Sulfur-fixing ash cement-based material and expansibility control method thereof

A technology for cement-based materials and sulfur-fixing ash, which is applied in the field of building materials, can solve problems such as needs and limited application scope, and achieve the effects of reducing pollution, reducing apparent density and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

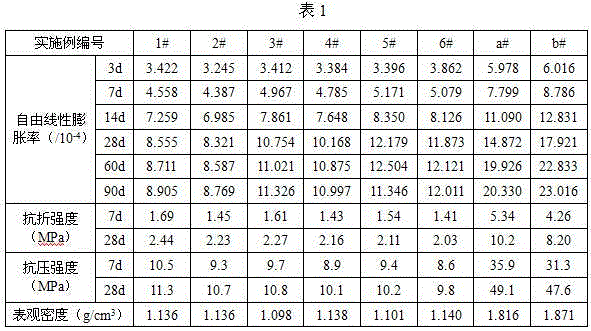

Examples

Embodiment 1

[0039] A method for controlling the expansibility of a sulfur-fixed ash cement-based material, specifically comprising the following steps:

[0040] 1) Weigh 45 parts of 42.5R ordinary Portland cement, 55 parts of sulfur-fixing ash, 75 parts of water and 0.28 parts of hydroxypropyl methylcellulose ether; the sulfur-fixing ash is a circulating fluidized bed The specific surface area of the discharged sulfur-fixed ash is 287m 2 / kg, the viscosity of hydroxypropyl methylcellulose ether is 200000MPa.s;

[0041] 2) Mix the cement, sulfur-fixed ash and hydroxypropyl methylcellulose ether weighed in step 1) evenly by dry mixing;

[0042] 3) Add the water weighed in step 1) to the mixture obtained in step 2), slowly add water while stirring, and stir for 5 minutes to obtain a slurry;

[0043] 4) Pour the slurry obtained in step 3) into the mold, and after curing for 24 hours at normal temperature and pressure, remove the film; then cure it in the air to the desired age, and then o...

Embodiment 2

[0045] A method for controlling the expansibility of a sulfur-fixed ash cement-based material, specifically comprising the following steps:

[0046] 1) Weigh 45 parts of 42.5R ordinary Portland cement, 55 parts of sulfur-fixing ash, 90 parts of water and 0.45 parts of hydroxypropyl methylcellulose ether; the sulfur-fixing ash is the sulfur-fixing ash discharged from the circulating fluidized bed Ash raw ash with a specific surface area of 350m 2 / kg, the viscosity of hydroxypropyl methylcellulose ether is 150000MPa.s;

[0047] 2) Mix the cement, sulfur-fixed ash and hydroxypropyl methylcellulose ether weighed in step 1) evenly by dry mixing;

[0048] 3) Add the water weighed in step 1) to the mixture obtained in step 2), slowly add water while stirring, and stir for 8 minutes to obtain a slurry;

[0049] 4) Pour the slurry obtained in step 3) into the mold, and after curing for 24 hours at normal temperature and pressure, remove the film; then cure it in the air to the des...

Embodiment 3

[0051] A method for controlling the expansibility of a sulfur-fixed ash cement-based material, specifically comprising the following steps:

[0052] 1) Weigh 40 parts of 42.5R ordinary Portland cement, 60 parts of sulfur-fixing ash, 75 parts of water and 0.28 parts of hydroxypropyl methylcellulose ether; the sulfur-fixing ash is the sulfur-fixing ash discharged from the circulating fluidized bed Ash raw ash, its specific surface area is 287m 2 / kg, the viscosity of hydroxypropyl methylcellulose ether is 200000MPa.s;

[0053] 2) Mix the cement, sulfur-fixed ash and hydroxypropyl methylcellulose ether weighed in step 1) evenly by dry mixing;

[0054] 3) Add the water weighed in step 1) to the mixture obtained in step 2), slowly add water while stirring, and stir for 5 minutes to obtain a slurry;

[0055] 4) Pour the slurry obtained in step 3) into the mold, and after curing for 24 hours at normal temperature and pressure, remove the film; then cure it in the air to the desired...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com