Preparation method of ordered mesoporous nano-silica microspheres

A nano-silica and microsphere technology, applied in the field of inorganic mesoporous materials, can solve the problems of long synthesis time and cumbersome operation, and achieve the effects of short reaction time, simple and easy-to-control preparation conditions, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 0.10 g of cetyltrimethylammonium bromide (CTAB) in 60 g of deionized water, add 0.06 g of NaOH, and stir at 80° C. for 120 min at a speed of 200 r / min. Add 0.80 g tetraethyl orthosilicate (TEOS), and continue to stir at 80° C. at a speed of 200 r / min for 8 h. The solution after the reaction is centrifuged (8500r / min), the surfactant template is washed away with deionized water and absolute ethanol, and the ordered mesoporous nano-silica can be obtained after drying in an oven. The mass of the generated product was 0.2115 g, and the yield was 91.7%.

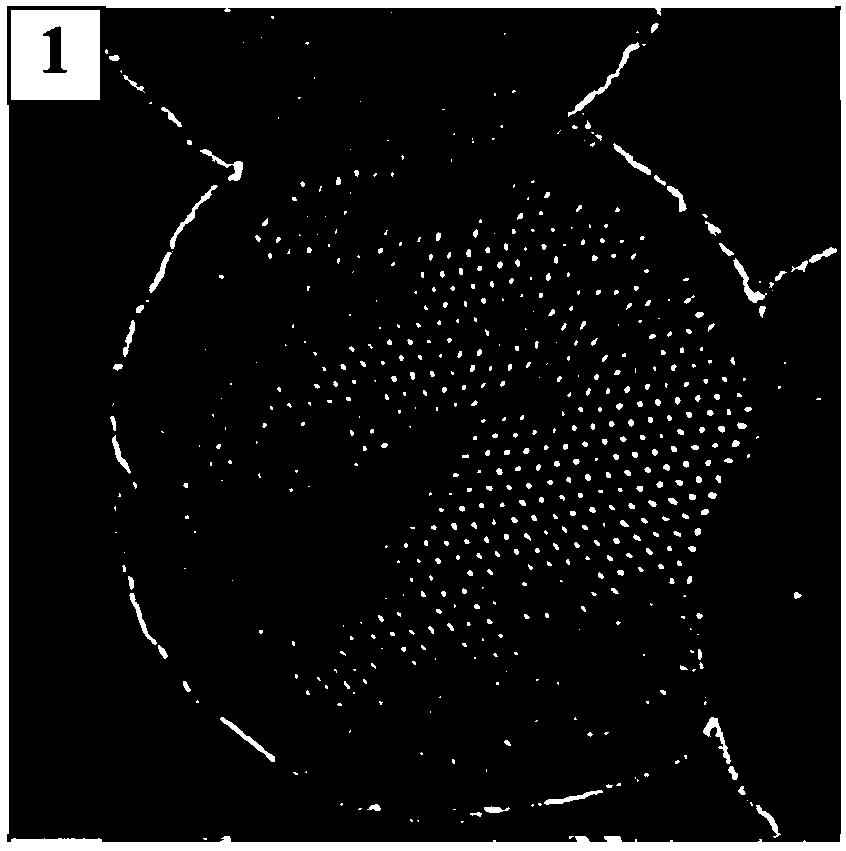

[0027] From figure 1 It can be seen that the ordered mesoporous nano-silica microspheres have a particle diameter of about 150 nm and a pore diameter of about 2.5-3 nm.

Embodiment 2

[0029] Dissolve 0.20 g of cetyltrimethylammonium bromide (CTAB) in 80 g of deionized water, add 0.05 g of NaOH, and stir at 80° C. for 120 min at a speed of 300 r / min. Add 1.00 g of tetraethyl orthosilicate (TEOS), and continue stirring at 80° C. at a speed of 300 r / min for 8 h. The solution after the reaction is centrifuged (8500r / min), the surfactant template is washed away with deionized water and absolute ethanol, and the ordered mesoporous nano-silica can be obtained after drying in an oven. The mass of the generated product was 0.2682 g, and the yield was 93.0%.

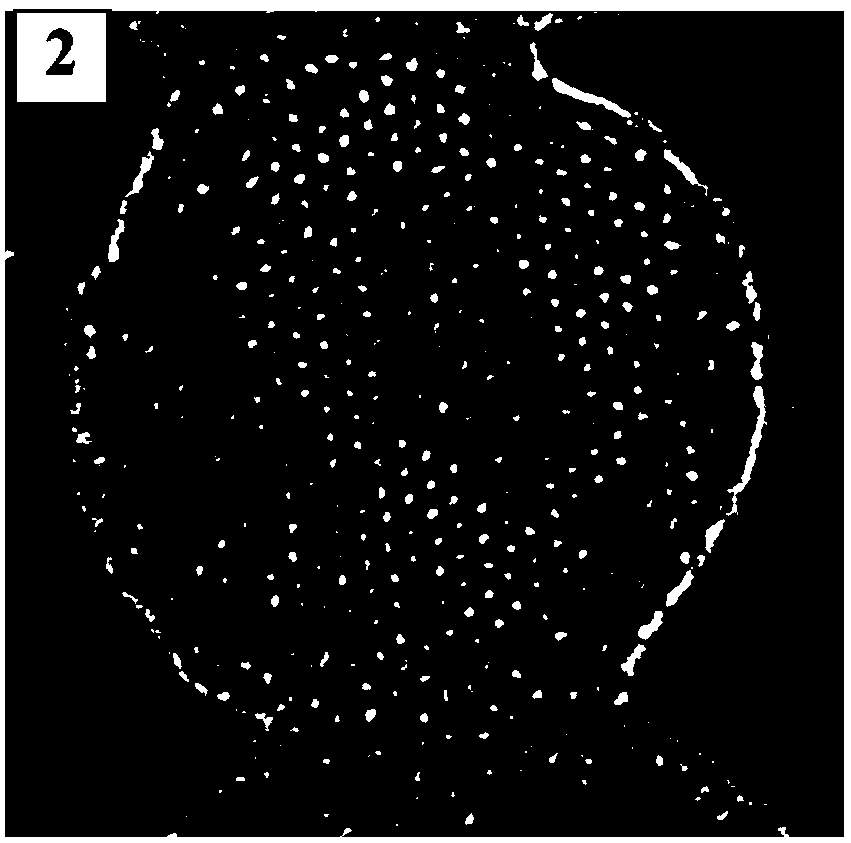

[0030] From figure 2 It can be seen that the ordered mesoporous nano-silica microspheres have a particle diameter of about 110 nm and a pore diameter of about 2.5-3 nm.

Embodiment 3

[0032] Dissolve 0.30 g of cetyltrimethylammonium bromide (CTAB) in 70 g of deionized water, add 0.08 g of NaOH, and stir at 70° C. for 90 min at a speed of 500 r / min. Add 1.20 g of tetraethyl orthosilicate (TEOS), and continue stirring at 70° C. at a speed of 500 r / min for 10 h. The solution after the reaction is centrifuged (7500r / min), the surfactant template is washed away with deionized water and absolute ethanol, and the ordered mesoporous nano-silica can be obtained after drying in an oven. The mass of the generated product was 0.3113 g, and the yield was 90.0%.

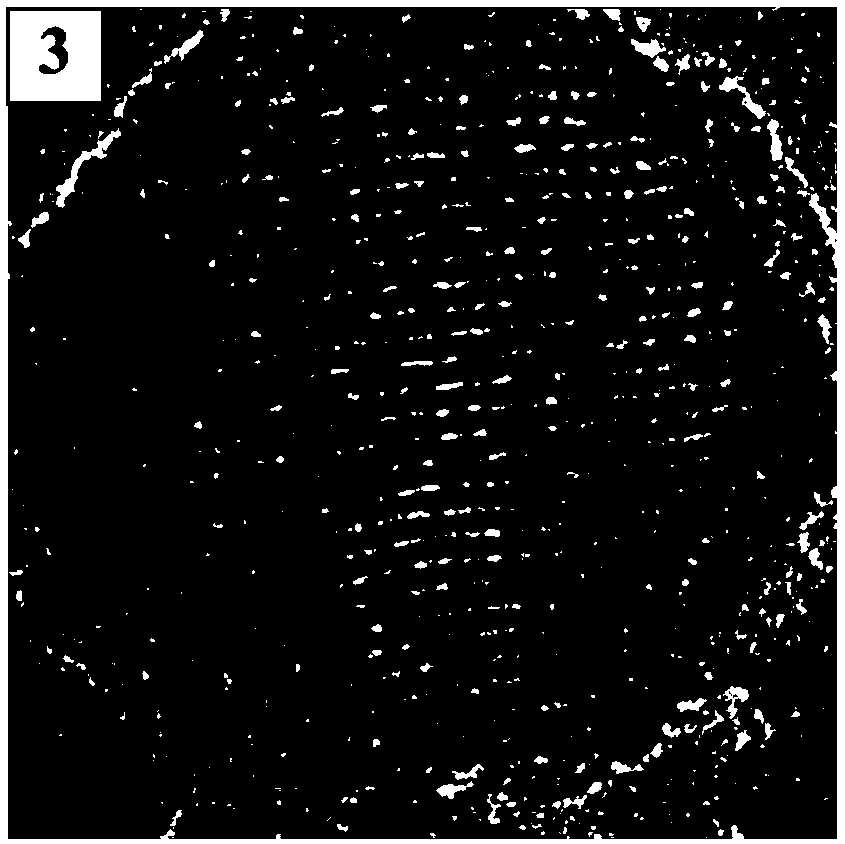

[0033] From image 3 It can be seen that the ordered mesoporous nano-silica microspheres have a particle diameter of about 130 nm and a pore diameter of about 2.5-3 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com