Preparation method of high purity nicotine

A high-purity, nicotine technology, which is applied in the field of separation and purification of natural biological products, can solve the inevitable problems such as naphthalene impurities, and achieve the effect of high product purity, positive smell, and avoiding impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the high-purity nicotine of the present embodiment comprises the following steps:

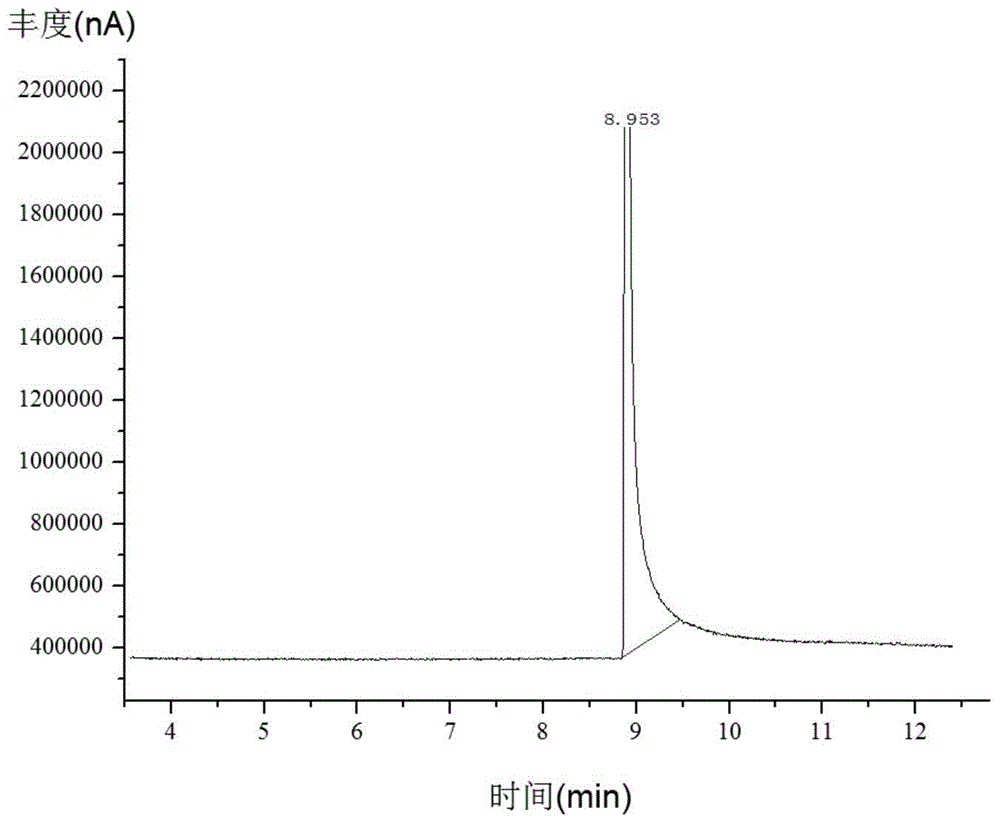

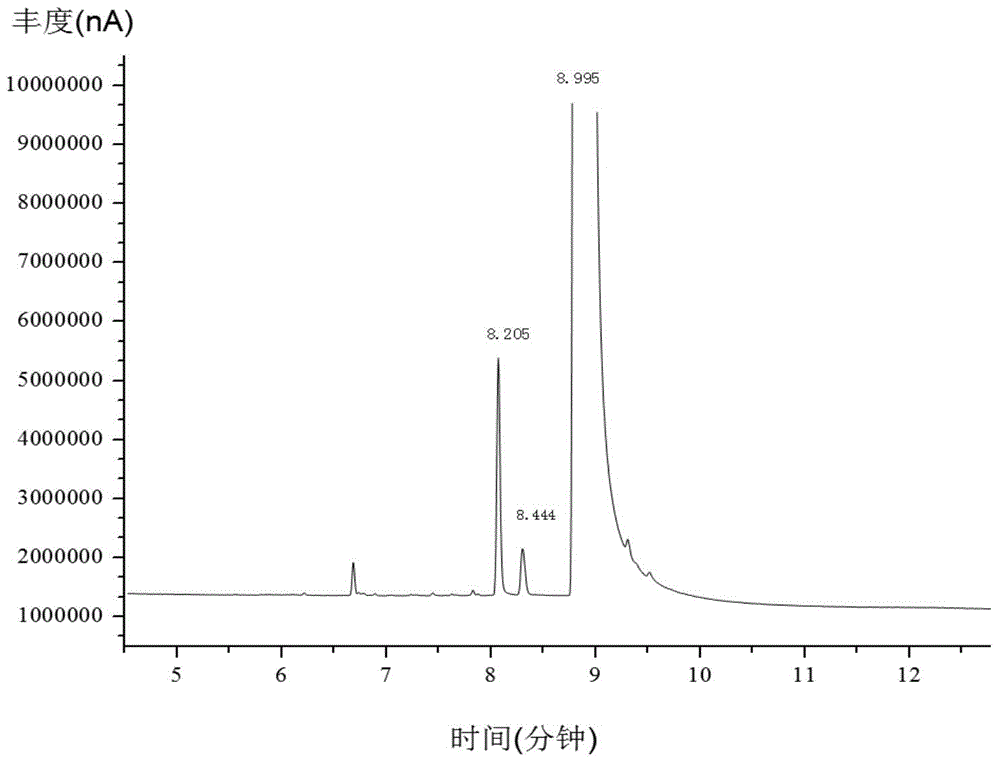

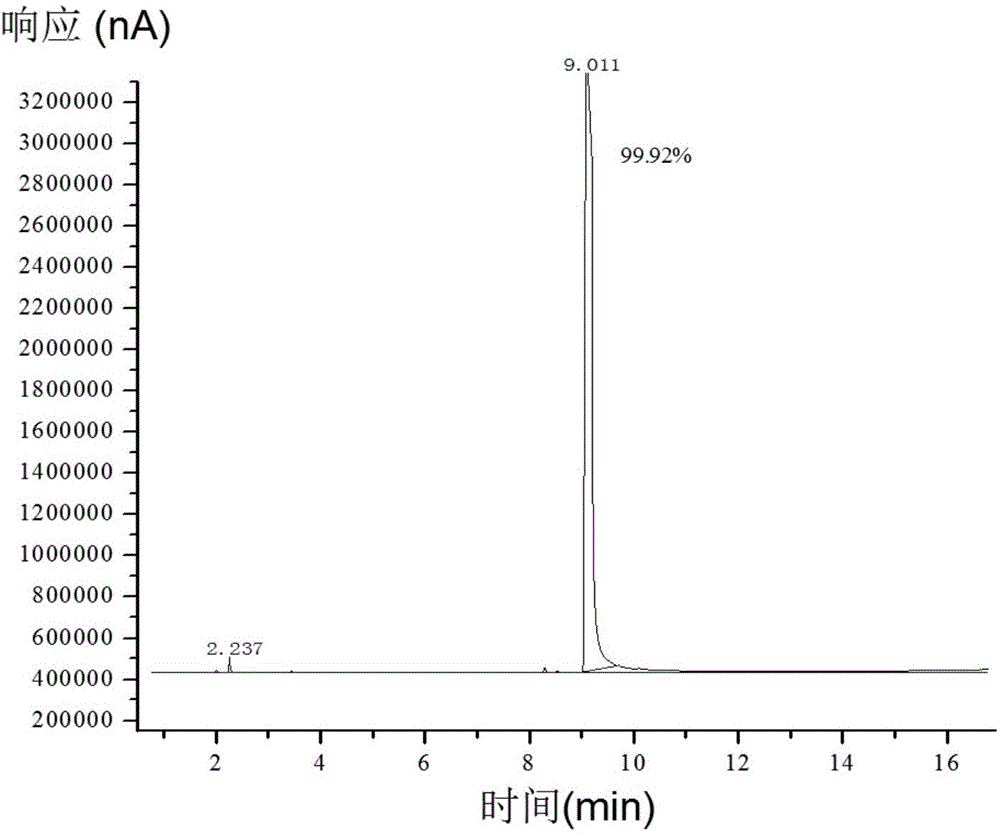

[0040] (1) Take 400L of crude nicotine containing methylnaphthalene with a purity of 97% in a 2000L extraction tank, add an equal volume of No. 6 reagent oil, mix well, add 400L of deionized water, oscillate, stand and separate, and collect the water phase Layer, repeatedly added deionized water to extract 6 times, combined the aqueous layer, the gas chromatography-mass spectrum of its nicotine solution is as follows figure 1 shown. Take 2400L of the aqueous phase layer solution, add 600L of No. 6 reagent oil, oscillate, stand for stratification, collect the No. 6 reagent oil layer, repeatedly add No. 6 reagent oil for extraction 4 times, merge the No. 6 reagent oil layer nicotine solution, and the gas phase of the nicotine solution Chromatography-mass spectrum such as figure 2 shown.

[0041] (2) Take 500L of primary purified nicotine solution, put it in a ...

Embodiment 2

[0046] The preparation method of the high-purity nicotine of the present embodiment comprises the following steps:

[0047] (1) Take 10L of crude nicotine that does not contain oil-soluble impurities such as naphthalene that has a similar boiling point to nicotine, and has a purity of 98%, pour it into a short-range molecular still, and control the vacuum degree of the first-stage vacuum distillation pump at 0.1mbar Around, the temperature is controlled at 60°C, the vacuum degree of the second-stage vacuum distillation pump is controlled at 0.08mbar, and the temperature is controlled at 35°C, and finally nearly colorless and transparent high-purity nicotine is obtained.

[0048] The components and content of the collected high-purity nicotine were analyzed by GC-MS, and the impurities were basically removed, while the content of nicotine could reach 99.86%, the moisture content was only 0.05%, and the yield

[0049] 91.8%.

Embodiment 3

[0051] The preparation method of the high-purity nicotine of the present embodiment comprises the following steps:

[0052] (1) Use 100 L of No. 6 solvent oil to extract 100 kg of waste shredded tobacco leaves for 2 to 4 hours in an extraction tank with temperature control at 50-80° C., and take out the tobacco leaves.

[0053] (2) Place the extracted nicotine solution in a solvent evaporator, adjust the vacuum of the solvent evaporator to about 100mbar, control the temperature at 45°C, cool the circulating water at -10°C, and concentrate the solvent. In order to avoid the deterioration of nicotine exposed to light, the entire solvent evaporator is shielded with a black plastic film.

[0054] (3) Pour the concentrated solution into a short-range molecular still, control the vacuum degree of the first-stage vacuum distillation pump at about 0.1mbar, and control the temperature at 50°C, turn off the second-stage vacuum distillation pump, first distill out the solvent part, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com