Silicon monoxide/silicon/lithium metasilicate composite negative electrode material and preparation method thereof

A technology of silicon oxide and lithium metasilicate, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low initial coulombic efficiency of SiO materials, limited initial coulombic efficiency of SiO, difficulty in large-scale production, etc. Operation and industrial production, low cost, effect of improving interface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

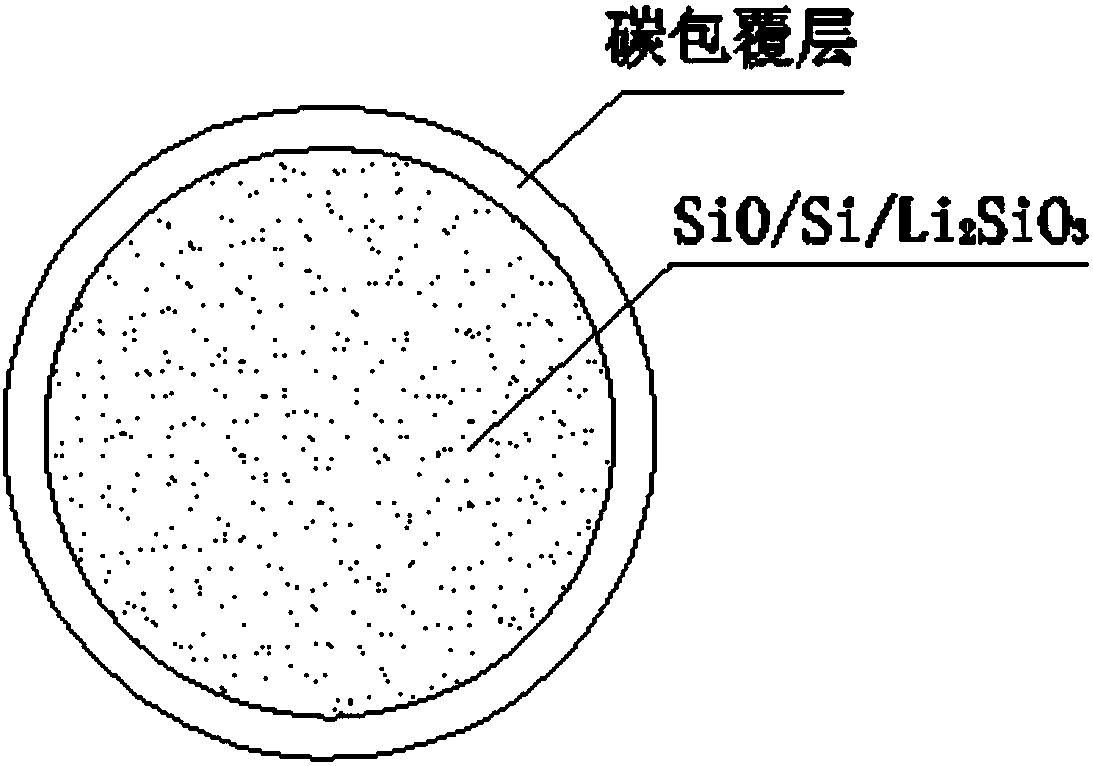

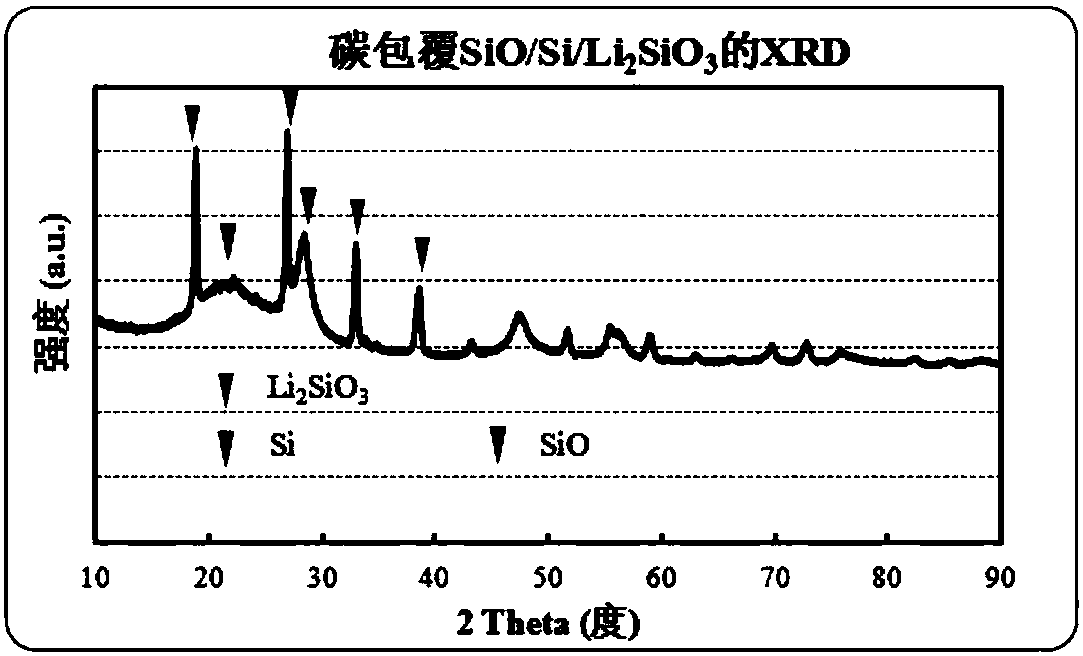

[0027] A silicon oxide / silicon / lithium metasilicate composite negative electrode material proposed by the present invention is composed of silicon oxide / silicon / lithium metasilicate composite material as an active material and coated on silicon oxide / silicon / silicon metasilicate The composition of the carbon coating layer outside the lithium acid composite material;

[0028] Wherein, the weight content of the silicon oxide / silicon / lithium metasilicate composite material in the composite negative electrode material is 90%, the weight content of the carbon coating layer in the composite negative electrode material is 10%, and its composition is [SiO / Si / Li 2 SiO 3 ] 0.9 / I 0.1 , where SiO / Si / Li 2 SiO 3 It is a silicon oxide / silicon / lithium metasilicate composite material, and I is a carbon coating layer.

[0029] The present invention also proposes a method for preparing the silicon oxide / silicon / lithium metasilicate composite negative electrode material, comprising the fo...

Embodiment 2

[0037] A silicon oxide / silicon / lithium metasilicate composite negative electrode material proposed by the present invention is composed of silicon oxide / silicon / lithium metasilicate composite material as an active material and coated on silicon oxide / silicon / silicon metasilicate The composition of the aluminum oxide cladding layer outside the lithium acid composite material;

[0038] Wherein, the weight content of the silicon oxide / silicon / lithium metasilicate composite material in the composite negative electrode material is 95%, the weight content of the aluminum oxide coating layer in the composite negative electrode material is 5%, and its composition is [SiO / Si / Li 2 SiO 3 ] 0.95 / I 0.05 , where SiO / Si / Li 2 SiO 3 It is a silicon oxide / silicon / lithium metasilicate composite material, and I is an aluminum oxide coating layer.

[0039] The present invention also proposes a method for preparing the silicon oxide / silicon / lithium metasilicate composite negative electrode ...

Embodiment 3

[0044] A silicon oxide / silicon / lithium metasilicate composite negative electrode material proposed by the present invention is composed of silicon oxide / silicon / lithium metasilicate composite material as an active material and coated on silicon oxide / silicon / silicon metasilicate The composition of the aluminum oxide cladding layer outside the lithium acid composite material;

[0045] Wherein, the weight content of the silicon oxide / silicon / lithium metasilicate composite material in the composite negative electrode material is 90%, the weight content of the aluminum oxide coating layer in the composite negative electrode material is 10%, and its composition is [SiO / Si / Li 2 SiO 3 ] 0.9 / I 0.1 , where SiO / Si / Li 2 SiO 3 It is a silicon oxide / silicon / lithium metasilicate composite material, and I is an aluminum oxide coating layer.

[0046] The present invention also proposes a method for preparing the silicon oxide / silicon / lithium metasilicate composite negative electrode m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com