Gas protective flux cored wire for welding vanadium-containing heat resistant steel

A technology of flux-cored welding wire and gas shielding, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., which can solve the problem of increasing the labor intensity of welders and welding costs, the inability to perform multi-layer continuous welding without slag cleaning, and welding process Poor performance and physical and chemical properties, etc., to achieve comprehensive performance and high welding efficiency, improve process performance and physical and chemical properties, and good welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: In this embodiment, a steel strip of (width×thickness) 14*0.9mm is used to make a metal sheath, and its chemical composition is C 0.04wt%, Mn 0.25wt%, Si 0.015wt%, S 0.01wt%, P 0.01wt% %, the surplus is iron, taking the preparation and production of 100Kg welding wire as an example, the present embodiment flux core accounts for 15wt% of the whole welding wire weight, and each composition in the flux core is: medium carbon ferromanganese 2.4Kg, ferrosilicon powder 1.0Kg, magnesium ( Mg) powder 0.2Kg, metal chromium (Cr) powder 1.5Kg, molybdenum iron powder 0.9Kg, vanadium iron powder 0.4Kg, fused magnesia 0.1Kg, fluoride (calcium fluoride) 0.2Kg, plus reduced iron powder 8.3Kg Until the total weight of the drug core ingredients is 15Kg; then mix the ingredients in the drug core evenly and set aside;

[0019] Put the steel strip in the welding wire forming machine, inject the ready-to-use flux core mixture into the groove of the steel strip that is bent tran...

Embodiment 2

[0026] Embodiment 2: the sheath of welding wire is identical with embodiment 1, is example with preparation and production 100Kg welding wire, and the flux core of present embodiment accounts for 20wt% of whole welding wire weight, and each composition is in the flux core: medium carbon ferromanganese 2.4Kg, ferrosilicon Powder 1.0Kg, magnesium (Mg) powder 0.2Kg, metal chromium (Cr) powder 1.5Kg, molybdenum iron powder 0.9Kg, vanadium iron powder 0.4Kg, fused magnesia 0.1Kg, calcium fluoride and potassium fluotitanate 0.2Kg (each 0.1Kg), add iron powder 13.3Kg to medicine core batching gross weight 20Kg; Stand-by after each composition in the medicine core is mixed then; All the other are identical with embodiment 1, it:

[0027] Chemical composition of deposited metal (%)

[0028] C

mn

Si

S

P

Cr

Mo

V

0.07

0.9

0.3

0.007

0.010

1.15

0.45

0.14

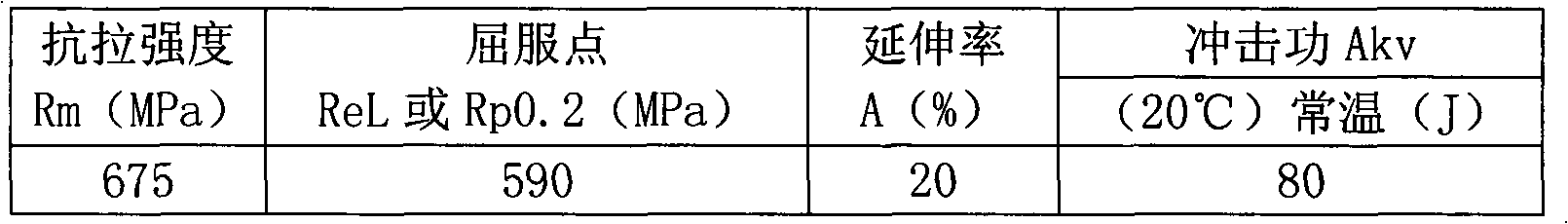

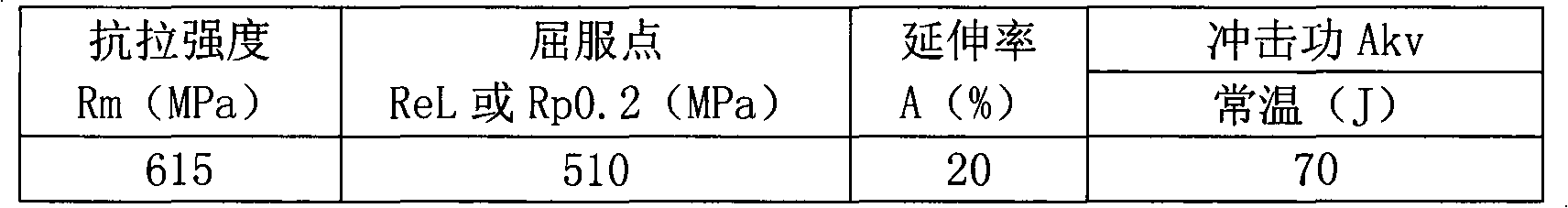

[0029] Mechanical properties o...

Embodiment 3

[0032] Embodiment 3: the sheath of welding wire is identical with embodiment 1, is example with preparation and production 100Kg welding wire, and the flux core of present embodiment accounts for 20wt% of whole welding wire weight, and each composition is in the flux core: medium carbon ferromanganese 2.4Kg, ferrosilicon Powder 1.0Kg, magnesium (Mg) powder 0.2Kg, metal chromium (Cr) powder 1.5Kg, molybdenum iron powder 0.9Kg, vanadium iron powder 0.4Kg, fused magnesia 0.1Kg, sodium fluoride and potassium fluotitanate 0.26Kg (each 0.13Kg), add atomized iron powder 13.24Kg to 20Kg of medicine core batching gross weight; Then each composition in the medicine core is mixed and stand-by;

[0033] Put the steel strip in the welding wire forming machine, inject the ready-to-use flux core mixture into the groove of the steel strip that is bent transversely into a "U" shape, and then roll it into a strip, and then draw it to the wire of Φ2.0mm. become.

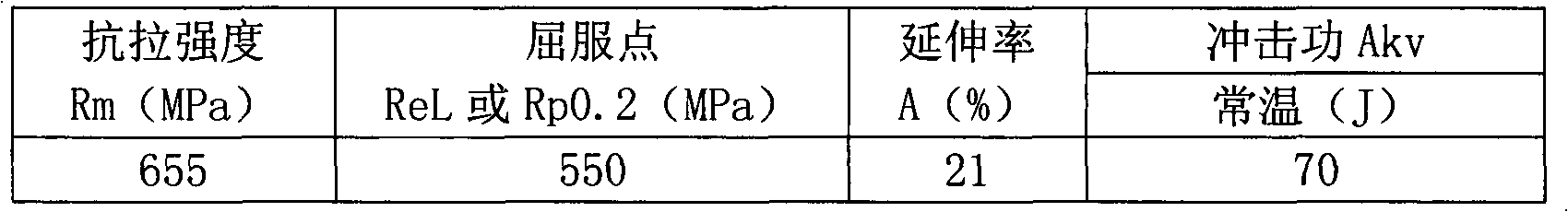

[0034] In this embodiment, wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com