Flux-cored welding wire with good toughness and low porosity

A flux-cored wire, good toughness technology, used in welding media, welding equipment, welding/cutting media/materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

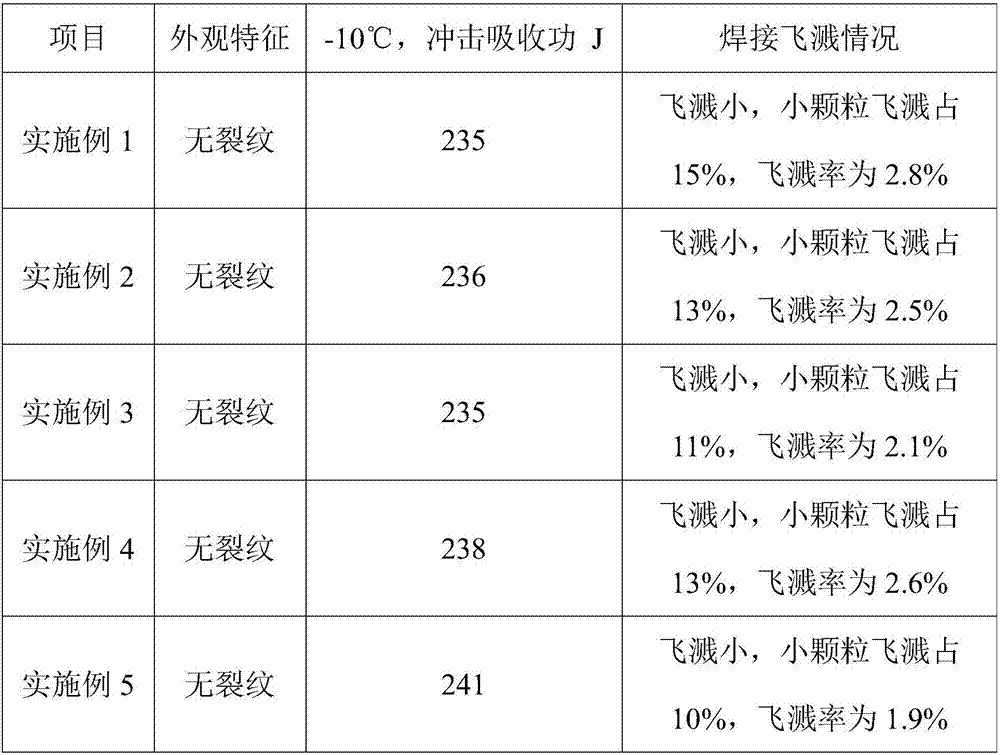

Examples

Embodiment 1

[0015] A flux-cored welding wire with low porosity and good toughness, comprising a low-carbon steel strip sheath and a flux core, wherein the raw materials of the flux core include: 0.5% graphite, 12% chromium powder, 3% manganese dioxide, 4.5% nickel powder, 4% niobium powder, 3% zirconium powder, 0.5% silicon dioxide, 9.5% rhenium oxide, 13% magnesium aluminum alloy, 7% fluoride, 3% lithium carbonate, and the balance is iron powder.

Embodiment 2

[0017] A flux-cored welding wire with low porosity and good toughness, comprising a low-carbon steel strip sheath and a flux core, wherein the raw materials of the flux core include: graphite 0.4%, chromium powder 14%, manganese dioxide 2%, Nickel powder 5.5%, niobium powder 3%, zirconium powder 4%, silicon dioxide 0.4%, rhenium oxide 10%, magnesium aluminum alloy 12%, fluoride 8%, lithium carbonate 1.5%, and the balance is iron powder;

[0018] Wherein, the fluoride is lithium fluoride and calcium fluoride, wherein the weight ratio of lithium fluoride to calcium fluoride is 4:1;

[0019] The raw materials of the drug core must be pretreated, and the pretreatment steps are: mixing the raw materials of the drug core, granulating, sintering at 800°C for 40 minutes, and crushing to 100 mesh;

[0020] The filling amount of the flux core is 48% of the total weight of the welding wire.

Embodiment 3

[0022] A flux-cored welding wire with low porosity and good toughness, comprising a low-carbon steel strip sheath and a flux core, wherein the raw materials of the flux core include: 0.6% graphite, 10% chromium powder, 4% manganese dioxide, Nickel powder 3.5%, niobium powder 5%, zirconium powder 2%, silicon dioxide 0.6%, rhenium oxide 9%, magnesium aluminum alloy 14%, fluoride 6%, lithium carbonate 4%, the balance is iron powder;

[0023] Wherein, the fluoride is lithium fluoride and calcium fluoride, wherein the weight ratio of lithium fluoride to calcium fluoride is 2:1;

[0024] The raw materials of the drug core must be pretreated, and the pretreatment steps are: mixing the raw materials of the drug core, granulating, sintering at 900°C for 20 minutes, and crushing to 200 mesh;

[0025] The filling amount of the flux core is 44% of the total weight of the welding wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com