Patents

Literature

55results about How to "Avoid carbon increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Double-layered alkali grain covering agent for middle ladle

The present invention relates to a double-layered alkali grain heat-insulting covering agent for middle ladle. The heat-insulting covering agent consists of top slag in 10-50 wt% and bottom slag in 50-90 wt%. The bottom slag consists of SiO2 8-15 wt%, CaO 50-60 wt%, MgO 10-20 wt%, Al2O3 1-5 wt%, Fe2O3 1-3 wt%, and fixed carbon 0.01-1 wt%. The top slag consists of SiO2 85-93 wt%, CaO 0.001-3 wt%, MgO 0.001-3 wt%, Al2O3 0.001-3 wt%, Fe2O3 0.003-0.5 wt%, and fixed carbon 0.01-1 wt%. The heat-insulting covering agent forms two layers of slag, the bottom layer covers molten steel to prevent secondary oxidation, reduce carbon content in molten steel and adsorb alumina floating to the surface of molten steel, and the top layer in porous and loose structure covers molten steel to prevent incrusting and carburization.

Owner:上海宝谊保温材料有限公司

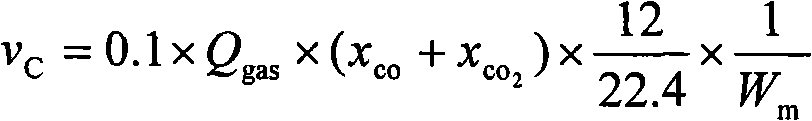

Method for continuously predicting carbon content of converter molten pool

ActiveCN101832967AGuaranteed to meltUniform compositionMaterial analysis by electric/magnetic meansMelting tankCommunications system

The invention discloses a method for continuously predicting carbon content of a converter molten pool, which comprises data acquisition, raw material control, operation control and technical process and specifically comprises the following steps of: in the data acquisition, detecting converter gas flow by using a converter gas flow meter, transmitting all detection information to a computer through a data communication system, and analyzing and calculating the detection information through the following two mathematical models w[C]=0.1*(sigma Cori-sigma Cde) / Wm (1); in the raw material control, controlling a waste steel ratio to be 8 to 13 percent, and controlling the weight percentage of light waste steel and heavy waste steel to be 14 to 70 percent; in the operation control, holding a fixed gun position and a fixed smoke hood in 2 to 3 minutes before finishing blowing; and in the technical process, ensuring that the carbon content of the molten pool meets the formula (1) when the oxygen blowing amount accounts for less than or equal to 75 percent of the total oxygen blowing amount and the carbon content of the molten pool meets the formula (2) when the oxygen blowing amount accounts for over 75 percent of the total oxygen blowing amount. The method fulfills the purpose of continuously predicting the carbon content of the converter molten pool by combining the mathematical models and the technical process.

Owner:ANGANG STEEL CO LTD

Lost foam casting production low-carbon steel upper core disc and impact seat processing method

InactiveCN104162633AAvoid crackingImprove compromiseFoundry mouldsFoundry coresManufacturing technologyHigh volume manufacturing

The invention discloses a lost foam casting production low-carbon steel upper core disc and impact seat processing method. The method comprises the following steps: making foam polystyrene EPS into a foaming member, which has the same shape as a cast and is a little bigger than the cast; painting a plurality of fireproof coatings on the surface of the foaming member, placing the foaming member in non-adhesive moulding sands, carrying out casting on the foaming member, wherein during the casting process, the foam polystyrene EPS foaming member is burnt and gasified under the assistance of vacummizing and vibration during the casting process, and finally the molten liquid replaces the foaming member as the cast. The lost foam technology is used to manufacture upper core disc and impact seat, is capable of reducing the metal tissue defects and improving the compactness and anti-fatigue strength of metals, moreover has the advantages of high precision in size, reducing on cleanness, reduced processing time, compact tissue of products, suitability for massive production, and high automation, can greatly improve the operation environment, and has greater advantages and a vaster prospect, compared to the conventional manufacture technology of upper core disc and impact seat.

Owner:XIANGTAN SANTAI MACHINERY MFG

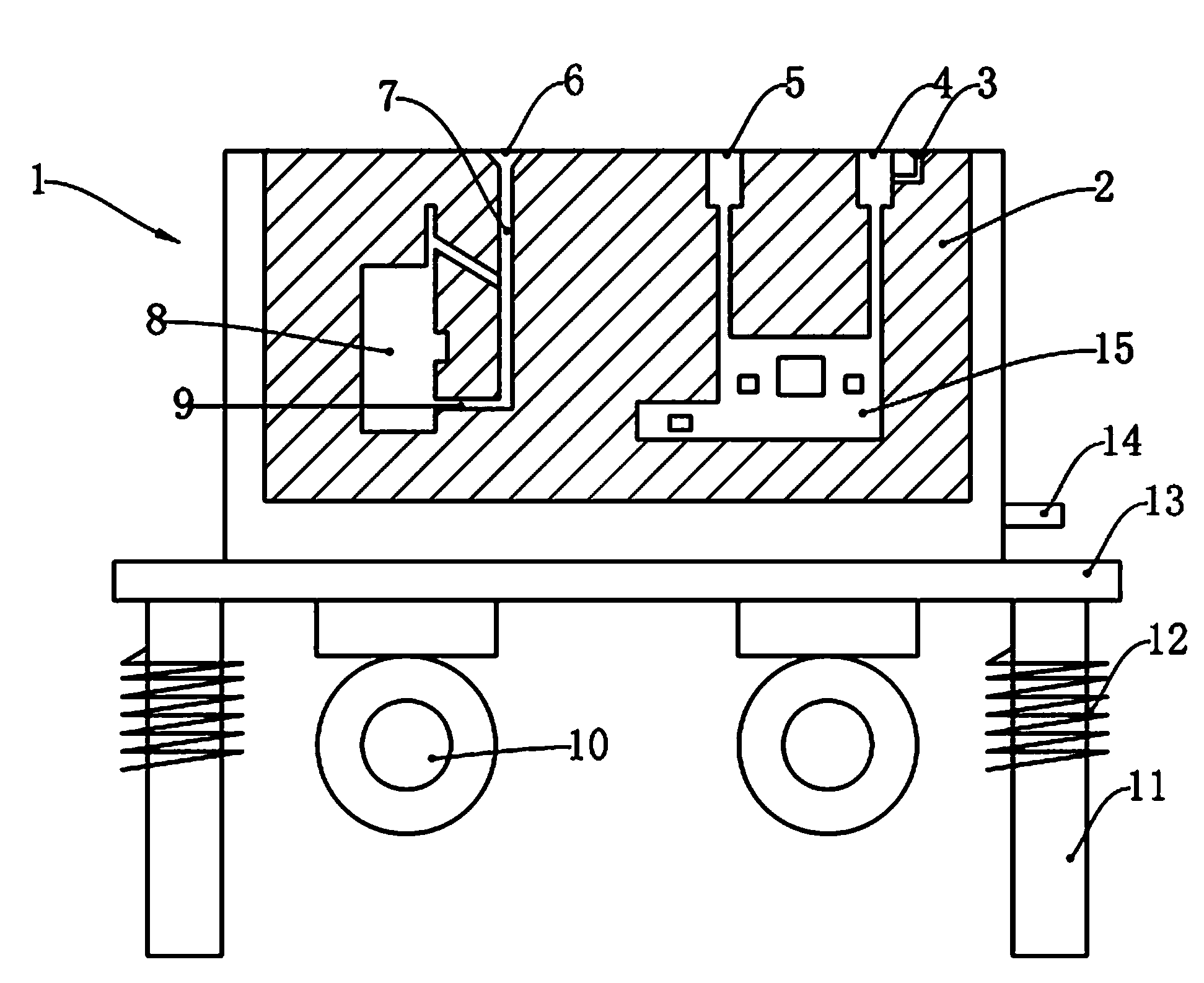

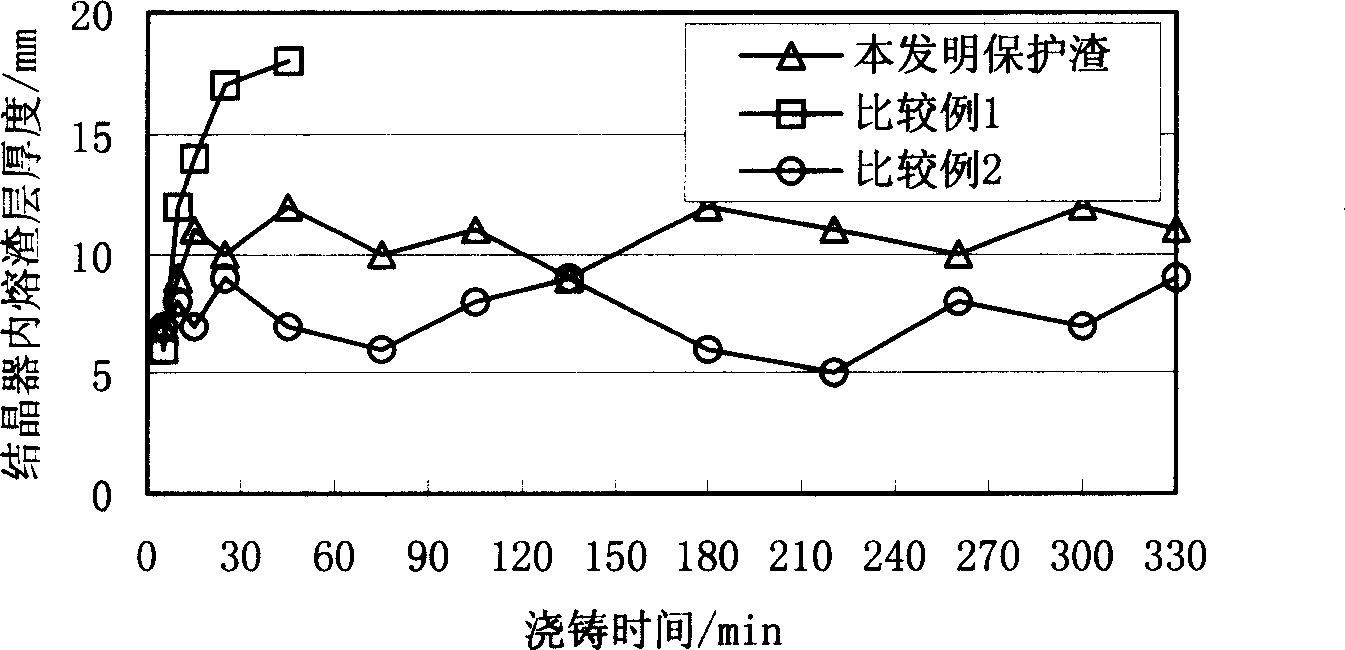

Protective slag for ultralow carbon steel continuous casting

The ultra-low carbon steel protecting slag for continuous casting consists of carbon material 0.5-1.6 wt%, metal smelting speed regulator 2-8 wt%, MgO 2-7 wt%, Na2O 6-12 wt%, F- 2-8 wt%, Al2O3 2-7 wt%, MnO 3-8 wt%, Fe2O3 1-3 wt%, except CaO and SiO2, where the weight ratio CaO / SiO2 is 0.75-1.05. The metal smelting speed regulator is one of Ca-Si alloy, Ca-Ba-Si alloy, Mn-Si alloy and Fe-Mn alloy or any composition of them. The ultra low carbon steel protecting slag is used for continuous casting, and has synergistic metallurgical functions and no carburization of the continuous cast billet.

Owner:CHONGQING UNIV

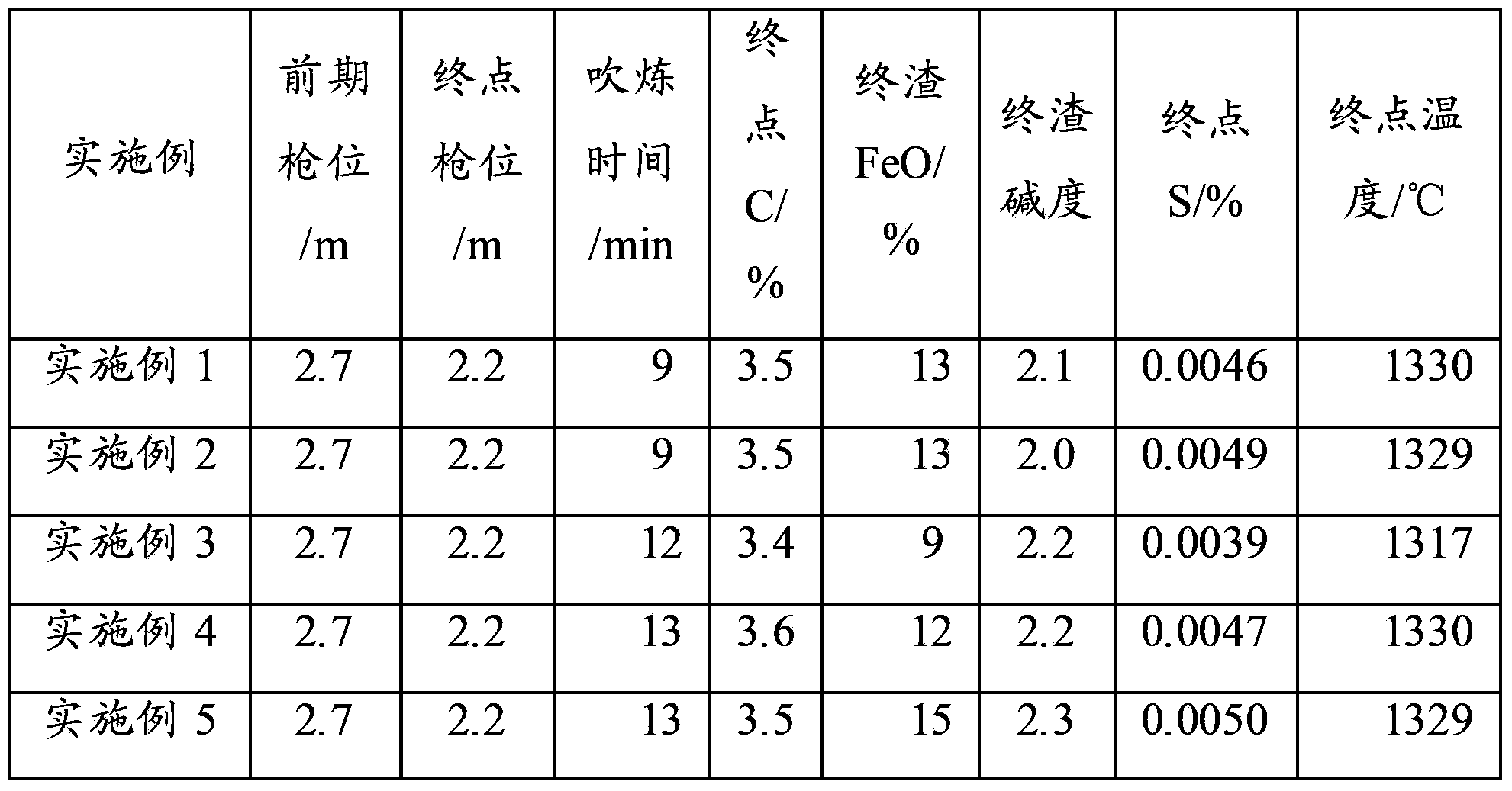

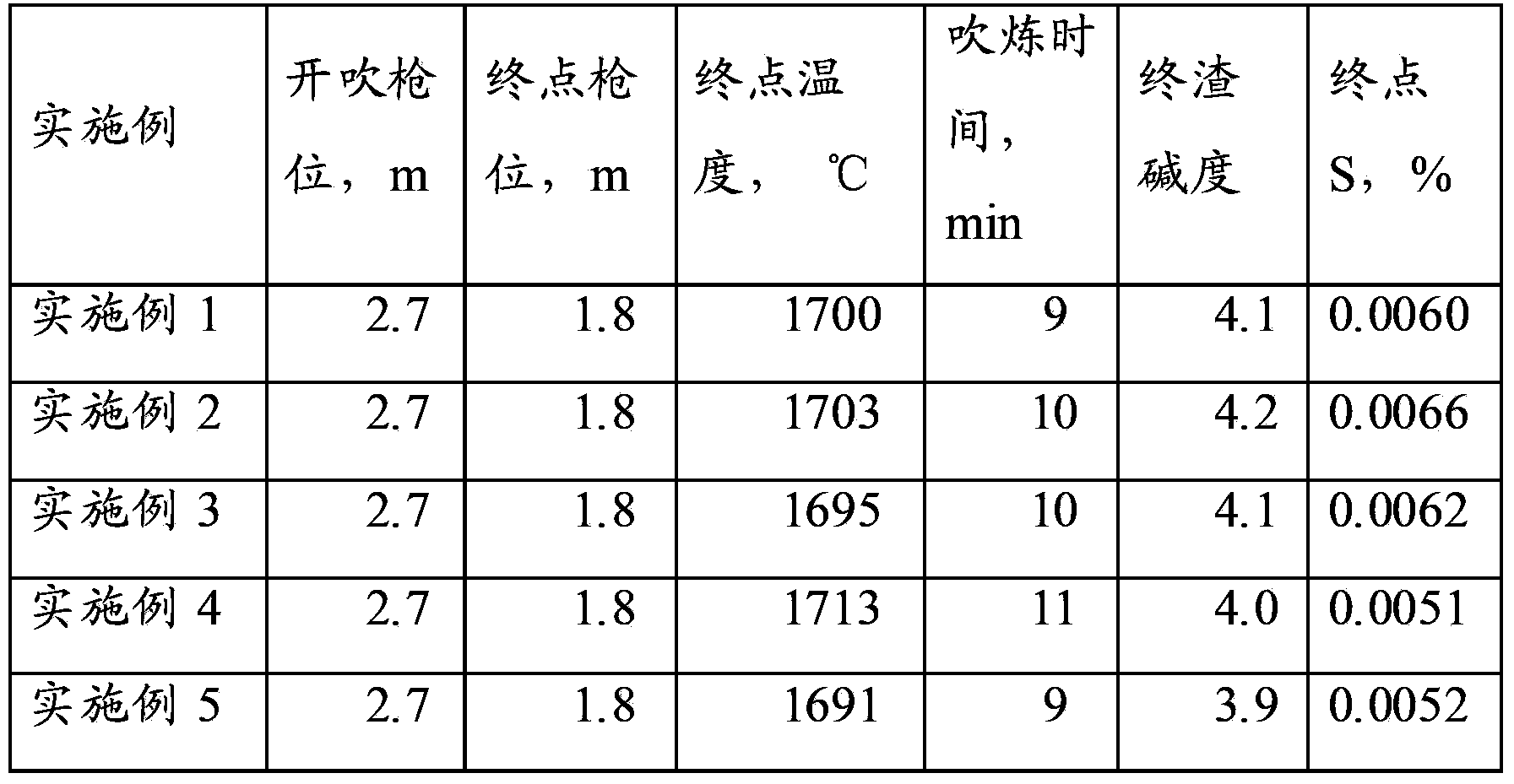

Production method of pipeline steel

The invention provides a production method of pipeline steel. The production method comprises following steps: molten iron in a foundry ladle is subjected to slagging treatment, to desulphurization after addition of a desulfurizer, and then to slagging treatment for a second time; the molten iron is added into a dephosphorization furnace, steel scraps and slag materials are added into the molten iron, the mixture is subjected to converting decarburization treatment so as to obtain molten steel, and then the molten steel is added into the dephosphorization furnace; slag materials are added into the molten steel in the dephosphorization furnace, the mixture is subjected to converting decarburization treatment so as to obtain decarburized molten steel; the decarburized molten steel is subjected to steel tapping treatment, and the molten steel is added into a steel ladle; the molten steel in the steel ladle is subjected to RH refining; and then the refined molten steel is subjected to teeming treatment by using a continuous caster. According to the production method of pipeline steel, ' three removal' pre-treatment technologies on full molten iron are employed, secondary refining desulphurization is not needed, low-sulfur molten steel with S less than 0.006% can be producted by raw material controlling and converter operation, production cost is low, and cleanliness of products is high.

Owner:SHOUGANG CORPORATION

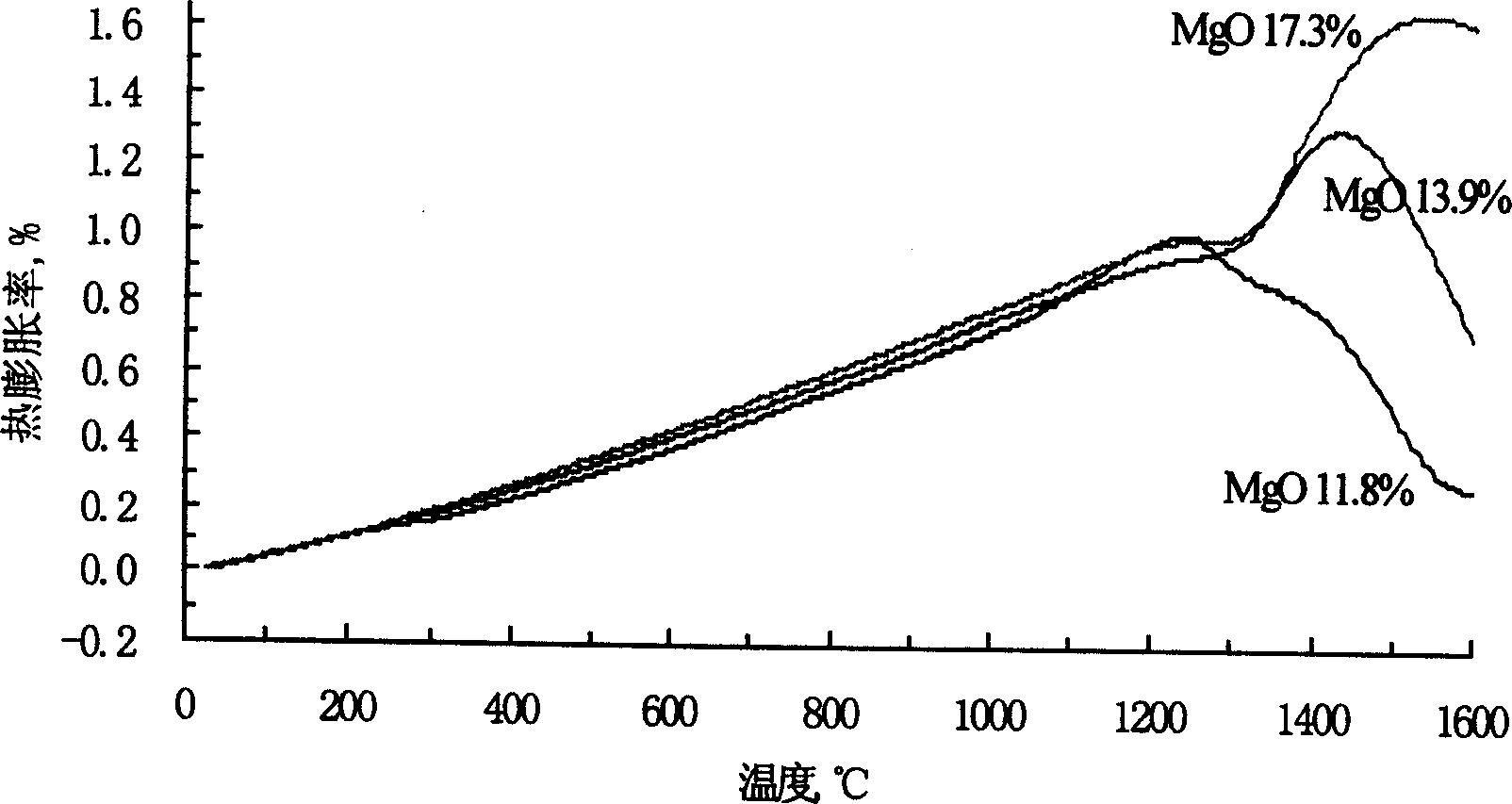

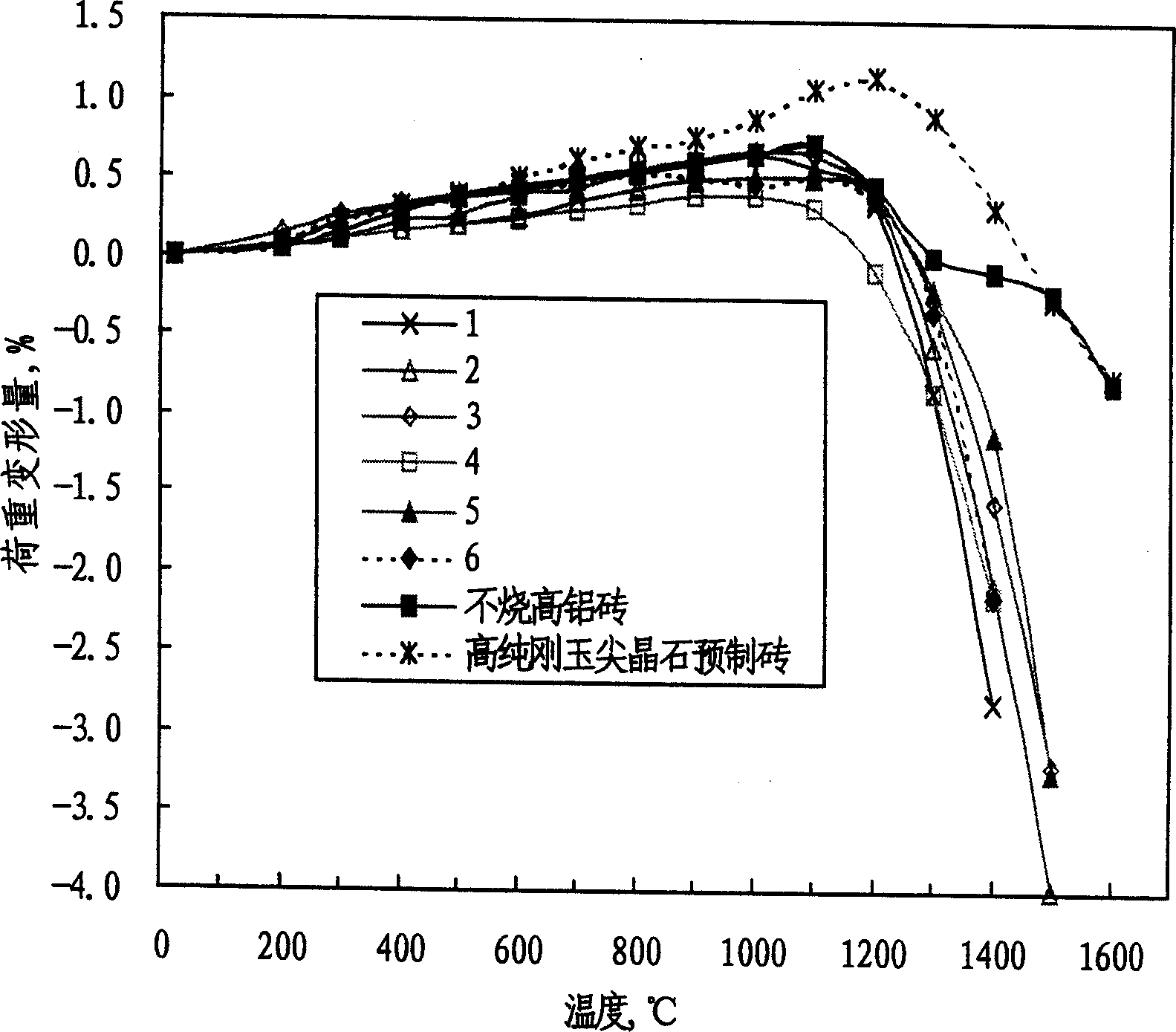

Non-phosphorus and low-carbon alumina-magnesia unburned brick for stainless steel ladle and manufacturing method of brick

The invention discloses a non-phosphorus and low-carbon alumina-magnesia unburned brick for a stainless steel ladle and a manufacturing method of the brick. The non-phosphorus and low-carbon alumina-magnesia unburned brick comprises the following components by mass percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 10-15% of bauxite less than or equal to 1mm in particle size, 10-15% of 3-1mm fused magnesite, 5-10% of fused magnesite less than or equal to 1mm in particle size, 10-15% of emery powder, 15-20% of spinel powder, 2-5% of aluminum oxide micropowder less than or equal to 25 micrometers, 0.1-2% of silicon carbide additive, 0.1-2% of wetting agent and a phenolic resin binding agent. Compared with the prior art, the brick and the method have the prominent advantages that a burning technology in the conventional method is omitted, energy sources are saved, the brick is free from phosphorus; aluminum and magnesium perform spinel reaction at the high temperature; and the brick is subjected to machine molding in the absence of the phosphorus, has higher density, avoids pollution of molten stainless steel, and has a longer service life.

Owner:长兴南冶冶金材料有限公司

Mold case for producing high-temperature alloy single crystal blades

The invention provides a mold case for producing high-temperature alloy single crystal blades in the directional solidification process. The surface layer of the mold case corresponds to a high-temperature alloy melt in the mold case, and the back layer of the mold case is made of a good heat conductor material which is silicon carbide or graphite. Then the back layer is made of silicon carbide, the surface layer of the mold case is made of silicon carbide or ceramic. When the back layer is made of graphite, the surface layer of the mold case is made of ceramic. According to the mold case which is made of the heat conduction material and used for producing high temperature alloy single crystal blades, the graphite and the silicon carbide serve as good heat conductors, the heat conducting properties of the graphite and the silicon carbide are much higher than those of ceramic materials and even obviously better than those of high-temperature alloys, so that the heat conducting property of the mold case is improved by more than one magnitude order, the cooling rate of a casting is greatly accelerated, the temperature condition of directional solidification is improved obviously, and the yield of single crystal or directional column crystal blades is improved.

Owner:DONGFANG TURBINE CO LTD

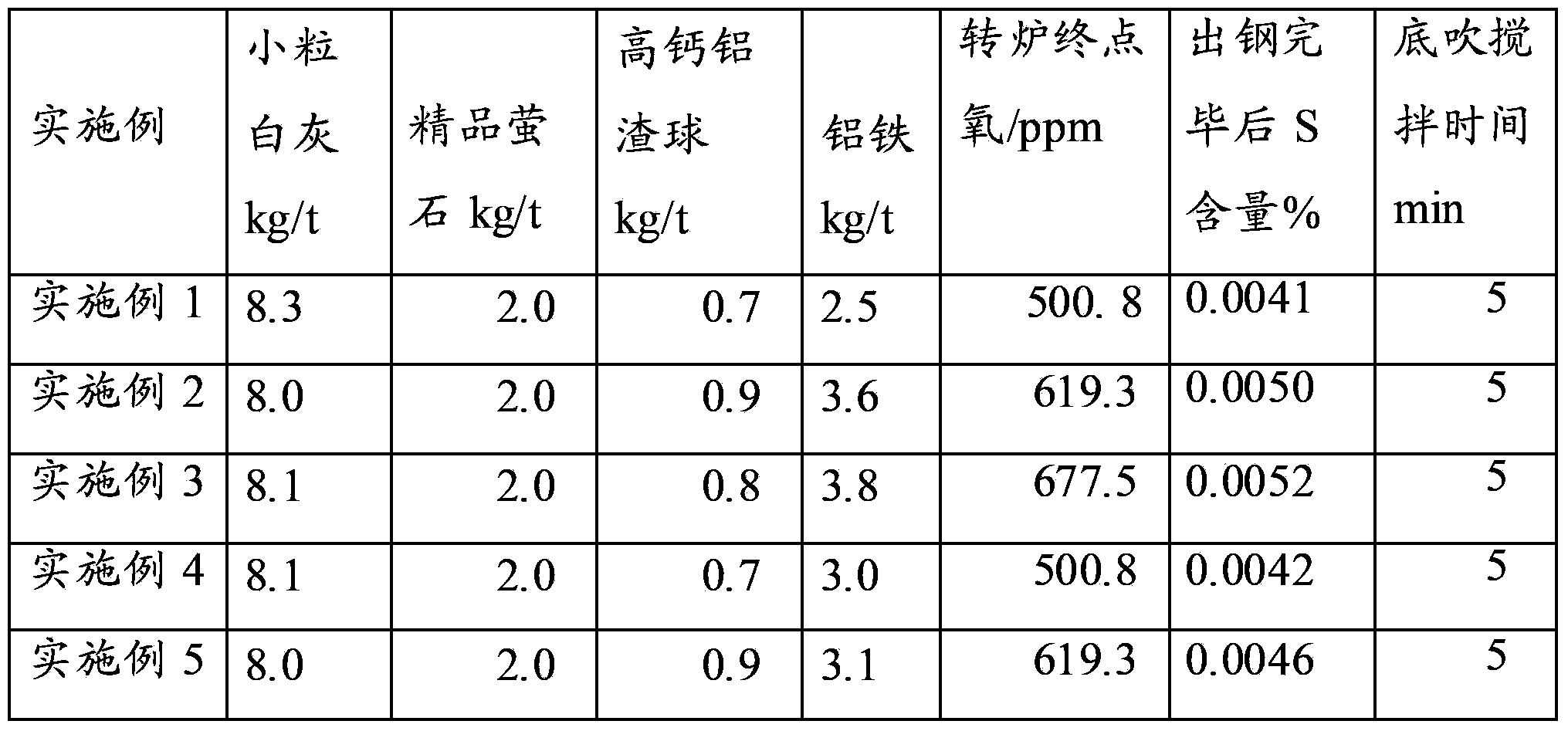

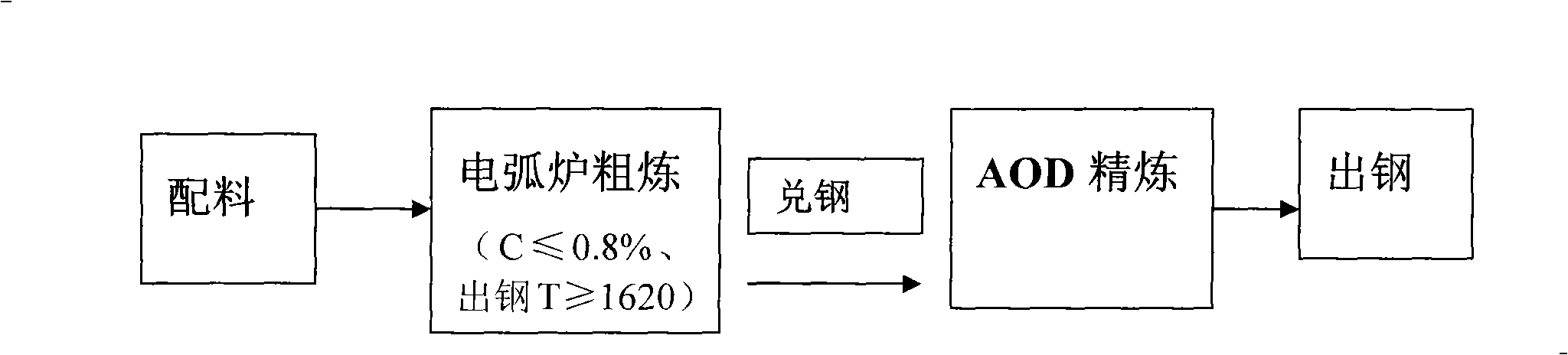

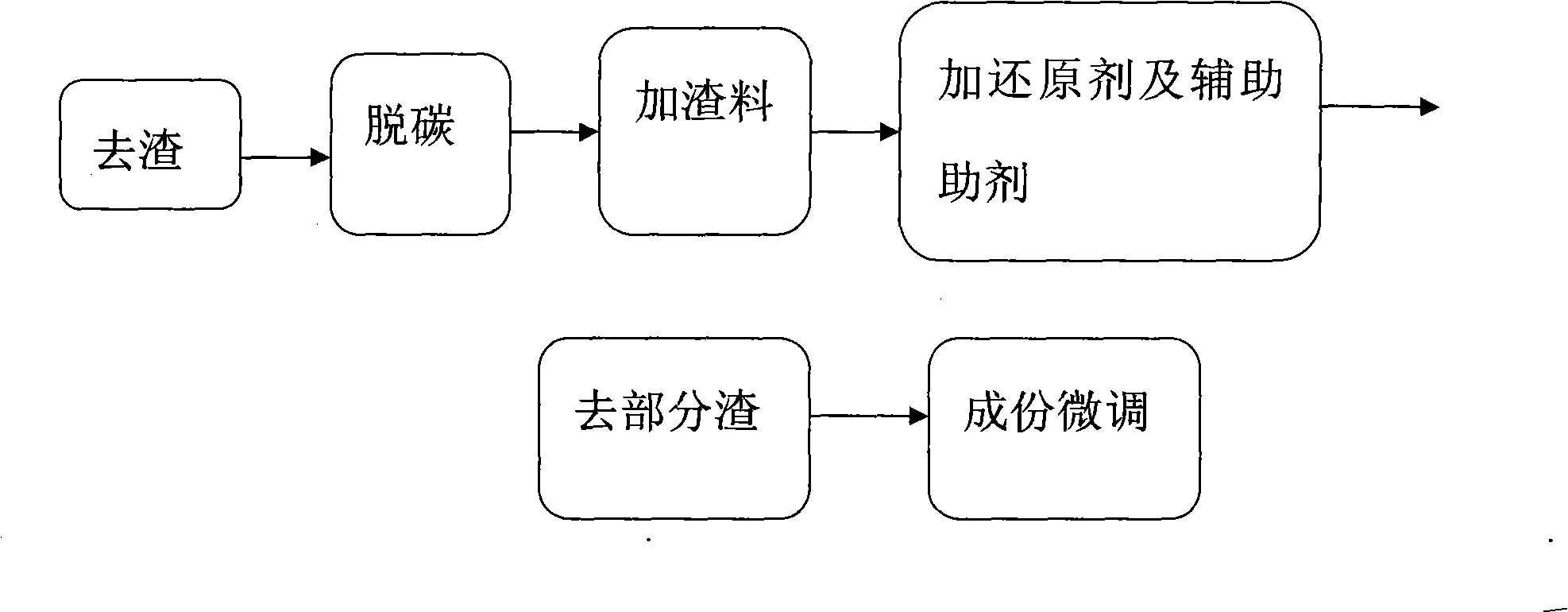

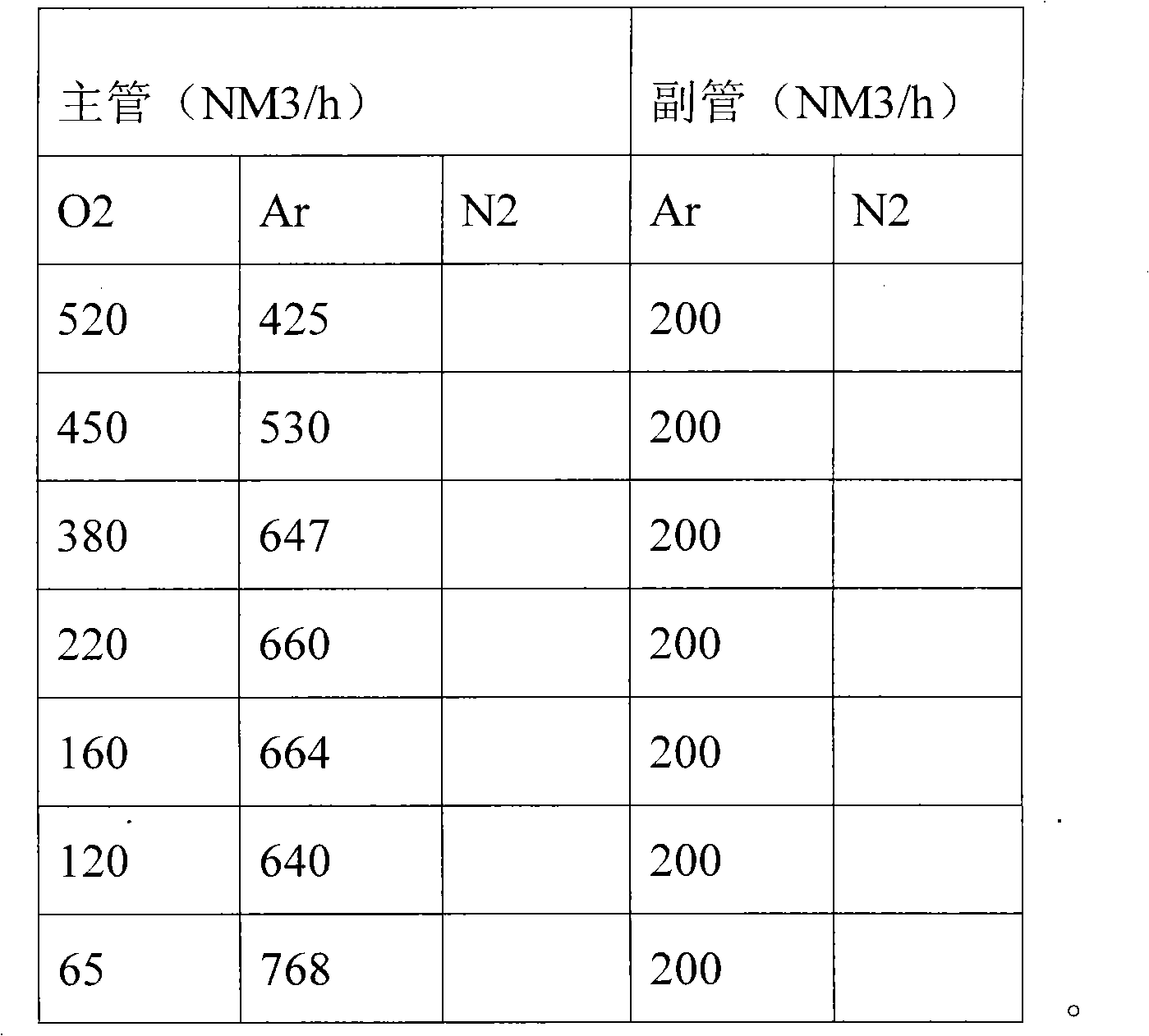

Method for smelting very-low carbon and high silicon stainless steel by AOD

The invention discloses a method for using AOD to smelt extra-low high sillca stainless steel which includes the following technical steps: batching-crude melting by an arc furnace-steel exchange-AOD refining-argon blowing-tapping; wherein, the AOD refining also includes the following steps: removing slag-decarbonizing-adding slag materials-adding a reducer and an auxiliary agent-removing partial slag-fine tuning on the components; the method is characterized in that: a, the argon oxygen blowing in the decarbonizing technique is divided into an initial decarbonizing period and a secondary decarbonizing period; the initial decarbonizing period and the secondary decarbonizing period are blown according to a different argon-oxygen ratio; b, the slag system adopted in the technique of adding the slag materials is a slag system of CaO, Al2O3, MgO and SiO2. The method of the invention leads a steel liquid to finish crude smelting in the arc furnace, namely being capable of stably producing the extra-low stainless steel ( the C is equal to or less than 0.015 percent) in the AOD without a vacuum device, saving the consumption of the reducer, having a low cost, being capable of carrying out industrial batch production, utilizing the existing smelting device to the largest extent as well and saving a plurality of investment.

Owner:YONGXING SPECIAL STAINLESS STEEL

Bottom fire-proof material of large steel ladle

A refractory material used as the bottom of large ladle for prparing ultralow-carbon steel is proportionally prepared from special-grade alumine, superfine megnesite, almag spinel powder, superfine silicon powder, megnesium adhesive and disperser.

Owner:BAOSHAN IRON & STEEL CO LTD

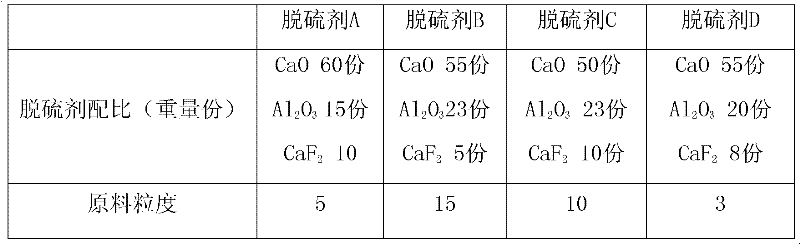

RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, preparation method thereof, and desulfurizing method using same

InactiveCN102199687AGuaranteed electromagnetic performanceReduce iron lossElectrical steelRefractory

The invention relates to an RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, a preparation method thereof, and a desulfurizing method using the same, belonging to the field of secondary refining of molten steel, so as to solve the problems that the RH vacuum treatment desulfurizing processes used for electrical steel in the prior art have serious erosion on refractory materials, high cost, slow melting speed and carburization risk to molten steel. The RH vacuum treatment desulfurizing agent used for non-oriented electrical steel is mainly composed of the following components: 50-60 weight parts of CaO, 10-25 weight parts of Al2O3 and 5-10 weight parts of CaF2. The invention also provides the preparation method of the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel, and the desulfurizing method using the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel. The RH vacuum treatment desulfurizing agent provided by the invention is mainly used for the RH vacuum treatment desulfurizing treatment of the non-oriented electrical steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

Embedded composite board blank manufacturing method

InactiveCN108176715AAvoid carbon increaseIncrease frictionAuxillary arrangementsMetal rolling arrangementsLiquid stateEngineering

The invention discloses an embedded composite board blank manufacturing method. The embedded composite board blank manufacturing method comprises the following steps: 1) pretreatment: two identical substrates are selected; matched bosses are milled around the substrates; rectangular grooves are machined in middles of the substrates; the bottoms of the substrates are machined as specific shapes; and the inner sides of the rectangular grooves are chamfered; 2) composite blank manufacturing: after cleaning, sandwich layers are uniformly sprayed to the surfaces of concave molds in a vacuum chamber, and drying is performed; liquid-state 316 L composite materials are poured until the surfaces of the concave molds are leveled; after cooling solidification, the surfaces of composite material blanks are milled away; an isolating agent is uniformly sprayed to the surfaces of the composite materials; and after spraying is finished, the two substrates are engaged for assembly, and joints at the periphery are welded; and 3) rolling combination: the blanks are fed in a rolling mill for rolling. The method not only can prevent recarburization of the substrates and the composite boards in the rolling process to prevent influence on the rolling effect by slippage or layering or cracks, but also can increase the rolling contact area to improve the interface bonding strength, and is suitable forlarge-batch factory production.

Owner:YANSHAN UNIV

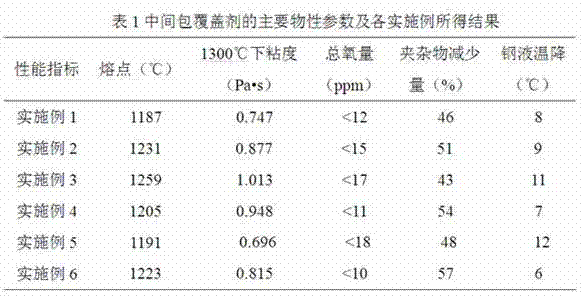

Tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and application thereof

InactiveCN105436447AContinuous casting production went smoothlyEffective absorptionAlkalinityThermal insulation

The invention provides a tundish covering agent for continuous casting of low-carbon steel containing Al and Ti and an application thereof. The tundish covering agent is prepared from, by mass, 32%-43% of CaO, 7%-14% of SiO2, 25%-32% of Al2O3, 6%-14% of MgO, 6%-13% of (Na2O+Li2O), 3%-7% of B2O3, 0.5%-1.5% of C and 1.1%-2% of TiO2. The tundish covering agent is low in melting temperature and viscosity and high in alkalinity. The tundish covering agent has the advantages that the tundish covering agent is suitable for continuous casting of the low-carbon steel containing Al and Ti, the mass percentage of C is smaller than or equal to 0.1%, the content of Al is smaller than or equal to 0.5%, and the content of Ti is smaller than or equal to 0.5%, inclusions in the low-carbon steel containing Al and Ti can be efficiently absorbed, the cleanliness of molten steel in a tundish is increased, secondary oxidation of the molten steel is well avoided, recarburization is avoided, the quality of a casting blank is improved, and meanwhile good thermal insulation performance is achieved.

Owner:CENT SOUTH UNIV

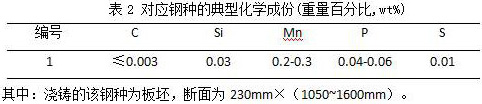

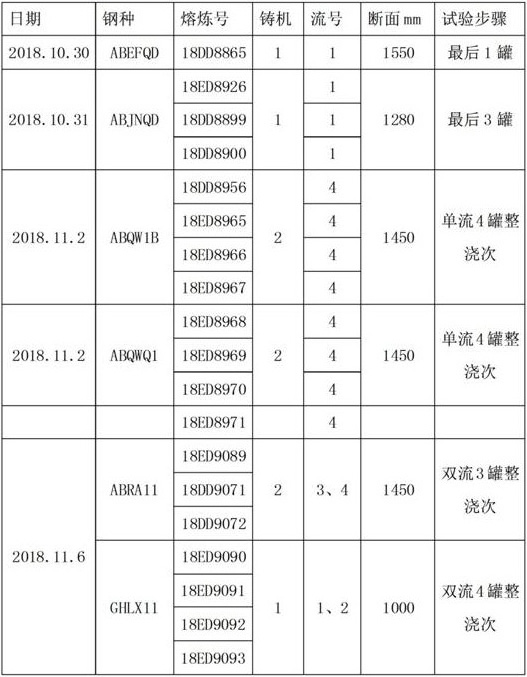

Method for smelting titanium-containing ferritic stainless steel through hot-metal bottle dephosphorization, finery and argon flushing station

The invention discloses a method for smelting titanium-containing ferritic stainless steel through a hot-metal bottle for dephosphorization, a finery and an argon flushing station. The method is characterized in that molten steel is composed of, by mass, less than or equal to 0.012% of C, 0.35-0.55% of Si, less than or equal to 0.80% of Mn, less than or equal to 0.030% of P, 0.010% of S, 11.0-11.75% of Cr, less than or equal to 0.012% of N, and the balance Fe and inevitable impurities, wherein the content of Ti is greater than 8*(C+N)%. According to the method, due to the fact that hot-metal bottle dephosphorization, the stainless steel finery and the argon flushing station are adopted for smelting, the situation that the probability of recarburization and nitrogen increase is increased due to electrode power transmission is avoided, the content of (C+N) of finished products is less than or equal to 150*10<-6>; and meanwhile, an adding method special for ferrotitanium and calcium-silicon, the alloy recovery rate is increased, the purity degree of the molten steel is ensured, a nozzle is prevented from being blocked in the continuous casting process, smooth production is ensured, and the smelting cost is reduced.

Owner:SHANDONG TAISHAN STEEL GROUP

Casting process of ultralow-temperature valve casting

ActiveCN109877274AImprove purityReduce inclusionsFoundry mouldsFurnace typesRare-earth elementAustenitic stainless steel

The invention discloses a casting process of an ultralow-temperature valve casting. The casting process comprises the steps of production preparation, smelting, casting, sand removing, finishing and the like. The content of ferrite in austenite is reduced by reducing the chromium / nickel equivalent ratio so as to avoid or reduce the ferrite embrittlement and martensite transformation of austeniticstainless steel. The element nitrogen is introduced to reduce the content of harmful elements sulfur and phosphorus. Silicon-calcium alloy and rare earth elements are introduced during molten steel deoxidation, so that the oxygen content and the impurity ratio are reduced. Measures such as the outage of a slagging process are adopted to improve the low-temperature impact resistance of the casting. In addition, more improvements have been made in the wall thickness difference of the casting, molten steel purification, a casting system, casting dead head cutting, shot blasting operation, heat treatment and the like since the start of the design of the casting process. Check results indicate that the valve casting produced by the casting process is stable in size stability and sealing performance after being subjected to treatment at the temperature of -196 DEG C, has the plasticity and toughness in a low-temperature environment, and is better in comprehensive usability.

Owner:JIANGSU EVALVE GRP

Molten steel and molten iron slag accretion heat insulation covering agent with sulphur and phosphorous removal function

The invention provides a molten steel and molten iron slag accretion heat insulation covering agent with a sulphur and phosphorous removal function and a preparation method thereof. The covering agent comprises the following components of, by weight, 10 parts to 20 parts of forsterite powder, 5 parts to 15 parts of magnesia powder, 10 parts to 20 parts of hollow glass bead powder, 10 parts to 20 parts of crushed crude pearlite, 5 parts to 15 parts of zeolite powder and 5 parts to 15 parts of palygorskite powder. By the combined action of the raw materials, the optimum sulphur and phosphorous removal function can be achieved. During covering of steel ladles and molten steel and molten iron in tundishes of steel works, good heat insulation and inclusion absorption of the molten steel and molten iron can be achieved, recarburization of the molten steel is prevented, and sulphur and phosphorous elements in the molten steel and molten iron are absorbed particularly.

Owner:新疆世全黄金矿业股份有限公司

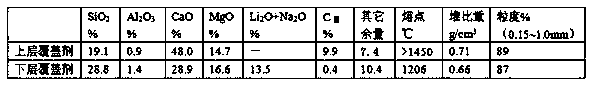

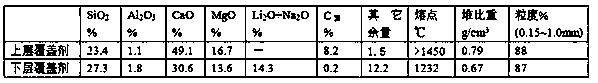

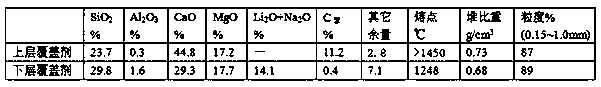

Double-layer tundish covering agent for ultrathin belt

ActiveCN109454210AReduce the speed of heat transfer to the outsideHeap specific gravitySpray GranulationMolten steel

The invention discloses a double-layer tundish covering agent for an ultrathin belt, and relates to the technical field of metallurgy. The upper covering agent and the lower covering agent are hollowgranular products which are subjected to spray granulation. The upper covering agent comprises the following chemical components of, in percentage by weight, 45%-55 wt% of CaO, 18.0-24.0 wt% of SiO2,14.0-18.0 wt% of MgO, less than or equal to 1.9 wt% of Al2O3, 7.5-11.5 wt% of C-solid and the balance inevitable impurities, and the melting point of the upper covering agent is greater than 1450 DEGC. The lower covering agent comprises the following chemical components of, in percentage by weight, 25.0-31.0 wt% of CaO, 27.0-37.0 wt% of SiO2, 13.0-18.0 wt% of MgO, less than or equal to 1.9 wt% ofAl2O3, 13.0-17.0 wt% of (Li2O + Na2O), less than or equal to 0.5 wt% of C-solid and the inevitable balance impurities, and the melting point of the lower covering agent is 1150-1250 DEG C. The product has the advantages that the specific gravity is light, the upper layer is carbon-containing and the lower layer is extremely few in carbon-containing, carbon-increasing is prevented and heat preservation is achieved, the content of Al2O3 in the upper layer and the lower layer is low, the impurities are fully absorbed, the melting point of the upper layer is high, the insulation of the air is isolated, the melting point of the lower layer is low, and rapid melting can be achieved so as to prevent the carbon-containing upper layer from being in contact with the molten steel to increase the carbon.

Owner:JIANGSU JIANAI HIGH TEMPERATURE MATERIAL

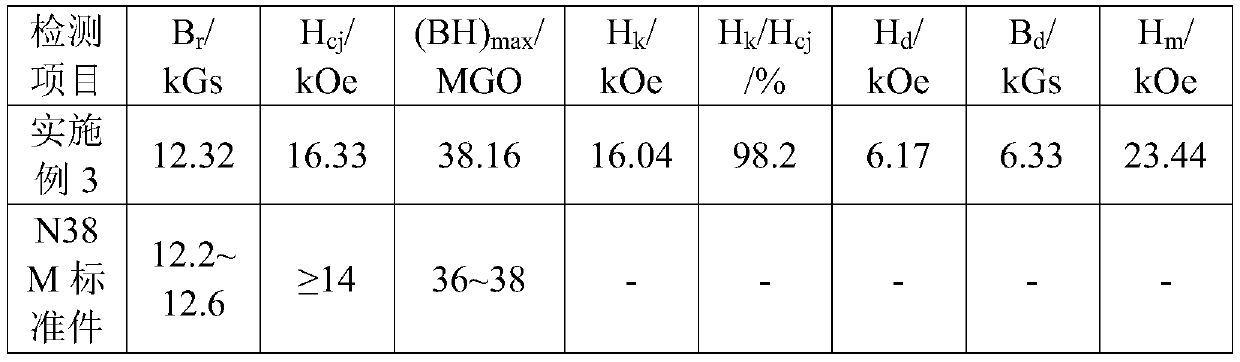

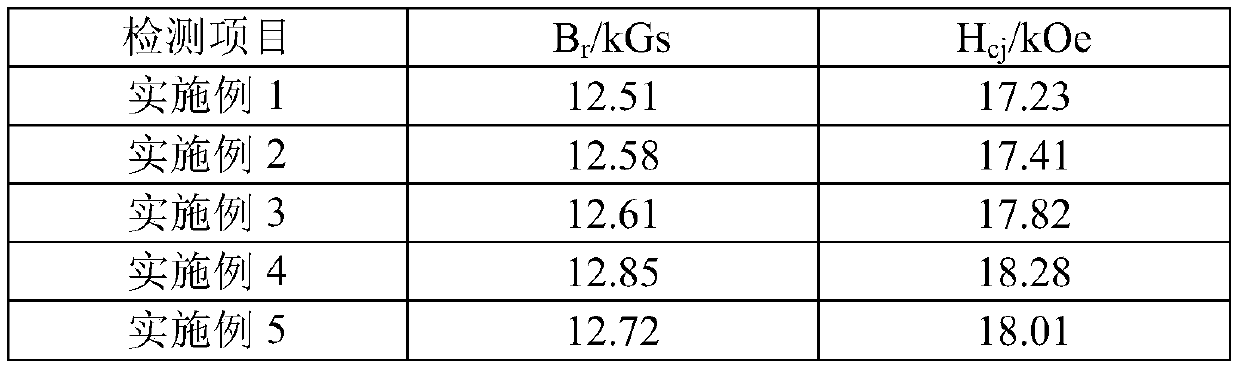

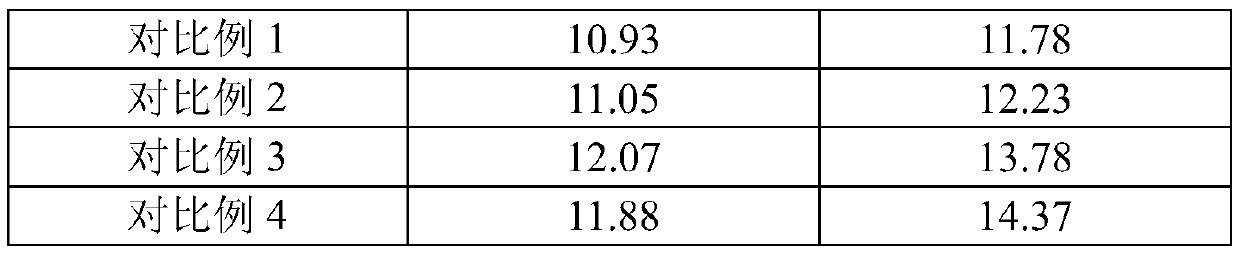

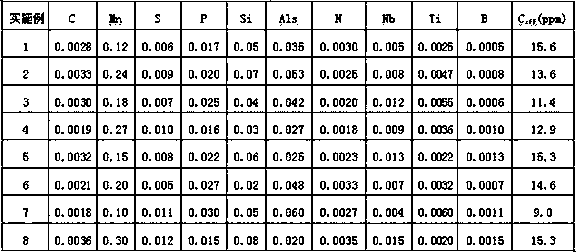

Method for preparing N38M type sintered neodymium-iron-boron magnetic material at low cost

InactiveCN111192754AImprove magnetic propertiesReduce manufacturing costInductances/transformers/magnets manufactureMagnetic materialsGasolineNitrogen gas

The invention discloses a method for preparing an N38M type sintered neodymium-iron-boron magnetic material at low cost. The method comprises the following specific steps: S1, preparing 78-82% by massof 38M waste, 0.08-0.12% by mass of an antioxidant, 0.08-0.12% by mass of gasoline and the balance of a mixed metal new material; S2, smelting the mixed metal new material to obtain a strip alloy; S3, enabling the strip alloy to be subjected to hydrogen decrepitation treatment, obtaining coarse crushing powder, crushing the coarse crushed powder and the 38M waste material by an airflow mill to obtain magnetic micro-powder; S4, pressing the magnetic micro powder into a blank; and S5, enabling the blank to be subjected to vacuum sintering under nitrogen protection. The magnetic material disclosed by the invention has the advantage of the high magnetic performance; in addition, the preparation method disclosed by the invention has the advantage of preparing the N38M type sintered neodymium-iron-boron magnetic material at low cost.

Owner:慈溪市兴发磁业科技有限公司

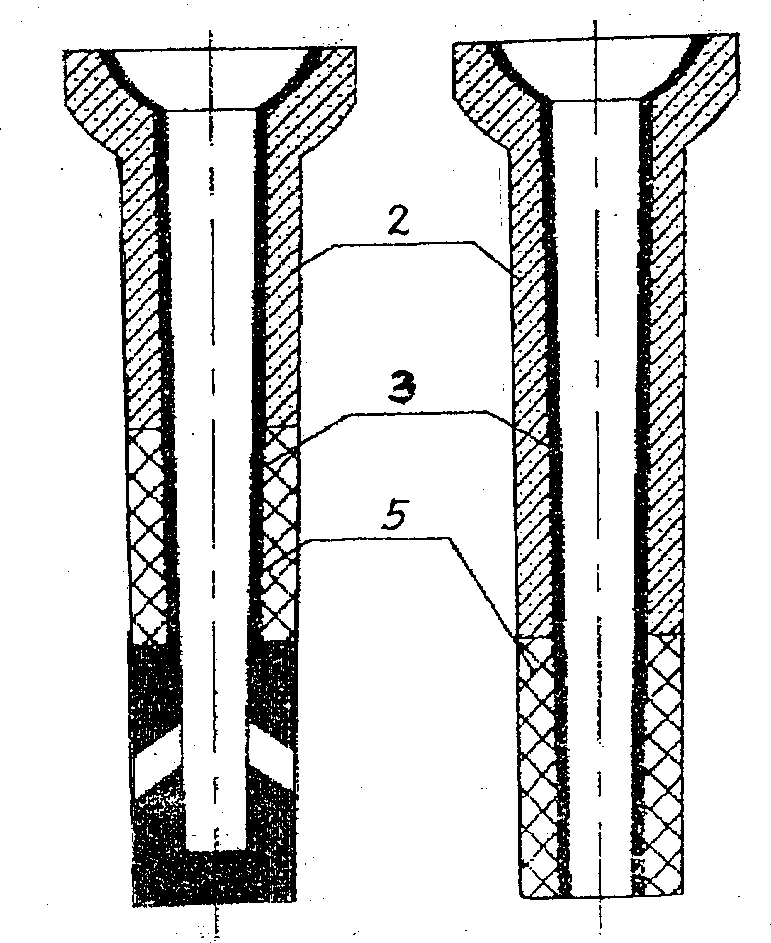

Soaked carbon-free protecting pipe

InactiveCN1362304ASolve the blockageExtended service lifeMelt-holding vesselsRefractoryThermal stability

The protecting pipe for continuously-casting steel is made up by using general refractory material as basis and adding ceramic material through the processes of mixing, forming and heat treatment. Said product possesses the features of resisting scouring abrasion, resisting corrosion, good thermal stability and long service life. Said invention is applicable to protecting pipe from steel ladle tointermediate ladle and from intermediate ladle to crystallizing device in the continuously-casting steel, and protecting pipe in the process of continuously casting sheet billet and impregnation protecting pipe.

Owner:于红芬

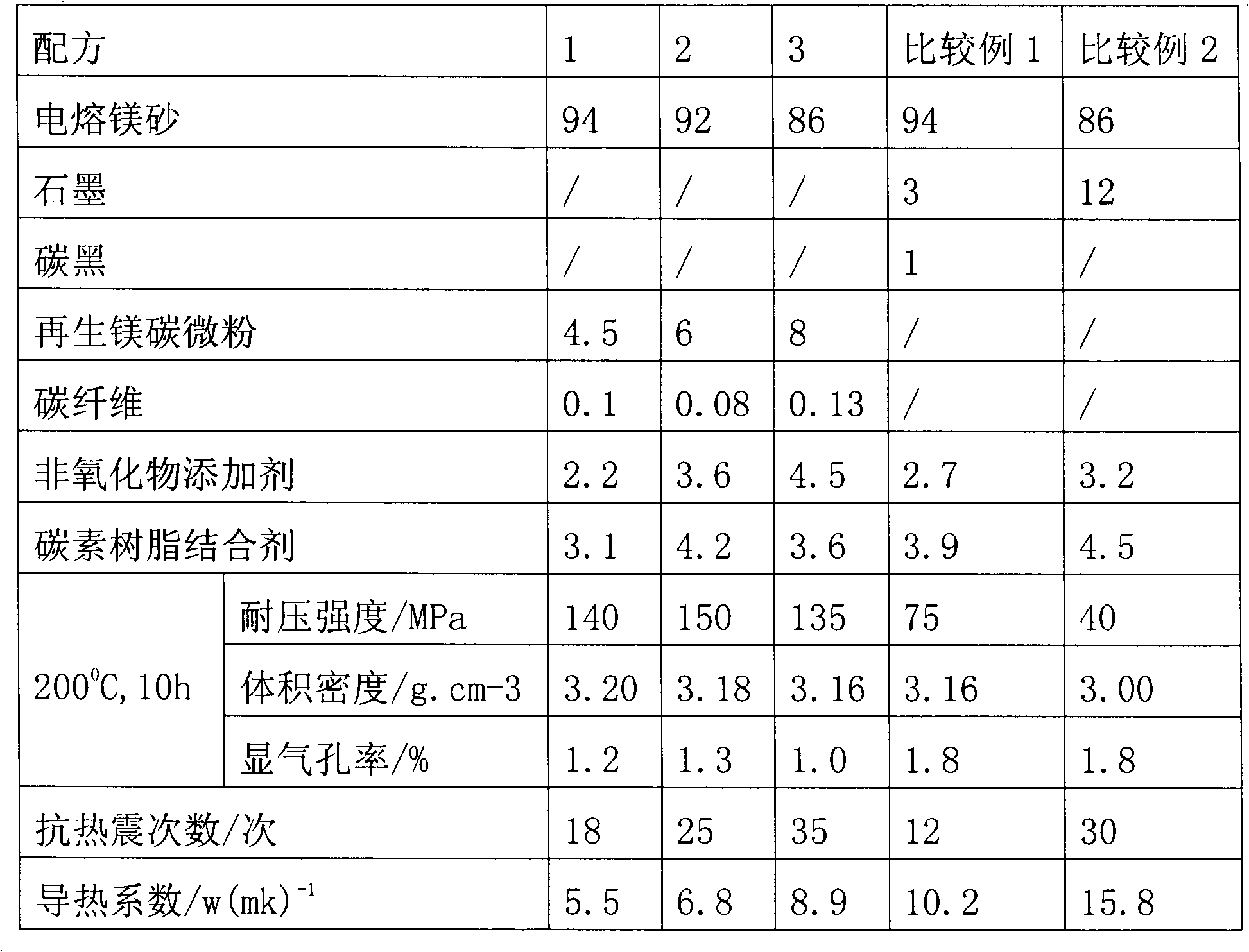

A low carbon magnesia carbon brick

The invention discloses a low-carbon magnesia-carbon brick, which is characterized in that it is prepared from the following raw materials in weight ratio: 80-95% of fused magnesia, 0-5% of non-oxide additives, magnesia-carbon brick Recycled material powder 3-9%, carbon resin binder 2-5%, carbon fiber 0.01-0.2%. The low-carbon magnesia-carbon bricks produced in this way have excellent performance, good thermal shock resistance, and high product performance, especially high strength. Adding regenerated magnesia-carbon brick powder and carbon fiber can realize resource recycling and be used in low-carbon steel and ultra-low carbon steel. It plays a very important role in improving the service life of the ladle lining and preventing the carburization of molten steel.

Owner:SHANDONG KEXIN NEW MATERIALS

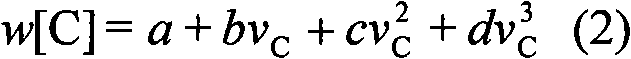

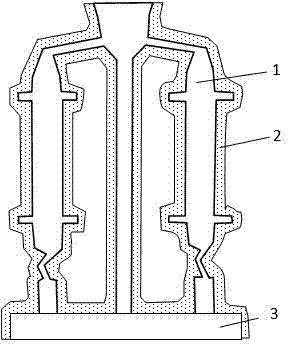

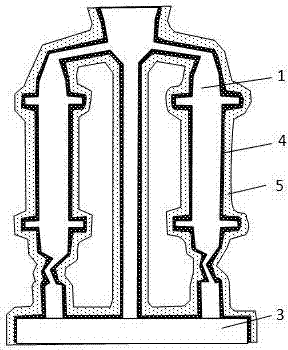

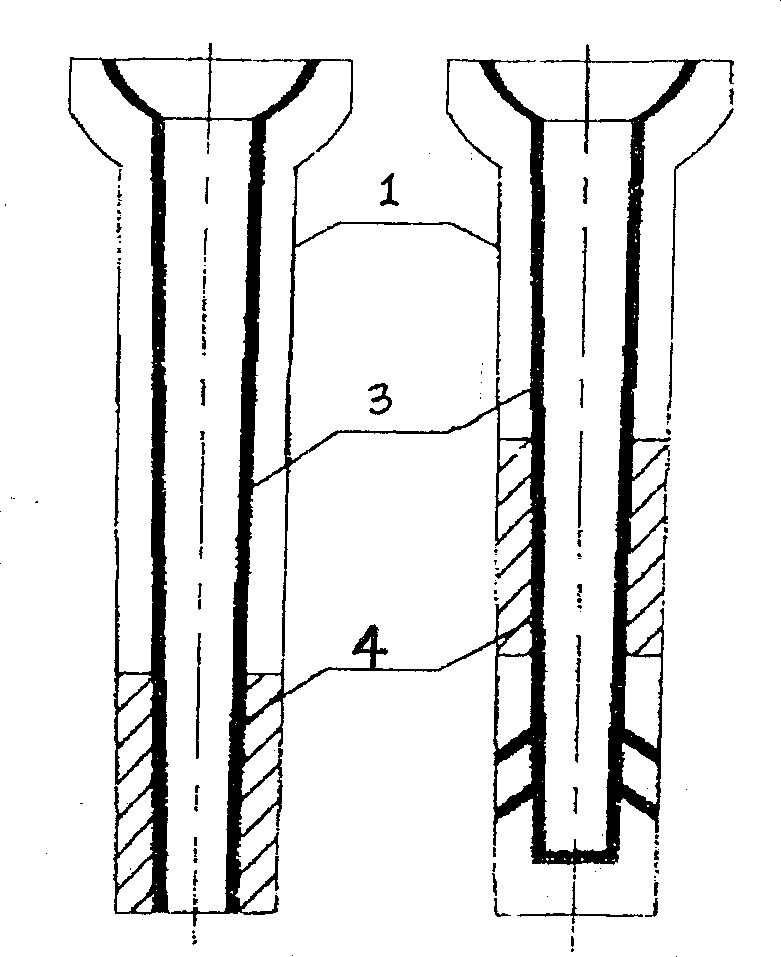

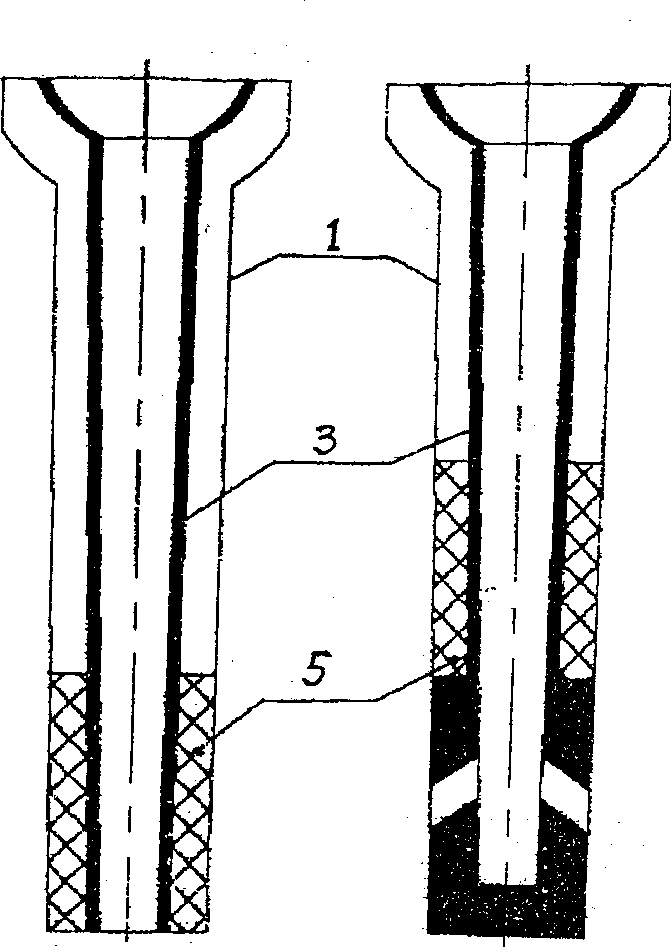

Refining method for preventing carbureting of molten steel in LF (ladle furnace) through utilizing argon plasmas

The invention relates to a refining method for preventing carbureting of molten steel in an LF through utilizing argon plasmas, and belongs to the field of refining technologies in steelmaking in the metallurgical industry. A technical scheme is characterized in that a solid graphite electrode of the LF is replaced by a hollow graphite electrode, the center hole of the hollow graphite electrode is used to access argon to form an argon plasma arc, so direct contact of the electrode with air and the molten steel is avoided; and the generated plasma arc is used to heat, so the heating time is shortened, the hollow graphite electrode consumption is reduced, the carbureting of the molten steel in the refining process is mitigated, and the carbureting amount of the molten steel is controlled at below 0.005%. The method has the following positive effects: the argon plasma LF can combine all refining functions of present LF technologies, so it is easy to realize an argon plasma furnace from the LF; the generated argon plasmas have the advantages of high heating efficiency, slugging benefiting and the like; the heating period and the smelting period can be shortened; and electric energy is saved. By controlling the carbureting amount in the LF refining process, a decarburization function of RH or VD can be partially replaced, so the steelmaking operation is reduced, and the production cost is saved.

Owner:HEBEI IRON AND STEEL

Ultra-low carbon crystallizer casting powder for continuous casting of automobile sheet and preparation method of ultra-low carbon crystallizer casting powder

The invention discloses ultra-low carbon crystallizer casting powder for continuous casting of an automobile sheet. The ultra-low carbon crystallizer casting powder comprises the following chemical components: 33%<CaO<41%, 35.5%< SiO2<43.5%, 1%<Al2O3< 6.0%, 0<MgO< 4%, 0<Fe2O3< 3%, 3.5%< F<->< 9.5%, 1.5%< R2O< 7.5%, 1.0%< C< 3%, and the balance of impurities. The preparation method comprises the following steps: weighing the raw materials, carrying out mixing granulation, melting in an electric furnace, and carrying out air cooling to obtain a pre-melting material; crushing and grinding the pre-melting material, adding a carbonaceous material, adding normal-temperature water and a binder into a ball mill, and performing fine grinding to obtain slurry; and feeding the slurry into a spray particle drying tower for spray granulation and drying. According to the ultra-low carbon crystallizer casting powder and the preparation method, the occurrence rate of recesses and slag inclusion on thesurface of the casting blank is reduced while improving casting blank lubrication, molten steel or the casting blank is prevented from being recarburized by casting powder, the surface and subsurfacequality of the casting blank is improved, continuous casting is facilitated, and the production efficiency of continuous casting is improved.

Owner:西峡县恒基冶材有限公司

Method for preparing N40M type sintered neodymium-iron-boron magnetic material by adding 38M waste

InactiveCN111180189AImprove magnetic propertiesReduce manufacturing costInorganic material magnetismPermanent magnet manufactureGasolineNitrogen gas

The invention discloses a method for preparing an N40M type sintered neodymium-iron-boron magnetic material by adding 38M waste. The preparation method comprises the following steps: S1, preparing 38Mwaste, an antioxidant and gasoline, the balance being a mixed metal new material; S2, smelting the mixed metal new material to obtain a strip alloy; S3, carrying out hydrogen decrepitation on the strip alloy to obtain coarse crushed powder, and crushing the coarse crushed powder, the 38M waste and the antioxidant by a jet mill to obtain magnetic micro powder; S4, pressing the magnetic micro powder into a blank; and S5, carrying out vacuum sintering on the blank under nitrogen protection. The magnetic material disclosed by the invention has the advantage of high magnetic performance; ad in addition, the preparation method disclosed by the invention has the advantage of preparing the N38M type sintered neodymium-iron-boron magnetic material at a low cost.

Owner:慈溪市兴发磁业科技有限公司

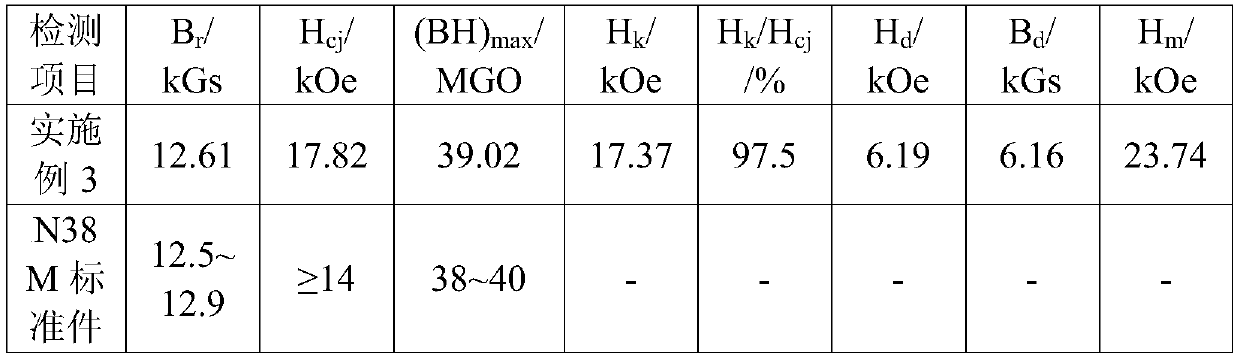

Galvanizing bake hardening steel plate with timeliness being larger than 6 months and production method of galvanizing bake hardening steel plate

InactiveCN110499471AReduce precipitation tendencySolve the lack of anti-agingHot-dipping/immersion processesSteel platesDecarburization

The invention discloses a galvanizing bake hardening steel plate with the timeliness being larger than 6 months and a production method of the galvanizing bake hardening steel plate. The steel plate includes, by mass, 0.0018%-0.0036% of C, 0.10%-0.30% of Mn, smaller than or equal to 0.012% of S, 0.015%-0.030% of P, smaller than or equal to 0.08% of Si, 0.020%-0.060% of Als, smaller than or equal to 0.0035% of N, 0.0040%-0.0150% of Nb, 0.0020%-0.0060% of Ti, smaller than or equal to 0.0015% of B and the balance Fe and inevitable impurities. The production method includes a molten iron pretreatment process, a decarburization converter process, a RH vacuum treatment process, a continuous casting process, a slab hot charging process, a hot rolling process, an acid continuous rolling process, acontinuous hot galvanizing process and an after-plating finishing process. The problem that traditional bake hardening steel is insufficient in timeliness resistance, and the timeliness resistance ofthe bake hardening steel is improved to 6 month or longer.

Owner:TANGSHAN IRON & STEEL GROUP +1

Carbon-free sliding plate and manufacturing method thereof

ActiveCN102898153AExcellent thermal shock resistance and erosion resistanceAvoid carbon increaseLiquid steelAluminium

The invention relates to a carbon-free sliding plate, which is characterized in that aluminum titanate synthesized through electrofusion is adopted as a raw material, and binding agent combination is performed to prepare the carbon-free sliding plate, wherein components in the aluminum titanate synthesized through electrofusion comprise, by mass, 50-54% of Al2O3, 40-43% of TiO2, 2-5% of a stabilizer, and the balance of impurities, and the stabilizer is one or more selected from magnesium oxide or cerium oxide. According to the present invention, the aluminum titanate synthesized through electrofusion is adopted as the main raw material, the binding agent is added, and processes of spray granulation, high pressure molding, drying and firing are sequentially performed, such that the sliding plate concurrently has excellent thermal shock resistance and anti-erosion property, carbon increasing in the liquid steel during the production process can be prevented, requirements of ultra-low carbon steel smelting and other special steel smelting are further met, and corresponding hardware conditions are provided for clean steel production.

Owner:BAOSHAN IRON & STEEL CO LTD

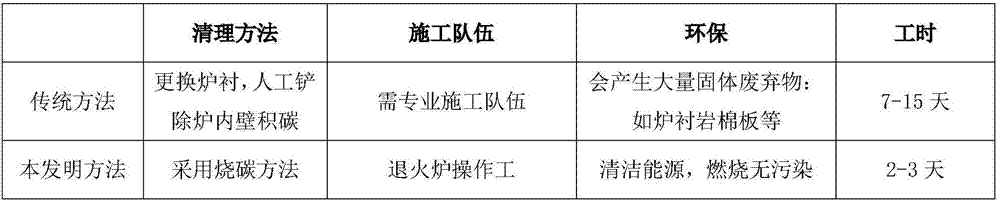

Method for eliminating carbon deposition in roller-bottom continuous nodulizing annealing furnace

InactiveCN107217132AEliminate depositsAvoid depositionFurnace typesHeat treatment furnacesMetallurgyInlet valve

The invention discloses a method for eliminating carbon deposition in a roller-bottom continuous nodulizing annealing furnace. The method comprises the following steps: closing an RX gas intake valve of the annealing furnace and furnace doors in the two sides in a no-load state of the annealing furnace; then heating the annealing furnace, controlling a temperature in a hearth to achieve 650+ / -10 DEG C and keeping constant temperature, and detecting tail gas of the annealing furnace; stopping heating when the content value of CO2 in the tail gas is not changed any more, and opening the furnace doors in the two sides; closing the furnace doors in the two sides again after air enters the annealing furnace and the hearth is fully filled with air, and repeating the heating treatment process; and stopping operation when the content value of CO2 in the tail gas is lowered to 0.3%-0.5%, and then completing elimination for the carbon deposition in the annealing furnace. The elimination method is capable of efficiently and thoroughly eliminating the carbon deposition in the roller-bottom continuous nodulizing annealing furnace, so that the annealing furnace recovers to an initial use effect; and moreover, the elimination method is short in elimination operation period, low in elimination and maintenance cost, and capable of effectively preventing recarburization in the case of ensuring no decarburization of an annealing material through regular implementation, thereby ensuring the annealing quality of refined wire products, reducing pollution to environment, and increasing the production efficiency.

Owner:邢台新翔金属材料科技股份有限公司

Preparation method of ferrosilicon nitride porous ceramic sliding plate

The invention belongs to the field of inorganic nonmetallic materials, and relates to a preparation method of a sliding plate for a steel-making ladle sliding gate mechanism, in particular to a preparation method of a ferrosilicon nitride porous ceramic sliding plate. The ferrosilicon nitride porous ceramic sliding plate disclosed by the invention is characterized in that the inner core of the sliding plate is prepared by directly cutting an original ferrosilicon nitride blank body; and the periphery of the sliding plate is poured and formed by adopting an unshaped fire-resistant material. The ferrosilicon nitride sliding plate is a carbon-free sliding plate; therefore, molten steel carburetion of the sliding plate generated in the use process can be avoided; the production requirements of clean steel in the future can be satisfied; the chrome-free property of the sliding plate is realized; pollution of chrome to the environment is avoided; the processing technology is simple; sintering and heat treatment are unnecessary; raw materials, energy, equipment, manpower and time are saved greatly; the cost is low; the preparation method is applied to large-scale industrial popularization; the porous ceramic material is applied in the sliding plate, so that the basic performances of the sliding plate are ensured, and simultaneously, the thermal shock resistance of the sliding plate is increased; the porous ceramic is applied in the sliding plate disclosed by the invention for the first time, so that a new field is created for developing the sliding plate material, and the development direction shows a promising future.

Owner:UNIV OF SCI & TECH BEIJING

High-efficiency slag collecting agent

InactiveCN105925748ASimple structureImprove propertiesProcess efficiency improvementSlagThermal insulation

The invention discloses a high-efficiency slag collecting agent which is prepared from the following components: clay, modified perlite, coal ash, forsterite powder, mullite powder, hollow glass microsphere powder, zeolite powder and palygorskite powder. The slag collecting agent provided by the invention has good spreadability, resists high temperature, has favorable heat-resistance and thermal-insulation effects, keeps a nodulizing process stable, has a high slag removal ratio and does not affect the components of molten iron; iron slag is fragile after being cooled, so that the iron slag is convenient to recover and the loss of the molten iron is can be reduced; and the slag collecting agent can change the form of desulfurized slag to reduce the slag content of the molten iron entering a converter and the phenomenon of molten iron resulfurization, the loss of iron is reduced by an average of 44%, and on average, the desulfurized molten iron contains about 0.007% of sulfur.

Owner:HEFEI CITY TENVER PRECISION CASTING

High-performance slag collecting agent

InactiveCN105925747AImprove structure and propertiesGood slag collecting performanceProcess efficiency improvementThermal insulationSlag

The invention discloses a high-performance slag collecting agent which is prepared from the following components: clay, modified perlite, straw ash, forsterite powder, pottery clay powder, zeolite powder, sepiolite powder, mullite powder, hollow glass microsphere powder, pyrophillite powder and palygorskite powder. The slag collecting agent provided by the invention resists high temperature, has favorable heat-resistance and thermal-insulation effects, keeps a nodulizing process stable, has high slag removal efficiency and does not affect the components of molten iron; iron slag is fragile after being cooled, so that the iron slag is convenient to recover and the loss of the molten iron is can be reduced; and the slag collecting agent can change the form of desulfurized slag to reduce the slag content of the molten iron entering a converter and the phenomenon of molten iron resulfurization, the loss of iron is reduced by an average of 48%, and on average, the desulfurized molten iron contains about 0.061% of sulfur.

Owner:HEFEI CITY TENVER PRECISION CASTING

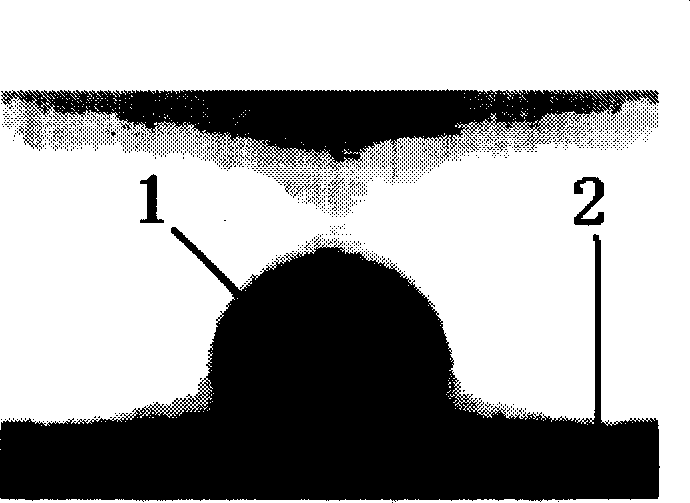

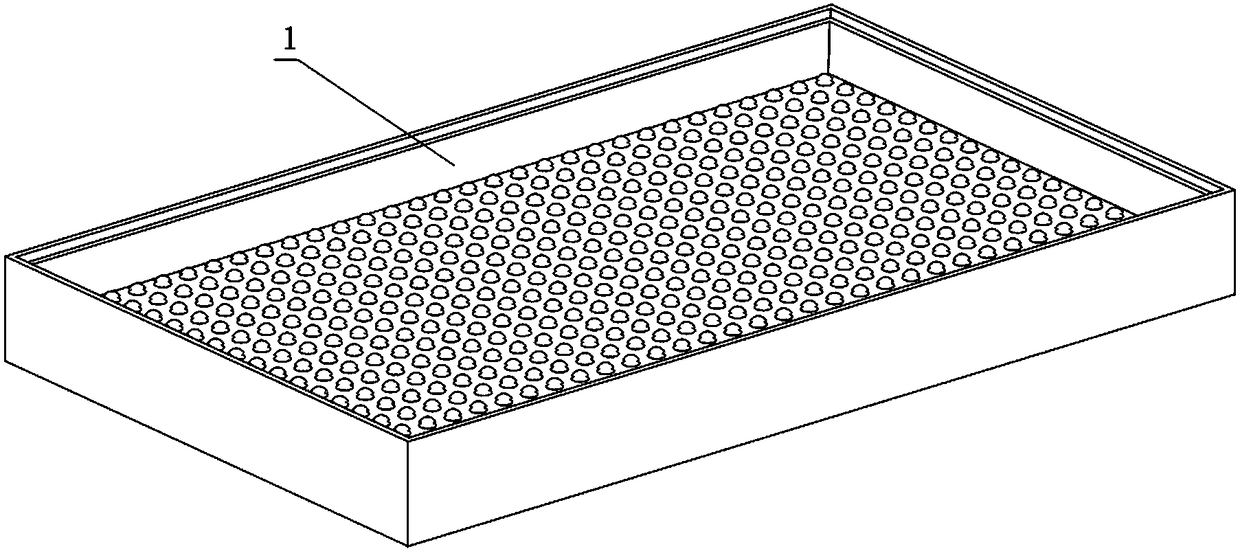

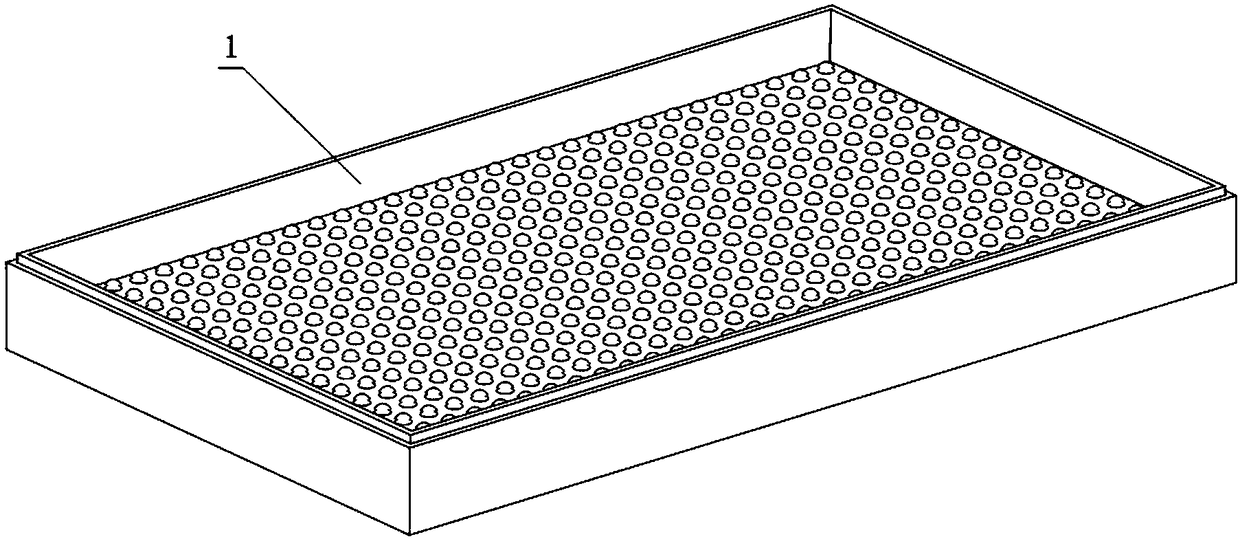

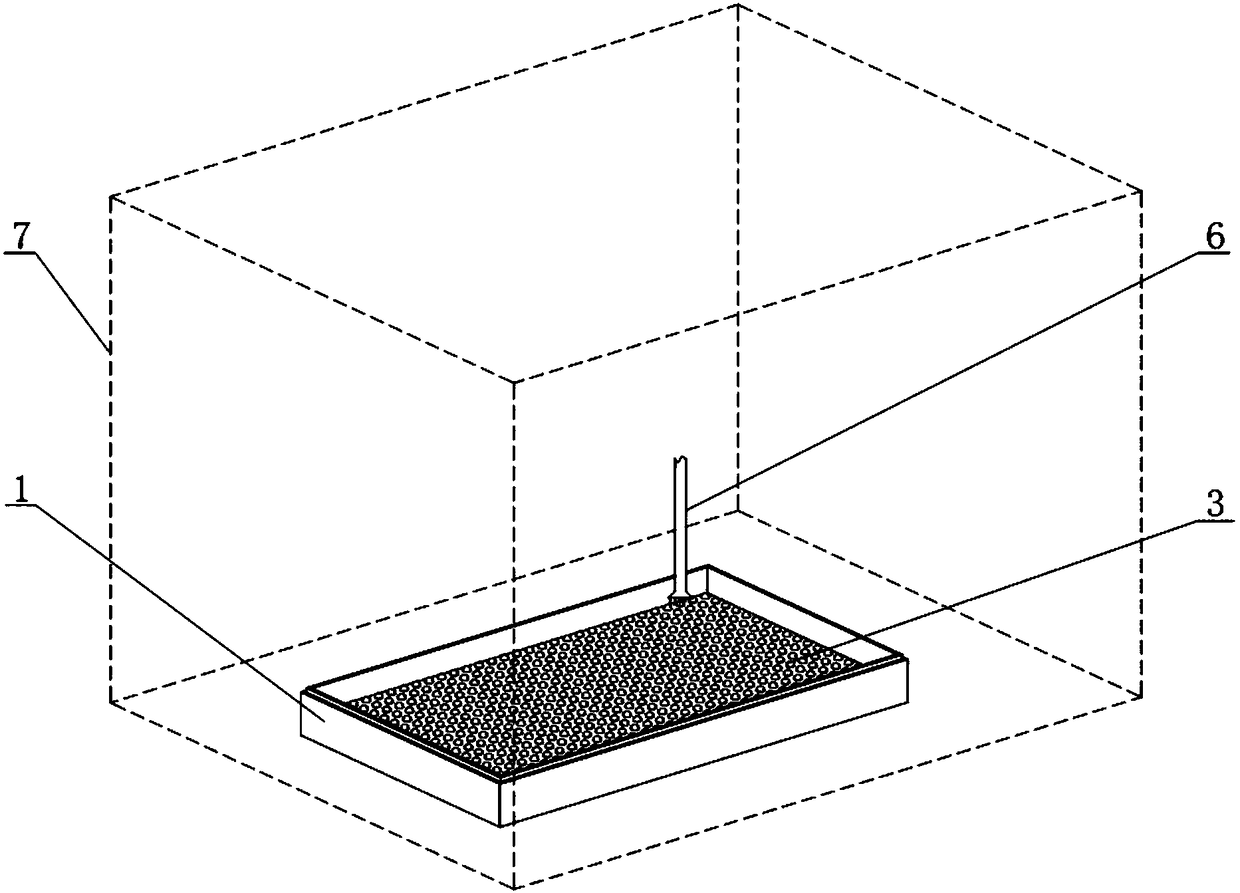

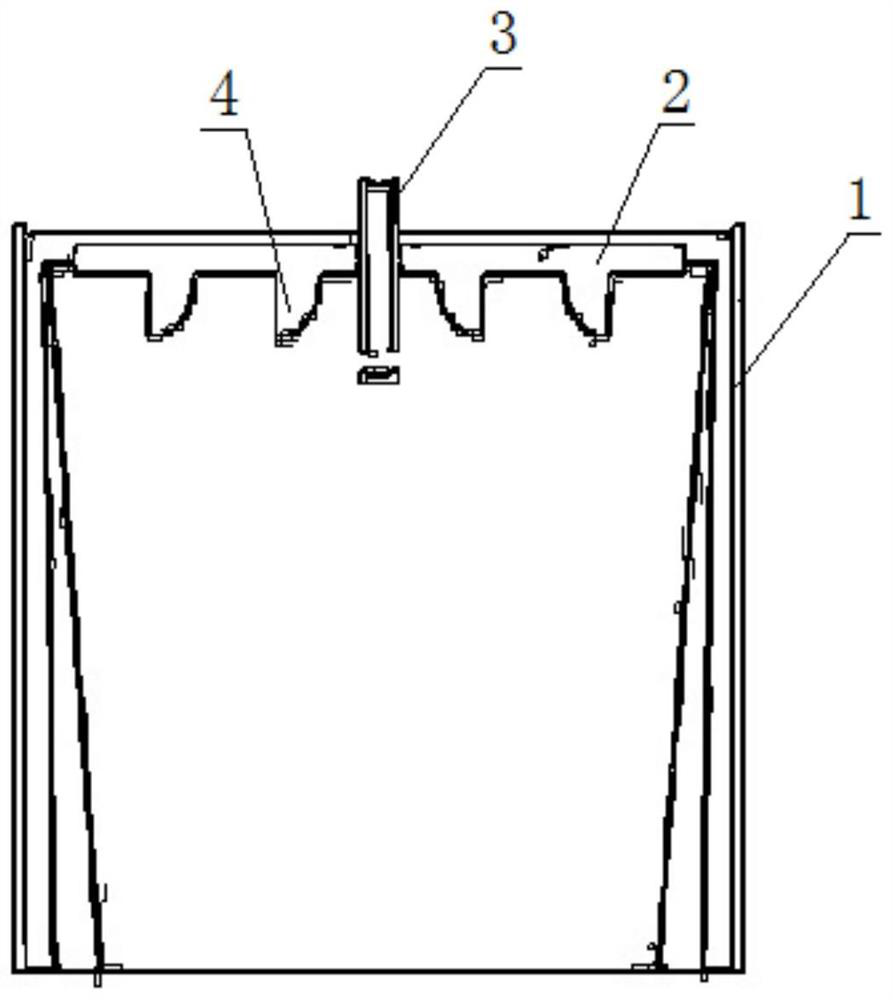

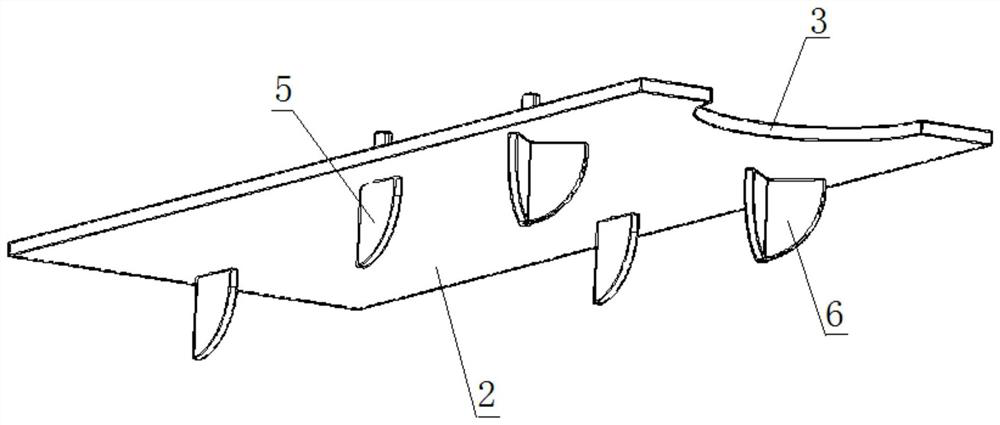

Isolating plate structure for continuous casting of molten steel

The invention relates to the technical field of metallurgy, and discloses an isolating plate structure for continuous casting of molten steel. The solating plate structure comprises a crystallizer, and an isolating plate is horizontally placed in the crystallizer; the isolating plate is not corroded by casting powder, and does not react with effective components in the molten steel; and the density of the isolating plate is higher than the density of liquid casting powder and lower than the density of the molten steel. The isolating plate is installed in the crystallizer through a plurality ofmounting brackets, the size of the isolating plate is smaller than the cross-section size of the crystallizer, and a clearance is reserved between the isolating plate and the wall of the crystallizer. According to the isolating plate structure for continuous casting of the molten steel, the reacting weight of strong reduction elements in the molten steel and casting powder is greatly reduced, andit is ensured that the the effect of the casting powder is achieved properly; the defects of slag entrapment and slag inclusion, and bleed-out accidents are reduced, and a crystallizer molten steel flow field and a temperature field are homogenized; and the casting blank quality is further improved.

Owner:万恩同

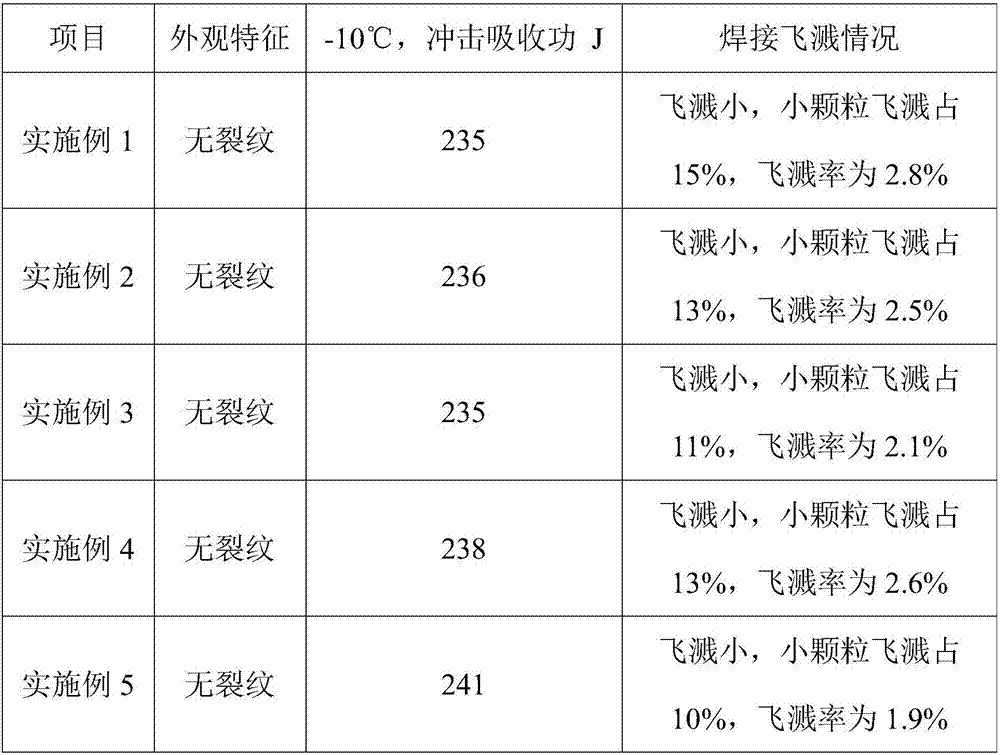

Flux-cored welding wire with good toughness and low porosity

InactiveCN107297583AWell mixedReduce surface tensionWelding/cutting media/materialsSoldering mediaPorositySilicon dioxide

The invention discloses a flux-cored welding wire with good toughness and low porosity. The welding wire includes a mild-carbon steel strip sheath and a flux core, wherein the flux core is prepared from, by weight, 0.4-0.6% of graphite, 10-14% of chromium powder, 2-4% of manganese dioxide, 3.5-5.5% of nickel powder, 3-5% of columbium powder, 2-4% of zirconium powder, 0.4-0.6% of silicon dioxide, 9-10% of rhenium oxide, 12-14% of magnalium, 6-8% of fluoride, 1.5-4.5% of lithium carbonate and the balance iron powder. The welding coating of the flux-cored welding wire has the advantages of being low in porosity, compact in coating microstructure and good in toughness.

Owner:安徽飞弧焊业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com