Casting smelting raw material transportation pulverizer

A pulverizer and raw material technology, which is applied in the field of machinery, can solve the problems of poor melting effect and low melting efficiency of metal raw materials, and achieve the effect of improving the effect and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

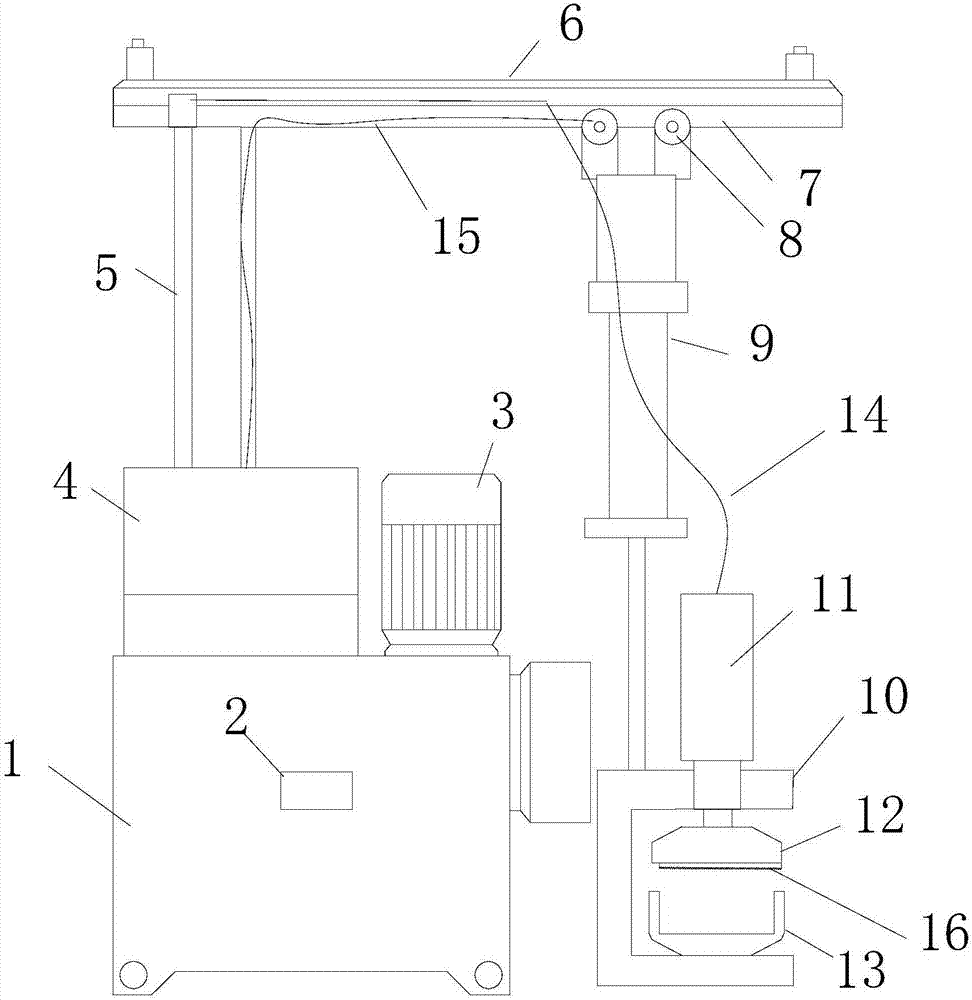

[0009] Embodiment: a casting smelting raw material transportation pulverizer, constituted as figure 1 As shown, including the oil tank 1, the oil pump 2 is arranged inside the oil tank 1, the oil pump 2 is connected to the drive motor 3, the electrical control box 4 is arranged above the oil tank 1, the column 5 is arranged above the electrical control box 4, and the beam 6 is arranged above the column 5 , the beam 6 is provided with a slide rail 7, and the slide rail 7 is provided with a traveling wheel 8. The traveling wheel can adopt a complete set of traveling equipment including a motor and a pulley, and the traveling wheel can be driven only through the electric control box through the wire. and control, the lower part of the walking wheel 8 is connected with a cantilever 9, a C-shaped transport block 10 is provided below the cantilever 9, a hydraulic cylinder 11 is provided on the upper part of the transport block 10, and a crushing block 12 is provided at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com