Method for preparing composite material containing tin dioxide nano-particles attached to honeycomb carbon

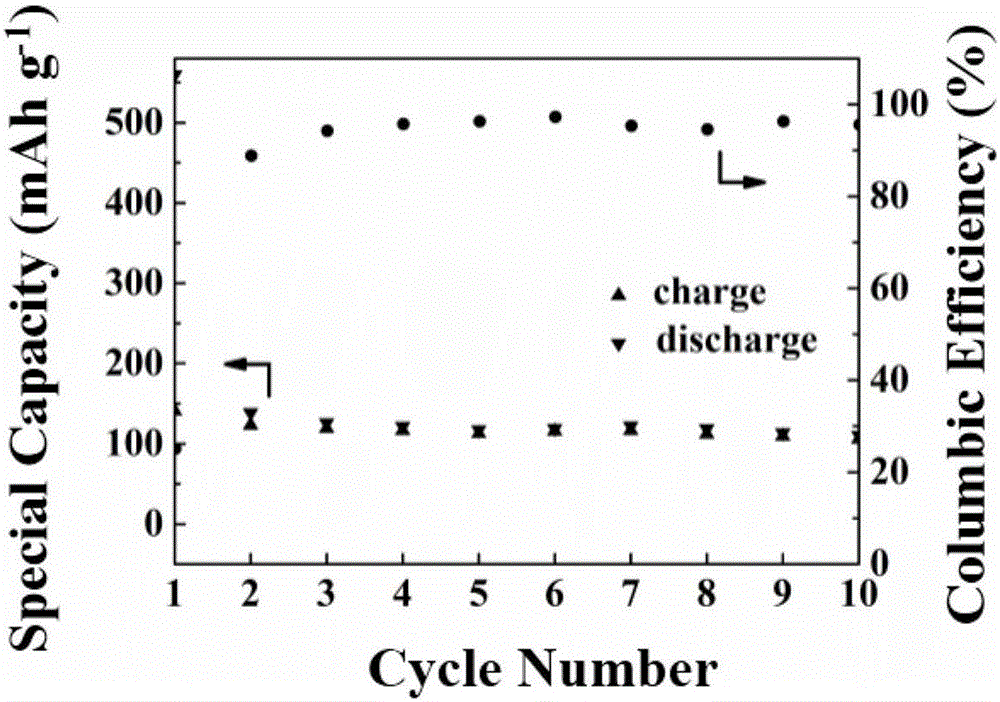

A nanoparticle, tin dioxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as shedding, battery performance degradation, active material pulverization, etc., to improve electrical conductivity. , the effect of increasing electrical conductivity and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

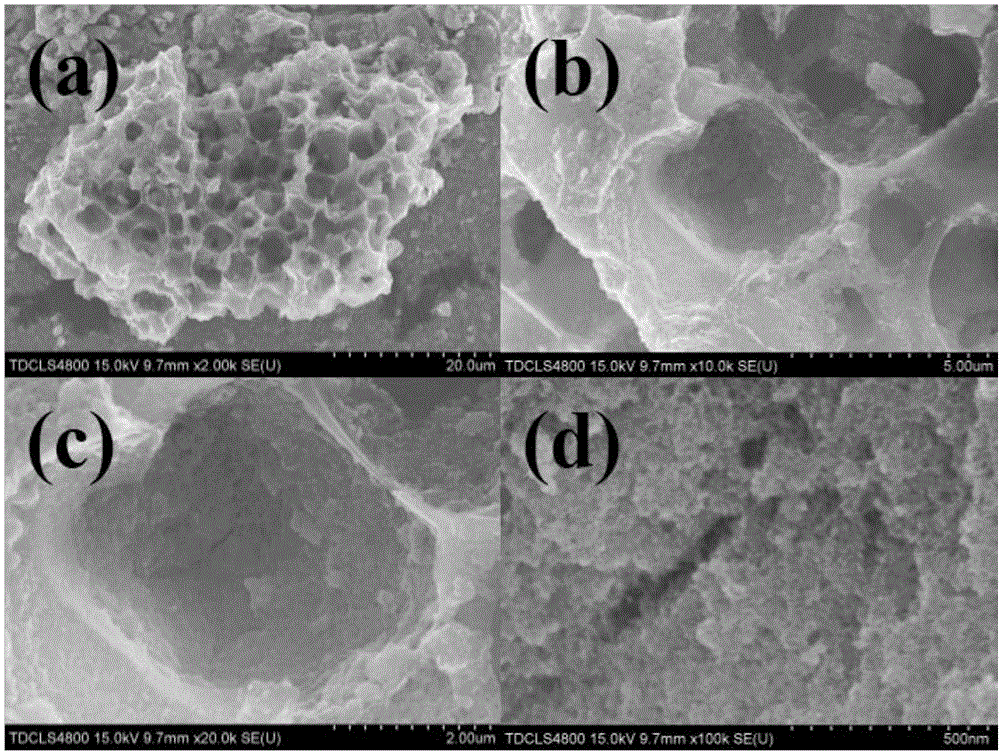

[0030] 1). Add 0.025mol of SnCl 4 ·5H 2 Add O into 100mL deionized water, stir and mix evenly with a magnet;

[0031] 2). Take 0.4g of honeycomb carbon with a pore size of less than 5 μm and add it to the 80mL SnCl obtained in step 1) 4 ·5H 2 O solution and sonicated;

[0032] 3). Take an appropriate amount of the precursor solution obtained in step 2 and transfer it to the lining of a polytetrafluoroethylene hydrothermal reaction kettle with a capacity of 100mL. The stainless steel reaction kettle is sealed and heated in an oven to 170°C and kept for 36 hours;

[0033] 4). After the reaction, cool to room temperature at room temperature, take out the reactant, wash with deionized water and ethanol three times, and dry at 60°C for 12 hours to obtain a dry product;

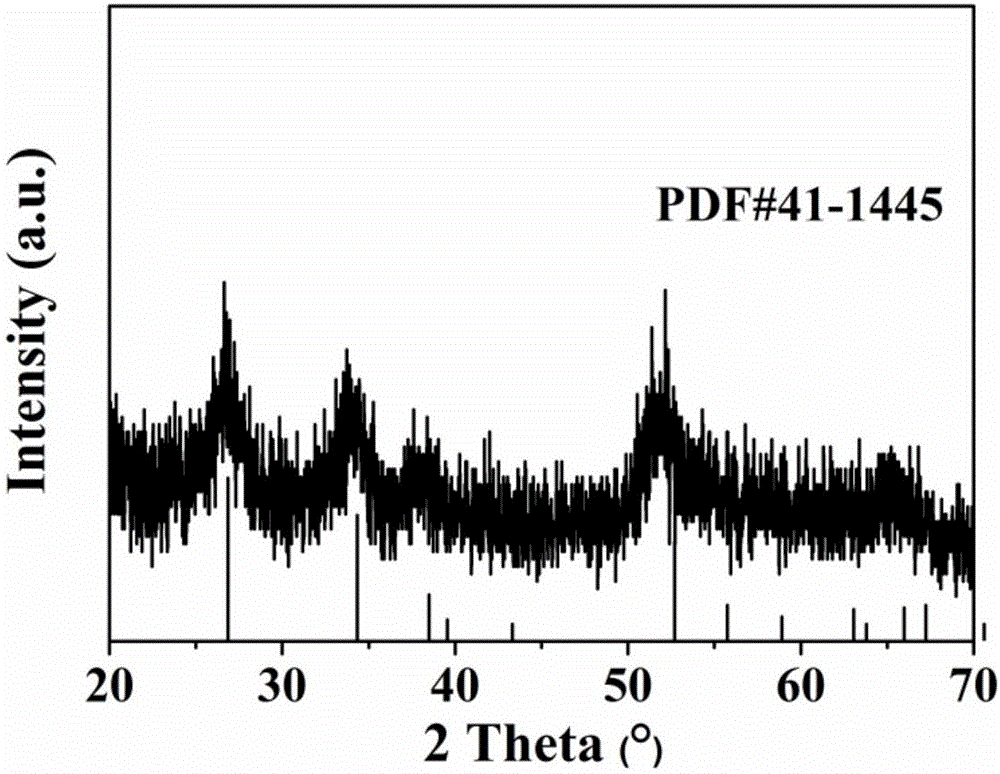

[0034] 5). Anneal the dried product obtained in step 4 under an argon atmosphere, set the heating rate to 5°C / min, keep it at 600°C for 200 minutes, and then cool it down to room temperature naturally to obtain...

Embodiment 2

[0037] 1). Add 0.05mol of SnCl 4 ·5H 2 Add O into 100mL deionized water, stir and mix evenly with a magnet;

[0038] 2). Take 0.5g of honeycomb carbon with a pore size of less than 5 μm and add it to the 80mL SnCl obtained in step 1) 4 ·5H 2 O solution and sonicated;

[0039] 3). Take an appropriate amount of the precursor solution obtained in step 2 and transfer it to the lining of a polytetrafluoroethylene hydrothermal reaction kettle with a capacity of 100mL. The stainless steel reaction kettle is sealed and heated in an oven to 180°C for 24 hours;

[0040] 4). After the reaction, cool to room temperature at room temperature, take out the reactant, wash with deionized water and ethanol for 4 times, and dry at 70°C for 10 hours to obtain a dry product;

[0041] 5). Anneal the dried product obtained in step 4 under an argon atmosphere, set the heating rate to 8°C / min, keep it at 625°C for 160min, and then cool it down to room temperature naturally to obtain a honeycomb ca...

Embodiment 3

[0044] 1). Add 0.1mol of SnCl 4 ·5H 2 Add O into 100mL deionized water, stir and mix evenly with a magnet;

[0045] 2). Take 0.6g of honeycomb carbon with a pore size of less than 5 μm and add it to the 80mL SnCl obtained in step 1) 4 ·5H 2 O solution and sonicated;

[0046] 3). Take an appropriate amount of the precursor solution obtained in step 2 and transfer it to the lining of a polytetrafluoroethylene hydrothermal reaction kettle with a capacity of 100mL. The stainless steel reaction kettle is sealed and heated in an oven to 190°C for 12 hours;

[0047] 4). After the reaction, cool to room temperature at room temperature, take out the reactant, wash with deionized water and ethanol for 5 times, and dry at 80°C for 8 hours to obtain a dry product;

[0048] 5). Anneal the dried product obtained in step 4 under an argon atmosphere, set the heating rate to 10°C / min, keep it at 650°C for 120min, and then cool it down to room temperature naturally to obtain a honeycomb car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com