Method for separating rhenium and molybdenum in molybdenum-rhenium ore concentrate

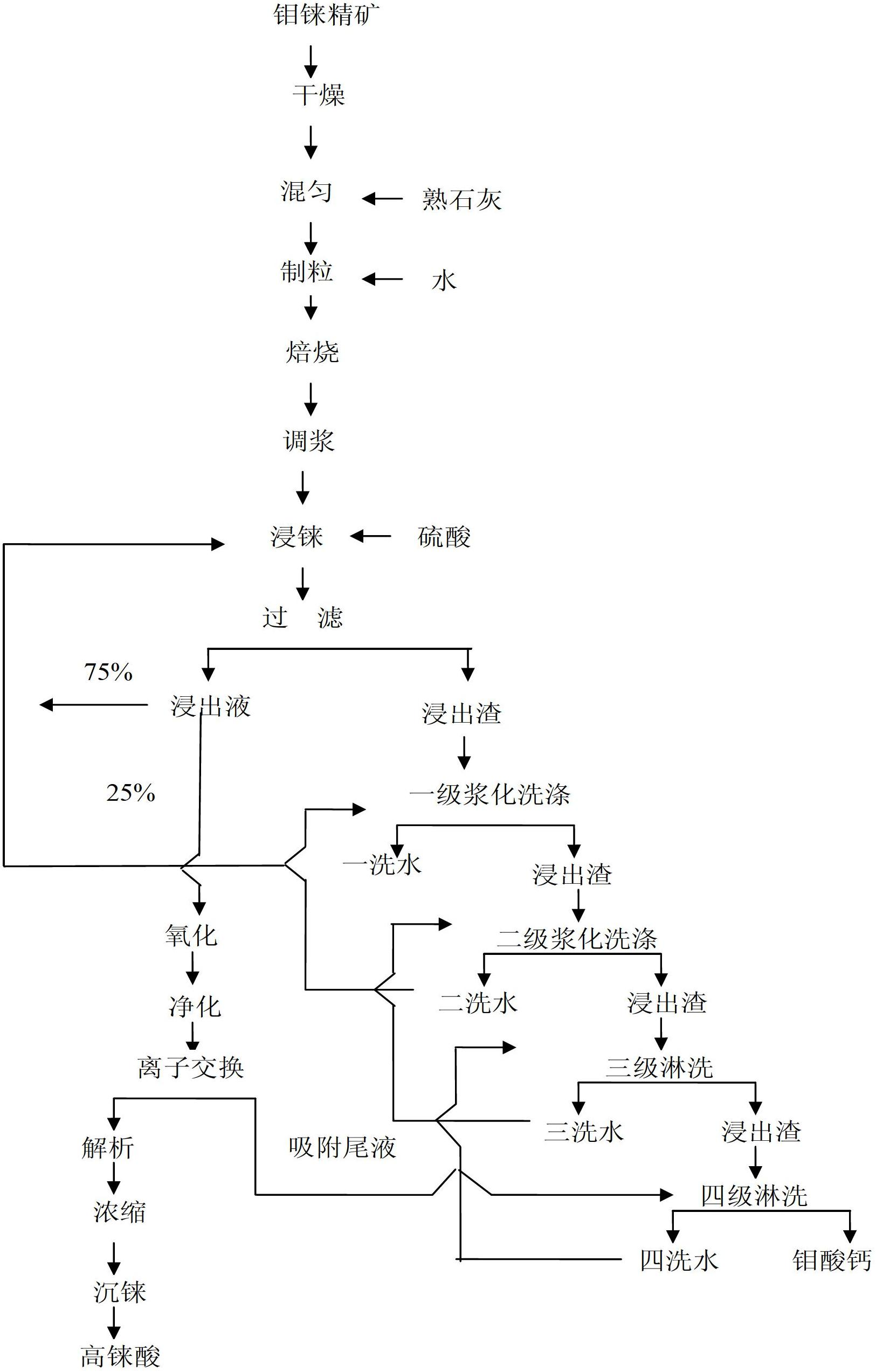

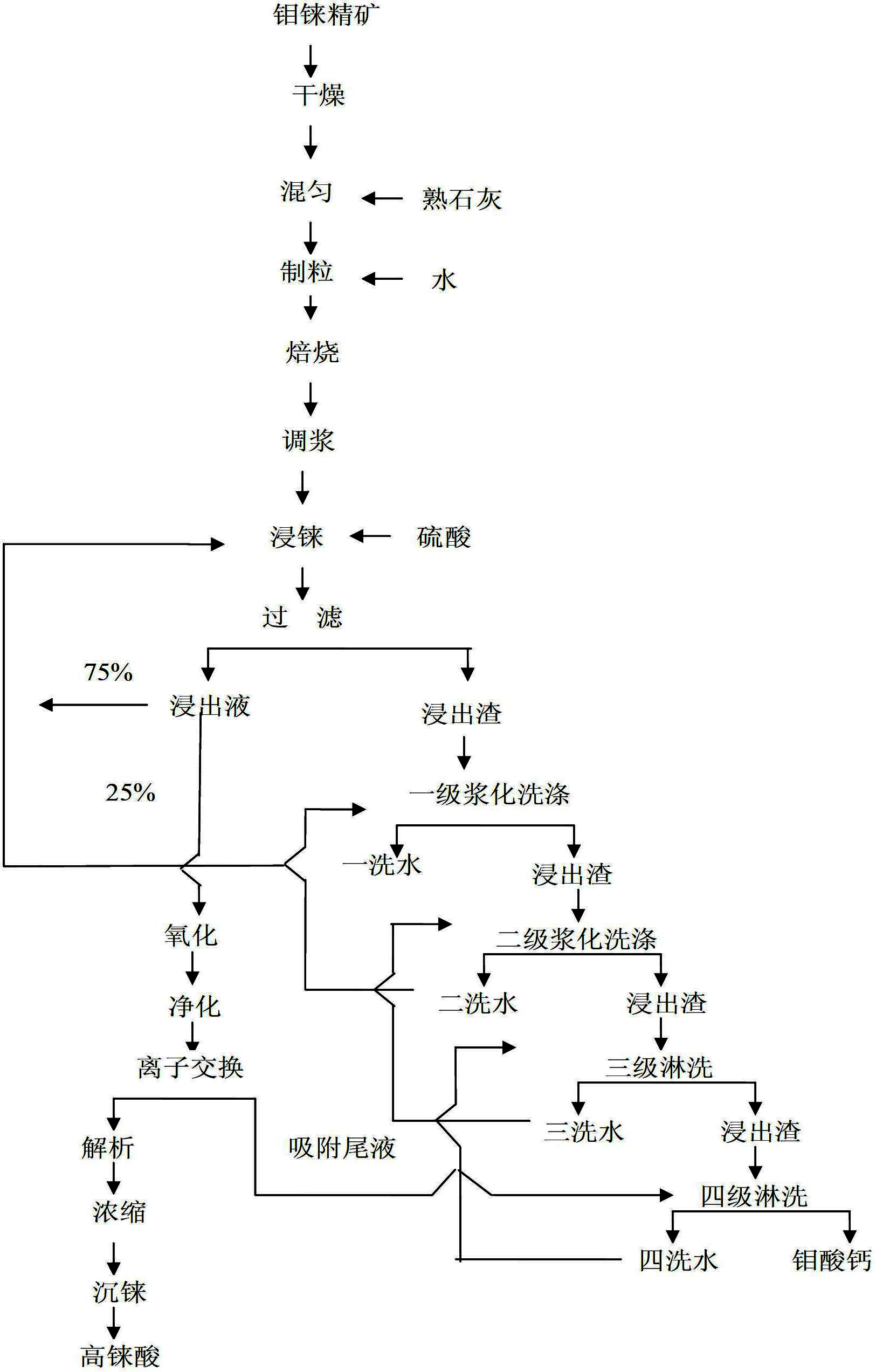

A molybdenum-rhenium and concentrate technology is applied in the field of separating rhenium and molybdenum in molybdenum-rhenium concentrate, which can solve the problems of complicated separation process and large investment, and achieve the effect of simplifying the operation process, reducing the separation load and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Dry the molybdenum-rhenium concentrate to 3% water content, granulate and control the particle size to Φ10mm; put the granulated molybdenum-rhenium concentrate particles into the muffle furnace for roasting, and grind the roasted ore until it reaches 80wt% in the grinding slurry after wet grinding The particle size of the solid matter is below 200 mesh, and the mass concentration of the solid matter in the grinding ore slurry is 50%; the mass concentration of the solid matter in the grinding ore slurry is adjusted to be 20%, and the sulfuric acid with a concentration of 10mol / L is added thereto to adjust The pH value of the grinding slurry is between 7 and 8; after 4 hours, filter the above-mentioned grinding slurry to obtain leaching slag containing calcium molybdate and leaching solution containing calcium perrhenate.

[0045] The leaching slag containing calcium molybdate enters the molybdenum smelting system.

[0046] Take 25% of the leaching solution and add sulfur...

Embodiment 2

[0049] Dry the molybdenum-rhenium concentrate to a water content of 3%, granulate, and control the particle size to Φ6mm; put the granulated molybdenum-rhenium concentrate particles into the muffle furnace for roasting, and grind the roasted ore to 80wt% in the grinding slurry after wet grinding The particle size of the solid matter is below 200 mesh, and the mass concentration of the solid matter in the grinding pulp is 40%; the mass concentration of the solid matter in the grinding pulp is adjusted to be 25%, and the sulfuric acid with a concentration of 10mol / L is added thereto to adjust The pH value of the grinding slurry is between 7 and 8; after 6 hours, the above-mentioned grinding slurry is filtered to obtain leaching slag containing calcium molybdate and leaching solution containing calcium perrhenate.

[0050] Calcium molybdate enters the molybdenum smelting system.

[0051] Take 50% of the leaching solution and add sulfuric acid to adjust the pH at 3.0~4.0, then add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com