Silicon-carbon composite lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as not being able to buffer volume expansion well, affecting material cycle performance, and nano-silicon shedding, so as to increase service life , The effect of compact particles and high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A method for preparing a silicon-carbon composite lithium-ion battery negative electrode material according to the present invention comprises the following steps:

[0033] Step 1, adding micro-silicon and dispersant into the solvent, and grinding to obtain nano-silicon slurry 1;

[0034] Step 2, adding the carbon matrix to the nano-silicon slurry 1, and stirring to obtain a mixed slurry 2; wherein the carbon matrix is one of flattened artificial graphite, flattened natural graphite, and flattened mesophase carbon microspheres or Several;

[0035] Step 3, drying the mixed slurry 2 to obtain a precursor material 1; adding the precursor material 1 to a fusion machine for fusion to obtain a precursor material 2; mixing the precursor material 2 with a coating agent to obtain a precursor material 3;

[0036] Step 4, granulating the precursor material 3 to obtain a precursor material 4, placing the precursor material 4 in a protective atmosphere for heat treatment to obtai...

Embodiment 1

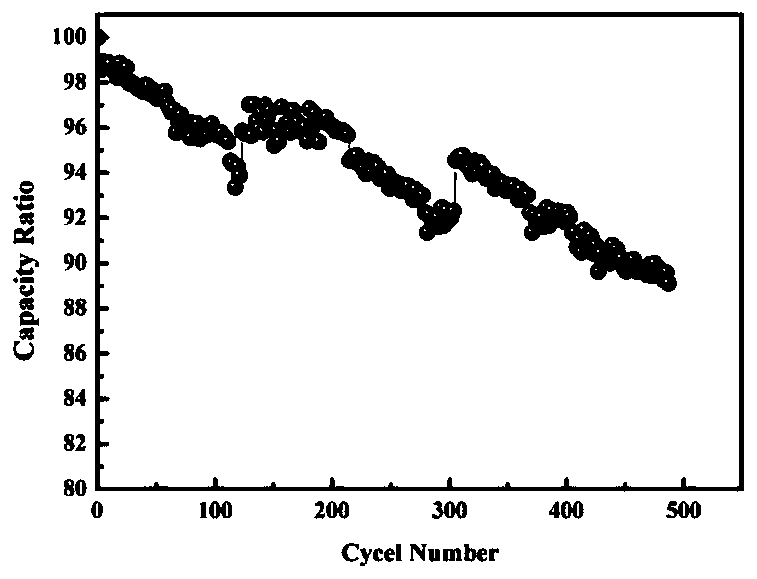

[0049] Disperse 500g of silicon powder with a median particle size of 5μm into 10000g of ethanol solvent, then add 5g of polyvinylpyrrolidone, and finally add it into a ball mill to obtain a nano-silicon slurry with a median particle size of 120nm, and obtain slurry 1; Flattened natural graphite with a particle size of 8-12 μm is added to the above nano-silicon slurry to obtain a mixed slurry 2; the slurry 2 is spray-dried to obtain a precursor material 1; the precursor material 1 is added to a fusion machine for fusion and shaping to obtain Precursor material 2, fusion machine knife spacing 0.1mm, rotating speed 850rpm / min, fusion time 15min; add precursor material 2 and 500g (25% of precursor material 3) coal tar pitch into VC mixer and mix to obtain precursor material 3 ; Place the precursor material 3 in a molding machine and press it into a block to obtain the precursor material 4, and then place it in a box furnace. In a nitrogen atmosphere, first heat it to 300°C and kee...

Embodiment 2

[0051] Disperse 1,000g of silicon powder with a median particle size of 3 μm into 25,000g of ethylene glycol solvent, add 10g of polyvinyl acid, and finally add it to a ball mill for ball milling to obtain a nano-silicon slurry with a median particle size of 120nm to obtain slurry 1; Flat artificial graphite with a median particle size of 5-8 μm is added to the above nano-silicon slurry to obtain a mixed slurry 2; the slurry 2 is spray-dried to obtain a precursor material 1; the precursor material 1 is added to a fusion machine for fusion shaping , to obtain precursor material 2, fusion machine knife spacing 1mm, rotating speed 400rpm / min, fusion time 30min; add precursor material 2 and 800g (20% of precursor material 3) petroleum asphalt into VC mixer and mix to obtain precursor material 3. Place the precursor material 3 in a double-roll machine and press it into a block to obtain the precursor material 4, and then place it in a box furnace. In an argon atmosphere, first heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com