Alloy special for computer hardware manufacturing and machining process thereof

A technology of computer hardware and processing technology, applied in the field of master alloys, can solve the problems of inconvenient and precise control, poor alloy quality, long sintering time, etc., and achieve the effect of accelerating vacuum sintering speed, saving materials, and reducing internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A special alloy for making computer hardware, in terms of mass percentage, comprising: Cr: 34.0%, Fe: 7.0%, Al: 0.6%, Mo: 2.8%, Ti: 8.5%, Mn: 0.3% and W: 4.3%, the remainder The amount is C and unavoidable impurities.

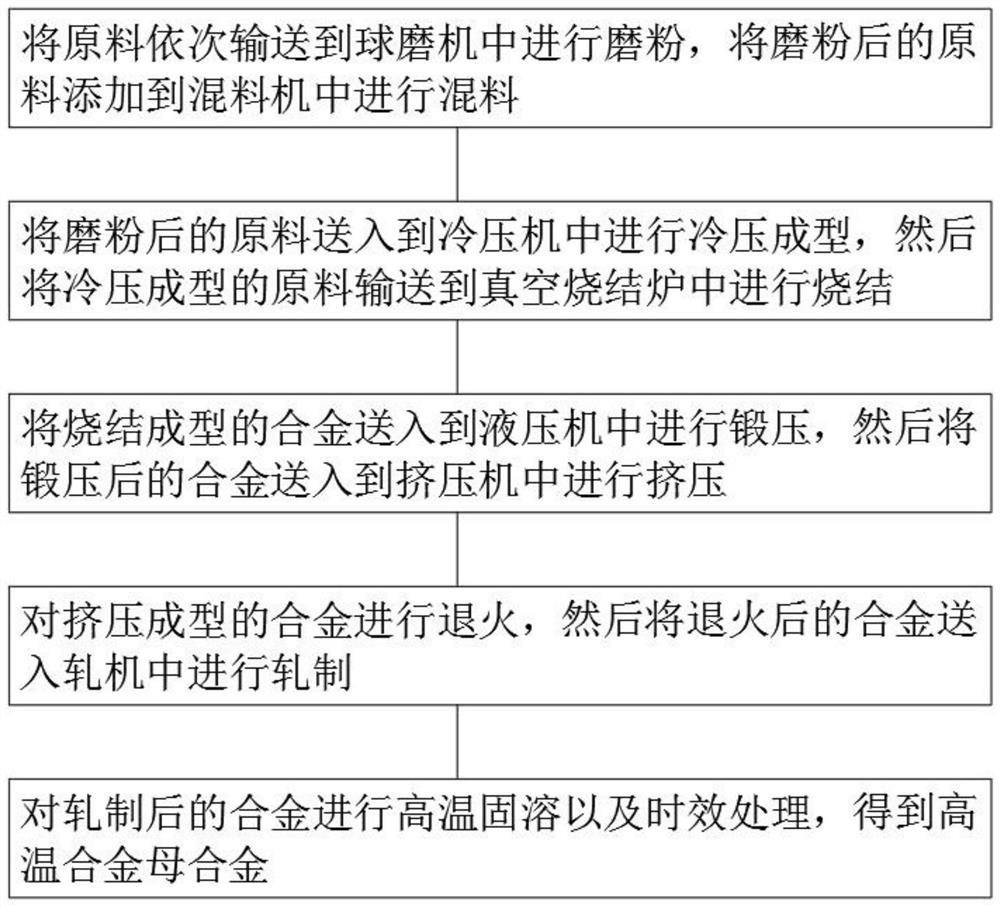

[0034] A processing technology for making special alloys for computer hardware, comprising the following steps:

[0035] ①. Send the raw materials to the ball mill in turn for grinding, and add the milled raw materials to the mixer for mixing;

[0036] The particle size of the powder after ball mill grinding is 100μm. After the raw materials are sent into the mixer, inert gas is added to the mixer, and the mixing starts after adding the inert gas.

[0037] ②. Feed the milled raw materials into the cold press for cold-press forming, and then transport the cold-press-formed raw materials to the vacuum sintering furnace for sintering;

[0038] The compression molding pressure of the cold press is 700MPa, and the raw material for compression molding is a c...

Embodiment 2

[0047] A special alloy for making computer hardware, in terms of mass percentage, comprising: Cr: 36.0%, Fe: 9.0%, Al: 0.7%, Mo: 3.2%, Ti: 9.2%, Mn: 0.3% and W: 4.6%, the remaining The amount is C and unavoidable impurities.

[0048] A processing technology for making special alloys for computer hardware, comprising the following steps:

[0049] ①. Send the raw materials to the ball mill in turn for grinding, and add the milled raw materials to the mixer for mixing;

[0050] The particle size of the powder after ball mill grinding is 100μm. After the raw materials are sent into the mixer, inert gas is added to the mixer, and the mixing starts after adding the inert gas.

[0051] ②. Feed the milled raw materials into the cold press for cold-press forming, and then transport the cold-press-formed raw materials to the vacuum sintering furnace for sintering;

[0052] The compression molding pressure of the cold press is 700MPa, and the raw material for compression molding is a c...

Embodiment 3

[0061] A special alloy for making computer hardware, in terms of mass percentage, comprising: Cr: 37.0%, Fe: 11.0%, Al: 0.9%, Mo: 3.8%, Ti: 9.4%, Mn: 0.3% and W: 4.7%, the remaining The amount is C and unavoidable impurities.

[0062] A processing technology for making special alloys for computer hardware, comprising the following steps:

[0063] ①. Send the raw materials to the ball mill in turn for grinding, and add the milled raw materials to the mixer for mixing;

[0064] The particle size of the powder after ball mill grinding is 100μm. After the raw materials are sent into the mixer, inert gas is added to the mixer, and the mixing starts after adding the inert gas.

[0065] ②. Feed the milled raw materials into the cold press for cold-press forming, and then transport the cold-press-formed raw materials to the vacuum sintering furnace for sintering;

[0066] The compression molding pressure of the cold press is 700MPa, and the raw material for compression molding is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com