Ultra high strength flux cored arc welded joint having excellent impact toughness and welding wire for manufacturing same

A technology of flux-cored wire and impact toughness, which is applied in the field of flux-cored arc welding joints and flux-cored arc welding wires. It can solve the problems of difficult to ensure arc characteristics, small diffused hydrogen, difficult to apply welding wire filling and surface, etc., and achieve excellent Impact toughness, effect of reducing diffusible hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

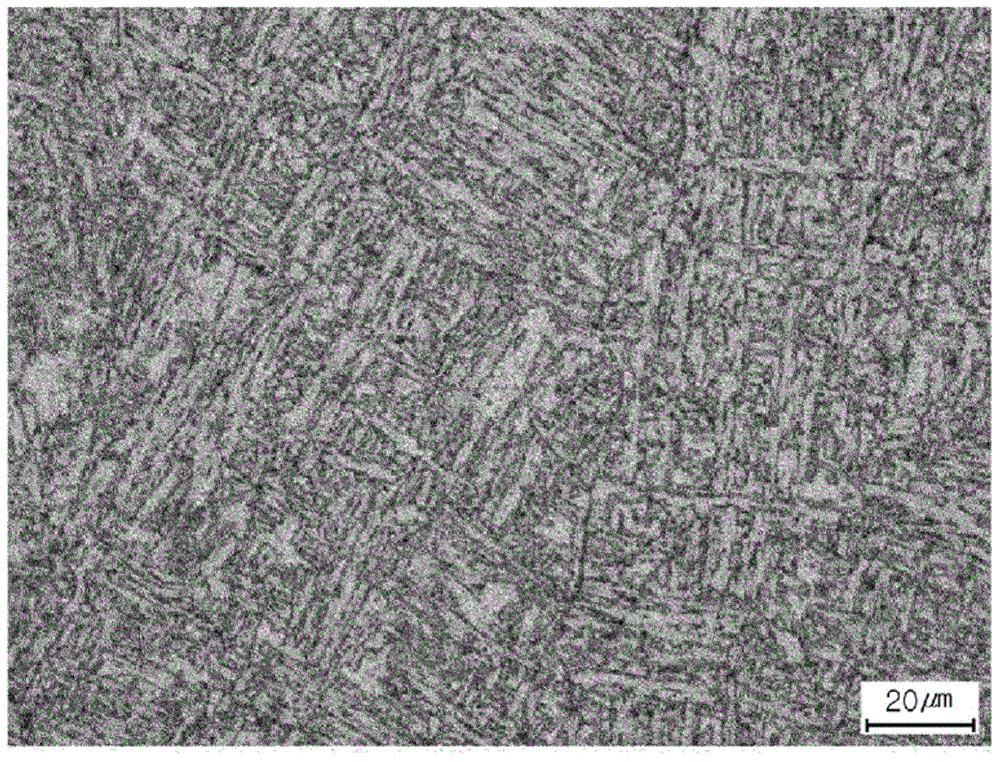

Image

Examples

Embodiment 1

[0140] For building steel HSA800 containing: C: 0.05%, Si: 0.13%, Mn: 2.5%, P: 0.008%, S: 0.002% and other Ni, Cr, Cu, Nb, Ti, B in weight % Steel, utilizes 1.6mm diameter wire and uses 100% CO 2 Shielding gas, flux-cored arc welding (FCAW) is implemented at a heat input of 20KJ / mm. When carrying out the FCAW, welding was performed under the conditions of current: 270 A, voltage: 28 V, welding speed: 23 cm / min, interpass temperature: 150° C. or less.

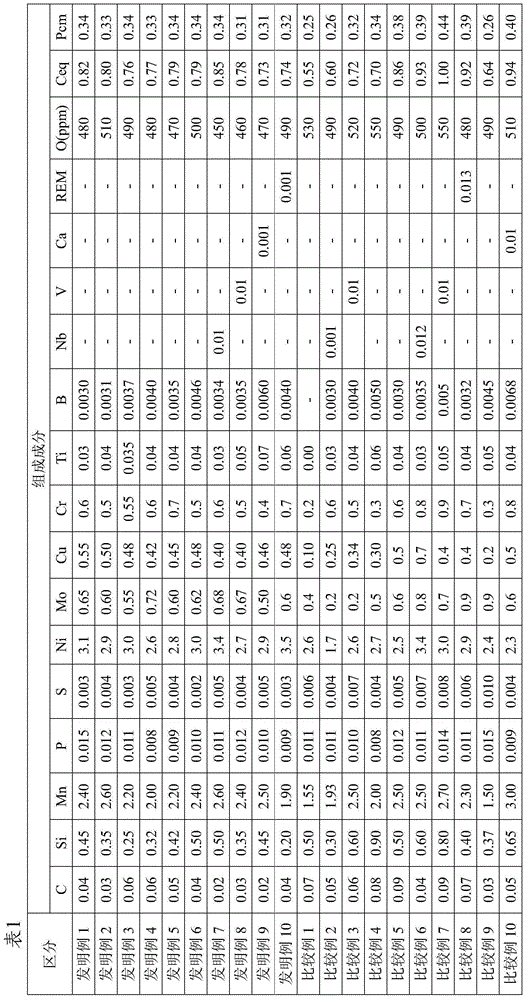

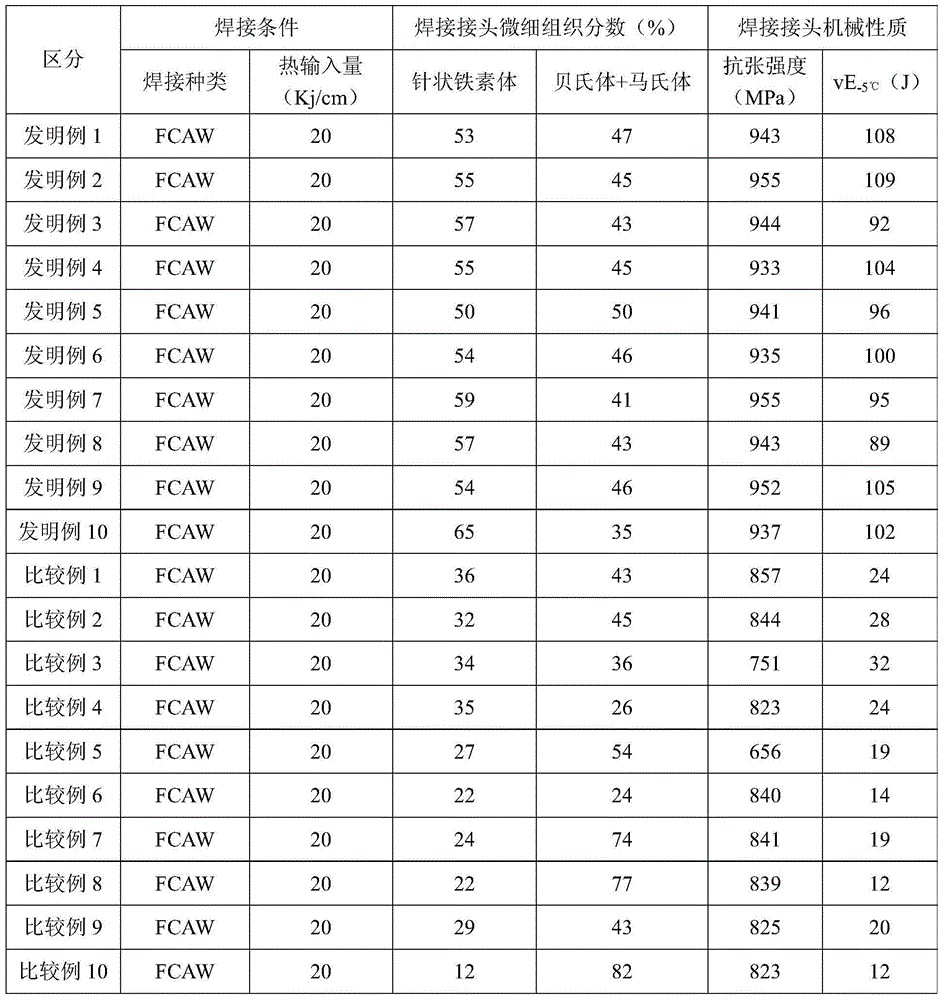

[0141] The following table 1 shows the composition results of the welded joints formed after the flux-cored arc welding, and measured the welding conditions during the welding, the microstructure and mechanical properties of the welded joints after welding, and compared them are shown in Table 2. The impact toughness among the above-mentioned mechanical properties was evaluated by Charpy impact test on the impact absorbed energy (vE) of the welded joint using KS standard (KS B 0809) impact test piece.

[0142]

[0143] Tab...

Embodiment 2

[0149] Flux-cored arc welding wires filled with flux having the composition shown in Table 3 below were manufactured.

[0150] Next, use the above welding wires to perform flux-cored arc welding under the conditions of welding current: 270-290A, voltage: 30-32V, welding speed: 25-27cm / min, and welding heat input: 18-25KJ / cm , and the composition of the welded joint formed after the above welding is shown in Table 4, and the results of evaluating the mechanical and physical properties of the welded joint, diffusible hydrogen and welding wire arc stability are shown in Table 3.

[0151] At this time, low-carbon (C)-based HSA800 steel with a tensile strength of 800 MPa or more and a low yield ratio was used as the base material for welding.

[0152] The test piece used for the tensile test was collected from the central part of the welded joint. The tensile test piece used No. 4 test piece of KS specification (KS B 0801), and the tensile test was carried out at the crosshead spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com