Condensed fluid stripping method matched with CO transforming device

A conversion device and condensate technology, which is applied in the direction of heating water/sewage treatment, degassed water/sewage treatment, etc., to achieve the effects of stable operation, reduced energy consumption, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

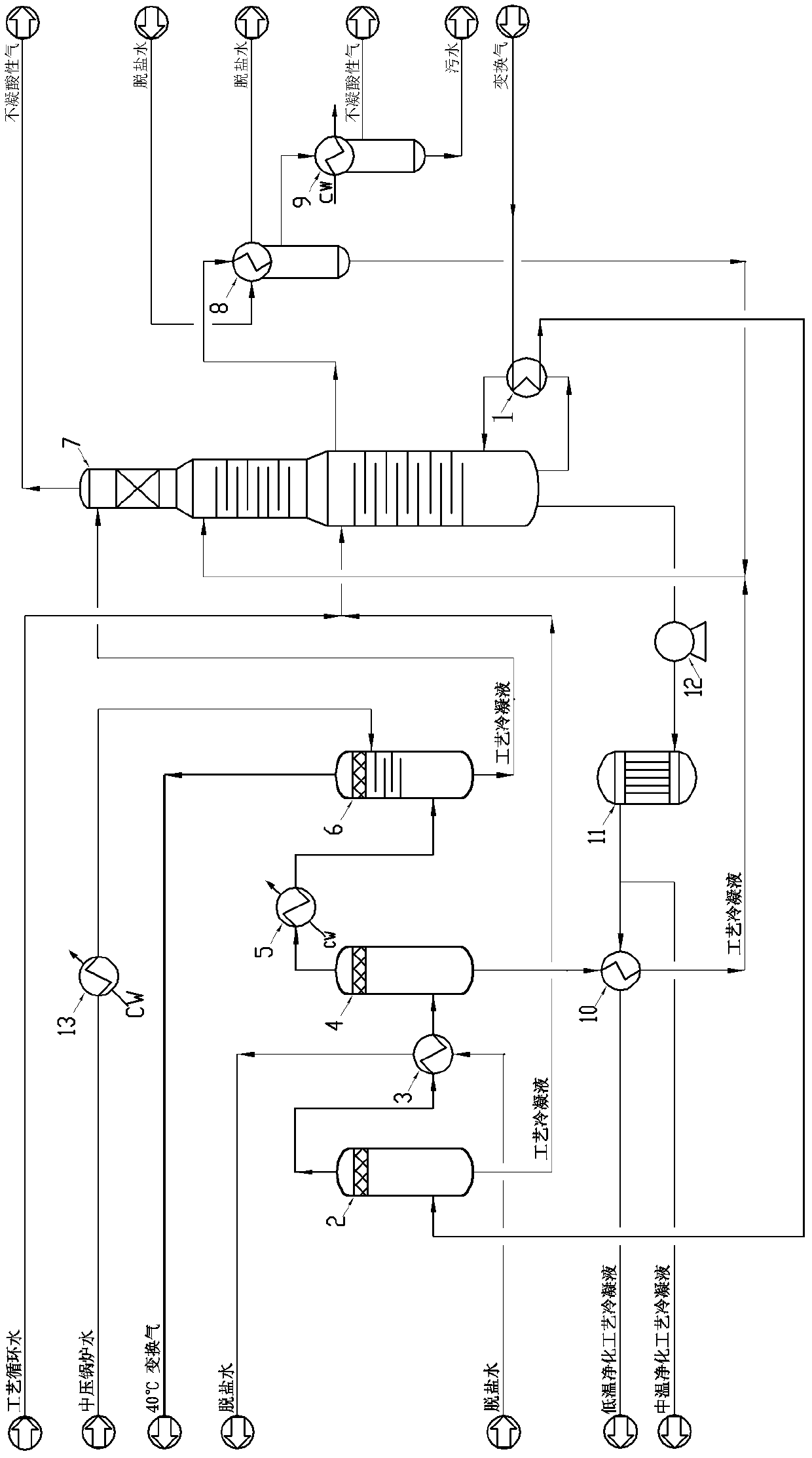

Method used

Image

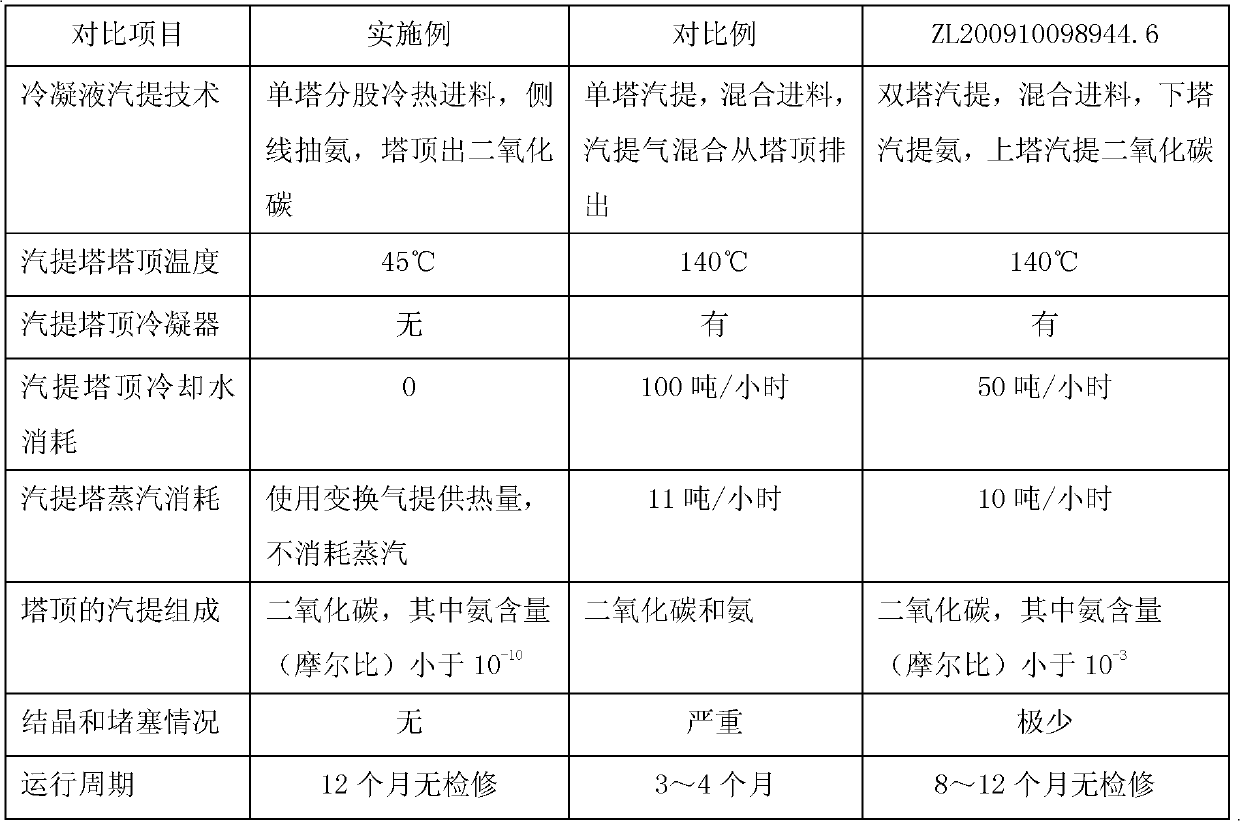

Examples

Embodiment

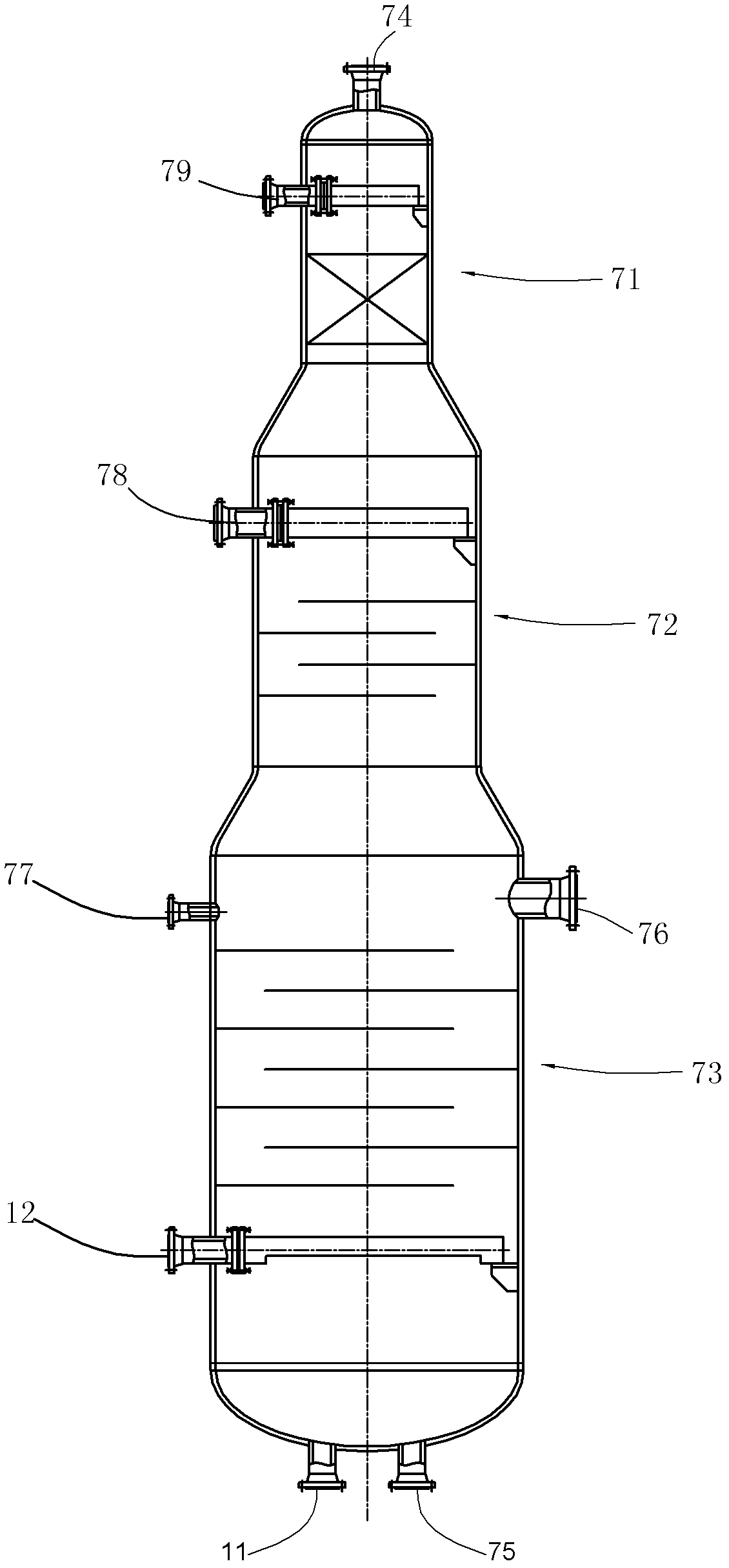

[0038] Such as figure 1 with figure 2 Shown, the structure of the used stripper 7 of embodiment is as follows:

[0039] The tower body of the stripping tower includes a lower section 73, a middle section 72, and an upper section 71 that are connected to each other and the tower diameters are successively reduced; wherein, the upper section 71 is a packed tower, and the upper section of the tower body is filled with fillers, and the height of the fillers is 2.0 meters; the middle section and the lower section It is a tray structure, and the number of theoretical trays is 4 and 5 respectively.

[0040] The bottom of the stripper is provided with a reboiler condensate outlet 11, and the bottom of the stripper is provided with a reboiler return port 12, and the stripper reboiler 1 provides heat to the stripper 7, and the The process condensate is stripped and separated; the top of the stripping tower is equipped with a CO 2 The first stripping gas outlet 74 for gas discharge, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com