Soaked carbon-free protecting pipe

A technology for protecting pipes and materials, which is applied in the direction of casting melt containers, manufacturing tools, metal processing equipment, etc., can solve problems such as short service life, poor corrosion resistance, and influence on steel quality, so as to improve service life and anti-scouring performance Effect of improvement, clogging up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

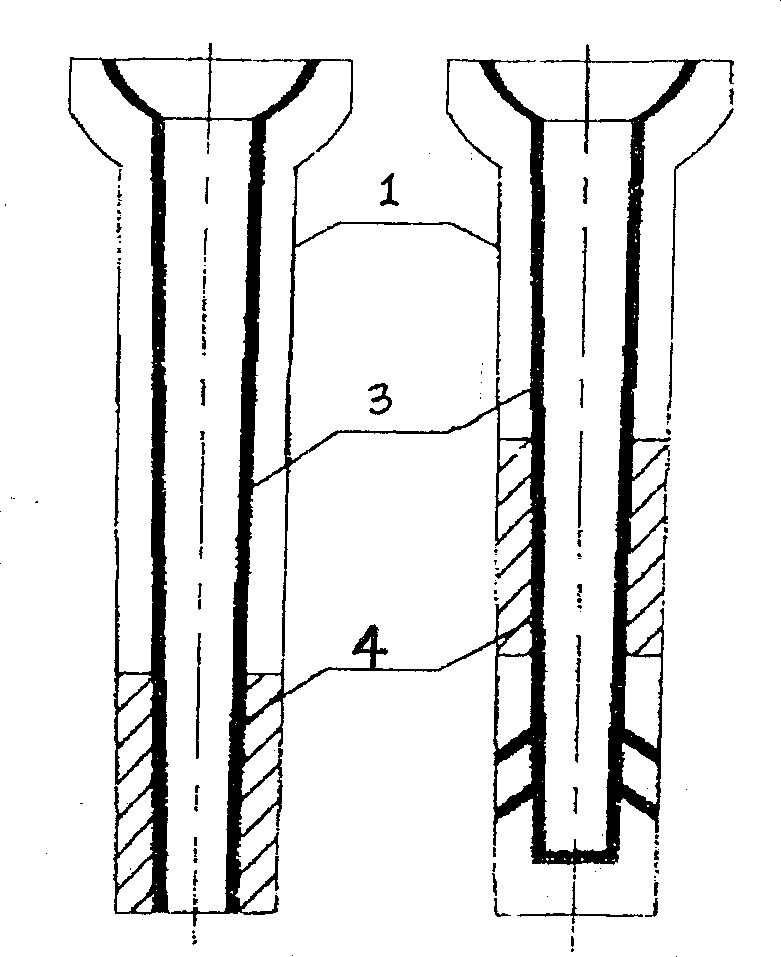

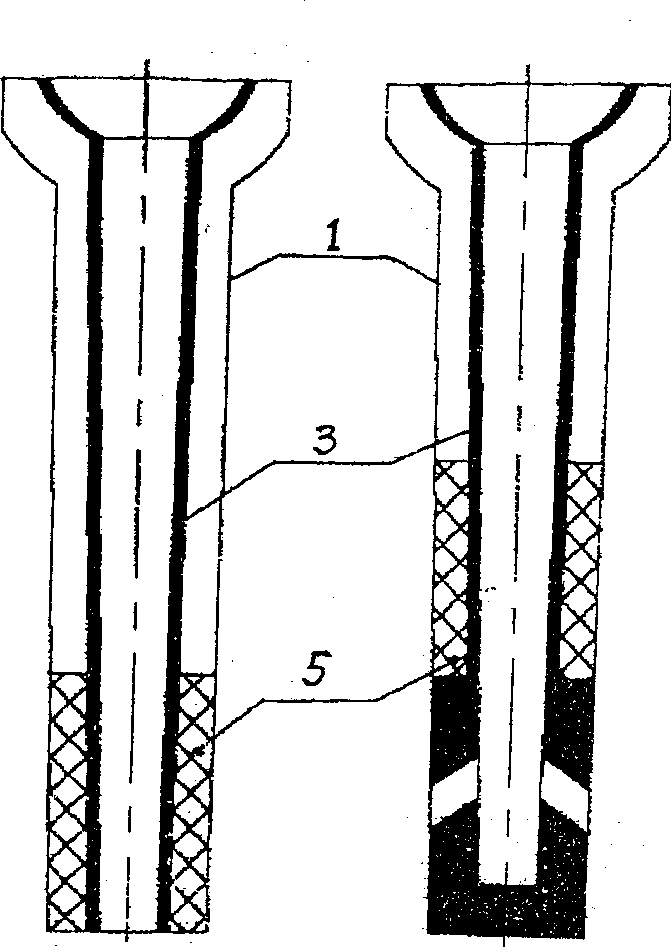

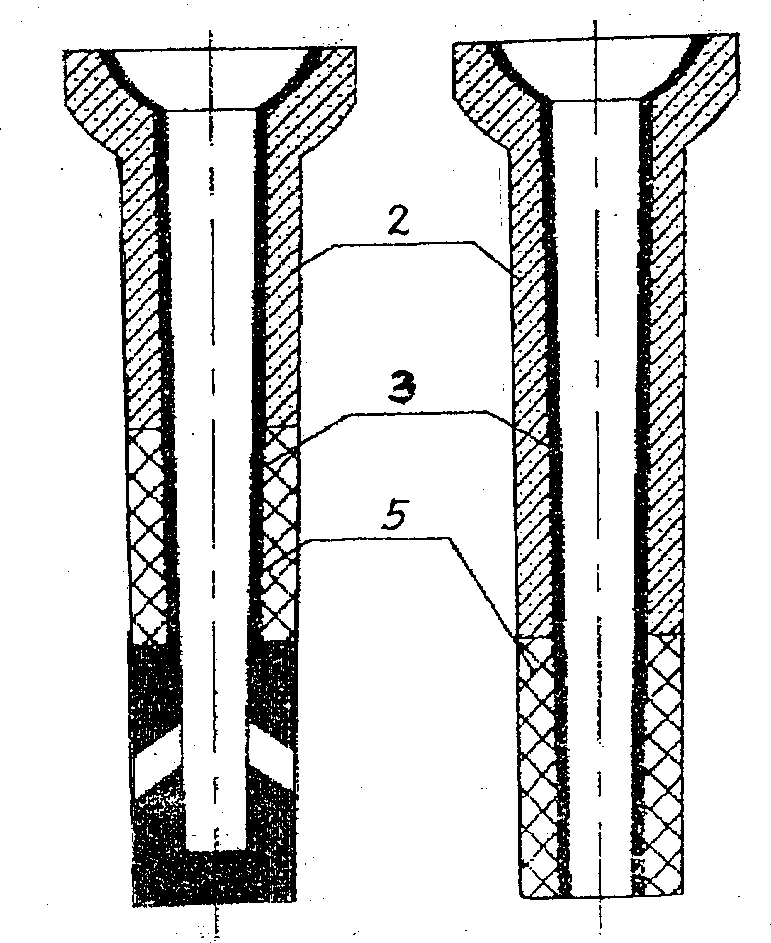

[0018] like figure 1 Shown: Fused corundum particles and fine powder 70%, graphite 30%, binder 12% to form the general body 1, zirconia particles and fine powder 100% additives and binder 5% to form the carbon-free layer 3, zirconia 100%, other materials 5%, and binder 5% constitute the slag line material 4. The three layers of materials are mixed separately, and the carbon-free impregnated protective tube shown in the figure is formed by one or more moldings.

[0019] The protection tube was used in stainless steel continuous casting in a steel factory, and the quartz protection tube was used for 2 hours and 05 minutes, while the protection tube of the present invention was used for 8 hours and 50 minutes, and had no carbonation effect on the steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com