Patents

Literature

65results about How to "Reduce separation load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

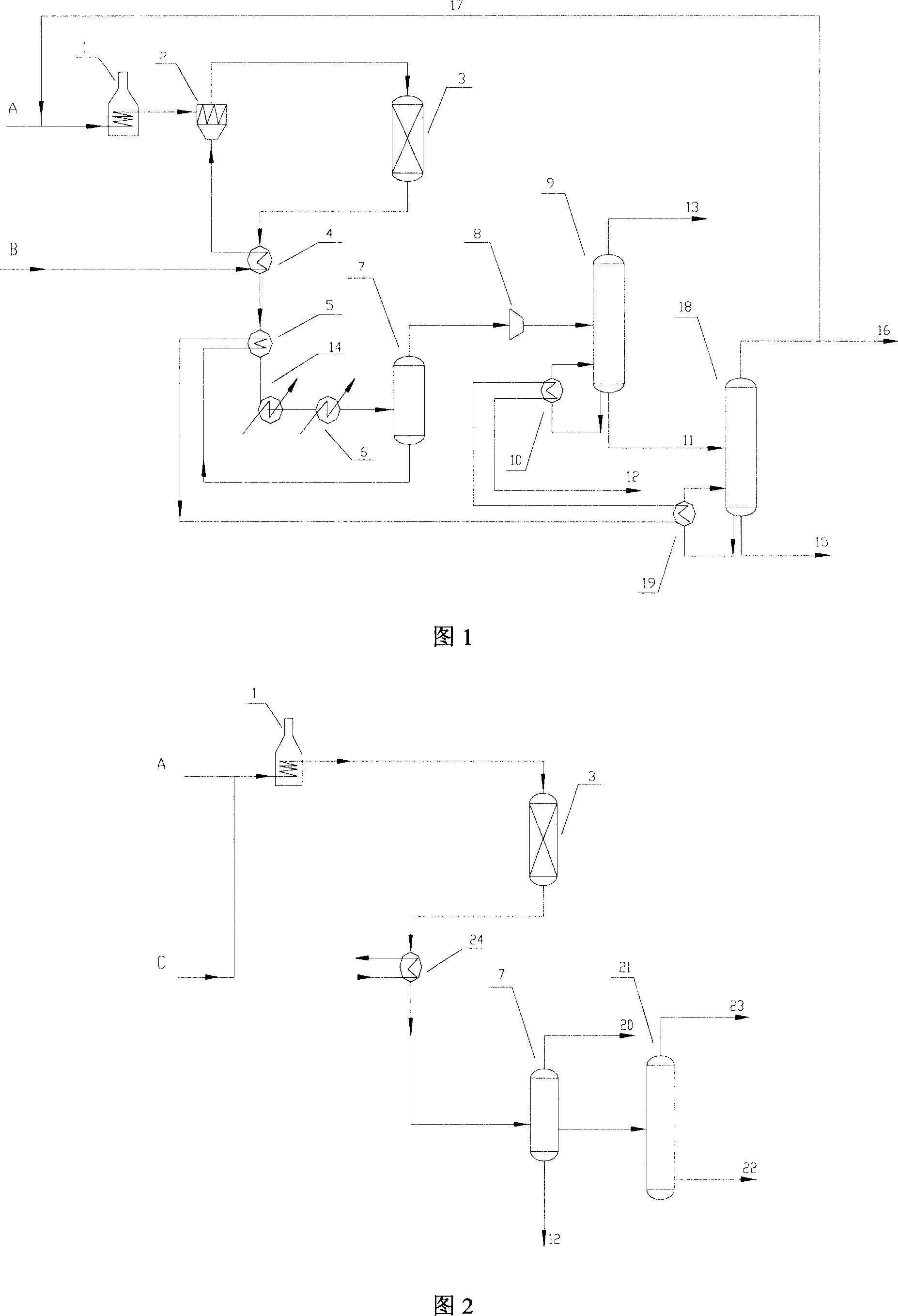

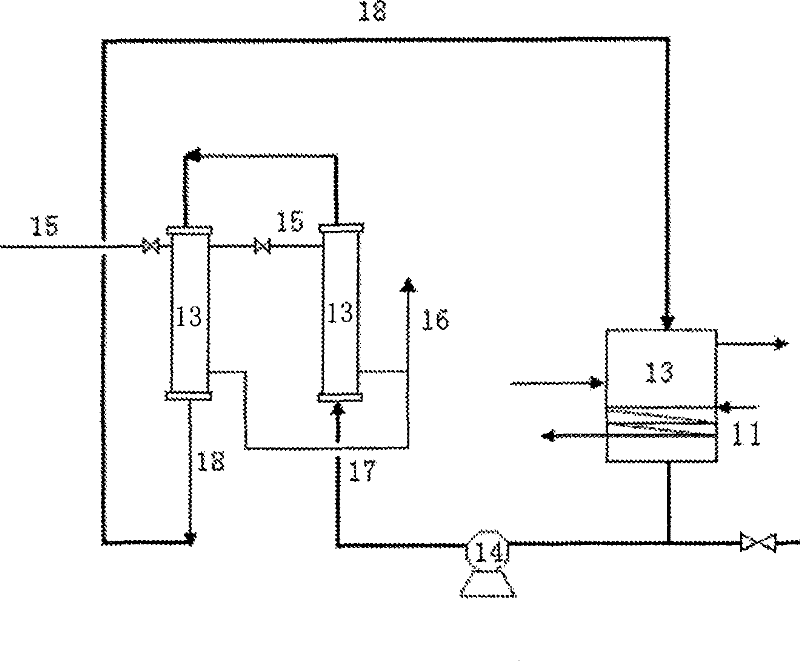

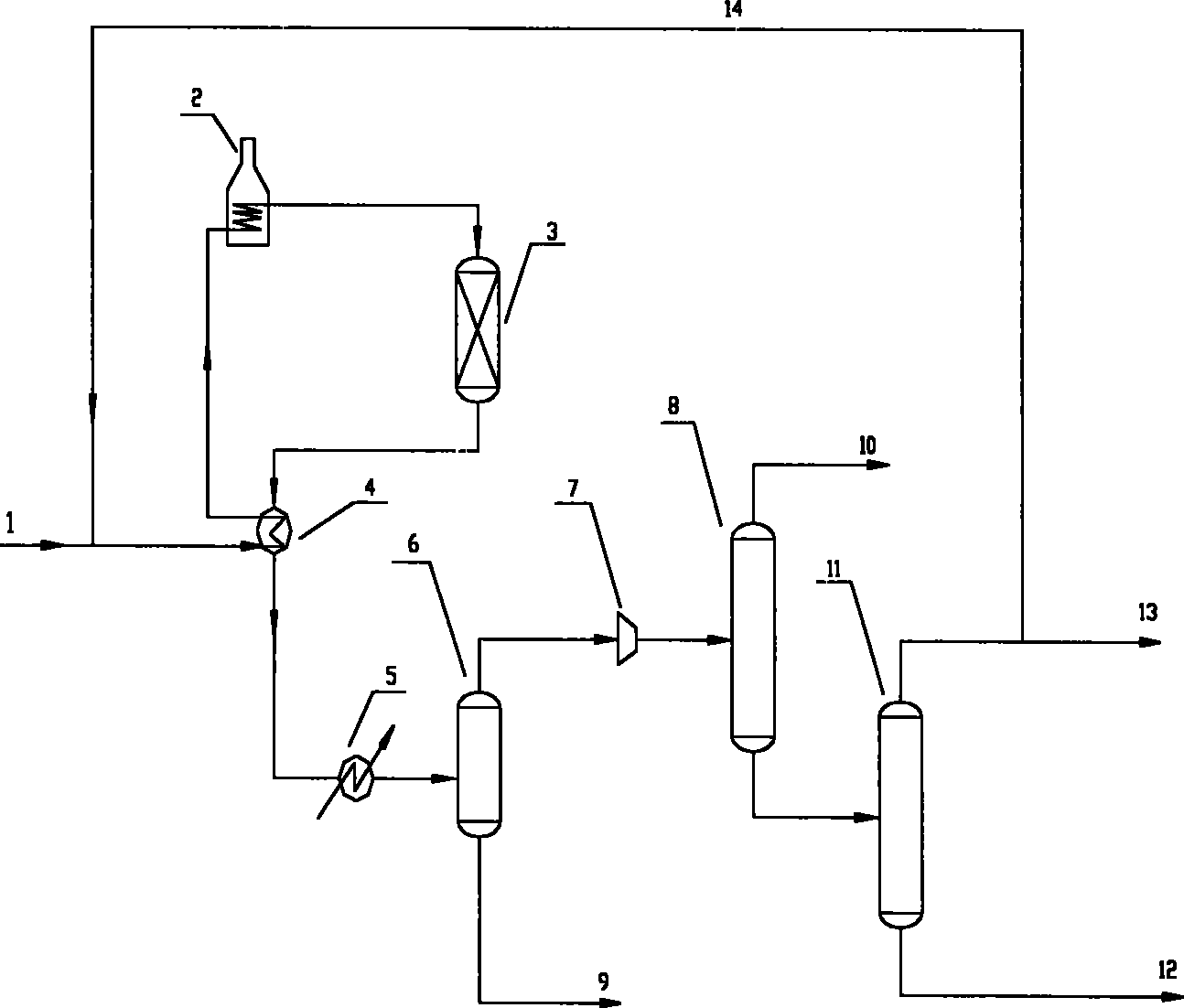

Method for preparing olefin in lightweight by catalytic cracking olefin of containing carbon

ActiveCN101092323AImprove conversion rateReduce energy consumptionBulk chemical productionHydrocarbon by hydrocarbon crackingReaction temperatureHeating furnace

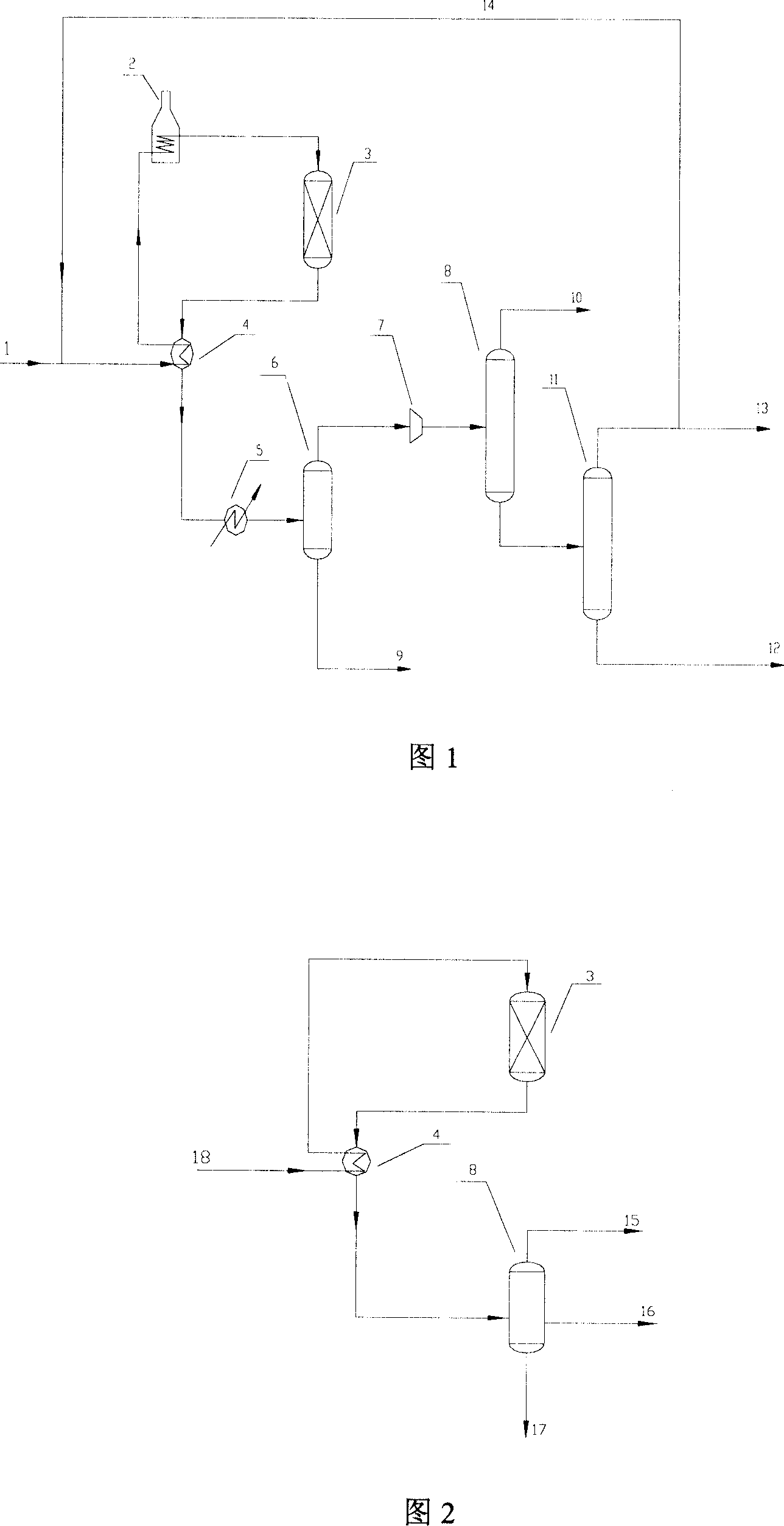

This invention relates to a method for preparing lightweight olefins from carbon-containing olefins by catalytic cracking. The method solves the problems of low added value of carbon-containing olefin mixture, low catalytic cracking conversion rate, and low associativity of catalytic cracking process faced by the previous technique. The method comprises: (1) gasifying and preheating liquid-phase carbon-containing olefin mixture by heat exchange with cracking products, and heating to the reaction temperature with a heating furnace; (2) partially condensing the cracking products, and separating C5 or higher fractions; (3) compressing the rest cracking products to 0.3-1.1 MPa, sending into a depropanizer, separating, sending C3 or lower fractions obtained at the overhead to an ethylene apparatus, and separating to obtain propylene and ethylene; (4) sending C4 or higher fractions into a debutanizer, sending 30-90 wt.% of C4 fraction obtained at the overhead to the reactor, and cracking again. The method can be used in industrial production of lightweight olefins such as propylene and ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

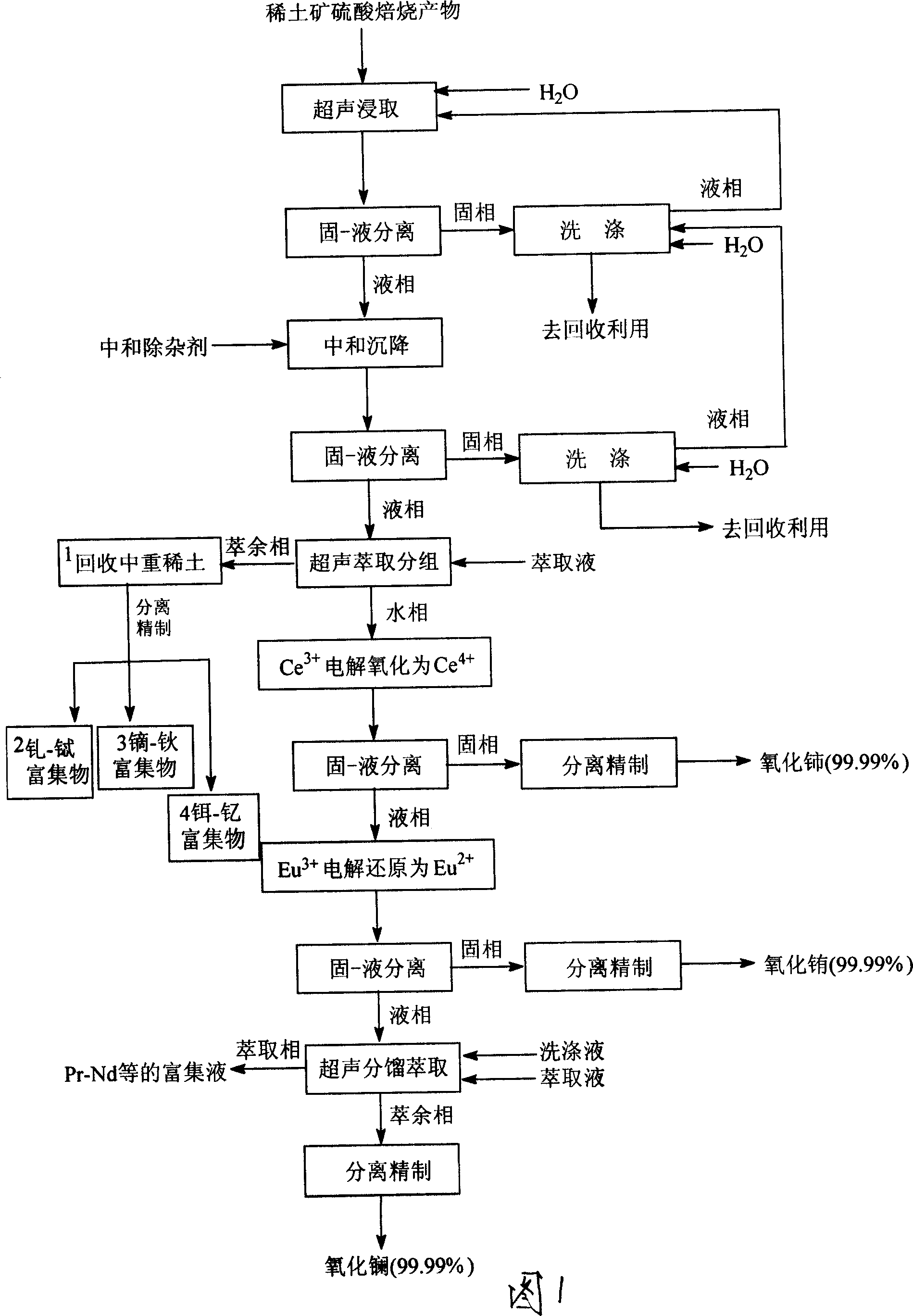

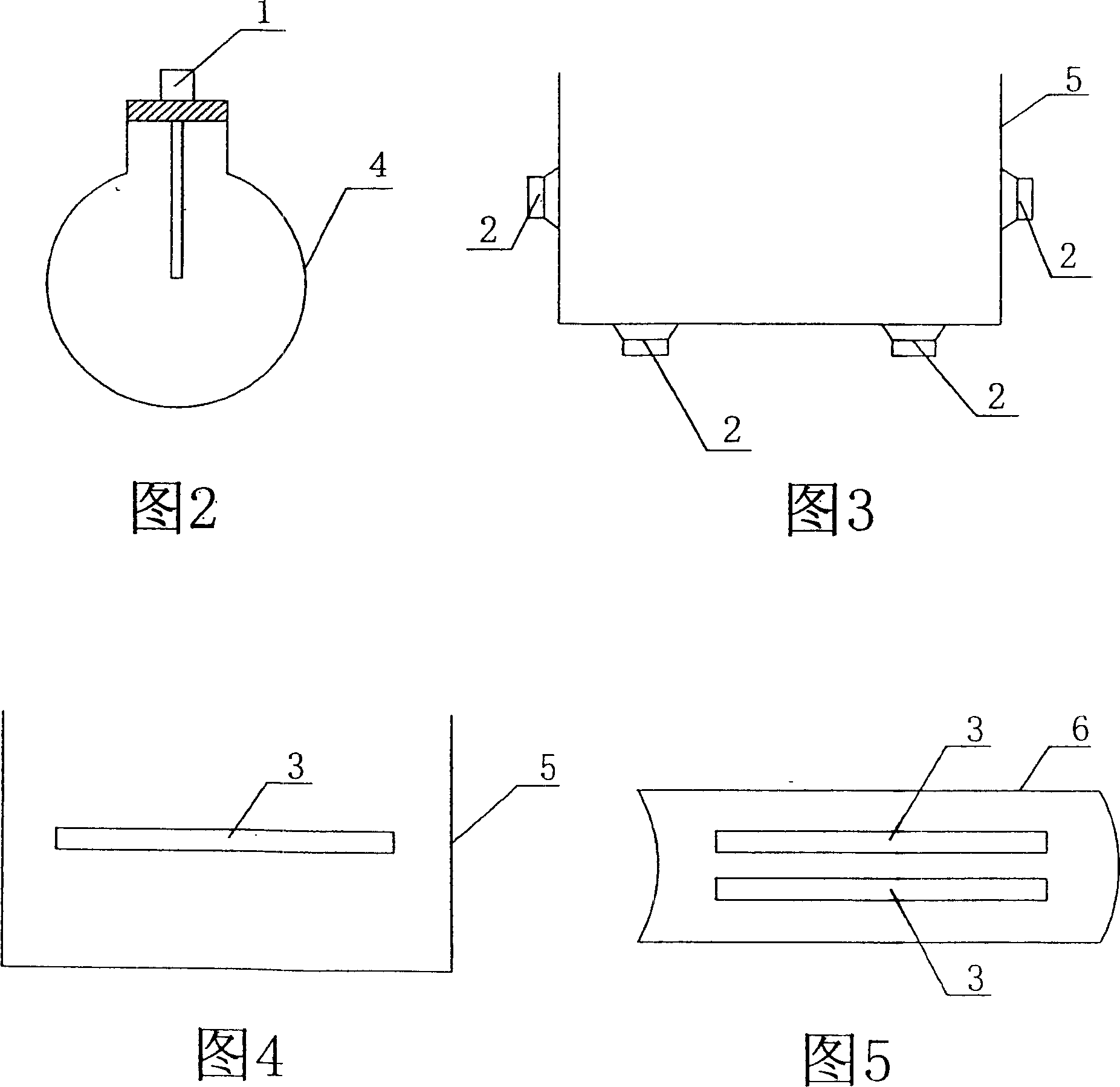

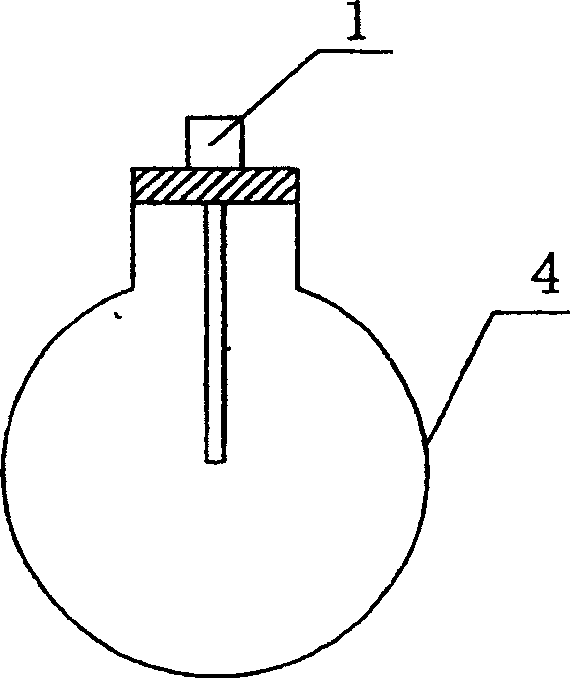

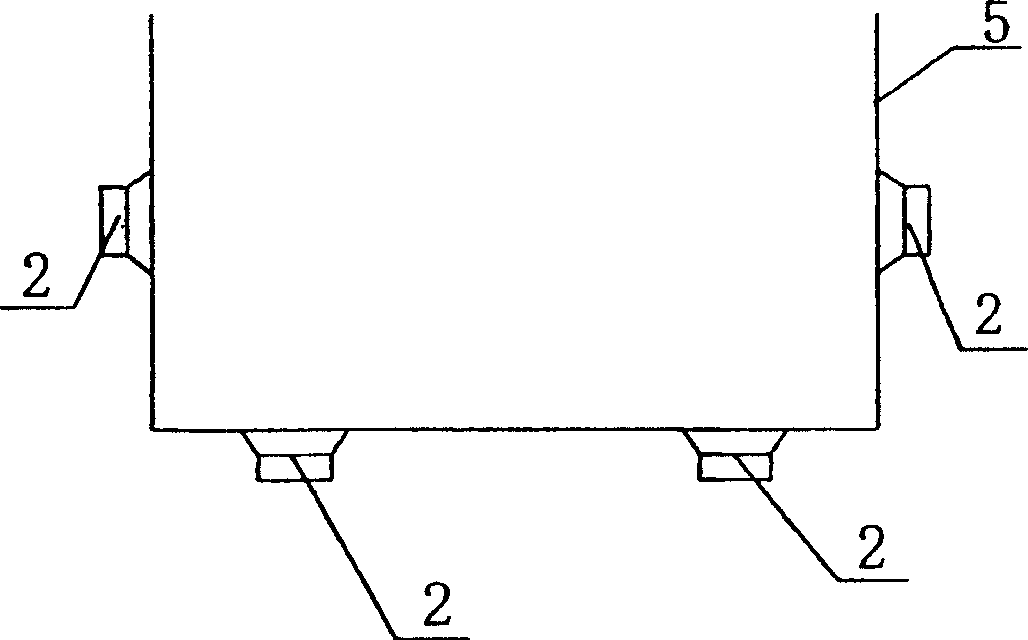

Method for separating highly-pure rare-earth oxide from sulphating roasting rare earth mine

InactiveCN101012499AHigh recovery rateAvoid generatingProcess efficiency improvementElectrochemical responseChemical treatment

The invention discloses a full-separating method of high-purity rare earth oxide from rare earth rare earth ore reinforced and sintered by sulfuric acid, which is characterized by the following: producing La2O3, Ce2O3, Pr5O11, Nd2O3, Sm2O3, Eu2O3, Gd2O3, Tb4O7, Dy2O3 and Y2O3 through ultrasonic extracting-electrochemical quantivalence-changing synthetic separating technique; oxidizing Ce3+ into Ce4+; reducing Eu3+ into Eu2+ t oseparate from other tervalent rare earths.

Owner:YANGZHOU UNIV +2

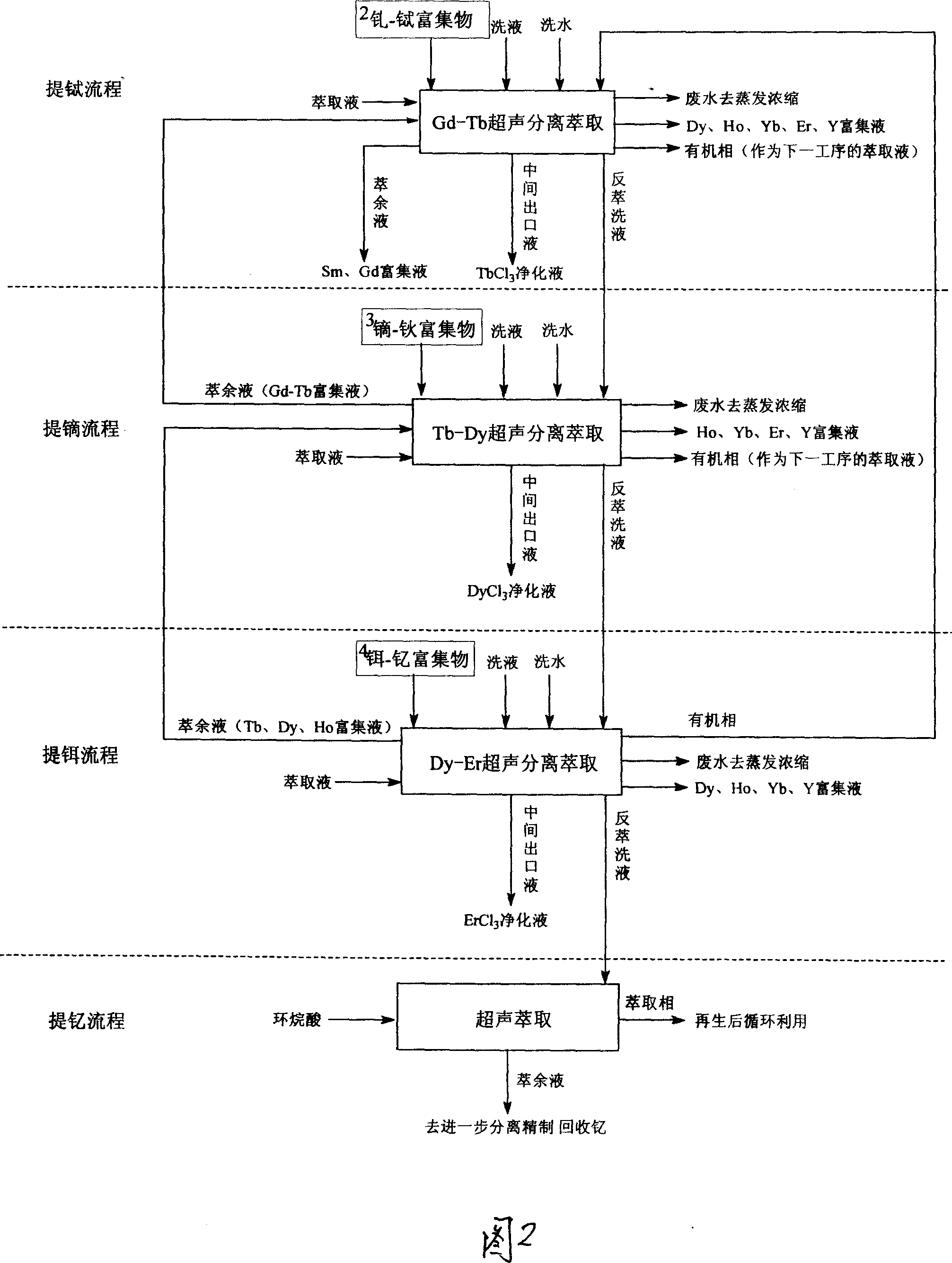

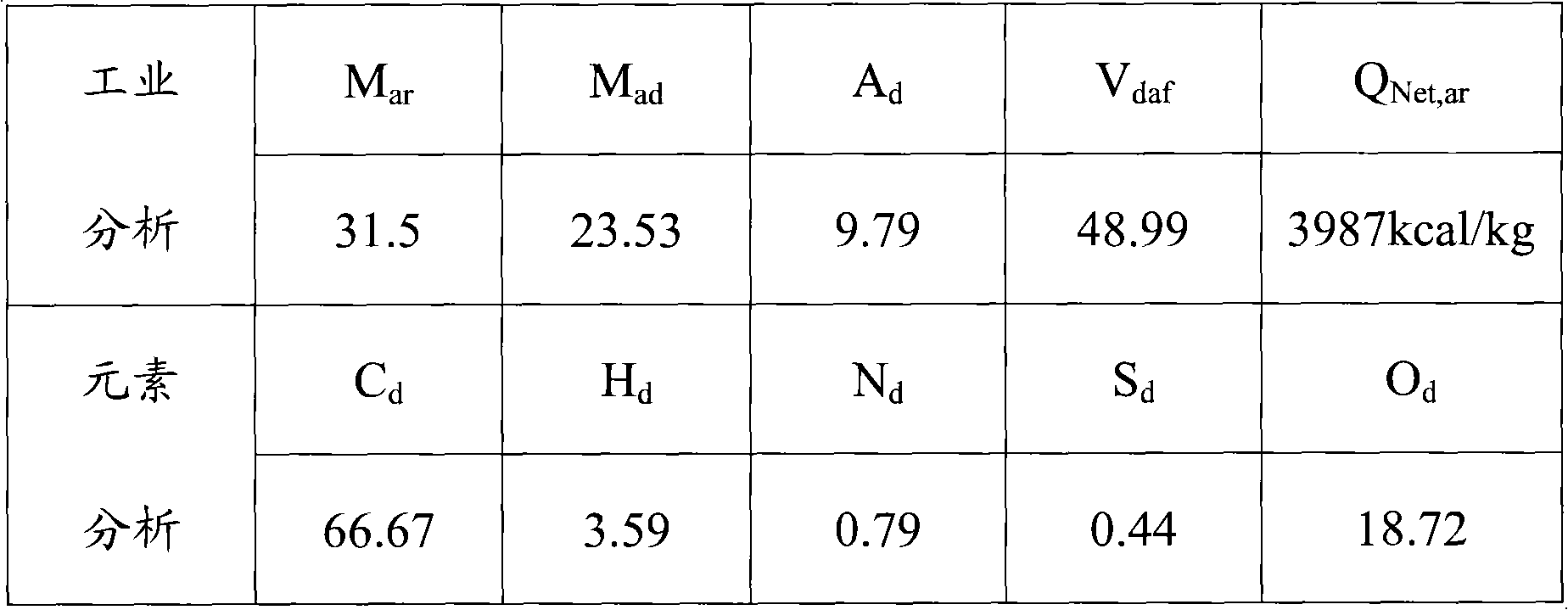

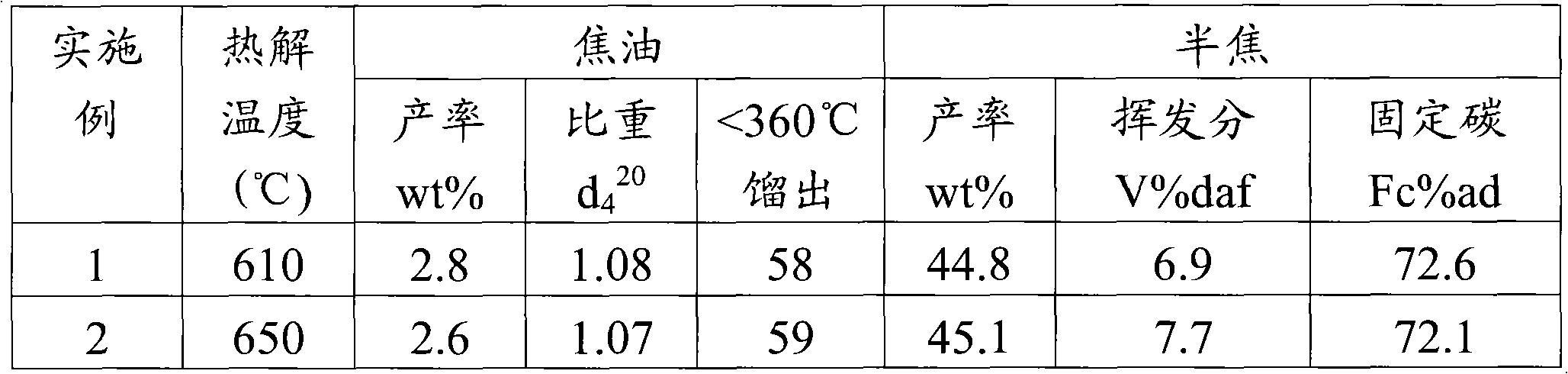

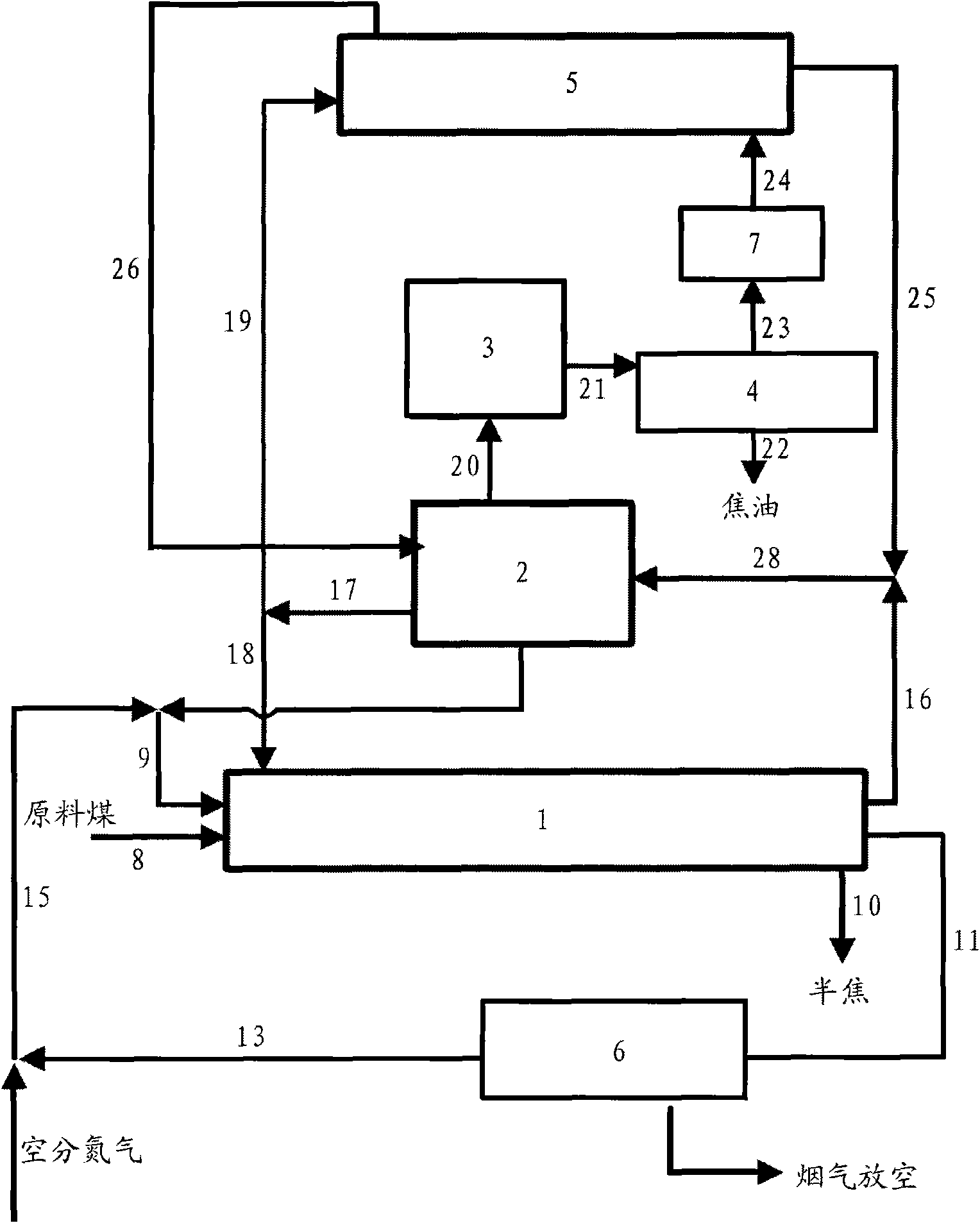

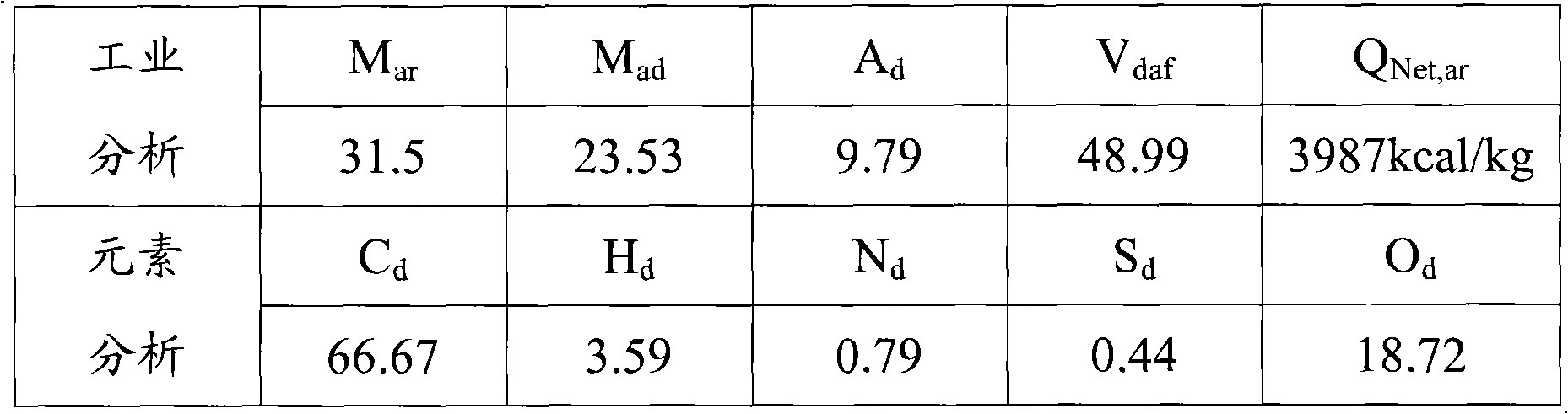

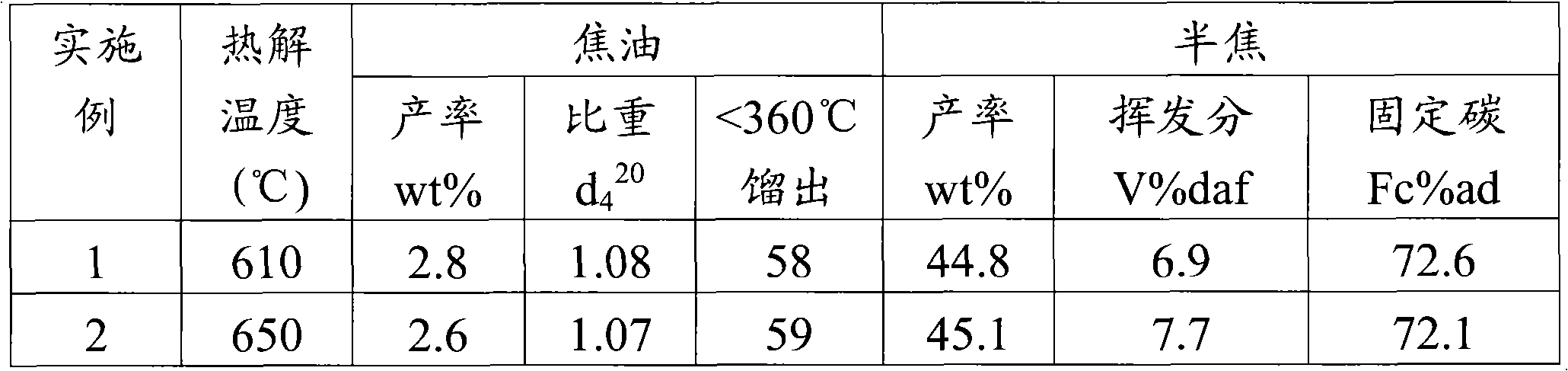

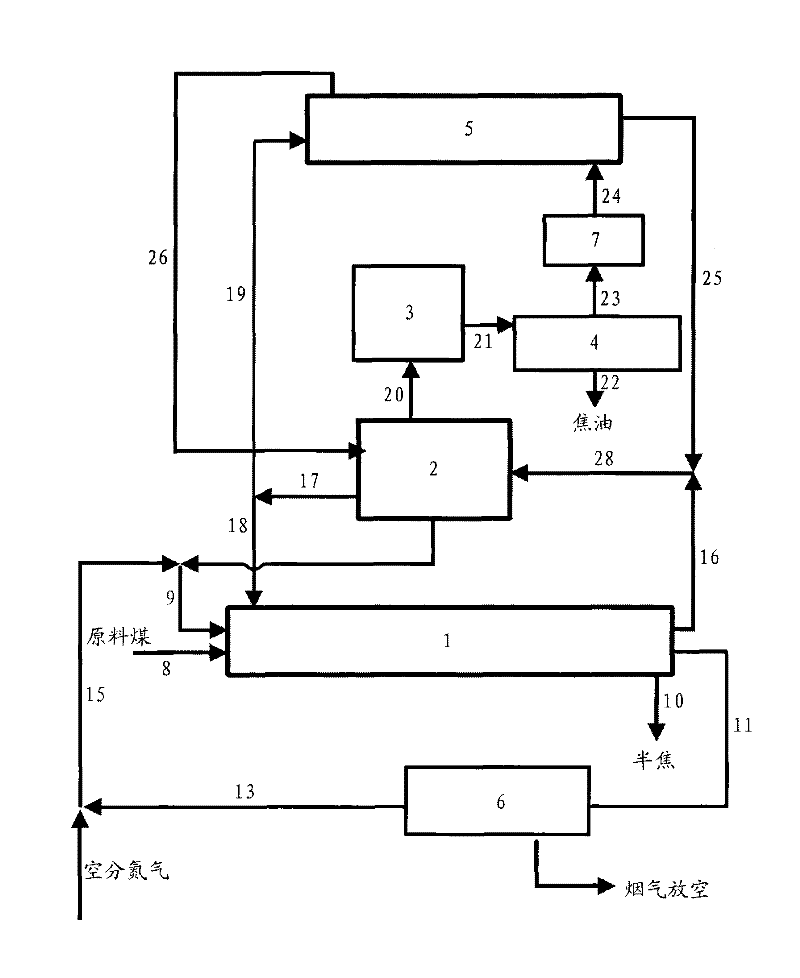

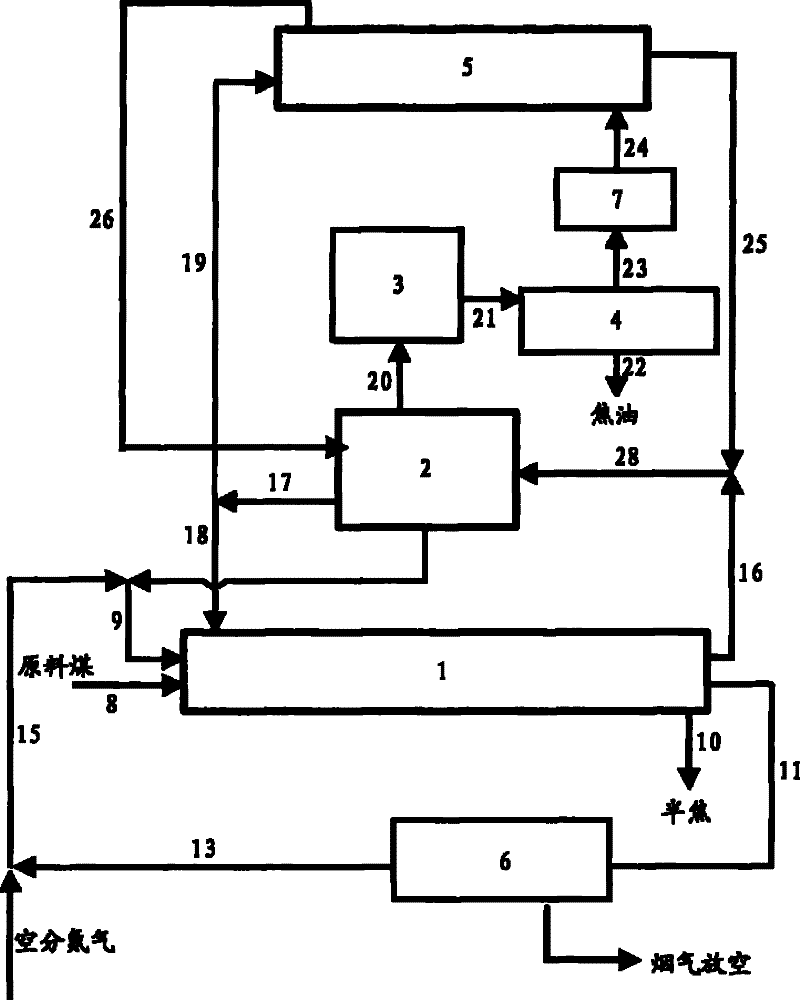

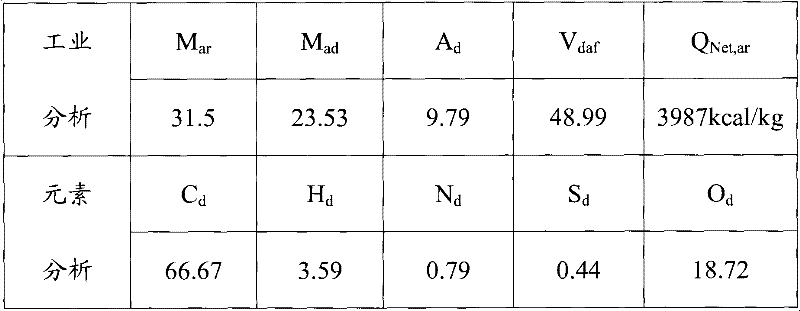

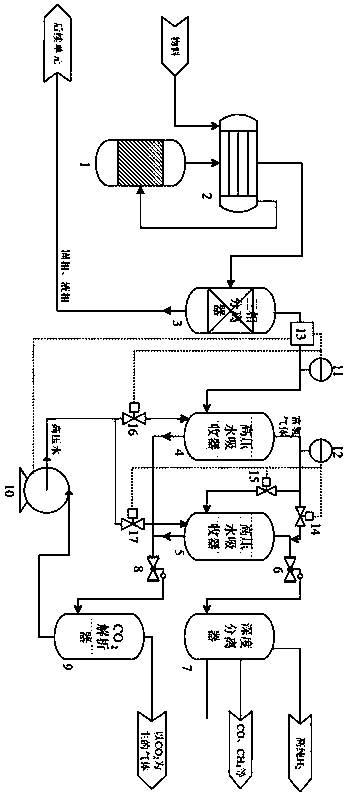

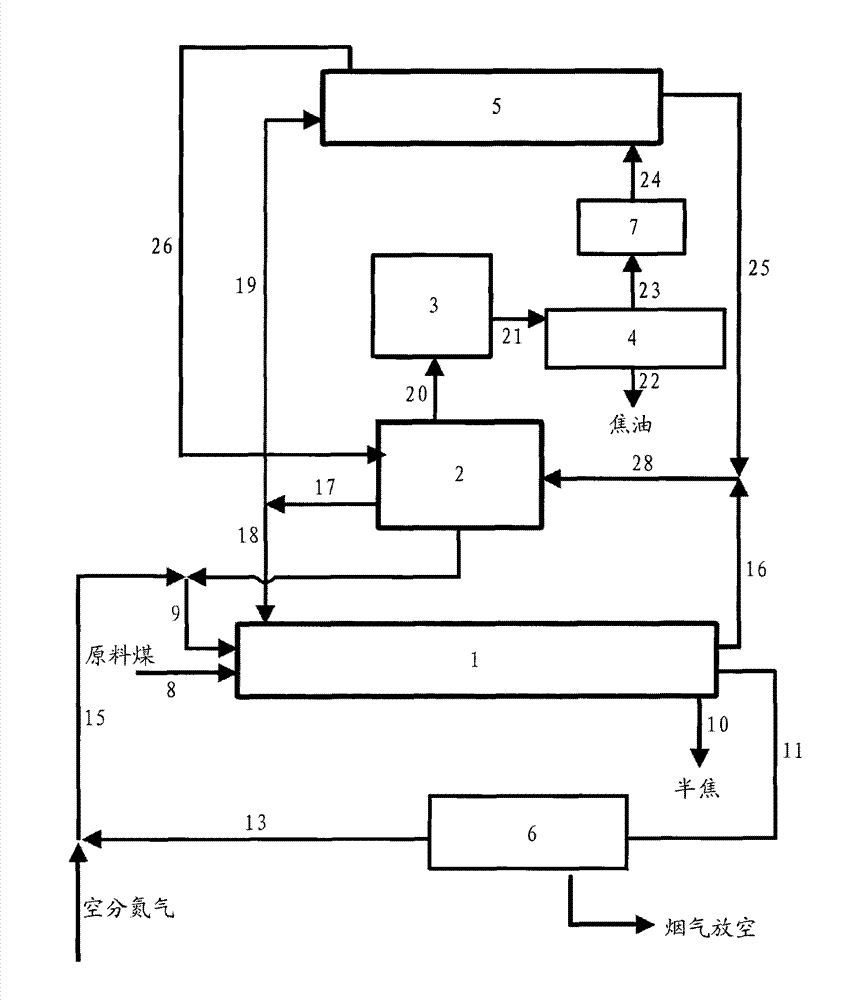

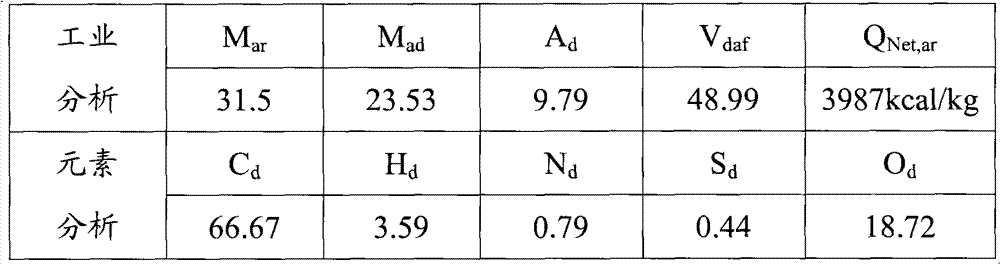

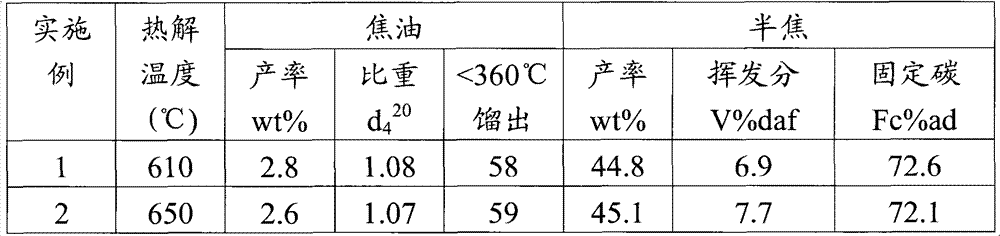

Method for upgrading coal pyrolysis

ActiveCN101608125AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

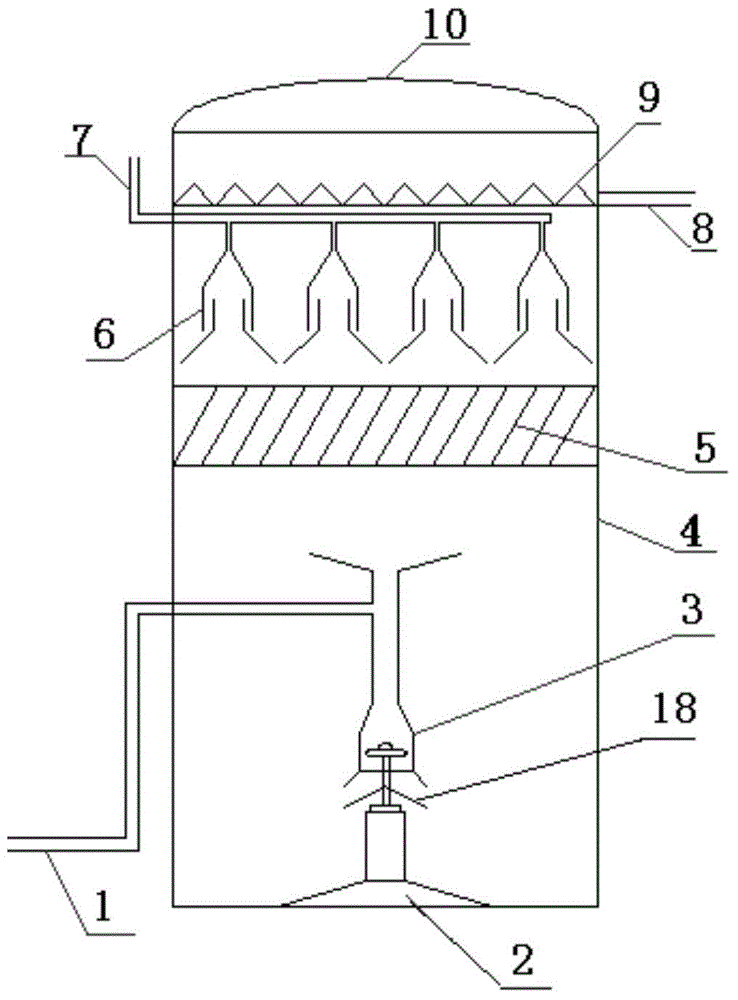

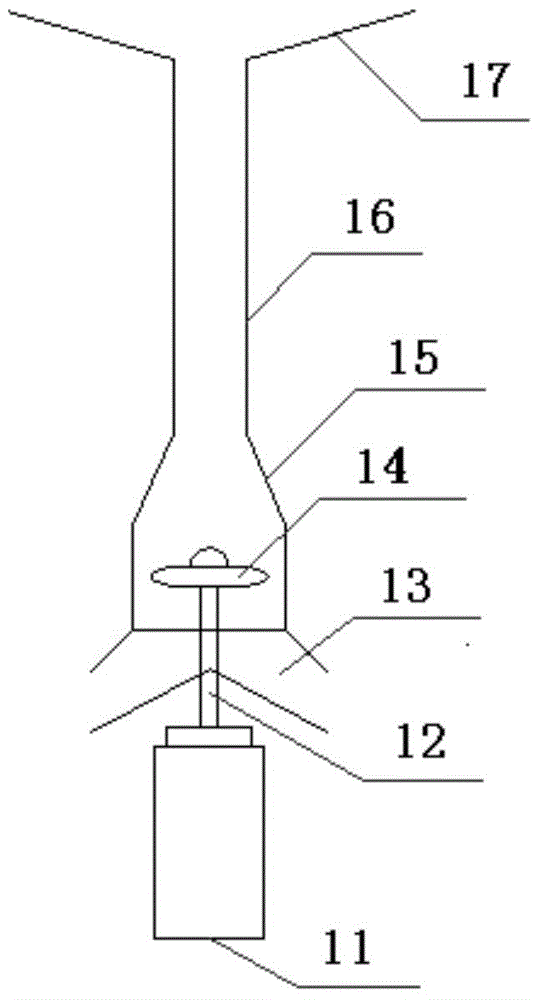

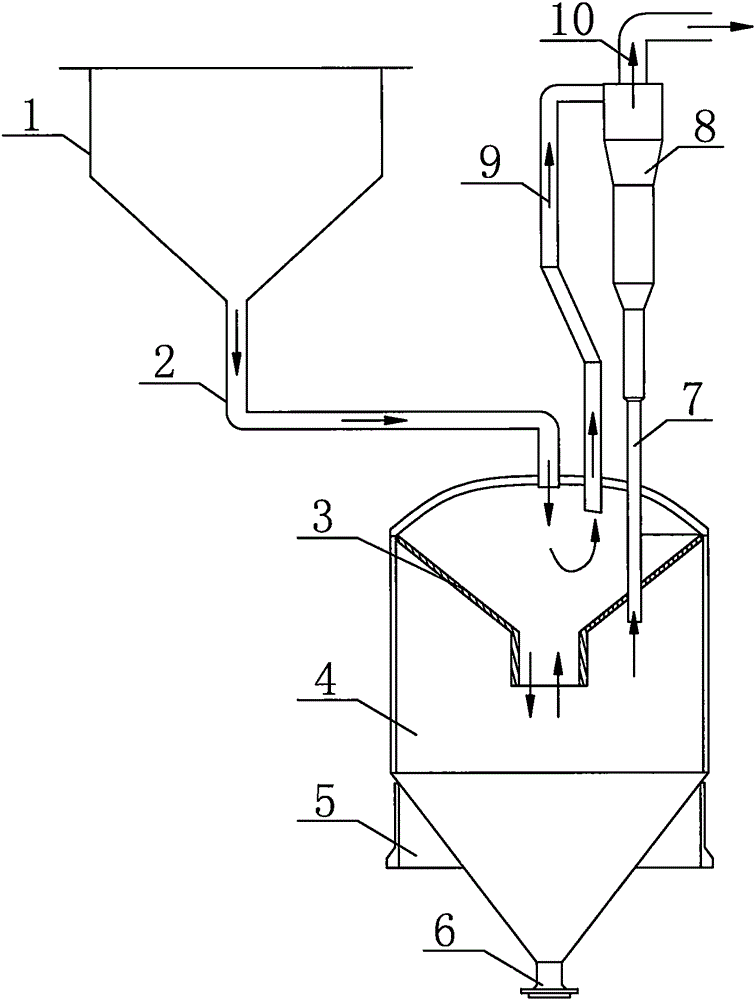

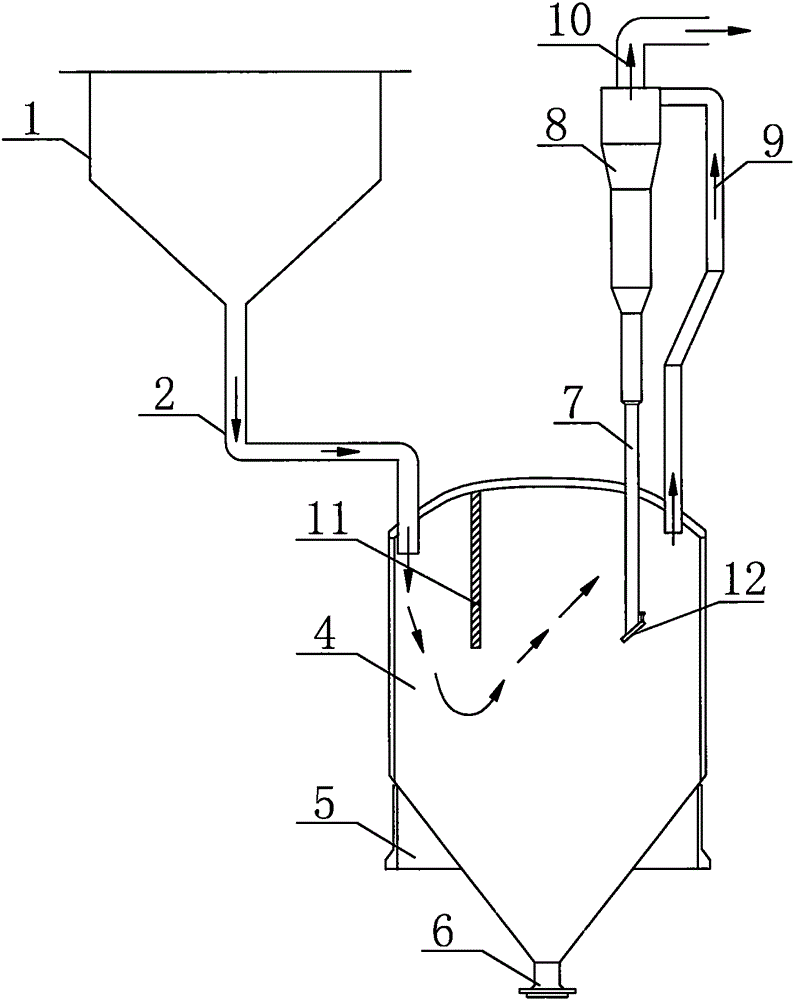

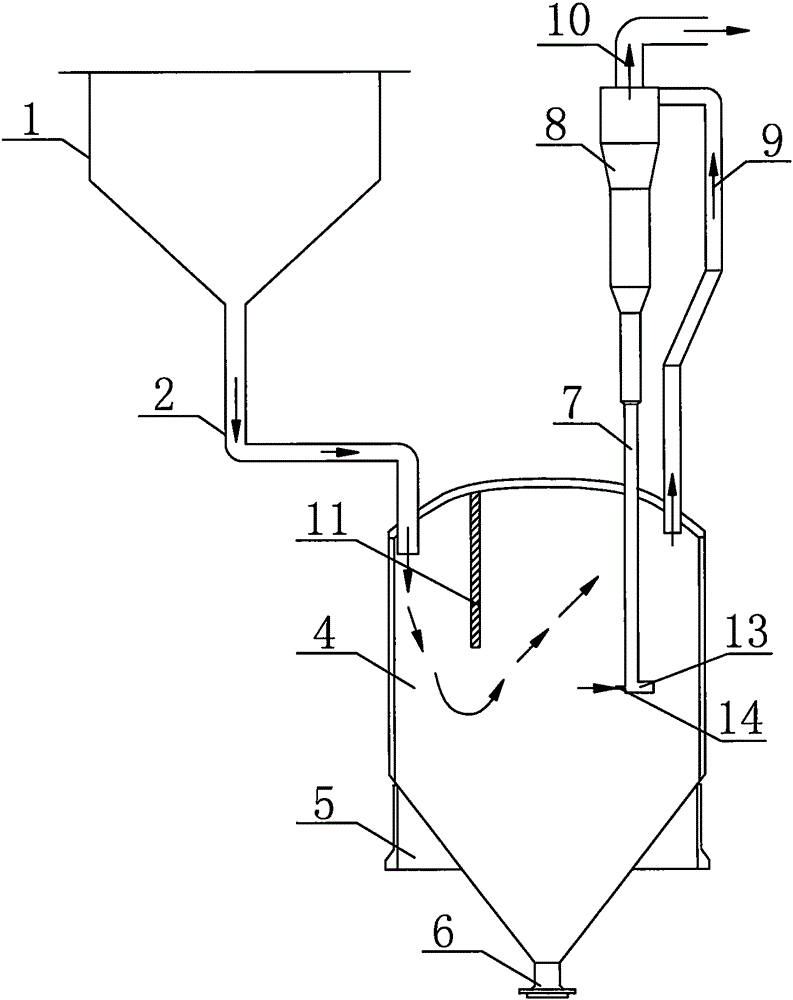

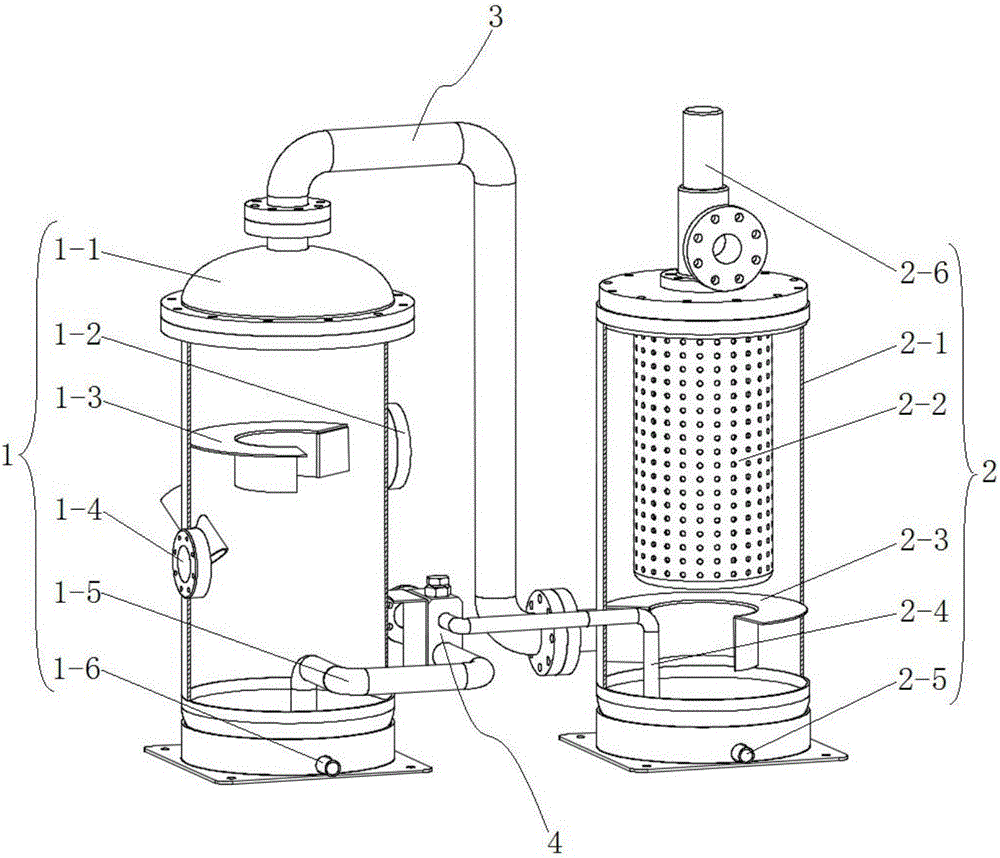

Device for improving quality of coal by pyrolysis

ActiveCN101608126AAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

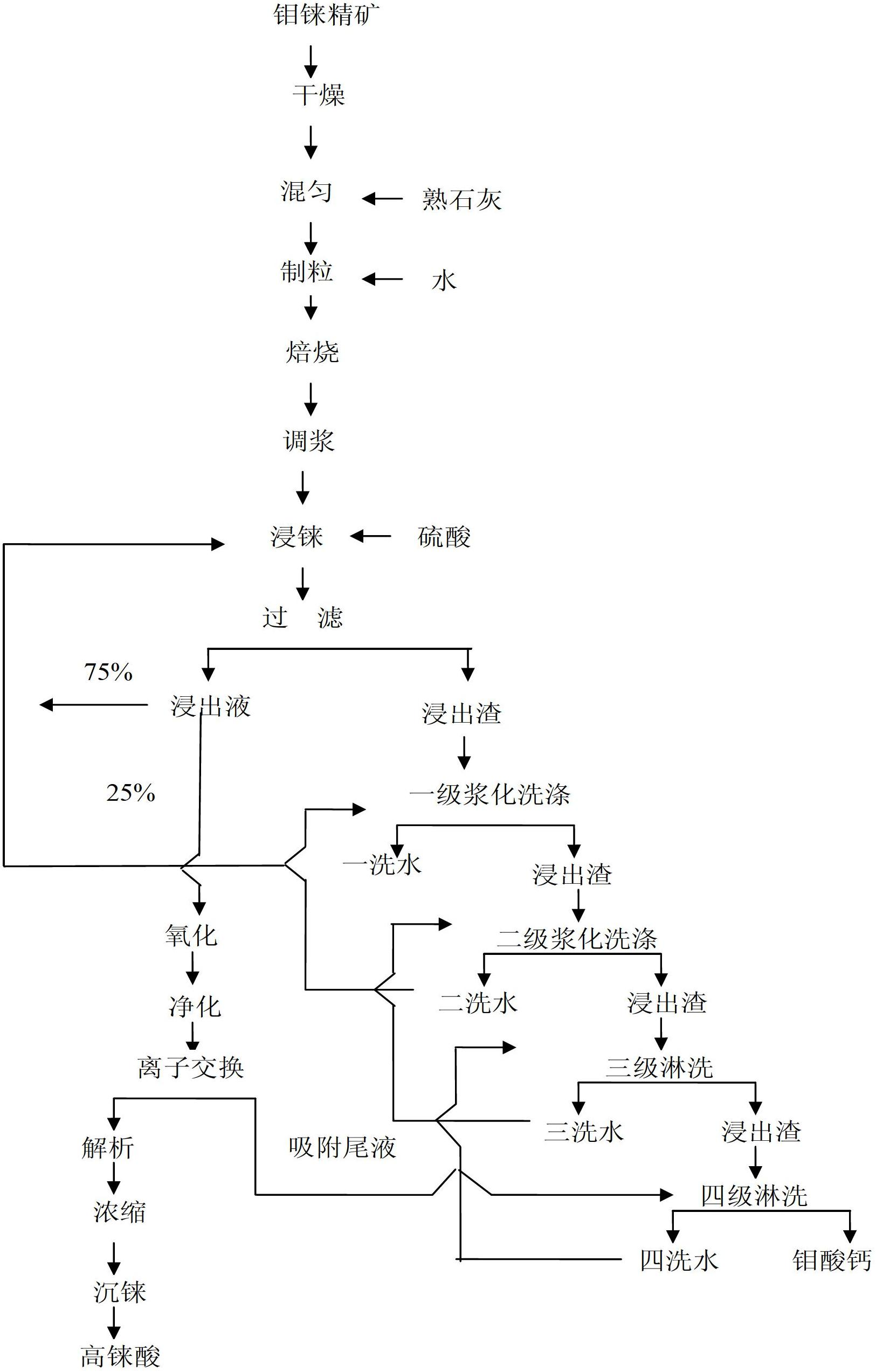

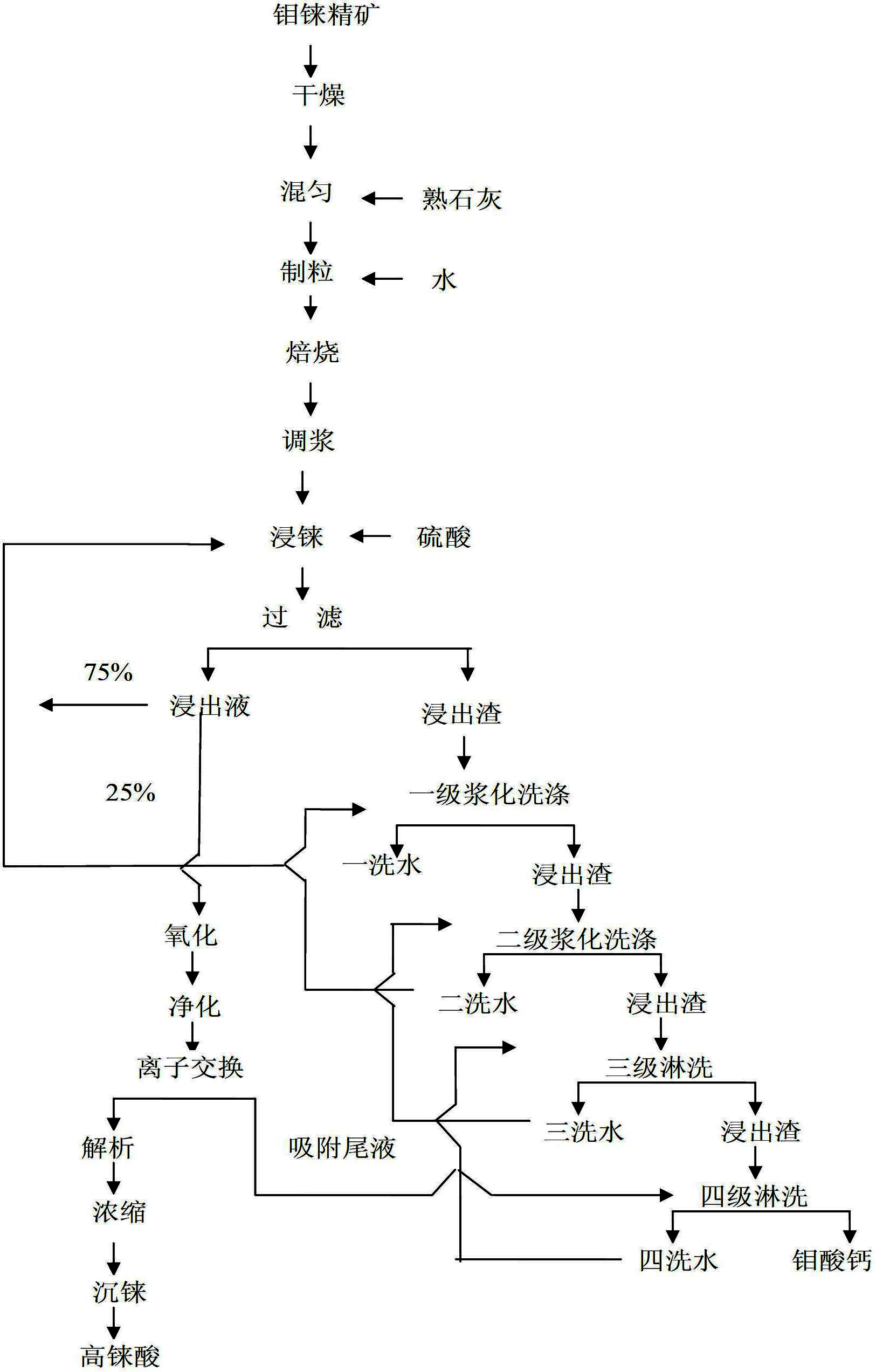

Method for separating rhenium and molybdenum in molybdenum-rhenium ore concentrate

InactiveCN102660676AEasy to follow upSimple operation processProcess efficiency improvementRheniumHydrogen

The invention provides a method for separating rhenium and molybdenum in a molybdenum-rhenium ore concentrate, comprising the following steps of: S1, carrying out wet grinding on a roasted ore obtained by lime roast-dissociation of molybdenum-rhenium ore concentrate, so as to obtain ore grinding pulp of which the mass concentration of solid substances is 40-60%; S2, adding acid into the ore grinding pulp to adjust the pH (Potential of Hydrogen) value of the ore grinding pulp to 7-8, so as to obtain a leaching solution containing the rhenium and leaching slag containing the molybdenum; separating the leaching solution from the leaching slag; S3, obtaining rhenium from the leaching solution; and S4, obtaining molybdenum from the leaching slag.. The molybdenum-rhenium ore concentrate and the lime are mixed and roasted to fix molybdenum and rhenium in the roasted ore; the roasted ore is wetly milled into smaller ore grains, which is convenient for subsequent treatment; and the pH value of the wetly-milled ore grinding pulp is adjusted to 7-8 so that molybdenum and rhenium are separated and recycling routes of the molybdenum and the rhenium are separated; an operation process is simplified and the separation load of equipment is reduced, so that equipment investment is reduced.

Owner:陕西炼石矿业有限公司 +1

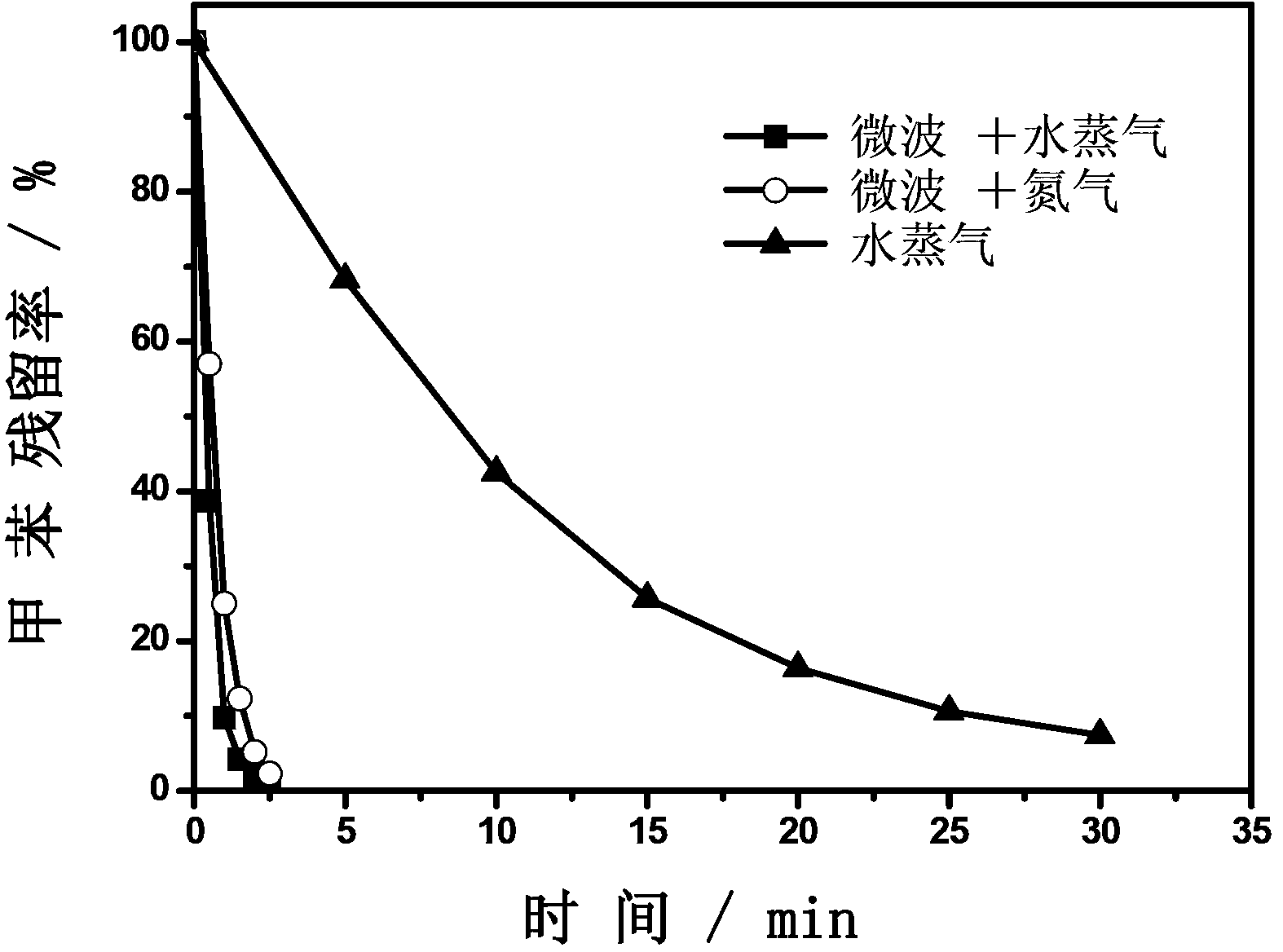

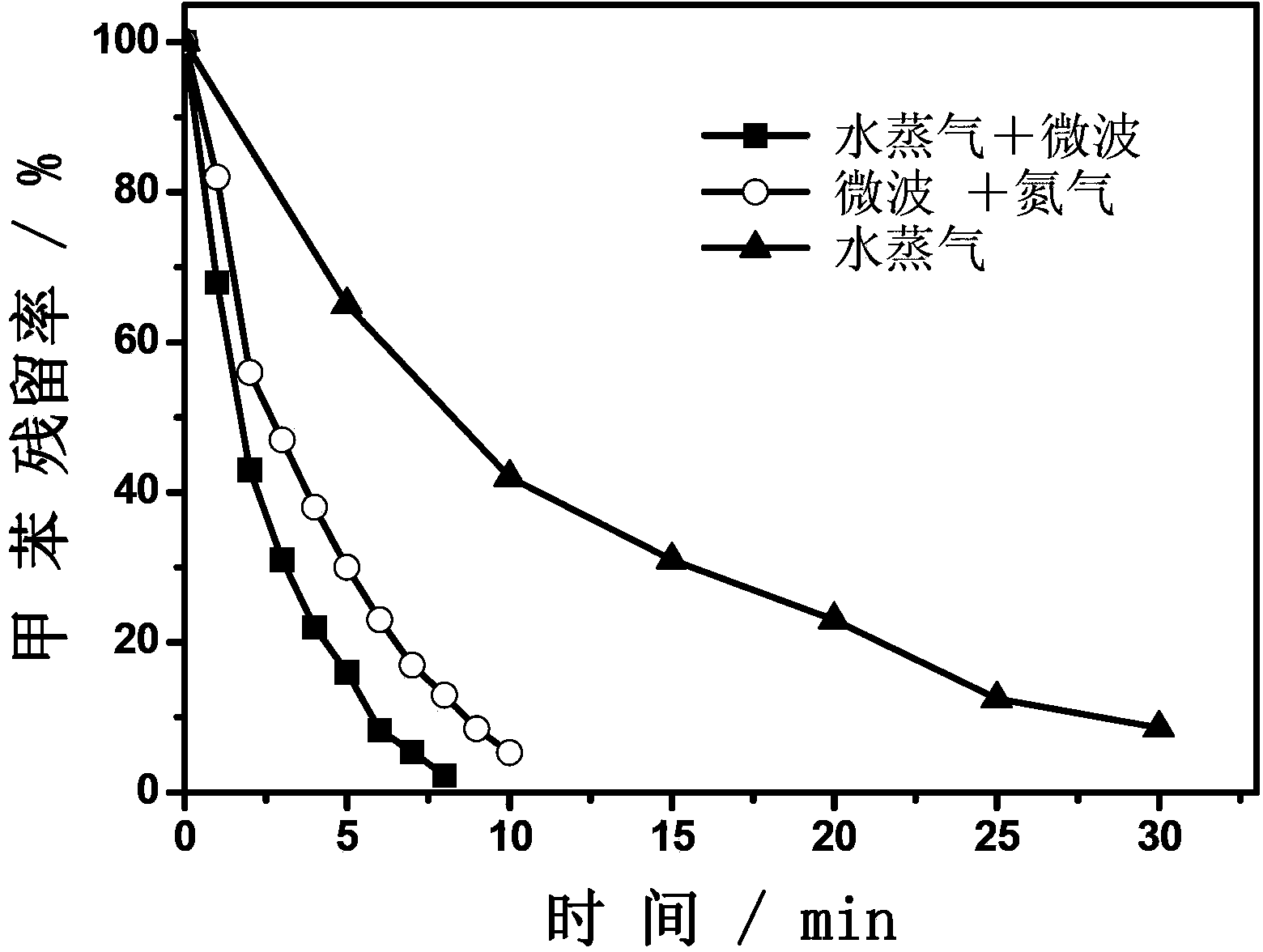

Desorption and regeneration method for organic matter adsorbent

InactiveCN103447015AReduce dosageReduce separation loadCombustible gas purificationEnergy based chemical/physical/physico-chemical processesDesorptionWater vapor

The invention discloses a desorption and regeneration method for an organic matter adsorbent. The method is characterized in that an organic matter adsorbent desorption and regeneration device of a microwave generator is arranged in a desorption tower; the to-be-desorbed adsorbent with organic matters is put in the desorption tower; steam is aerated from the top of the desorption tower; the microwave generator is started, wherein the microwave power is 500-10000W; desorption is carried out for 2-30 minutes; the desorbed organic matters and steam flow out from a steam outlet at the bottom of the desorption tower and enter a condenser for condensation; then the steam is cut off, nitrogen is aerated from the top of the desorption tower, and the nitrogen flows out from the bottom, wherein the microwave power is 200-2000W; drying treatment is carried out for 2-20 minutes; the microwave generator is turned off, and the nitrogen is cut off; the desorbed adsorbent is obtained. According to the method, the desorption rate is improved by a large margin by combining steam and the microwave technology, and less desorption residue is left.

Owner:ZHEJIANG UNIV OF TECH

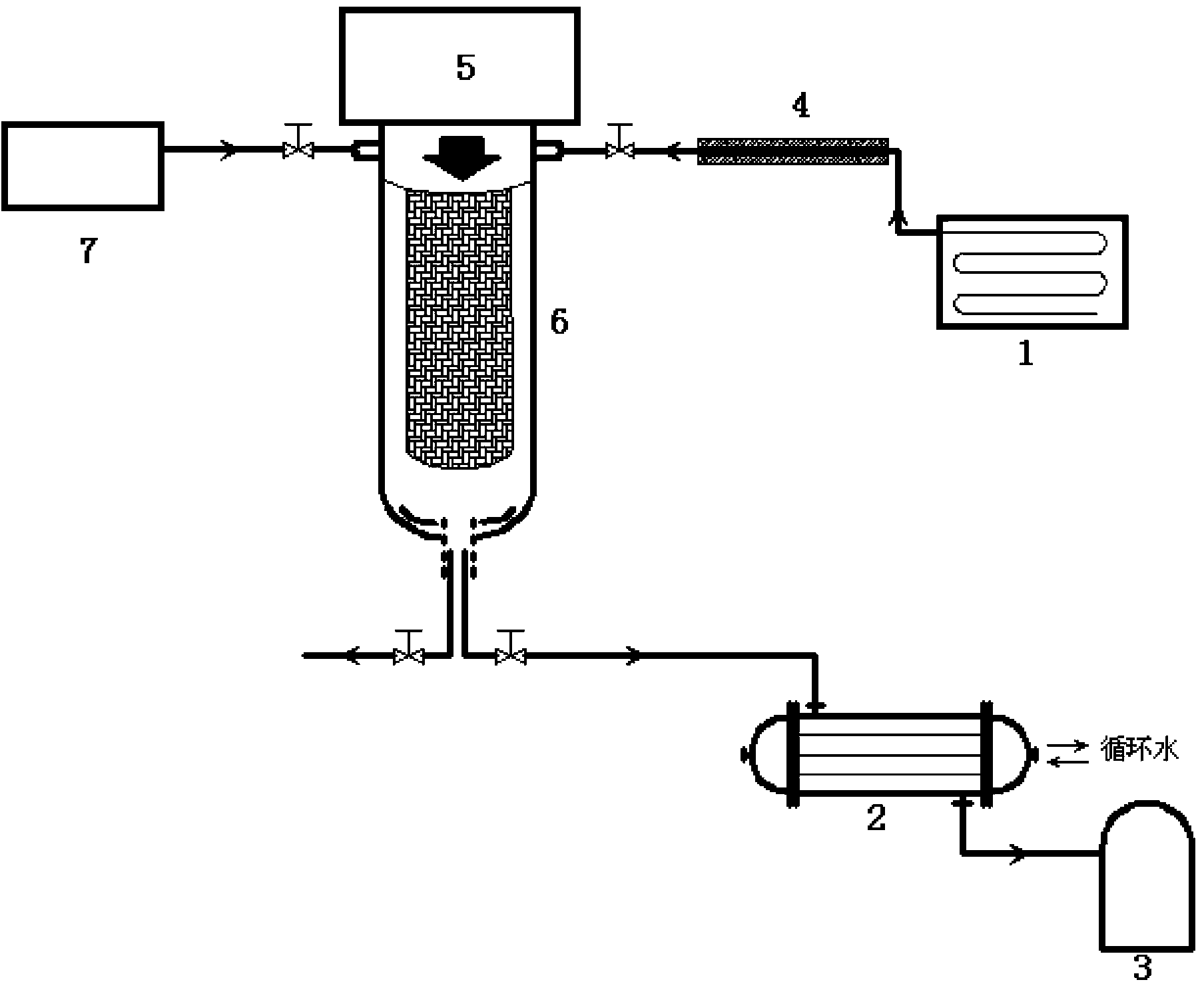

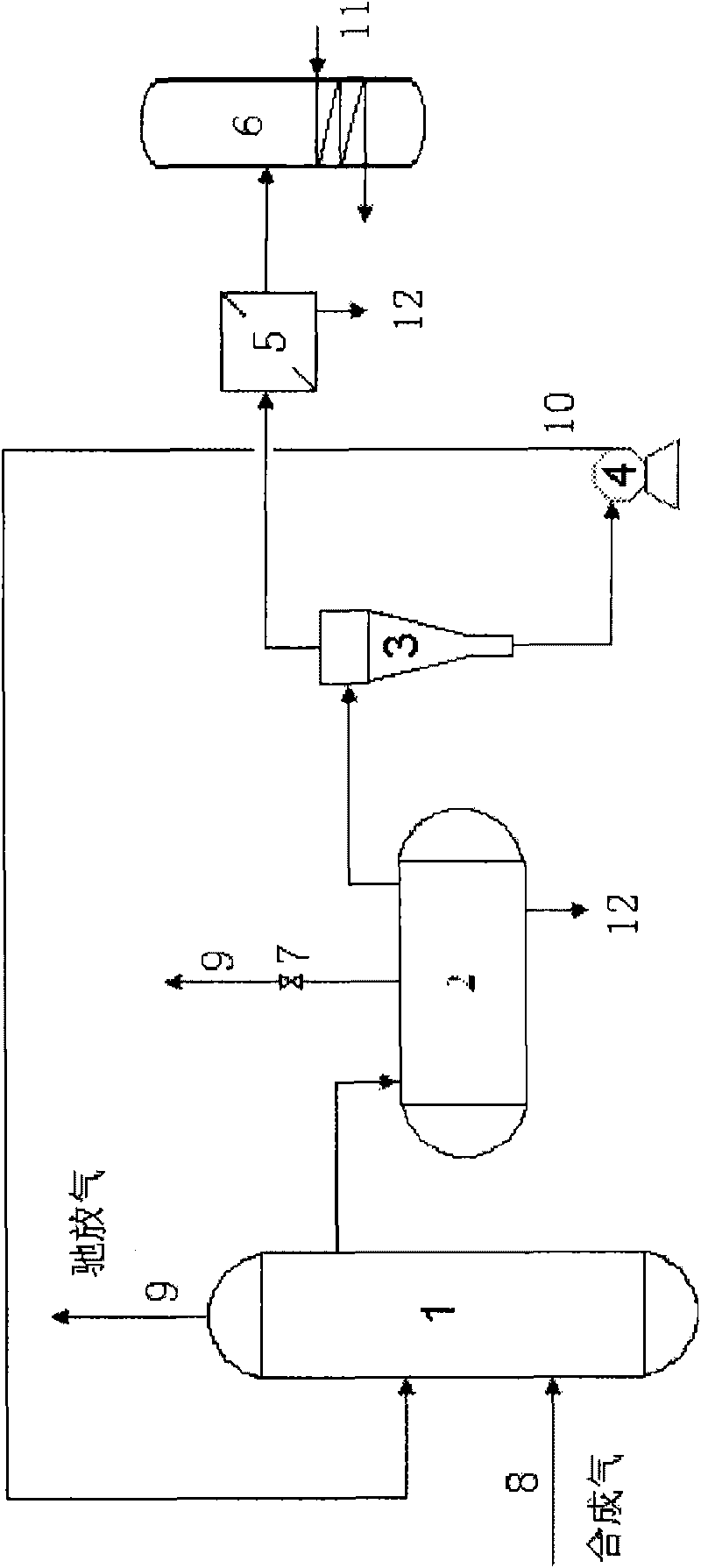

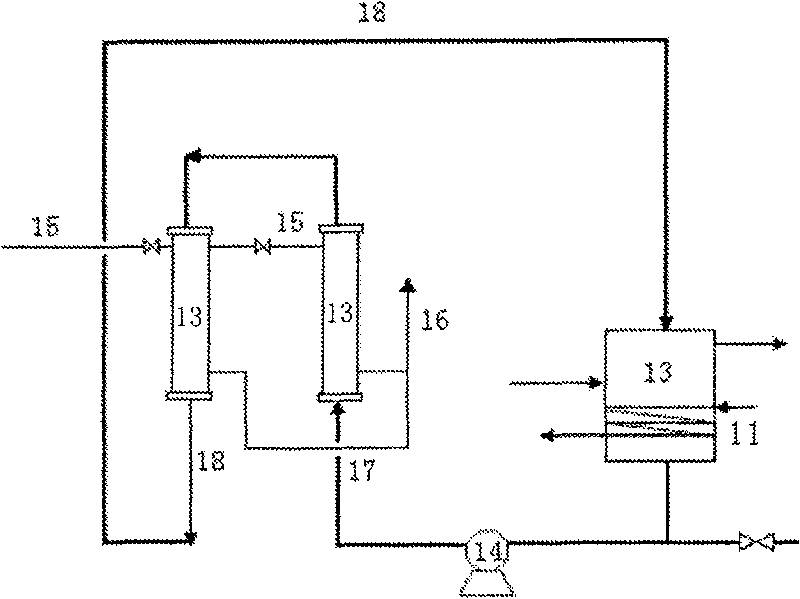

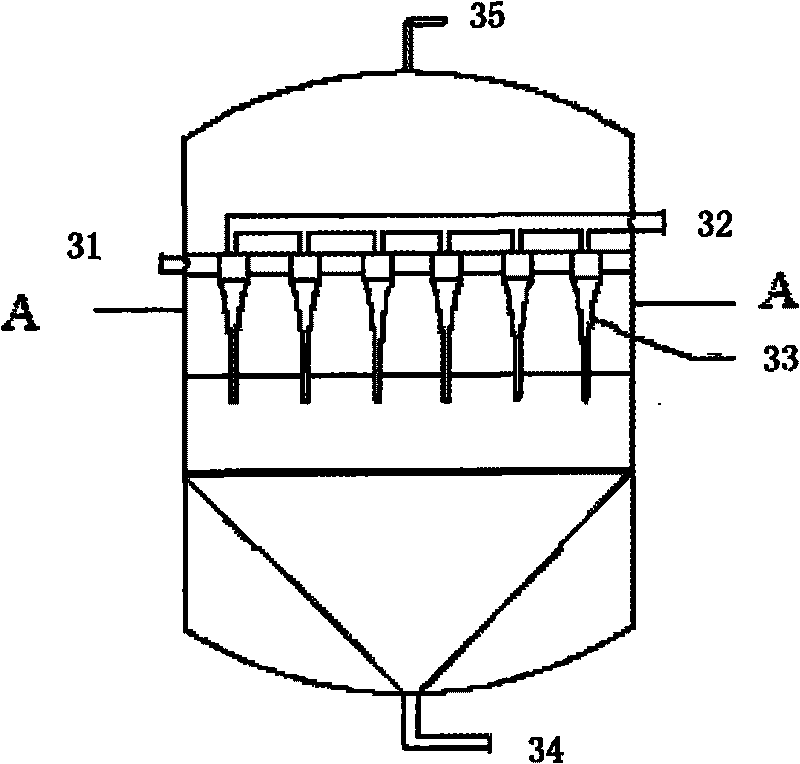

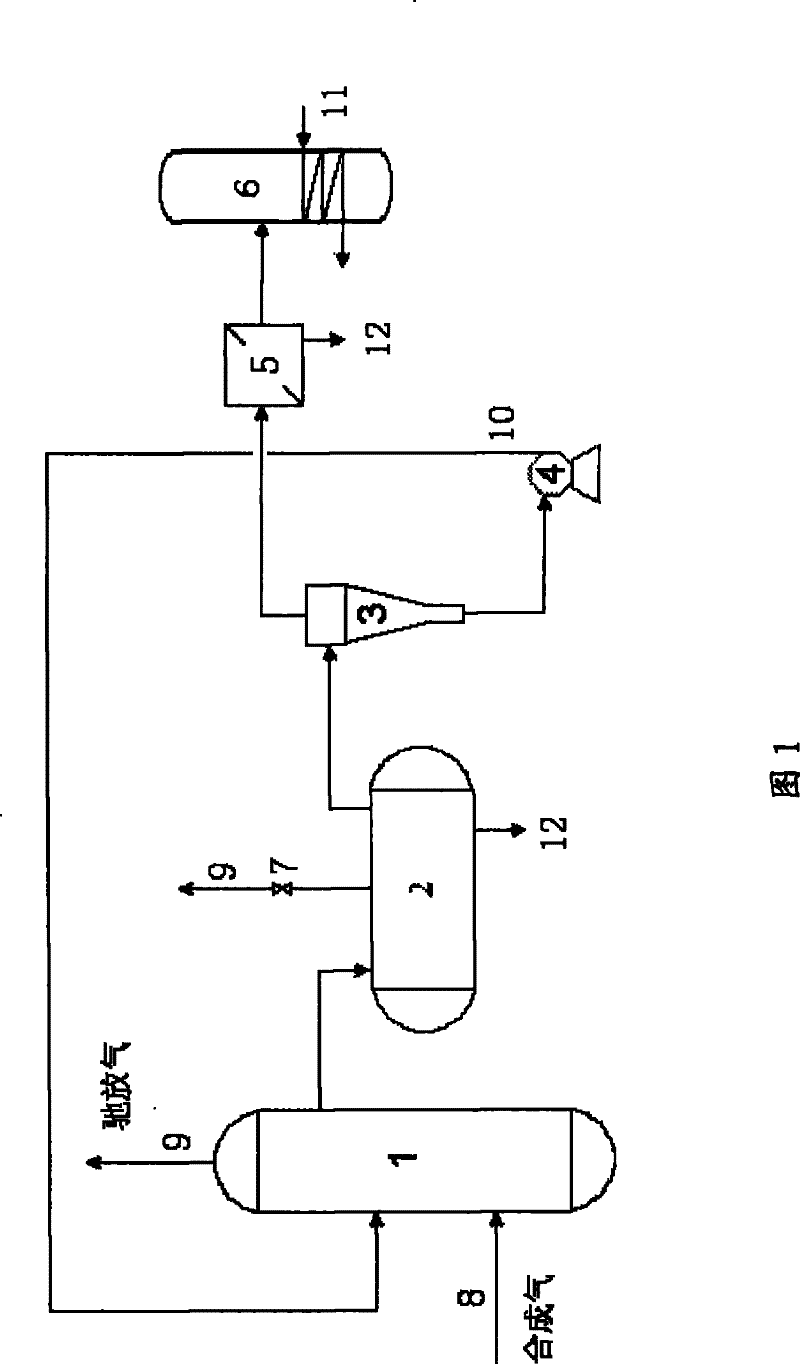

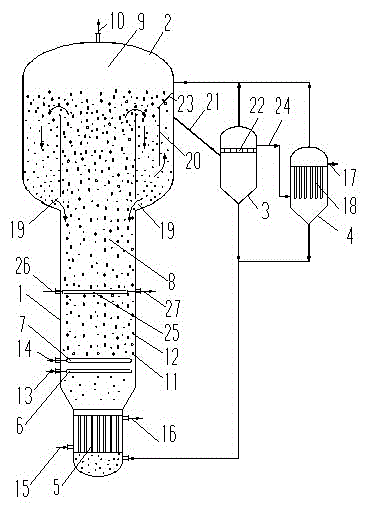

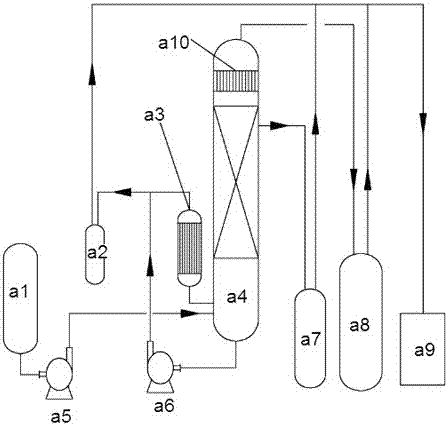

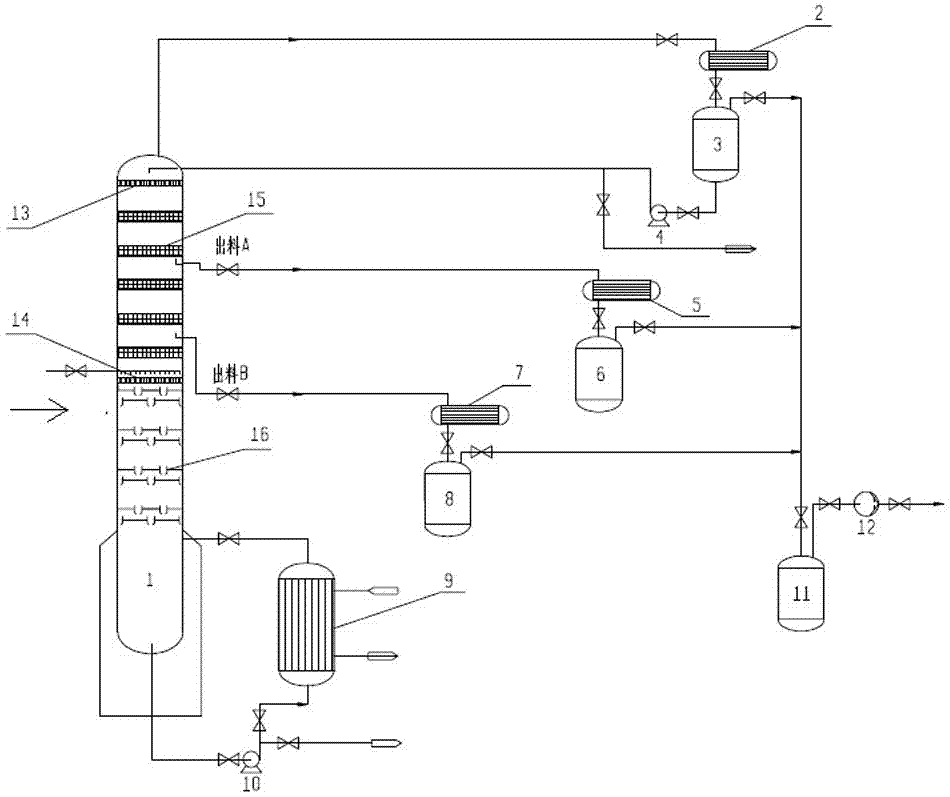

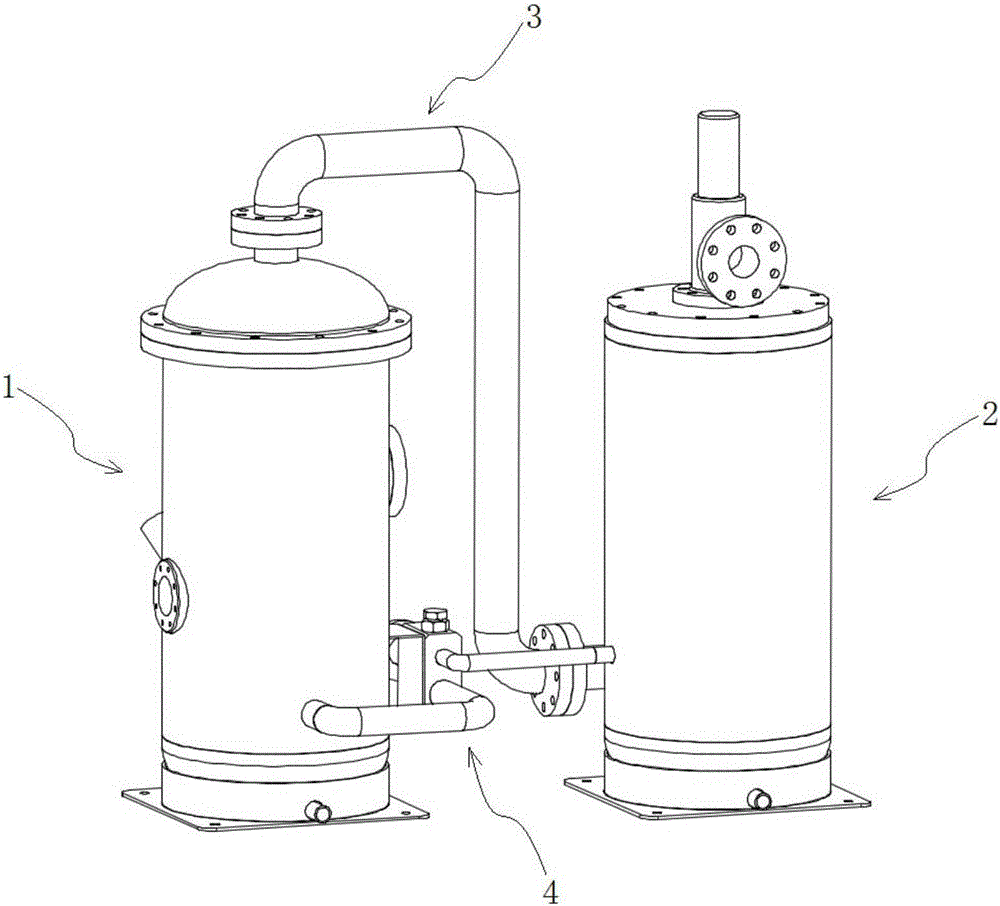

Solid-liquid separation device and solid-liquid separation method for slurry bed reactor

ActiveCN101733045AReduce separation loadReduce wearHydrocarbon from carbon oxidesChemical/physical processesCycloneSlurry

The invention provides a solid-liquid separation device for a slurry bed reactor. The device comprises the slurry bed reactor, a solid-liquid settling separation system connected with the slurry bed reactor, a solid-liquid cyclone separation system connected with the solid-liquid settling separation system and a membrane separation system connected with the solid-liquid cyclone separation system. The invention also provides a solid-liquid separation method for the slurry bed reactor, wherein slurry discharged from the slurry bed reactor sequentially passes through the solid-liquid settling separation system, the solid-liquid cyclone separation system and the membrane separation system and is separated, wherein the membrane separation system is used for separating catalyst particles with particle sizes less than 10 mum. The technical scheme of the invention not only can meet the solid-liquid separation accuracy, but also can ensure long-period running of the device.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing propylene by catalytic cracking olefin of containing carbon

ActiveCN101092325AImprove conversion rateReduce energy consumptionHydrocarbon by hydrocarbon crackingHydrocarbon mixturesReaction temperature

This invention relates to a method for preparing propylene by catalytic cracking of hydrocarbons. The method solves the problems of low added value, low conversion rate and low associativity of catalytic cracking process faced by traditional technique. The method comprises: gasifying liquid-phase hydrocarbon mixture by heat exchange with catalytic cracking product, mixing with overheated diluted steam to reach the reaction temperature, performing heat exchange between catalytic cracking product and condensed steam, passing through an air cooler and a cooler for cooling and separating out condensed steam, performing heat exchange between condensed steam and catalytic cracking product, utilizing as the heat source for the following debutanization and depropanization columns, compressing the catalytic cracking product to 0.3-1.1 MPa, sending into the depropanization column, separating to obtain C3 or below fractions at the overhead, separating with an ethylene apparatus to obtain propylene and ethylene, sending C4 or higher fractions at the bottom into the debutanization column, separating C4 fractions at the overhead, and recycling 30-90 wt.% into the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

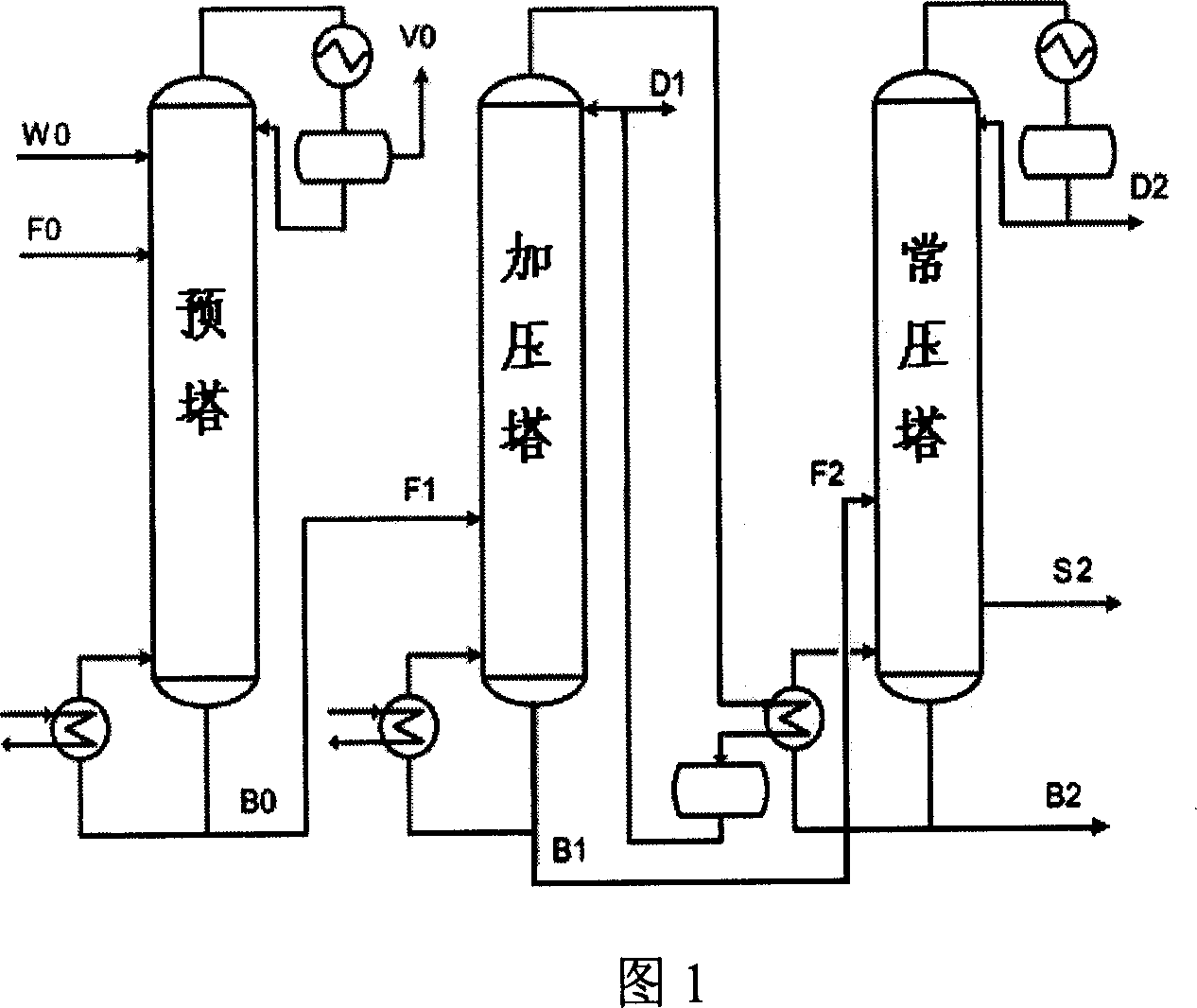

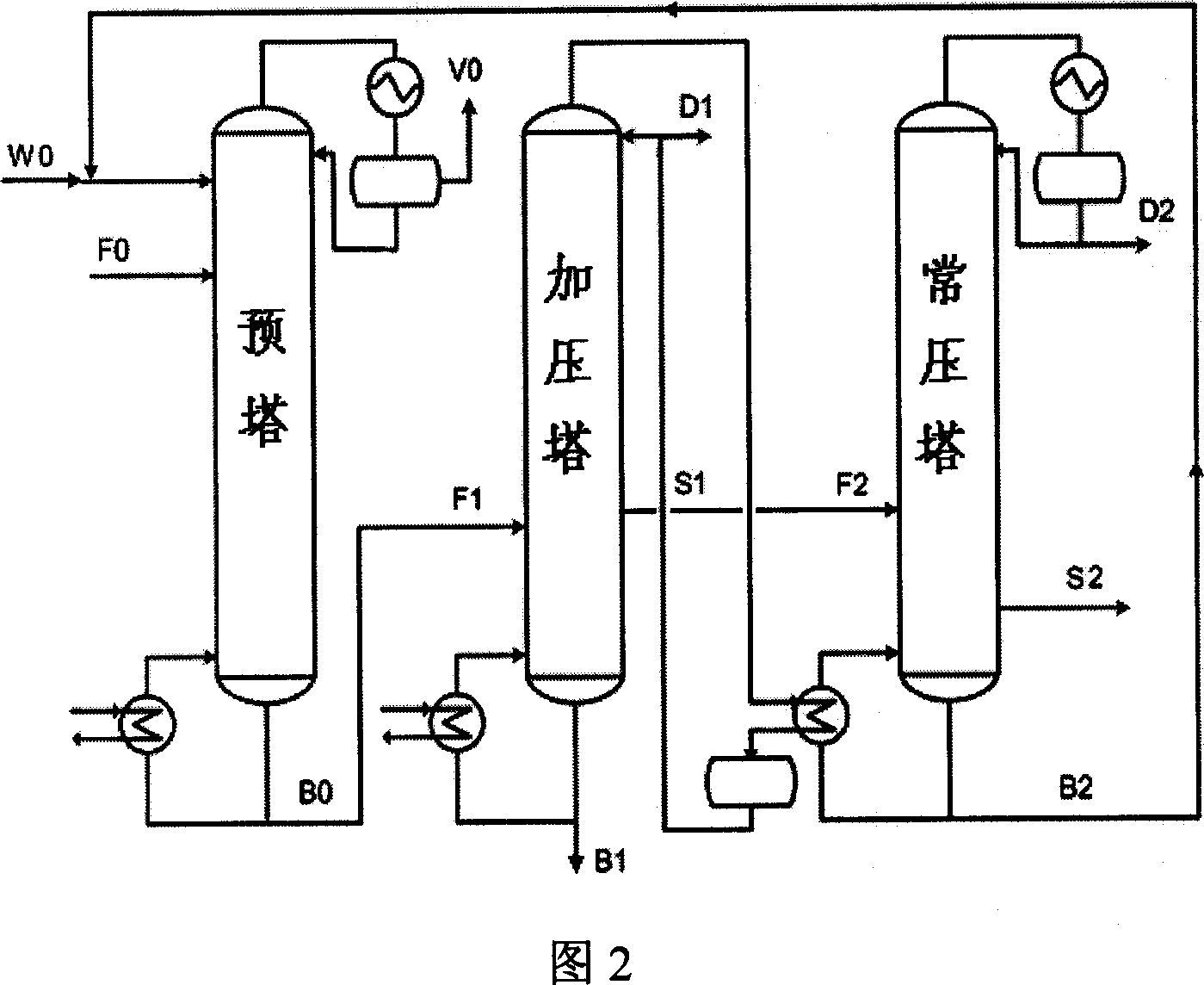

Rectifying and refining process of synthetic coarse methanol

InactiveCN1931807AIncrease feed concentrationReduce the amount of waterOrganic compound preparationHydroxy compound preparationAlcoholWastewater

The rectifying and refining process of synthetic coarse methanol includes the following steps: initial rectification of coarse methanol in a pre-rectifying tower with sodium hydroxide and extracting water fed from the tower top, and discharging the initially rectified methanol through the tower bottom while exhausting light impurity through the tower top; rectification in the pressurized tower and recovering rectified methanol from the tower top while exhausting waste water and discharging residual coarse methanol; rectification in the normal pressure tower and recovering rectified methanol while exhausting hetero alcohol oil from the side of the tower and returning industrial soft water from the tower bottom to the pre-rectifying tower. The present invention has low steam consumption and circular utilization of industrial soft water.

Owner:ZHEJIANG UNIV

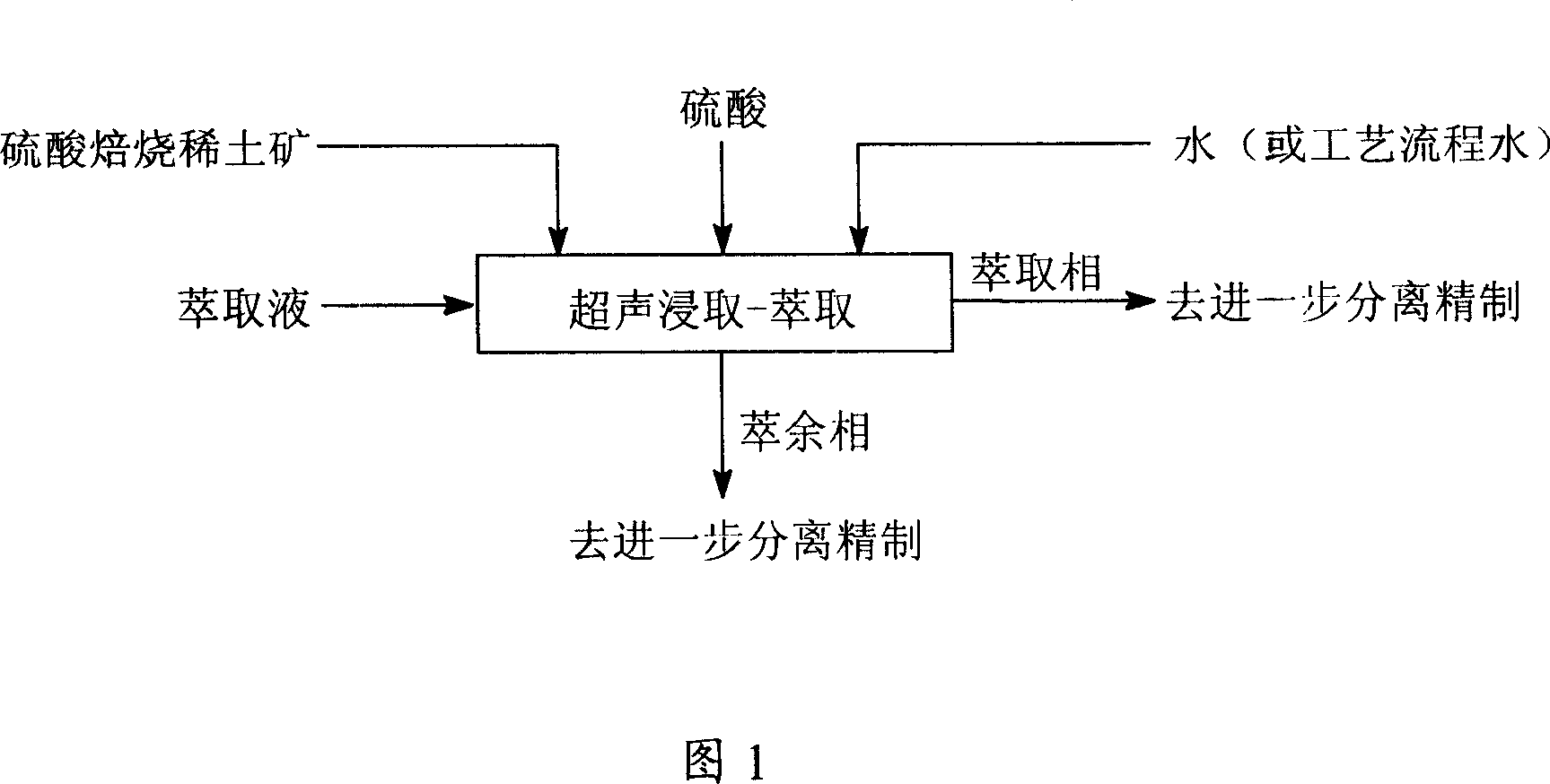

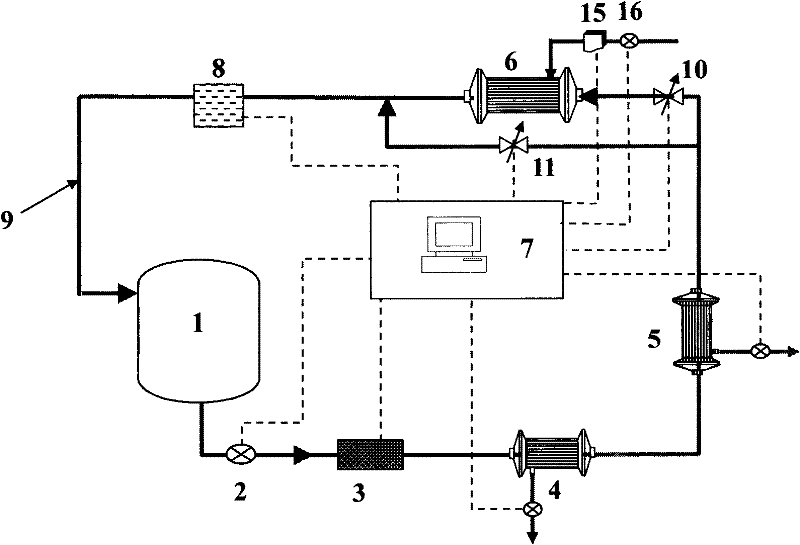

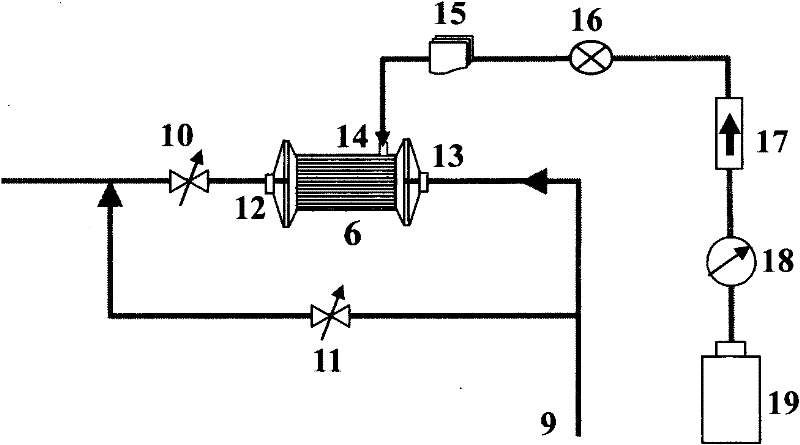

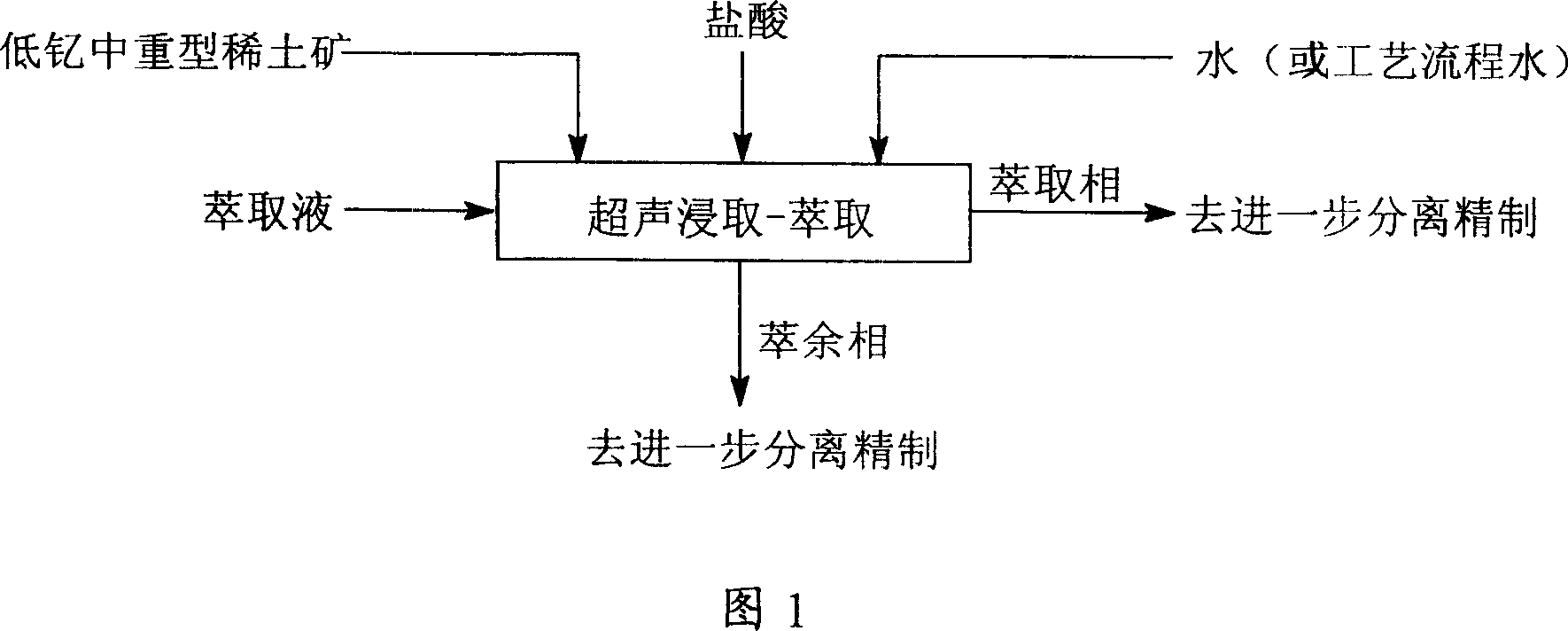

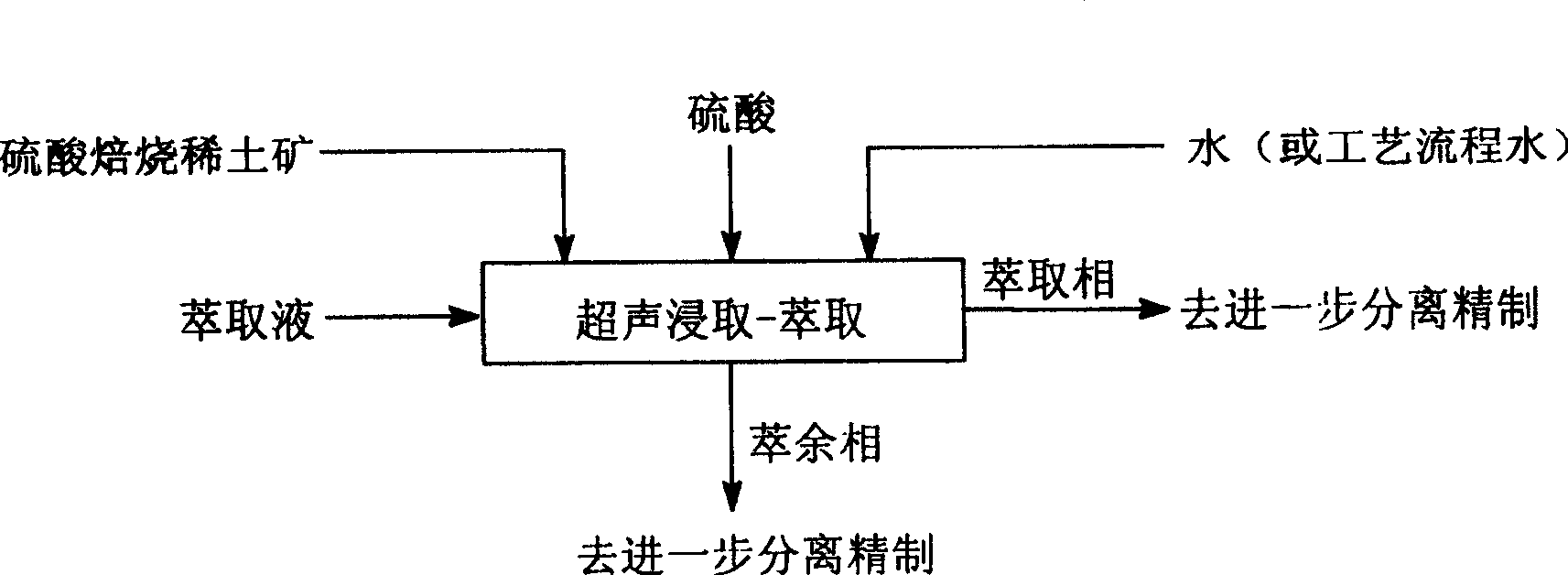

Ultrasonic leaching-extracting separation method for sulphating roasting rare earth mine

InactiveCN101012503AGood removal effectReduce processingProcess efficiency improvementRare-earth elementSulfate

The invention discloses an ultrasonic leaching-extracting separating method of rare earth ore sintered by sulfuric acid, which comprises the following steps: adopting sulfuric acid solution as leaching liquid; allocating extracting liquid through P204, P507 and kerosene; proceeding leaching-extracting separating operation for rare earth ore through ultrasound with strength at 0.2-20.0W / cm2 and frequency at 19-80kHz under 5-60 deg.c; obtaining the enriched product of middle heavy rare earth (yttrium group rare earth element) sulfate as extracting phase and light rare earth (cerium group rare earth element) sulfate as residual phase.

Owner:YANGZHOU UNIV +2

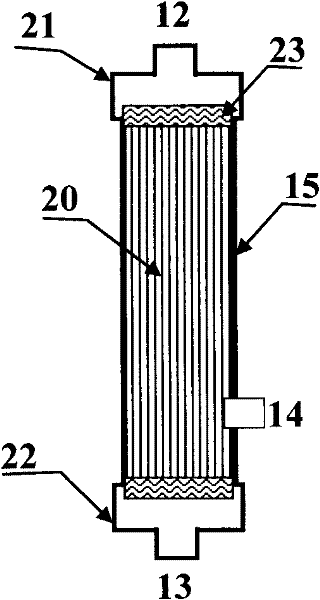

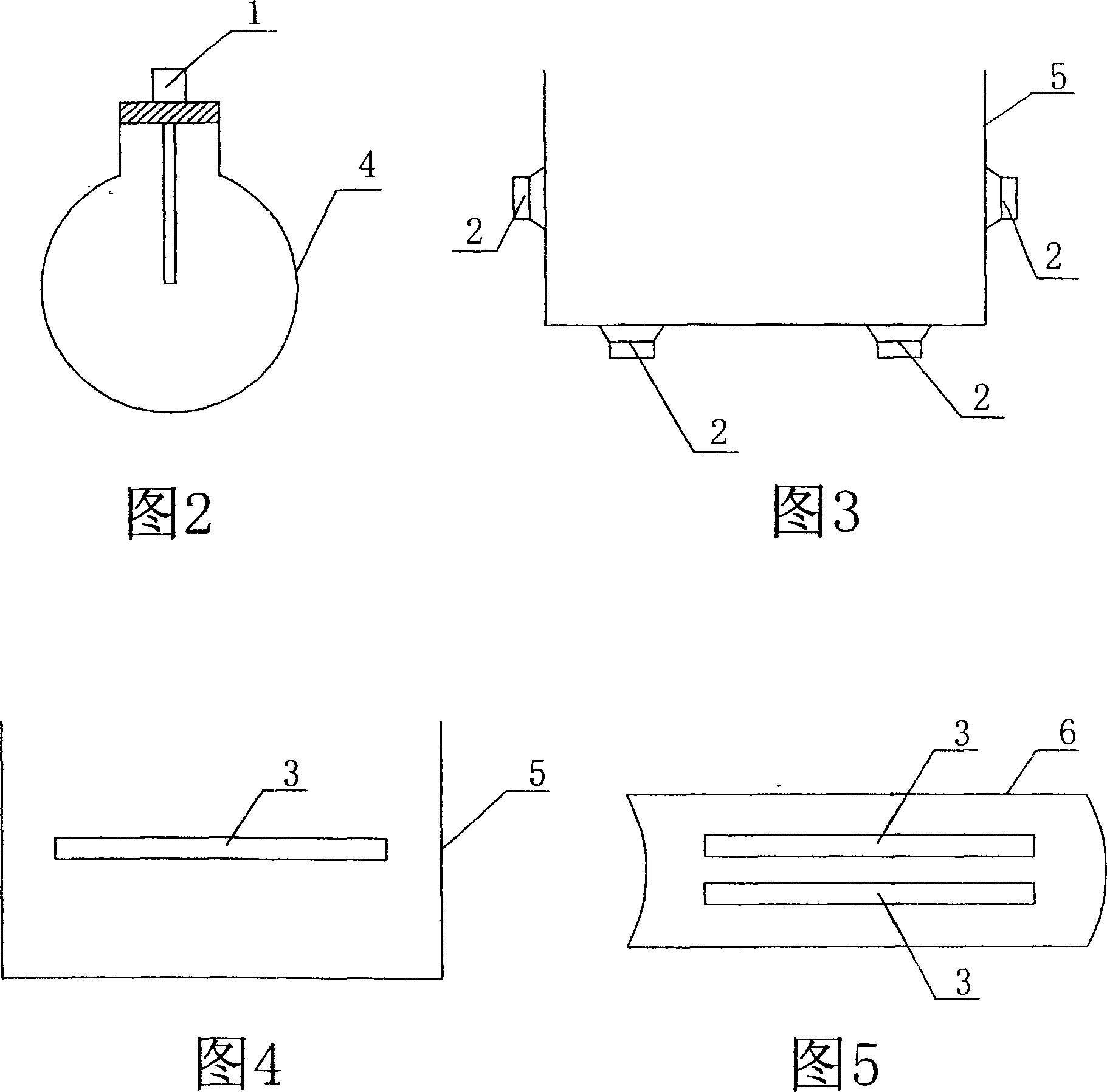

Oxygen supply device for space wastewater treatment

InactiveCN102241431AImprove permeabilityImprove absorption and utilizationTreatment using aerobic processesSustainable biological treatmentEpoxyYarn

The invention discloses an oxygen supply device for space wastewater treatment. The device is connected serially in a wastewater treating fluid circulation loop. The oxygen supply device mainly comprises an oxygen supply membrane module, a pressure sensor, an electromagnetic valve, a flowmeter, a relief valve and an oxygen storage bottle. Membrane yarns in the oxygen supply membrane module are prepared from a hydrophobic polyvinylidene fluoride (PVDF) material with high oxygen permeability; and the two ends of each membrane yarn are encapsulated at both ends of the shell of the oxygen supply membrane module by virtue of epoxy resin in bundles. Oxygen passes through micropores on the wall of a membrane pipe from the outside of the membrane yarns at a certain pressure and enters the wastewater treating fluid flowing through the membrane pipe so as to be absorbed and utilized by microorganisms. The oxygen supply mode is determined by the dissolved oxygen (DO) of the wastewater treating fluid and the gas presssure of the oxygen supply membrane module. The oxygen supply device is suitable for equipment used for treating wastewater with microorganisms under a future space condition and can also provide a new technical means for basic researches such as the research on the ground wastewater microorganism treatment characteristic.

Owner:中国人民解放军总装备部航天医学工程研究所

Solid-liquid separation device and solid-liquid separation method for slurry bed reactor

ActiveCN101733045BReduce separation loadReduce wearHydrocarbon from carbon oxidesFiltration circuitsProcess engineeringSlurry

Owner:CHINA PETROLEUM & CHEM CORP

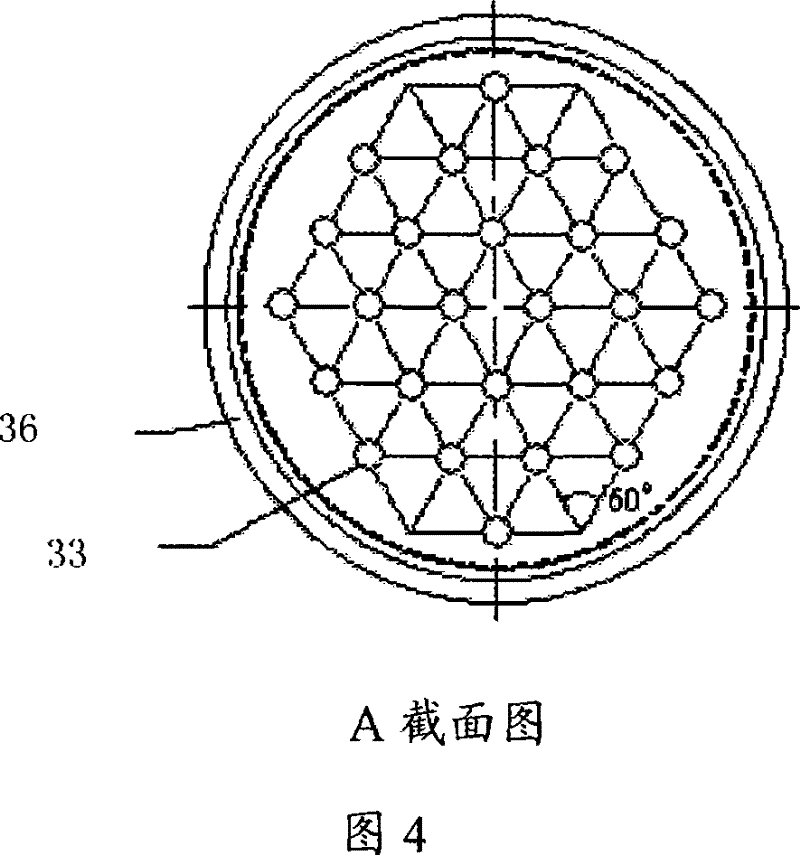

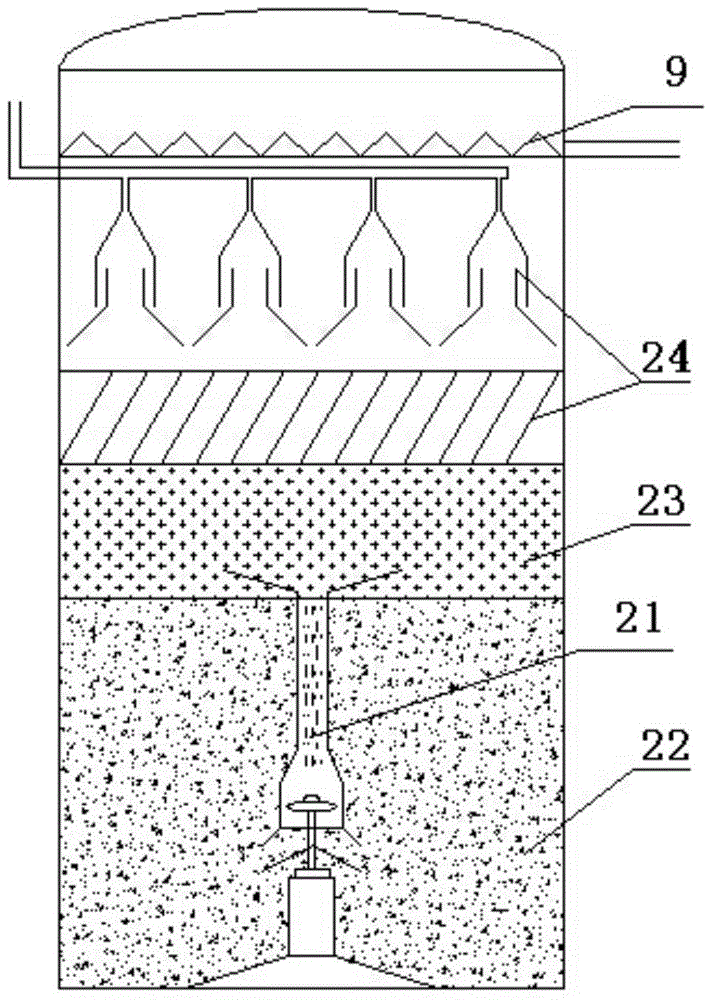

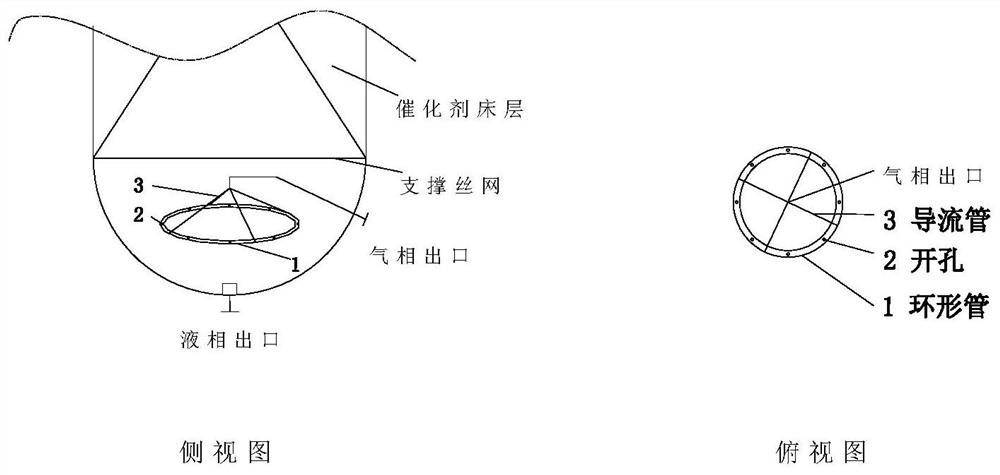

Slurry bed reactor and application of slurry bed reactor in producing hydrogen peroxide

ActiveCN105056845AInto the uniformControl temperature changesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesPtru catalystFluid phase

The invention discloses a slurry bed reactor. The slurry bed reactor comprises an ascension pipe, an expansion section, a cooler, a catalyst settler and a filter. The upper portion of the ascension pipe is connected with the expansion section, part of the ascension pipe extends into the expansion section, and the part, in the expansion section, of the ascension pipe is provided with a slurry return port communicated with a reaction chamber. The bottom of the ascension pipe is connected with the cooler, and the cooler and the ascension pipe are integrated. Materials are fed into the catalyst settler in a tangent mode from the middle portion, the upper portion of the catalyst settler is provided with a barrier with a certain height so as to form a standing region, the top of the catalyst settler is connected with a gas-liquid separation chamber through a balance pipe, and the bottom of the catalyst settler is connected with the cooler. The top of the filter is connected with the gas-liquid separation chamber through a balance pipe, the bottom of the filter is connected with the cooler, and the filter is provided with a back washing device. The lower portion of the ascension pipe is provided with a liquid-phase raw material inlet and a gas-liquid raw material inlet. The reaction chamber is formed in the ascension pipe, and a liquid feed distributor and a gas feed distributor are arranged at the bottom of the reaction chamber. The hydrogenation efficiency of 14-16 g / l of hydrogenated liquid is achieved.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

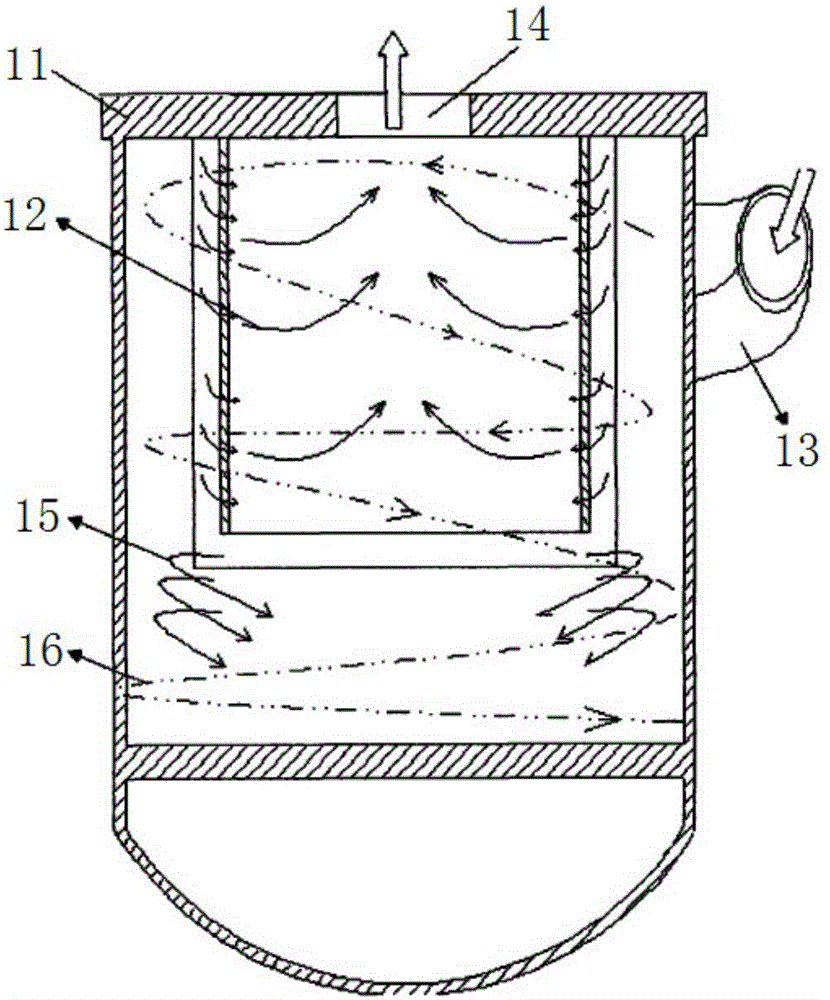

Mechanical internal circulation jet-flow anaerobic reactor and wastewater treatment method thereof

ActiveCN104445605AChange cloth waterChange the way of beingTreatment with anaerobic digestion processesHigh concentrationFluidized bed

The invention discloses a mechanical internal circulation jet-flow anaerobic reactor and a wastewater treatment method thereof, and belongs to the technical field of biological sewage treatment. The mechanical internal circulation jet-flow anaerobic reactor comprises a reactor tank body, a multi-phase separator, a water outlet weir and an internal circulation jet-flow device, wherein the internal circulation jet-flow device comprises an upper part and a lower part; the upper part comprises a jet-flow hole, a diffusion hole, a flow guide pipe and a flow stabilization hole; the lower part comprises a motor, a rotary shaft and high-speed blades. The wastewater treatment method comprises the following steps: forming a fluidized bed layer, forming a suspended bed layer, separating a separation region and discharging water from the water outlet weir. Due to the use of the internal circulation jet-flow device, the difficult problems of low treatment load, instable effect and relatively narrow application range in the treatment process of an existing conventional anaerobic reactor are solved; the mechanical internal circulation jet-flow anaerobic reactor has the advantages of high treatment load, good water impact resistance, high concentration of biological toxicity resistance matters, quick starting and the like.

Owner:NANJING UNIV

Arrangement method of catalytic cracking tetra-cyclone separator

InactiveCN106492570AExtended service lifeReduce particle concentrationCombination devicesCycloneFlue gas

The invention discloses an arrangement method of a catalytic cracking tetra-cyclone separator (referred to as a tetra-cyclone). The tetra-cyclone separator system mainly comprises a tertiary cyclone discharge pipe, a material storage tank, a tetra-cyclone gas inlet pipe and a tetra-cyclone. A dilute phase space at the upper part of the material storage tank is provided with a vertical partition plate. The vertical partition plate divides the dilute phase space of the material storage tank into an inertial separation zone and a sedimentation separation zone. Dust-containing flue gas in the tertiary cyclone discharge pipe is introduced from the top of the inertial separation zone, passes through the inertial separation zone and the sedimentation separation zone and then enters the tetra-cyclone through the tetra-cyclone gas inlet pipe at the top of the sedimentation separation zone. Gas subjected to dedusting in the tetra-cyclone enters a downstream critical nozzle. Solid particles separated by the tetra-cyclone enter a bottom material layer of the material storage tank along a dipleg. The inertial separation zone realizes gas and solid separation through difference of gas and solid particles. The sedimentation separation zone realizes gas-solid separation by a lower section gas velocity. Through the above two kinds of particle pre-separation measures, a particle concentration at the inlet of the tetra-cyclone and separation load are reduced. A gas-locking device is arranged at a tetra-cyclone dipleg particle outlet so that backflow of gas in the dipleg is prevented and smooth delivery of particles in the dipleg is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A continuous rectification separation method and equipment for a propylene carbonate crude product

ActiveCN106916135AReasonable distributionReduce distributionOrganic chemistryFractional distillationRefluxFiltration

The invention relates to a continuous rectification separation method and equipment for a propylene carbonate crude product. According to a technical scheme, the propylene carbonate crude product is fed into the middle part of a propylene carbonate rectifying column; the inner cavity of the propylene carbonate rectifying column is provided with a reflux distributor, a plurality of rhombic reaction promoting units, a feed distributor and a plurality of liquid stripping filtration disks from top to bottom; the outside of the propylene carbonate rectifying column is connected to a rectifying column overhead condenser, an A discharging line condenser, a B discharging line condenser and a rectifying column bottom reboiler respectively; the crude product is fed from the middle part of the rectifying column and subjected to sufficient gas-liquid material exchange under negative pressure and heating conditions in the column, thus achieving separation of high-purity propylene carbonate from other impurities; and the high-purity propylene carbonate product is distilled out from a product side line. The method and the equipment are advantageous in that the feeding point is at the middle of the column, amounts of rising gas and descending liquid in rectification and stripping sections are distributed more reasonably, the separating efficiency is increased, operation is simple and stable, product purity is high, and battery-grade purity requirements on the propylene carbonate are met.

Owner:DONGGUAN UPC IND & TRADE +1

Splitting type three-stage oil and gas separating device of gas compressor

InactiveCN105771521AHigh filtration precisionImprove running stabilityCombination devicesSeparation technologyThree stage

The invention discloses a splitting type three-stage oil and gas separating device of a gas compressor, and belongs to the technical field of oil and gas separating. The splitting type three-stage oil and gas separating device comprises a first oil and gas bucket, a second oil and gas bucket and a flow mixing assembly, wherein a gas outlet of the first oil and gas bucket and a gas inlet of the second oil and gas bucket are communicated by an oil and gas pipeline; the first oil and gas bucket comprises a first cylinder, a first gas inlet, a first gas inlet protecting plate and a first oil return pipe; the second oil and gas bucket comprises a second cylinder, an oil separating core, a second gas inlet protecting plate and a second oil return pipe; the flow mixing assembly is connected with the first oil return pipe and the second oil return pipe respectively, and is used for adjusting the flow rate of the second oil return pipe. The splitting type three-stage oil and gas separating device has the advantages that the three-stage separating of mixing gas is realized by the first oil and gas bucket and the second oil and gas bucket, the first oil and gas bucket is used as an oil storage part, and the second oil and gas bucket is used as a separating part of the oil separating core, and is also used as a buffer gas tank, so that the filtering accuracy and operational stability of the gas compressor are further improved; the size is smaller, the layout of the gas compressor is easy, and the installation and maintenance are more convenient and rapid.

Owner:釜玛机械(江苏)有限公司

Method for upgrading coal pyrolysis

ActiveCN101608125BAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalFlue gasGranularity

The invention provides a method for upgrading coal pyrolysis, comprising the following steps: (a) sending raw coal with granularity being less than and equal to 30mm into a rotary drier, so that the raw coal and hot flue gas are connected with each other by the means of parallel flow and directly change heat, and the raw coal exchanges heat indirectly with hot semicoke from a pyrolyzer in the rotary drier, to dry the raw coal; (b) mixing the dried raw coal with the high-temperature semicoke from a heating rotary kiln and sending the mixture into the pyrolyzer, wherein the coal material directly changes heat with the high-temperature semicoke and pyrolyzes to generate hot semicoke, tar steam and coal gas, wherein final pyrolyzing temperature is 500 DEG C-700 DEG C; and (c) sending a part of the hot semicoke generated into the heating rotary kiln for processing by means of heating, and sending the rest part of the hot semicoke into the rotary drier for exchanging heat directly with the raw coal. The method for upgrading coal pyrolysis has flexible operation, wide granularity range of the coal material, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

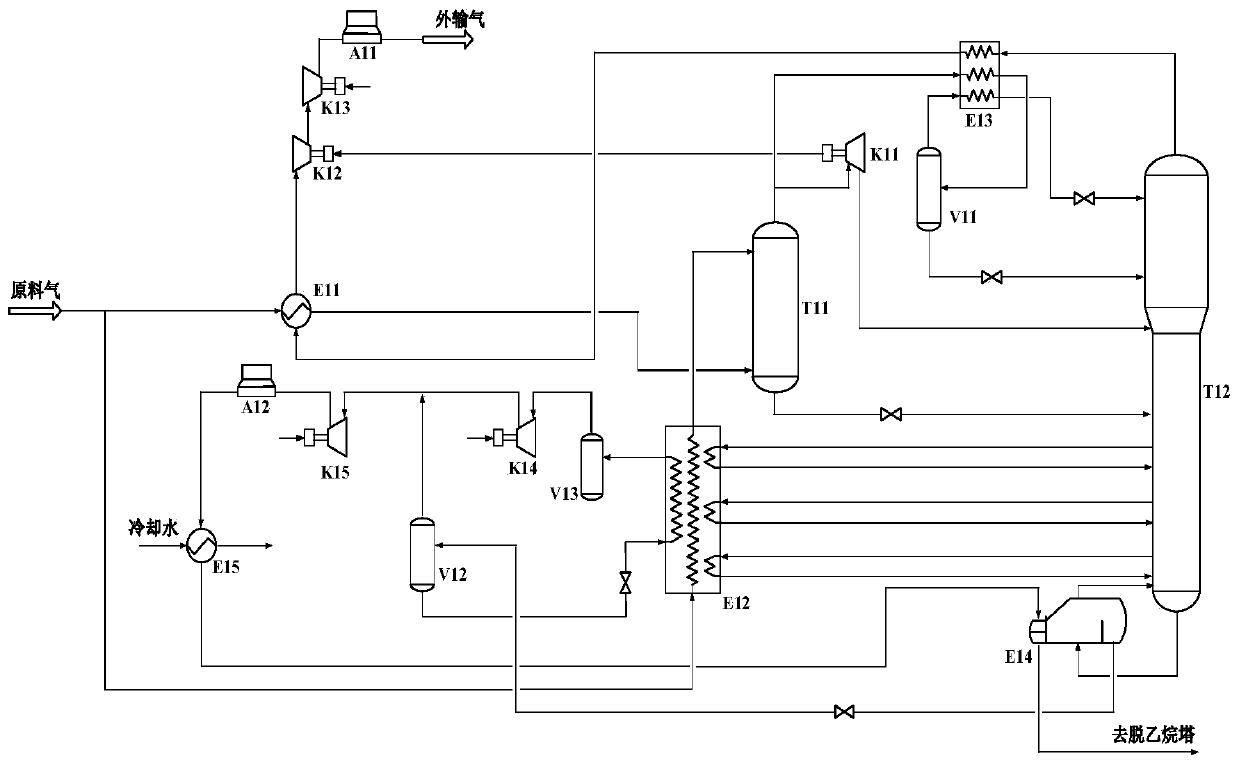

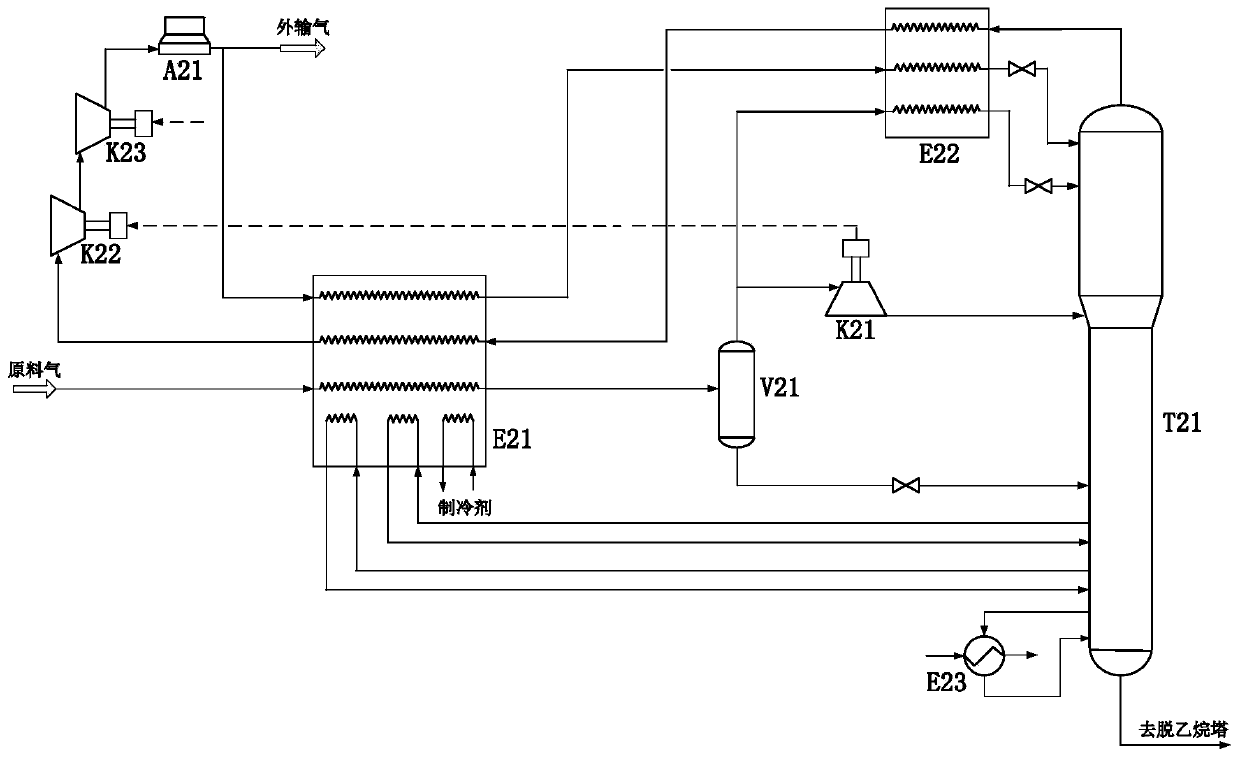

Ethane recycling method applied to rich gas and with self-cooling circulation

The invention discloses an ethane recycling method applied to rich gas and with self-cooling circulation, and relates to the technical field of natural gas treatment technologies. The raw gas is divided into two strands in an inlet, one strand is cooled through a pipe-shell heat exchanger and enters the bottom of an absorption tower, the other strand is cooled in a first cooling box and enters thetop of the absorption tower, a liquid-phase discharged material at the tower bottom of the absorption tower enters the middle of a demethanation tower, and a gas-phase discharged material at the tower top of the absorption tower enters a turbo expander and a second cooling box; and three strands of liquid-phase material is extracted from the side line of the lower part of the demethanation towerand enters the first cooling box for reheating to pre-cool the raw gas, the tower bottom condensation liquid of the demethanation tower is used as a mixture refrigerant of the self-cooling circulationto provide the cooling capacity for the first cooling box. By means of the ethane recycling method, the tower bottom condensation liquid of the demethanation tower is used as a mixture refrigerant inthe self-cooling circulation, the lower refrigerating temperature level can be provided, the process thermal integration degree is improved, higher ethane recycling under the rich gas condition is ensured, meanwhile, compared with a conventional ethane recycling process, the outer conveyed dry gas reflux is eliminated, and the power consumption of an outer conveying compressor can be significantly reduced.

Owner:SOUTHWEST PETROLEUM UNIV

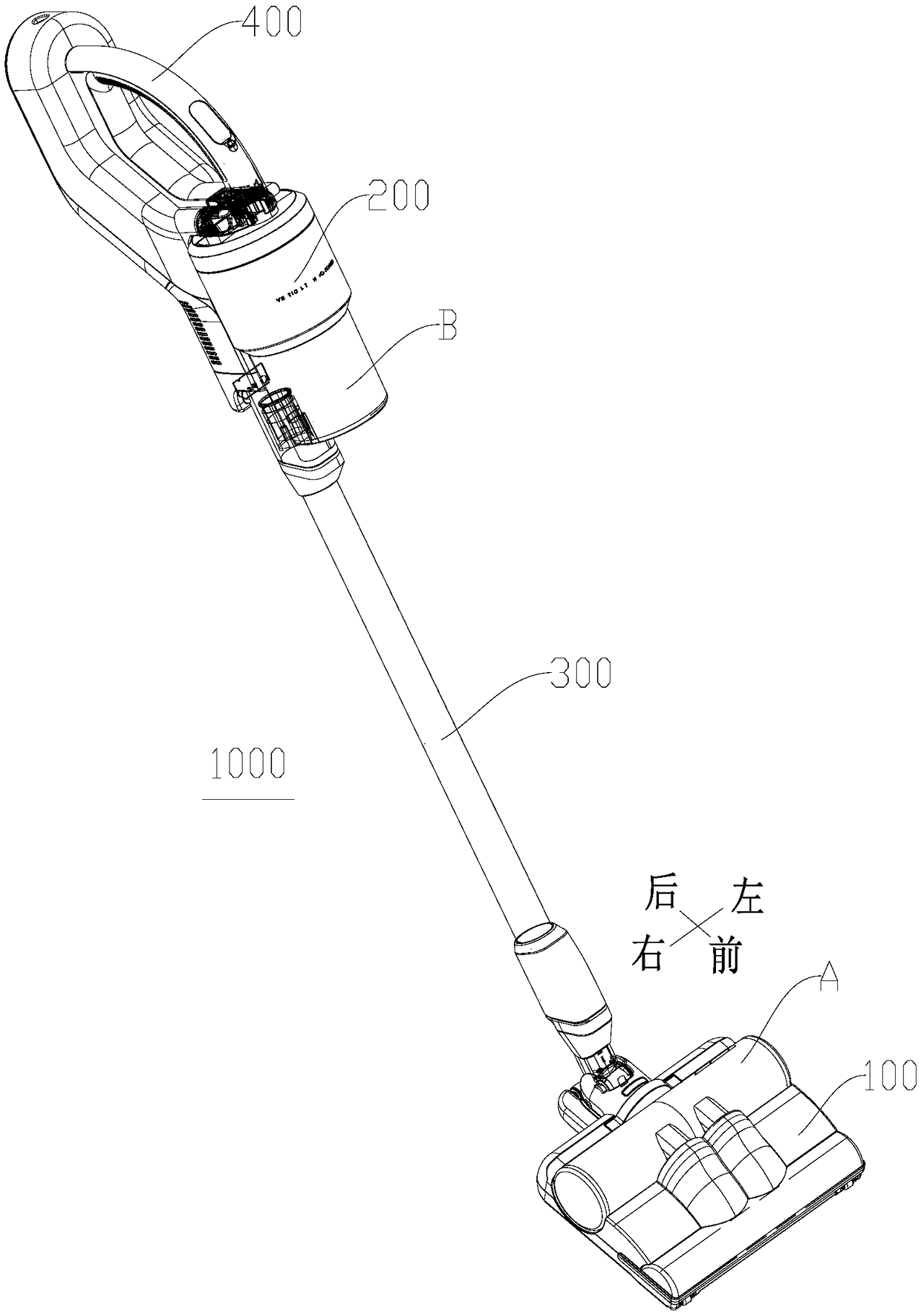

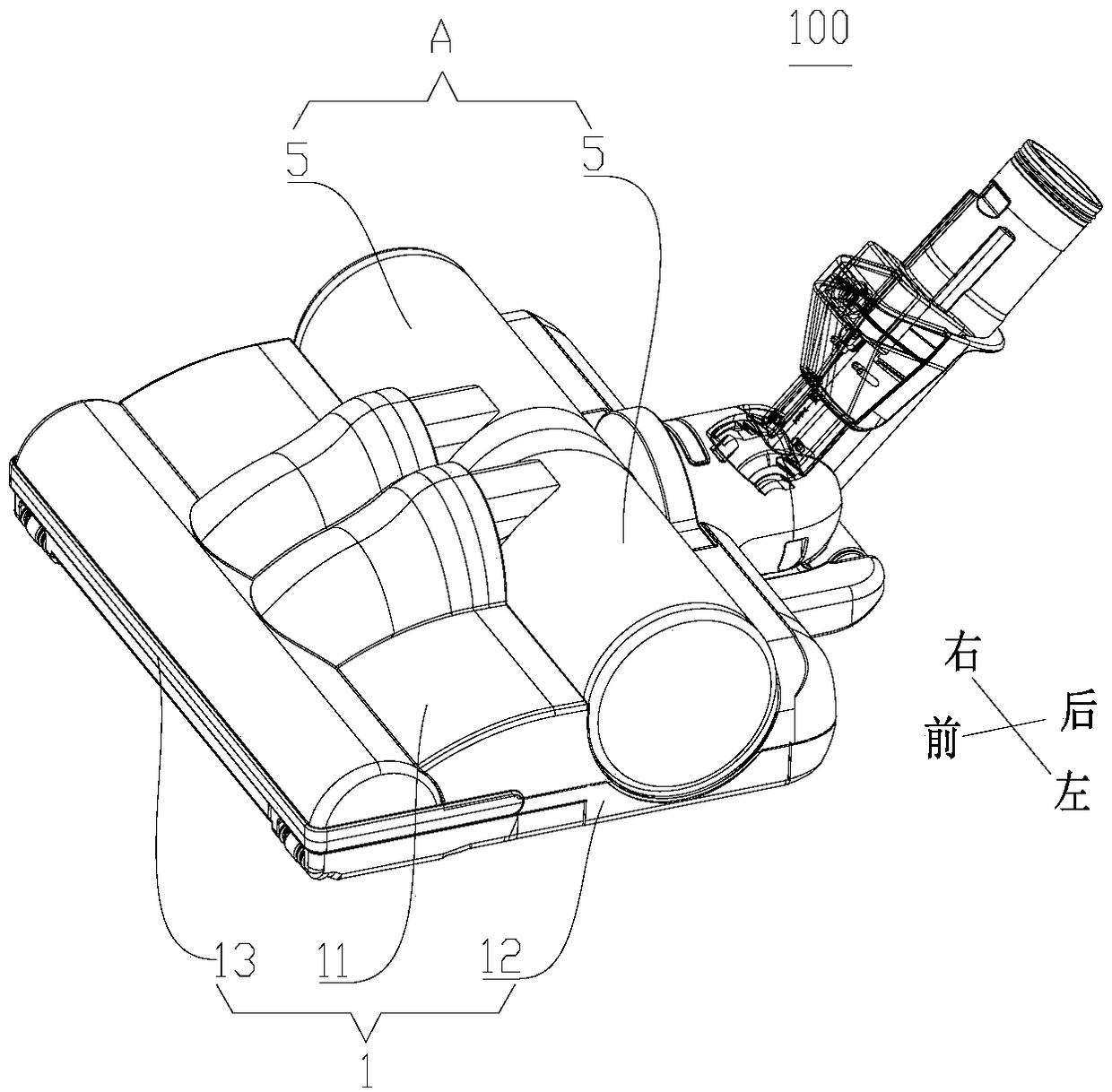

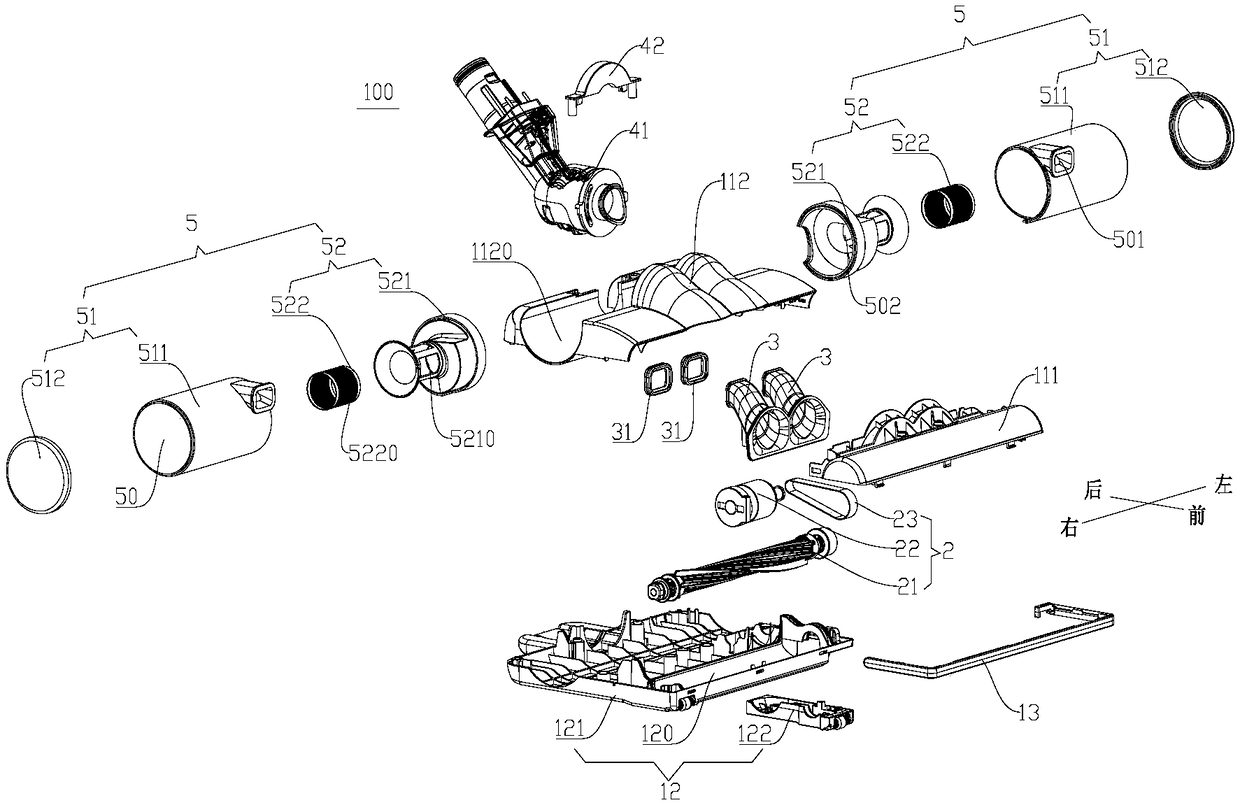

Handheld cleaning device

InactiveCN108606717AReduce separation loadReduce dust collection spaceSuction filtersAirflowCyclonic separation

The invention discloses a handheld cleaning device, comprising a floor brush component and a body component. The floor brush component comprises a dirty air inlet and a first cyclone separator; an airinlet of the first cyclone separator is in fluid communication with the dirty air inlet; the body component is movably connected with the floor brush component; the body component includes a second cyclone separator; an air inlet of the second cyclone separator is in fluid communication with an air outlet of the first cyclone separator such that an air flow separated by the first cyclone separator runs to the second cyclone separator for secondary separation. The handheld cleaning device according to the invention has the advantages that since the floor brush component has the first cyclone separator capable of pretreating an air flow, separation load can be relieved for the second cyclone separator of the body component, dust collection space required by the second cyclone separator is downsized, the second cyclone separator has less structural complexity, lower cost and reduced weight, and the problems are solved that, for instance, the second cyclone separator experiences flow choking.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

Ultrasonic leaching-extracting separation method for low-yttrium middle-heavy rare earth mine

InactiveCN101012513AIncrease concentrationShort processProcess efficiency improvementRare-earth elementKerosene

The invention discloses an ultrasonic leaching-extracting separating method of low-yttrium middle-heavy typed rare earth ore, which is characterized by the following: adopting low-yttrium middle-heavy typed rare earth ore as raw material and alcaine solution as leaching liquid; blending P507 or P204 and kerosene as extracting liquid; leaching low-yttrium middle-heavy typed rare earth ore to extract and separate at 5-60 deg.c; setting the ultrasonic frequency at 19-80kHz and ultrasonic strength at 0.2-20.0W / cm2; obtaining yttrium rare earth element hydrochlorate enriched material as extracting phase and cerium group rare earth hydrochlorate enriched material as residual phases.

Owner:YANGZHOU UNIV +2

Method for synthesizing cinnamyl alcohol by selective hydrogenation of cinnamyl aldehyde

ActiveCN111116311AHigh selectivityContinuous responseMolecular sieve catalystsOrganic compound preparationPtru catalystFixed bed

The invention discloses a method for synthesizing cinnamyl alcohol through selective hydrogenation of cinnamyl aldehyde. A tubular reactor is adopted, a small-particle solid special catalyst is arranged in the tubular reactor, the cinnamyl aldehyde and hydrogen are used as reaction raw materials, and the cinnamyl alcohol is synthesized by catalyzing the cinnamyl aldehyde to be selectively hydrogenated under the conditions that the reaction temperature is 50-120 DEG C and the reaction pressure of hydrogen is 0.5-5.0 MPa. Compared with the traditional kettle type, fixed bed and trickle bed reactors, the method provided by the method can obtain higher cinnamyl alcohol selectivity, cinnamyl alcohol yield and stability, and has better economic benefits.

Owner:NANJING POLYTECHNIC INSITUTE

Variable pressure absorption separation system and method for supercritical water gasification hydrogen-making gas-phase product

ActiveCN111217332AReduce separation loadNo lossHydrogen separation by selective and reversible uptakeProductsFluid phaseEngineering

The invention discloses a variable pressure absorption separation system for a supercritical water gasification hydrogen-making gas-phase product. An outlet of a supercritical water gasification reactor is connected to a hot fluid side inlet of a heat exchanger, a hot fluid side outlet of the heat exchanger is connected to an inlet of a three-phase separator, reaction materials enter the supercritical water gasification reactor along a cold fluid side of the heat exchanger, a liquid phase outlet and a solid phase outlet of the three-phase separator are connected to a subsequent unit, a gas phase outlet is connected to an inlet of a pressure regulator, an outlet of the pressure regulator is connected to an inlet of a high-pressure water absorber 1, a gas phase outlet of the high-pressure water absorber 1 is divided into two paths after passing through a gas path valve 1 and a gas pressure reducing valve in sequence, one path is connected to a high-purity H pipeline through a gas path valve 2, the other path is connected to an inlet of a depth separator through a gas path valve 3, and a liquid phase outlet of the high-pressure water absorber 1 is connected to an inlet of a CO2 resolver through a liquid pressure reducing valve, and a liquid phase outlet of the CO2 resolver is connected back to the high-pressure water absorber 1 through a waterway valve 1. According to the invention, step-by-step variable-pressure absorption and separation of a gas phase product can be realized under a high-pressure condition, and the energy utilization efficiency is improved.

Owner:XI AN JIAOTONG UNIV

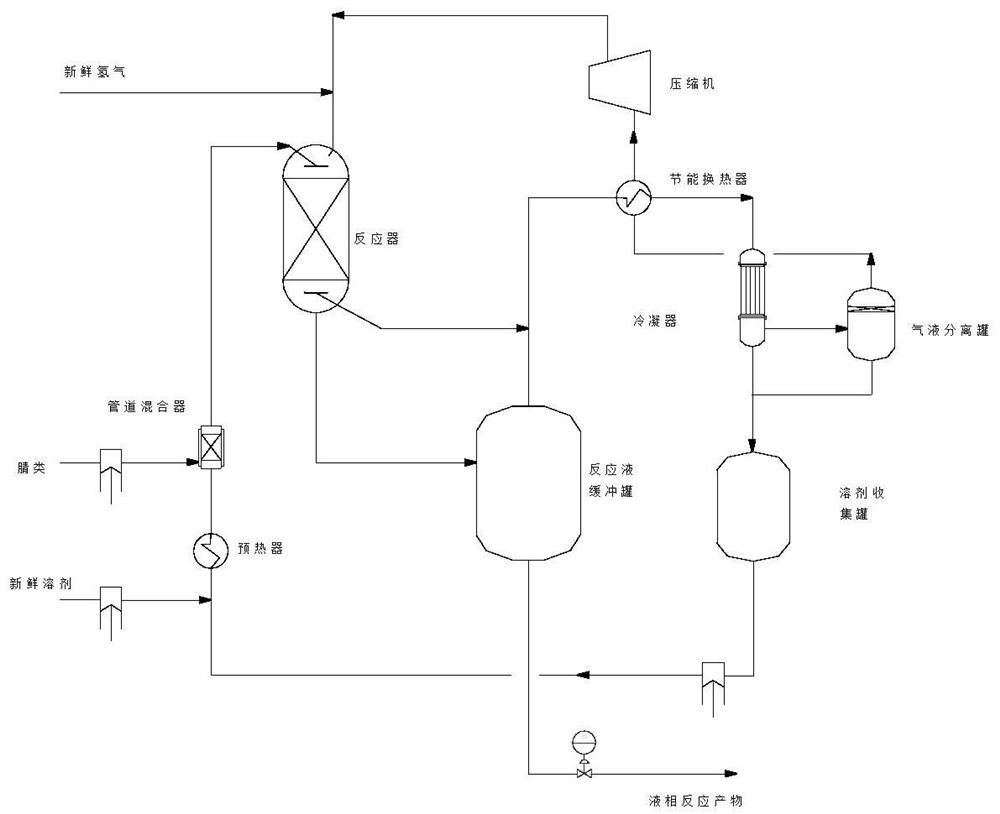

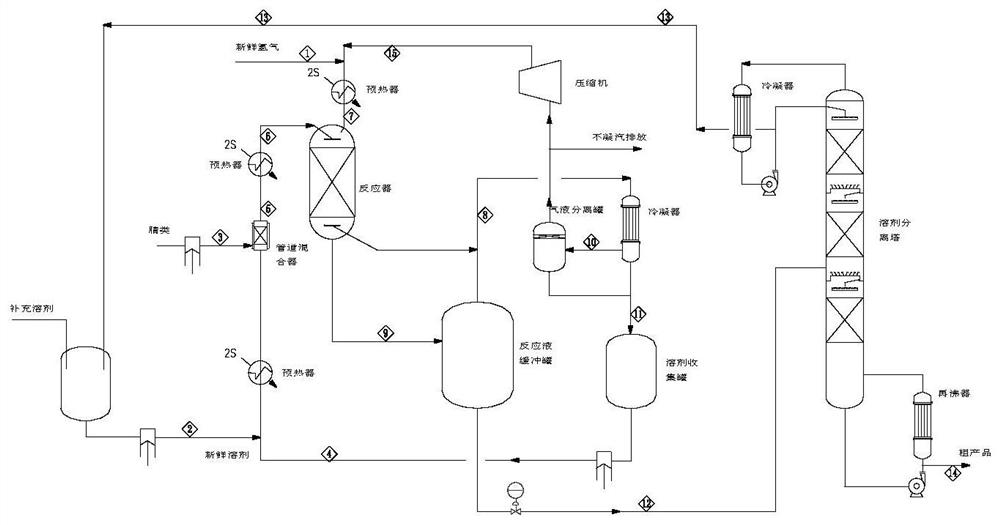

Energy-saving method for preparing amine compound by continuous hydrogenation of nitrile compound

PendingCN112538020AIncrease buffer timeImprove conversion rateAmino compound purification/separationOrganic compound preparationFluid phaseOrganosolv

The invention relates to an energy-saving method for preparing an amine compound by continuous hydrogenation of a nitrile compound. The method comprises the following steps: 1) mixing a nitrile compound with an ammonia-containing organic solvent, feeding the mixture into a reactor filled with a catalyst, introducing hydrogen at the same time, and carrying out a hydrogenation reaction in a catalystfilling layer; 2) separating the material after the hydrogenation reaction in the step 1) into a gas phase and a liquid phase, and then separately leading the gas phase and the liquid phase out of the reactor; (3) separating the gas phase led out of the reactor in the step (2) to recover the ammonia-containing organic solvent, then replacing part of a fresh ammonia-containing organic solvent in the step (1) with the recovered ammonia-containing organic solvent, mixing the ammonia-containing organic solvent with the nitrile compound, and then circulating the mixture back to the reactor; and 4)removing the solvent from the liquid phase led out of the reactor in the step 2) to obtain the amine compound. According to the method, the solvent separation load is reduced by 40% or more on the basis of maintaining high conversion rate of raw materials and high selectivity of products, and the production energy consumption and equipment investment are greatly reduced.

Owner:WANHUA CHEM GRP CO LTD

Device for improving quality of coal by pyrolysis

ActiveCN101608126BAvoid enteringReduce separation loadDirect heating destructive distillationOven incrustations prevention/removalGranularityFlue gas

The invention provides a device for improving the quality of the coal by pyrolysis, comprising a rotary drier, a pyrolyzer and a heating rotary kiln. The rotary drier is used for receiving and drying raw coal with granularity being less than and equal to 30mm, and is provided with a sleeve structure to directly change heat between the raw coal and the hot flue gas and indirectly change heat between the raw coal and hot semicoke; the pyrolyzer receives mixture of the dried raw coal and the high-temperature semicoke by a feed line of solid material, directly changes heat between the raw coal and the hot semicoke, pyrolyzes the mixture, and is further provided with a heat clamping sleeve accompanied with high-temperature flue gas; and the heating rotary kiln is used for receiving the hot semicoke from the pyrolyzer and processing the hot semicoke by the means of heating. The device for improving the quality of the coal by pyrolysis has flexible operation, good quality of the generated semicoke and the generated tar, high cascade utilization of energy and high system thermal efficiency, properly solving the technical problems such as dust and tar blocking, high dust content in the tar, etc.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

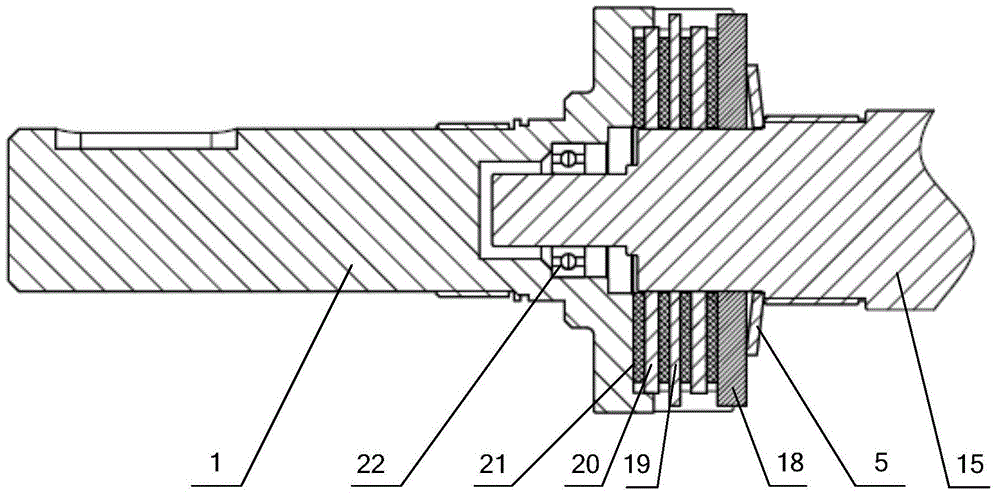

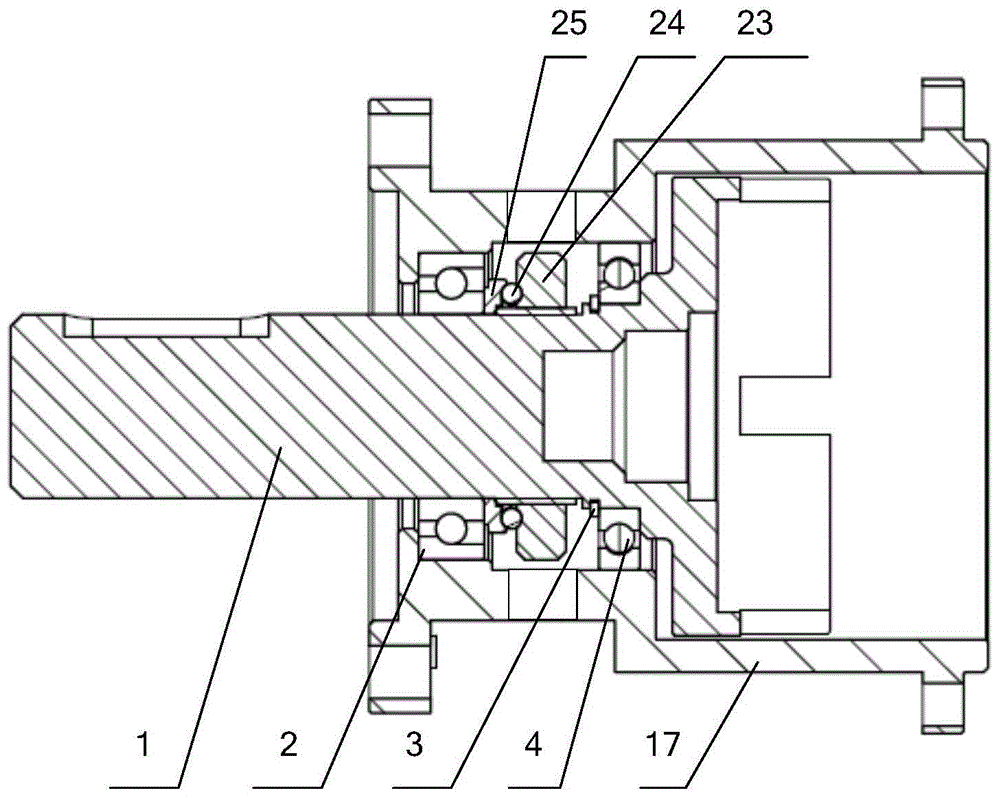

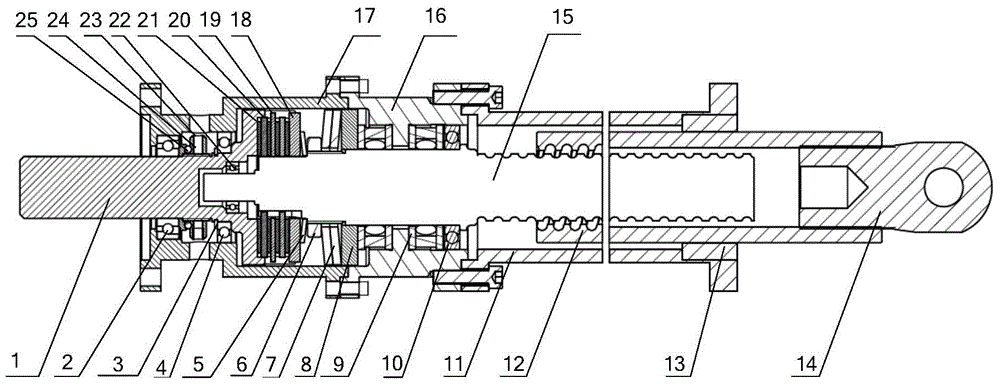

Axial tension safe clutch for large load

InactiveCN104632933ADisengagement process safetyAct as overload protectionAutomatic clutchesClutchEngineering

The invention provides an axial tension safe clutch for large load. The axial tension safe clutch for the large load comprises a shell, an input shaft, a lead screw, a friction engaging and disengaging mechanism, a reset pre-tightening adjusting mechanism and a lead screw nut matched with the lead screw, wherein the input shaft and the lead screw penetrate through the shell to be arranged in a rotating mode, the friction engaging and disengaging mechanism is used for transmission between the input shaft and the lead screw, and the reset pre-tightening adjusting mechanism is arranged on the input shaft. The friction engaging and disengaging mechanism comprises an input friction disc axially fixed to the input shaft, an output friction disc axially fixed to the lead screw, and a reset spring arranged between the lead screw and the output friction disc. The reset pre-tightening adjusting mechanism comprises a reset locking nut fixed at the axial position and is arranged on the input shaft through threaded connection. When the driving tension load of the input shaft or the lead screw is smaller than the corresponding separation load, the input friction disc and the output friction disc rotate synchronously under the effect of the pre-tightening force. When the driving tension load of the input shaft or the lead screw is not smaller than the corresponding separation load, the input friction disc and the output friction disc slip.

Owner:NO 771 INST OF NO 9 RES INST CHINA AEROSPACE SCI & TECH

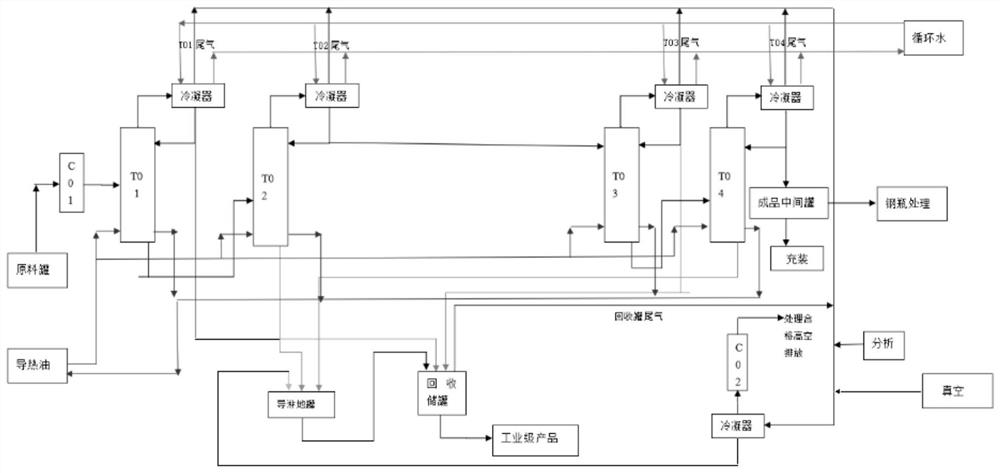

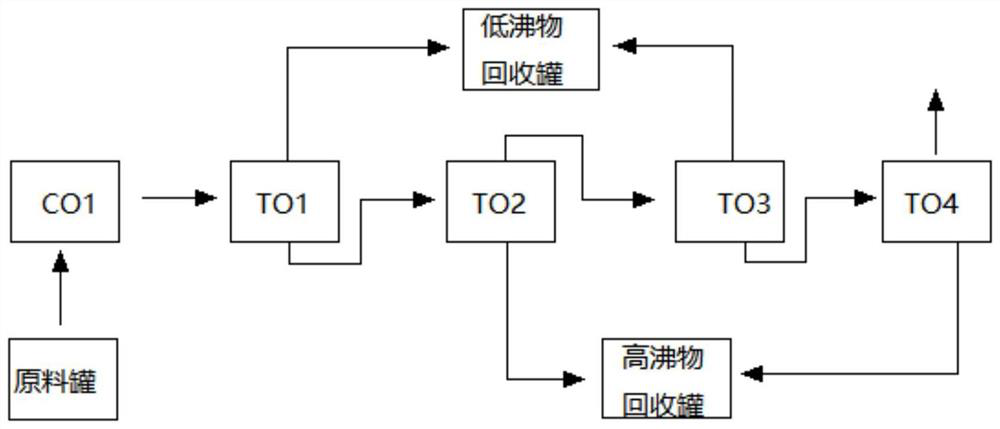

Purification method and purification system of electronic-grade tetraethoxysilane

PendingCN113292588AReduce separation loadReduce complexitySilicon organic compoundsEthyl esterDiethyl ether

The invention discloses a purification method and a purification system of electronic-grade tetraethoxysilane. The purification method comprises the following steps: S100) carrying out nitrogen filling; S200) carrying out adsorption operation on a crude tetraethoxysilane crude product to obtain a product of which impurities are preliminarily removed; and S300) carrying out a multi-tower continuous rectification process on the product from which the impurities are preliminarily removed to obtain the electronic-grade tetraethoxysilane, by adopting an adsorption column and a multi-tower continuous rectification process, component impurities such as silicon tetrachloride, ethanol, diethyl ether and monomethoxytriethoxysilane are separated, and various metal impurities are removed, so that the electronic-grade tetraethoxysilane product is obtained; and the adsorption column is arranged at the front section of a rectification tower, so that part of metal ions can be removed, the separation load of the rectification tower is greatly reduced, and the complexity of the system is reduced.

Owner:SUZHOU JINHONG GAS CO LTD

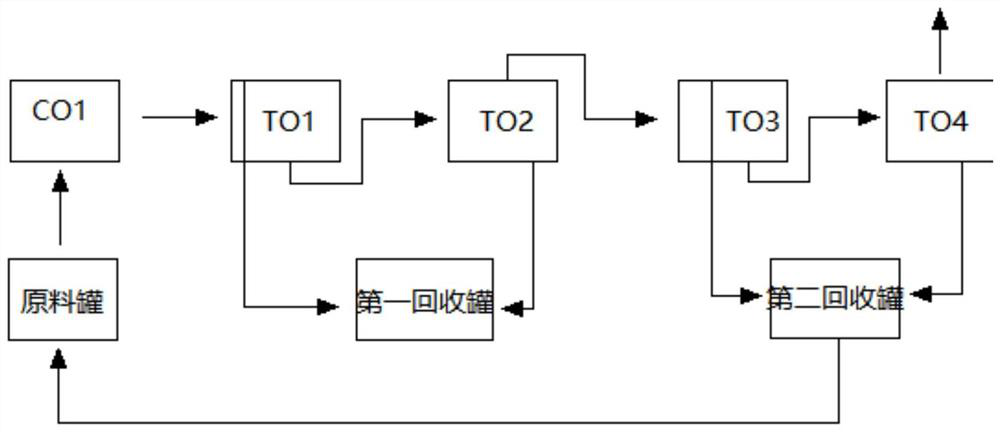

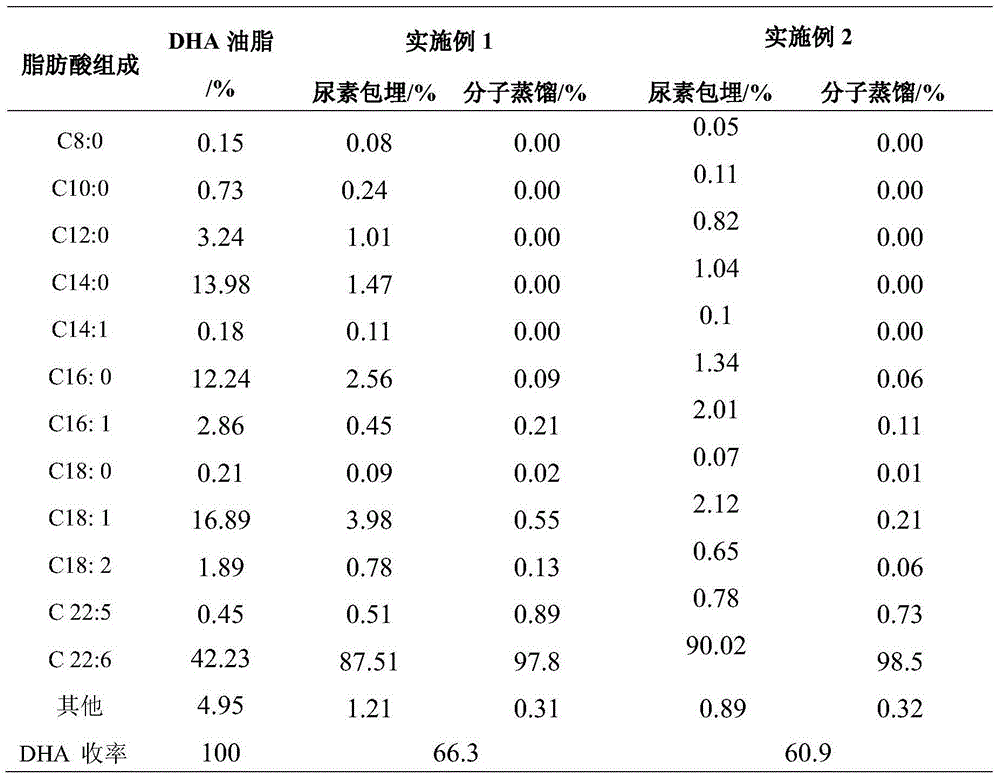

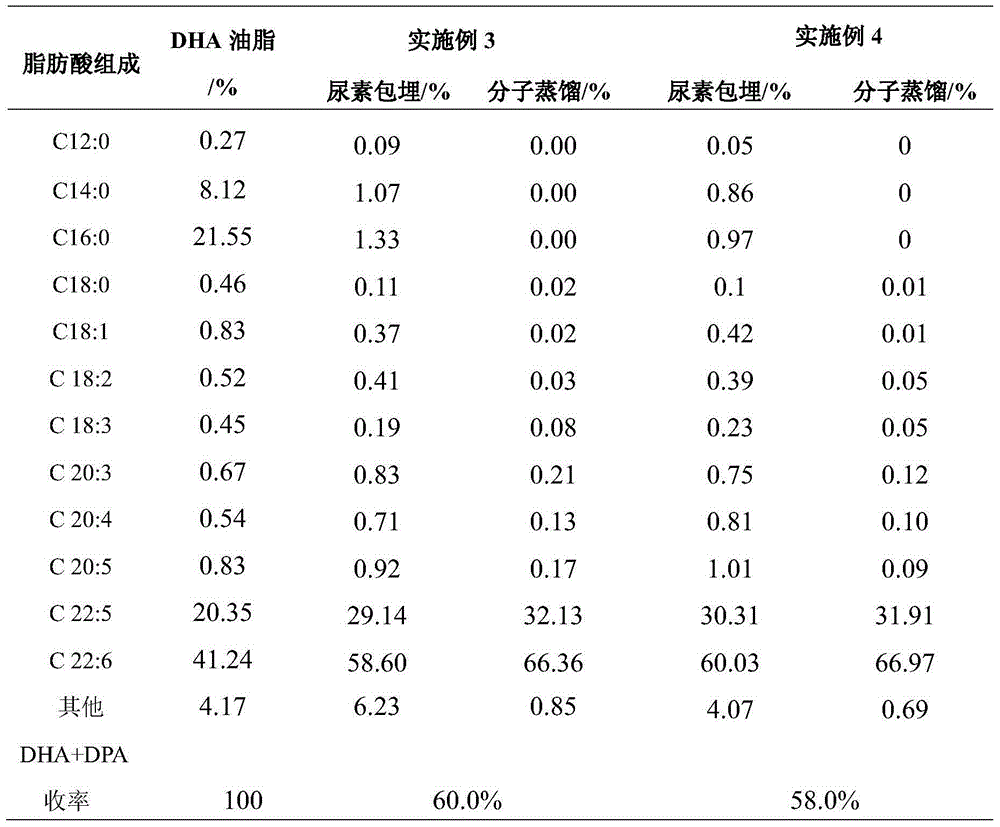

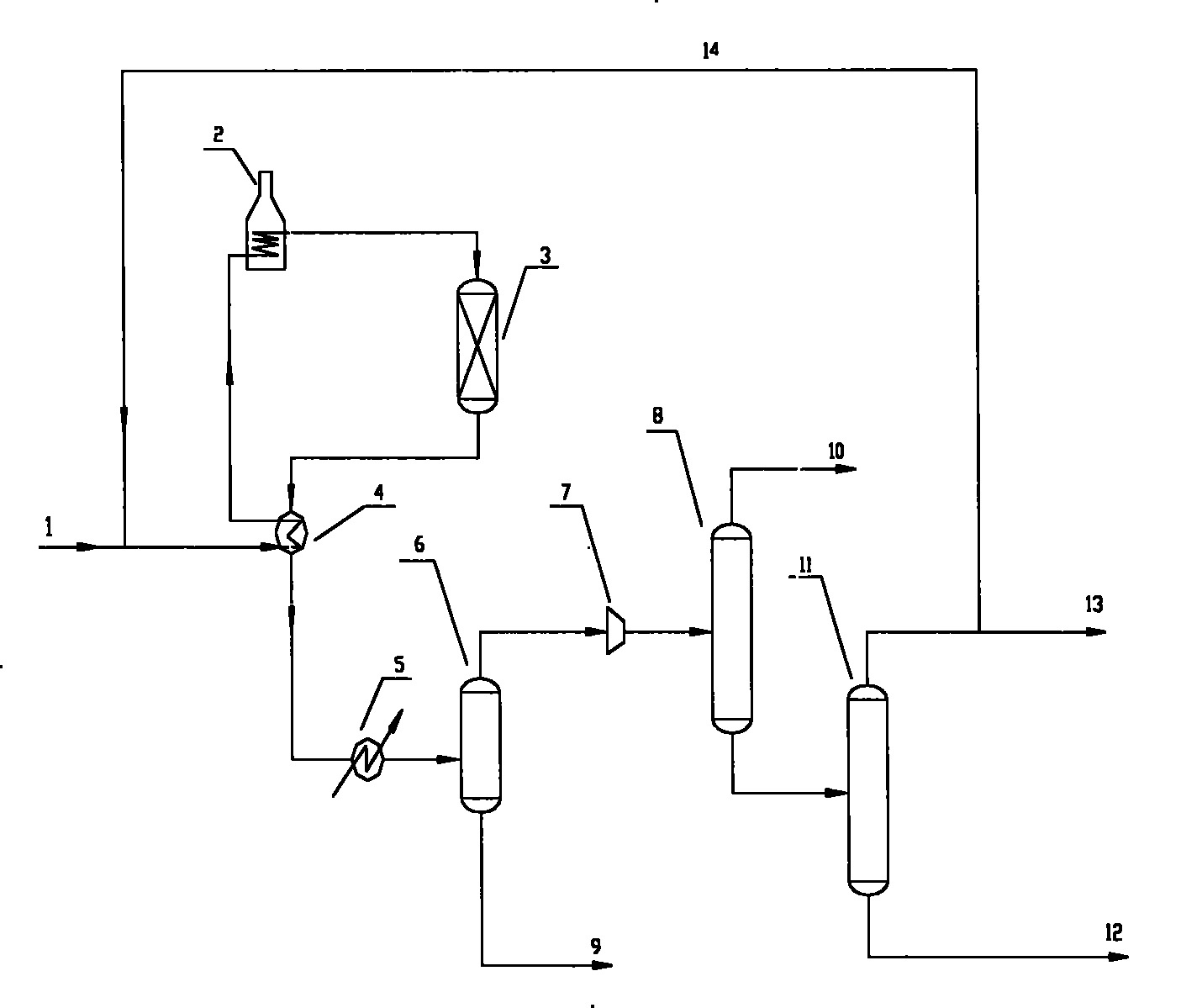

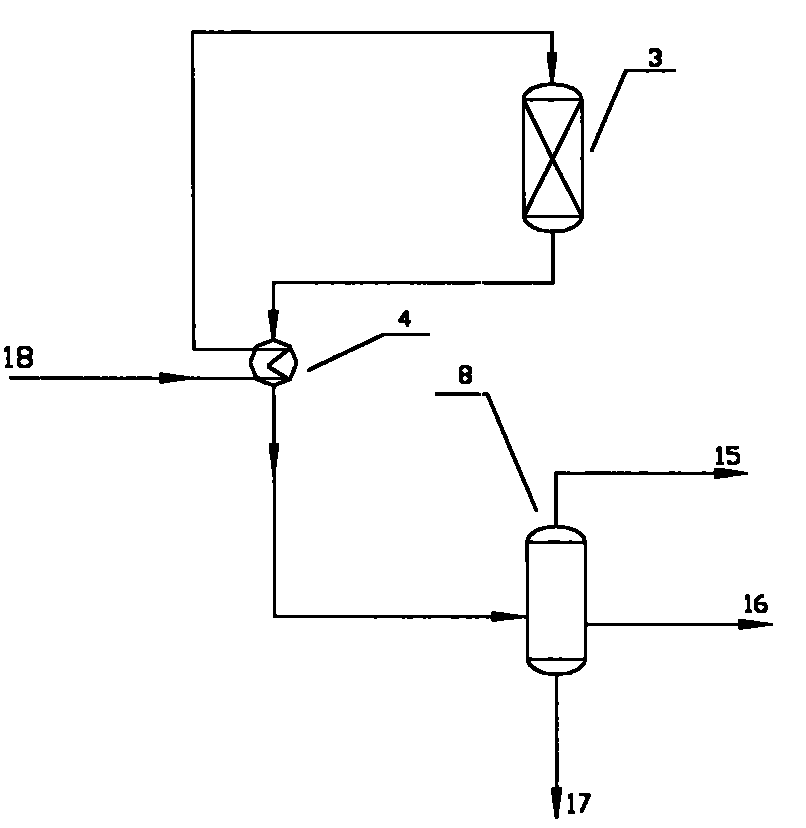

Method for separating and purifying DHA ethyl ester from DHA oil fermented by microorganisms

ActiveCN103864614BSolve various problems in separation and purificationEasy to separateFatty acid esterificationOrganic compound preparationMicroorganismDistillation

The invention relates to a method for separating and purifying DHA (docosahexaenoic acid) from DHA oil produced by microbial fermentation. The method for separating and purifying DHA from DHA oil produced by microbial fermentation comprises the following steps: (1) taking the DHA oil, and carrying out esterification; (2) carrying out primary separation on esterified DHA oil by adopting a urea embedding-gradient freezing crystallization method; (3) carrying out molecular distillation on primarily separated fatty acid ethyl ester and then separating, so that high-purity DHA ethyl ester is prepared. The method for separating and purifying DHA from DHA oil produced by microbial fermentation is formed on the basis of coupling of multiple separation and purification means, DHA purification is obviously improved, DHA oil produced by crypthecodinium cohnii is taken as a raw material, and DHA ethyl ester with the purity more than 98% can be prepared; DHA oil produced by schizochytrium limacinum is taken as the raw material, and a product with the content of DHA ethyl ester and DPA ethyl ester more than 98% can be obtained.

Owner:JIANGSU ZHONGBANG PHARMA

Method for preparing olefin in lightweight by catalytic cracking olefin of containing carbon

ActiveCN101092323BImprove conversion rateReduce energy consumptionBulk chemical productionHydrocarbon by hydrocarbon crackingReaction temperatureHeating furnace

This invention relates to a method for preparing lightweight olefins from carbon-containing olefins by catalytic cracking. The method solves the problems of low added value of carbon-containing olefin mixture, low catalytic cracking conversion rate, and low associativity of catalytic cracking process faced by the previous technique. The method comprises: (1) gasifying and preheating liquid-phase carbon-containing olefin mixture by heat exchange with cracking products, and heating to the reaction temperature with a heating furnace; (2) partially condensing the cracking products, and separatingC5 or higher fractions; (3) compressing the rest cracking products to 0.3-1.1 MPa, sending into a depropanizer, separating, sending C3 or lower fractions obtained at the overhead to an ethylene apparatus, and separating to obtain propylene and ethylene; (4) sending C4 or higher fractions into a debutanizer, sending 30-90 wt.% of C4 fraction obtained at the overhead to the reactor, and cracking again. The method can be used in industrial production of lightweight olefins such as propylene and ethylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultrasonic leaching-extracting separation method for sulphating roasting rare earth mine

InactiveCN100471963CGood removal effectReduce processingProcess efficiency improvementRare-earth elementSulfate

The invention discloses an ultrasonic leaching-extracting separating method of rare earth ore sintered by sulfuric acid, which comprises the following steps: adopting sulfuric acid solution as leaching liquid; allocating extracting liquid through P204, P507 and kerosene; proceeding leaching-extracting separating operation for rare earth ore through ultrasound with strength at 0.2-20.0W / cm2 and frequency at 19-80kHz under 5-60 deg.c; obtaining the enriched product of middle heavy rare earth (yttrium group rare earth element) sulfate as extracting phase and light rare earth (cerium group rare earth element) sulfate as residual phase.

Owner:YANGZHOU UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com