Preparation method of cathode active material and preparation method of capacitor

A technology of negative electrode active material and positive electrode active material, which is applied in the field of capacitors and can solve the problems of low energy density of electrochemical hybrid capacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

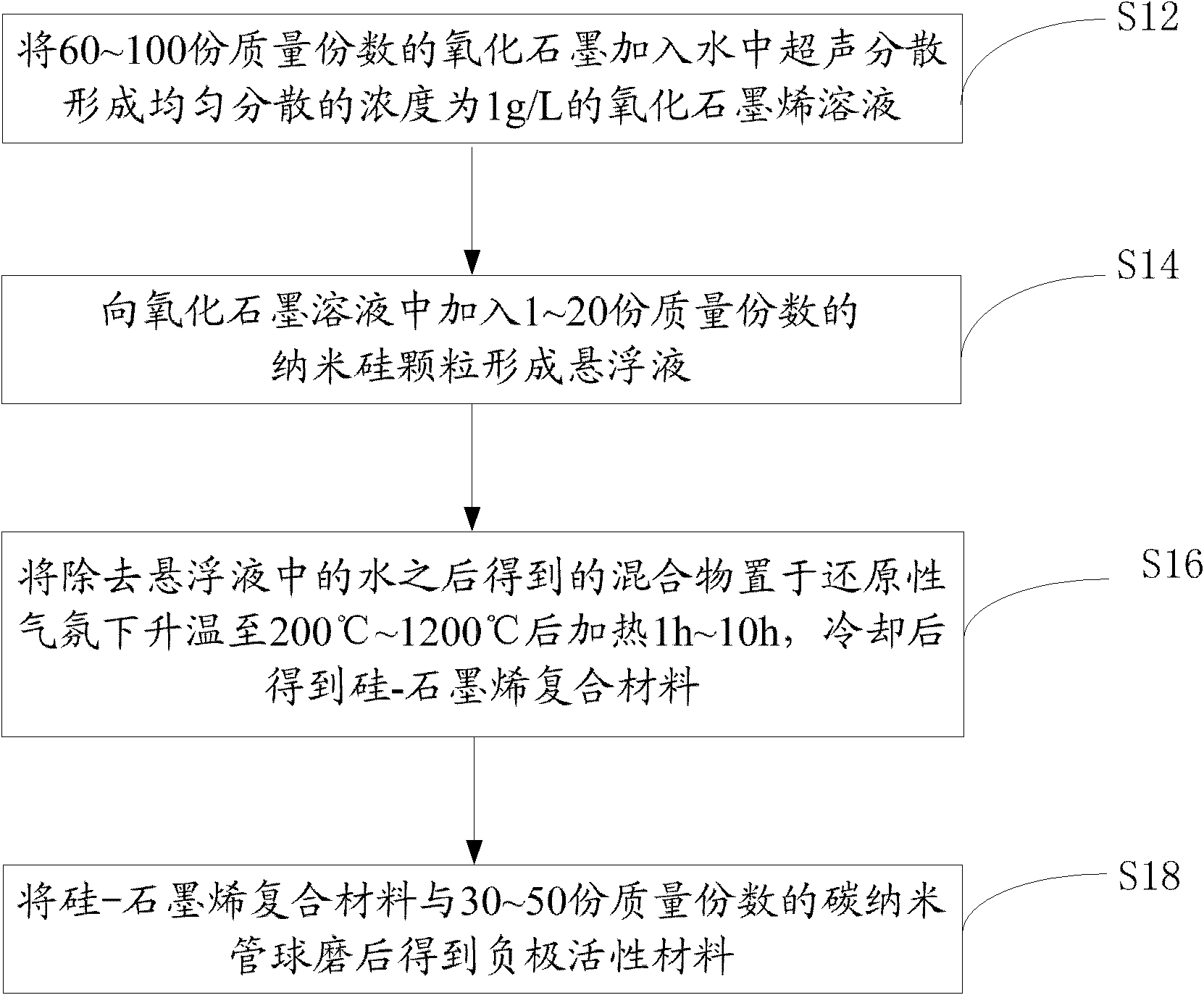

[0021] see figure 1 , the preparation method of the negative electrode active material of an embodiment, comprises the following steps:

[0022] Step S12, adding 60-100 parts by mass of graphite oxide into water for ultrasonic dispersion to form a uniformly dispersed graphene oxide solution with a concentration of 1 g / L.

[0023] In this embodiment, graphite oxide is added into water and ultrasonically dispersed for 1 hour to form a graphene oxide solution uniformly dispersed in a single sheet.

[0024] Step S14, adding 1 to 20 parts by mass of nano-silicon particles to the graphene oxide solution to form a suspension.

[0025] In this embodiment, the nano-silicon particles are added to the graphene oxide solution and then mechanically stirred to form a suspension.

[0026] Step S16 , placing the mixture obtained after removing the water in the suspension in a reducing atmosphere and raising the temperature to 200° C. to 1200° C., heating for 1 hour to 10 hours, and cooling ...

Embodiment 1

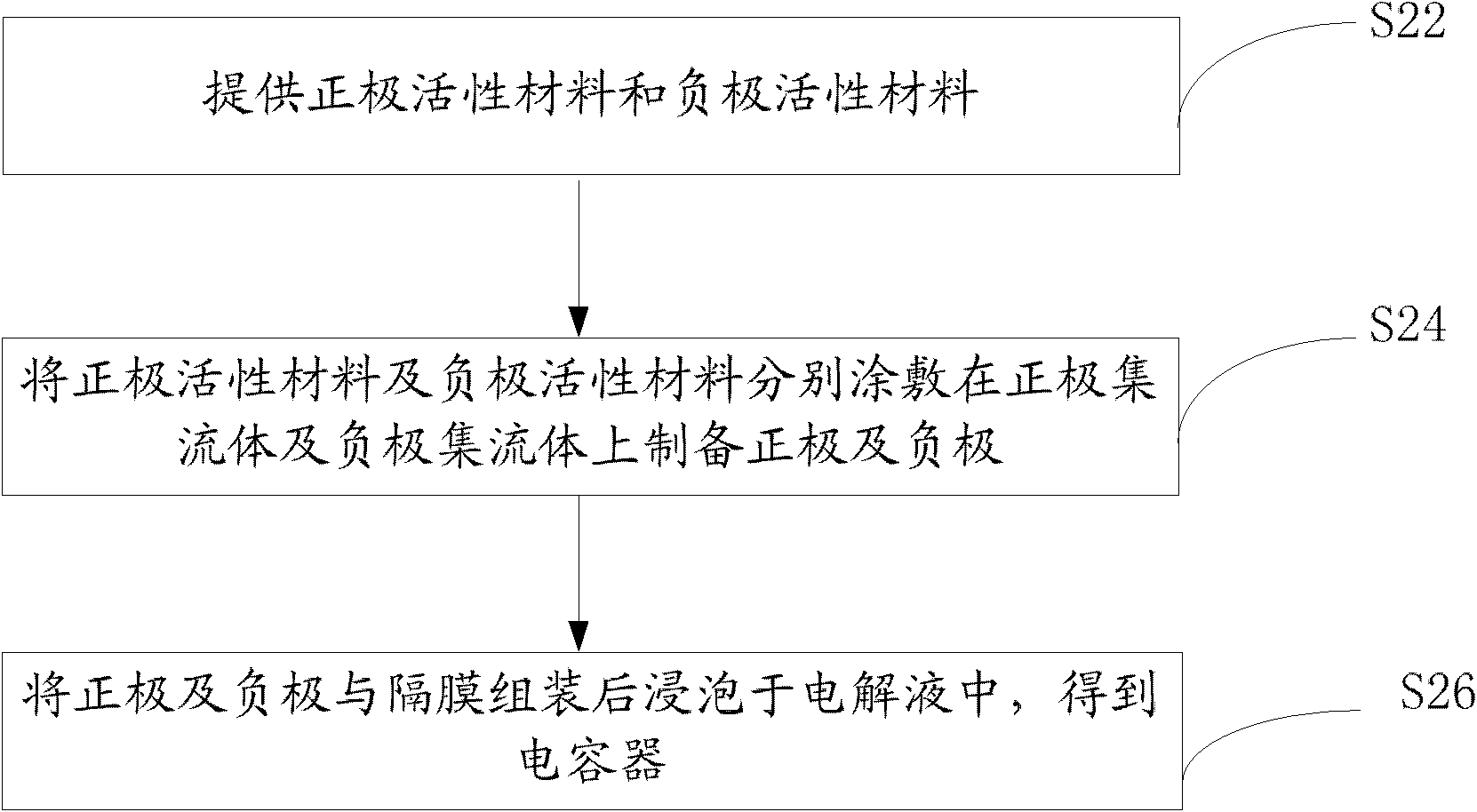

[0047] Positive electrode: The positive electrode active material activated carbon, binder (PVDF) and conductive agent (acetylene black) are mixed in a mass ratio of 85:10:5 to form a positive electrode material, and a solvent (NMP) is added to form a viscosity of 2500 Newton seconds / square meter Positive electrode slurry, the positive electrode slurry is coated on the aluminum foil, and then dried, rolled and cut to make the positive electrode.

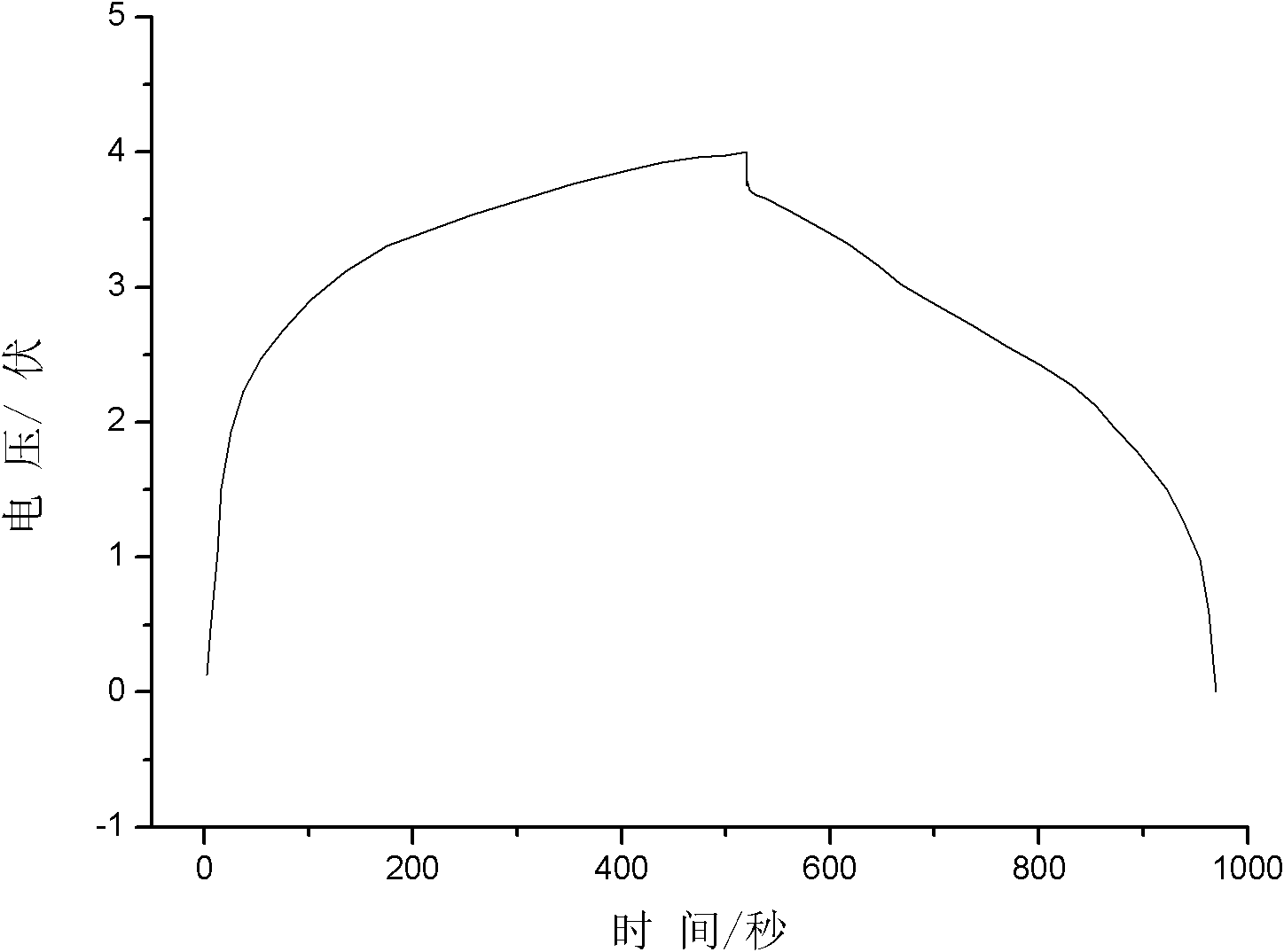

[0048] Negative electrode: (1) Add 80g of graphite oxide into water and ultrasonically disperse to form a graphene oxide solution uniformly dispersed in a monolithic layer, add 20g of nano-silicon particles to the graphene oxide solution to form a suspension, remove the The mixture obtained after the water is placed in a reducing atmosphere and heated to 800° C. at a rate of 10° C. / min and heated for 5 hours. After cooling, a silicon-graphene composite material is obtained. The silicon-graphene composite material is mixed with 40 g of...

Embodiment 2

[0054] Positive electrode: active carbon and lithium iron phosphate material with a mass ratio of 70:30 are prepared as the positive electrode active material. Mix the prepared positive electrode active material with binder (PVDF) and conductive agent (conductive carbon black Super P) in a mass ratio of 85:5:10 to form a positive electrode material, and add a solvent (NMP) to form a viscosity of 1500 Ns / Square meters of positive electrode slurry, the positive electrode slurry is coated on aluminum foil, and then dried, rolled and cut to make positive electrodes.

[0055] Negative electrode: (1) Add 100g graphite oxide into water and ultrasonically disperse to form a graphene oxide solution uniformly dispersed in a monolithic layer, add 1g nano-silicon particles to the graphene oxide solution to form a suspension, remove the The mixture obtained after the water is placed in a reducing atmosphere and heated to 1200° C. at a rate of 100° C. / min. and then heated for 1 h. After co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com