Process of producing stainless steel molten semisteel by coal-made synthesis gas

A technology for producing synthetic gas and stainless steel from coal is applied in the production process of stainless steel half molten steel, which can solve the problems of high energy consumption, achieve the effects of low energy consumption, avoid coking process pollution and good environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

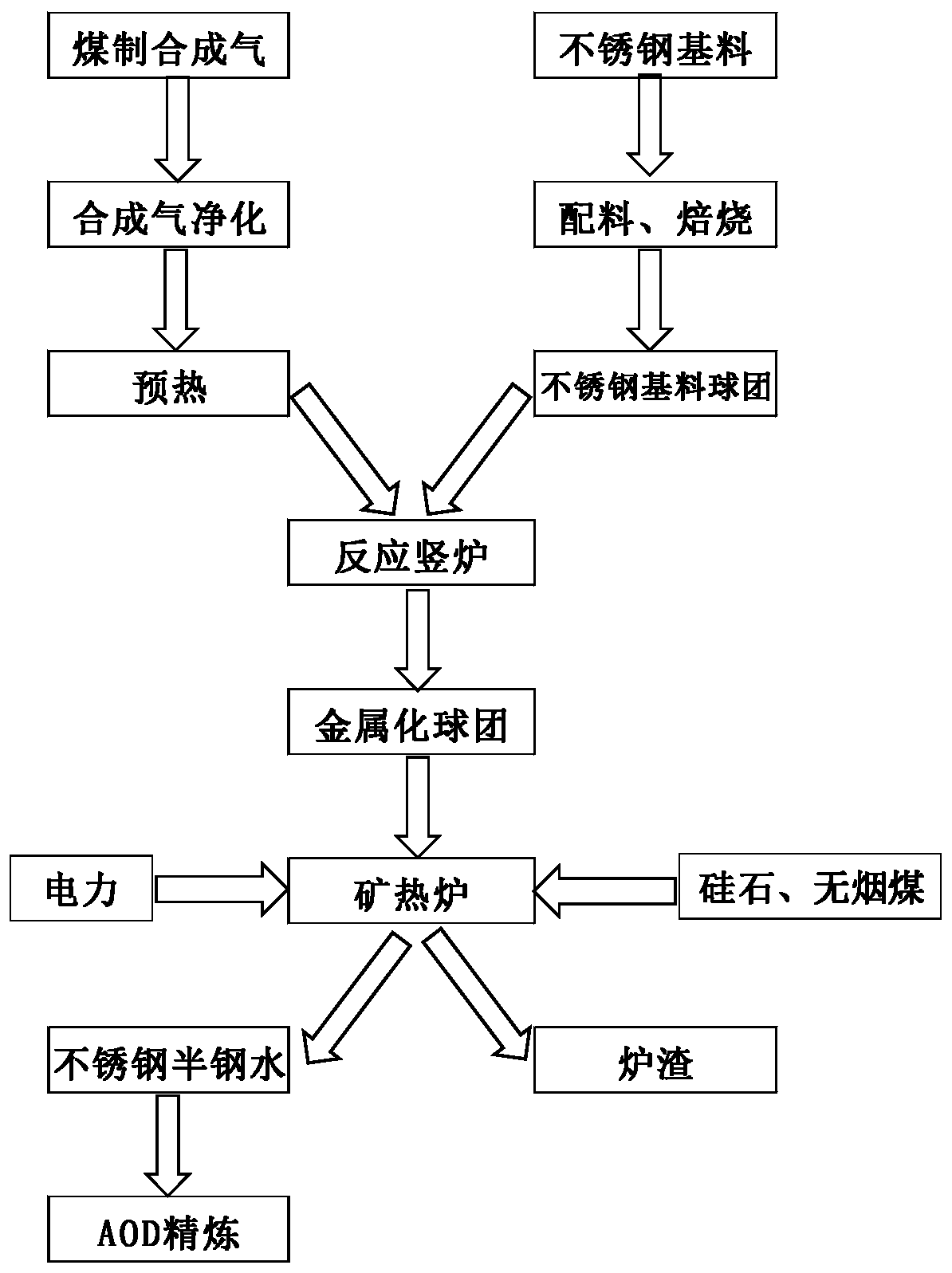

[0027] A kind of coal-to-synthesis gas is produced the technology of semi-stainless steel molten steel, comprises the steps:

[0028] 1) Preparation of coal-to-synthesis gas and stainless steel base material pellets;

[0029] 2) After the coal-based synthesis gas is purified and preheated, it is fed into the reaction shaft furnace from below, and the stainless steel base material pellets are added into the reaction shaft furnace from above, and the coal-based synthesis gas and the falling stainless steel base material pellets are in countercurrent contact for reduction reaction to generate metallized pellets;

[0030] 3) Send the generated metallized pellets into the submerged arc furnace through a heat conveying device, add a flux and a reducing agent, melt them, and separate the slag and iron to obtain molten stainless steel;

[0031] 4) The stainless steel semi-steel produced by melting in the submerged arc furnace is hydrothermally sent to the stainless steel steelmaking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com