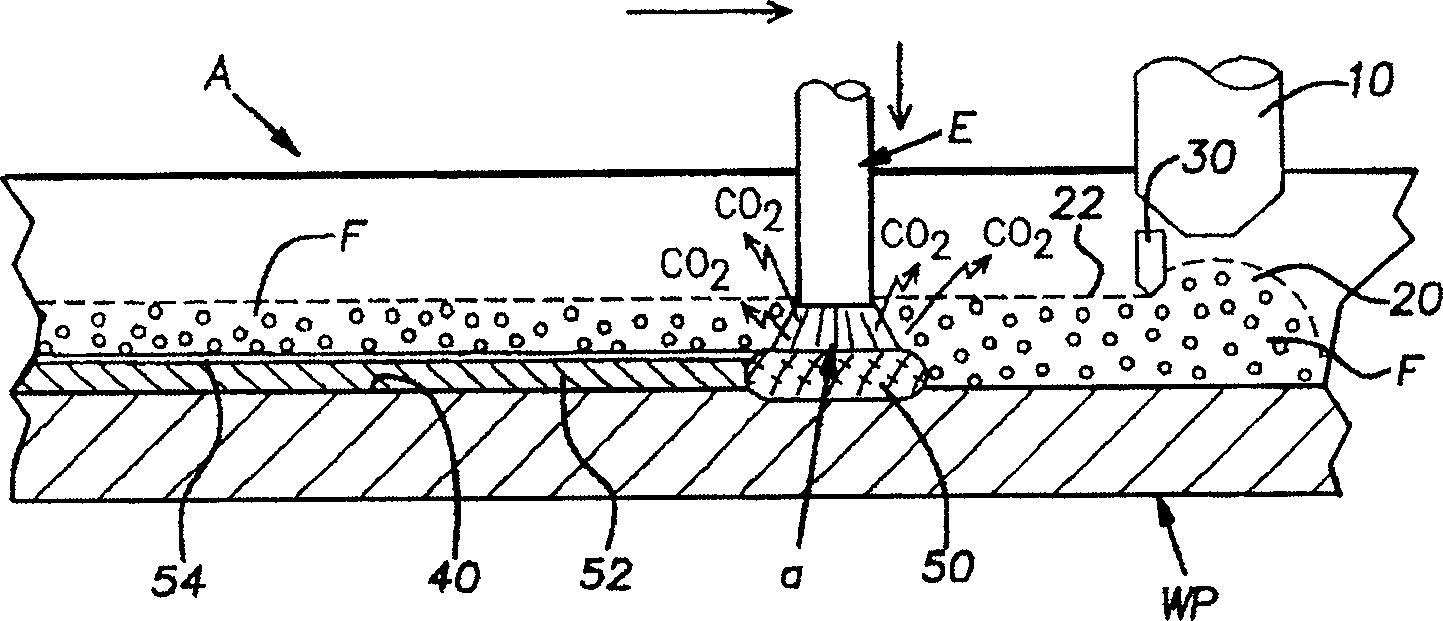

Gas-shielded flux-cored wire with recyclable welding slag

InactiveCN102139424ALow diffusible hydrogen contentReduce sensitivityWelding/cutting media/materialsSoldering mediaCrack resistanceHydrogen

A gas-shielded flux-cored wire with recyclable welding slag belongs to the welding field. In the invention, the skin of the gas-shielded flux-cored wire is made from a mild steel strip, and welding slag powder is partially or completely instead of natural rutile, thus the purposes of saving the resource and reducing the cost are achieved. The powder of the flux-cored wire comprises the following chemical components in percentage by weight: 15-35% of the welding slag powder of the flux-cored wire (including 20-65% of TiO2, 5-15% of MnO, 5-15% of MgO, 5-15% of SiO2, 1-10% of Fe2O3 and 1-10% of Al2O3), 15-35% of TiO2, 2-7% of Si, 3-8% of Mn, 0.5-5% of Al-Mg, 0-5% of Na, 0-5% of K, 1-5% of Mg and the balance of ferrous powder. When the flux-cored wire manufactured by adopting the welding slag powder is applied to welding, the gas-shielded flux-cored wire has the advantages of excellent technical performance of welding and omnibearing welding adaptability, attractive appearance good humidity resistance, low content of diffusible hydrogen in a welding seam, excellent crack resistance, high connection strength and good low-temperature impact toughness.

Owner:BEIJING UNIV OF TECH

Low-hydrogen welding rod for ultra-low-temperature high-manganese steel manual arc welding

InactiveCN109623194AReduce manufacturing costAvoid microstructureWelding/cutting media/materialsSoldering mediaRare earthFerrosilicon

The invention discloses a low-hydrogen welding rod for ultra-low-temperature high-manganese steel manual arc welding. The low-hydrogen welding rod for the ultra-low-temperature high-manganese steel manual arc welding comprises a welding rod core and a coating, wherein chemical components of the welding rod core comprise 0.30-0.75 wt% of C, 20-26 wt% of Mn, 6.5-8.5 wt% of Ni, 3.0-5.5 wt% of Cr, 2.5-4.0 wt% of W, less than or equal to 0.002 wt% of P, less than or equal to 0.001 wt% of S, and the balance Fe and inevitable impurities; and chemical components of the coating comprise 35-40 wt% of marble, 16-22 wt% of fluorite, 3-5 wt% of quartz sand, 3-6 wt% of zircon sand, 4-10 wt% of titanic schorl, 5-10 wt% of ferrotitanium, 5-8 wt% of low carbon ferromanganese, 3-6 wt% of silicon iron, 1-2 wt% of rare earth ferrosilicon, 2-3 wt% of synthetic mica, and 1-2 wt% of sodium carbonate, wherein the sum of the weight percentages of all the components is 100%. The low-hydrogen welding metal has excellent low-temperature toughness and the strength which is matched with the ultra-low-temperature high-manganese steel, and can meet the technical requirements for the strength and the ultra-low-temperature toughness of the ultra-low-temperature high-manganese steel to be welded.

Owner:NANJING IRON & STEEL CO LTD +1

Electric welding rod for welding large scale low temperature spherical tank steel

ActiveCN101537544ASimple welding processEasy to strike the arcWelding/cutting media/materialsSoldering mediaCrack resistanceAdhesive

The invention relates to an electric welding rod for welding large scale low temperature spherical tank steel, consisting of a core welding-wire, an electrode covering and adhesive. The electric welding rod is manufactured according to the conventional manufacturing technique of the electric welding rod; the strength and the toughness of the electric welding rod can be enhanced by strictly controlling the lower percentage composition of S and P in auxiliary materials of the core welding-wire and the electrode covering. The invention has the advantages that the ultralow hydrogen sodium type electric welding rod has high strength and toughness, good welding technological properties, easy arc initiation, soft voltaic arc, little splatter, convenient slag detachability, delicate shaped weld mark, beautiful appearance and all-position welding; deposited metal is well purified and thinned, and has excellent low-temperature impact ductility and cracking resistance, low content of diffusible hydrogen as well as good performances of hot crack and cold crack resistance as well as reheating crack resistance; the welded deposited metal adapts to wide range of heat treatment parameter and has good actual construction adaptability, thus being applicable to welding a spherical tank, especially large scale spherical tanks made of propylene, ethylene and LPG.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP +1

Low-cost gas shielded flux-cored wire with recycled welding slag

InactiveUS20120241432A1Low costSave resourcesWelding/cutting media/materialsSoldering mediaIron powderSlag

A gas shielded flux-cored wire (FCW) comprises s steel sheath and core flux, in which recycled welding slag powder is used to partially replace the natural rutile. The core flux contains (by weight): 10-50% recycling welding slag powder, 10-45% TiO2, 2-7% Si, 5-20% Mn, 0.5-5% Al—Mg (Al / Mg=1), 0-11.52% Na2CO3, 0-8.85% K2CO3, 0-10% MgO, 0.5-10% fluoride, and iron powder as balance. The recycling welding contains (by weight): TiO2: 20-65%, MnO: 5%-15%, MgO: 5%-15%, SiO2: 5%-15%, Fe2O3: 1%-10%, Al2O3: 1%-10%.

Owner:BEIJING UNIV OF TECH

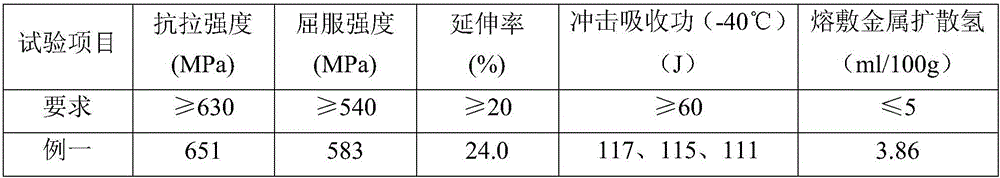

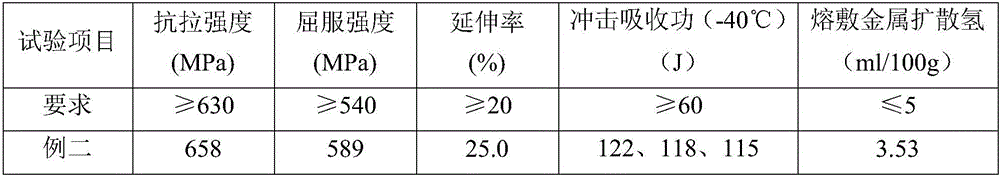

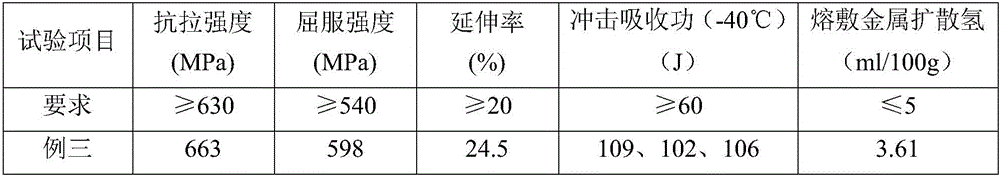

Non-preheating strength gradient matched welding technology for low-alloy high-strength steel with yield strength of 800MPa

The invention provides a non-preheating strength gradient matched welding technology for low-alloy high-strength steel with the yield strength of 800MPa, which belongs to the field of the non-preheating welding technology for the low-alloy high-strength steel. The welding technology mainly adopts welding wires with the tensile strength of 500MPa for backing welding and welding wires with the tensile strength of 800MPa for padding and cosmetic welding. The technology mainly solves the technical problem that in the background art, as backing welded joints in a high restraint-intensity welding structure have higher tensile strength, cracks can not be thoroughly eliminated under a non-preheating condition. The technology is used for the non-preheating high-quality welding for the low-alloy high-strength steel with the yield strength of 800MPa.

Owner:HARBIN WELDING INST LTD

High-toughness verylow hydrogen basic Co2 Cored welding wire

InactiveCN1814396AIncrease coverageEasy to remove slagArc welding apparatusWelding/cutting media/materialsHydrogenShielding gas

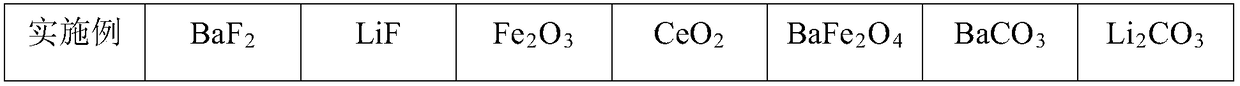

The invention belongs to the field of welding material, putting a high toughness and low hydrogen alkaline CO2 welding wire using general 08Al strip as skin, pulled intoa small diameter rolling 1.2-1.6mm, cored alkaline slag and a large amount of deoxidizer and alloying added, the proportion of the filler is 11-18%, the main components and weight percentages are: BaCO3 4-10, MgO 15-25, CaF2 6-12, Na2SiF6 6-15,SiO2 4-10,TiO28-17,ReF 0.3-3,Al-Mg 3-5,10-15 iron added, pure metal powder 12-20,the invention of the alkaline welding wire use pure CO2 as a protective gas, which has s excellent welding properties. It can be conducted plate, grounding upward welding, established downward welding, welding and other horizontal position welding.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

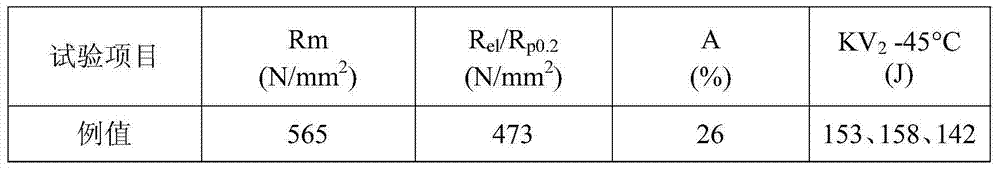

High-strength and high-toughness gas shielded flux-cored wire used for bridge steel

ActiveCN106334884AHigh tensile strengthHigh elongationArc welding apparatusWelding/cutting media/materialsManganeseZircon

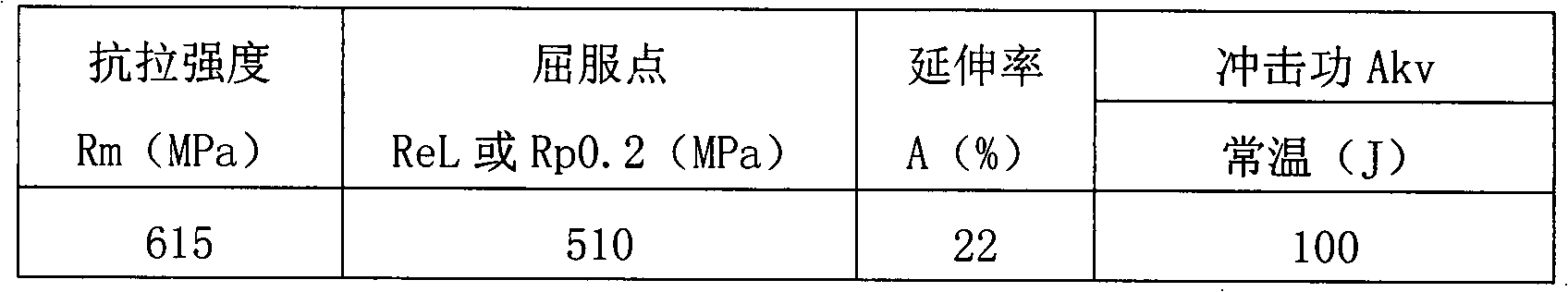

The invention provides a high-strength and high-toughness gas shielded flux-core wire used for bridge steel. The high-strength and high-toughness gas shielded flux-core wire comprises a skin and a flux core wrapped by the skin. The flux core comprises, by weight, 30%-50% of rutile, 2%-8% of feldspar, 1%-6% of quartz, 0.5%-5% of zircon, 0.5%-5% of sodium fluoride, 0.1%-1.5% of lithium fluoride, 1%-8% of potassium-sodium arc stabilizers, 10%-25% of silicon-manganese alloys, 1%-8% of manganese metal, 1%-6% of magnesium powder, 5%-15% of nickel powder, 0.1%-1.5% of ferrotitanium, 0.05%-0.6% of ferroboron, and the balance iron powder, and the weight percents of the ingredients add up to 100%. According to the high-strength and high-toughness gas shielded flux-core wire used for the bridge steel, all the gradients and properties of the wire can meet the engineering using requirements of high-strength steel plates, and the wire is especially suitable for welding of Q500qE.

Owner:TIANJIN YONGCHANG WELDING WIRES +1

Ultralow-hydrogen high-toughness submerged arc welding flux core and submerged arc flux-cored wire

InactiveCN102848103AEasy to operateImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaBorideCrack resistance

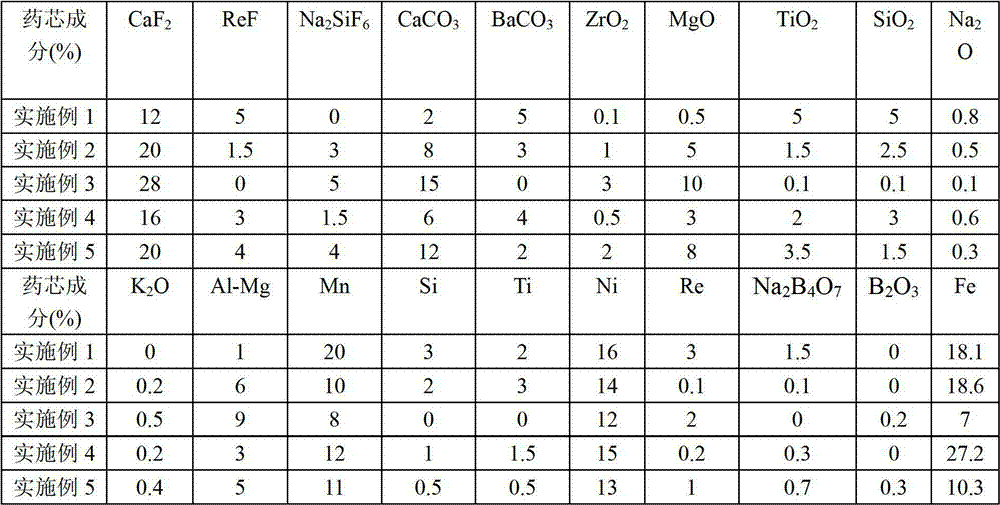

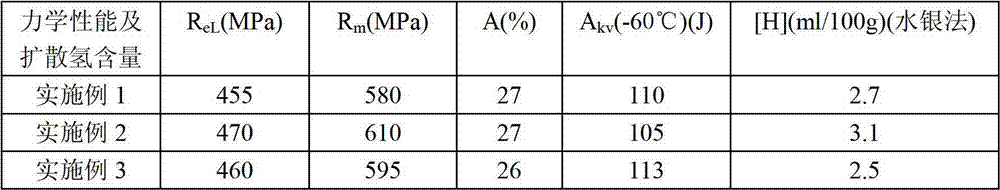

The invention relates to an ultralow-hydrogen high-toughness submerged arc welding flux core and a submerged arc flux-cored wire. The welding flux core comprises the following components of: CaF2, Na2SiF6, ReF, BaCO3, CaCO3, MgO, TiO2, SiO2, ZrO2, boride, Na2O, K2O, Mn, Al-Mg, Ni, Ti, Si, Re and the balance of Fe. When the welding flux core is matched with a high-alkalinity sintering welding flux, the weld metal has the impact absorbed power of more than 80J at the temperature of 60 DEG C below zero; when the welding flux core is matched with a low-hygroscopicity smelting welding flux, the weld metal has the impact absorbed power of more than 90J at the temperature of 40 DEG C below zero; and when the welding flux core is matched with any one welding flux, weld diffusion hydrogen content is less than 5ml / 100g. The standard specific ultralow-hydrogen range is achieved; and the submerged arc flux-cored wire is high in cold crack resistance, has high in fracture toughness value, is suitable for low-alloy high-strength steel and can be used for welding important structures.

Owner:TIANJIN UNIV +1

Novel alloy tool steel welding electrode

InactiveCN101920407AGuaranteed welding strengthLow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaManganeseRare earth

The invention provides a superlow-hydrogen, high-strength and high-toughness alloy tool steel welding electrode with outstanding anticracking performance, which comprises a core wire and a welding electrode covering composition, wherein the electrode covering composition comprises the following components in percentage by weight: 35 to 45 percent of marble, 20 to 30 percent of fluorite, 2 to 4 percent of titanium white, 8 to 13 percent of ferrotitanium, 0.5 to 1.5 percent of alkali, 3 to 6 percent of metal chromium, 4 to 8 percent of metal manganese, 4 to 8 percent of nickel powder, 3 to 6 percent of ferromolybdenum, 2 to 6 percent of rare earth silicon, 2 to 6 percent of quartz and 2 to 6 percent of feldspar. The core wire is made of H08A steel or H08E steel, and potassium sodium mixed water glass is used as a bonder. The alloy tool steel welding electrode can be used as a superlarge-section alloy tool steel (5CrNiMo) structure welding electrode which used to lack and can be used for welding other high-strength alloy steel structure products. The welding electrode has an excellent welding process property, high welding strength, rigidity, plasticity and ductility.

Owner:SHIYAN JINKE CHEM

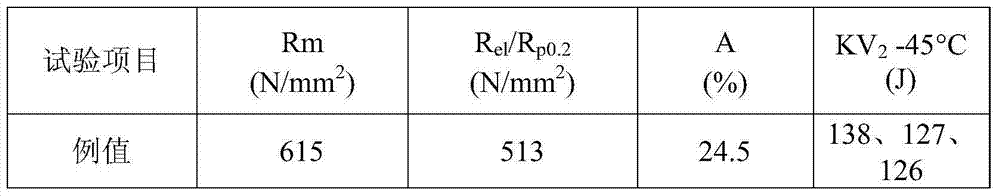

Metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel

ActiveCN104259687ALow diffusible hydrogen contentImprove deposition efficiencyArc welding apparatusWelding/cutting media/materialsFerrosiliconRare earth

The invention discloses a metal powder-cored wire for welding X80 high-strength low-alloy pipeline steel. The metal powder-cored wire consists of a carbon steel strip and a metal powder core, wherein a formula of metal powder consists of low-carbon ferromanganese, ferrosilicon, ferrotitanium, nickel powder, ferromolybdenum, ferroboron, magnesium powder, rare earth fluoride and the balance of iron powder. The metal powder-cored wire is characterized by adopting an Ni-Mo-Ti-B alloy system to be applied to the root welding, filling and cover surface welding of the X80 high-strength low-alloy pipeline steel, in particular to the backing welding, so that the melting speed is fast, the melting efficiency is high, the all-position welding can be realized, the content of diffusible hydrogen is lower, and KV2(-45 DEG C) is higher than 100 J.

Owner:TIANJIN YONGCHANG WELDING WIRES

Ultralow-hydrogen type high efficiency iron powder welding rod for low alloy high streagth steel

InactiveCN1657224AImprove low temperature toughnessGood pressure coating processWelding/cutting media/materialsSoldering mediaIron powderHydrogen

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Coated welding wire for welding low-alloy high-strength steel and manufacturing method

InactiveCN106736013AMeet welding requirementsHigh strengthWelding/cutting media/materialsSoldering mediaHigh intensityImpurity

The invention discloses a coated welding wire for welding low-alloy high-strength steel. The coated welding wire comprises a welding wire substrate and a coating which coats the surface of the welding wire substrate, wherein the welding wire substrate is made from the following components in percentage by weight: 0.029 to 0.041 percent of Ti, 0.01 to 0.015 percent of Al, 0.083 to 0.11 percent of Nb, 0.1 to 0.15 percent of C, 0.2 to 0.3 percent of Cr, 0.3 to 0.5 percent of Si, 0.01 to 0.03 percent of N, 1.4 to 1.7 percent of Ni, 0.1 to 0.6 percent of Mo, less than or equal to 0.002 percent of P, less than or equal to 0.002 percent of S, and the balance of iron and unavoidable impurities, wherein as specified by the following formula, K is between 0.013 and 0.032, K=29[Ti]+52[Al]+27[Nb]-100[N]; [Al], [Ti], [Nb] and [N] represent the weight percentage contents of Al, Ti, Nb and N in the welding wire substrate respectively. The invention further discloses a manufacturing method of the coated welding wire for welding the low-alloy high-strength steel. By adopting the coated welding wire, high strength of welding metal is ensured, the welding performance of the low-alloy high-strength welding wire is improved finitely, the occurrence of cold cracks is controlled, a low splashing rate is achieved, and the welding requirement of the high-strength low-alloy steel is met.

Owner:安徽飞弧焊业股份有限公司

Hot roll surfacing submerged arc flux-cored welding wire and preparation method for same

InactiveCN103785976AUniform hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsCrack resistanceThermal fatigue

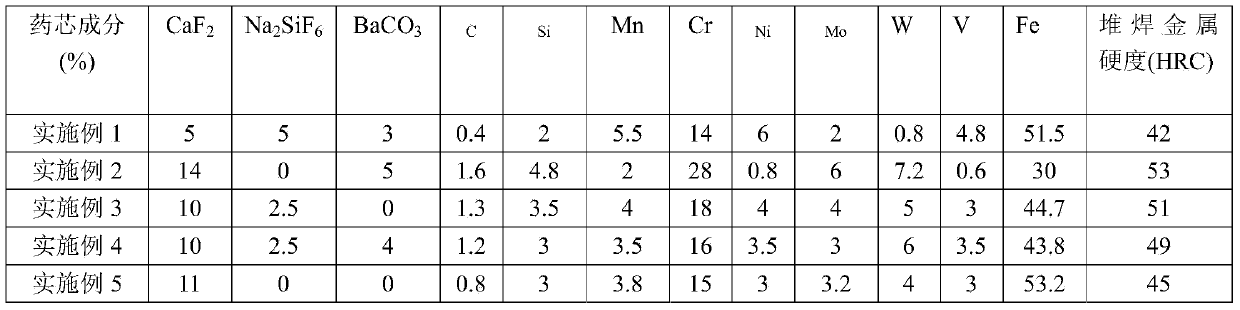

The invention relates to a hot roll surfacing submerged arc flux-cored welding wire and a preparation method for the same. The hot roll surfacing submerged arc flux-cored welding wire comprises the following ingredients in percent by weight: 5%-14% of CaF2, 0%-5% of Na2SiF6, 0%-5% of BaCO3, 0.1%-0.4% of C, 2.0%-5.5% of Mn, 14%-28% of Cr, 0.8%-6% of Ni, 2%-4.8% of Si, 0.6%-4.8% of V, 0.8%-7.2% of W, 2%-6% of Mo and the balance Fe. A steel belt of the flux-cored welding wire is low-carbon, and the content of the carbon of the steel belt is smaller than 0.05%; and powder filling rate is 18%-28%, and the particle size of powder is 80-200 meshes. The submerged arc flux-cored welding wire has the advantages that metal alloy elements of a surfacing layer are distributed uniformly; carbide is scattered; the hardness is uniform; contents of impurities and diffusible hydrogen are low; the crack resistance, the thermal fatigue resistance and the wear resistance are high; the hardness of the surfacing layer is uniform; and the service life is long.

Owner:TIANJIN UNIV +1

High-toughness and anti-hydrogen induction sulfide stress corrosion crack metal powder flux-cored wire and preparation method

ActiveCN103071941AImprove efficiencyImprove welding efficiencyWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention discloses a high-toughness and anti-hydrogen induction sulfide stress corrosion crack metal powder flux-cored wire which comprises outer skin and a flux core; the outer skin is a low-carbon steel thin strip; the weight of the flux core accounts for 12 percent to 20 percent of the total weight of the wire; and the diameter of the flux core is 1.20mm to 2.4mm. According to the wire welding process, the process performance and physical and chemical properties are good, the amount of slag after welding is effectively reduced, welding of a plurality of layers is carried out without clearing the slag, so that the overall performance and the welding efficiency of a welding seam are effectively improved, the performance of the welding process is good, the electric arc is stable, splashing seldom occurs, the welding seam has attractive appearance, such purposes as vertical downward welding can be achieved through short-circuit transition; and good mechanical properties and the anti-hydrogen induced crack purpose are achieved.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

Gas protective flux cored wire for welding vanadium-containing heat resistant steel

ActiveCN102489895AAdvanced technologyImprove physical and chemical propertiesWelding/cutting media/materialsSoldering mediaFerrosiliconMolten slag

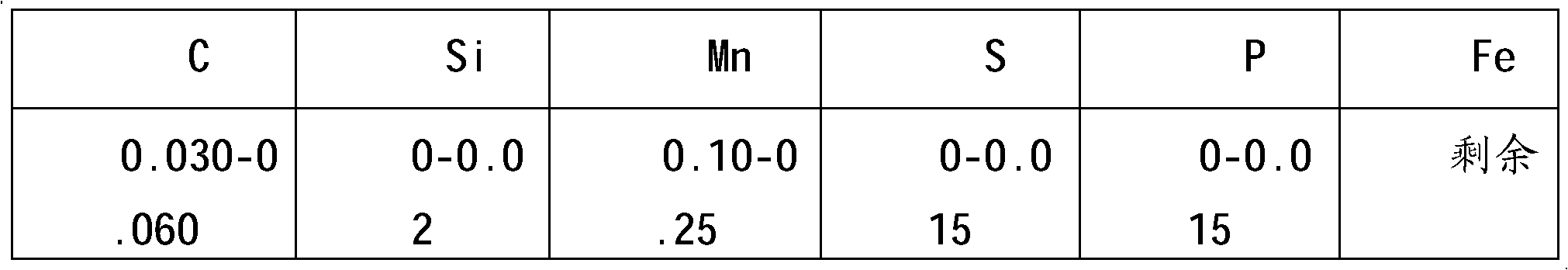

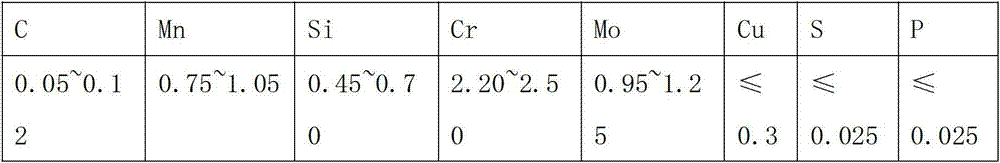

The invention belongs to a metal powder type gas protective flux cored wire for welding vanadium-containing heat resistant steel. The metal powder type gas protective flux cored wire comprises low-carbon steel skin and a flux core, wherein the low-carbon steel skin comprises the following components in percentage by weight: 0.01 to 0.1 percent of C, 0.1 to 0.4 percent of Mn, 0.01 to 0.03 percent of Si, 0.005 to 0.015 percent of S, 0.005 to 0.015 percent of P and the balance of iron; the flux core accounts for 14 to 25 percent of the total weight of the welding wire and comprises the following components in percentage by weight: 1.2 to 3.0 percent of medium-carbon ferromanganese, 0.20 to 2.0 percent of ferrosilicon powder, 0.05 to 0.5 percent of magnesium powder, 1.5 to 2.0 percent of metal chromium powder, 0.2 to 2.0 percent of ferromolybdenum powder, 0.1 to 1 percent of ferrovanadium, 0.05 to 0.2 percent of electrically fused magnesia, 0.01 to 0.2 percent of fluoride and 7 to 15 percent of iron powder; and the components are mixed uniformly, the mixture is coiled on a thin steel strip to form strips, and the strips are drawn to form wires. The metal powder type gas protective flux cored wire has the characteristics of no molten slag on deposited metal after welding, capability of performing continuous multi-layer welding without slag removal, high welding speed, high efficiency and welding process property, stable electric arcs, small splatter, attractive appearance and the like, and vertical downward welding can be realized by short circuiting transfer.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

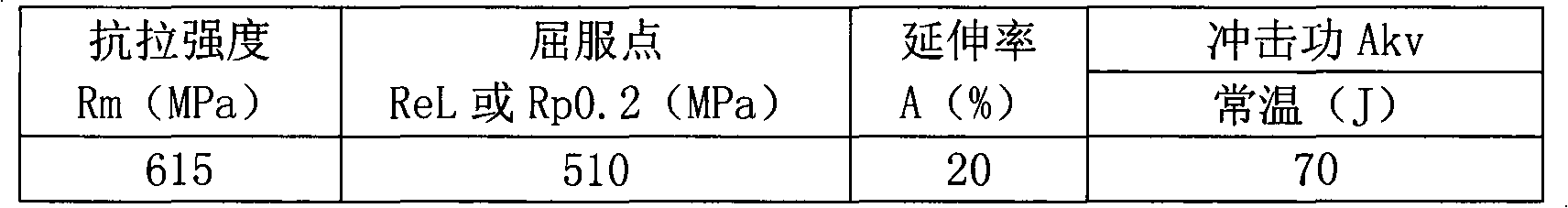

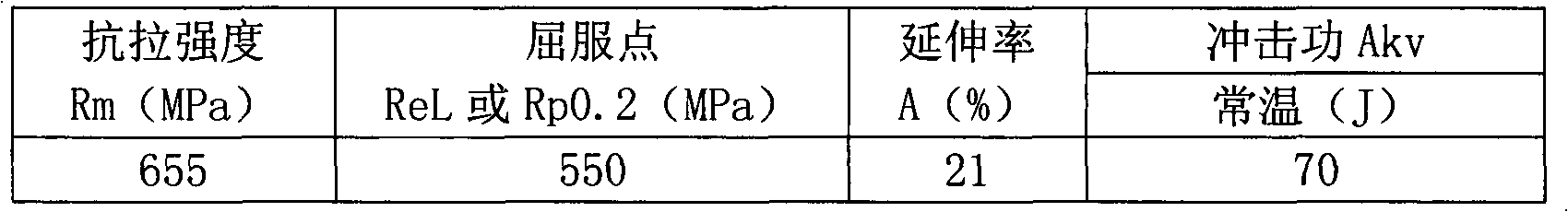

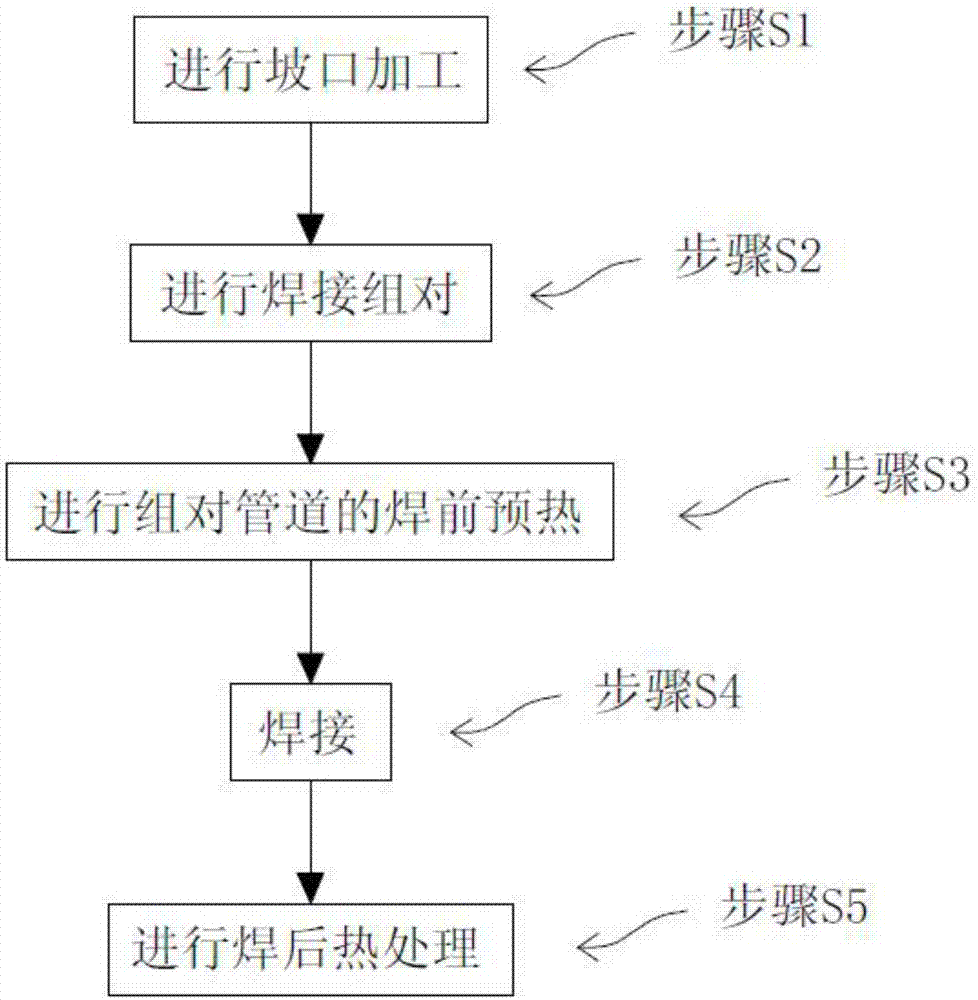

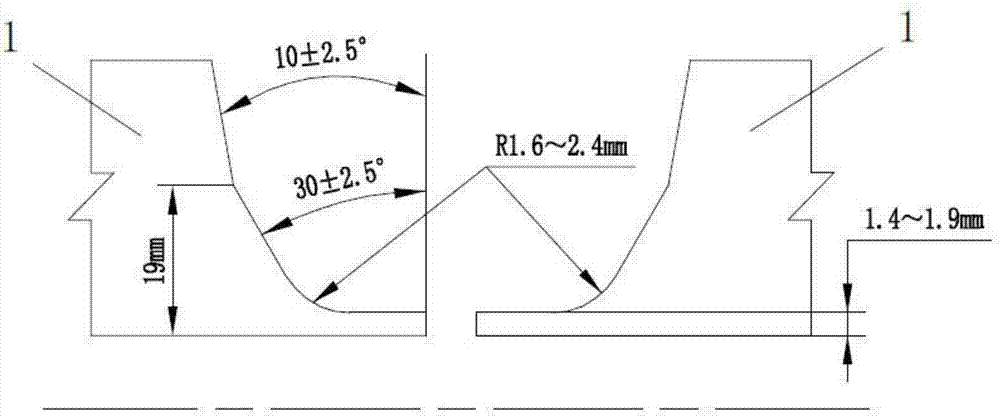

AP1000 main steam pipeline welding method

InactiveCN107457473AAvoid indentation defectsPrevent collapseArc welding apparatusNuclear powerShielding gas

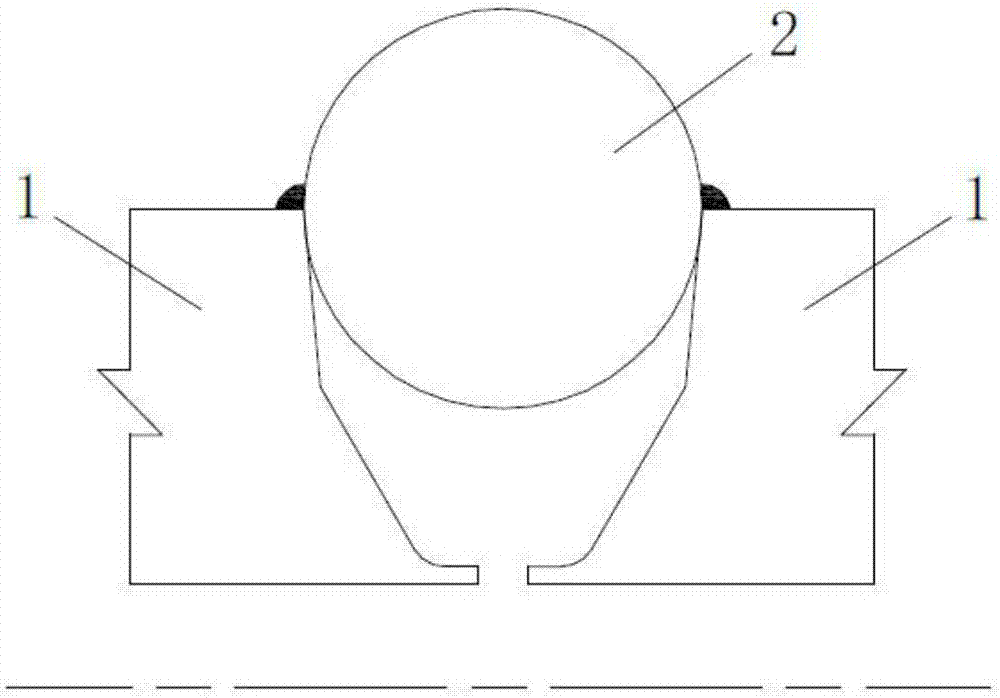

The invention belongs to the technical field of AP1000 nuclear power, and particularly relates to an AP1000 main steam pipeline welding method. In order to solve the problems that an air filling protection device is difficult to install and potential safety hazards exist in the good health of operators when a conventional air filling protection device is used for auxiliary welding of an AP1000 main steam pipeline, the AP1000 main steam pipeline welding method is disclosed. The welding method particularly includes the following several steps of S1, chamfering; S2, welding assembly; S3, weld preheating; S4, welded connection; and S5, postweld heat treatment. When the welding method is used for welding the AP1000 main steam pipeline, through adjustment matching of the groove dimensions and welding parameters, welded joints formed in the welding process can still achieve a continuous and uniform forming effect without the supporting action of backing gas, and therefore installation of the air filling protection device is omitted and the influence on the good health of the operators by protective gas is avoided.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

Sintered flux for submerged-arc welding of steel structure U-shaped rib plate

ActiveCN105945453AImprove bindingNo crackArc welding apparatusWelding/cutting media/materialsSubmerged arc weldingMetallurgy

The invention discloses sintered flux for submerged-arc welding of a steel structure U-shaped rib plate. The sintered flux comprises, by mass percent, 15%-25% of MgO, 3%-8% of CaO, 15%-25% of CaF2, 2%-5% of MnO, 25%-35% of Al2O3, 10%-20% of SiO2, 3%-7% of TiO2 and 1%-3% of SiFe. According to the sintered flux, the welding speed can be increased, the stable fusion depth can be provided in the high-speed welding state, and welding forming is attractive.

Owner:武汉天高熔接股份有限公司

Ultralow hydrogen ceramic welding flux for chrome molybdenum heat resistant steel and preparation method thereof

ActiveCN103934594ALow diffusible hydrogen contentWelding/cutting media/materialsSoldering mediaHydrogenSlag

Ultralow hydrogen ceramic welding flux for chrome molybdenum heat resistant steel comprises the following components, by mass percent, 28%-35% of MgO, 6%-15% of CaO, 17%-22% of CaF2, 13%-20% of Al2O3, 5%-10% of SiO2, 1%-5% of K2O + NaO, 0.5%-3.5% of ferromanganese, 0.5%-2% of ferrosilicon, and 6%-8% of MgCO3. The ultralow hydrogen ceramic welding flux for the chrome molybdenum heat resistant steel contains magnesia, fluoride, silicate, carbonate, the ferromanganese and the ferrosilicon serving as reducing agents and quartz which improves slag detachability and appearance of welding seams. When the ultralow hydrogen ceramic welding flux for the chrome molybdenum heat resistant steel is used for welding, the electric arc is stable, the slag detachability in the welding seams is good, the appearance of the welding seams is attractive, and the surfaces of the welding seams are free of cracks, air holes, indentations and other welding defects.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

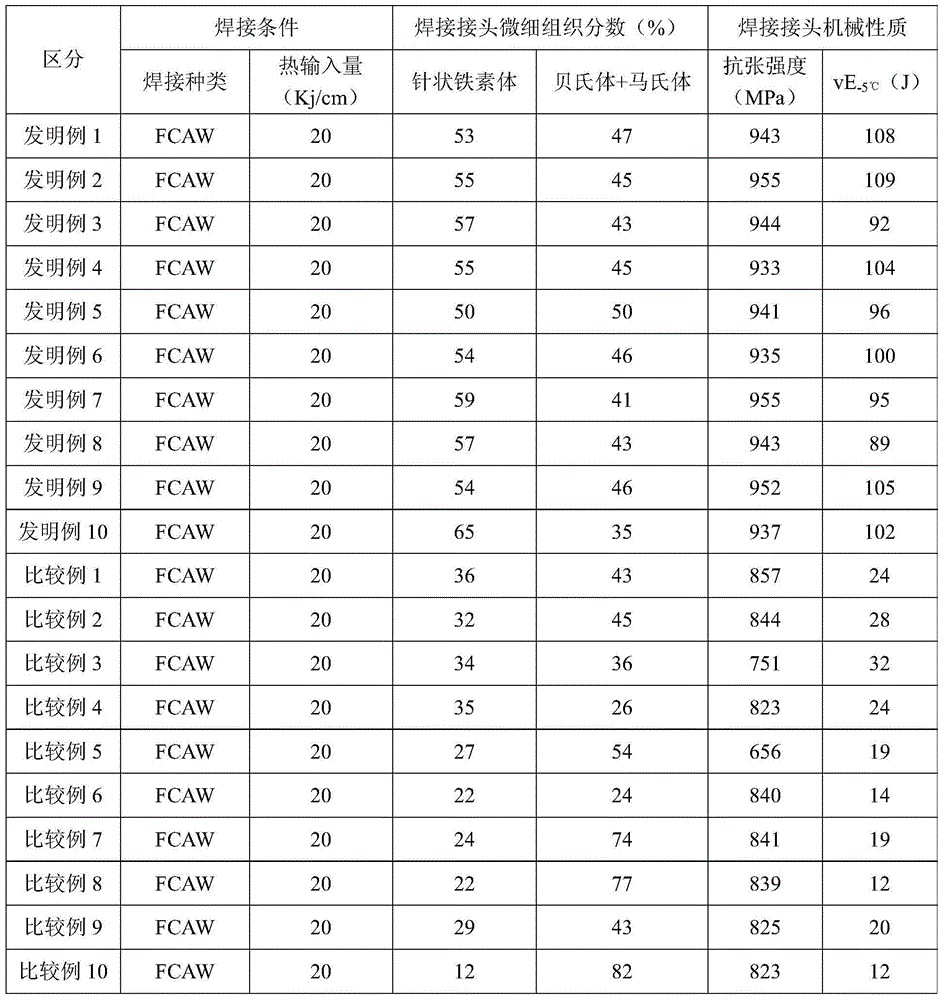

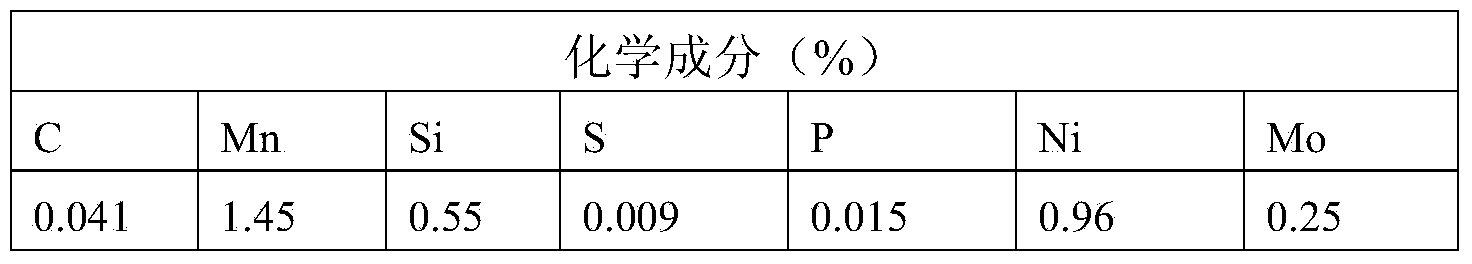

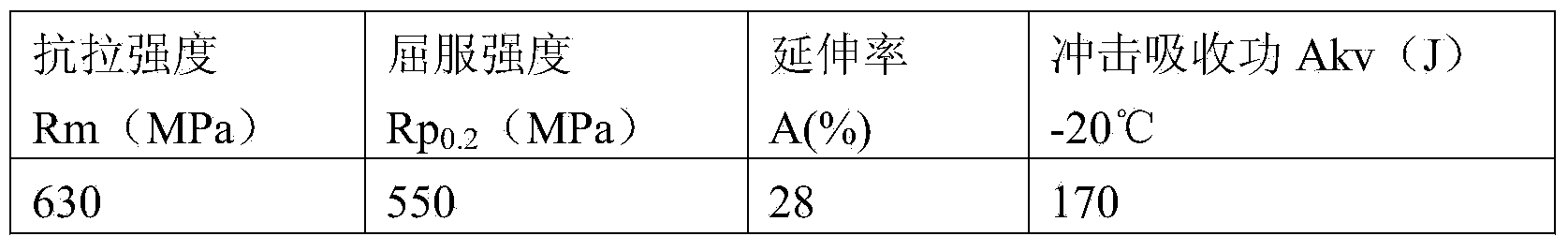

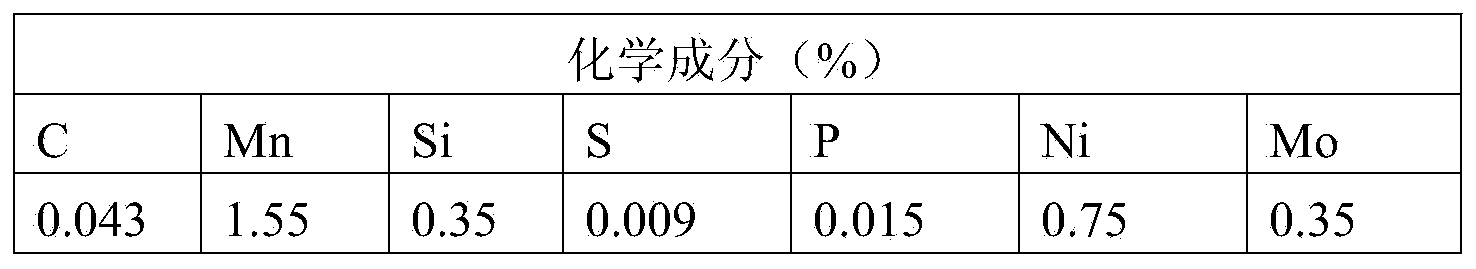

Ultra high strength flux cored arc welded joint having excellent impact toughness and welding wire for manufacturing same

InactiveCN104903046AHigh strengthImprove impact toughnessWelding/cutting media/materialsWelding/soldering/cutting articlesEngineeringMechanical engineering

The present invention relates to a flux cored arc welded joint which can be obtained by performing a flux cored arc welding on high tension steel of an ocean structure, a building, a bridge, etc. High strength and high toughness of the welded joint are obtained by controlling a composition and a microstructure of the welded joint.

Owner:POHANG IRON & STEEL CO LTD

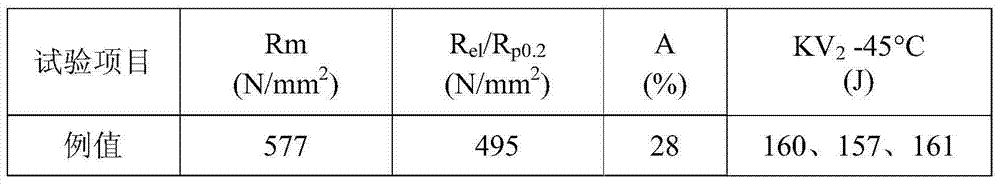

Ultralow-hydrogen high-toughness welding rod for welding of water-diversion steel penstock in hydropower station

ActiveCN103921019ASolving recipe problemsImprove dehydrogenation capacityWelding/cutting media/materialsSoldering mediaManganeseFerrosilicon

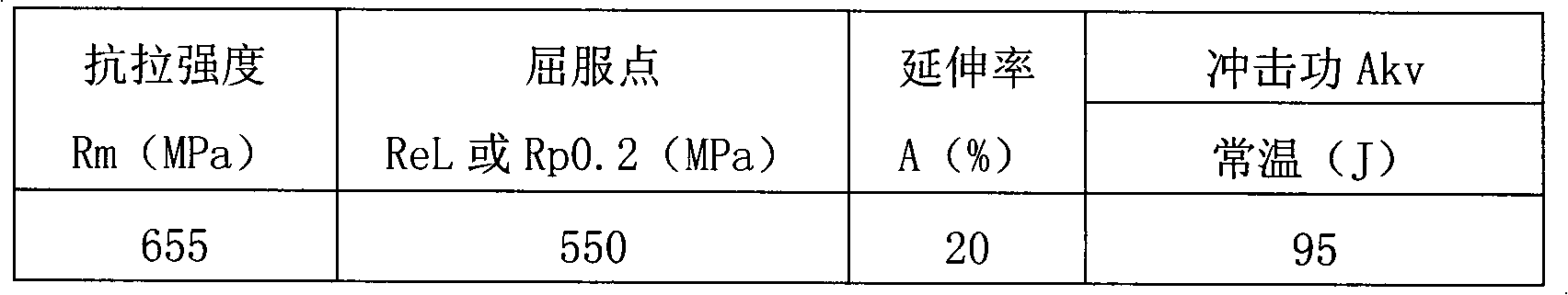

The invention provides an ultralow-hydrogen high-toughness welding rod for welding of a water-diversion steel penstock in a hydropower station. A coating of the welding rod comprises, by mass, 40%-50% of marble, 2%-4% of dolomite, 18%-30% of fluorite, 2%-6% of quartz, 1%-3% of dehydrated feldspar, 1%-3% of zircon sand, 2%-4% of potassium titanate, 3%-6% of atomized ferrosilicon, 4%-8% of electrolytic manganese, 7%-12% of ferrotitanium, 1%-3% of light rare earth silicon iron, 0.5%-1.0% of ferromolybdenum, 2%-4% of nickel powder, and 0.5%-1.0% of rare earth fluoride. All the components are mixed according to the ratios to form the coating of the welding rod, potassium and sodium mixed water glass is added, an H04E welding core is coated with the mixture through a welding rod pressure coater, and the coated welding core is dried and shaped to form the electric welding rod. The deposited metal diffusible hydrogen content of the welding rod is 1.8 ml / 100 g, the low temperature impact toughness at minus 20 DEG C is stabilized within the range from 160 J to 180 J, and the welding requirement of the water-diversion steel penstock in a 610 MPa hydropower station can be met.

Owner:HUBEI CHUANWANG SPECIAL WELDING MATERIALS

Gas protective welding flux cored wire for welding heat resistant steel

ActiveCN102489901ALow diffusible hydrogen contentImprove performanceWelding/cutting media/materialsSoldering mediaFerrosiliconMolten slag

The invention belongs to a gas protective welding flux cored wire for welding heat resistant steel. The gas protective welding flux cored wire comprises low-carbon steel metal skin and a flux core, wherein the low-carbon steel metal skin comprises the following components in percentage by weight: 0.01 to 0.1 percent of C, 0.1 to 0.4 percent of Mn, 0.01 to 0.03 percent of Si, 0.005 to 0.015 percent of S, 0.005 to 0.015 percent of P and the balance of iron; the flux core accounts for 14 to 25 percent of the total weight of the welding wire and comprises the following components in percentage by weight: 1.2 to 3.0 percent of medium-carbon ferromanganese, 0.20 to 2.0 percent of ferrosilicon powder, 0.05 to 0.5 percent of magnesium powder, 1.5 to 2.0 percent of metal chromium powder, 0.2 to 2.0 percent of ferromolybdenum powder, 0.05 to 0.2 percent of electrically fused magnesia, 0.01 to 0.3 percent of fluoride and 7 to 15 percent of iron powder; and the components are mixed uniformly, the mixture is coiled on a thin steel strip made of low-carbon steel to form strips, and the strips are drawn to form wires. The gas protective welding flux cored wire has the characteristics of no molten slag on deposited metal after welding, capability of performing continuous multi-layer welding without slag removal, high welding process property, stable electric arcs, small splatter, attractive appearance of weld joints and the like, the welding efficiency is improved by 20 to 40 percent, and vertical downward welding can be realized by short circuiting transfer.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

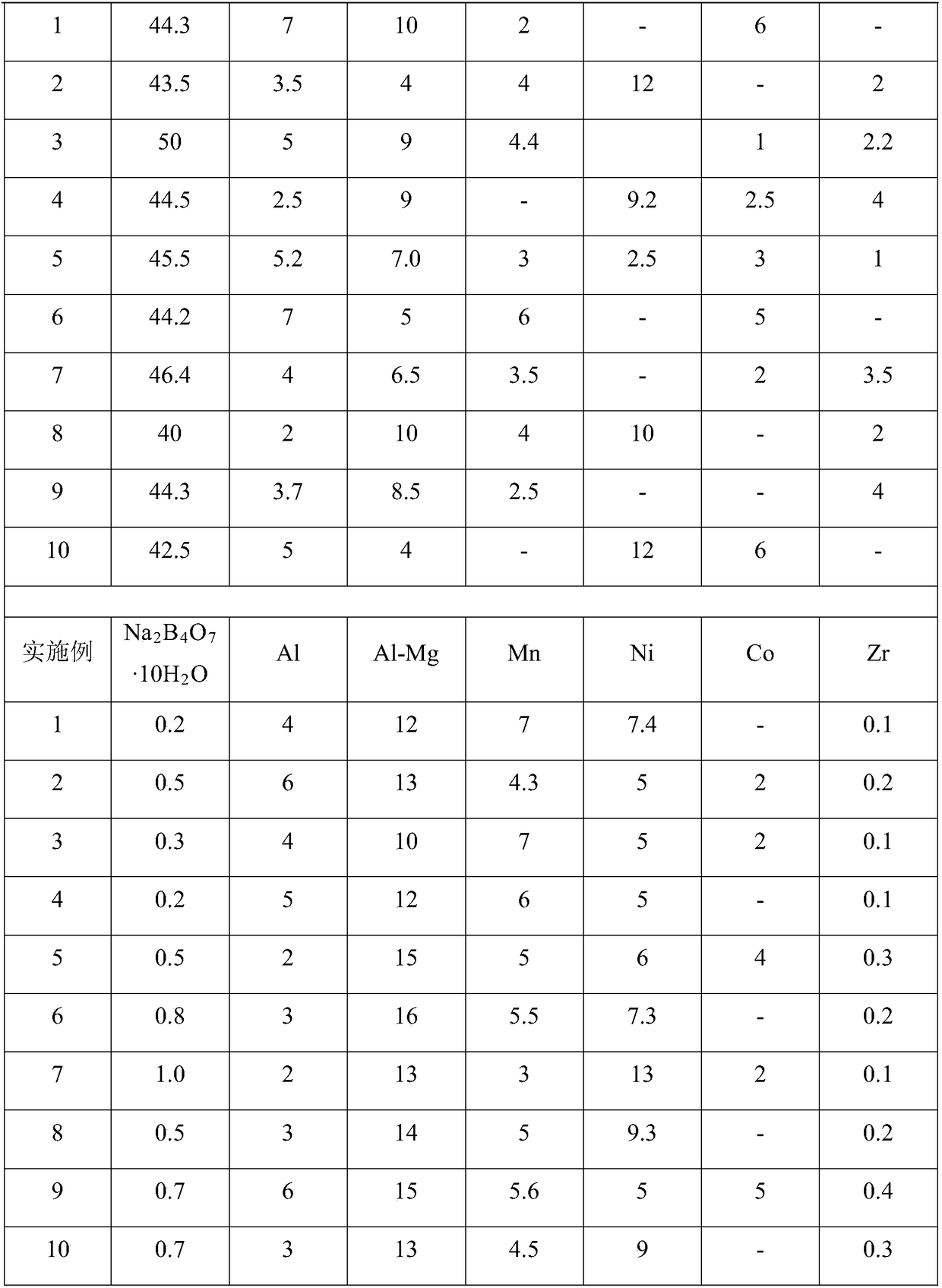

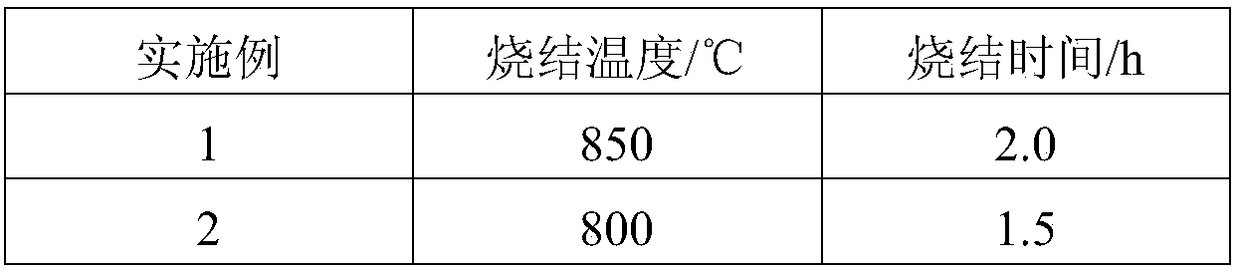

Low-hydrogen high-tenacity self-protection flux-cored wire and preparation method thereof

InactiveCN108544137AIncreased diffusible hydrogen contentPrevent intrusionWelding/cutting media/materialsSoldering mediaManganeseConductor Coil

The invention discloses a low-hydrogen high-tenacity self-protection flux-cored wire and a preparation method thereof and belongs to the field of metal welding materials. The low-hydrogen high-tenacity self-protection flux-cored wire is composed of low-carbon steel steel strip and a flux core, wherein the flux core is composed of the following components in percentage by mass: 45-55% of fluoride,10-20% of oxide, 2-8% of carbonate, 0.2-1.0% of sodium borate, 2-6% of metallic aluminium, 10-16% of aluminium magnesium alloy, 3-7% of metallic manganese, 5-13% of metallic nickel, 0-5% of metallic cobalt and 0.1-0.4% of metallic zirconium, and the sum of the mass percent of the components is 100%. The preparation method comprises the following steps: mixing fluoride, oxide, carbonate and sodiumborate to obtain a mixture, carrying out sintering pretreatment on the mixture, then, adding other raw materials, uniformly mixing to obtain flux core powder, adding the flux core powder in the steelstrip, and carrying out reducing, straightening, disc winding and packaging to obtain the finished product of the welding wire.

Owner:SHENYANG AEROSPACE UNIVERSITY

Ultralow-carbon austenitic welding wire material for welding of stainless steel

InactiveCN102319965AReduced cold crack susceptibilityReduce sensitivityWelding/cutting media/materialsWelding/soldering/cutting articlesRare-earth elementChemical composition

The invention provides an ultralow-carbon austenitic welding wire material for the welding of stainless steel. According to percentage in weight, the specific chemical components of the welding wire material are as follows: less than or equal to 0.023 percent of C; 3.87 to 4.45 percent of Si; 0.57 to 0.89 percent of Mn; less than or equal to 0.023 percent of P; less than or equal to 0.013 percent of S; 18.59 to 19.32 percent of Cr; 13.57 to 14.87 percent of Ni; less than or equal to 0.33 percent of Mo; less than 0.044 percent of N; 0.09 to 0.29 percent of Cu; and the balance of Fe and inevitable impurities; and the welding wire material also comprises 0.02 to 0.042 percent by weight of rare-earth element Re. The welding wire material has the beneficial effects that: the component design is scientific, the welding wire material is convenient to use, the cold-cracking sensitivity of metal at the weld is low after welding, the performance result of the metal at the weld is near to the performance result of parent metal, and moreover, the welding wire material has high low-temperature impact toughness and corrosion resistance; and in particular, the ultralow-carbon austenitic welding wire material for the welding of stainless steel can resist the corrosion of concentrated nitric acid.

Owner:JIANGSU XINGHAI SPECIAL STEEL

Low-hydrogen type stainless steel self-protecting flux-cored wire suitable for underwater environment

ActiveCN111571066ALow diffusible hydrogen contentRealize underwater weldingWelding/cutting media/materialsSoldering mediaArc stabilitySS - Stainless steel

The invention belongs to the field of welding materials, and relates to a low-hydrogen type stainless steel self-protecting flux-cored wire suitable for underwater environment. The low-hydrogen type stainless steel self-protecting flux-cored wire comprises outer layer metal skin and inner medicine cores, wherein the outer layer metal skin is 316L stainless steel band. The low-hydrogen type stainless steel self-protecting flux-cored wire is characterized in that the inner medicine core consists of components in percentage by mass of 40-60% of a gas making slagging agent, 2-5% of an arc stabilizer, 3-15% of a deoxidizer and 30-50% of an alloying agent. According to the self-protecting flux-cored wire, the gas making slagging agent achieves the effect of protecting weld metals, welding and arc starting are easy, and arc stability is good. Full-position underwater welding of metal structures of low-alloy steels, stainless steels and the like can be realized, the obtained welding contacts are high in quality, and can be used for high-quality repair and welding on metal structures associated with underwater environment of nuclear power, marine, and the like.

Owner:JIANGSU UNIV

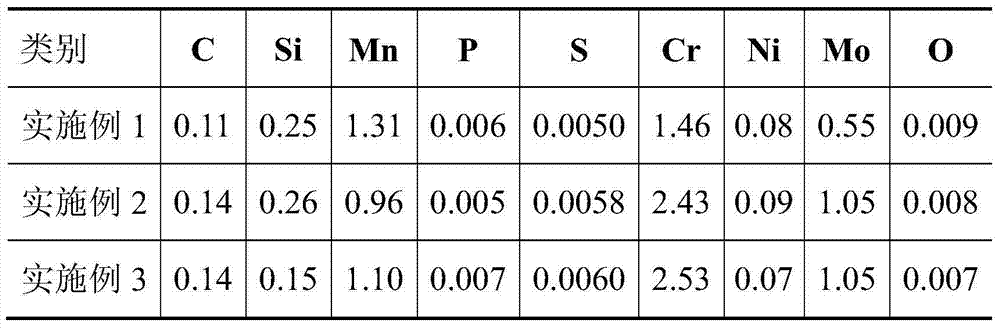

T/P91 steel electrode and manufacturing method thereof

InactiveCN103111774AArc stabilizationReduced chance of splashingWelding/cutting media/materialsSoldering mediaNiobiumWeight coefficient

The invention discloses a T / P91 steel electrode manufacturing method. An R40 welding wire is used as a core wire. Medical powder comprises, by weight percentage, marble 31-35, fluorite 26-29, titanium dioxide 4-7, quartz 1-2, mica 1-2, chromium metal 13-15, atomization nickel powder 1-2, ferrotitanium 7-9, ferromolybdenum 1-2, ferroniobium 0.5-1, ferrovanadium 1-2, and vanadium-nitrogen alloy 1-2. After the powder is mixed in a drying mode, water glass is added according to a ratio of 3:1 and is mixed with the powder in a wet mode, and suppression is carried out after uniform stirring is carried out. Electrode coating weight coefficient is controlled to be 0.95-1.0, cracking of a coating after being dried is avoided, the compression environmental temperature is over 20 DEG C, the products are placed into a drying box after being dried for 3 hours, and is dried for 2 hours when temperature is 100 DEG C, 125 DEG C per hour is risen into 450 DEG C, and then furnace cooling of the products is carried out after being warmed for two hours. The steel electrode is good in welding process performance, little in splatter, low in smoke amount, and attractive in appearance of weld. All the performances can reach foreign imported similar steel electrode technological level. Production cost is greatly reduced.

Owner:天津诚信达金属检测技术有限公司

Submerged arc flux

ActiveCN1876313ALow diffusible hydrogen contentGood diffusible hydrogen contentArc welding apparatusWelding/cutting media/materialsHydrogenParticle flux

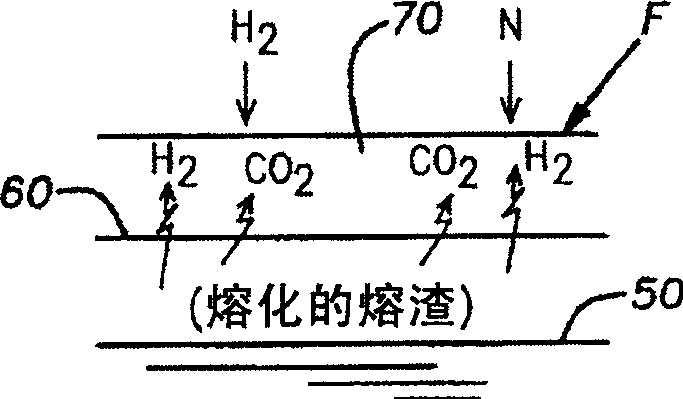

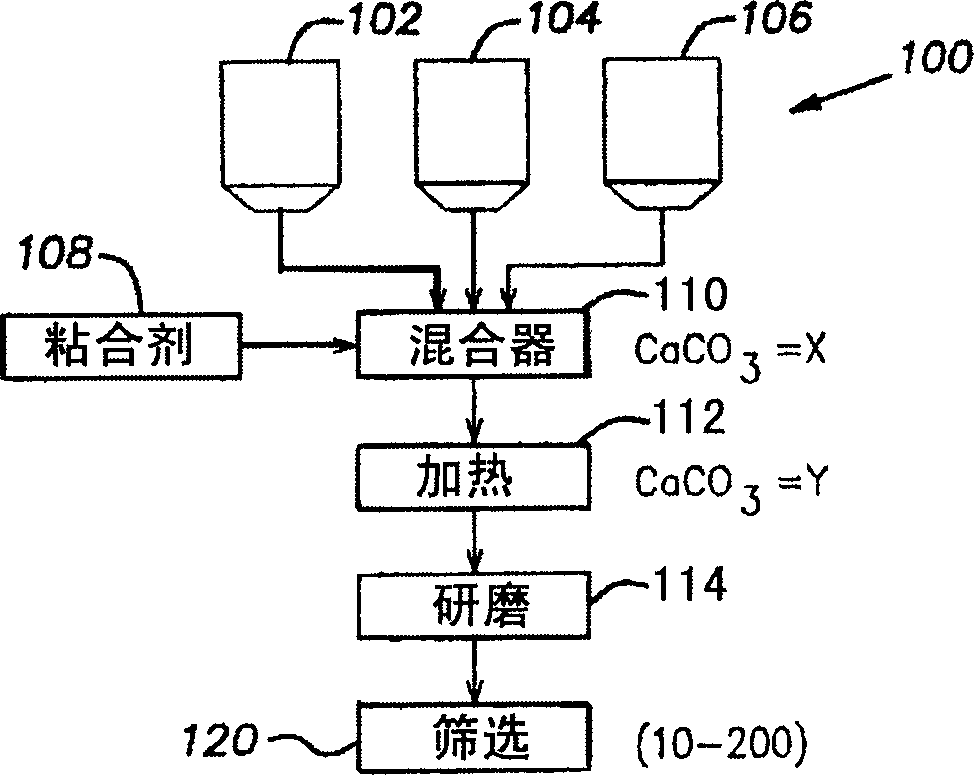

A highly basic particle flux for submerged arc welding that produces less than 7 ml / 100 g of diffusible hydrogen in the weld metal, which flux comprises a carbon dioxide containing compound with an effective amount of heat releasable carbon dioxide in the range of 0.5-3.5% by weight of the flux over 10% by weight of a low melting point compound and a binder.

Owner:LINCOLN GLOBAL INC

High-strength galvanized steel sheet and method for producing the same

ActiveUS20200032364A1Excellent delayed fracture resistanceHigh strengthHot-dipping/immersion processesFurnace typesHydrogen contentMartensite

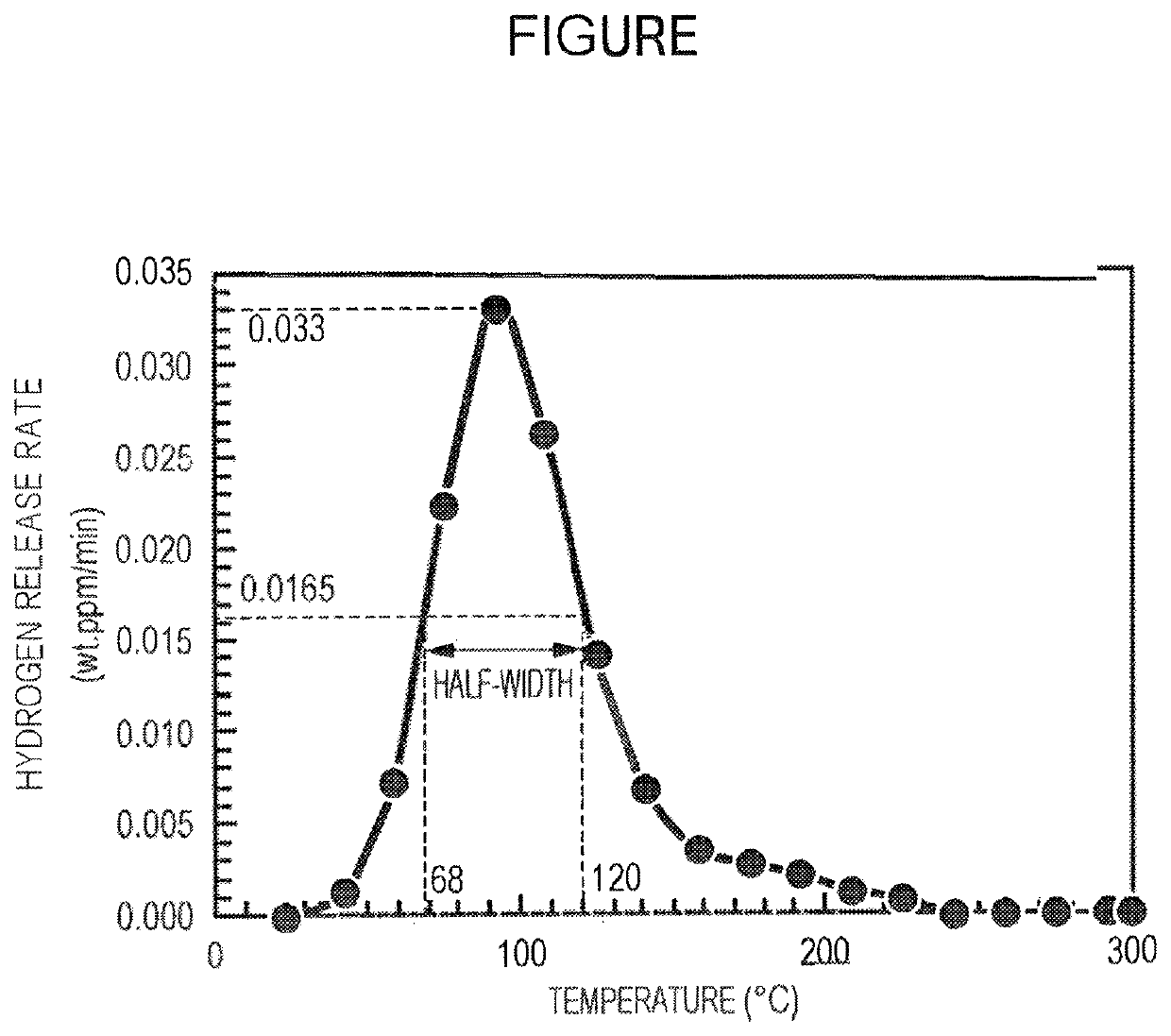

Provided are a high-strength galvanized steel sheet having excellent delayed fracture resistance by reducing the diffusible hydrogen content in the steel and a method for producing the same.The high-strength galvanized steel sheet includes a steel sheet having a prescribed composition and a microstructure including martensite and tempered martensite, the total area fraction of the martensite and the tempered martensite being 30% or more, and a galvanizing layer formed on the surface of the steel sheet. The diffusible hydrogen content in the high-strength galvanized steel sheet is 0.50 wt. ppm or less. The half-width of the hydrogen release peak of the high-strength galvanized steel sheet is 70° C. or less. The diffusible hydrogen content and the half-width of the hydrogen release peak are determined by a prescribed analysis method.

Owner:JFE STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com