A low carbon magnesia carbon brick

A carbon magnesia carbon brick and magnesia carbon brick regeneration technology, which is applied in the field of metallurgy, can solve the problems of rapid heat loss in molten steel, high thermal conductivity, and increased carbon content, and achieve the goal of preventing carbon increase in molten steel, low thermal conductivity, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1, take by weight 94 parts of fused magnesia, by B 4 C, 2.2 parts of non-oxide additives mixed with Al, Si, Al-Mg alloy powder in any weight ratio, 4.5 parts of regenerated magnesia-carbon brick powder produced in the process of processing used magnesia-carbon bricks, composed of phenolic 3.1 parts of carbon resin binder and 0.1 part of carbon fiber mixed with resin, pitch and furan resin in any weight ratio. The production process is mainly divided into three stages: kneading, forming and heat treatment:

[0013] (1) Mixing: According to the weight ratio of the above formula, pour the fused magnesia granules, magnesia-carbon brick recycled micropowder, carbon fiber and non-oxide additives into the mixing machine for pre-mixing for 2-4 minutes, then add phenolic Resin binder, mixed for 25-30 minutes to discharge;

[0014] (2) Forming: Pour the mud material into the 630T friction press according to the calibrated single weight, according to the forming rule ...

Embodiment 2

[0017] Embodiment 2, take by weight 92 parts of fused magnesia, by B 4 C, 3.6 parts of non-oxide additives mixed with Al, Si, Al-Mg alloy powder in any weight ratio, 6 parts of regenerated magnesia-carbon brick powder produced in the process of processing used magnesia-carbon bricks, composed of phenolic 4.2 parts of carbon resin binder and 0.08 parts of carbon fiber are formed by mixing resin, pitch and furan resin in any weight ratio. The production process and effect are the same as above.

Embodiment 3

[0018] Embodiment 3, take by weight 86 parts of fused magnesia, by B 4 C, 4.5 parts of non-oxide additives mixed with Al, Si, Al-Mg alloy powder in any weight ratio, 8 parts of regenerated magnesia-carbon brick powder produced in the process of processing used magnesia-carbon bricks, composed of phenolic 3.6 parts of carbon resin binder and 0.13 parts of carbon fiber are formed by mixing resin, pitch and furan resin in any weight ratio. The production process and effect are the same as above.

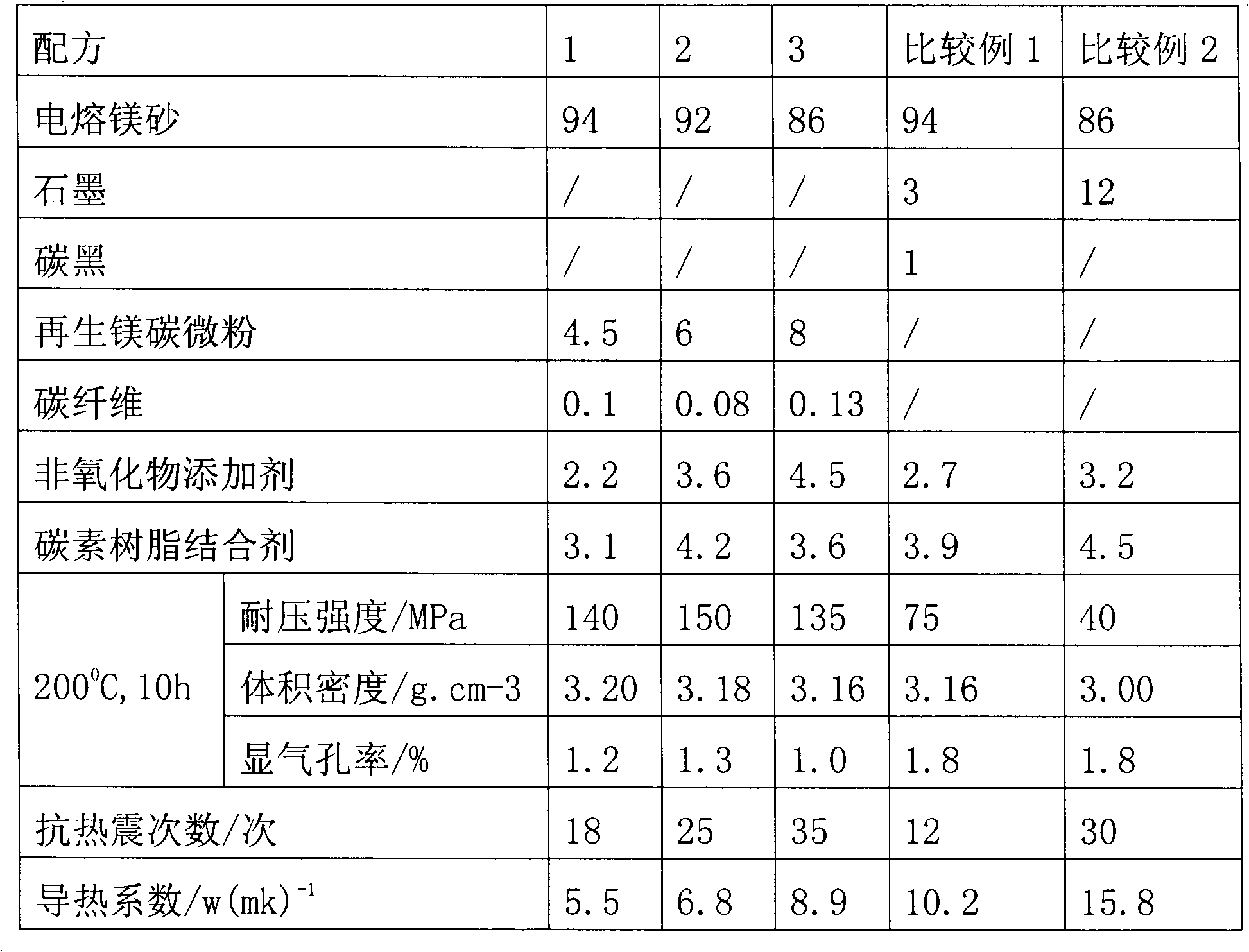

[0019] The following table is a comparative analysis of the performance of the low-carbon magnesia-carbon brick products obtained in the above three examples and the common formula magnesia-carbon brick products.

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com