Patents

Literature

114results about How to "Improve volume expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

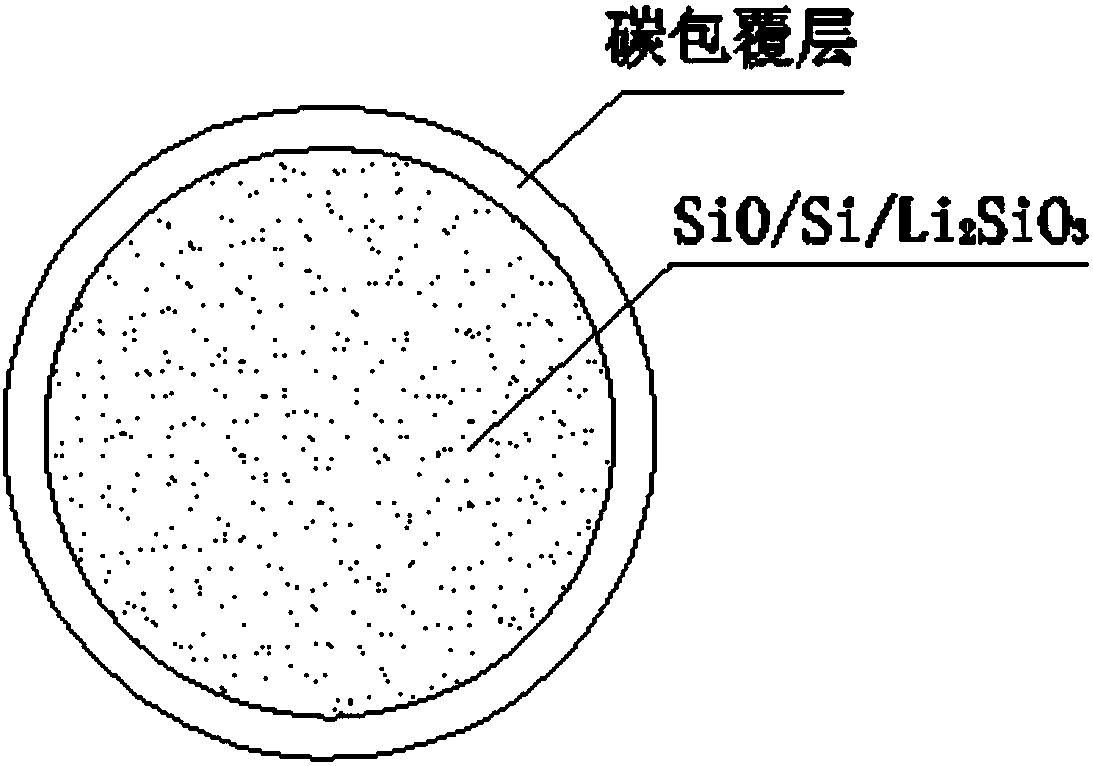

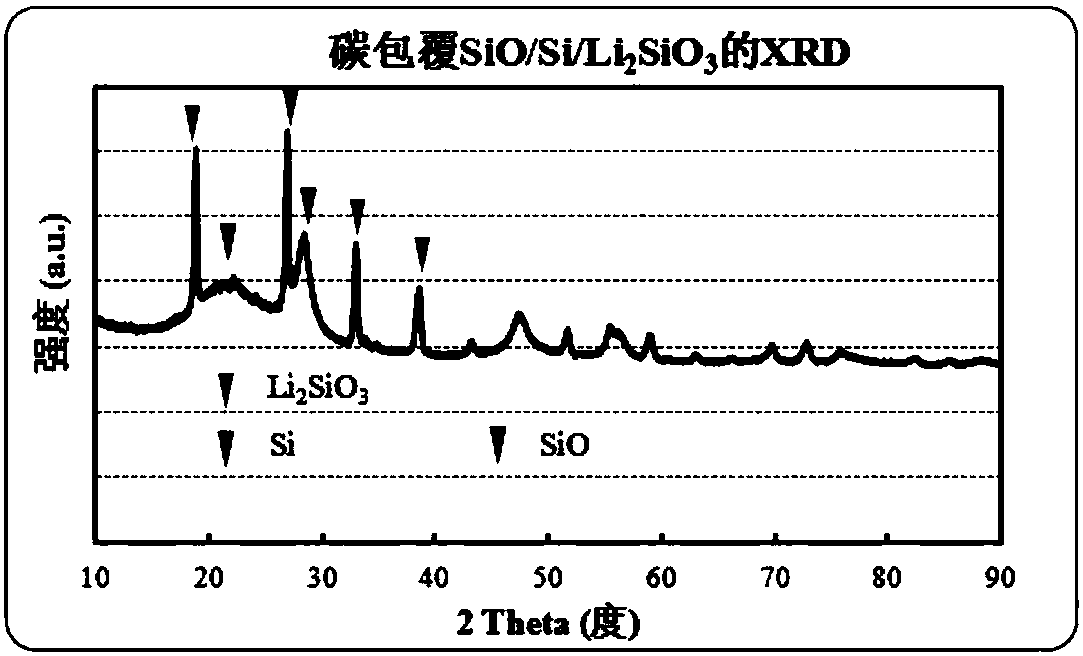

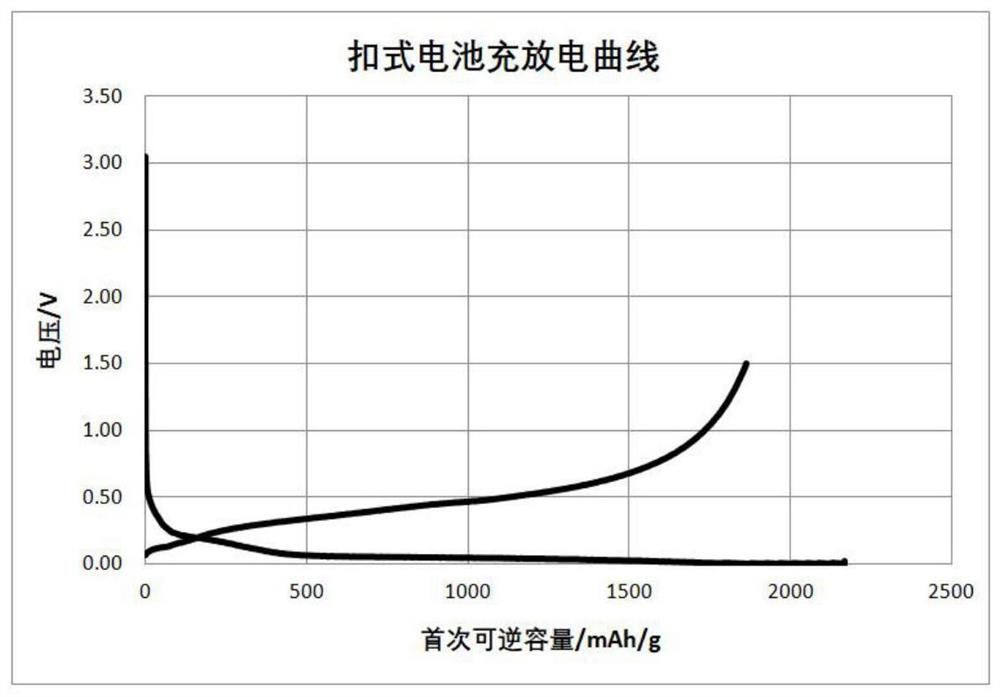

Silicon monoxide/silicon/lithium metasilicate composite negative electrode material and preparation method thereof

InactiveCN108269979AIncrease capacityImprove the first Coulombic efficiencyCell electrodesSilicon monoxideShielding gas

The invention discloses a silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The silicon monoxide / silicon / lithium metasilicate composite negative electrode material comprises a silicon monoxide / silicon / lithium metasilicate composite material and an inorganic matter coating layer. The invention also provides a preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material. The preparation method comprises the following steps: taking silicon monoxide and an inorganic compound of lithium element, mixing and ball-milling the silicon monoxide and the inorganic compound of the lithium element, sintering the obtained mixture in a protection gas environment, and naturally cooling the sintered mixture to obtain the silicon monoxide / silicon / lithium metasilicate composite material; and mixing and ball-milling the silicon monoxide / silicon / lithium metasilicate composite material and sintering the obtained mixture undera protection gas condition. The preparation method of the silicon monoxide / silicon / lithium metasilicate composite negative electrode material has the advantages of simplicity, safety, low cost, and easiness in operation and industrial production, and the obtained composite negative electrode material has the advantages of high reversible capacity, excellent cycle performances and high initial Coulomb efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

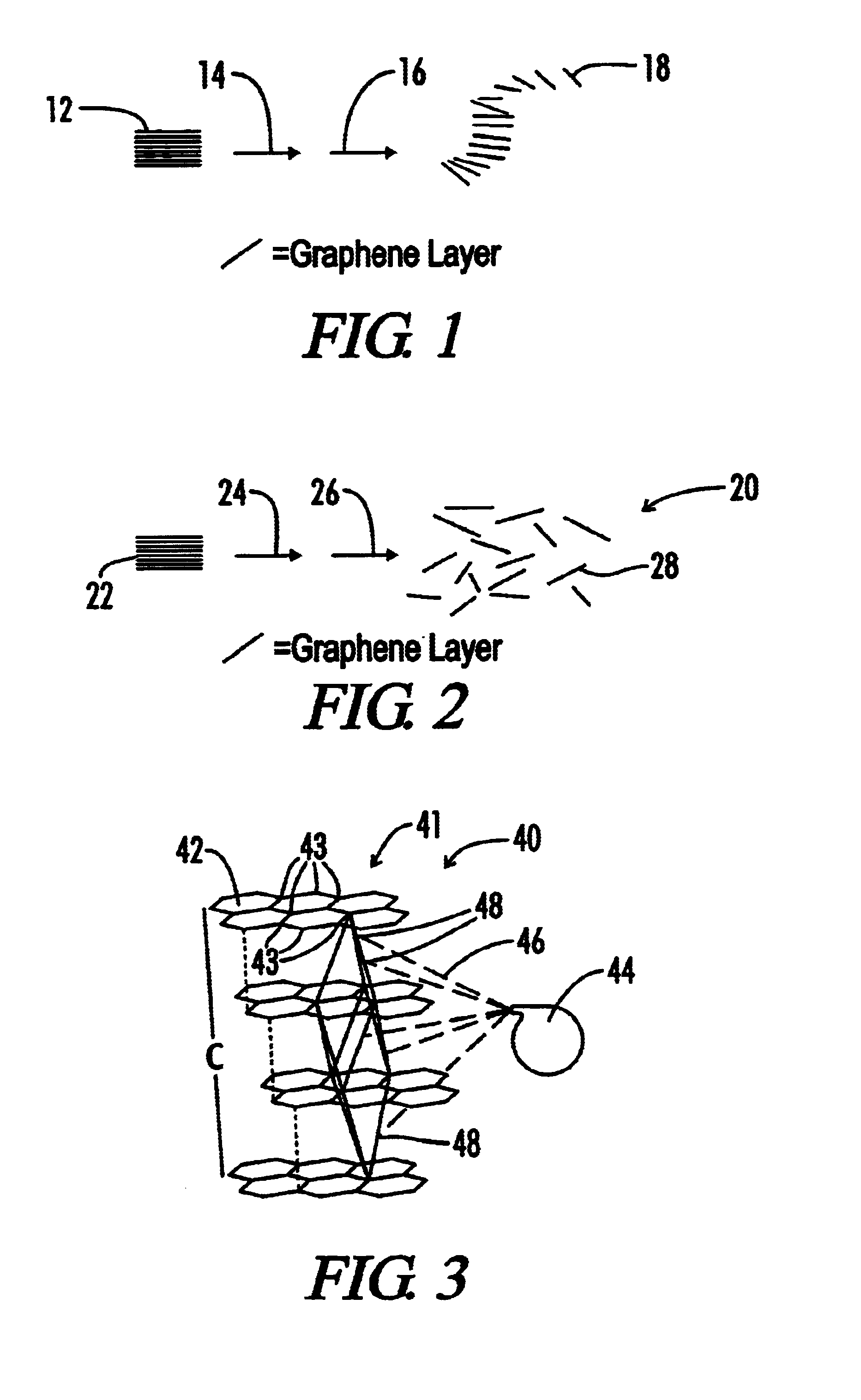

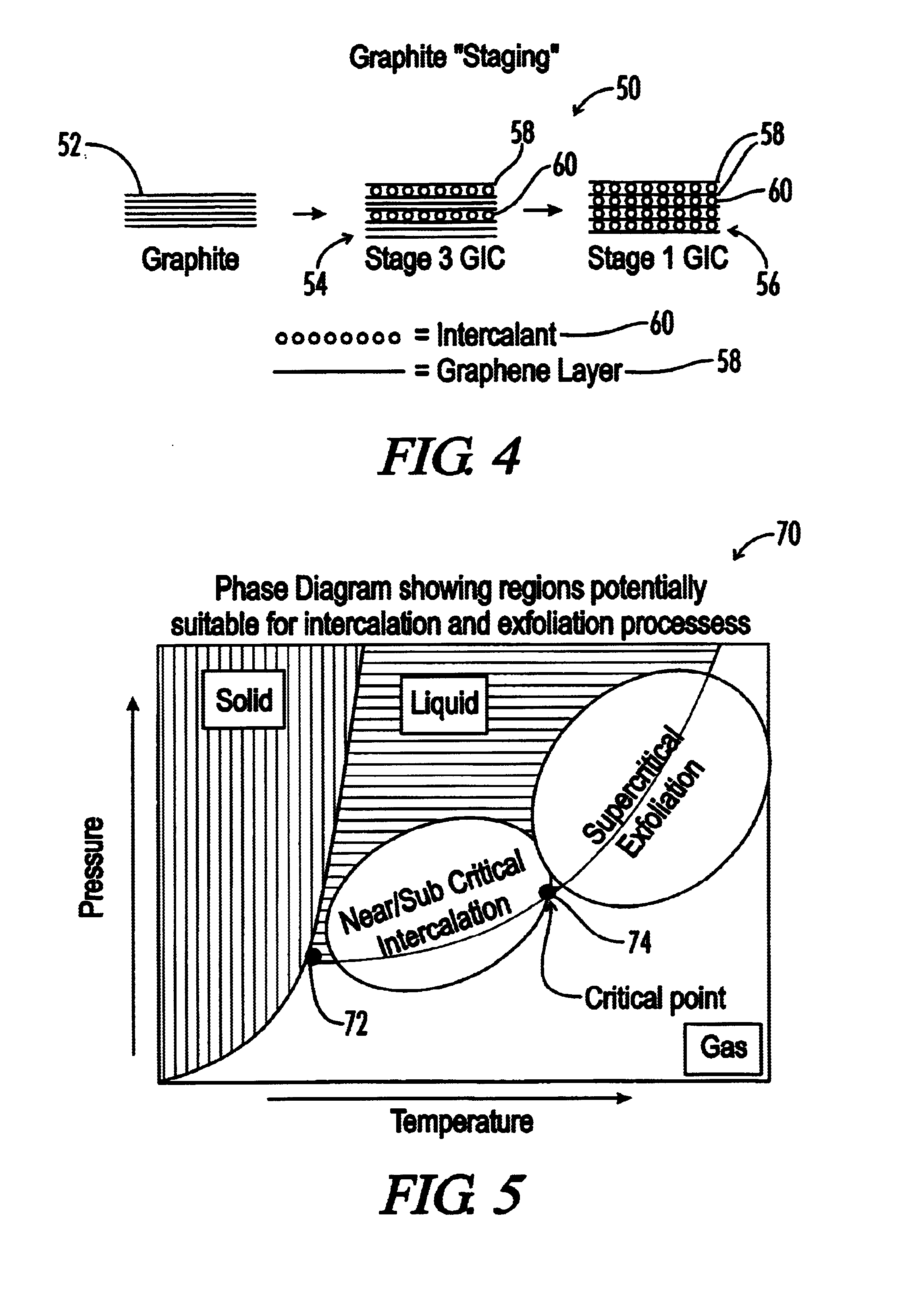

Graphite composites and methods of making such composites

InactiveUS6927250B2Improve volume expansionReduce needSpecial tyresBulk chemical productionConductive polymerPolymer composites

The invention may be practiced to make graphite composites. Preferred composites which may be made in accordance with the invention include conductive polymeric composites (thermally or electrically), paint composites, battery composites, capacitor composites, and pollution abatement catalyst support composites. One method of making the graphite aforementioned composites includes introducing an intercalant into at least one interstice of at least one flake of natural graphite. The method also includes introducing a fluid into the at least one interstices of the flake. Preferably, the fluid comprises at least one of a sub-critical fluid, near critical point fluid, or a supercritical fluid. Furthermore the method includes blending the flake with a polymer, thereby forming a graphite-polymeric composite.

Owner:GRAFTECH INT HLDG INC

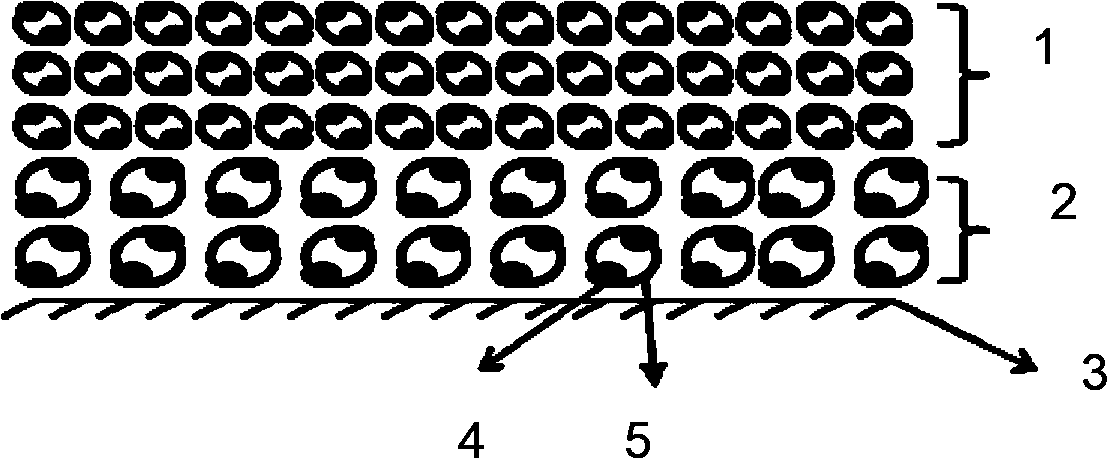

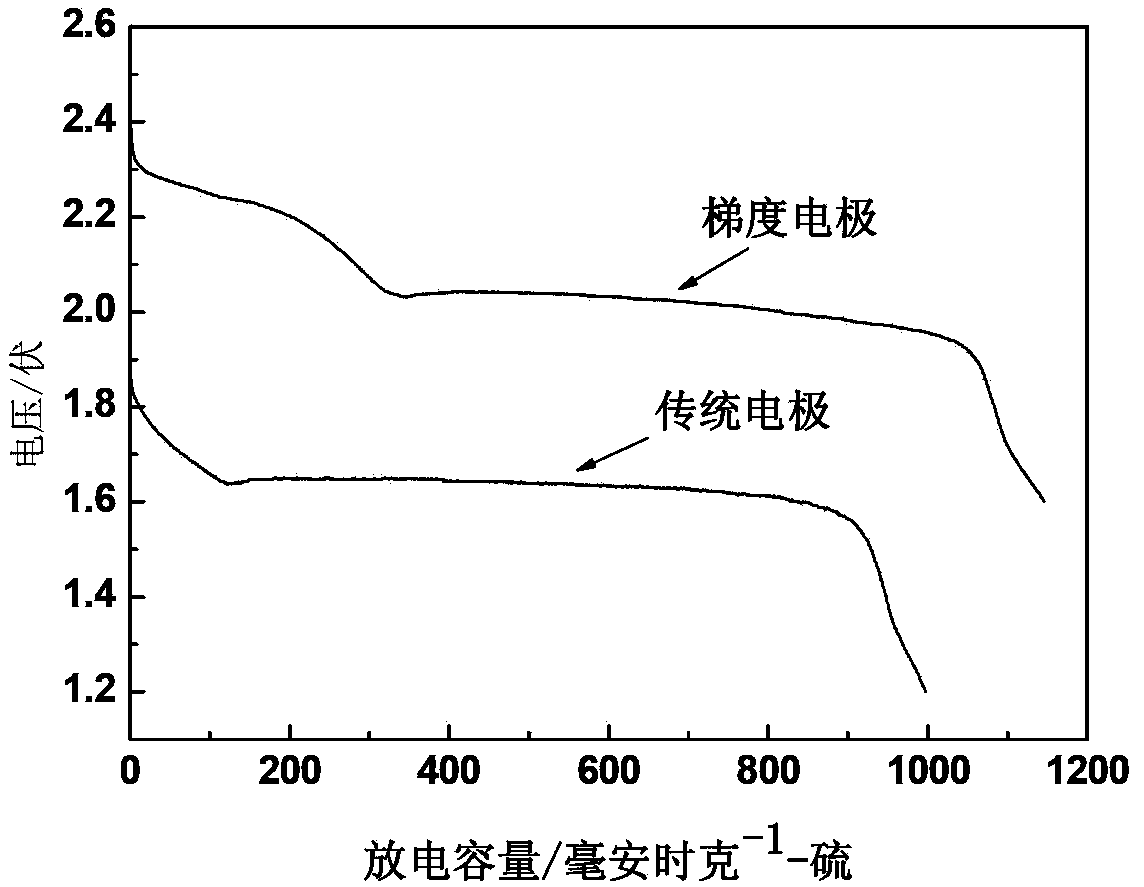

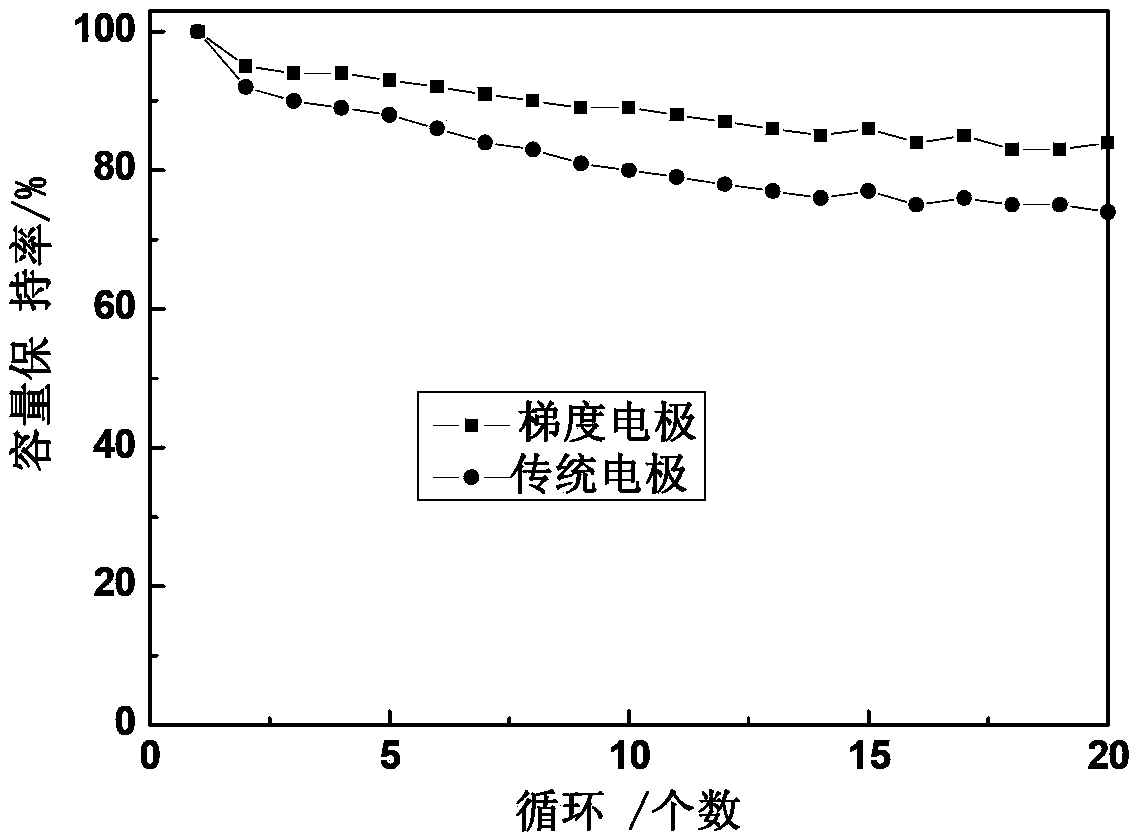

Lithium-sulfur battery positive electrode structure and preparation method thereof

ActiveCN103840125AEasy transferImprove discharge ratePositive electrodesElectrode collector coatingSulfurLithium–sulfur battery

The present invention relates to a lithium-sulfur battery positive electrode structure and a preparation method thereof. According to the lithium-sulfur battery positive electrode structure, a current collector is adopted as a substrate, two carbon-sulfur complex layers with different pore sizes are attached onto the substrate, the structure sequentially comprises the current collector, the large pore size carbon-sulfur complex layer and the small pore size carbon-sulfur complex layer, the thickness of the large pore size carbon-sulfur complex layer is 50-500 mum, the thickness of the small pore size carbon-sulfur complex layer is 10-200 mum, the large pore size carbon material is a carbon material with a pore size of greater than 100 nm and less than 1 mum and a pore volume accounting for 50-90% of the total pore volume, and the small pore size carbon material is a carbon material with a pore size of 0.5-100 nm and a pore volume accounting for more than 50-90% of the total pore volume. With the lithium-sulfur battery positive electrode structure, the mass transfer curvature of the lithium ions in the electrode is effectively increased, the lithium ion transmission path is prolonged, provision of the capacity of the high supporting capacity active substance is easily achieved, and the energy density of the battery is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Room-temperature moisture cured one-component water-expansion polyurethane sealant

InactiveCN101885957AGood adhesionEasy constructionProductsNon-macromolecular adhesive additivesAdjuvantPolyether polyurethane

The invention discloses a room-temperature moisture cured one-component water-expansion polyurethane sealant which is paste and comprises the following raw materials in parts by weight: 30-50 parts of liquid polyether polyurethane prepolymer base material, 10-25 parts of plasticizer, 0.5-1 part of a coupling agent, 10-30 parts of super water absorbent resin, 10-30 parts of other fillers, 0.01-0.05 part of catalyst and 0.2-3 parts of adjuvant. The preparation method of the sealant comprises the following steps: 1. placing di-functionality polyether glycol and tri-functionality polyether glycol in a container according to a weight ratio, stirring and dehydrating by a vacuum pump, and then adding polyisocyanate and the catalyst under stirring to obtain the liquid polyether polyurethane prepolymer base material for later use; 2. adding the plasticizer and the coupling agent to the liquid polyether polyurethane prepolymer base material to obtain a mixture; and 3. adding the super water absorbent resin and other fillers to the mixture, then adding the catalyst and the adjuvant, evenly dispersing into paste, and then packing the paste into a packaging substance for sealing. The sealant of the invention has good adhesive property on a sealed surface, and the paste is cured under a moisture condition, thus achieving the purpose of avoiding leakage.

Owner:SHANDONG NORTH MODERN CHEM IND

Electrolyte applicable to silicon carbon negative and lithium ion battery comprising electrolyte

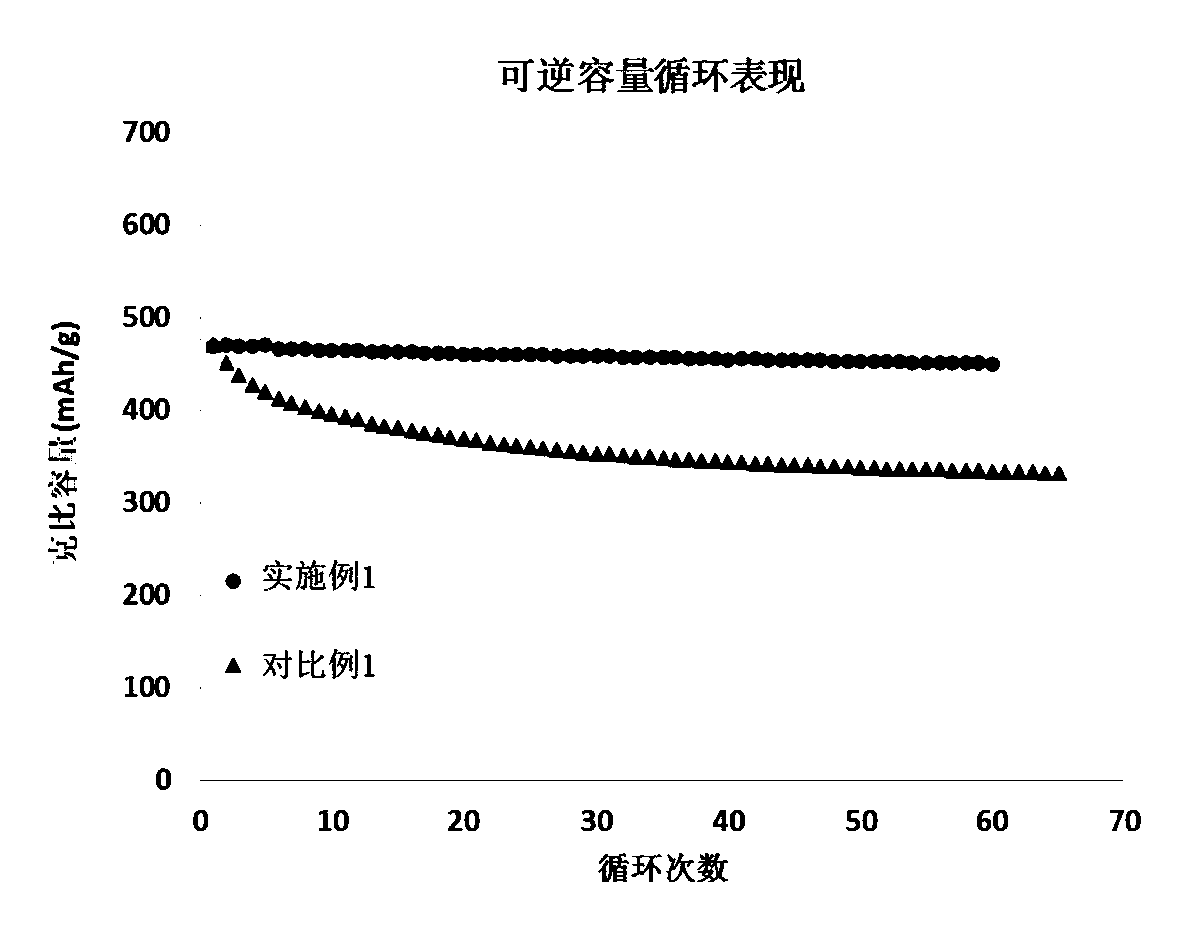

ActiveCN109873205AImproved reversible capacity performanceImprove cycle performanceSecondary cells servicing/maintenanceHigh temperature storageSodium-ion battery

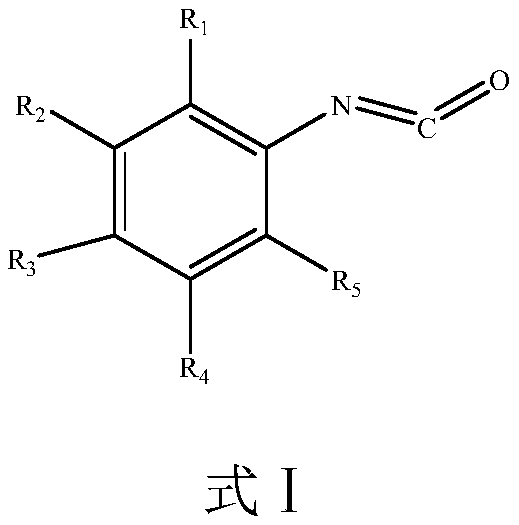

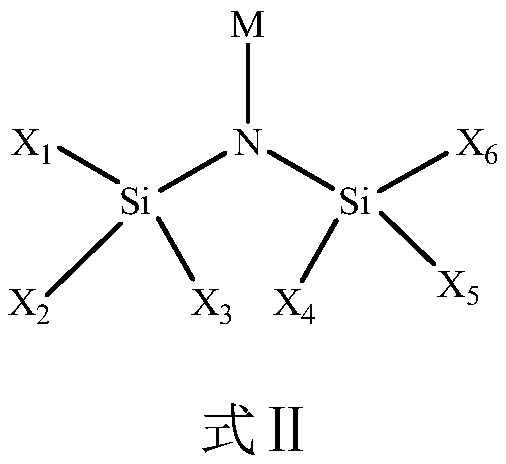

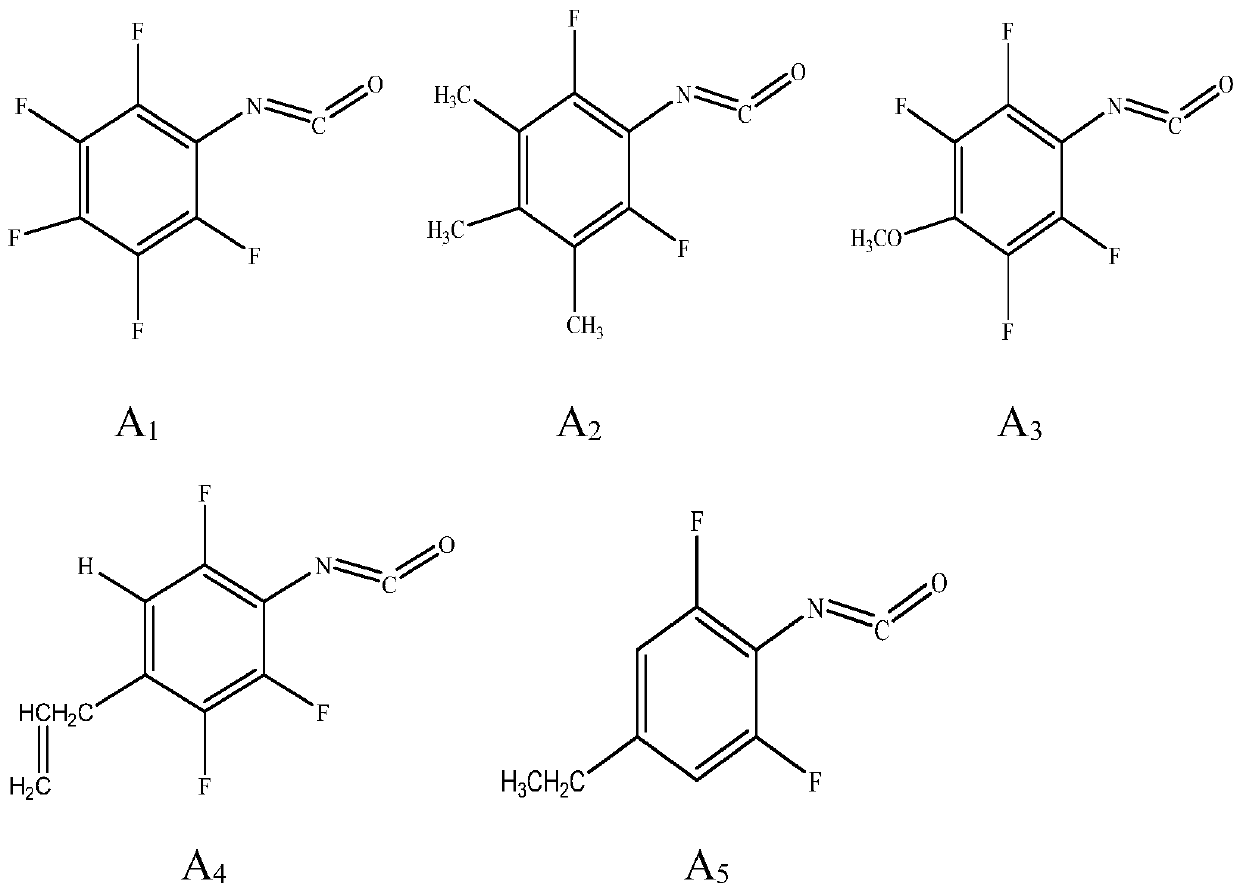

The invention belongs to the technical field of a lithium ion battery, and particularly relates to an electrolyte applicable to a silicon carbon negative and a lithium ion battery comprising the electrolyte. The electrolyte comprises an electrolyte lithium salt, a non-aqueous organic solvent and an additive. Wherein the additive comprises a negative film formation additive, a fluorine-substitutedphenyl isocyanate compound additive with a formula I structure and a dosilane nitrogen-based compound additive. Compared with the prior art, the actual discharging capability, the cycle stability andthe high-temperature storage performance of a silicon carbon negative electrode lithium ion battery are effectively improved by means of a synergic effect generated by combined application of variousadditives, gas generation is prevented, the problems of volume expansion and pole plate pulverization of the battery during the charge-discharge process are solved very well, and meanwhile, the electrolyte is compatible with relatively good high- and low-temperature performance.

Owner:SHANSHAN ADVANCED MATERIALS QUZHOU CO LTD

Preparation method of ordered mesoporous nano-silica microspheres

The invention discloses a preparation method of ordered mesoporous nano-silica microspheres. A cationic surfactant is dissolved in deionized water; then, inorganic alkaline is added; uniform mixing isperformed under the heating condition; then, a silicon source is added; stirring is performed for 4h to 10h; centrifugation, washing and drying are performed to obtain the ordered mesoporous nano-silica microspheres, wherein the mass ratio of the surfactant to the silicon source is (0.10 to 0.40):(0.60 to 1.50). The ordered mesoporous nano-silica microsphere prepared by the method has small graindiameter, uniform pore diameter, ordered mesoporous channel long range and high yield being 90 percent or higher. The goal of fast producing the nano-silica microspheres with ordered mesoporous channel height in large scale under the condition of low energy consumption can be realized. The preparation method has the advantages that the operation is simple; the reaction time is short; the requiredconditions are mild and can be easily controlled; the synthesis cost is low; the environment-friendly effect is achieved, and the like.

Owner:SHAANXI UNIV OF SCI & TECH

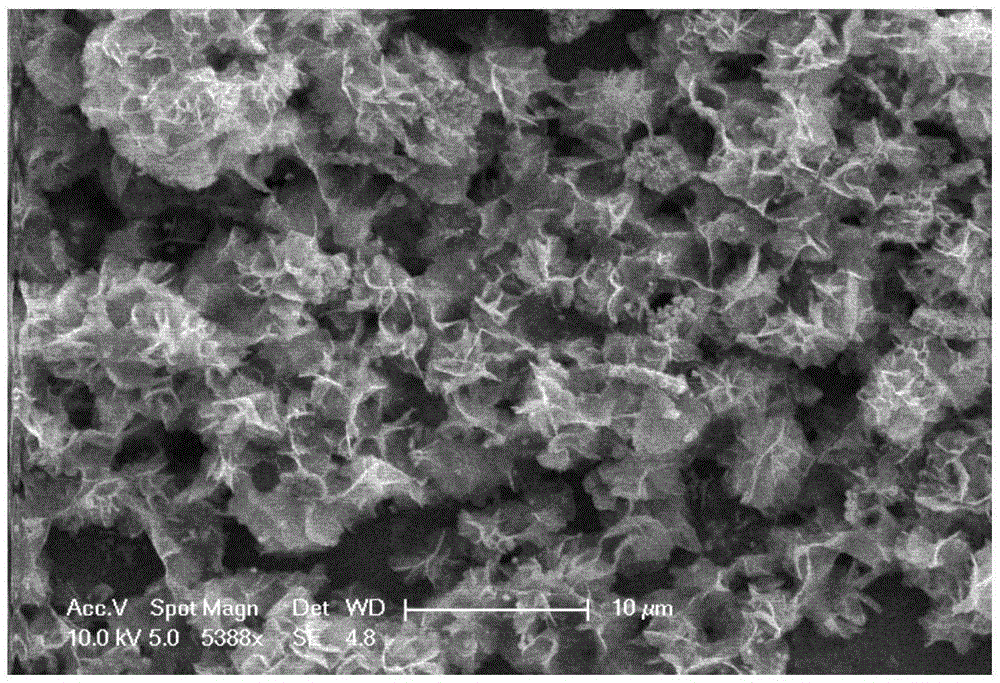

Silicon-carbon composite lithium ion battery negative electrode material and preparation method thereof

ActiveCN110707314AGood dispersionNot easy to collapseNegative electrodesSecondary cellsCarbon compositesElectrolytic agent

The invention provides a silicon-carbon composite lithium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps of adding micron silicon and a dispersing agent into a solvent, and grinding to obtain nano silicon slurry 1; adding a carbon matrix into the nano silicon slurry 1, and stirring to obtain mixed slurry 2, wherein thecarbon matrix is one or more of flattened artificial graphite, flattened natural graphite and flattened mesocarbon microbeads; and drying the mixed slurry 2, adding into a fusion machine for fusion,mixing with a coating agent, granulating, carrying out heat treatment in a protective atmosphere, carrying out high-temperature carbonization treatment in the protective atmosphere, crushing, gradingand demagnetizing to obtain the silicon-carbon composite negative electrode material. According to the present invention, the structure with better volume expansion can be buffered, the dispersion andcomplete coating of the nano silicon on the carbon matrix are realized, and the direct contact between the nano silicon and the electrolyte is isolated, so that the composite material can form a stable SEI film, and the service life of the battery is greatly prolonged.

Owner:SHAANXI COAL & CHEM TECH INST

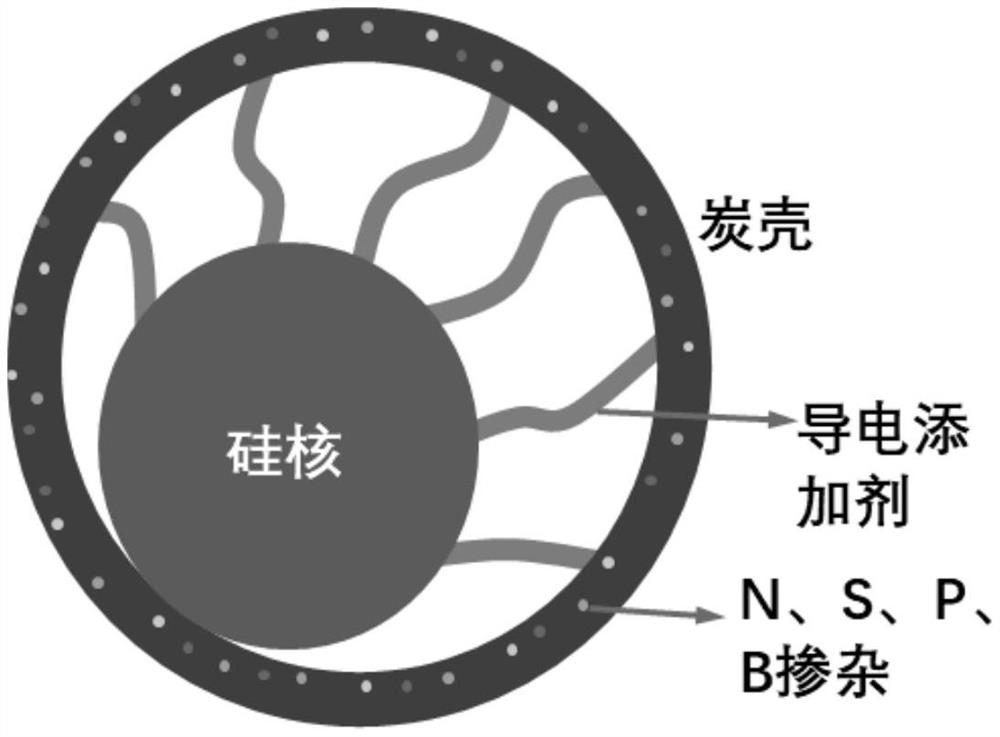

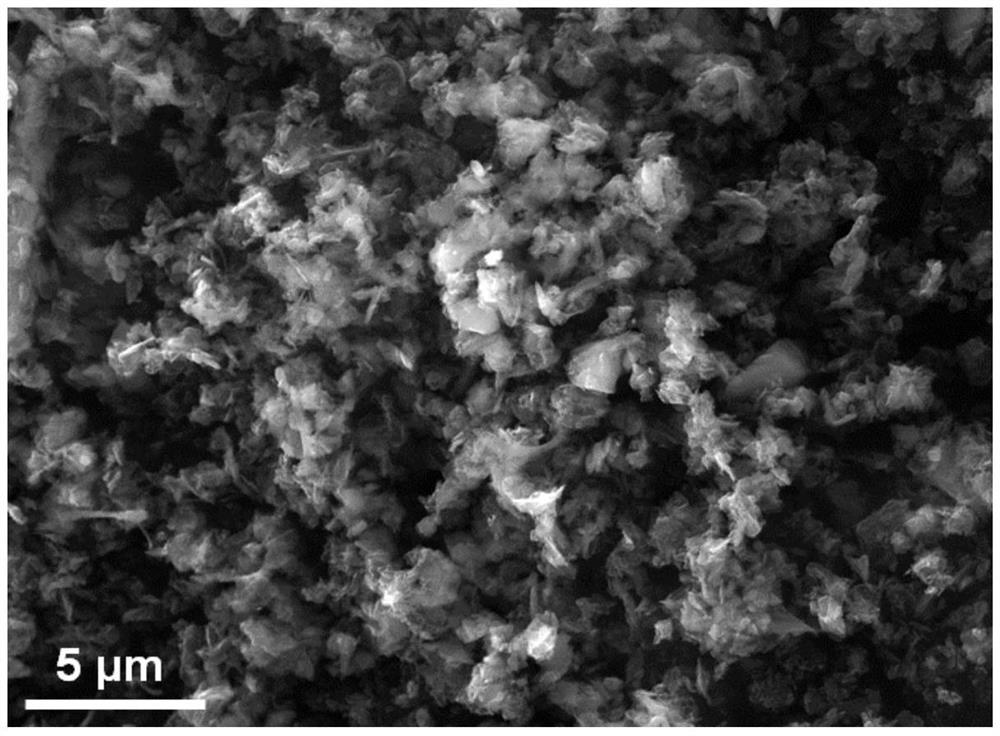

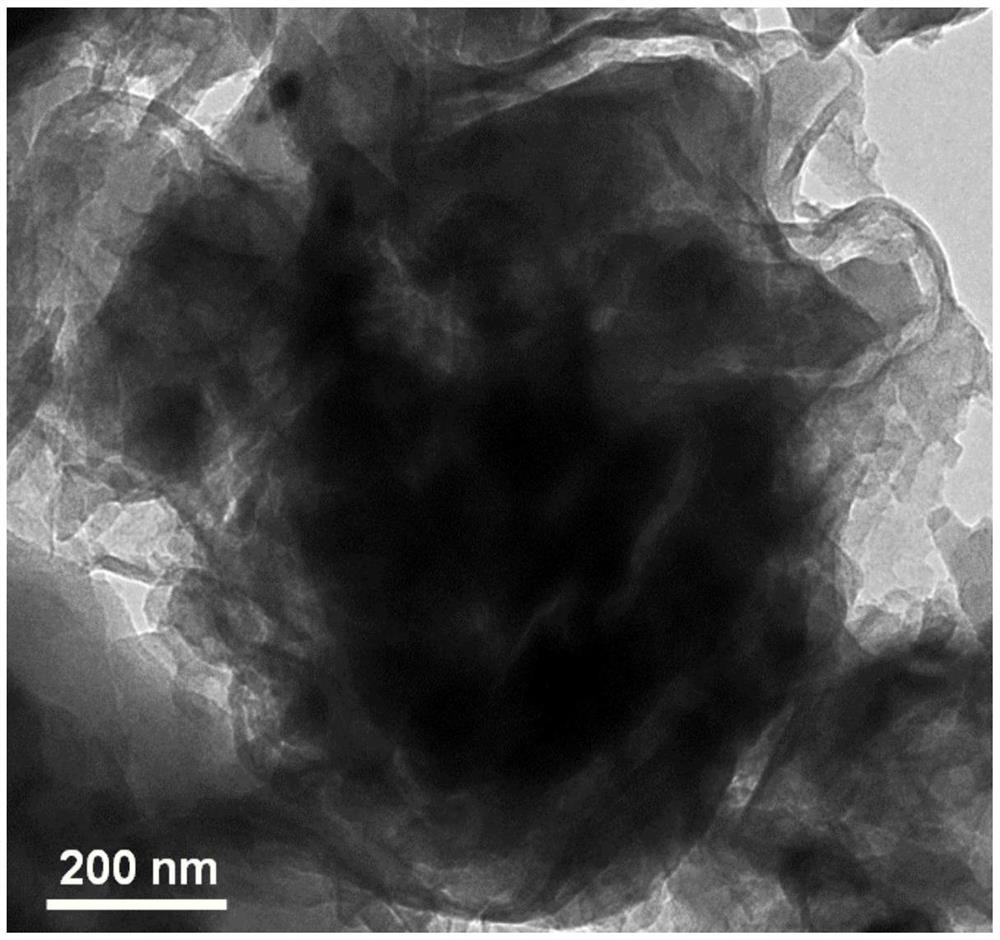

Multi-heteroatom co-doped carbon shell coated silicon composite material and preparation method thereof

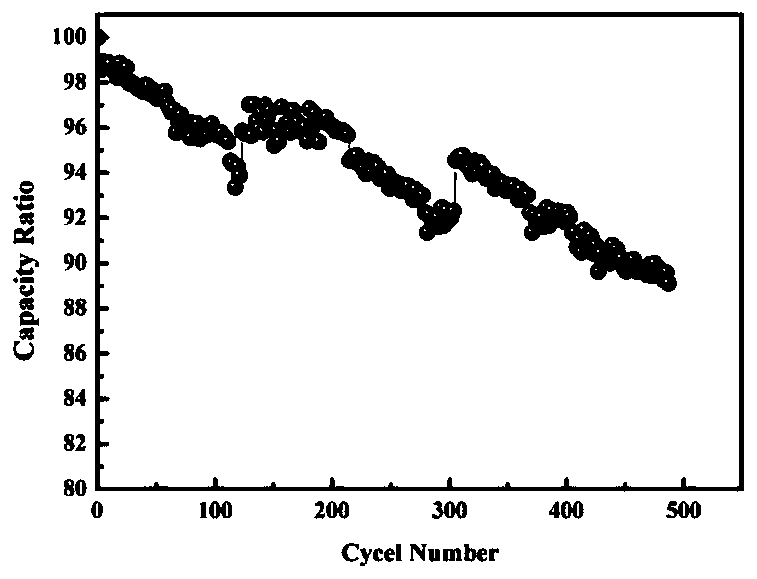

ActiveCN111682173AImprove cycle performanceImprove electronic conductivityCell electrodesSecondary cellsCarbon nanofiberSilicon particle

The invention belongs to the field of lithium ion battery negative electrode materials, and particularly relates to a multi-heteroatom co-doped carbon shell coated silicon composite material and a preparation method thereof. According to the composite material, nanoscale silicon particles serve as a core, a multi-heteroatom co-doped carbon material serves as a shell, a cavity exists between the silicon core and the carbon shell, and the silicon core and the carbon shell are connected through a conductive additive; the types of heteroatoms in the multi-heteroatom co-doped carbon material are one or more of N, S, P and B types; and the conductive additive is one or more of carbon nanotubes, conductive carbon black, graphene and carbon nanofibers. Meanwhile, the invention further provides a preparation method and application of the composite material. The prepared material is good in cycle performance. The size of the cavity can be regulated and controlled through the heat treatment time;whole conductive performance is good.

Owner:HUNAN UNIV

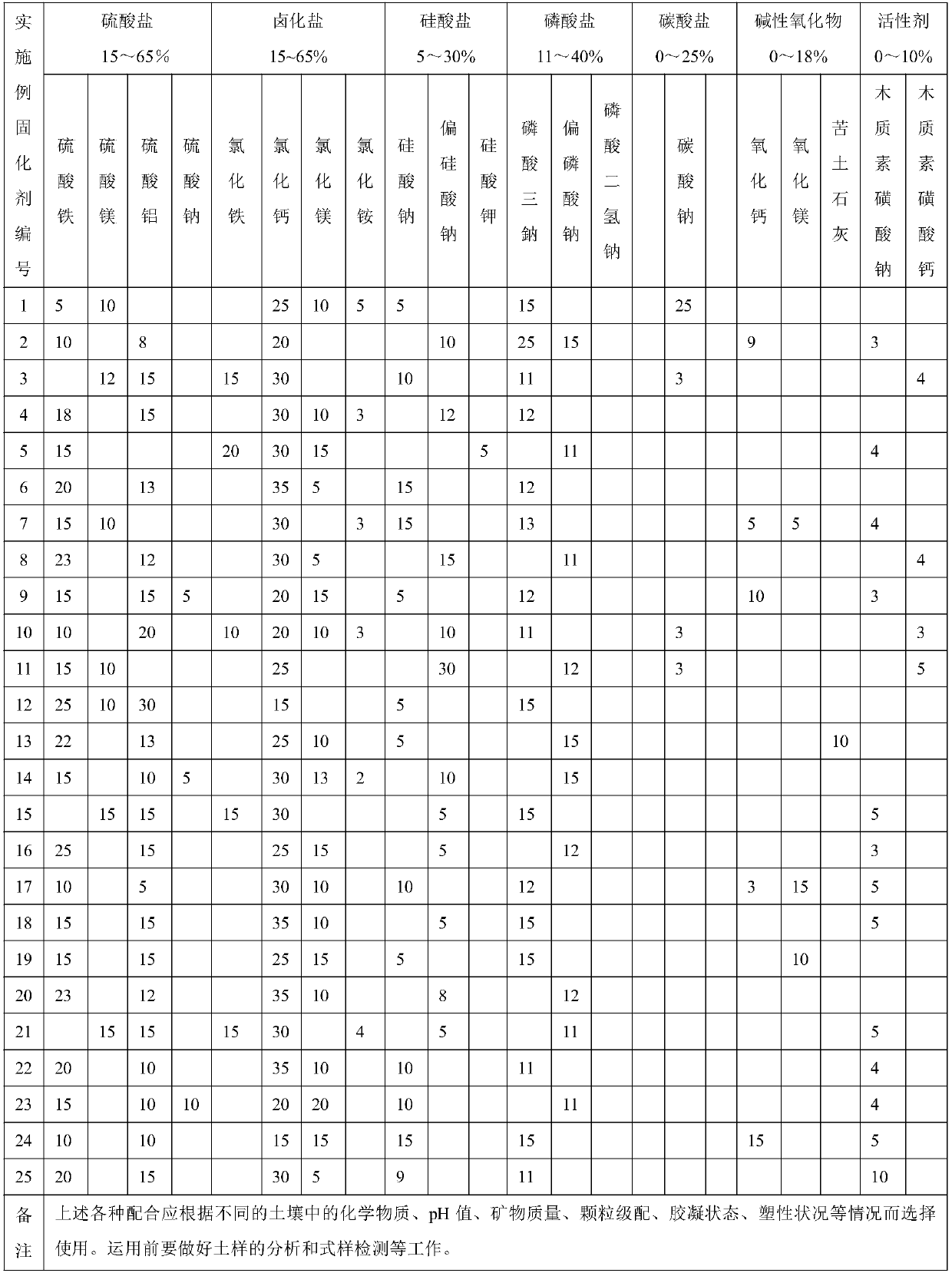

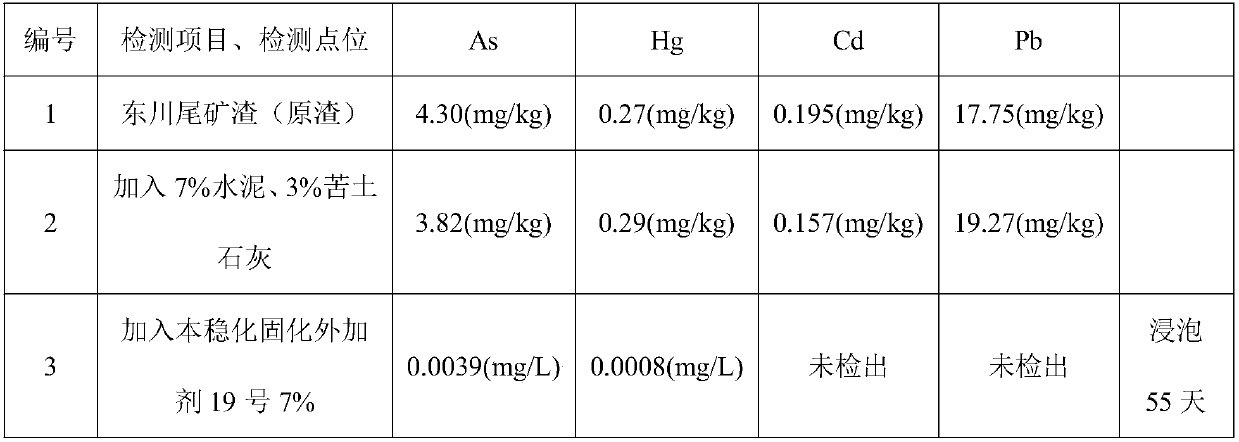

Environment-friendly inorganic soil solidification additive

InactiveCN105950157AImprove compatibilityFull effectOther chemical processesBuilding constructionsSoil propertiesHazardous substance

The invention provides an environment-friendly inorganic soil solidification additive which comprises, by mass, 15-65% of sulfate, 15-65% of halide salt, 11-40% of phosphate, 5-30% of silicate, 0-25% of carbonate, 0-18% of basic oxide and 0-10% of lignosulfonate. The environment-friendly inorganic soil solidification additive is characterized in that all components in soil directly or indirectly undergo soil particle surface chemical modification and modification of substances among soil particles, and generation of colloidal gel materials and generation of various materials of crystal structures are promoted. As time goes, hardened skeletons such as ettringite needle-shaped crystals and apatite crystals appear gradually in solidified soil, soil solidification compressive strength, hydrophobicity, water permeability, stability of heavy metal and other harmful materials and other physical and chemical solidification effects are good, and the environment-friendly inorganic soil solidification additive can adapt to various climates, geographies and soil properties and is high in compatibility and obvious in stabilization and solidification effect on heavy metal and other harmful materials.

Owner:松田勤

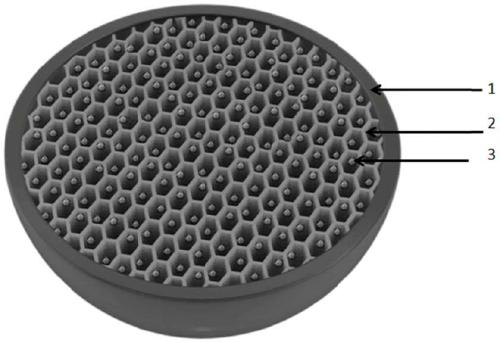

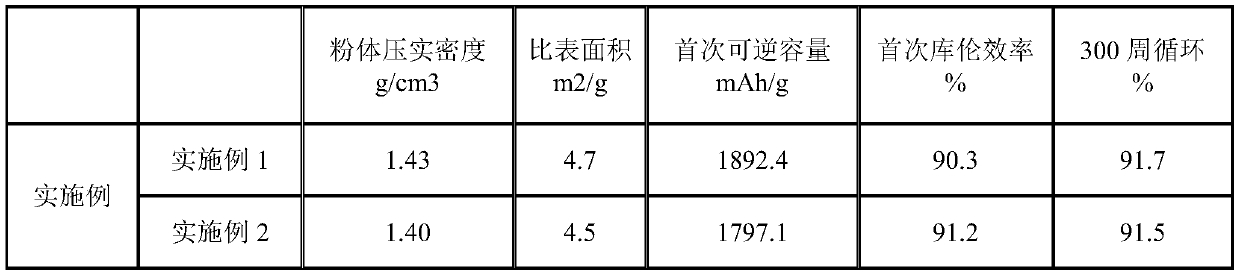

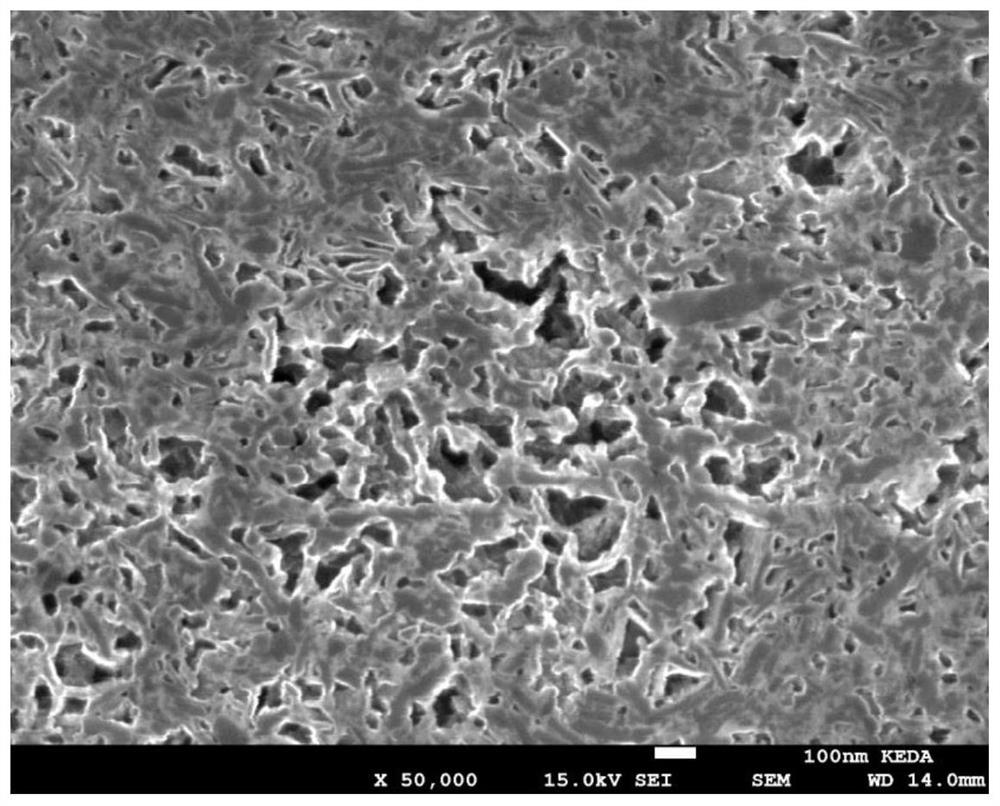

Porous core-shell structure silicon-carbon negative electrode material for lithium ion battery and preparation method thereof

ActiveCN111146430AReduce absolute volume expansionIncrease migration rateMaterial nanotechnologySecondary cellsNano siliconPorous carbon

The invention belongs to the field of lithium ion battery negative electrode materials and electrochemistry, and particularly relates to a porous core-shell structure silicon-carbon negative electrodematerial for a lithium ion battery and a preparation method thereof. The silicon-carbon negative electrode material is of a porous core-shell structure, wherein the inner core is formed by homogeneously compounding nano silicon and porous carbon, and the shell is coated with carbon formed by an organic cracking carbon source. According to the porous core-shell structure silicon-carbon negative electrode material prepared by the invention, the porous carbon is formed by combustion and carbonization of a carbon precursor, the nano-silicon is embedded into pores of the porous carbon, and the prepared negative electrode material is high in specific capacity, good in cycle performance and high-rate performance charge-discharge performance, simple in preparation process, low in cost and suitable for industrialization.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

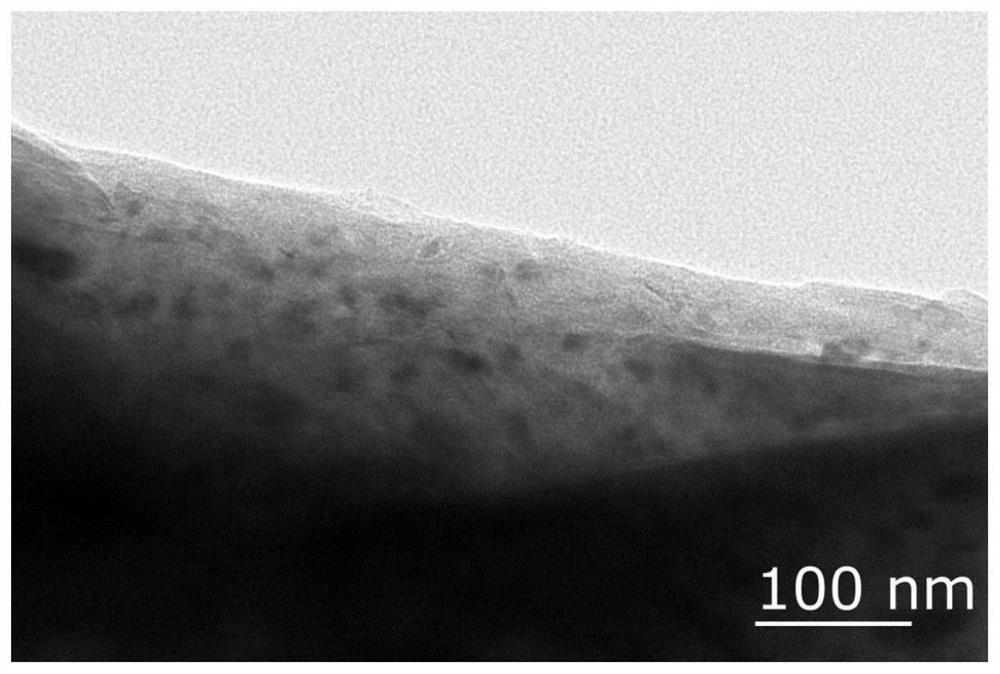

Hollow-structure carbon and silicon negative pole material used for lithium ion battery, and preparation method of hollow-structure carbon and silicon negative pole material

ActiveCN108258230AImprove volume expansionImprove performanceNegative electrodesSecondary cellsCarbon coatingTransmission channel

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a hollow-structure carbon and silicon negative pole material used for a lithium ion battery. The inner side of the negative pole material is of a hollow structure, and a wall layer of the negative pole material comprises an inner wall and an outer wall; the inner wall is subjected to homogeneous phase compounding by nanometer silicon and a low carbon residue carbon source; the outer wall is a carbon coating layer formed by an original pyrolysis carbon source; the particle size of the nanometer silicon is 5-300nm; the softening point of the low carbon residue carbon source is less than 200DEG C, and a carbon residue rate is less than 40%; the thickness of the outer wall is 0.1-10 microns; thethickness of the inner wall is 1-8 microns. The invention designs the large hollow-structure carbon and silicon negative pole material used for the lithium ion battery, a large hollow part is reservedfor the volume expansion of silicon, the volume expansion problem of a silicon negative pole can be obviously solved, the formation of the large hollow structure is guaranteed by the low carbon residue carbon source, meanwhile, the nanometer silicon is subjected to homogeneous phase dispersion, a transmission channel and rate of electrons and lithium ions can be guaranteed, and the carbon coatinglayer coats the outmost layer so as to form a protection shell for isolating electrolyte.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD

Method for preparing aluminum-free deep-fried dough sticks

InactiveCN102239898AImprove volume expansionPre-baking dough treatmentBakery productsAluminiumTexture profile analysis

The invention relates to a method for preparing aluminum-free deep-fried dough sticks. The method is characterized by specifically comprising the following steps of: (1) mixing raw materials in a ratio, namely mixing 100 mass parts of wheat flour, 45 to 65 mass parts of water, 1.0 to 2.0 mass parts of table salt, 1.0 to 3.0 mass parts of sodium bicarbonate, and four enzyme preparations, namely glucose oxidase, pentopan, lipase and fungal alpha-amylase; (2) making a dough, namely uniformly mixing the raw materials, and beginning to knead to obtain the smooth, soft and glutinous dough; and (3) making green bodies of deep-fried dough sticks, and deep-frying to obtain the aluminum-free deep-fried dough sticks. The made deep-fried dough sticks do not contain ingredients which are harmful to the health of human bodies, and have better sensory evaluation results and volume expansibility than deep-fried dough sticks which are prepared according to the traditional formula; and through texture profile analysis, indexes of the aluminum-free deep-fried dough sticks such as hardness, elasticity, cohesion, chewiness, resilience and the like all reach the standard of the traditional product.

Owner:SOUTH CHINA UNIV OF TECH

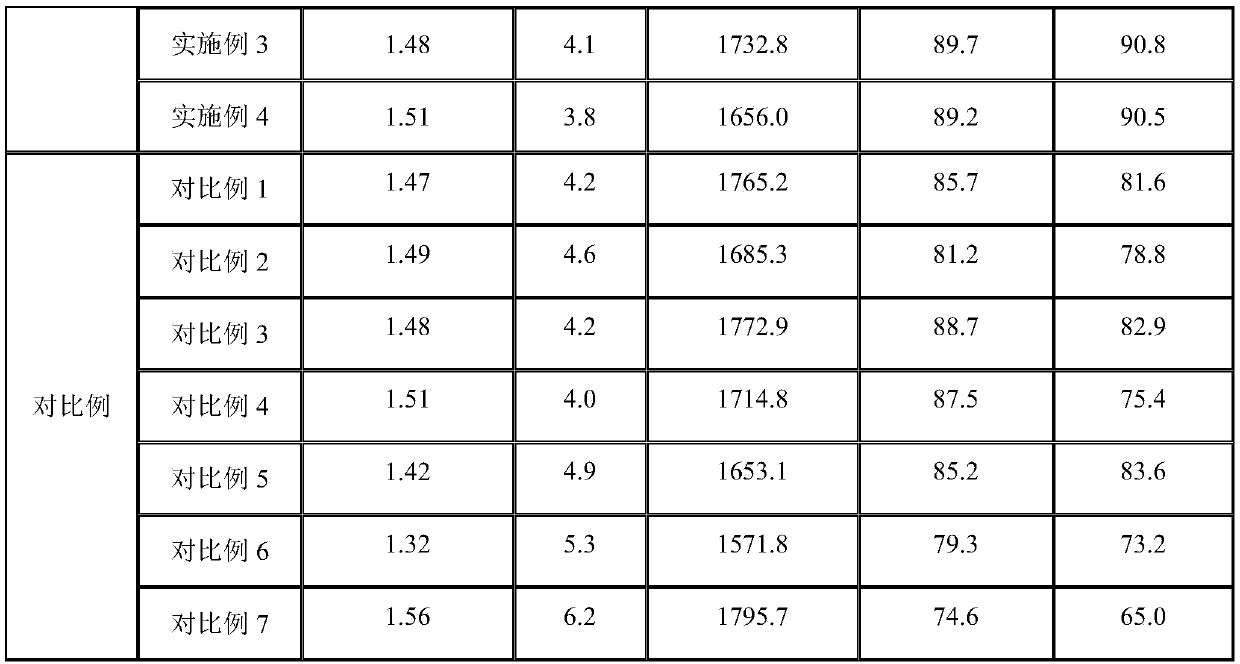

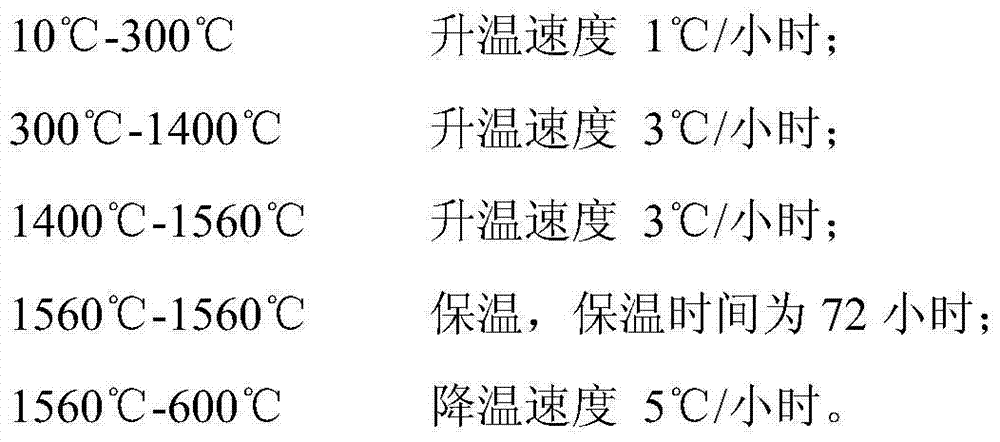

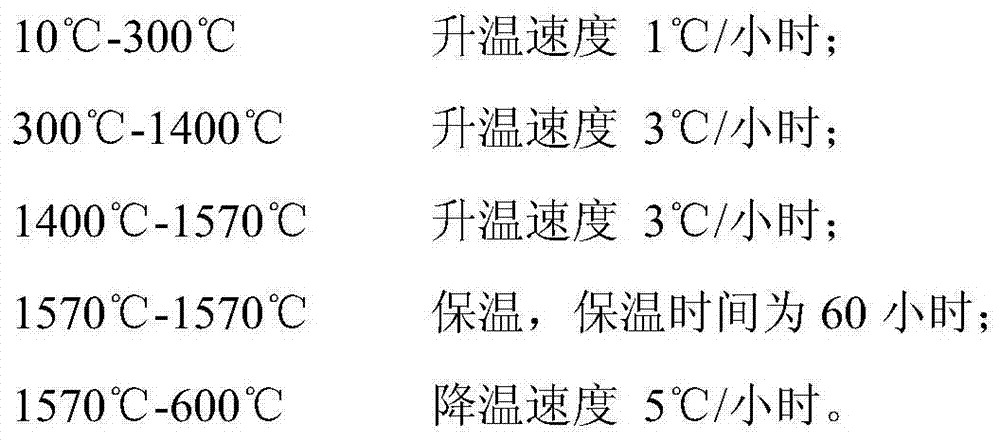

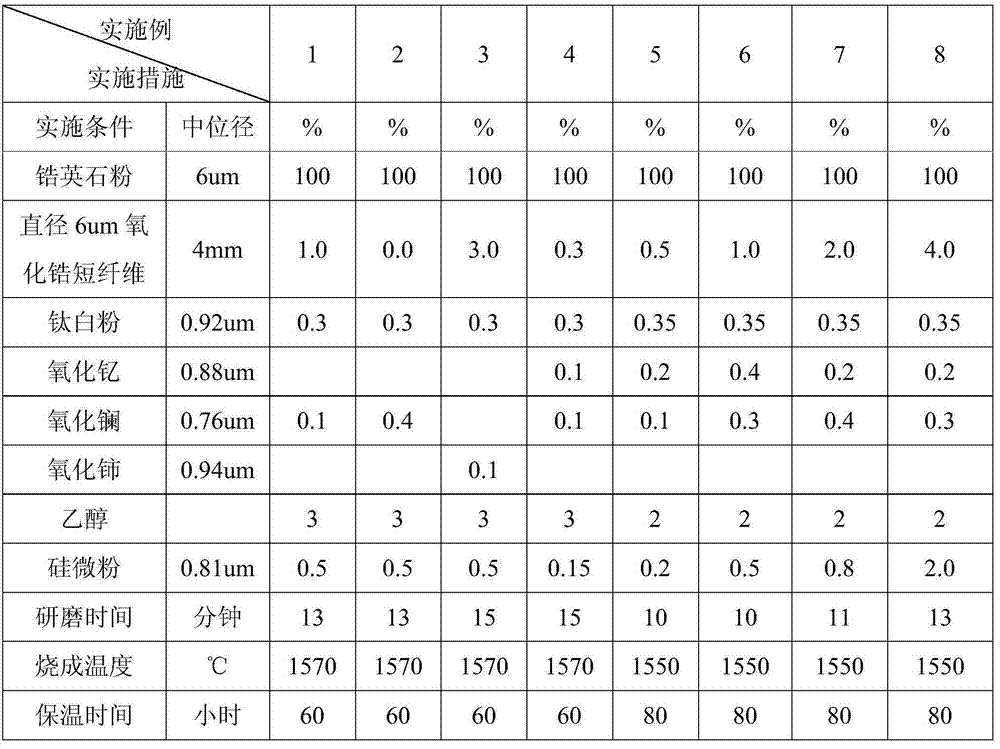

Low-creep zircon overflowing brick and preparation method thereof

ActiveCN103524139AHigh temperature low flexural strengthImproved high temperature flexural strengthFiberPolymer science

The invention relates to a low-creep zircon overflowing brick and a preparation method thereof. The low-creep zircon overflowing brick comprises, by mass, 100% of zircon powder, wherein zircon oxide short fibers account for, by mass, 0.0-4.0% of the zircon powder, silicon oxide powder accounts for, by mass, 0.1-2.0% of the zircon powder, and composite additives account for, by mass, 0.1-0.8% of the zircon powder. The composite additives can be La2O3, or CeO2, or combination of La2O3 and Y2O3, or combination of CeO2 and Y2O3, or combination of La2O3, CeO2 and Y2O3. According to the low-creep zircon overflowing brick and the preparation method thereof, strength of green bodies is improved, firing shrinkage of the green bodies is reduced, manufacturing yield of products is improved, bonding strength of crystal boundaries of zircon is enhanced, the high-temperature bend-creep rate of products is effectively lowered, and the service life of super-large-size overflowing bricks is prolonged.

Owner:ZIBO GT INDAL CERAMICS

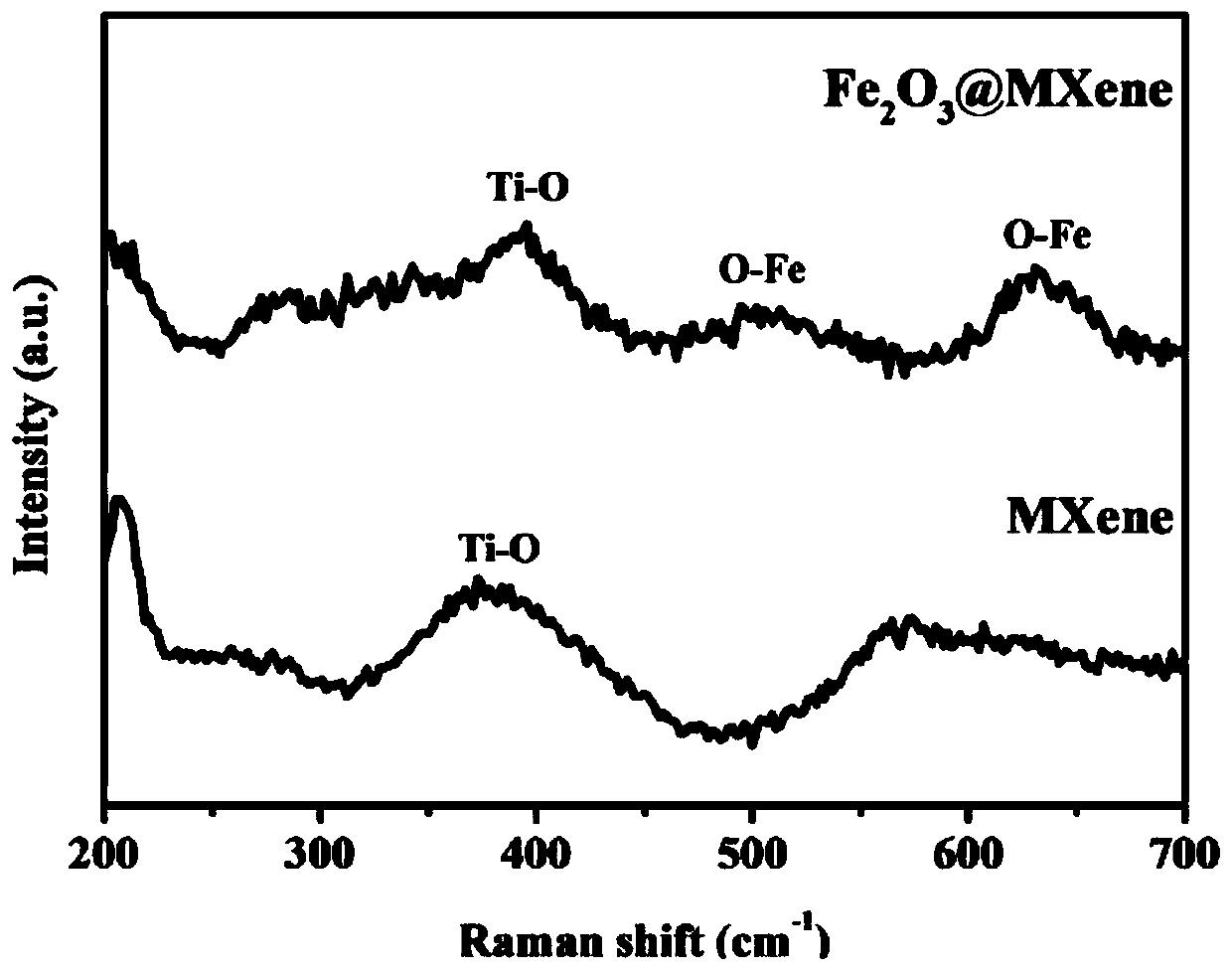

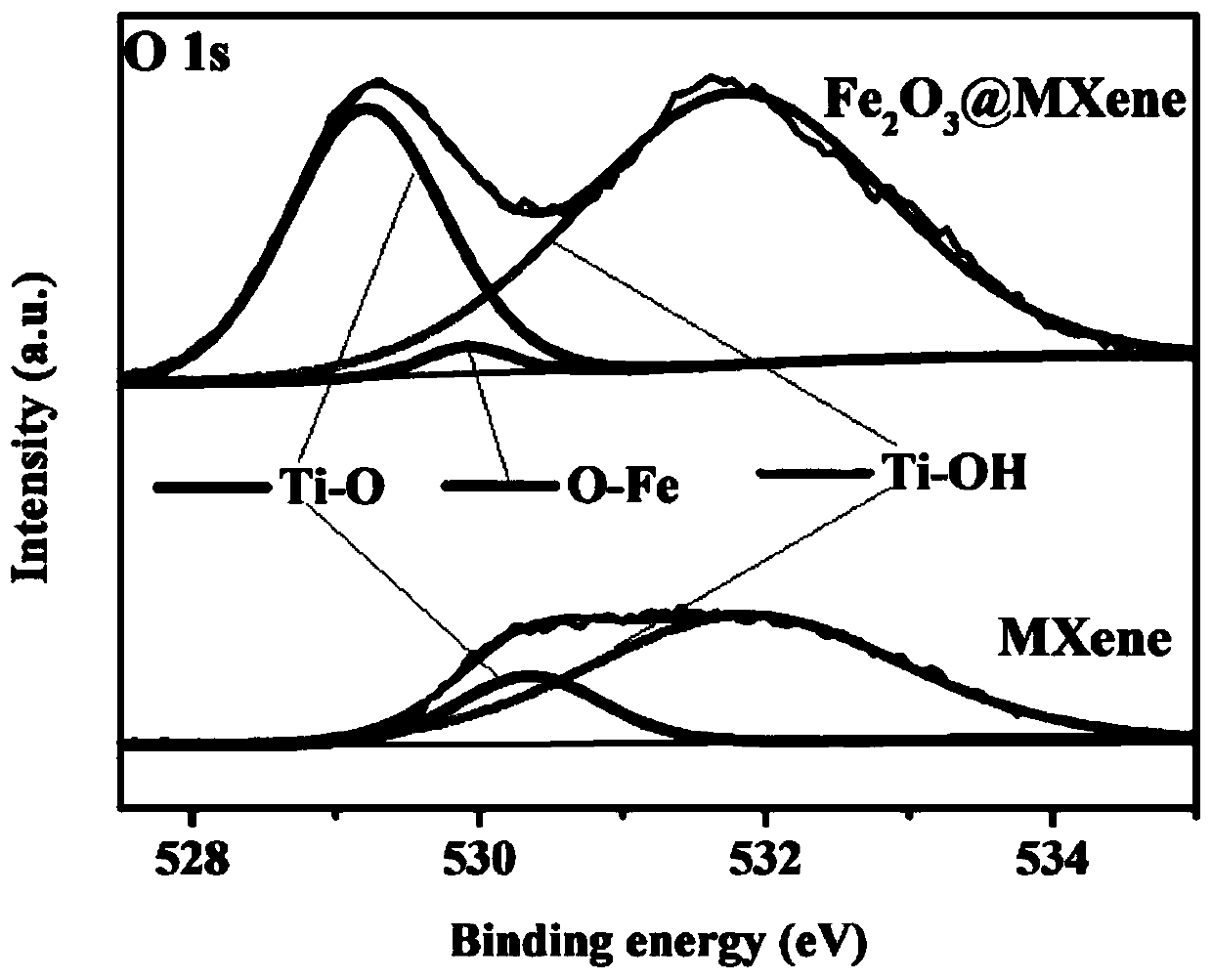

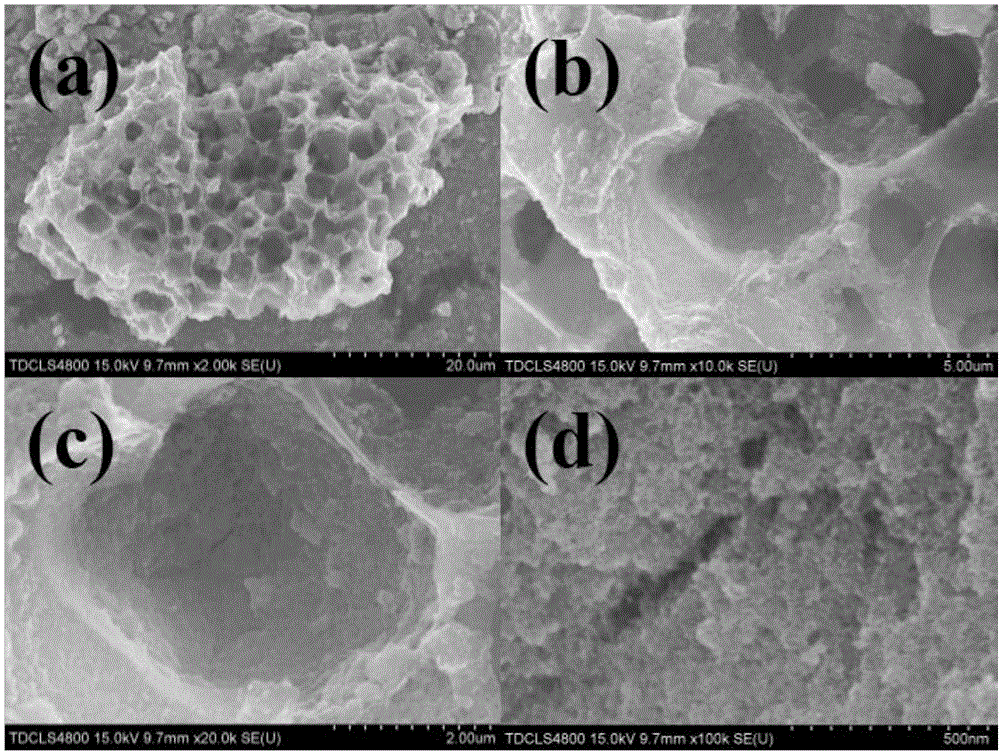

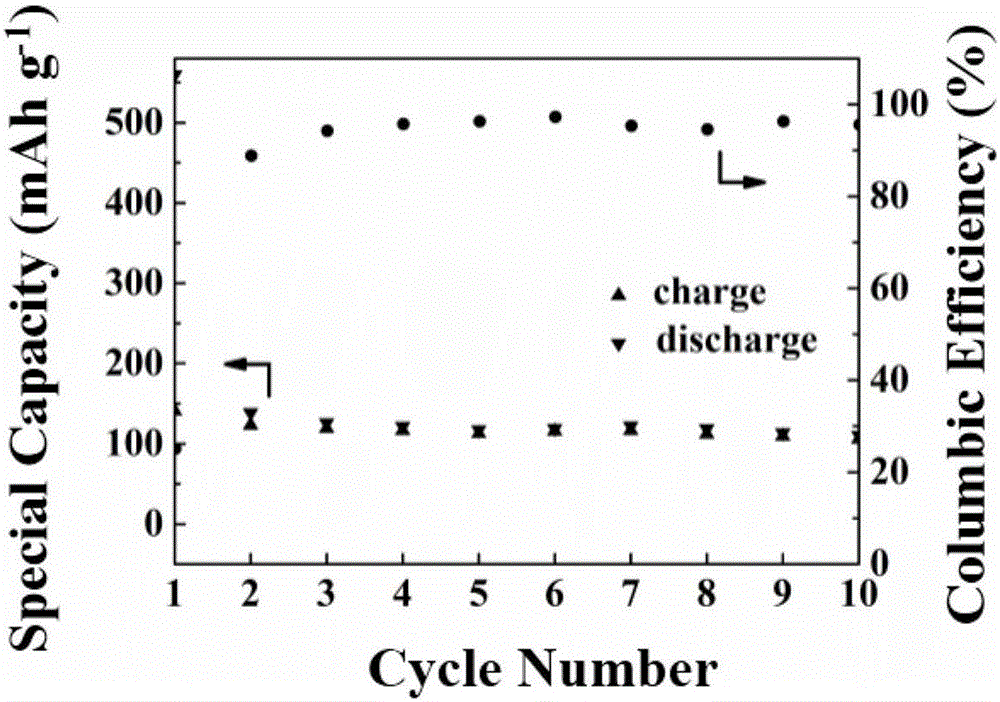

MXene-induced and grown nanocrystalline iron oxide composite material, preparation method and application thereof

ActiveCN109904426ASmall growth particle sizeSmall particle sizeMaterial nanotechnologyCell electrodesTetramethylammonium hydroxideAmmonium hydroxide

The invention provides a preparation method of MXene-induced and grown nanocrystalline iron oxide composite material. The preparation method comprises the following steps: A) adding Ti3AlC2 into a HFsolution, and etching to obtain an etching product; B) mixing the etching product and a tetramethyl ammonium hydroxide solution, performing intercalation, and then adding LiOH, reacting to obtain an intermediate product, wherein the mass ratio of the LiOH and the etching product is (0.04-0.09): 1; C) dispersing the intermediate product in the water, ultrasonically treating for 1-1.5, and then centrifuging, wherein the obtained supernatant is MXene solution; and D) orderly adding a ferric salt solution and alkali solution in the MXene solution, performing in-situ growth to obtain the nanocrystalline iron oxide composite material, wherein the ferric salt solution comprises ferric salt and the dispersant. The invention further provides a MXene-induced and grown nanocrystalline iron oxide composite material, and application thereof.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

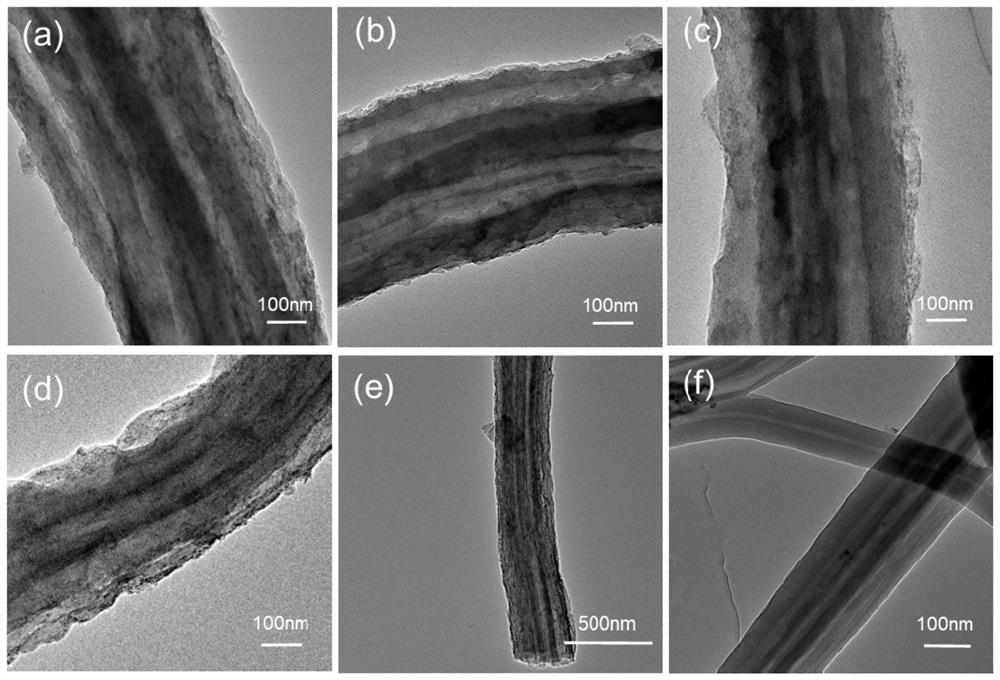

Low-expansion silicon-based composite material and manufacturing method thereof, silicon-based anode material and lithium ion battery

InactiveCN109546108ASmall volume expansionImprove stabilityCell electrodesSecondary cellsCarbon coatingCarbon composites

The invention relates to a low-expansion silicon-based composite material and a manufacturing method thereof, a silicon-based anode material and a lithium ion battery. The low-expansion silicon-basedcomposite material is a core-shell structure, and a core is a silicon-carbon composite material, including a carbon micrometer tube and silicon particles attached to the carbon micrometer tube, and ashell is a carbon coating layer. The low-expansion silicon-based composite material uses the carbon micrometer tube as the core and the carbon coating layer as the shell, to form the core-shell structure. Tests show that the tubular silicon-based material can greatly reduce volume expansion of the material during charge and discharge processes. After carbon coating treatment, electrical conductivity is good and stability of the material is improved, and side reaction between the material and an electrolyte is reduced, thereby being beneficial for forming a stable SEI film, reducing exposure and breakage of the silicon particles during charging and discharging processes are reduced, and greatly improving cycle life of the battery.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

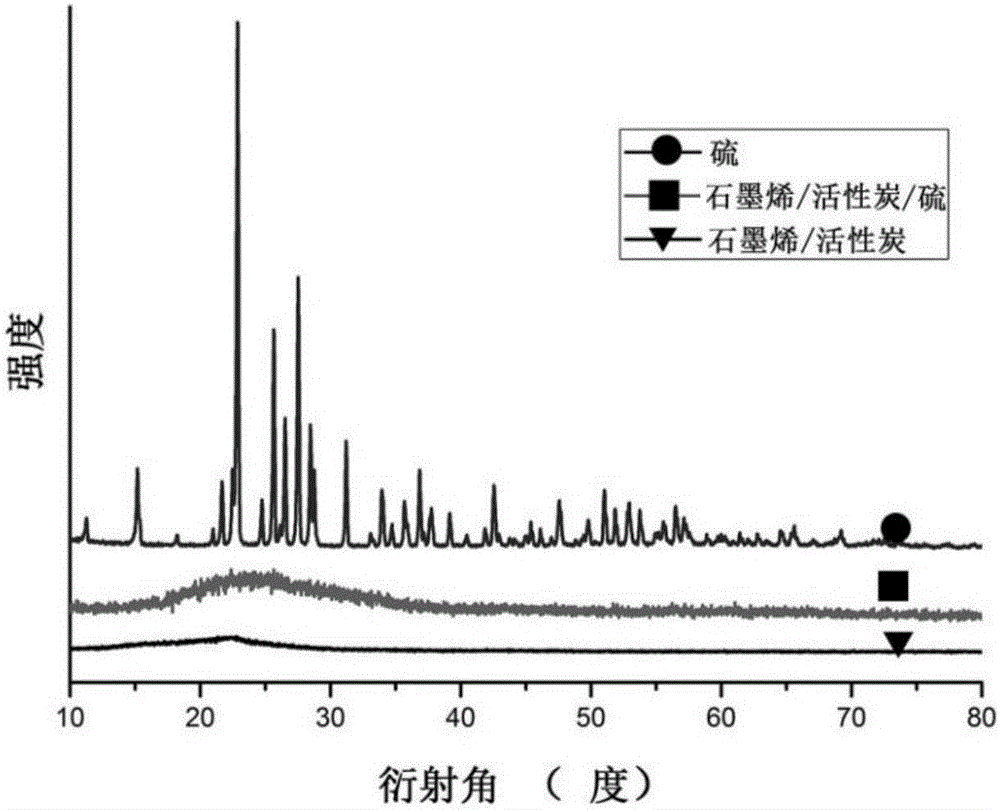

Method for preparing positive electrode composite material

InactiveCN106784757AImprove conductivityIncrease profitCell electrodesLi-accumulatorsArgon atmosphereSodium ascorbate

The invention relates to a method for preparing a positive electrode composite material. The method comprises the following steps: adding activated carbon subjected to acid treatment to graphene oxide suspension to obtain a mixed solution; and then adding a sodium ascorbate solution to obtain graphene hydrogel; and drying the graphene hydrogel, mixing and grinding the dry graphene hydrogel with sulfur, calcining the mixture at 150-200 DEG C for 3-15h in an argon atmosphere to obtain a graphene / activated carbon / sulfur positive electrode composite material. The method for preparing the positive electrode material of lithium-sulfur batteries provided by the invention has the advantages that the used raw materials are cheap and easy to obtain, the preparation process is simple, the flow is short, the process is easy to control, and the industrial production is easy to realize.

Owner:青岛亨迈新能源有限公司

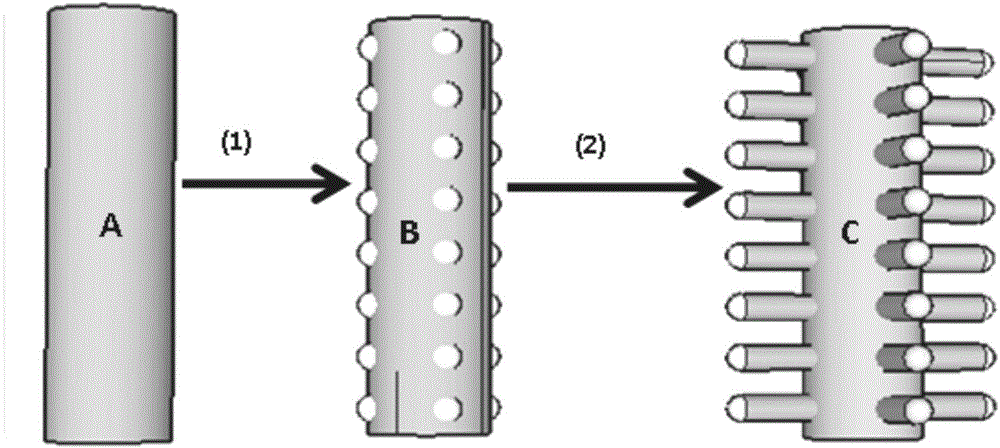

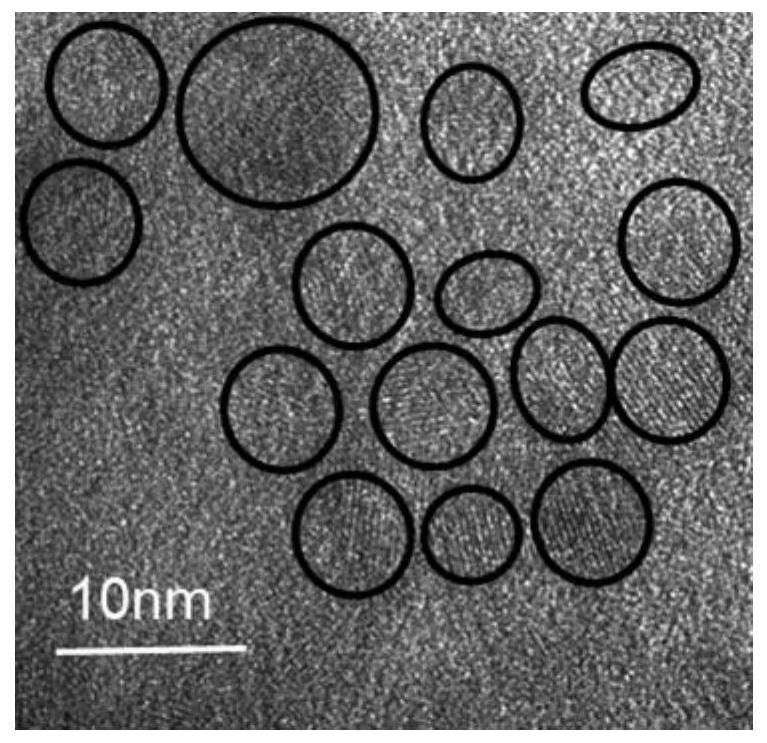

Nano heterostructure material for anode material of lithium battery, and preparation

InactiveCN104103817AIncrease the areaHigh specific capacityMaterial nanotechnologyCell electrodesVapor liquidNanoparticle

The invention discloses a nano heterostructure material for an anode material of a lithium battery. A one-dimensional metal oxide (SnO2 or In2O3 or SnOx, InxOy, Sn doped InxOy, In doped SnOx, TiOx and VxOy) nano structure with good conductivity serves as a trunk material; a one-dimensional Si or Ge nano structure with poor conductivity serves as a branch material; and the branch material is grafted onto the trunk material. In a grafting process, a SnO2 (In2O3) nano trunk is subjected to hydrogen treatment, and then Sn (In) nano particles are formed on the surface of the nano trunk, and direct epitaxy of Si (Ge) nano branches can be achieved by taking the Sn (In) nano particles as a catalyst through a VLS (Vapor-Liquid-Solid) growth process. For a branch part in a heterostructure, the one-dimensional Si (Ge) nano structure growing with the Sn nano particles on the head is also a good lithium storage system.

Owner:NANJING UNIV

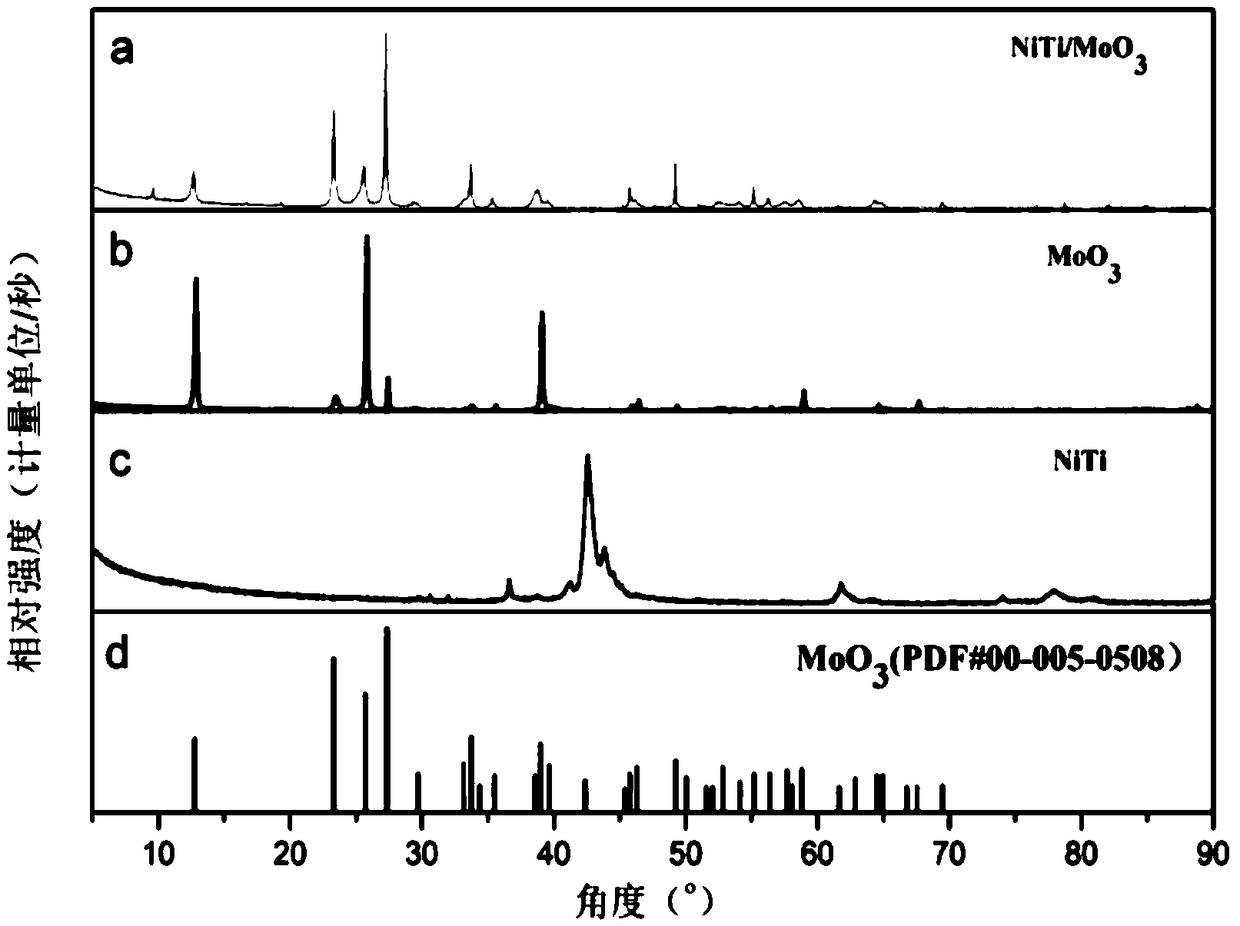

Flower-shaped multistage structure molybdenum trioxide material induce by nickel-titanium alloy and preparation method and application thereof

ActiveCN109244382AImprove conductivityImprove structural stabilityCell electrodesSecondary cellsSpherical shapedHigh pressure

The invention discloses a flower-shaped multistage structure molybdenum trioxide material induced by a nickel-titanium alloy and a preparation method and application thereof. At first, (NH4) 6Mo7O24.4H2O aqueous solution and HNO3 are uniformly mix; Then adding 60-120 nm spherical or near-spherical nickel-titanium alloy powder into the aqueous solution, uniformly mixing, transferring the solutionto a tetrafluoroethylene-lined high-pressure reaction kettle, and reacting at 150-210 DEG C for 3-24 hours; At that end of the reaction, aft cooling to room temperature, the reaction product is collect by centrifugation, washed with water and ethanol for several times respectively, and then the product is vacuum dry to obtain flower-like multi-stage structure molybdenum trioxide material. The preparation method of the invention has strong controllability and simple operation, can be used for large-scale production of lithium ion secondary battery electrode material, and can remarkably improvethe cycle and rate performance of the electrode material.

Owner:SOUTH CHINA UNIV OF TECH

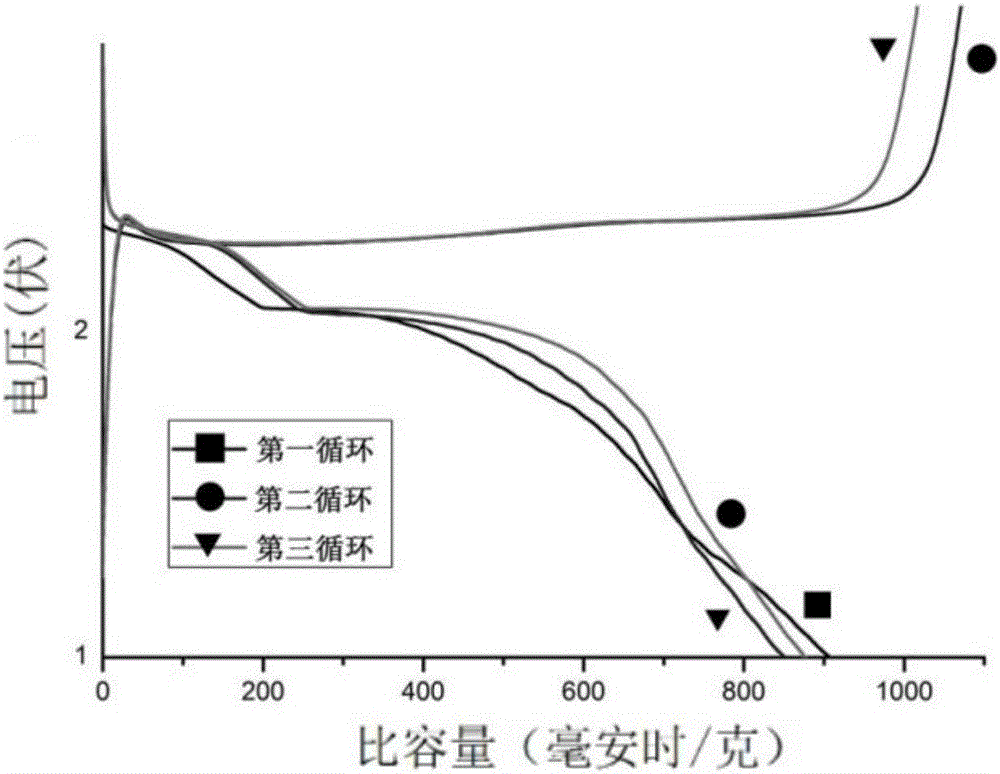

Preparation method for positive electrode material of graphene coated sulfur-lithium sulfur battery

InactiveCN105810913AImprove volume expansionImprove electrochemical performanceCell electrodesLi-accumulatorsMicrosphereMechanical property

The invention relates to a preparation method for a positive electrode material of a graphene coated sulfur-lithium sulfur battery, and belongs to the field of a battery material. The preparation method comprises the following steps of taking intermediate-phase carbon microspheres as a raw material to prepare a conductive network and graphene with a large area to serve as a sulfur carrying substrate; taking sodium thiosulfate as a sulfur source, growing sulfur on the graphene in an in-situ way by a chemical deposition method, and preparing an activated graphene / sulfur composite material; and mixing and coating the activated graphene / sulfur composite material and polyvinylidene fluoride onto an aluminum foil to prepare a positive electrode plate. The graphene is provided with a unique two-dimensional porous network geometric structure having excellent conductivity, large specific area, chemical stability and high mechanical property, an electron and ion transmission path in the lithium sulfur battery can be shortened, and the electrochemical activity of elemental sulfur is improved; and generated soluble polysulfide lithium can be coated with a layered graphene structure at the periphery during circulation of charging and discharging and is limited in the electrode material, a shuttle effect can be further relieved, the columbic efficiency is improved, thus, the specific capacity of an electrode is improved, and the cycle lifetime of the battery is prolonged.

Owner:周荣

Method for preparing composite material containing tin dioxide nano-particles attached to honeycomb carbon

InactiveCN106784699AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesElectrochemical responseTin dioxide

Owner:TIANJIN UNIV

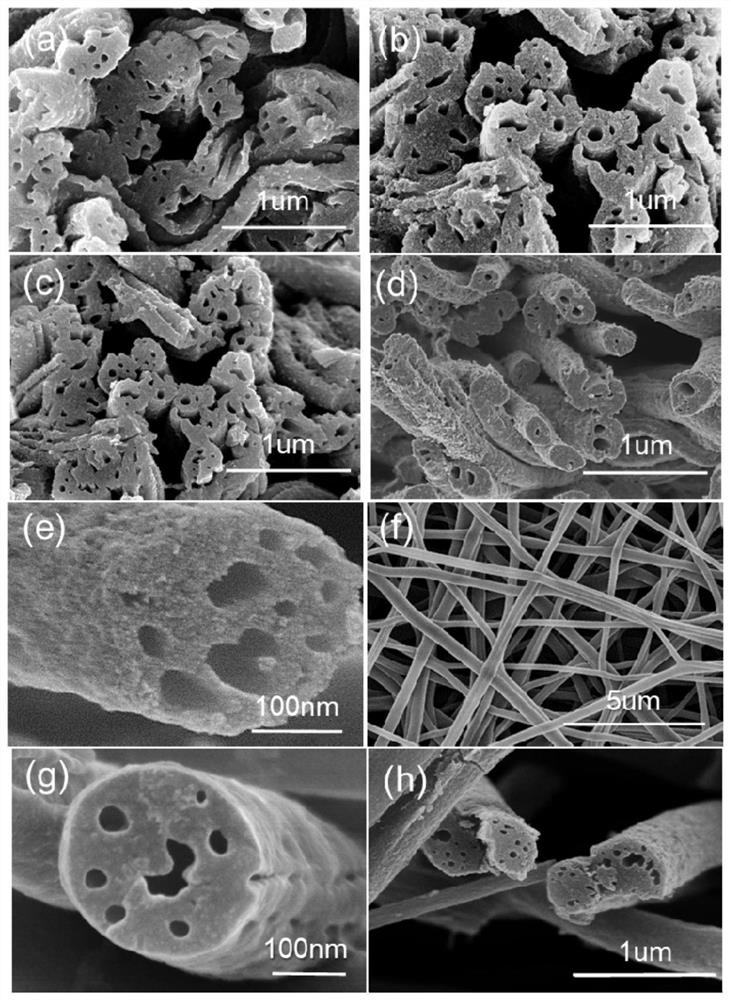

Porous multi-hollow flexible composite nanofiber membrane material and preparation method thereof

ActiveCN113073426AImprove flexibilityHigh mechanical strengthHollow filament manufactureNon-woven fabricsHollow fibreFiber

The invention relates to a porous multi-hollow flexible composite nanofiber membrane material and a preparation method thereof. According to the method, a porous multi-hollow flexible composite nanofiber membrane is prepared through coaxial electrostatic spinning, wherein an outer layer solution for coaxial electrostatic spinning consists of a sacrificial high-molecular polymer, a retained high-molecular polymer and a solvent A, and an inner layer solution for coaxial electrostatic spinning is composed of a sacrificial high-molecular polymer, a material capable of generating a substance with semiconductor characteristics and low surface energy in the spinning process, and a solvent B; and then the sacrificial high-molecular polymer in the porous multi-hollow flexible composite nanofiber membrane is removed to obtain the membrane material formed by stacking porous multi-hollow nanofibers, wherein the porous multi-hollow nanofibers are provided with a plurality of hollow pipelines and three-dimensional penetrating through hole micro-nano structures with the hollow surfaces. The membrane material disclosed by the invention has relatively high flexibility and mechanical strength, and the problems of fragility, low mechanical strength and the like of a porous composite fiber material and a single hollow fiber material are solved.

Owner:DONGHUA UNIV

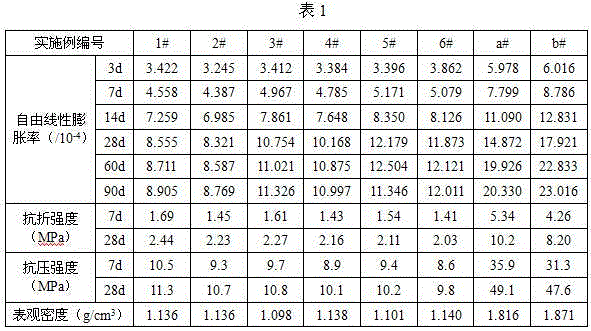

Sulfur-fixing ash cement-based material and expansibility control method thereof

InactiveCN103979894ARealize resource utilizationLow apparent densitySolid waste managementCelluloseMethyl cellulose

The invention discloses a sulfur-fixing ash cement-based material. The sulfur-fixing ash cement-based material comprises 30-50 parts of cement, 50-70 parts of sulfur-fixing ash, 0.18-0.84 part of hydroxypropyl methyl cellulose ether and 60-120 parts of water. The final product has good volume stability, low performance density and good heat insulation performance. The invention also discloses an expansibility control method for the sulfur-fixing ash cement-based material. The method comprises the following specific steps: (1) weighing all the raw materials according to the sulfur-fixing ash cement-based material; (2) uniformly mixing the cement, sulfur-fixing ash and hydroxypropyl methyl cellulose ether; (3) slowly adding water and stirring for at least 5 minutes; (4) curing for 24 hours at normal pressure and temperature, then demoulding to obtain the sulfur-fixing ash cement-based material. The steps can be carried out at normal pressure and temperature and have strong operability; the prepared sulfur-fixing ash cement-based material can be used in the building energy conservation field, and takes the sulfur-fixing ash as the raw material, so that the pollution of the sulfur-fixing ash to the environment is reduced, and recycling of the sulfur-fixing ash is realized.

Owner:CHONGQING UNIV

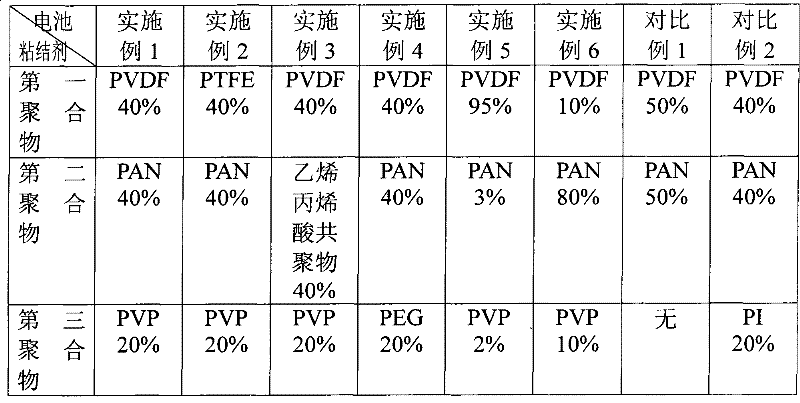

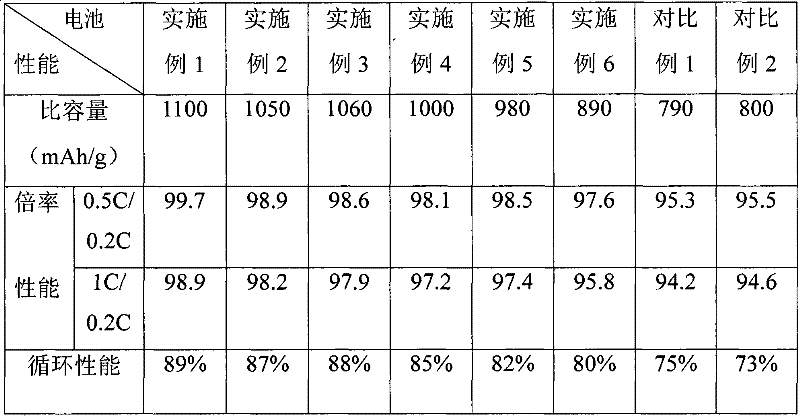

Silicon cathode and lithium ion battery comprising same

ActiveCN101740747BHigh specific capacityImproved magnification performanceSecondary cellsActive material electrodesMethacrylateAdhesive

The invention provides a silicon cathode, which comprises a current collector and a silicon cathode material loaded on the current collector; the silicon cathode material comprises a silicon cathode active substance and an adhesive, wherein the adhesive comprises a first polymer, a second polymer and a third polymer; the first polymer is a fluorine-containing polymer; the second polymer is a polymer containing at least one of acrylonitrile unit, methacrylonitrile unit, acrylic ester unit and methacrylate unit; and the third polymer is one or more of polyvinylpyrrolidone, poly alkylene glycol,acrylamide and polyethylene glycol. Compared with the silicon cathode in the prior art, the silicon cathode has high specific capacity and good rate discharge characteristic, and particularly solves the problem of cycle performance of the silicon cathode in the prior art. Simultaneously, the invention also provides a good-performance battery comprising the silicon cathode.

Owner:BYD CO LTD

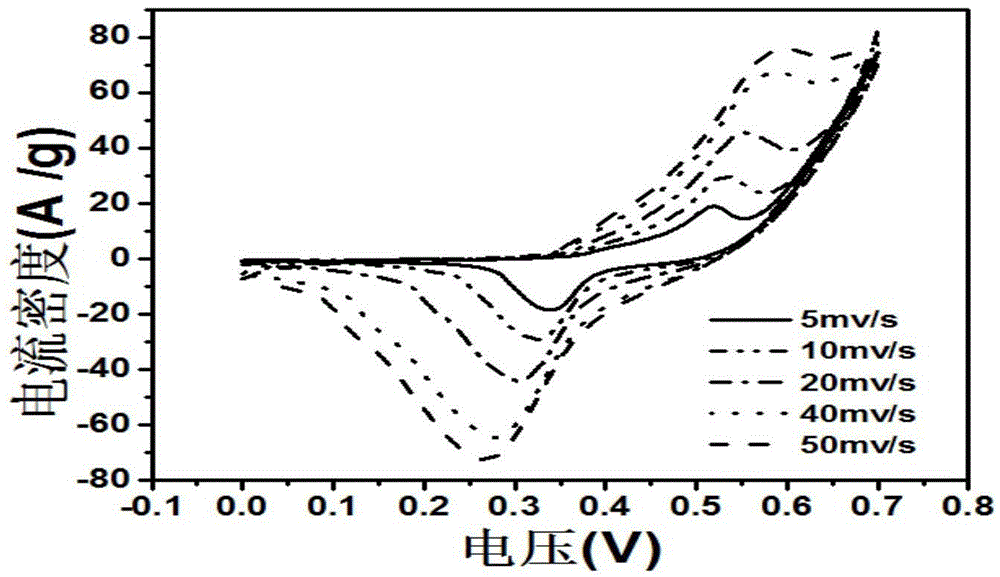

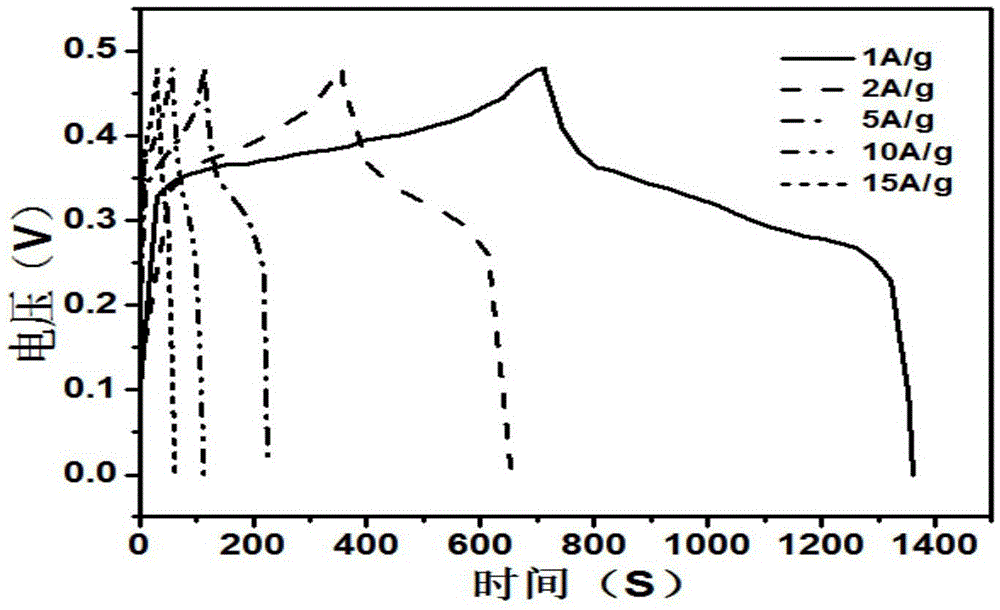

Preparation method of flower-like nickel sulfide material and application of flower-like nickel sulfide material in super capacitor

ActiveCN105489390ASimplified quantityLarge specific surface areaHybrid capacitor electrodesNickel sulfidesCapacitanceThiourea

The invention provides a preparation method of a flower-like nickel sulfide material. The method comprises the following steps: dissolving a nickel source precursor nickel acetate into deionized water, adding ethanol for ultrasonic dispersion and then adding a precursor thiourea of a sulfur source and a surfactant for ultrasonic dispersion again to obtain a reaction liquid; transferring the obtained reaction liquid into a hydrothermal reactor for solvothermal reaction and controlling the temperature for reaction; and respectively washing the obtained reaction liquid with the deionized water and the ethanol, and then carrying out drying to obtain the flower-like nickel sulfide material. An electrochemical test proves that the obtained flower-like nickel sulfide material has excellent charge and discharge properties and cycling stability. An experiment proves that the specific capacitance of the material is 1350F / g at 1A / G charge and discharge currents; the preparation method has the advantages that reaction conditions are easy to control; the preparation technology is simple; the obtained product is good in uniformity; and industrial production of nickel sulfide is facilitated.

Owner:SHANGHAI INST OF TECH

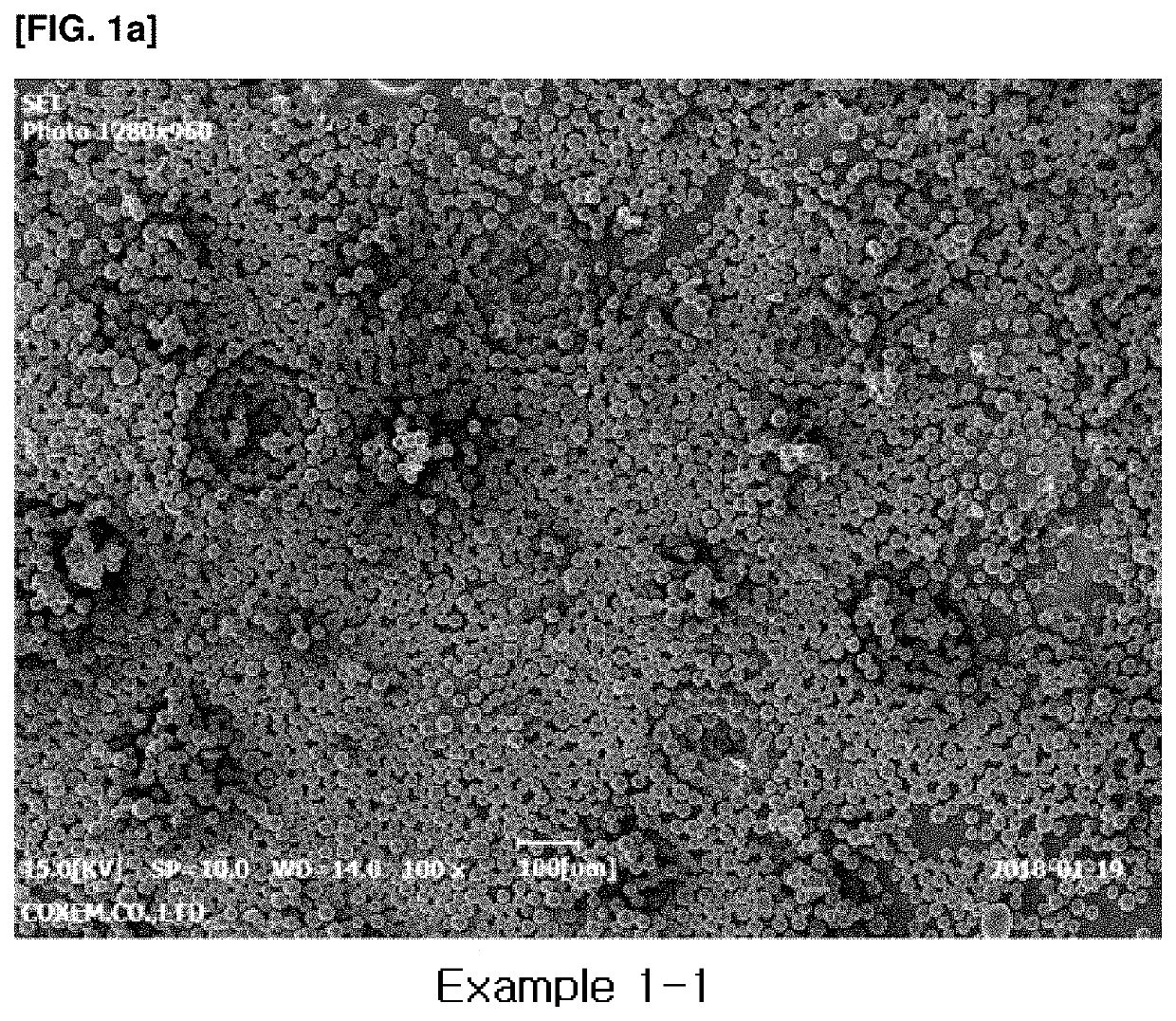

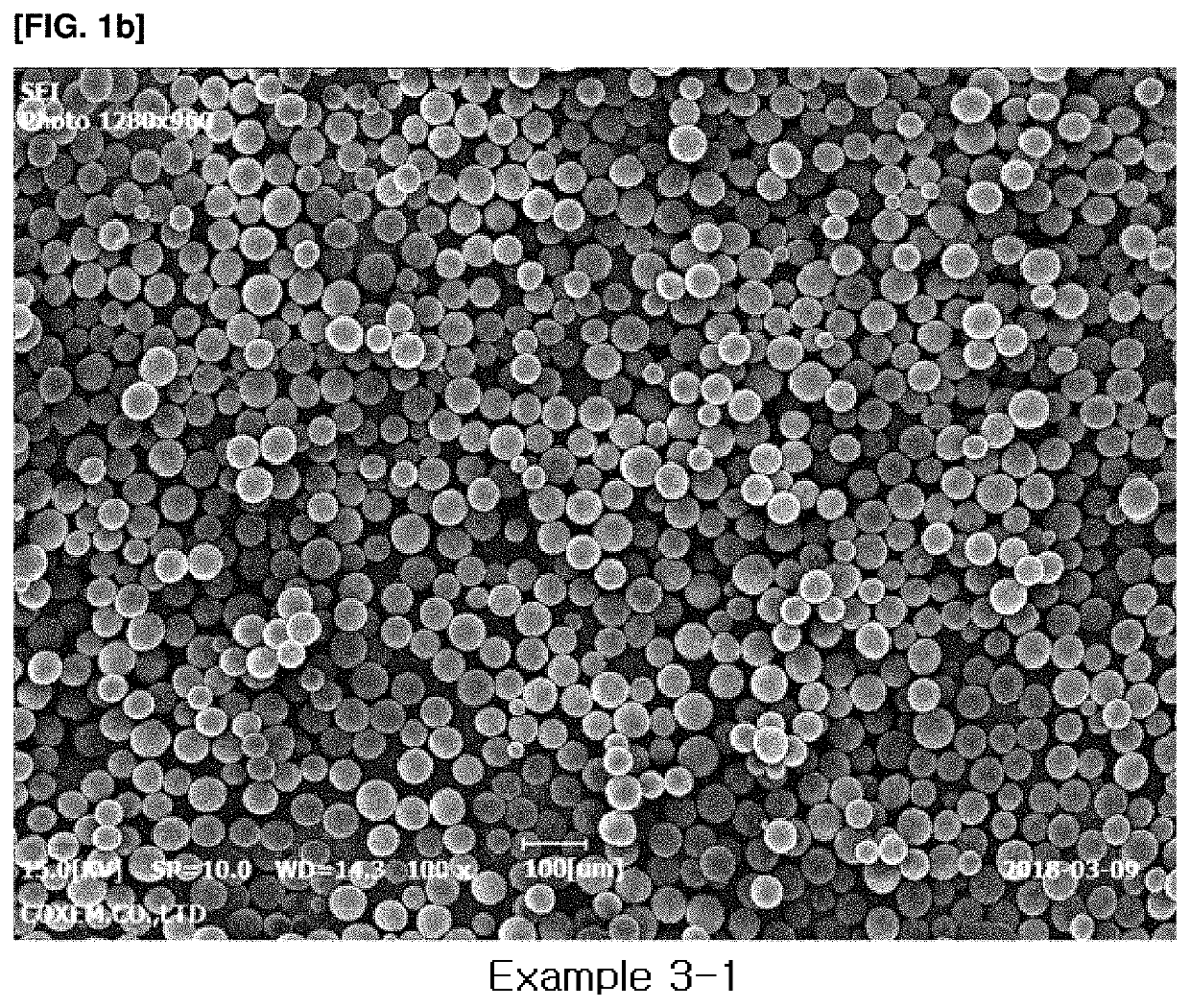

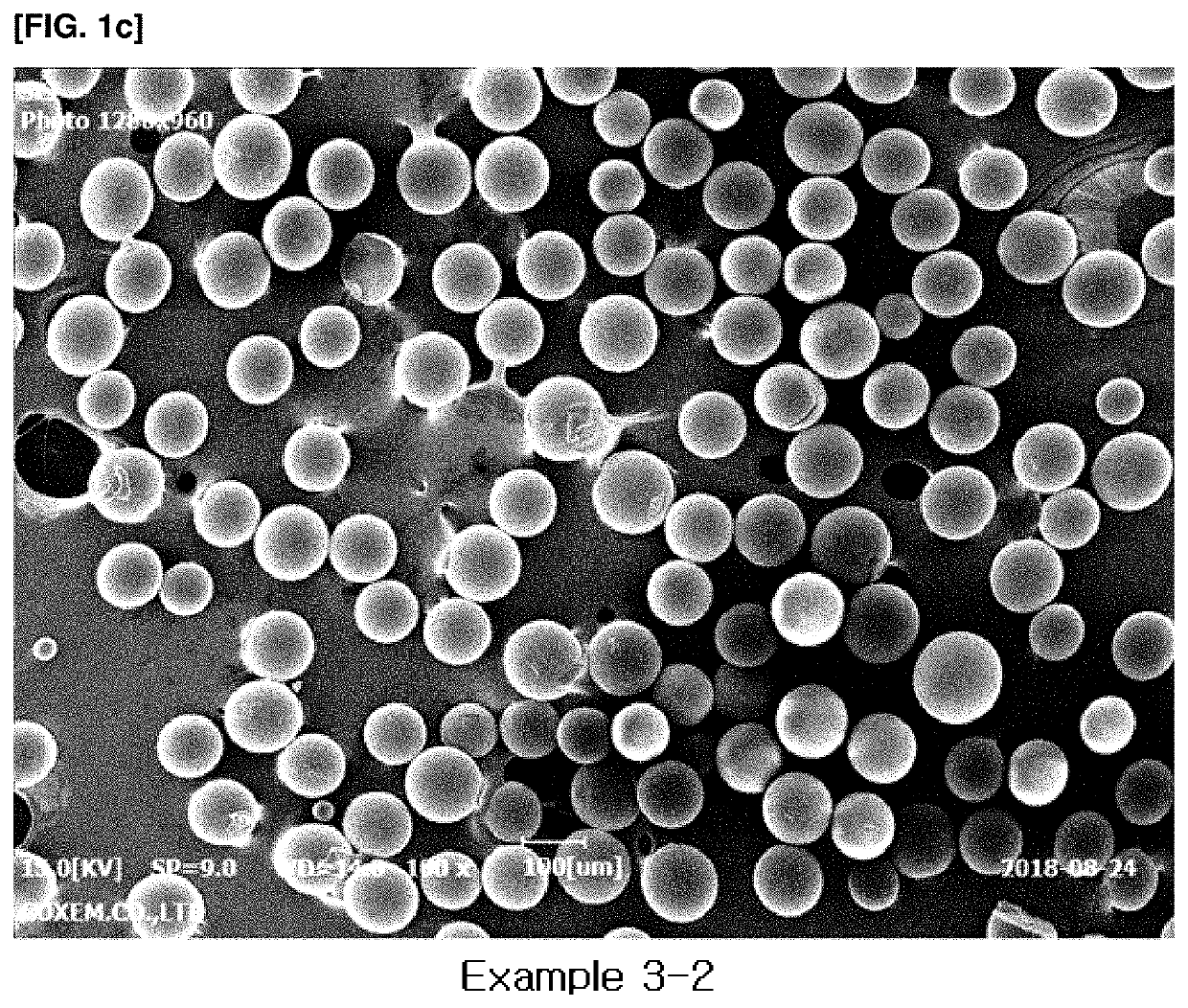

Collagen peptide-containing polycaprolactone microsphere filler and preparation method therefor

PendingUS20200353127A1Rapid collagen formation effectImprove tissue repair abilityCosmetic preparationsToilet preparationsTissue repairMicrosphere

The present disclosure relates to a polycaprolactone microsphere filler containing collagen peptide and a preparation method therefor. Provided is a polycaprolactone microsphere filler obtained by encapsulating collagen peptide in polycaprolactone microspheres, which, when injected into a living body, exhibits a rapid collagen formation effect as well as a high tissue restoration property and maintains the effects for a long period of time, thereby showing excellent restoration or volume expansion or wrinkle improvement properties of soft tissues such as cheeks, breasts, nose, lips, and buttocks.

Owner:G2GBIO INC

Silicon-oxygen negative electrode material and preparation method thereof, negative electrode plate and secondary battery

ActiveCN113937296AEnsure stabilityImprove the failure phenomenonMaterial nanotechnologyNegative electrodesSilicon oxygenCarbon Nanoparticles

The invention provides a silicon-oxygen negative electrode material and a preparation method thereof, a negative electrode plate and a secondary battery. The preparation method comprises the steps of S1, adding a silicon-oxygen material into an alkaline solution with the pH value of 8-9 for dispersion, adding dopamine hydrochloride for continuous dispersion, washing, centrifuging and drying to obtain silicon-oxygen dopamine nanoparticles, and sintering the silicon-oxygen dopamine nanoparticles to obtain silicon-oxygen carbon nanoparticles; S2, mixing and stirring the silicon-oxygen carbon nanoparticles and a titanium source, heating, cooling, washing, centrifuging and drying to obtain titanium-silicon-oxygen carbon nanoparticles; and S3, dissolving the titanium-silicon-oxygen carbon nanoparticles in water, carrying out ultrasonic dispersion, then adding dopamine hydrochloride, continuing to dissolve and disperse, then adding a strongly alkaline substance, stirring, washing, centrifuging, and drying to obtain the dopamine modified silicon-oxygen negative electrode material. Compared with the prior art, the obtained negative electrode material has the advantages that the problem of volume expansion of the current silicon material in the charge-discharge process is solved, the structural stability of the silicon material in the charge-discharge process is ensured, and various properties of the battery are improved.

Owner:浙江锂威能源科技有限公司

Silicon-containing negative electrode material for lithium ion battery and preparation method of silicon-containing negative electrode material

InactiveCN111755683ANanoization energy reductionReduce absolute volume expansionMaterial nanotechnologyCell electrodesCarbon layerSilica particle

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a silicon-containing negative electrode material for a lithium ion battery and a preparation method of the silicon-containing negative electrode material. The negative electrode material contains silica particles, porous carbon and coated carbon. The negative electrode material comprises the following components in percentage by weight: 30%-60% of silica particles, 10%-40% of porous carbon and 10%-30% of coated carbon; the silica particles can be represented by SiOX, wherein x is greater than 0 and less than 0.5; the porous carbon material is combined with silica particles in the negative electrode material, and the formed porosity is 10%-50% by volume; the surface layer part of the negativeelectrode material is covered by a carbon layer, and the thickness of the carbon layer is 10-1000nm. Compared with the prior art, the prepared silicon-containing negative electrode material for the lithium ion battery has excellent electrochemical performance.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD +2

Negative pole piece, electrochemical device comprising negative pole piece and electronic device

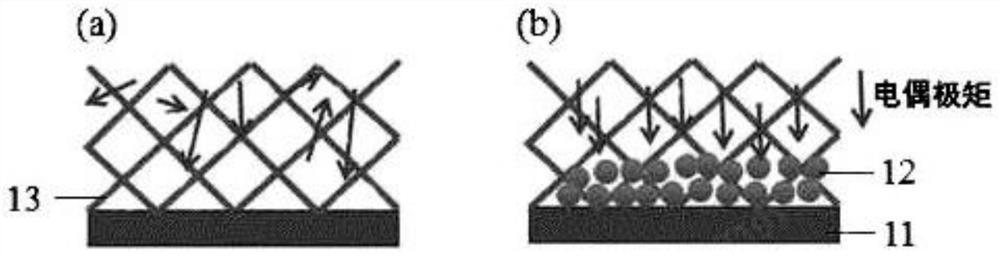

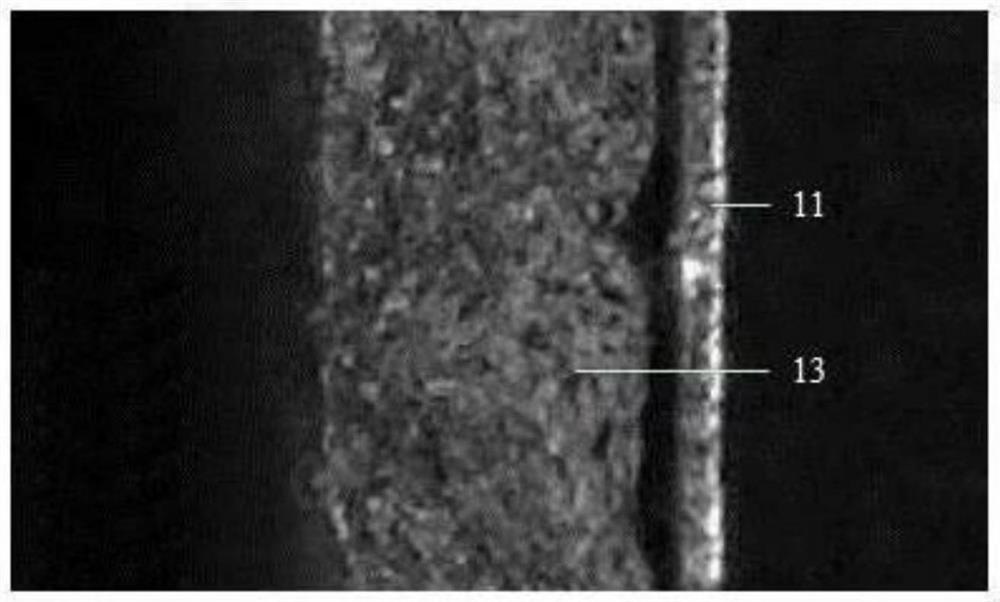

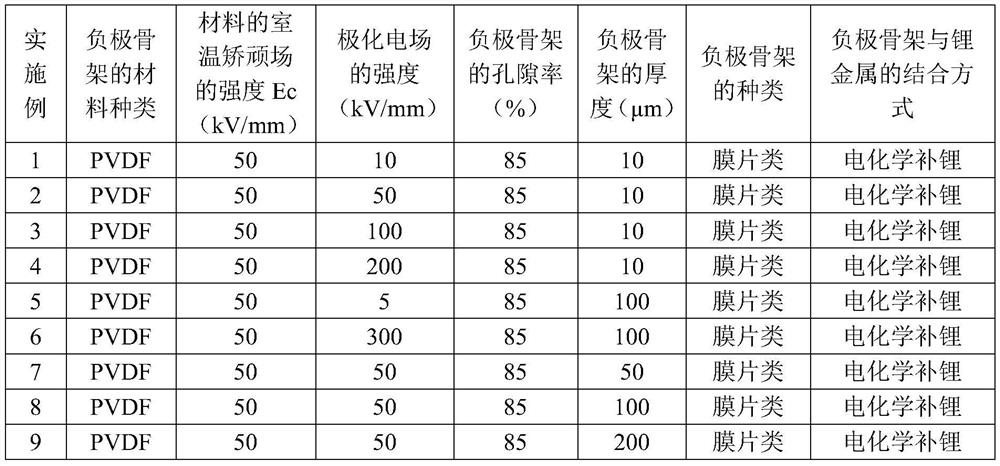

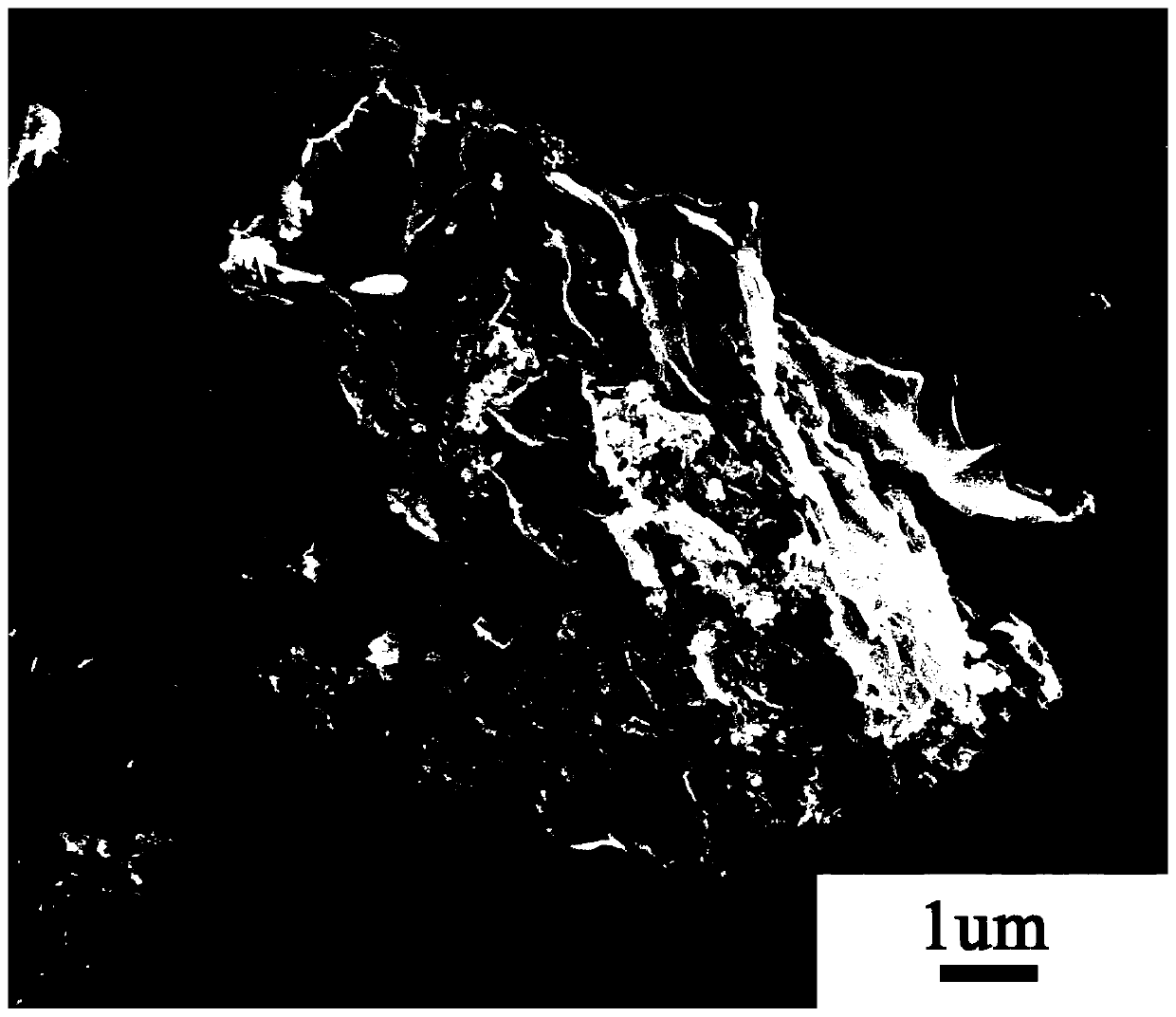

PendingCN114175304AImprove volume expansionImprove cycle performanceElectrode carriers/collectorsNegative electrodesPhysicsLithium dendrite

The invention provides a negative pole piece, an electrochemical device comprising the negative pole piece and an electronic device, the negative pole piece comprises a negative pole current collector, a lithium metal negative pole and a negative pole framework, a polarization electric field exists in the negative pole framework, the direction of the polarization electric field is from the surface of the negative pole to the negative pole current collector, and the material of the negative electrode framework comprises at least one of piezoelectric polymer, piezoelectric ceramic or piezoelectric single crystal. The negative pole piece can control lithium deposition sites and effectively inhibit growth of lithium dendrites, so that the volume expansion performance of the electrochemical device is effectively improved, and the cycle performance of the electrochemical device is further improved.

Owner:NINGDE AMPEREX TECH

Preparation method of graphene/silicon nanosheet/carbon nanotube composite material

The invention discloses a preparation method of a graphene / silicon nanosheet / carbon nanotube composite material. The composite material is composed of a graphene layer, a silicon nanosheet and a carbon nanotube layer. The preparation method comprises the steps of preparing a silicon nanosheet solution; preparing a carbon nanotube solution; preparing carbon nanotubes attached with a silicon nanosheet material; preparing a graphite oxide solution; preparing a graphite oxide / silicon nanosheet / carbon nanotube composite material; and drying and then carrying out heat treatment in a hydrogen-argon atmosphere for reduction to obtain the graphene / silicon nanosheet / carbon nanotube composite material. The preparation method has the advantages of simple implementation, strong controllability and highrepeatability. In addition, the graphene / silicon nanosheet / carbon nanotube composite material prepared according to the invention has the advantages of high specific capacity, excellent rate performance, good cycle stability and the like, and has broad application prospects in the field of lithium-ion battery negative electrode materials.

Owner:HARBIN INST OF TECH

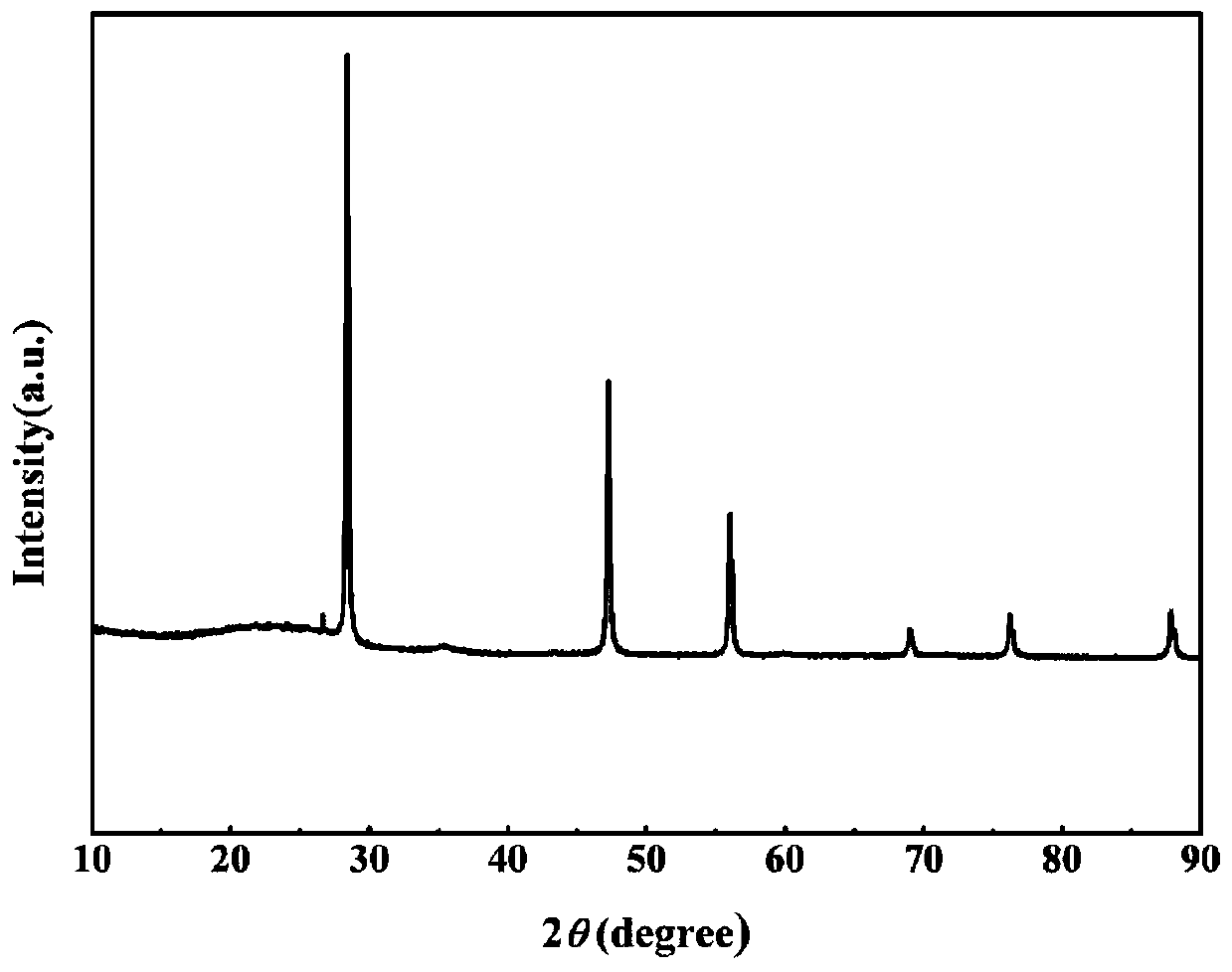

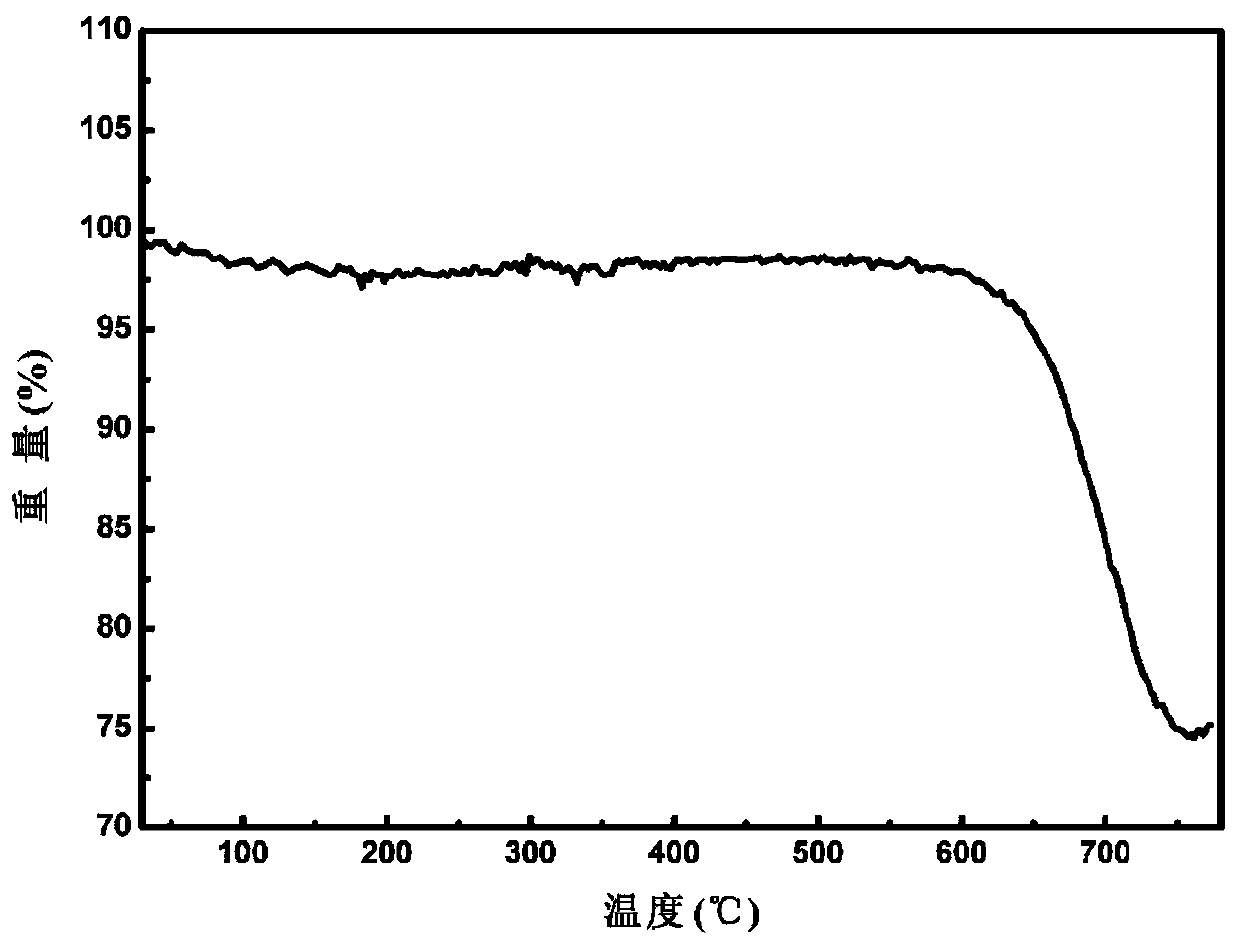

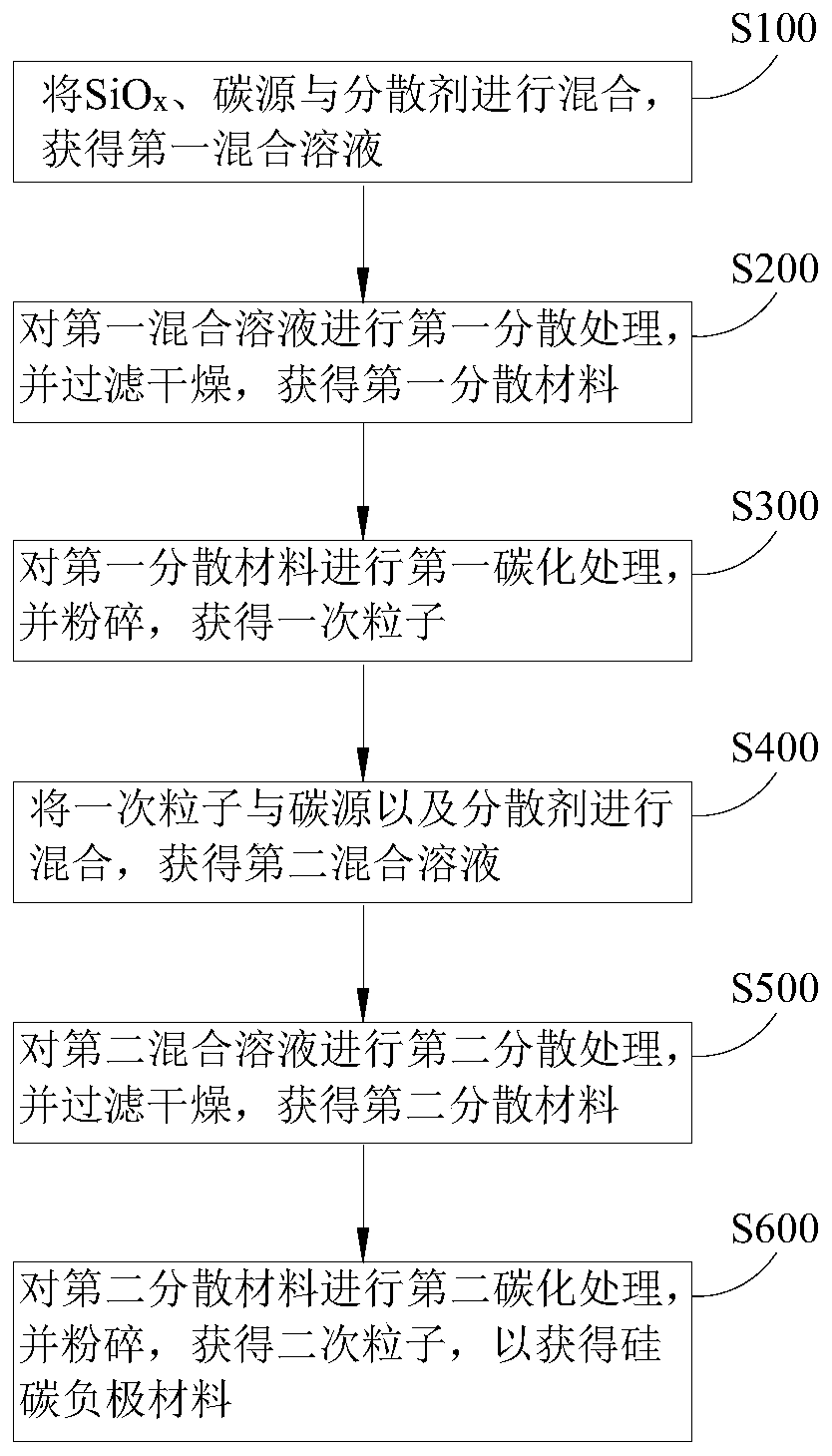

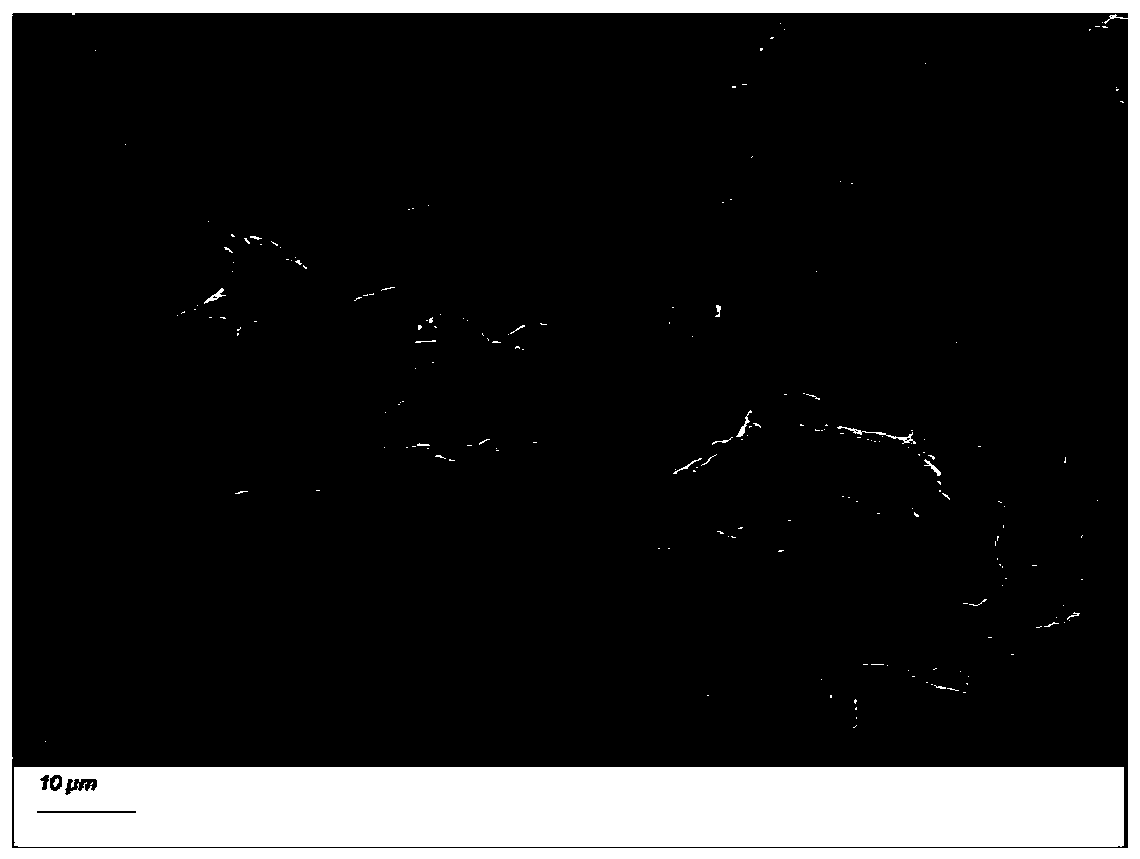

Silicon-carbon negative electrode material, preparation method and lithium ion battery

ActiveCN109713280AReduce expansion stressImprove dynamic performanceCell electrodesSecondary cellsCarbonizationSodium-ion battery

The invention provides a silicon-carbon negative electrode material, a preparation method and a lithium ion battery. The method for preparing the silicon-carbon negative electrode material comprises the steps: mixing SiOx, a carbon source and a dispersing agent to obtain first mixed solution, wherein x is equal to 0.5-1; 1.0; carrying out first dispersion treatment of the first mixed solution, andperforming filtering and drying to obtain a first dispersion material; carrying out first carbonization treatment of the first dispersion material, and performing crushing to obtain primary particleswith the particle size of 0.5-1 micron; mixing the primary particles with the carbon source and the dispersing agent to obtain second mixed solution; carrying out second dispersion treatment of the second mixed solution, and performing filtering and drying to obtain a second dispersion material; carrying out second carbonization treatment of the second dispersion material, performing crushing toobtain secondary particles with the particle size of 10-15 microns, and obtaining a silicon-carbon negative electrode material. According to the method disclosed by the invention, the finally obtainedsilicon-carbon negative electrode material has a relatively small volume expansion and a good cycle performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com