Phosphate-doping silicon carbon negative electrode material for lithium ion battery and preparation method of phosphate-doping silicon carbon negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of not improving the electronic conductivity of silicon materials, etc., and achieve convenient follow-up processing. Improvement of electronic conductivity and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

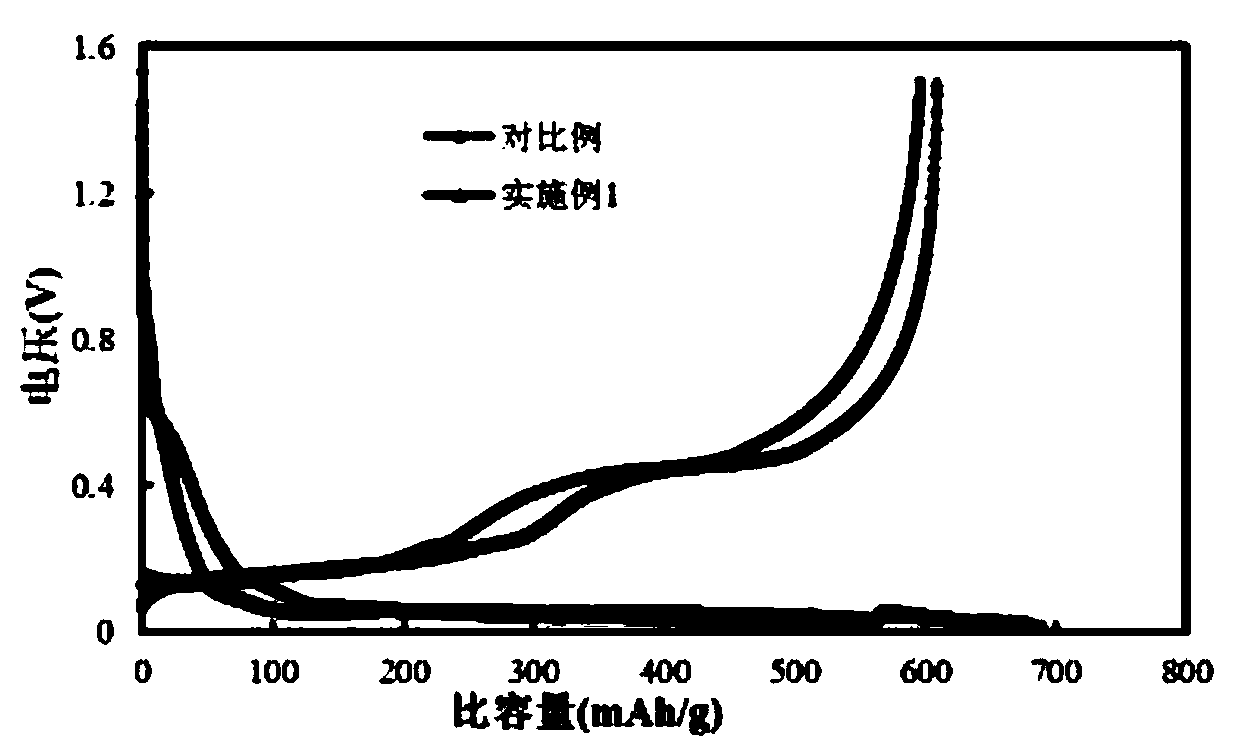

Embodiment 1

[0025] The invention proposes a phosphorus-doped silicon-carbon negative electrode material for lithium-ion batteries, wherein the phosphorus-doped silicon-carbon negative electrode material is formed by spraying and granulating phosphorus-doped nano-silicon material, graphite and an organic carbon source and then sintering;

[0026] Wherein, in the phosphorus-doped silicon-carbon negative electrode material, the mass percentage of the phosphorus-doped nano-silicon material is 10%, and the balance is graphite and amorphous pyrolytic carbon.

[0027] A kind of preparation method of described lithium-ion battery phosphorus-doped silicon-carbon negative electrode material that the present invention proposes, comprises the following steps:

[0028] S1. Evenly disperse 10g of nano silicon powder in 1mol / L of H 3 PO 4 In the solution, after stirring for 0.5h, it is sprayed and granulated. The temperature of the air inlet of the spray granulator is 160°C, and the temperature of the ...

Embodiment 2

[0039] The invention proposes a phosphorus-doped silicon-carbon negative electrode material for lithium-ion batteries, wherein the phosphorus-doped silicon-carbon negative electrode material is formed by spraying and granulating phosphorus-doped nano-silicon material, graphite and an organic carbon source and then sintering;

[0040] Wherein, in the phosphorus-doped silicon-carbon negative electrode material, the mass percentage of the phosphorus-doped nano-silicon material is 95%, and the balance is graphite and amorphous pyrolytic carbon.

[0041] A kind of preparation method of described lithium-ion battery phosphorus-doped silicon-carbon negative electrode material that the present invention proposes, comprises the following steps:

[0042] S1. Evenly disperse 10g of nano silicon powder in 0.1mol / L H 3 PO 4 In the solution, after stirring for 0.5h, it is sprayed and granulated. The temperature of the air inlet of the spray granulator is 160°C, and the temperature of the a...

Embodiment 3

[0045] The invention proposes a phosphorus-doped silicon-carbon negative electrode material for lithium-ion batteries, wherein the phosphorus-doped silicon-carbon negative electrode material is formed by spraying and granulating phosphorus-doped nano-silicon material, graphite and an organic carbon source and then sintering;

[0046] Wherein, in the phosphorus-doped silicon-carbon negative electrode material, the mass percentage of the phosphorus-doped nano-silicon material is 3%, and the balance is graphite and amorphous pyrolytic carbon.

[0047] A kind of preparation method of described lithium-ion battery phosphorus-doped silicon-carbon negative electrode material that the present invention proposes, comprises the following steps:

[0048] S1. Evenly disperse 10g of nano silicon powder in 1mol / L of H 3 PO 4 In the solution, after stirring for 0.5h, it is sprayed and granulated. The temperature of the air inlet of the spray granulator is 160°C, and the temperature of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com