Patents

Literature

32results about How to "Less harmful impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raw material for preparing aluminum-silicon alloy by electrothermal process

This invention relates to the raw material in aluminum silicon alloy production, being composed of in weight percentage kleit 49-58% containing Fe2O3 up to or less than 1%, aluminum oxide 5-13%, smoke coal 34-38% containing >=32% of volatile share weight, 1.100-1.200grams / centimeter lignosulphonate liquid prepared from 20-22% gross weight of above three raw materials as well as 30-60 DEG C hot water. The cost is low, which causes the aluminum silicon alloy cost to reduce 15-20%, simultaneously aluminum silicon alloy contains few deleterious substance,and it is simple to remove the impurity. Aluminum silicon alloy prepared in the invention contains in weight percentage aluminum 56.7, silicon 38.8, titanium 0.87, iron 1.3, calcium 0.37, carbon 1.5 and other impurities 0.5 in average.

Owner:登封电厂集团铝合金有限公司 +1

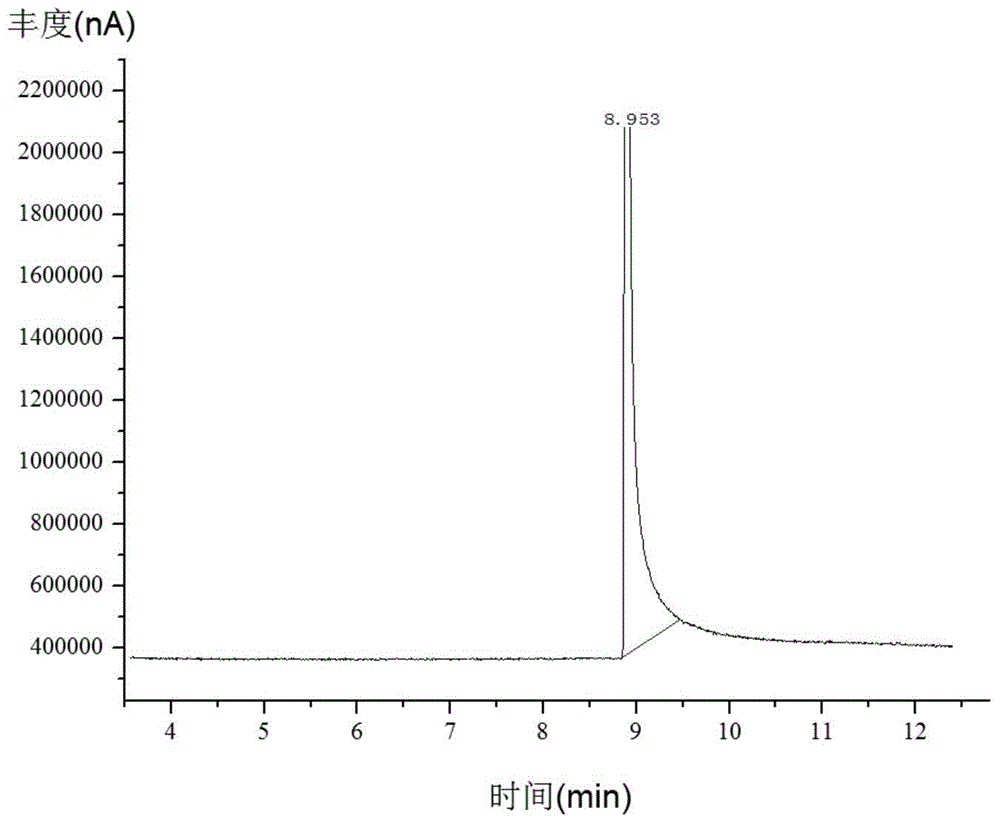

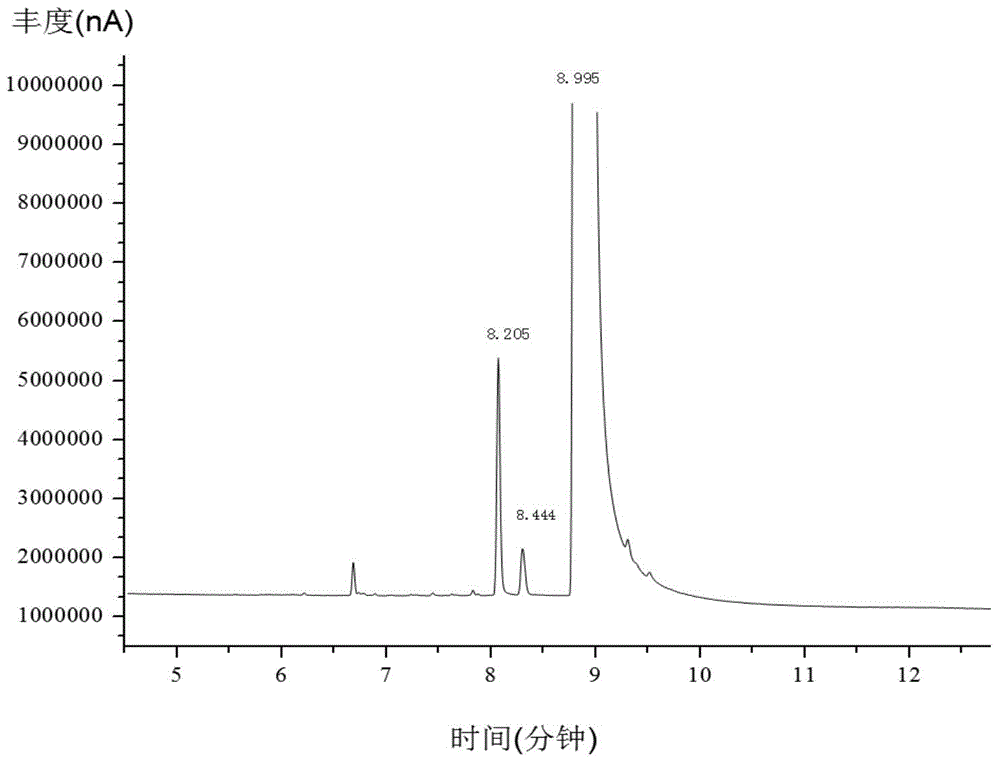

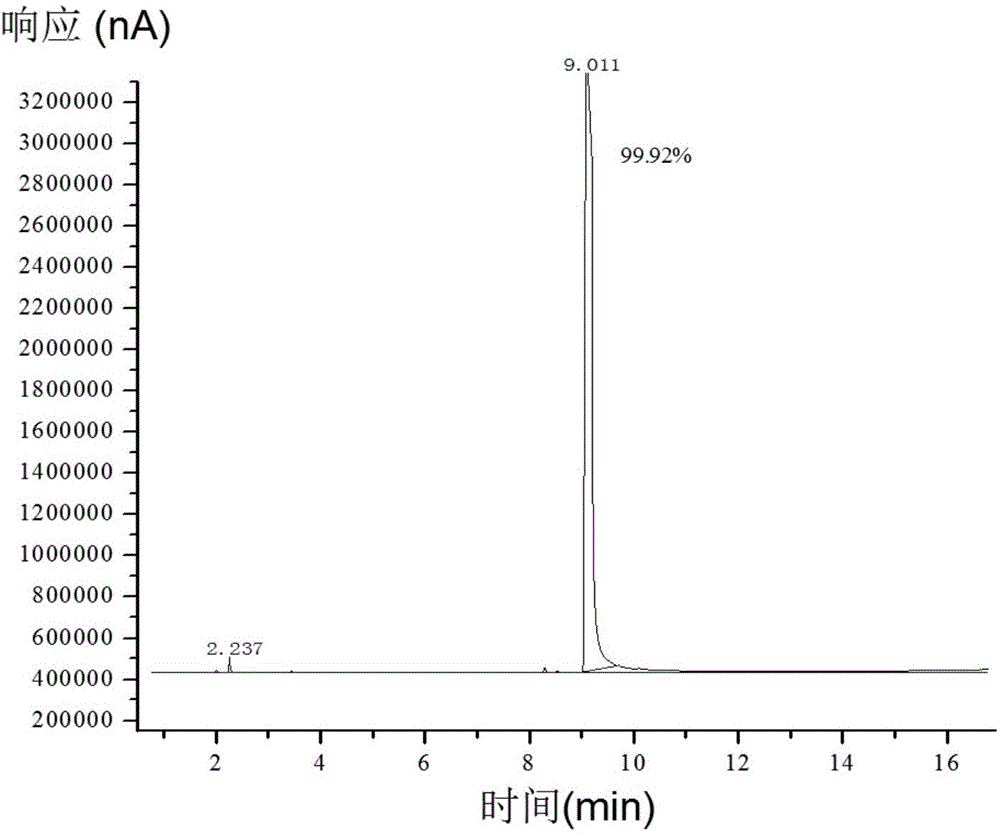

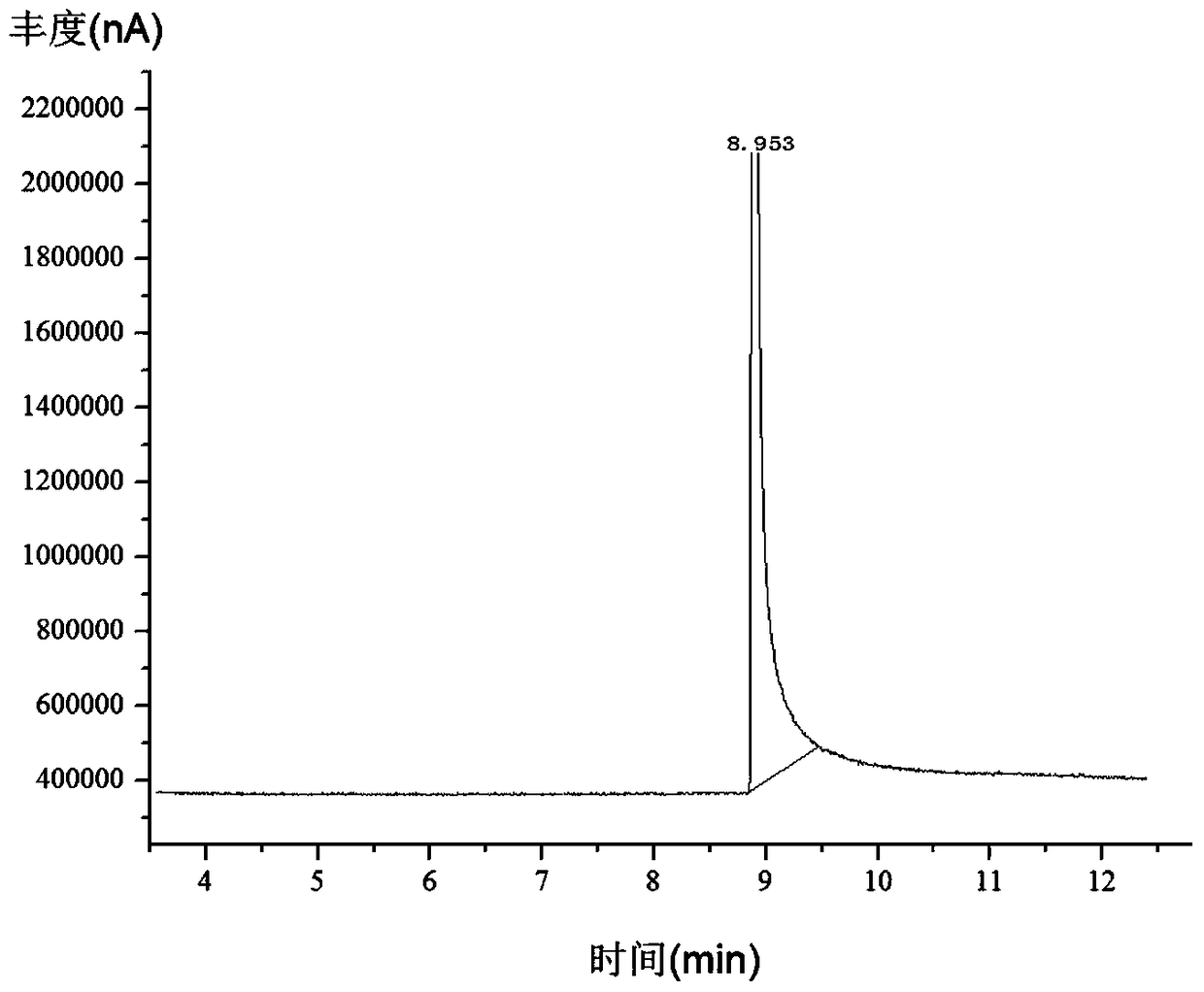

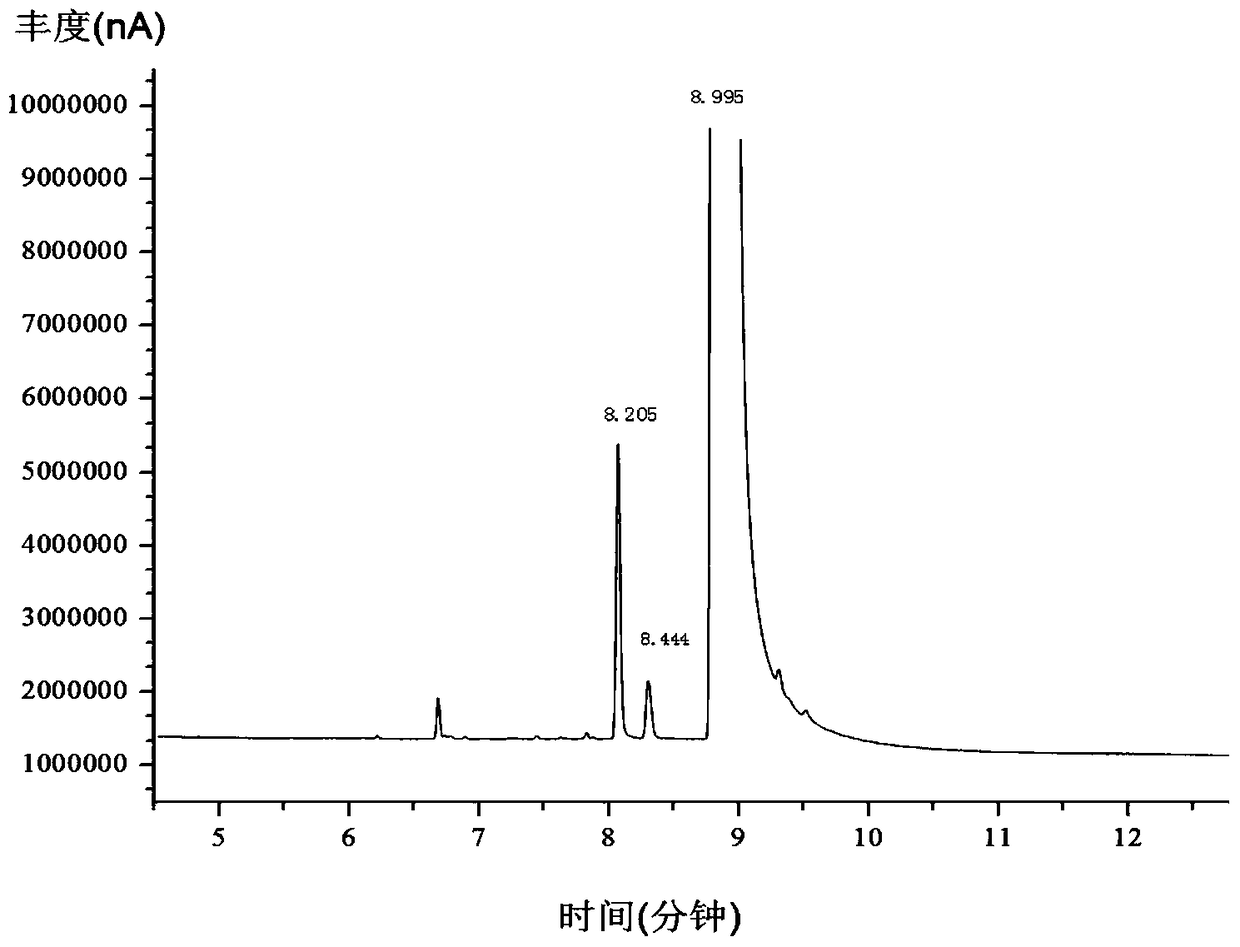

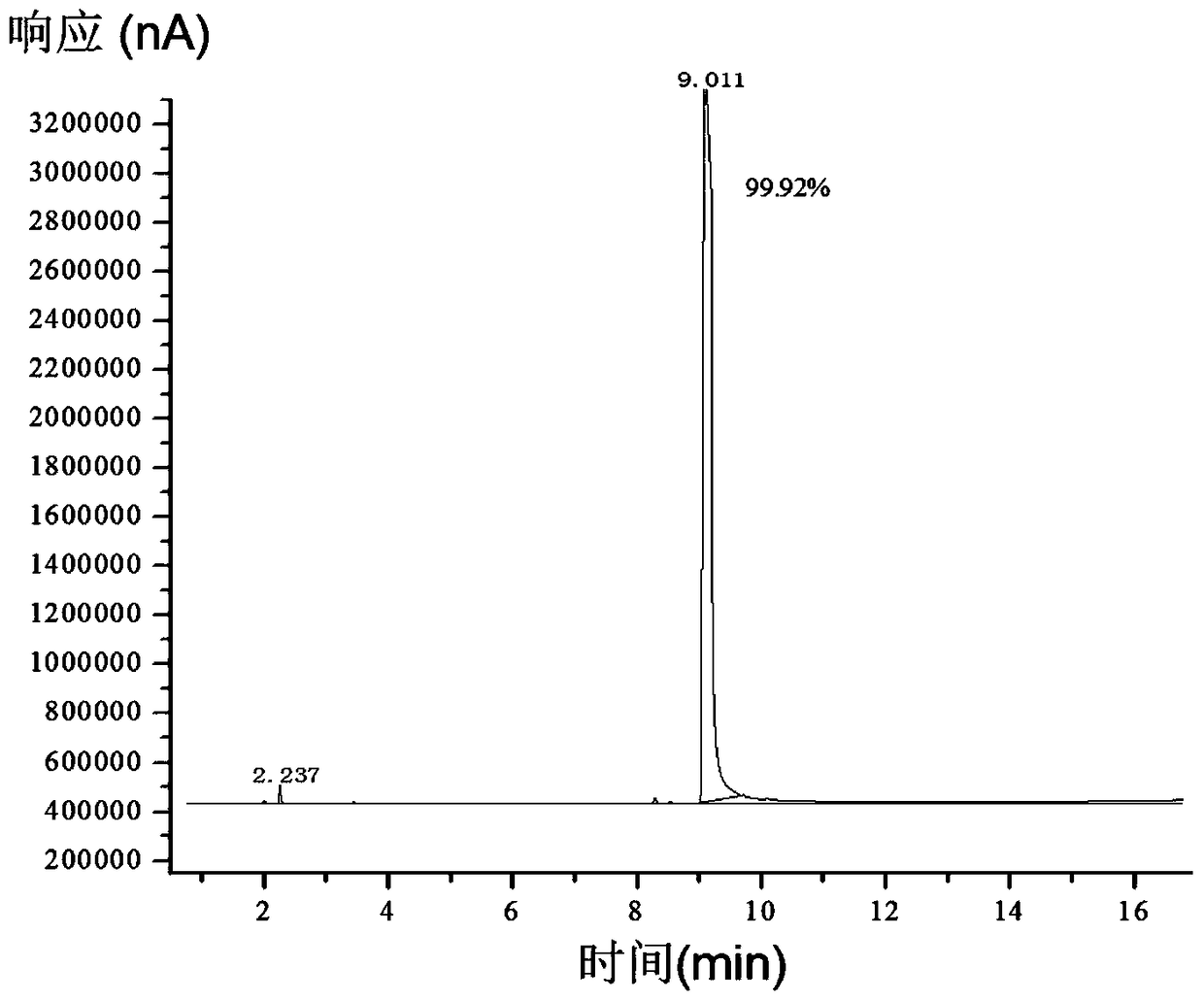

Preparation method of high purity nicotine

The invention relates to natural biological product separation and purification and concretely relates to a preparation method of high purity nicotine. The preparation method comprises pouring a nicotine organic solution without naphthalene oil-soluble impurities and high-boiling point alkaloid impurities into a short-path molecular distillation device and carrying out rectification on the nicotine organic solution at a temperature of 0-100 DEG C under pressure of 0.001-1mbar to obtain high purity nicotine. The invention provides a method for removing naphthalene oil-soluble impurities with boiling points similar to that of nicotine and high-boiling point alkaloid impurities in nicotine through extraction-back extraction. The preparation method is carried out at a low temperature at a high degree of vacuum and prevents impurities produced through nicotine pyrolysis and oxidation. The product has purity of 99.92%, good appearance, a good smell and a high extraction yield.

Owner:北京本草通汇科技中心

Efficient wood particle active carbon for automobile carbon tank and preparation method thereof

ActiveCN107140636AImprove efficiencyHigh purityNon-fuel substance addition to fuelCarbon compoundsSodium BentoniteDesorption

The invention discloses wood particle active carbon for an automobile carbon tank and a preparation method thereof, and belongs to the fields of active carbon for the automobile carbon tank and the preparation method of the active carbon. The weight ratio of major raw material ingredient of wood active carbon powder to organic sodium-based bentonites to water is 1:(0.2 to 0.25):(0.8 to 1.0); the three kinds of raw materials are uniformly stirred and are then pelleted; after pelleted particles are dried, physical activation is performed to obtain the wood particle active carbon; the wood active carbon powder is formed by mixing aged wood chips and thermal-process food stage phosphoric acid with the concentration being 85 percent according to a weight ratio of 1:(1.2 to 1.5) through fully stirring, still soaking, high-temperature carbonization activation, recovery, rinsing, drying and powder preparation. The preparation method comprises two major work procedures of wood active carbon powder preparation and wood particle active carbon preparation. The product strength is high; the effective aperture pore volume is more developed; the distribution is more uniform; the adsorption and desorption performance is good; the gas flowing resistance is small.

Owner:湖南御洁新材料科技有限公司

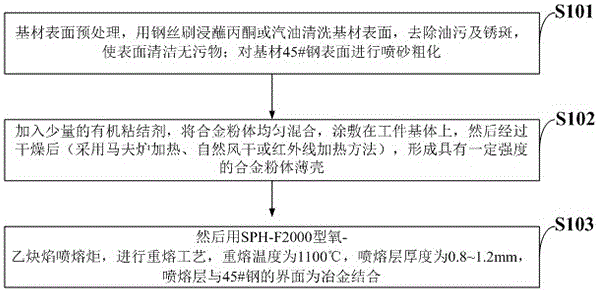

Abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material and application thereof

The invention discloses an abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material and application thereof. The abrasive-wear-resistant rare-earth-containing Ni-Cr-Fe alloy powder material comprises the following components in percentage by weight: 2.0%-3.0% of C, 3.0%-4.0% of B, 2.5%-3.5% of Si, 18%-20% of Ni, 16%-18% of Cr, 0.3%-0.5% of Ce and Fe in balancing amount. Rear earth is added into the powder material, so that the performance of the powder material is improved, and the content of a precious metal in powder material is reduced to lower the cost of the powder material; owing to the addition of rear earth, the hard phase in a coating structure is distributed uniformly, the binding force between the coating structure and a matrix is enhanced, the coating structure is hindered from stripping during an abrasive wear process, and the abrasive-wear resistance of the coating structure is improved; and problems about surface protection and workpiece repair of large-scale equipment and key parts are solved, the cost is saved, and economic benefits are created.

Owner:LANZHOU INST OF TECH

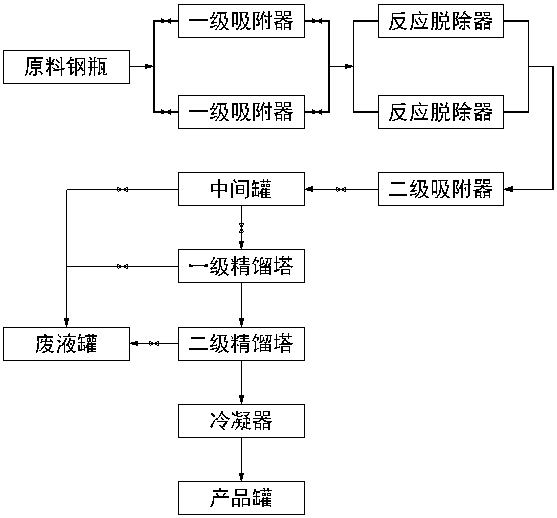

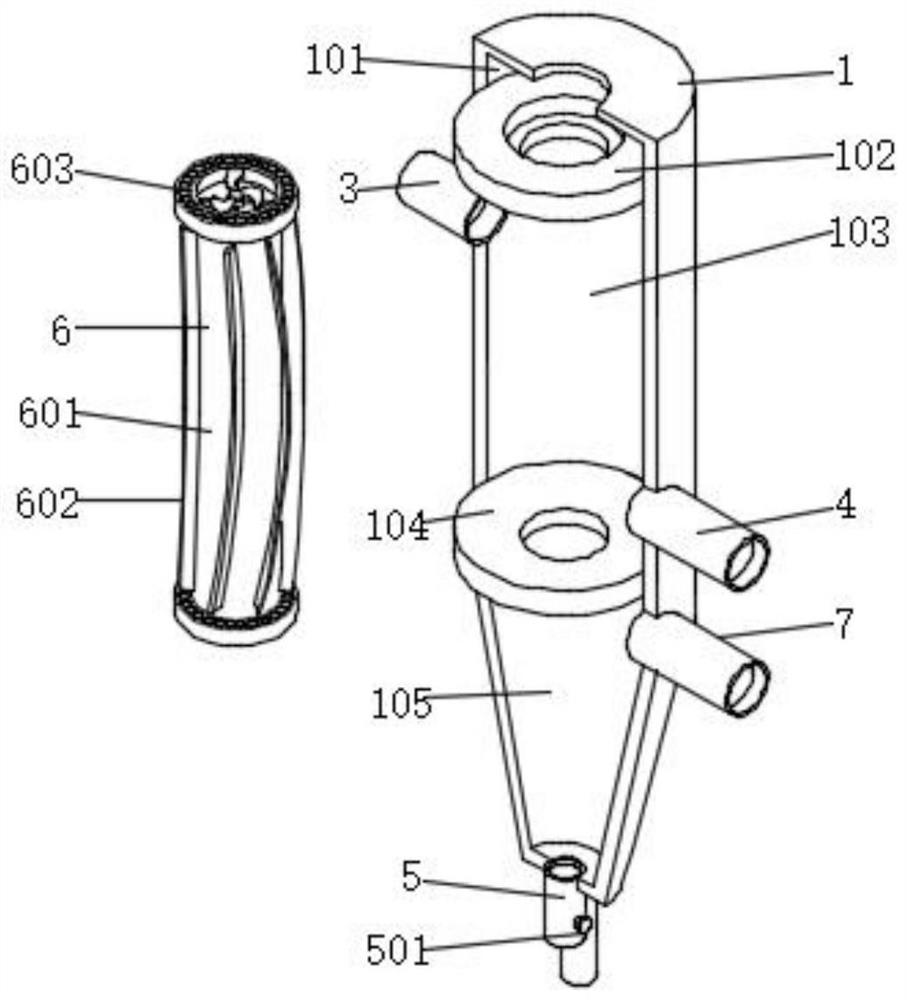

Boron trichloride purification apparatus

InactiveCN108163868AExcellent adsorption effectImprove adsorption efficiencyBoron halidesCooling coilDecomposition

The invention discloses a boron trichloride purification apparatus, and belongs to the technical field of boron trichloride purification. The apparatus comprises a raw material steel cylinder, a primary adsorber, a reaction remover, a secondary adsorber, an intermediate tank, a primary rectification tower, a secondary rectification tower, a condenser and a product tank which are sequentially connected, the primary adsorber is a two-channel parallel structure, the reaction remover is a two-channel parallel structure, a heating and cooling coil jacket is arranged in the outer periphery of the tank body of the intermediate tank, and the residual waste liquid discharging openings of the intermediate tank, the primary rectification tower and the secondary rectification are connected with a waste liquid tank. Adsorption, decomposition, reaction, distillation and condensation can gradually performed through above devices and process steps in order to reduce the content of harmful impurities in a boron trichloride raw material to 0.5 ppm or less and make the raw material fully meet the requirements of the LED industry and the chip industry.

Owner:SHANGHAI HELI IND GAS CO LTD

Passivating metal magnesium particles and passivating method thereof

ActiveCN103695884AEvenly wrappedPrecise active magnesium contentLiquid surface applicatorsMetallic material coating processesGraphiteOrganosilicon

The invention discloses passivating metal magnesium particles and a passivating method thereof. The passivating metal magnesium particles comprise the following components in percentage by weight: less than or equal to 99% and greater than or equal to 92% of Mg, less than or equal to 0.002% of S, less than or equal to 0.01% of Cu, less than or equal to 0.001% of P and less than or equal to 1.2% and greater than or equal to 0.1% of H2O. The passivating method comprises the following steps: (I), preparing a metal magnesium particle passivator, placing metal magnesium particles in the passivator, and then naturally cooling to room temperature; (II), coating a coating on the surface of the magnesium particles: firstly, coating an organic silicon compound on the surface of the metal magnesium particles, coating magnesium oxide on the surface of the metal magnesium particles, then, coating compound rare earth on the on the surface of the metal magnesium particles, and finally coating graphite powder on the surface of the metal magnesium particles; and (III), sieving the metal magnesium particles cooled to room temperature. The metal magnesium particle passivating layer is uniform in coating, and the storage and use safety is ensured.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

Composite carbonaceous reductant for industrial silicon and preparation method thereof

ActiveCN104003395AQuality improvementHigh fixed carbon content in cokeSilicon compoundsTrace elementNew energy

The invention relates to a composite carbonaceous reductant for industrial silicon and a preparation method thereof, and belongs to the industrial silicon smelting and new energy resource technical fields. The composite carbonaceous reductant is of a pellet shape, the fixed carbon content reaches above 75 wt.%, the volatile matter content is 15 wt.%-20 wt.%, the ash content is below 4 wt.%, and the contents of trace elements of Fe, Al and Ca in ash are controlled respectively below 0.15 wt.%, below 0.5 wt.% and below 0.6 wt.%. The preparation method comprises the steps: finely grinding petroleum coke and low-ash coal, mixed evenly, adding a binder and water, then pressing into pellets under the condition of the pressure of 5-10 MPa, drying the pellets, and thus obtaining the composite carbonaceous reductant. The composite carbonaceous reductant for industrial silicon is high in fixed carbon content and good in reaction activity; and the preparation method of the composite carbonaceous reductant for industrial silicon is simple in process and easy to industrialize.

Owner:KUNMING UNIV OF SCI & TECH

Safe and environment-friendly fuel and preparing method thereof

ActiveCN105038895ALow impurity contentLess harmful impuritiesSolid fuelsFuel additivesChemistryEnvironmentally friendly

Safe and environment-friendly fuel comprises, by mass, 80-90% of hexamethylenetetramine, 3-10% of paraffin, 5-11% of stearic acid and 0.005-0.015% of ferrocene. The safe and environment-friendly fuel is prepared through the method including the steps that paraffin, stearic acid and ferrocene are mixed and smashed after being sealed for 10-14 hours, and a mixture A is obtained; hexamethylenetetramine is heated, the constant temperature from 100 DEG C to 150 DEG C is kept, stirring is conducted for 15-20 minutes, the mixture A is added to hexamethylenetetramine, and a mixture B is obtained; the mixture B is fully stirred, and 3-10% of calcium oxide solution is sprayed to the mixture B, wherein time is 60-100 minutes, and the temperature is 100-150 DEG C; the mixture B is smashed to be 80 meshes to 110 meshes and is forcefully stirred; briquetting forming is conducted. According to the safe and environment-friendly fuel and the preparing method thereof, the prepared solid fuel has the advantages of being high in calorific value, free of toxin and extraneous odor during burning, safe, environmentally friendly and the like.

Owner:随州市熠生火新能源有限公司

Special wild boar meat food and preparation method thereof

The present invention relates to the technical field of special wild boar meat food production, and particularly relates to a special wild boar meat food and a preparation method thereof. The special wild boar meat is subjected to curing process with curing agents for 2-3 hours and stir-frying or boiling process, thus making the prepared special wild boar meat food delicious in taste, bright and beautiful in color, fine and tender in meat texture, unique in flavor, and tender and smooth and refreshing; and then the special wild boar meat food is prepared by combining the ratios of raw materials and the selection of ingredients, thus making the obtained special wild boar meat food relatively good in meat quality, rich in nutrition, and convenient to eat.

Owner:GUIZHOU KANGZHENG ANIMAL HUSBANDRY TECH

Anticorrosion lead-acid battery fiberglass diaphragm

InactiveCN105655522AIncrease liquid absorptionImprove hydrophilicityCell seperators/membranes/diaphragms/spacersFinal product manufacturePorosityFiber

The invention provides an anticorrosion lead-acid battery fiberglass diaphragm, comprising a fiberglass composite anticorrosion layer, a polymer and water-soluble resin composite layer arranged on two surfaces of a fiberglass and polyvinyl alcohol fiber composite layer, and a nanoparticle coating arranged on the outer surface of the polymer and water-soluble resin composite layer. Fiberglass is applied in the manufacture of battery diaphragms, a produced battery diaphragm will have better properties than those of a common battery diaphragm, such as higher liquid absorbing capacity, higher liquid absorbing speed and better hydrophilicity, and a high liquid absorbing rate of the diaphragm is maintained in a whole lifetime; meanwhile, the fiberglass diaphragm has large surface specific area, high porosity, small pore size, high chemical purity, few harmful impurities, excellent acid resistance, excellent antioxidant property, small resistance and the like.

Owner:JIANGSU HUAFU STORAGE NEW TECH DEV

A kind of safe environment-friendly fuel and preparation method thereof

ActiveCN105038895BLow impurity contentRelease fullySolid fuelsFuel additivesParaffin waxHexamethylenetetramine

Safe and environment-friendly fuel comprises, by mass, 80-90% of hexamethylenetetramine, 3-10% of paraffin, 5-11% of stearic acid and 0.005-0.015% of ferrocene. The safe and environment-friendly fuel is prepared through the method including the steps that paraffin, stearic acid and ferrocene are mixed and smashed after being sealed for 10-14 hours, and a mixture A is obtained; hexamethylenetetramine is heated, the constant temperature from 100 DEG C to 150 DEG C is kept, stirring is conducted for 15-20 minutes, the mixture A is added to hexamethylenetetramine, and a mixture B is obtained; the mixture B is fully stirred, and 3-10% of calcium oxide solution is sprayed to the mixture B, wherein time is 60-100 minutes, and the temperature is 100-150 DEG C; the mixture B is smashed to be 80 meshes to 110 meshes and is forcefully stirred; briquetting forming is conducted. According to the safe and environment-friendly fuel and the preparing method thereof, the prepared solid fuel has the advantages of being high in calorific value, free of toxin and extraneous odor during burning, safe, environmentally friendly and the like.

Owner:随州市熠生火新能源有限公司

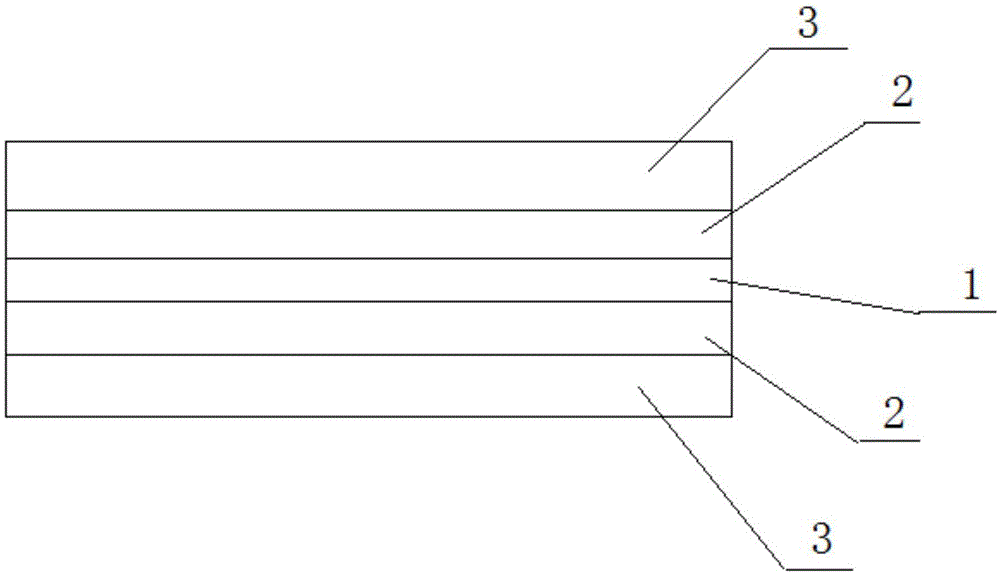

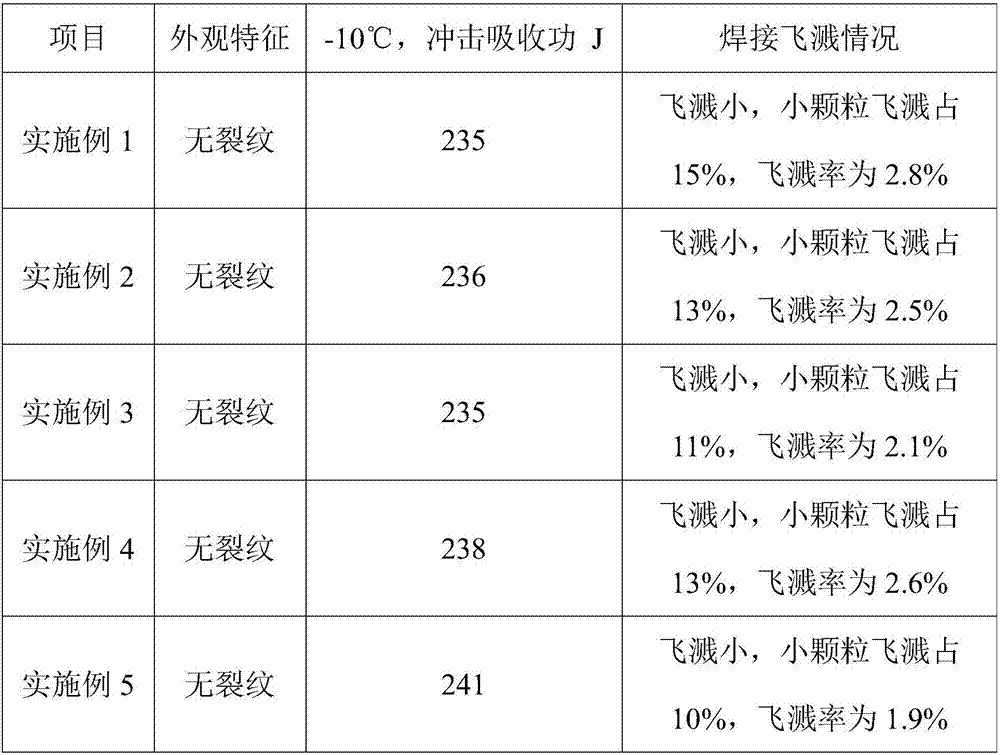

Flux-cored welding wire with good toughness and low porosity

InactiveCN107297583AWell mixedReduce surface tensionWelding/cutting media/materialsSoldering mediaPorositySilicon dioxide

The invention discloses a flux-cored welding wire with good toughness and low porosity. The welding wire includes a mild-carbon steel strip sheath and a flux core, wherein the flux core is prepared from, by weight, 0.4-0.6% of graphite, 10-14% of chromium powder, 2-4% of manganese dioxide, 3.5-5.5% of nickel powder, 3-5% of columbium powder, 2-4% of zirconium powder, 0.4-0.6% of silicon dioxide, 9-10% of rhenium oxide, 12-14% of magnalium, 6-8% of fluoride, 1.5-4.5% of lithium carbonate and the balance iron powder. The welding coating of the flux-cored welding wire has the advantages of being low in porosity, compact in coating microstructure and good in toughness.

Owner:安徽飞弧焊业股份有限公司

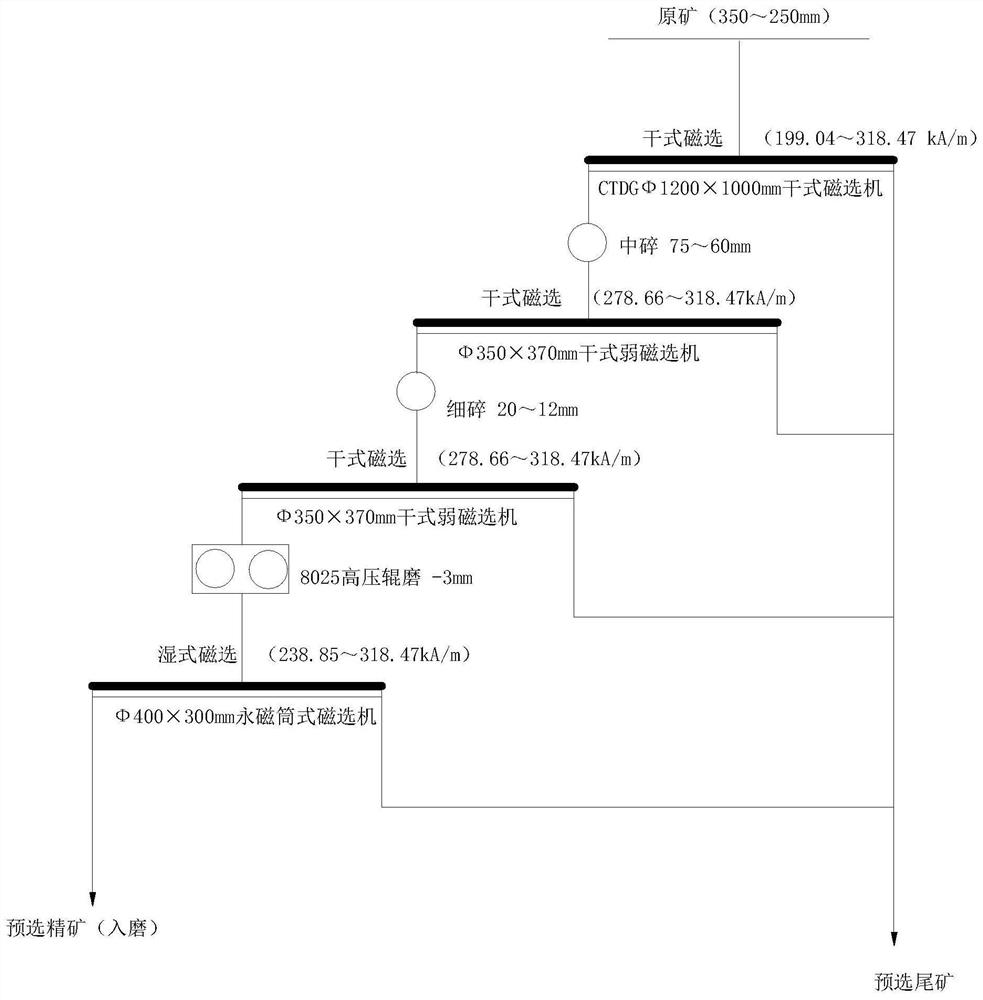

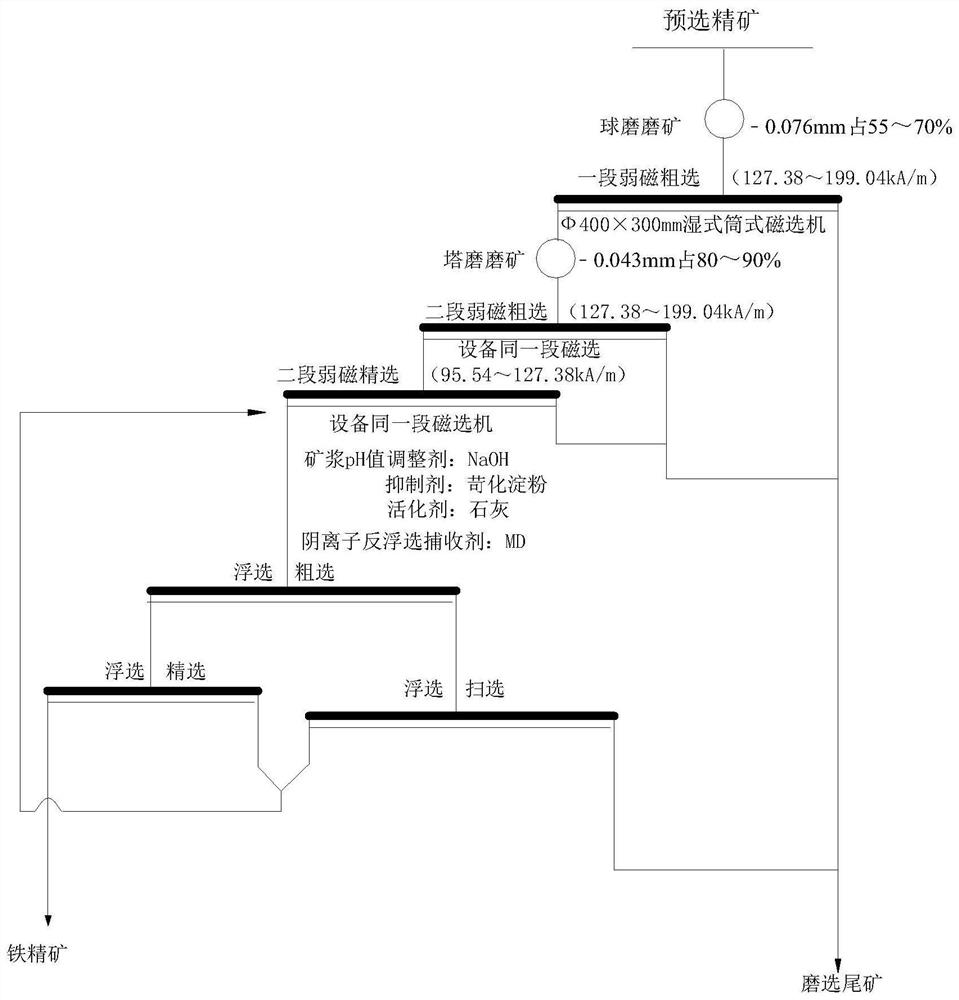

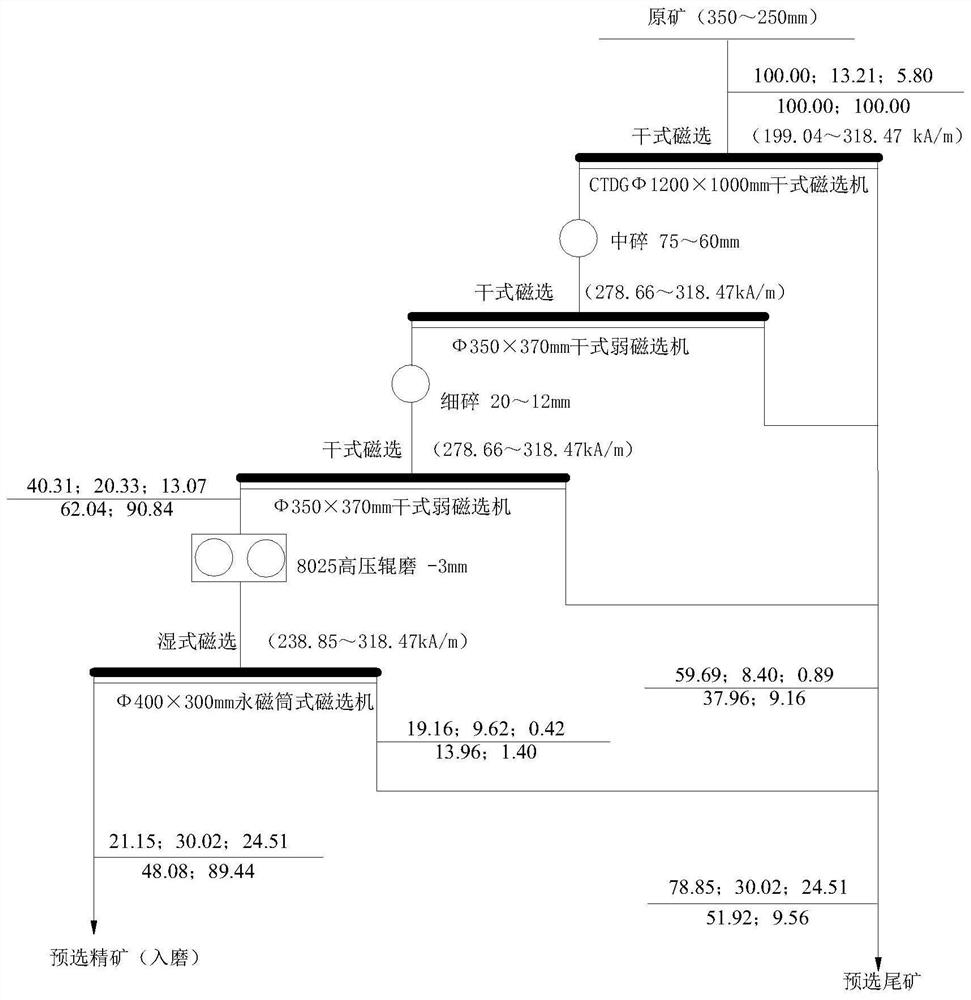

Beneficiation method for recovering high-grade iron ore concentrate from iron-containing waste rocks in waste dump

PendingCN113877718AEmission reductionReduce the amount of feedWet separationMining engineeringWaste dump

The invention discloses a beneficiation method for recovering high-grade iron ore concentrate from iron-containing waste rocks in a waste dump. The high-grade iron ore concentrate with the TFe content larger than or equal to 65.0% is obtained through the steps of 1, raw ore stage crushing and stage dry type magnetic separation waste throwing operation, 2, fine crushing dry type pre-selection concentrate high-pressure roller grinding-wet type magnetic separation tailing throwing operation, 3, wet type magnetic separation pre-selection concentrate stage grinding-stage wet type magnetic separation operation and 4, magnetic separation concentrate anion reverse flotation operation in sequence, building material products with different lumpiness and different size fractions can be produced, and the resource utilization rate of the iron-containing waste rocks reaches up to 80%. By means of the beneficiation method, a conventional crushing-high-pressure roller milling selective disintegrating technology is adopted for pre-selecting and tailing throwing, so that the discharge amount of fine tailings is reduced, and the ore grinding amount is reduced; and a superfine grinding technology including a vertical tower mill is adopted for pre-selecting the concentrate, the number of ball-milling grinding sections is reduced, the dissociation performance of ore is improved, the particle size distribution of the ore is more uniform, the condition for obtaining the high-quality iron ore concentrate is met, and the energy-saving, consumption-reducing and emission-reducing effects are remarkable.

Owner:包钢集团矿山研究院(有限责任公司) +3

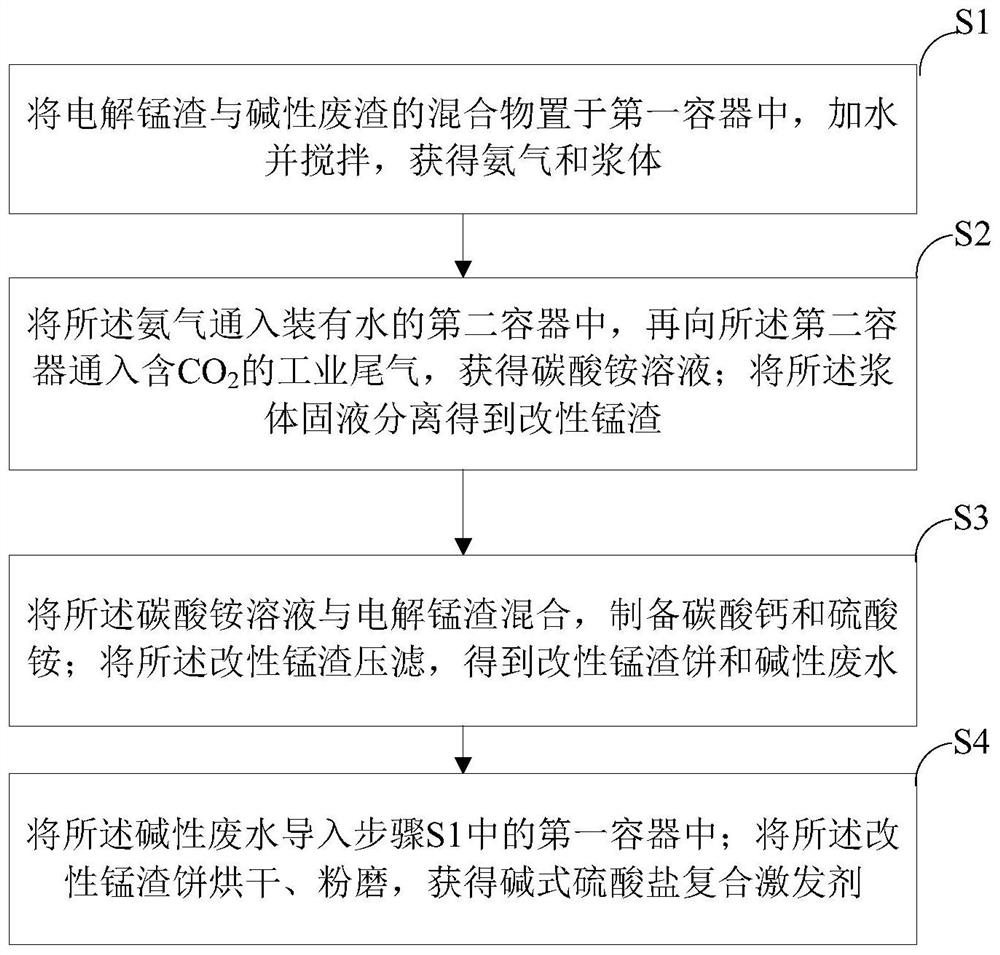

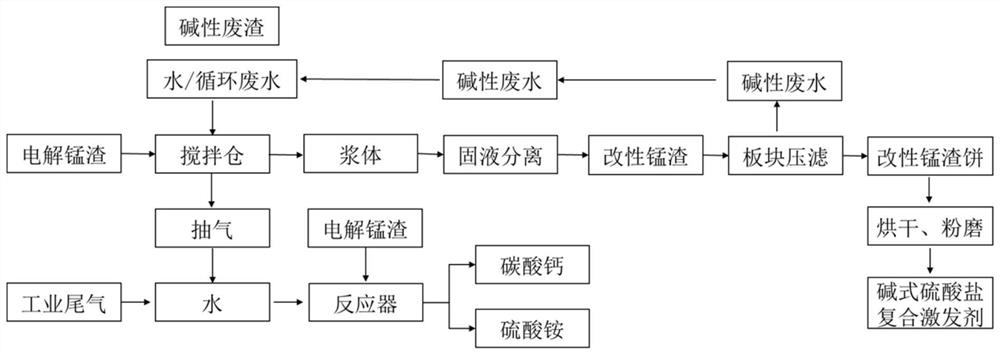

Industrial solid waste electrolytic manganese residue mineralization CO2 resource utilization method

ActiveCN114804177AEfficient cascade utilizationIncrease profitCalcium/strontium/barium carbonatesAmmonium salt fertilisersManganeseWastewater

The invention provides an industrial solid waste electrolytic manganese residue mineralization CO2 resource utilization method, which comprises: placing a mixture of electrolytic manganese residue and alkaline waste residue in a first container, adding water, and stirring to obtain ammonia gas and slurry; secondly, introducing ammonia gas into a second container filled with water, and introducing industrial tail gas containing CO2 into the second container to obtain an ammonium carbonate solution; carrying out solid-liquid separation on the slurry to obtain modified manganese slag; thirdly, mixing the ammonium carbonate solution with the electrolytic manganese residues to prepare calcium carbonate and ammonium sulfate; carrying out filter pressing on the modified manganese slag to obtain a modified manganese slag cake and alkaline wastewater; finally, introducing the alkaline wastewater into a first container; and drying and grinding the modified manganese slag cake to obtain the basic sulfate composite exciting agent. According to the method, efficient and gradient utilization of the electrolytic manganese residues is achieved, high-added-value utilization of the electrolytic manganese residues is achieved, the mineralized CO2 treatment cost is reduced, and the method has good application prospects and popularization value and has important significance in achieving carbon peak reaching and carbon neutralization.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

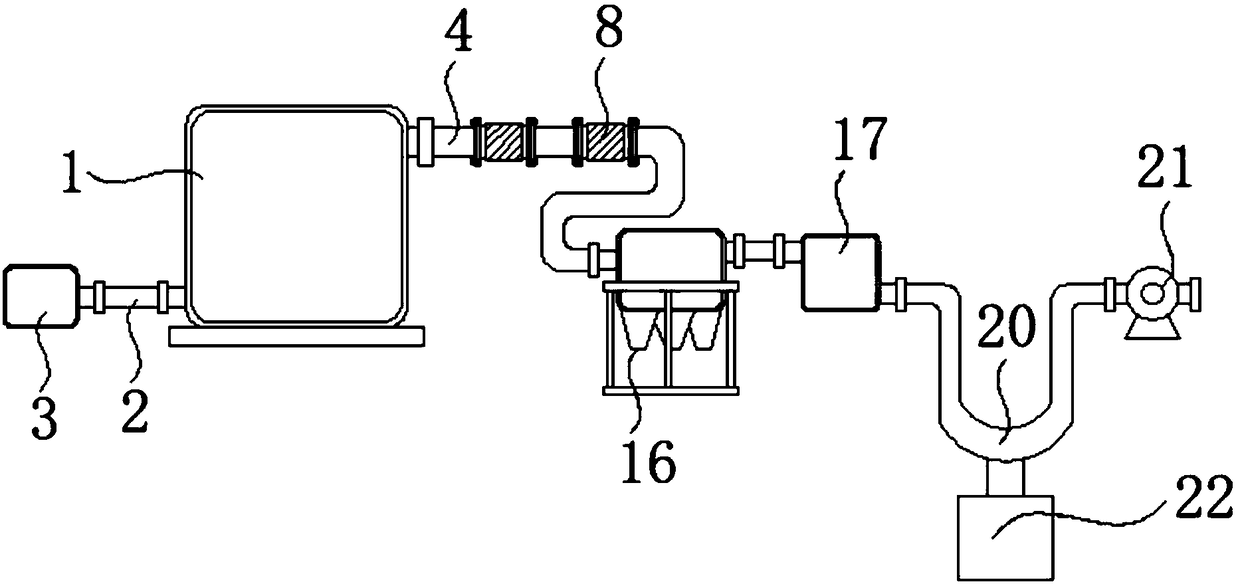

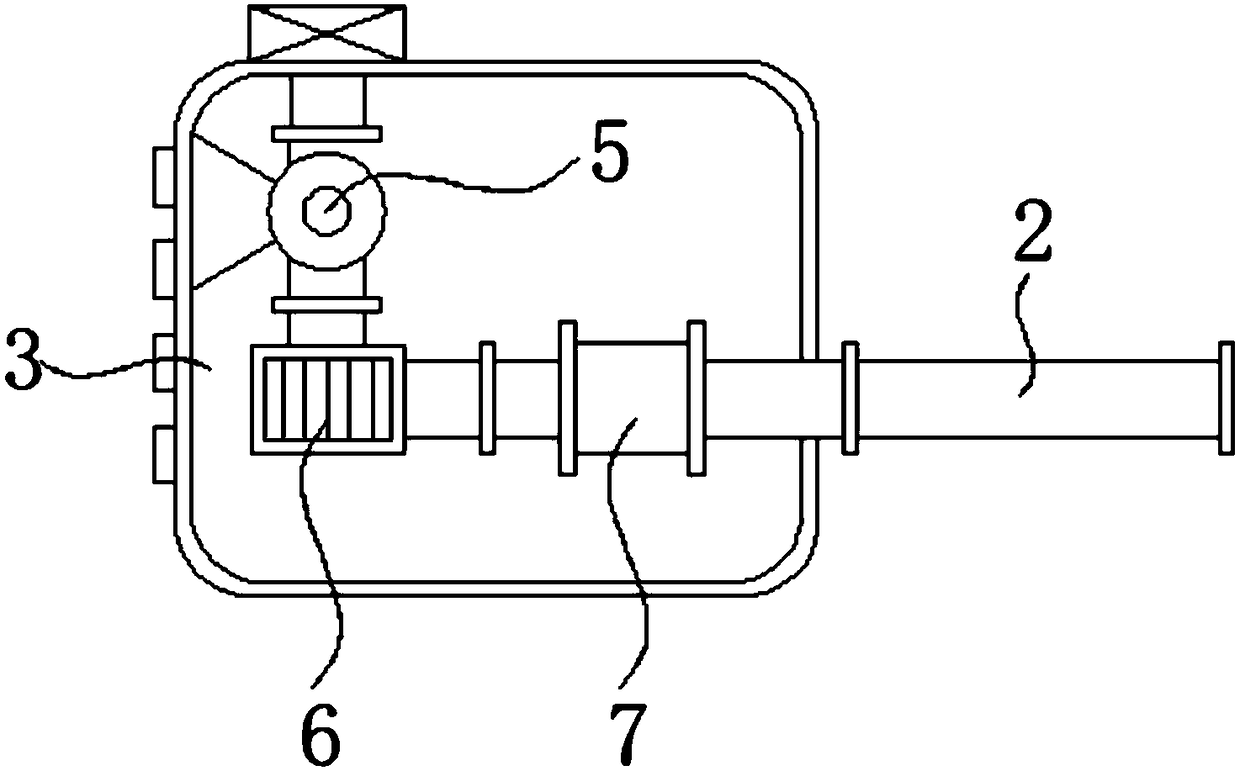

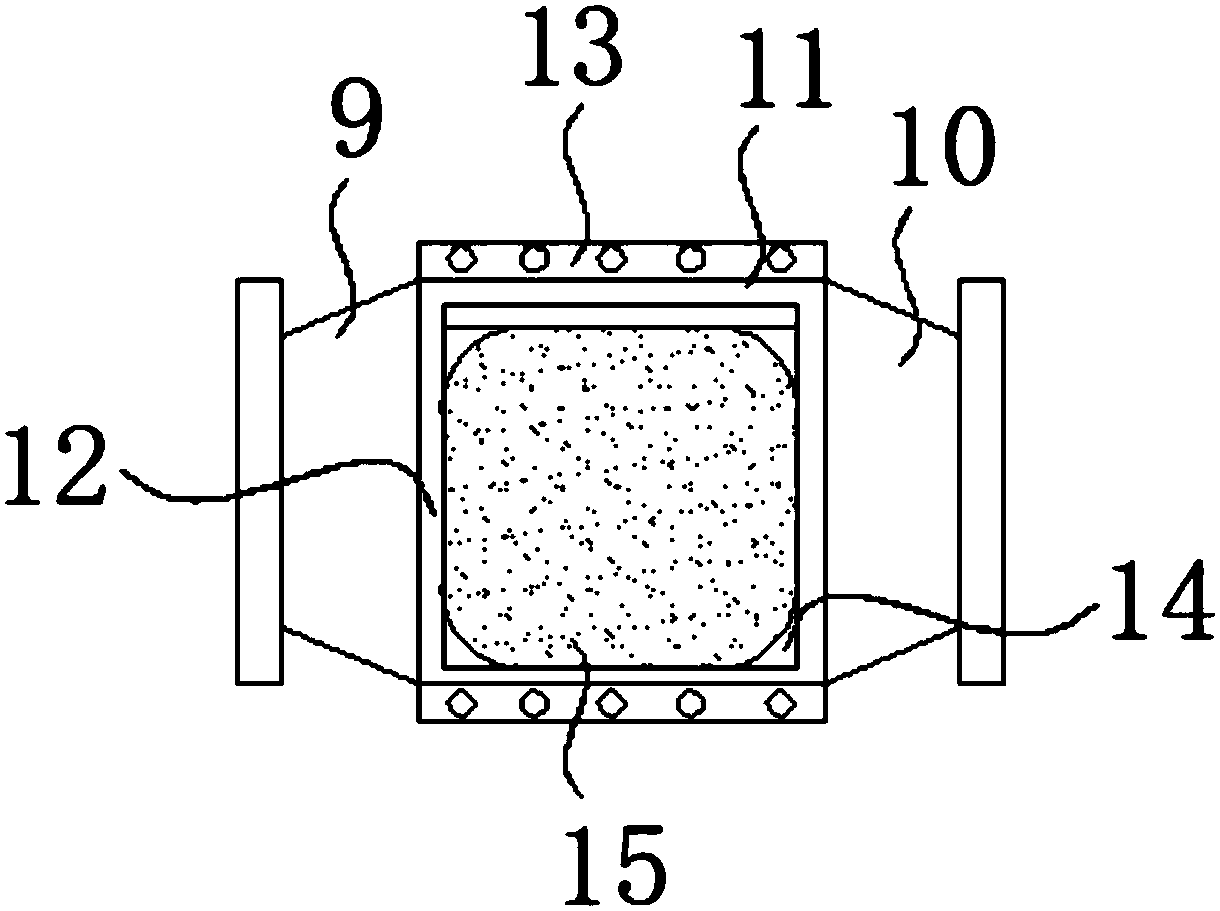

Glass bead heating furnace waste gas treatment device

InactiveCN108187440ALess harmful impuritiesSave resourcesCombination devicesWater pipeHeating furnace

The invention discloses a glass bead heating furnace waste gas treatment device. The glass bead heating furnace waste gas treatment device comprises a furnace body, an air inlet in one side of the furnace body is communicated with an air outlet of a heating chamber through a heating pipeline, a waste gas outlet in one side of the furnace body is connected with a waste gas pipeline, an air outlet of the waste gas pipeline is communicated with an air inlet pipe of a high temperature bag-type dust collector, and an air outlet of the high temperature bag-type dust collector is communicated with anair inlet of a condensing device through a pipeline. An air outlet of the condensing device is communicated with an air inlet of a U-shaped condensing pipe, one side of the U-shaped condensing pipe is connected with an induced draft fan, and a cold water pipe at the bottom of the U-shaped condensing pipe is connected with a cold water tank. The glass bead heating furnace waste gas treatment device adsorbs harmful impurities in the waste gas by utilizing active carbon, the adsorption effect is good, then the high temperature bag-type dust collector is utilized to remove dust in the impurities,the dust collection effect is good, and meanwhile, waste heat of the heating furnace is recovered and reused.

Owner:安徽环泰新材料科技有限公司

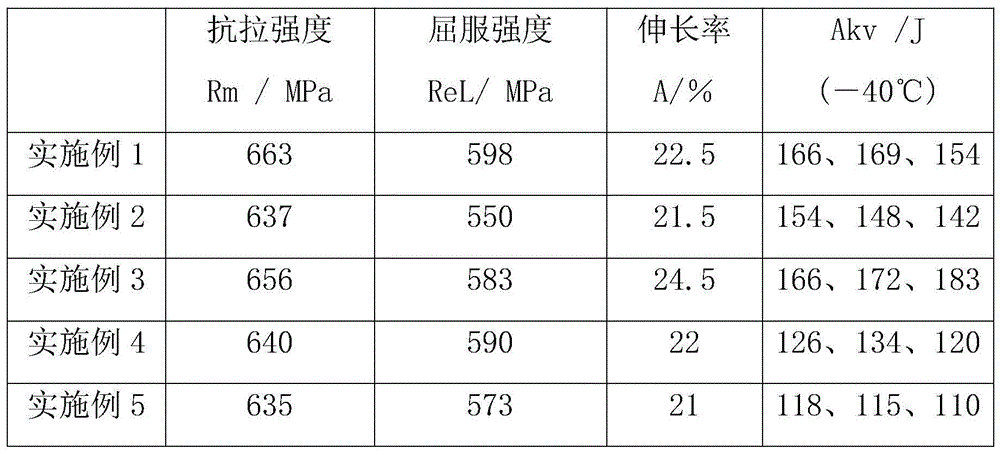

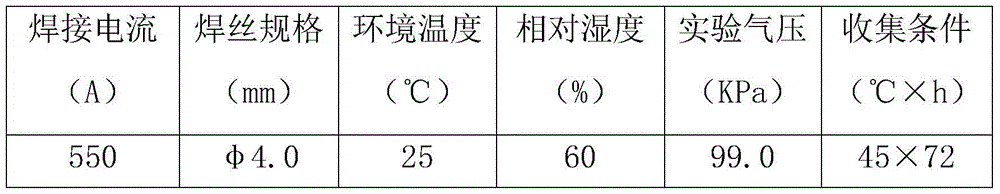

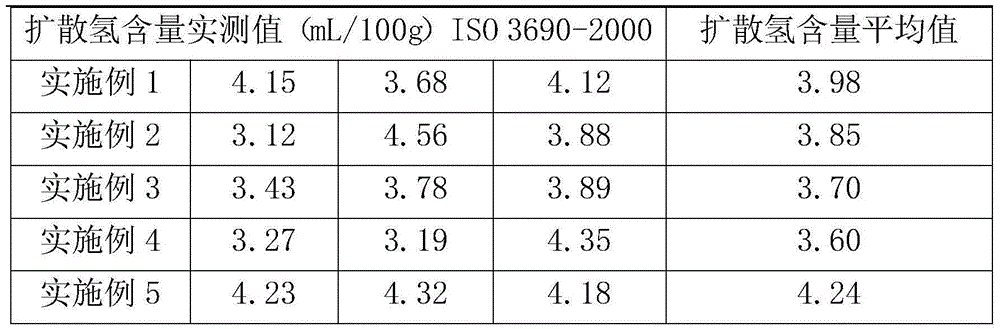

High-toughness and low-hydrogen type sintered flux for ocean engineering and preparation method thereof

ActiveCN105081615BEasy to remove slagGood anti-porosityWelding/cutting media/materialsSoldering mediaHydrogenToughness

The invention provides high tenacity and low hydrogen type agglomerated flux for ocean engineering. The high tenacity and low hydrogen type agglomerated flux is composed of, by weight, 18%-23% of MgO, 28%-32% of CaF2, 18%-22% of Al2O3, 1%-5% of TiO2, 18%-22% of SiO2, 3%-7% of CaO, 2%-5% of Na3AIF6, 2%-6% of MnO, 0-0.015% of S and 0-0.025% of P. By means of the high tenacity and low hydrogen type agglomerated flux, weld metal has good welding process properties such as sediment separation and pore resistance and a good anti-cracking property; the Charpy impact energy is relatively high at the temperature of -40 DEG C and the content of diffusible hydrogen meets the requirement of ultra-low-hydrogen.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

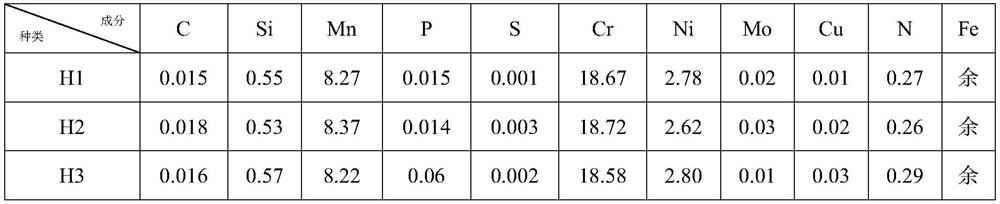

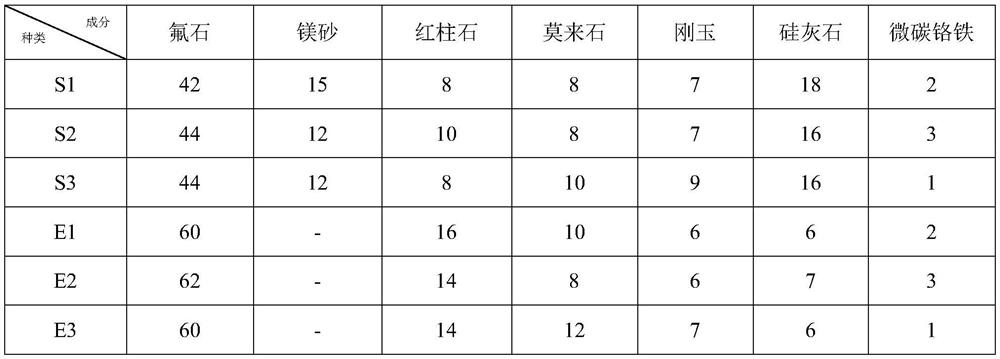

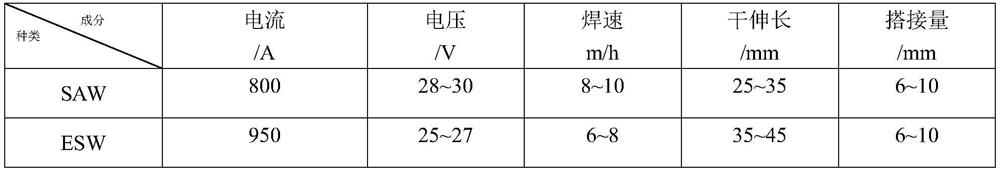

A kind of welding strip for surfacing welding of nickel-saving and high-nitrogen austenitic stainless steel strip and supporting flux and preparation method thereof

ActiveCN113146096BPromote formationGuaranteed corrosion resistanceWelding/cutting media/materialsSoldering mediaSilicic acidMullite

A welding strip for surfacing welding of nickel-saving and high-nitrogen austenitic stainless steel strips, a matching flux and a preparation method thereof. The invention belongs to the field of welding materials. The invention solves the technical problem of low corrosion resistance and hydrogen stripping resistance of the surfacing layer metal when welding low-nickel nitrogen-containing austenitic stainless steel at present. The chemical composition of the welding strip of the present invention is calculated as: C:≤0.04%, Si:≤0.65%, Mn: 5.00%~9.00%, P≤0.020%, S≤0.015%, Cr: 18.00%~22.00 %, Ni: 2.50% to 3.00%, Mo: ≤ 0.65%, Cu: ≤ 0.75%, N: 0.10% to 0.30%, and the balance is Fe. The flux is prepared from dry powder and potassium sodium silicate; the dry powder is mixed from fluorspar, magnesia, corundum, wollastonite, andalusite, mullite and micro-carbon ferrochrome. Method: Dry mixing of dry powder raw materials, adding potassium and sodium silicate to continue stirring, then drying at low temperature, sintering at high temperature, and sieving to obtain flux. The welding strip of the invention has low cost and excellent flux performance. The surfacing metal has good corrosion resistance and hydrogen stripping resistance.

Owner:BEIJING JINWEI WELDING MATERIAL +2

Wear-resistant repairing additive of lubricating oil and production thereof

An anti-wear repair additive for lubricating oil and a preparation method thereof. It relates to a lubricating oil additive and a preparation method thereof. Adding the lubricating oil additive into the lubricating oil can increase the hardness of the surface of the friction pair, improve its wear resistance, and repair the wear defects that have occurred, so as to prolong the working life of the friction pair. The invention consists of the following components according to the weight ratio: 1-10% of silicon powder, 0.5-5% of magnesium oxide, 20-70% of aluminum powder, 0.5-5% of titanium powder, 0.1-1% of nickel powder, and 0.1% of chromium oxide -1%, lithium nitride 1-5%, gold powder 0.1-1%, boron powder 5-20%; all the above components are crushed into particles with a diameter of 50μm-3nm and mixed evenly. When used in lubricating oil, under low temperature conditions, a high-hardness cermet layer can be formed, which not only has extremely high hardness, but also has an extremely low coefficient of friction and a temperature expansion coefficient similar to that of the friction pair. It can be used as lubricating oil anti-wear repair additive for cylinders, air compressors and other components.

Owner:王爱国 +1

Electric heating preparation method for copper-aluminum alloy raw material

The invention discloses an electric heating preparation method for a copper-aluminum alloy raw material. The copper-aluminum alloy raw material comprises the following components of, by weight percent, 49-58% of kaolin with Cu2O3 weight percentage less than or equal to 1%, 5-13% of aluminum oxid, 34-38% of bituminous coal with volatile weight percentage more than or equal to 32%, and sodium ligninsulfonate liquid accounting for 20-22% of the total weight of the three mentioned raw materials, prepared by hot water at 30-60 DEG C and having a density of 1.100-1.200 g / cm<3>. According to the electric heating preparation method for the copper-aluminum alloy raw material, the high-quality kaolin and the bituminous coal produced in China are adopted, cost of the copper-aluminum alloy raw material is low and reduced by 15-20%, meanwhile harmful substances contained in the copper-aluminum alloy are less, and an impurity removal process is simple and convenient. The copper-aluminum alloy prepared by the preparation method for the copper-aluminum alloy raw material equally includes the following elements of, by weight percent, 56.7% of Al, 38.8% of Si, 0.87% of Ti, 1.3% of Fe, 0.37% of Ca, 1.5% of C and 0.5% of other impurities.

Owner:李康宁

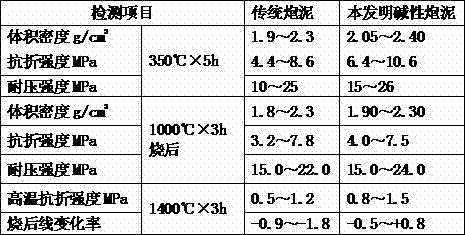

Alkaline stemming

The invention relates to alkaline stemming which is prepared from the following raw materials: 25%-50% of sintered magnesia, 5%-20% of dust coke, 10%-25% of magnesium-carbon reclaimed material, 1%-10% of carbon-containing resin powder, 5%-10% of silicon carbide, 5%-10% of Jiaozuo clay, 1%-5% of alpha aluminum oxide, 5%-20% of light burning magnesium powder, 5%-10% of andalusite, and stemming-dedicated resin accounting for 10%-20% of the total weight of the raw materials. The alkaline stemming provided by the invention has the advantages of good plasticity and adhesion, appropriate porosity, slight volume expansion at high temperature, good sintering property, high strength, scouring resistance, erosion resistance, easiness in tapping and environmental friendliness, and does not discharge pollutant gas in the sintering process; the molten iron scouring resistance of the alkaline material is fully played, and the alkaline stemming does not bring pollution or harmful impurities to molten iron; the harmful impurities in the molten iron can be reduced to purify the molten iron; the harmful components such as phosphorus, sulfur and silicon in the molten iron are reduced; the alkaline stemming provided by the invention has the advantages of long service life, short sintering time, high strength and easiness in tapping, reduces the maintenance cost of an iron notch and is conducive to the stable operation and stable and high yield of a blast furnace.

Owner:通化耐博新材料股份有限公司

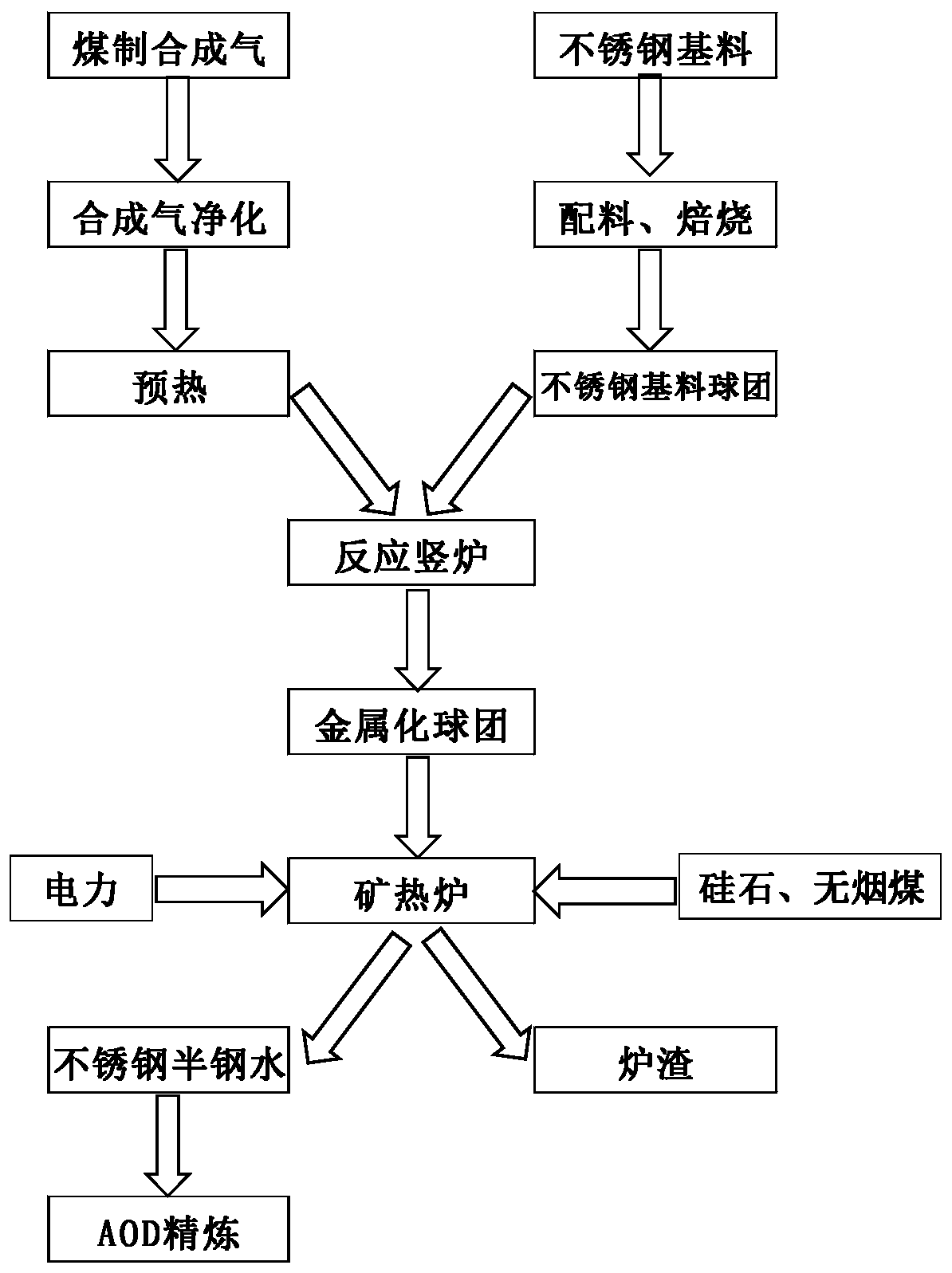

Process of producing stainless steel molten semisteel by coal-made synthesis gas

The invention provides a process of producing stainless steel molten semisteel by coal-made synthesis gas. The process comprises the following steps of 1) preparing the coal-made synthesis gas and stainless steel base material pellets; 2) purifying and preheating the coal-made synthesis gas, feeding the coal-made synthesis gas into a reaction vertical furnace from the lower side, and adding the stainless steel base material pellets into the reaction vertical furnace from the upper side, wherein the coal-made synthesis gas is in contact with the descending stainless steel base material pelletsto perform a reduction reaction to generate a metalized pellets; and 3) feeding the generated metalized pellets into a submerged arc furnace, adding flux and a reducer for fusion, and separating slagfrom iron to prepare the stainless steel molten semisteel. The process throws away a link of smelting the stainless steel base material by an electric furnace, so that dust and noise pollution of theelectric furnace are avoided, the electric consumption is reduced, and the metal yield is improved, and meanwhile, the stainless steel base material pellets are reduced by means of purified synthesisgas, so that few impurities of a product are generated.

Owner:明拓集团铬业科技有限公司

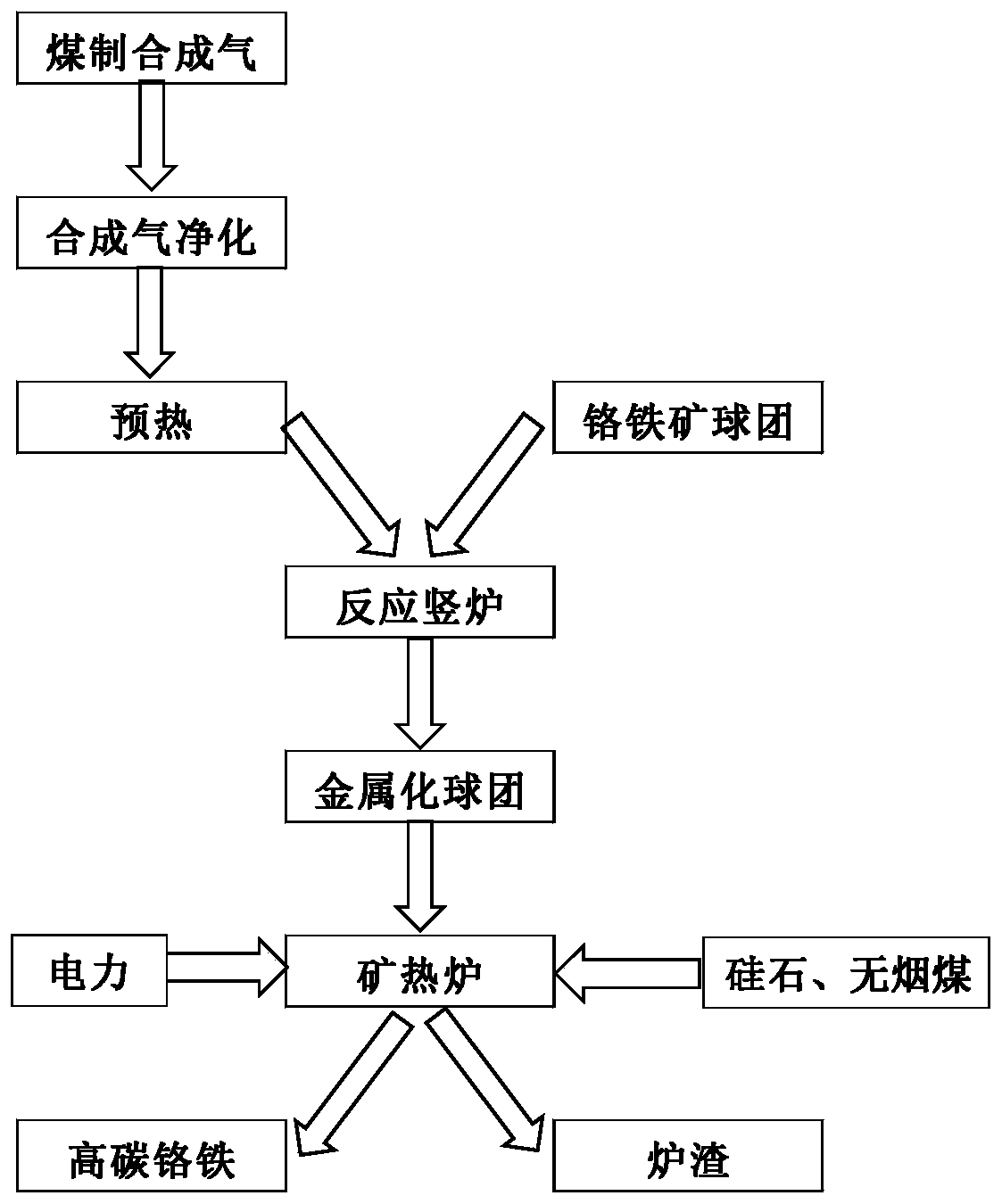

Process for producing high-carbon ferrochrome from coal synthesis gas

InactiveCN110904331AChanging the Smelting Reduction ProcessAvoid Coking Process PollutionShaft furnaceSyngasShaft furnace

The invention provides a process for producing high-carbon ferrochrome from coal synthesis gas. The process comprises the following steps of: 1) preparing the coal synthesis gas and chromite pellets,2) purifying and preheating the coal synthesis gas, feeding the coal synthesis gas into a reaction shaft furnace from the lower part, adding the chromite pellets into the reaction shaft furnace from the upper part, and performing reduction reaction after the coal synthesis gas is in contact with the descending chromite pellets to generate metallized pellets, and 3) feeding the generated metallizedpellets into a submerged arc furnace, adding a fluxing agent and a reducing agent, melting, and separating slag from iron to obtain high-carbon ferrochrome. The process reduces power consumption andemission, is relatively environment-friendly, and reduces chromite pellets by utilizing purified synthesis gas, so that the generated product has few impurities.

Owner:明拓集团铬业科技有限公司

A kind of preparation method of high-purity nicotine

ActiveCN105566289BLess harmful impuritiesAvoid degradationOrganic chemistryBoiling pointDistillation

The invention relates to natural biological product separation and purification and concretely relates to a preparation method of high purity nicotine. The preparation method comprises pouring a nicotine organic solution without naphthalene oil-soluble impurities and high-boiling point alkaloid impurities into a short-path molecular distillation device and carrying out rectification on the nicotine organic solution at a temperature of 0-100 DEG C under pressure of 0.001-1mbar to obtain high purity nicotine. The invention provides a method for removing naphthalene oil-soluble impurities with boiling points similar to that of nicotine and high-boiling point alkaloid impurities in nicotine through extraction-back extraction. The preparation method is carried out at a low temperature at a high degree of vacuum and prevents impurities produced through nicotine pyrolysis and oxidation. The product has purity of 99.92%, good appearance, a good smell and a high extraction yield.

Owner:北京本草通汇科技中心

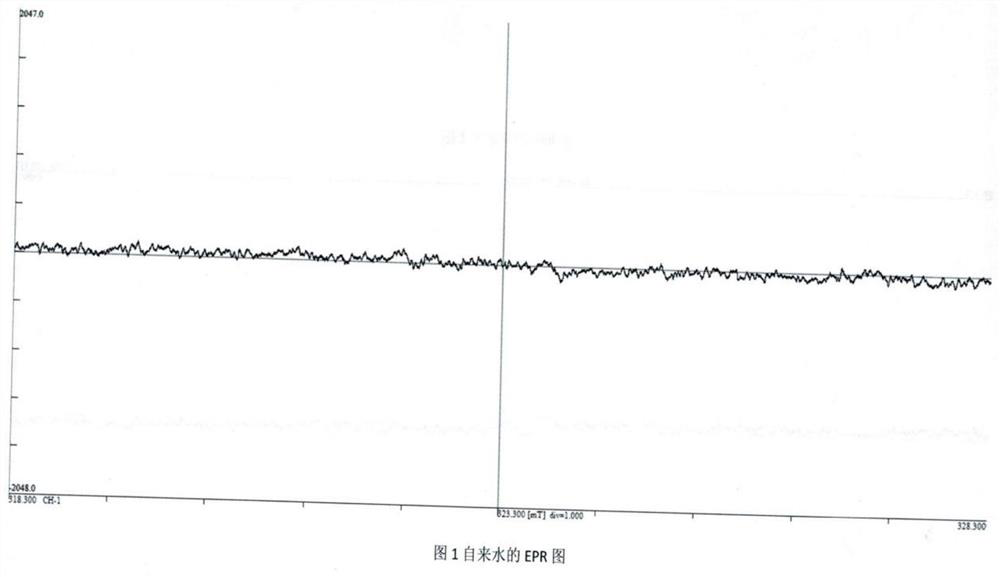

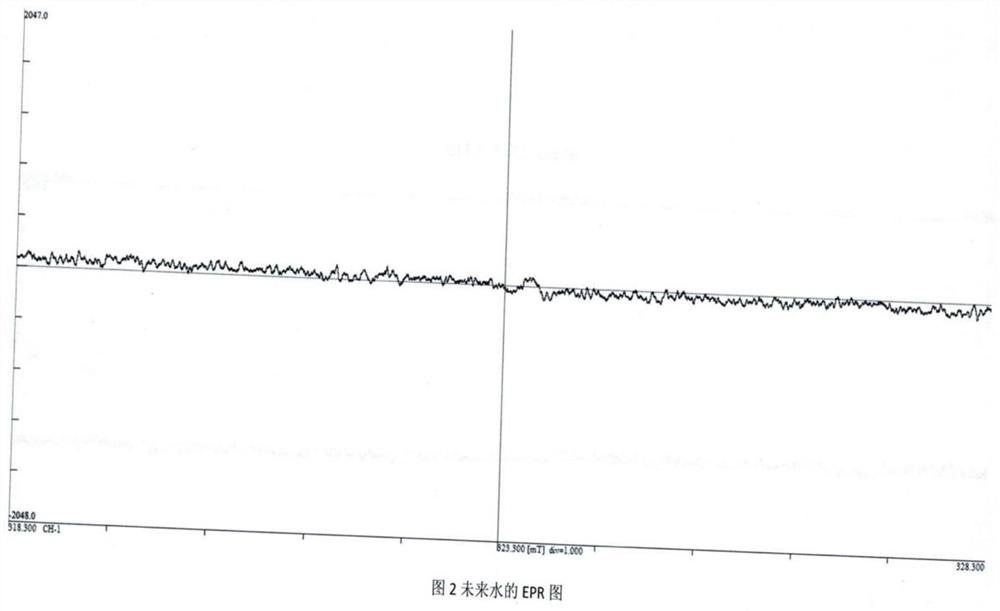

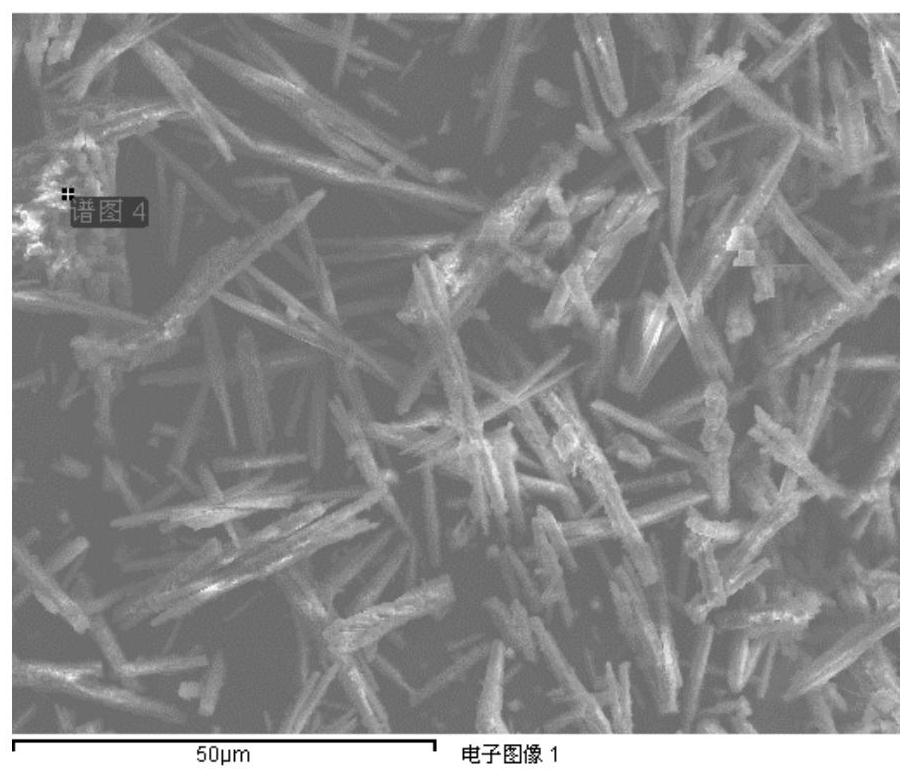

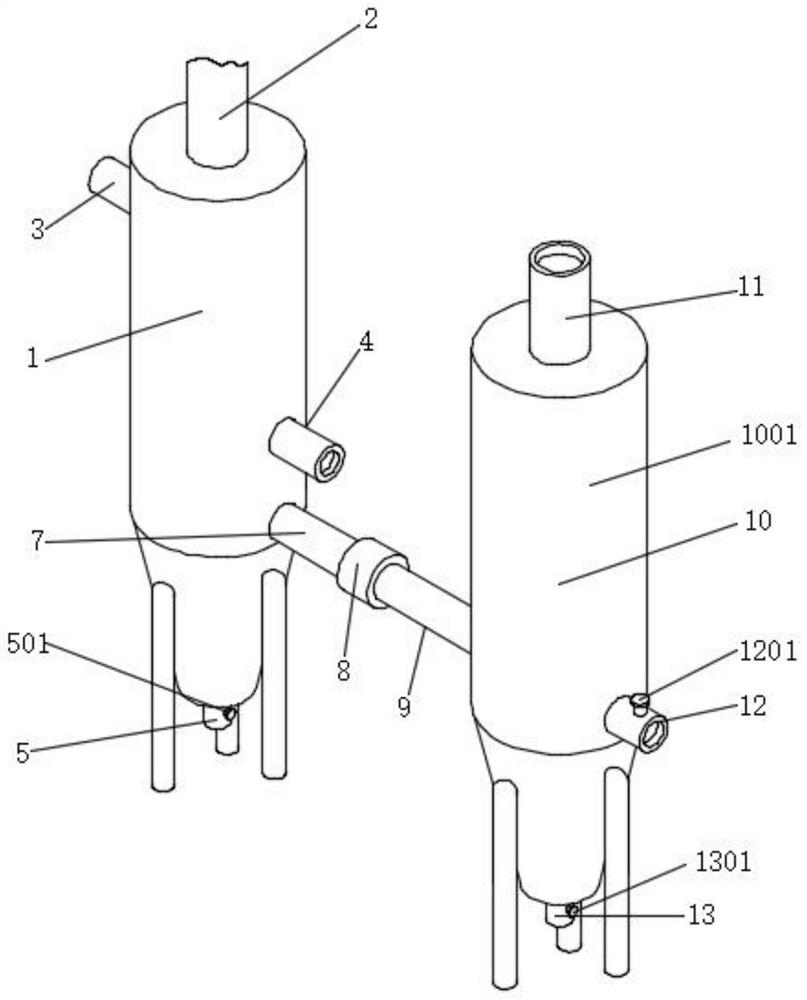

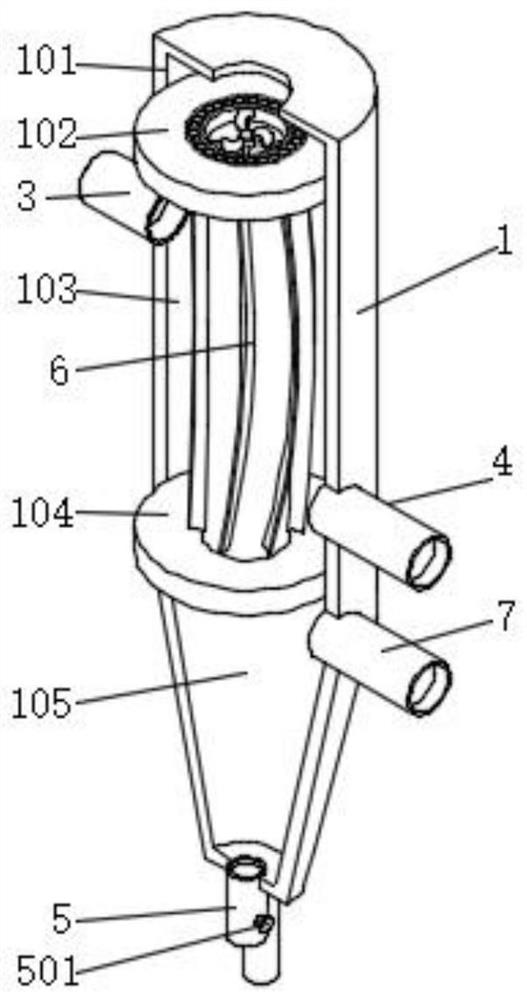

Multifunctional water purifier

InactiveCN114133045AIncrease dissolved oxygenLess harmful impuritiesWater treatment parameter controlWater/sewage treatment by irradiationRare-earth elementOxide ceramic

The invention discloses a multifunctional water purifier, which comprises a sintered body and an aluminum oxide ceramic body arranged in the sintered body, and is characterized in that the sintered body is prepared from the following raw materials: alkaline earth metal titanate, rare earth element oxide, aluminum oxide, silicon dioxide, magnesium oxide and kaolin; the multifunctional water purifier is good in water purification effect, rich in raw material source, simple in preparation process and low in price. The multifunctional water purifier can be applied to various drinking water treatment devices and aquaculture devices.

Owner:北京方德鹏达科技有限公司

A collection mechanism for electroplating chrome-plated chrome mist collectors for conveying cylinders

The invention discloses a collection mechanism for a chrome-plated chrome mist recovery device for conveying cylinders, relates to the technical field of electroplating chrome mist collection equipment, and includes a recovery tank, a condensation mechanism, a purification mechanism, and an aeration mechanism. The top of the recovery tank is provided with a As for the air intake pipe, a cooling liquid inlet pipe is provided at one end of the outer wall of the recovery tank close to the top position, and a cooling liquid outlet pipe and a No. 1 connecting pipe are provided at the end of the outer wall of the recovery tank far away from the cooling liquid inlet pipe. The present invention is provided with recovery tank, air intake cabin, No. 1 fixed plate, cooling cabin, No. 2 fixed plate, collecting cabin, air intake pipe, cooling liquid inlet pipe, cooling liquid outlet pipe, condensation pipe, condensation chamber, arc-shaped blades, The rotating bearing, rotating fan blade and fixed rod can realize the recovery of chromium plating solution in chromium mist.

Owner:常德嘉腾电镀有限公司

A kind of passivation metal magnesium particle and passivation method thereof

ActiveCN103695884BLong flame retardant timeImprove hydrophobicityLiquid surface applicatorsMetallic material coating processesRoom temperatureRare earth

The invention discloses passivating metal magnesium particles and a passivating method thereof. The passivating metal magnesium particles comprise the following components in percentage by weight: less than or equal to 99% and greater than or equal to 92% of Mg, less than or equal to 0.002% of S, less than or equal to 0.01% of Cu, less than or equal to 0.001% of P and less than or equal to 1.2% and greater than or equal to 0.1% of H2O. The passivating method comprises the following steps: (I), preparing a metal magnesium particle passivator, placing metal magnesium particles in the passivator, and then naturally cooling to room temperature; (II), coating a coating on the surface of the magnesium particles: firstly, coating an organic silicon compound on the surface of the metal magnesium particles, coating magnesium oxide on the surface of the metal magnesium particles, then, coating compound rare earth on the on the surface of the metal magnesium particles, and finally coating graphite powder on the surface of the metal magnesium particles; and (III), sieving the metal magnesium particles cooled to room temperature. The metal magnesium particle passivating layer is uniform in coating, and the storage and use safety is ensured.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

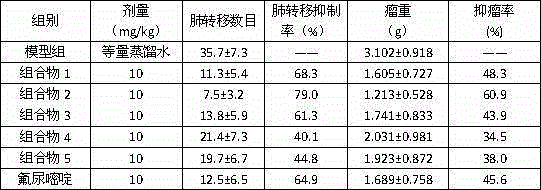

Traditional Chinese medicinal composition as well as preparation method, preparation and application thereof

ActiveCN105055933AImprove securityImprove effectivenessAntineoplastic agentsPlant ingredientsMedicinal herbsChinese knotweed

The invention discloses a traditional Chinese medicinal composition as well as a preparation method, a preparation and application thereof. The traditional Chinese medicinal composition consists of the following medicinal raw materials in parts by weight: 11-63 parts of herba polygoni perfoliati, 9-58 parts of Chinese lobelia herb, 4-52 parts of oldenlandia diffusa, 13-76 parts of leaf of Yunnan glorybower root, 2-17 parts of dactylicapnos root, 18-73 parts of India madder root, 4-52 parts of Chinese knotweed root, 19-75 parts of lalang grass rhizome, 9-58 parts of root of houttuynia cordata, 11-63 parts of radix gentianae and 5-57 parts of selfheal, and the traditional Chinese medicinal composition is prepared by pre-processing, extracting and drying the medicinal raw materials. The traditional Chinese medicinal composition disclosed by the invention has the characteristics of multiple targets and multiple action channels, and has unique advantages in anti-cancer and anti-mutation aspects. The traditional Chinese medicinal composition disclosed by the invention is reasonable in prescription, clear in medicinal material base source and administration part, scientific in preparation method, clear and controllable in quality index, high in safety and significant in curative effect, and the traditional Chinese medicinal composition has extensive application prospect.

Owner:KPC PHARM INC

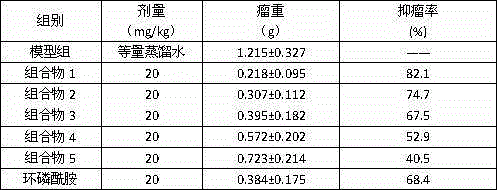

Alloy special for computer hardware manufacturing and machining process thereof

The invention discloses an alloy special for computer hardware manufacturing and a machining process thereof. The alloy comprises, by mass, 32.0-40.0% of Cr, 5.0-12.0% of Fe, 0.5-1.0% of Al, 2.0-5.0% of Mo, 6.0-12.0% of Ti, 0.1-0.4% of Mn and 4.0-5.0% of W. According to the alloy special for computer hardware manufacturing and the machining process thereof, the produced high-temperature alloy mother alloy is high in alloy strength, good in abrasion resistance and high-temperature oxidation resistance, small in surface crack quantity in the manufacturing process, good in plasticity and capable of eliminating segregation, so that the produced mother alloy is uniform in structure, low in harmful impurity content in the alloy, small in internal defect quantity and high in yield, materials are saved, and the production cost of the mother alloy is low. An oxidation film on the surface of a raw material can be removed, the vacuum sintering speed is increased, the alloy production efficiency is improved, the oxygen content in the raw material is reduced, and better use prospects are brought.

Owner:马鞍山安慧智电子科技有限公司

Raw material for preparing aluminum-silicon alloy by electro-thermal process

This invention relates to the raw material in aluminum silicon alloy production, being composed of in weight percentage kleit 49-58% containing Fe2O3 up to or less than 1%, aluminum oxide 5-13%, smoke coal 34-38% containing >=32% of volatile share weight, 1.100-1.200grams / centimeter lignosulphonate liquid prepared from 20-22% gross weight of above three raw materials as well as 30-60 DEG C hot water. The cost is low, which causes the aluminum silicon alloy cost to reduce 15-20%, simultaneously aluminum silicon alloy contains few deleterious substance,and it is simple to remove the impurity. Aluminum silicon alloy prepared in the invention contains in weight percentage aluminum 56.7, silicon 38.8, titanium 0.87, iron 1.3, calcium 0.37, carbon 1.5 and other impurities 0.5 in average.

Owner:登封电厂集团铝合金有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com