Steam stripping method of process condensate in CO conversion

A condensate and stripping technology, applied in the direction of heating water/sewage treatment, degassed water/sewage treatment, etc., can solve the problems affecting the long-term operation of the conversion device, ammonium salt crystals block the pipeline and condenser, etc., and achieve a solution The effect of ammonium salt crystallization blockage, improvement of recycling rate, and reduction of wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

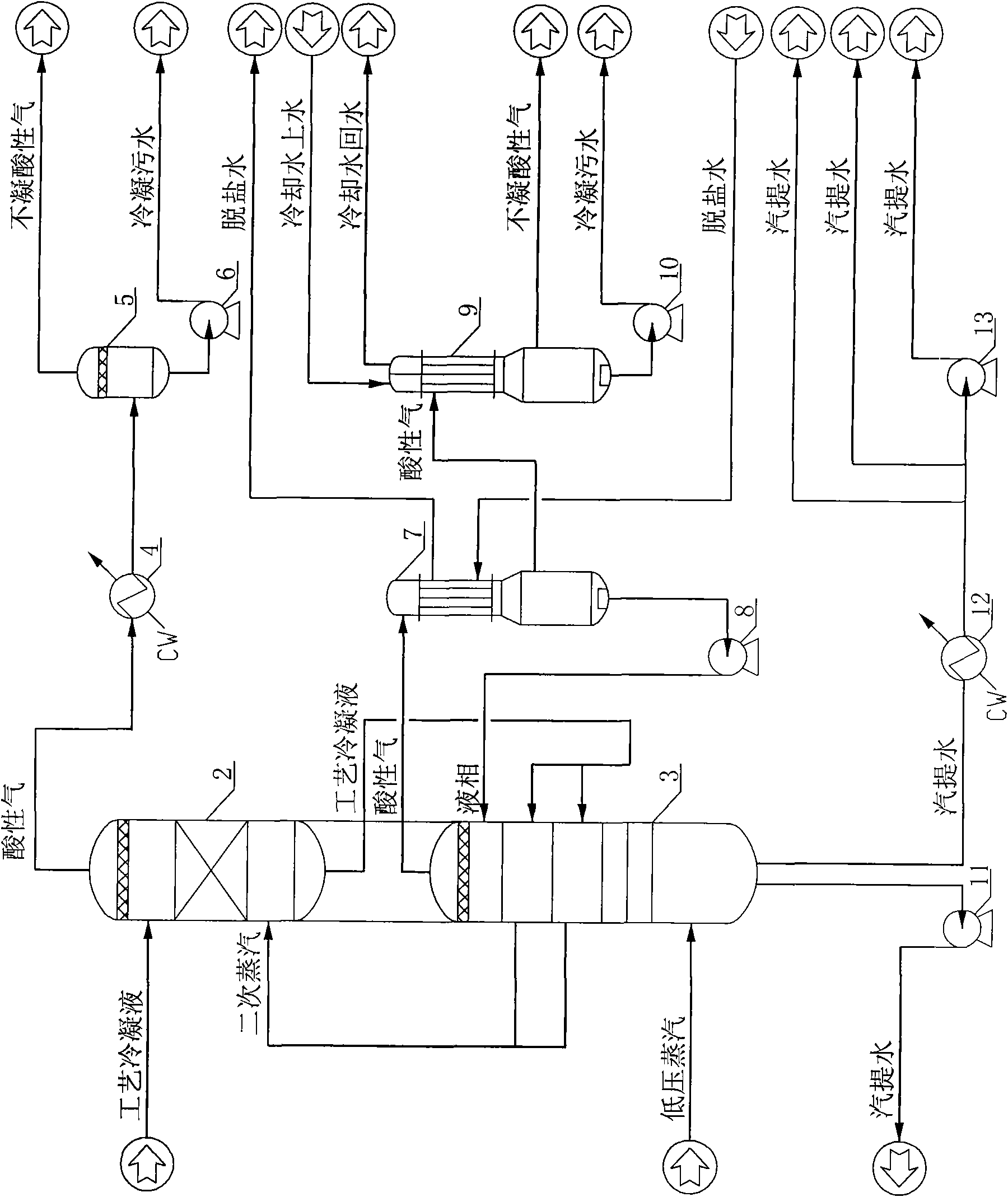

[0021] The process condensate (temperature: 110°C; pressure (gauge pressure) 0.8MPa) from the gas-liquid separator in the conversion process first enters the carbon dioxide stripper 2 (operating temperature of the carbon dioxide stripper 2: 140°C; operating pressure (gauge pressure) ) 0.27MPa, packing height is 0.5 meter) upper part carries out flashing, and the secondary steam (temperature: 142 ℃; pressure (gauge pressure) 0.28MPa) from the ammonia stripper 3 upper part enters from the carbon dioxide stripper 2 bottom, Countercurrent contact stripping of carbon dioxide with the process condensate after flash evaporation, the acid gas (temperature: 138°C; pressure (gauge pressure) 0.27MPa) stripped from the top of the tower enters the carbon dioxide stripping tower condenser 4 to cool, and then passes through the carbon dioxide stripping tower Extractor separator 5, non-condensable acid gas (temperature of non-condensable acid gas: 50°C; pressure (gauge pressure) 0.20MPa) is se...

Embodiment 2

[0025] The process condensate (the temperature of the process condensate: 125°C; the pressure (gauge pressure) 1.0MPa) from the gas-liquid separator in the conversion process first enters the carbon dioxide stripper 2 (the operating temperature of the carbon dioxide stripper 2: 157°C; The operating pressure (gauge pressure) is 0.52MPa, and the packing height is 1.5 meters), and the upper part is flashed, and the secondary steam from the upper part of the ammonia stripper 3 (the temperature of the secondary steam: 160°C; the pressure (gauge pressure) 0.52MPa) Enter from the bottom of the carbon dioxide stripping tower 2, and carry out countercurrent contact with the flashed process condensate to strip carbon dioxide, and the acid gas (temperature of acid gas: 157°C; pressure (gauge pressure) 0.52MPa) stripped from the top of the tower is fed into carbon dioxide The stripper condenser 4 is cooled, and then through the carbon dioxide stripper separator 5, the non-condensable acid ...

Embodiment 3

[0029] The process condensate (the temperature of the process condensate: 115°C; the pressure (gauge pressure) 0.90MPa) from the gas-liquid separator in the conversion process first enters the carbon dioxide stripper 2 (the operating temperature of the carbon dioxide stripper 2: 144°C; The upper part of the operating pressure (gauge pressure) is 0.34MPa, and the packing height is 1.0m), and the upper part is flashed, and the secondary steam from the upper part of the ammonia stripper 3 (the temperature of the secondary steam: 148°C; pressure (gauge pressure) 0.35MPa) Enter from the bottom of the carbon dioxide stripping tower 2, and carry out countercurrent contact with the process condensate after flashing to strip carbon dioxide, and the acid gas (temperature of acid gas: 144°C; pressure (gauge pressure) 0.34MPa) stripped from the top of the tower is fed into carbon dioxide The stripper condenser 4 is cooled, and then through the carbon dioxide stripper separator 5, the non-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com