Lithium-sulfur battery positive electrode structure and preparation method thereof

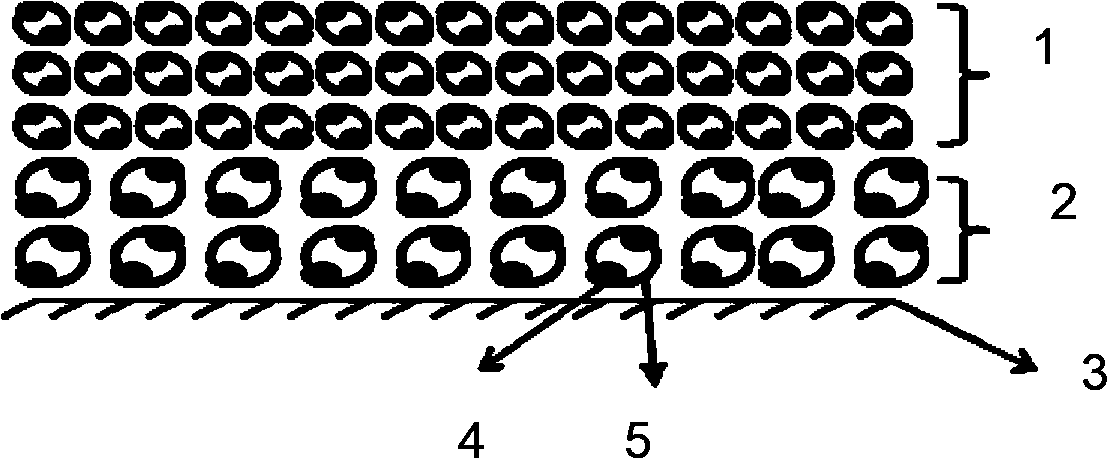

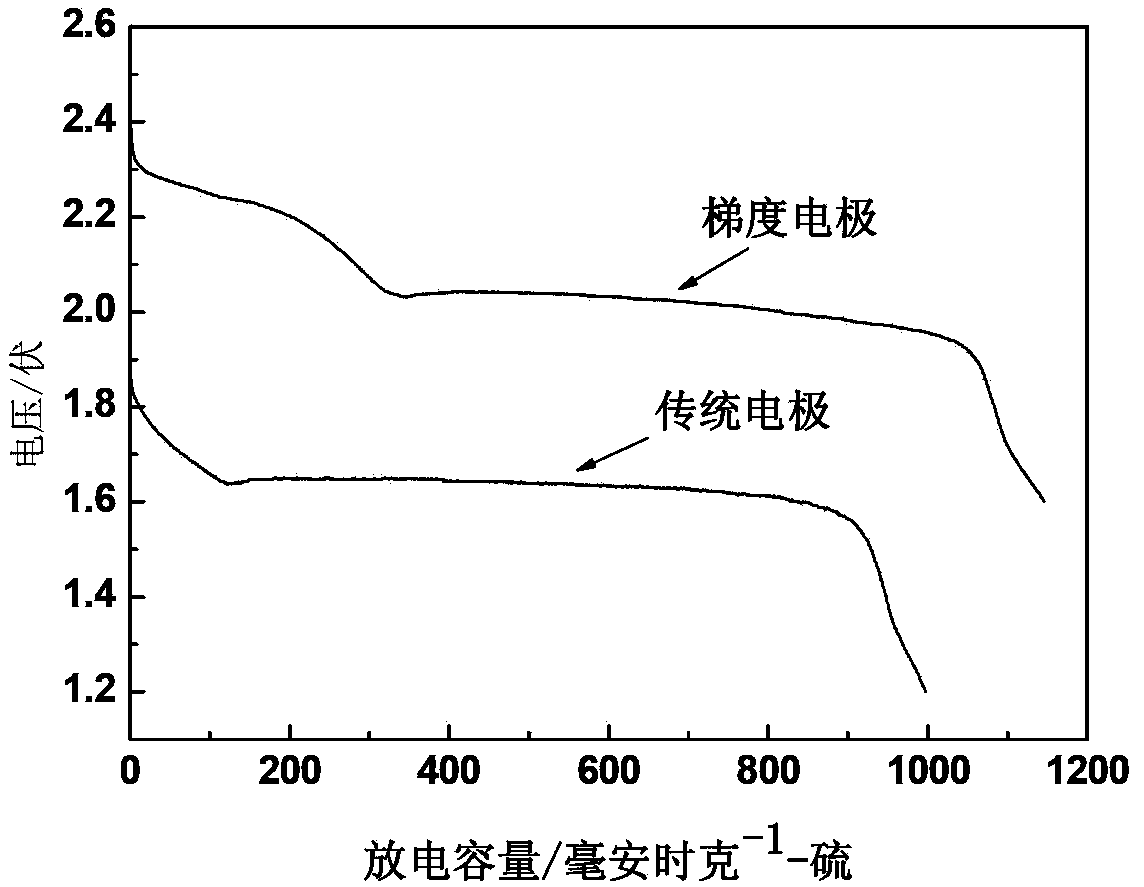

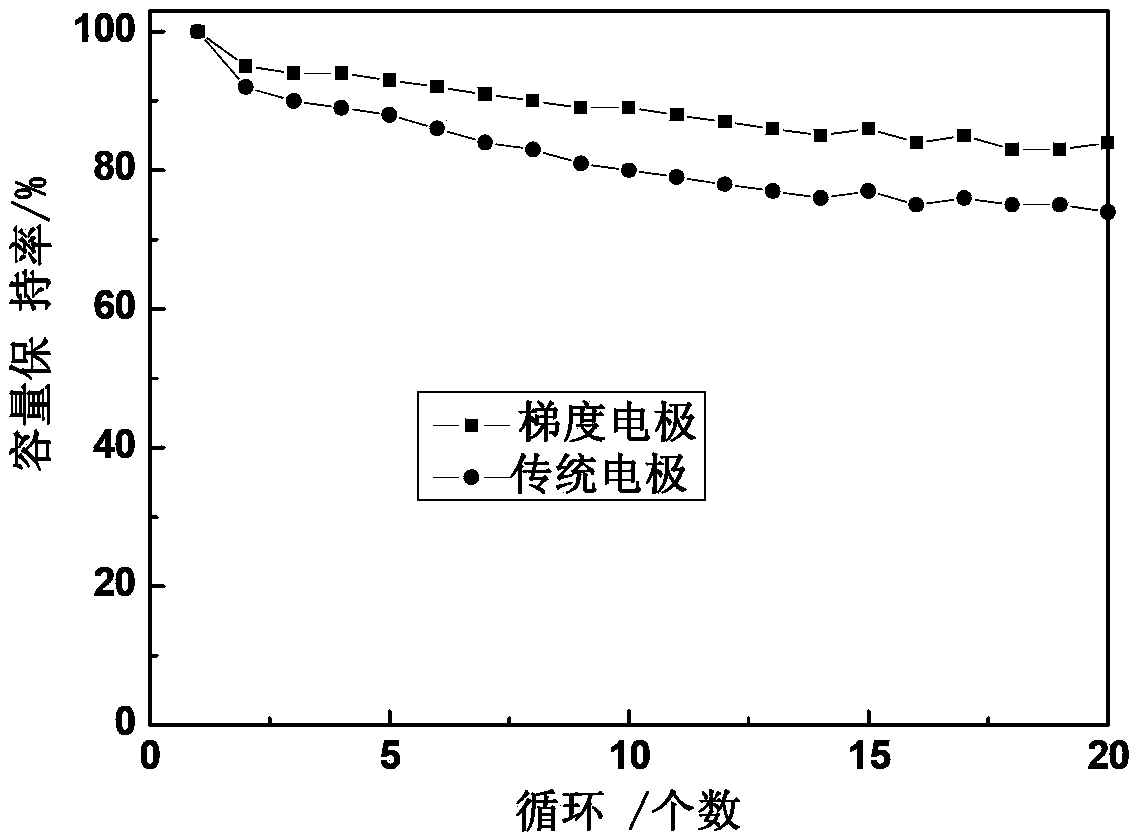

A lithium-sulfur battery and positive electrode technology, applied in the field of positive electrode structure and preparation, to achieve the effects of reducing mass transfer polarization, increasing discharge voltage platform, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]Elemental sulfur and ordered mesoporous carbon (pore diameter 50nm, specific surface 60) are compounded by hot-melt method to prepare carbon-sulfur composite A, and the sulfur filling amount is 70%. Take A, conductive graphite, carboxymethyl cellulose The sodium is mixed evenly by ball milling at a mass ratio of 8:1:1, dispersed in the aqueous solution, and stirred to obtain the positive electrode active layer slurry B, wherein the solid content of the slurry is 15%, and the slurry is evenly scraped on the aluminum foil current collector , after vacuum drying at 80°C, press to obtain a large-diameter carbon-sulfur composite layer with a thickness of 50 μm.

[0035] Elemental sulfur and activated carbon (pore diameter 0.5nm, specific surface 300) are compounded by hot-melt method to prepare carbon-sulfur composite C, and the sulfur filling amount is 50%. 9:0:1 ball milling to mix evenly, disperse in N-methylpyrrolidone, stir to obtain positive electrode active layer slurr...

Embodiment 2

[0040] Composite elemental sulfur and graphene by hot-melt method to prepare carbon-sulfur composite A, the amount of sulfur filling is 95%, take A, conductive graphite, sodium carboxymethyl cellulose according to the mass ratio of 8:1:1 ball mill and mix evenly Afterwards, it was dispersed in an aqueous solution, and stirred to obtain positive electrode active layer slurry B, wherein the solid content in the slurry was 10%, and the slurry was uniformly scraped and coated on the aluminum foil current collector, and after vacuum drying at 50°C, it was pressed to obtain a large-pore size slurry B. The carbon-sulfur composite layer has a thickness of 500 μm.

[0041] Composite elemental sulfur and carbon nanotubes by hot-melt method to prepare carbon-sulfur composite C, the amount of sulfur filling is 10%, take C, acetylene black, and polyvinylidene fluoride in a mass ratio of 9:0:1 and mix them evenly by ball milling Disperse in N-methylpyrrolidone and stir to obtain positive el...

Embodiment 3

[0044] Prepare carbon-sulfur composite A by mechanically mixing elemental sulfur and conductive carbon black, the sulfur filling amount is 10%, take A, conductive graphite, and sodium carboxymethyl cellulose in a mass ratio of 1:1:0.5 and ball mill and mix them evenly Then disperse in the aqueous solution and stir to obtain positive electrode active layer slurry B, wherein the solid content in the slurry is 5%, and the slurry is uniformly scraped and coated on the aluminum foil current collector, and after vacuum drying at 50°C, it is pressed to obtain a carbon with a large pore size. The sulfur composite layer has a thickness of 100 μm.

[0045] The elemental sulfur and carbon nanofibers were prepared into a carbon-sulfur composite C by in-situ reaction composite method, and the sulfur filling amount was 95%, and C, acetylene black, and polyvinylidene fluoride were ball-milled and mixed uniformly at a mass ratio of 1:1:0.05 Then disperse in N-methylpyrrolidone, and stir to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com