Ultralow-hydrogen high-toughness submerged arc welding flux core and submerged arc flux-cored wire

A flux-cored wire, high toughness technology, used in welding media, welding equipment, welding/cutting media/materials, etc., to achieve the effects of excellent process performance and mechanical properties, stable welding arc, and high fracture toughness value.

Inactive Publication Date: 2013-01-02

TIANJIN UNIV +1

View PDF8 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Neither of the above two submerged arc welding flux-cored wires mentions that an appropriate amount of slag agent is added to the wire, which is suitable for high-alkalinity sintered flux and low-moisture-absorbing smelting flux at the same time, so as to reduce the diffusion of hydrogen in the weld and improve low-temperature toughness and resistance. cracking content

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

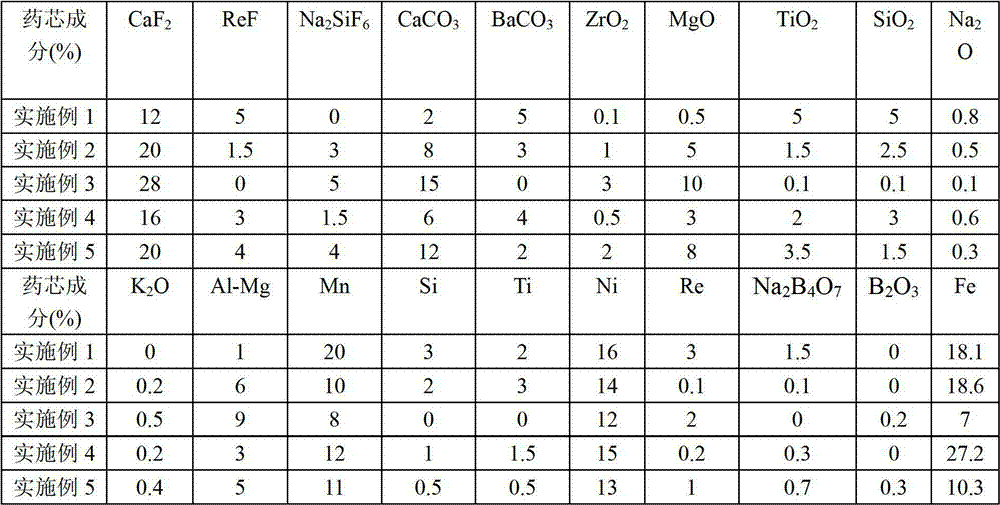

[0021] Table 1 Example drug core composition (weight %)

[0022]

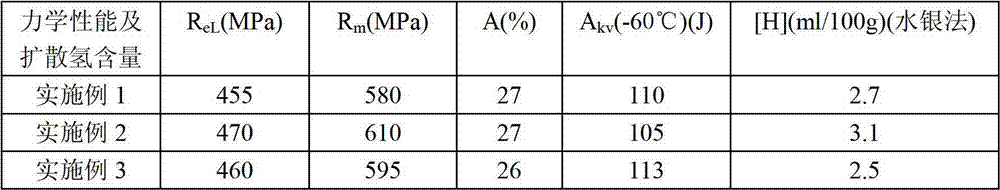

[0023] Table 2 The mechanical properties and diffusible hydrogen content of the deposited metal in combination with the sintered flux SJ102

[0024]

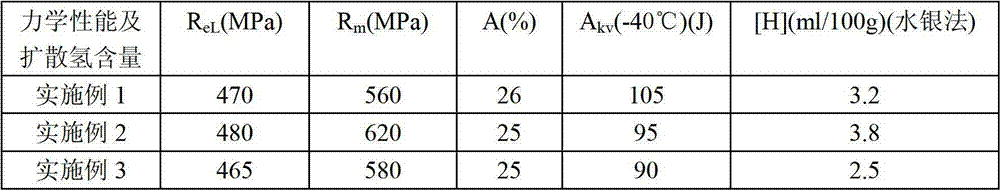

[0025] Table 3 The mechanical properties and diffusible hydrogen content of the deposited metal in combination with the example and the melting flux HJ250

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an ultralow-hydrogen high-toughness submerged arc welding flux core and a submerged arc flux-cored wire. The welding flux core comprises the following components of: CaF2, Na2SiF6, ReF, BaCO3, CaCO3, MgO, TiO2, SiO2, ZrO2, boride, Na2O, K2O, Mn, Al-Mg, Ni, Ti, Si, Re and the balance of Fe. When the welding flux core is matched with a high-alkalinity sintering welding flux, the weld metal has the impact absorbed power of more than 80J at the temperature of 60 DEG C below zero; when the welding flux core is matched with a low-hygroscopicity smelting welding flux, the weld metal has the impact absorbed power of more than 90J at the temperature of 40 DEG C below zero; and when the welding flux core is matched with any one welding flux, weld diffusion hydrogen content is less than 5ml / 100g. The standard specific ultralow-hydrogen range is achieved; and the submerged arc flux-cored wire is high in cold crack resistance, has high in fracture toughness value, is suitable for low-alloy high-strength steel and can be used for welding important structures.

Description

technical field [0001] The invention relates to the field of welding materials, in particular to an ultra-low hydrogen and high toughness submerged arc welding flux core and a submerged arc flux cored welding wire. Background technique [0002] As an automatic and efficient welding process, submerged arc welding has been widely used. However, due to the large welding line energy, the cooling rate of the welding zone is slow, and the weld metal structure is easy to coarsen, resulting in a decrease in low temperature toughness. Therefore, there is always a contradiction between the high efficiency of the welding process and the high toughness of the joint metal in this process. At the same time, the high-alkalinity sintered flux combined with high-toughness welding wire has the disadvantages of high moisture absorption, high content of diffusible hydrogen in the weld, and easy formation of hydrogen-induced cracks under the condition of large degree of restraint. [0003] At p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K35/368B23K35/30

Inventor 张智李尧铭冯灵芝

Owner TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com