Alkaline stemming

A blast furnace clay and alkaline technology, which is applied in the field of blast furnace taphole alkaline blast clay, can solve the problems of unfavorable environmental influence and difficulty in adapting to the requirements of the furnace, and achieve the reduction of harmful impurities, easy opening of holes, and short sintering time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

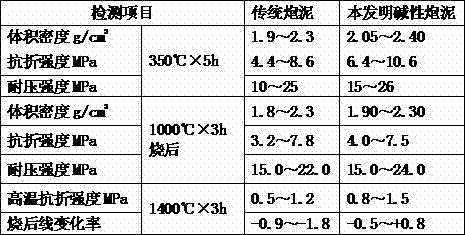

Image

Examples

Embodiment 1

[0025] Embodiment 1 A kind of alkaline gun clay is made from the following raw materials in terms of weight percentage:

[0026] Sintered magnesia (particle size ≤ 5mm, MgO content ≥ 90%) 30%, coke foam 15%, andalusite (particle size ≤ 1mm, Al 2 o 3 content ≥ 55%) 5%, magnesium carbon recycled material 12%, carbon resin powder (CARBORES?P, 200 mesh) 3%, silicon carbide (200 mesh) 10%, Jiaozuo clay (200 mesh) 5%, light burning Magnesium powder 10%, α-alumina 5%, andalusite powder 5%, and 15% of the total weight of the above raw materials plus special resin for gun clay (CARBORES ? T60);

[0027] Take sintered magnesia, andalusite, magnesia-carbon recycled materials, carbon-containing resin powder, silicon carbide, coke clay, lightly burned magnesium powder, α-alumina, and andalusite powder in a wet mill according to the weight ratio Mix for 4 minutes, then add resin and mix and grind for 25 minutes, so that the resin is fully soaked into the mixed powder, has a certain degr...

Embodiment 2

[0029] Embodiment 2 A kind of alkaline gun clay is made from the following raw materials in terms of weight percentage:

[0030] Sintered magnesia (particle size ≤ 5mm, MgO content ≥ 90%) 35%, coke foam 10%, andalusite (particle size ≤ 1mm, Al 2 o 3 content ≥55%) 10%, magnesium carbon recycled material 15%, carbon resin powder (CARBORES?P, 200 mesh) 2%, silicon carbide (250 mesh) 8%, Jiaozuo clay (250 mesh) 6%, light burning 10% magnesium powder, 4% α-alumina, and 17% of the total weight of the above raw materials plus resin (CARBORES ? T60);

[0031] The preparation method of the above-mentioned gun clay is the same as the conventional method.

Embodiment 3

[0032] Embodiment 3 A kind of alkaline gun clay is made from the following raw materials in weight percentage:

[0033] Sintered magnesia (particle size ≤ 5mm, MgO content ≥ 90%) 25%, coke foam 15%, andalusite (particle size ≤ 1mm, Al 2 o 3 content ≥ 55%) 8%, magnesium carbon recycled materials 24%, carbon resin powder (CARBORES?P, 200 mesh) 4%, silicon carbide (250 mesh) 5%, Jiaozuo clay (250 mesh) 5%, light burning 10% magnesium powder, 4% α-alumina, and 18% of the total weight of the above raw materials plus resin (CARBORES ? T60).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com