Nano heterostructure material for anode material of lithium battery, and preparation

A nano-heterostructure, lithium battery anode technology, applied in nanotechnology for materials and surface science, battery electrodes, lithium batteries, etc. Improve the specific capacity and cycle stability, improve the performance of lithium batteries, good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

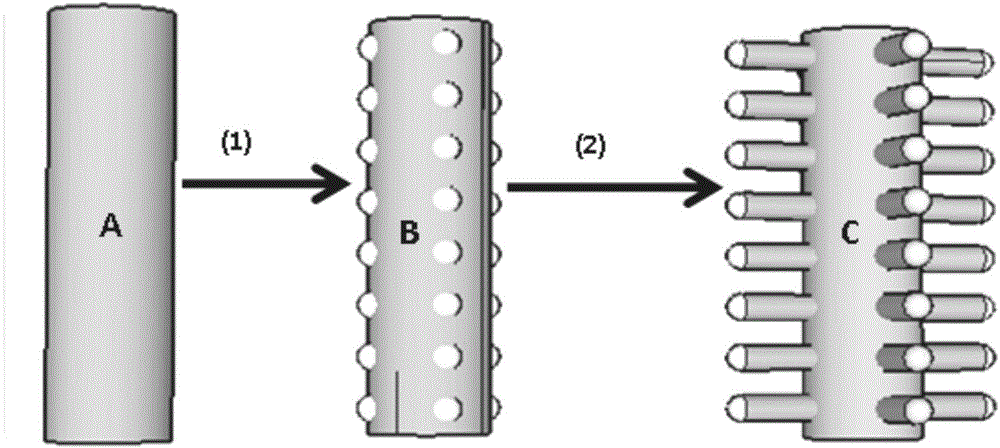

[0023] In order to make the purpose, technical solutions and advantages of the present invention clearer, the following in conjunction with specific examples, and with reference to the appended figure 1 , to further describe the present invention in detail.

[0024] Figure shows epitaxial dendritic Si(Ge) / SnO 2 (In 2 o 3 ) Basic processes of nanoheterostructures. Due to SnO 2 (In 2 o 3 ) has good electrical conductivity, and the volume expansion is small during the lithiation process, so in the lithiation process, the SnO grown on the current collector is used 2 (In 2 o 3) nanowires as the backbone, which can maintain a good electrical contact between it and the current collector, a complete structure, and a good one-dimensional electron transport channel. Using Si(Ge) nanowires with large specific capacity as branches can increase the surface area of Si(Ge) nanowires exposed to the electrolyte, thereby providing more active sites for the reaction with lithium ions....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com