Patents

Literature

78results about How to "Inhibit the "shuttle effect"" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

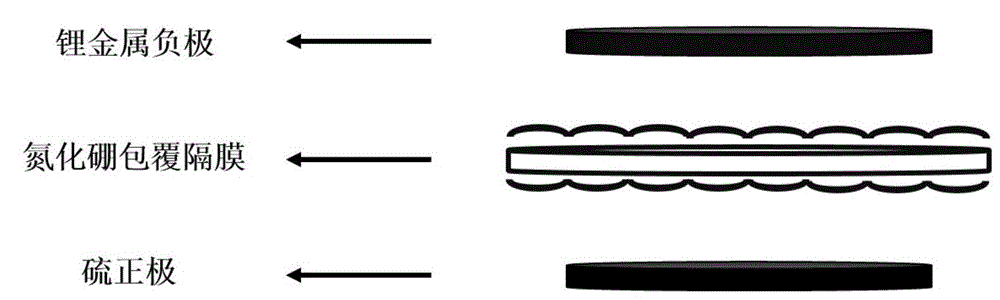

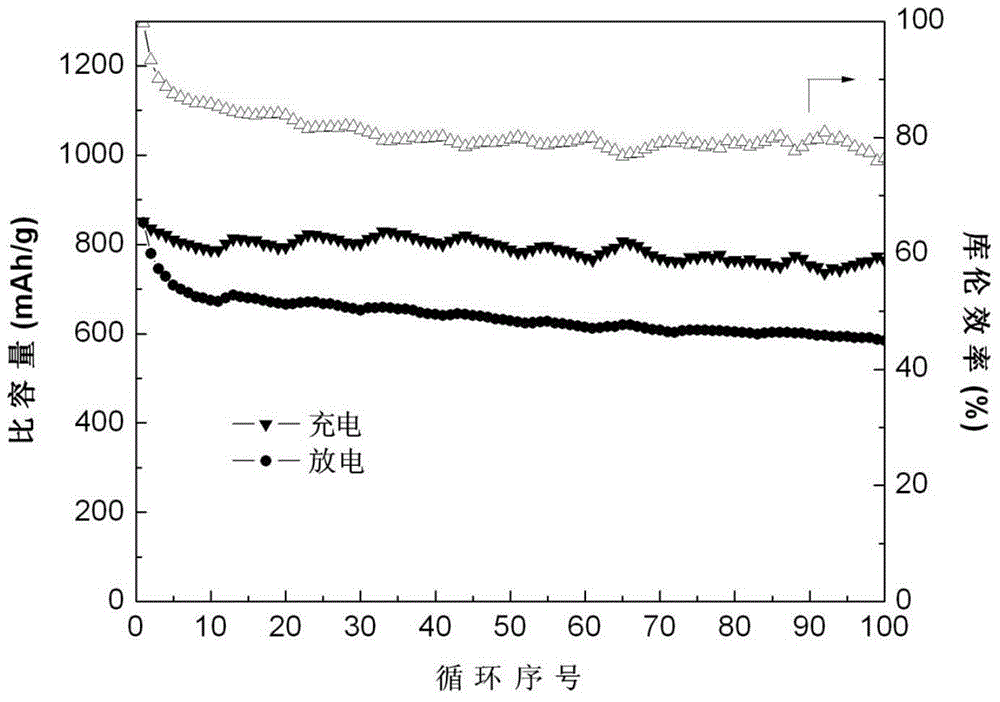

Production method of boron nitride coated diaphragm of lithium-sulfur battery

ActiveCN104993083AIncrease capacityImprove Coulombic efficiencyLi-accumulatorsCell component detailsHexagonal boron nitrideBoron nitride

The invention relates to a production method of a boron nitride coated diaphragm of a lithium-sulfur battery. The diaphragm is produced from a commercial polypropylene diaphragm, two sides of the diaphragm are uniformly covered with hexagonal boron nitride, and the characteristics of hexagonal boron nitride 'white graphite' are used, so lithium ions are allowed to pass, shuttle of polysulfide anions is obstructed, a reaction of a lithium negative electrode with the polysulfide anions is inhibited, formation of lithium dendrites, lithium sulfide precipitate and fixed lithium is prevented, the capacity, the coulombic efficiency and the cycle stability of the lithium-sulfur battery are improved, the growth of the negative electrode metal dendrite in the cycle process is effectively inhibited, and the safety of the battery is improved. The method has the advantages of simple process route and clear purpose, and the produced diaphragm has multiple functions, and can greatly overcome disadvantages of present technologies.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

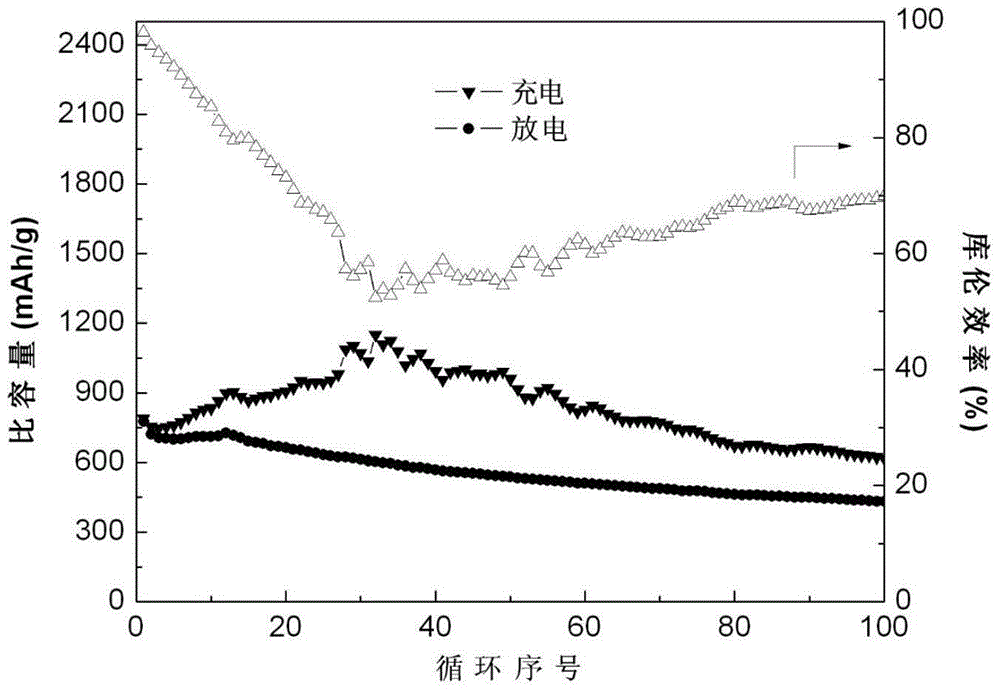

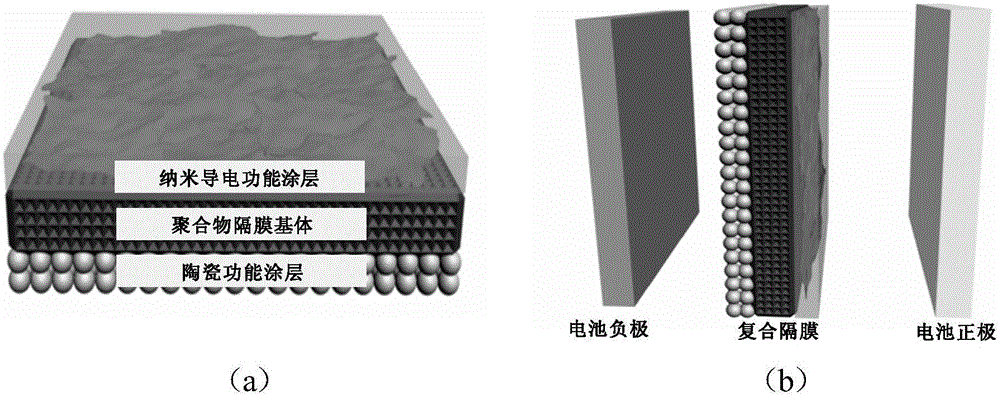

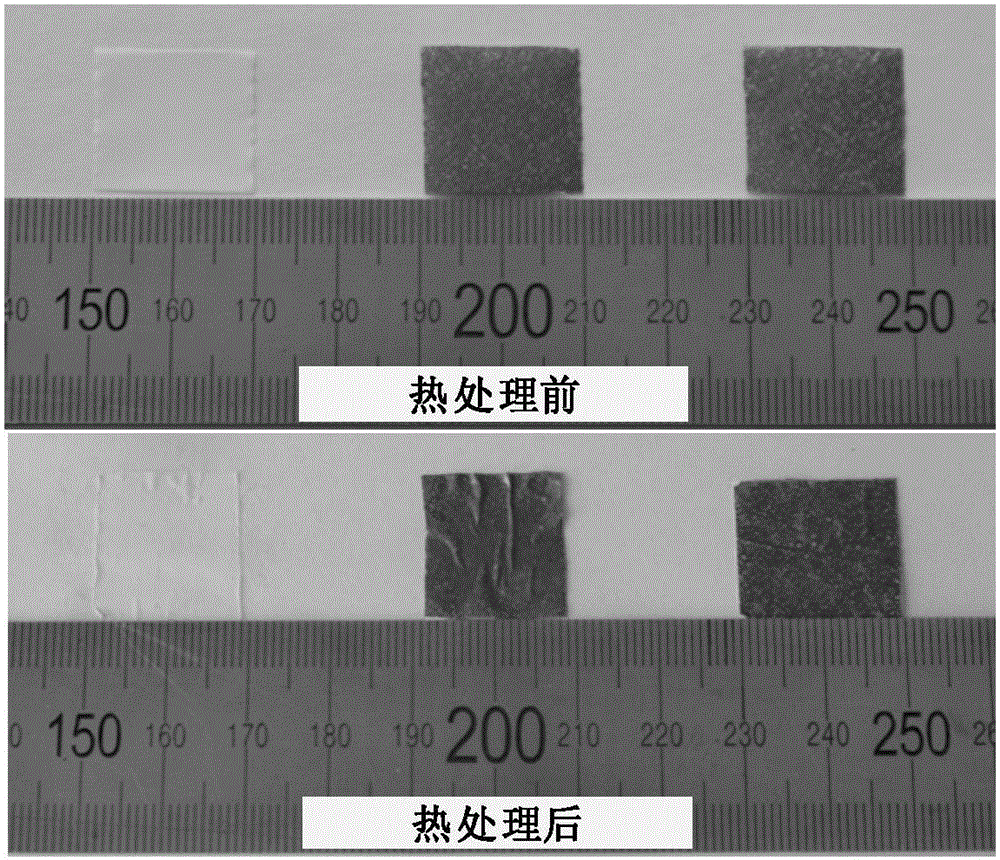

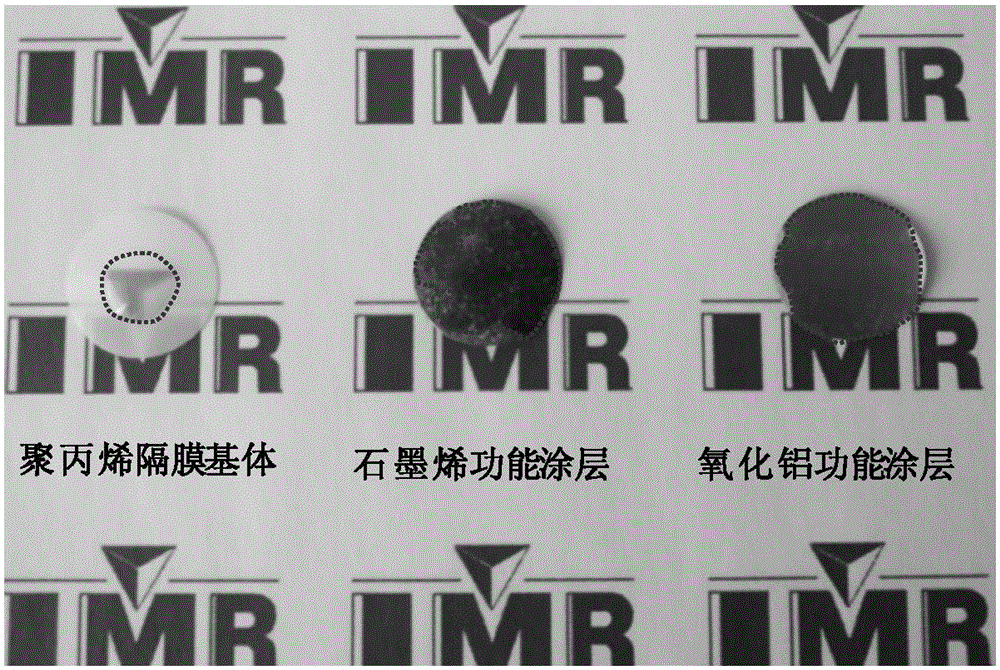

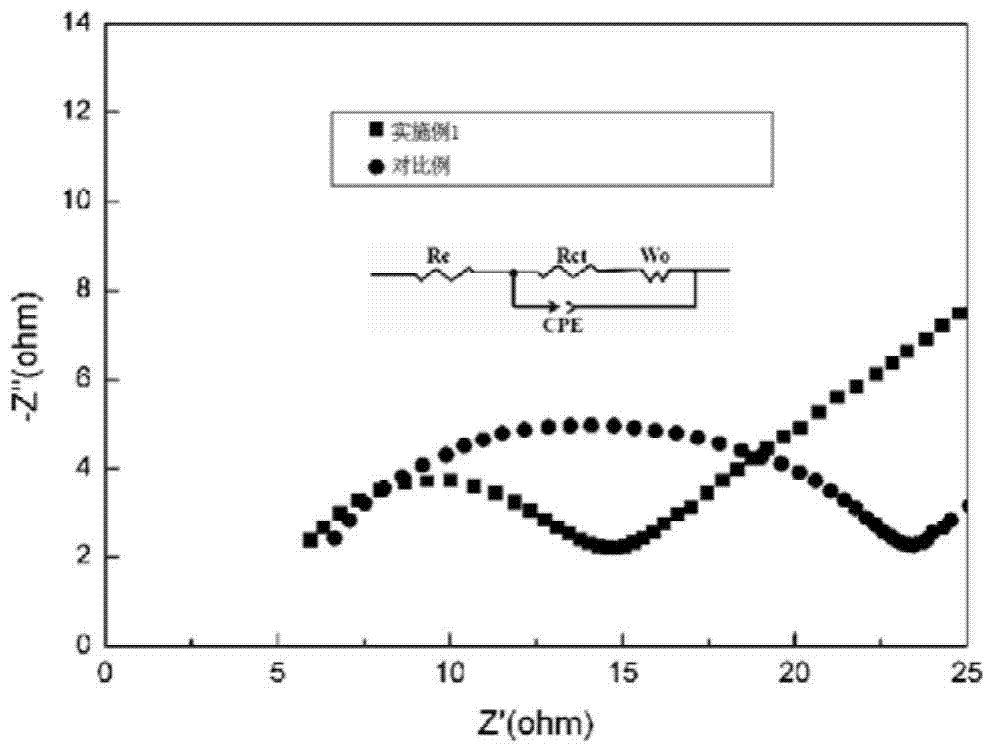

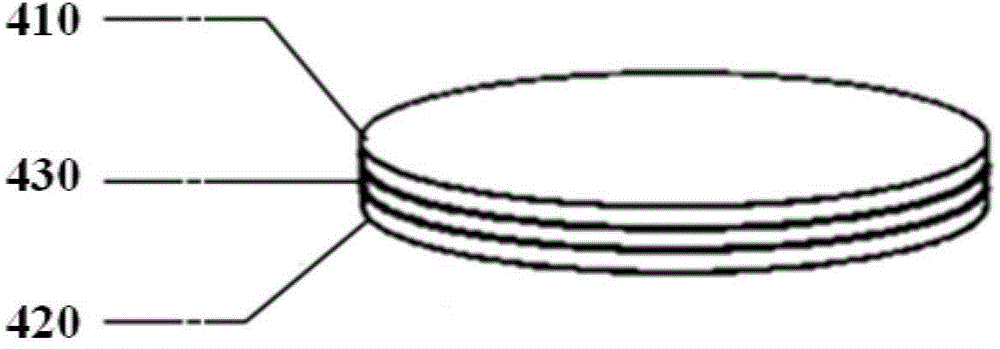

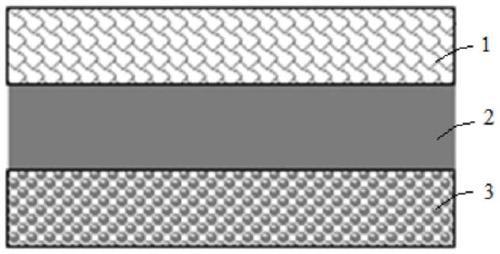

Composite diaphragm for lithium ion battery for lithium-sulfur battery and preparation method and application of composite diaphragm for lithium ion battery

InactiveCN106356488AFacilitates fast transfersImproved thermal stability and safety performanceCell component detailsElectrochemical energy storageLithium electrode

The invention discloses a composite diaphragm for lithium ion battery for a lithium-sulfur battery and a preparation method and application of the composite diaphragm for lithium ion battery, and belongs to the technical field of electrochemical energy storage. The composite diaphragm of the battery is a three-layer composite diaphragm prepared by respectively coating two sides of a polymer base body with a nano conductive functional coating layer and a ceramic functional coating layer. The nano conductive functional coating layer can accelerate quick transmission of electrons and ions in the battery, and the ceramic functional coating layer can improve the heat stability and the safety of the battery at high temperature, so that the battery prepared based on the composite diaphragm is excellent in electrochemical performance and heat stability. The method is simple in process and liable for industrialization; the prepared composite diaphragm can be widely applied to various lithium ion batteries and lithium-sulfur batteries.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

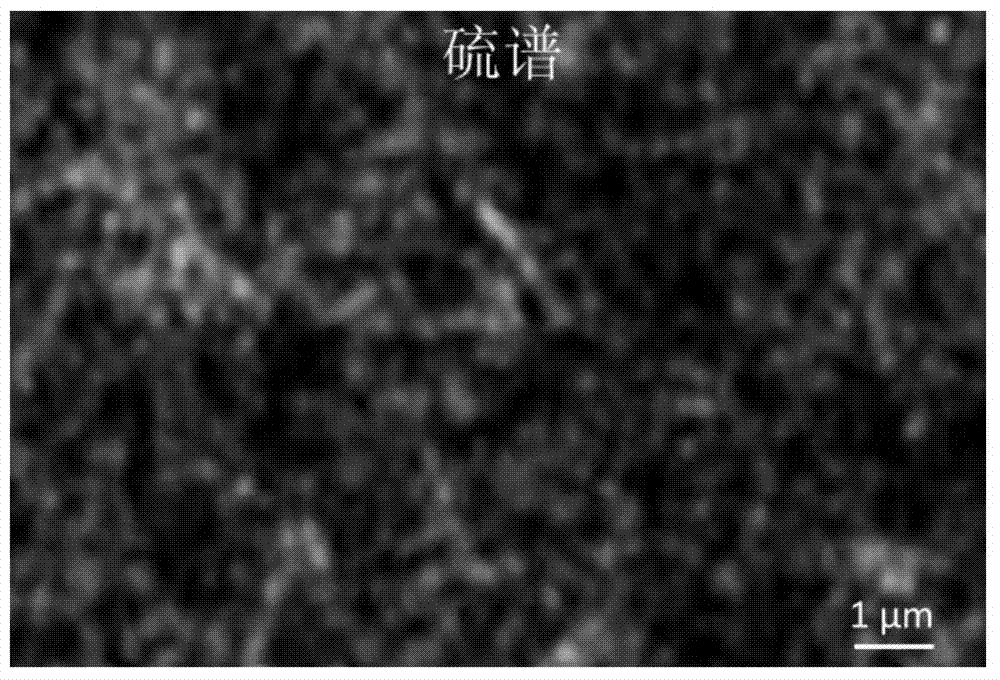

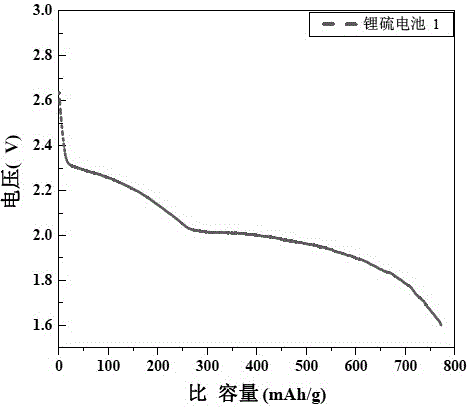

Lithium-sulfur battery cathode material, preparation method, and lithium-sulfur battery

ActiveCN104779376AKeep the structure stableInhibition of the shuttle effectMaterial nanotechnologyPositive electrodesCyclic stabilityCarbon matrix

The invention discloses a lithium-sulfur battery cathode material, a preparation method, and a lithium-sulfur battery, and belongs to the technical field of lithium-sulfur battery materials. The lithium-sulfur battery cathode material is a carbon-sulfur composite material, which is coated by a carbon cladding layer with a micro-porous structure. In the preparation method, under a vacuum condition, the raw materials are heated, just in one step, the sulfur and the carbon matrix are uniformly combined, the carbon precursor is carbonized, and the coating on the carbon-sulfur composite material is achieved. Compared with the conventional low-temperature coating method, the carbon cladding layer, which is carbonized at a high temperature and has a micro-porous structure, can form interactions just like the chemical bonds with the carbon-sulfur composite material; so that the micro-porous carbon cladding layer and the carbon-sulfur composite material are tightly combined together, thus the sulfur and discharge products cannot be easily dissolved in the electrolyte, the shuttling effect is prevented, the utilization rate of sulfur is improved, at the same time, the conductivity of the cathode material is better improved, and the cycle stability and capacity retention rate of the lithium-sulfur battery are both improved.

Owner:HENAN NORMAL UNIV

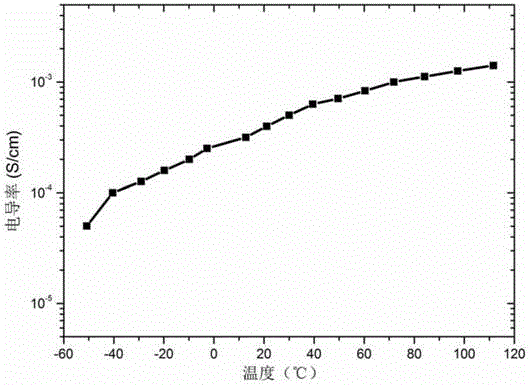

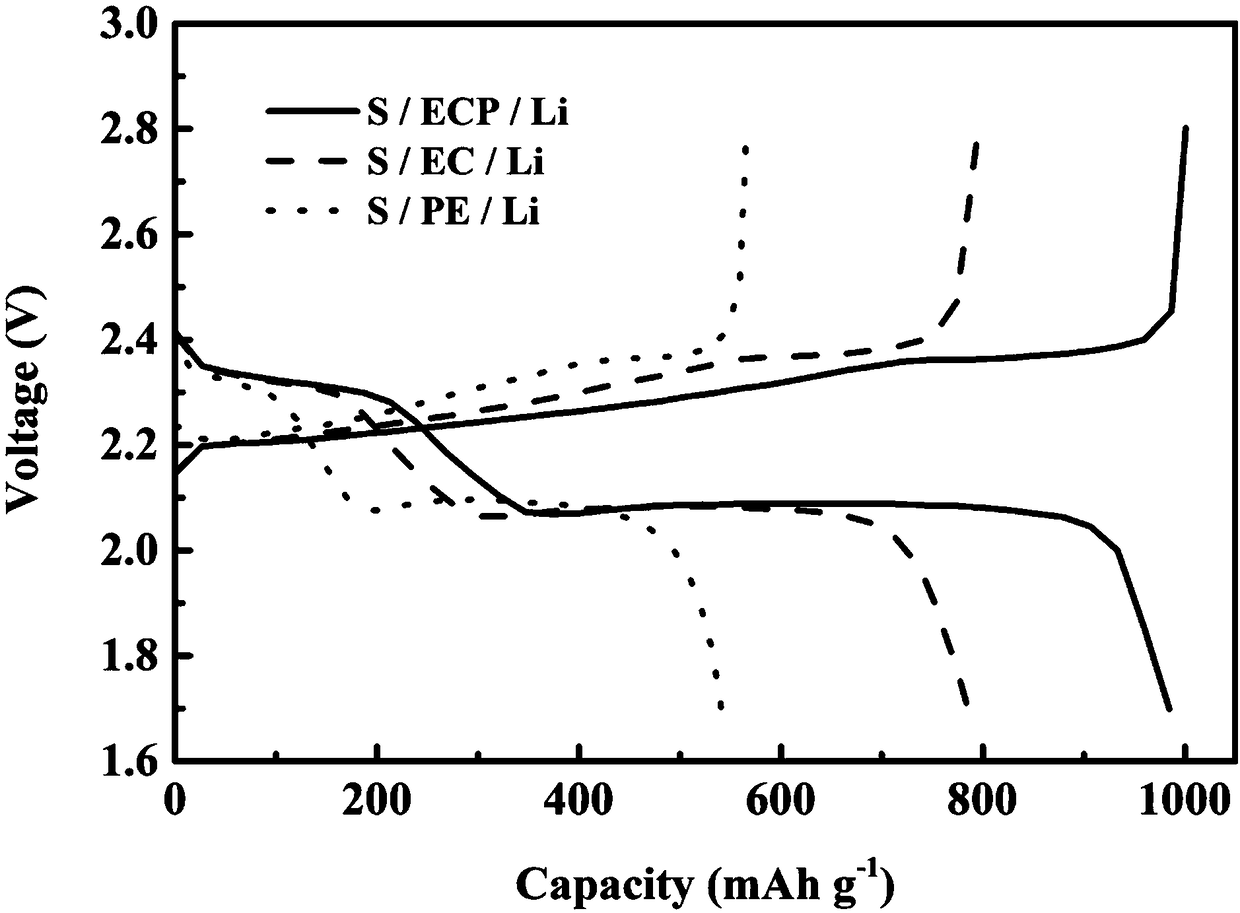

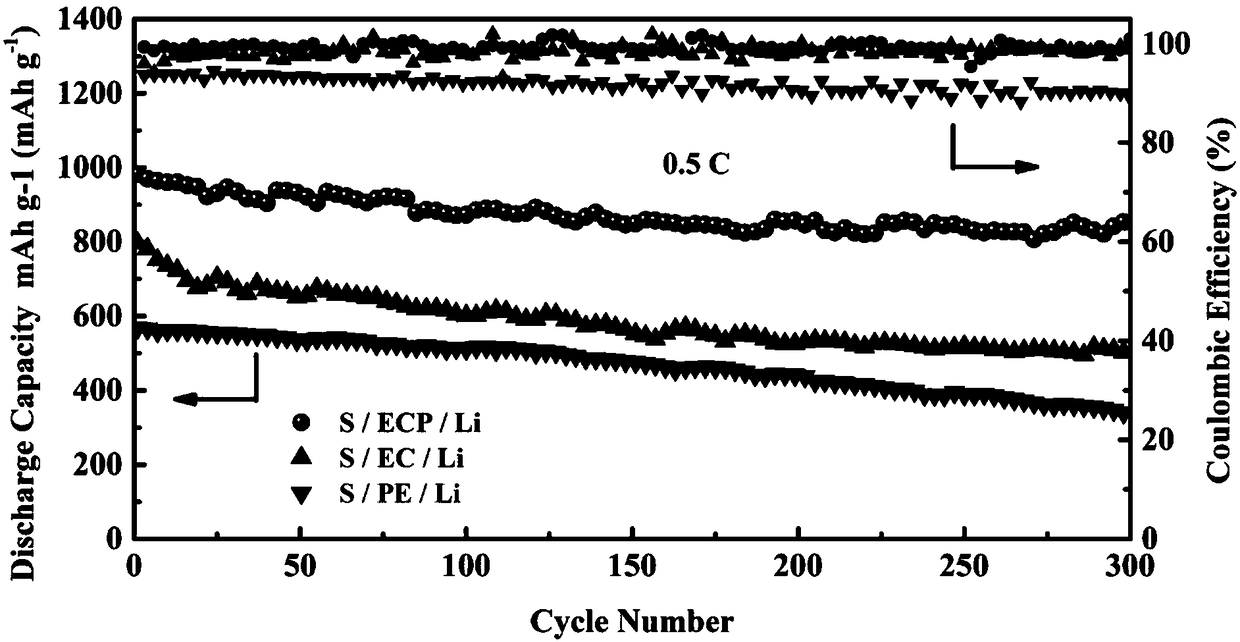

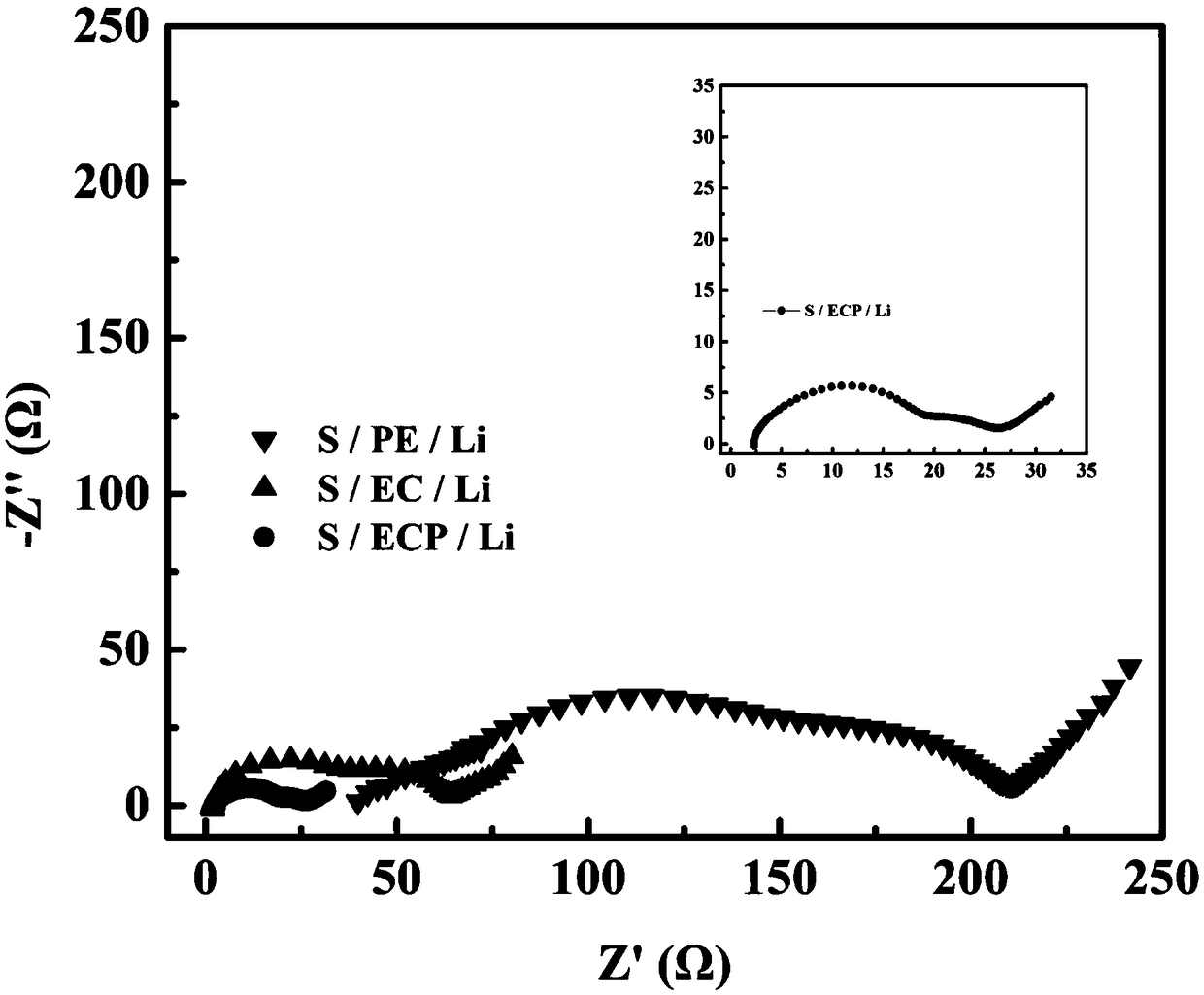

Polymer composite solid electrolyte and preparation method and application thereof

ActiveCN106450424AImprove conductivityImprove cycle lifeCell electrodesSecondary cellsQuinoneSolid state electrolyte

The invention discloses a polymer composite solid electrolyte and a preparation method and application thereof. The polymer composite solid electrolyte is prepared from polyphenylene sulfide, a lithium salt and an organic quinones electron acceptor and is taken as a polymer composite solid electrolyte of a lithium-sulfur battery, the polymer composite solid electrolyte, carbon black and elemental sulfur are fabricated to a composite sulfur electrode material, and thus, a novel lithium-sulfur battery system is formed. The high-molecular polymer composite solid electrolyte provides a relatively good lithium ion migration passage, the lithium ion conductivity of a composite positive electrode material is improved, the high-molecular polymer composite solid electrolyte has certain rigidity and toughness, the volume change of a positive electrode after charge and discharge of the lithium-sulfur battery is buffered, the discharge specific capacity of the lithium-sulfur battery is improved, and the cycle lifetime of the lithium-sulfur battery is prolonged.

Owner:NANJING BOCHI NEW ENERGY CO LTD

Diaphragm of lithium-sulfur battery

ActiveCN103855349AHigh electrolyte absorption capacityImprove storage capacityLi-accumulatorsCell component detailsIonizationNegative charge

The invention belongs to the technical field of lithium-sulfur batteries and in particular relates to a composite membrane of a lithium-sulfur battery. The composite membrane is a negative ion type composite multi-stage porous diaphragm and comprises a mixture of a negative charge ionization polymer and a lithium ion conduction polymer, wherein the composite multi-stage porous diaphragm has a macropore channel structure of 50 nanometers to 2 microns; micropores of 1-50 nanometers are formed in the side walls of macropore channels; the porosity is 50%-80%; macro pores account for 40%-70% of all pores and the rest pores are micropores. The composite multi-stage porous diaphragm provided by the invention has the characteristics and the beneficial effects that the macro pores of the composite membrane are good in electrolyte solution absorption and storage capacity, and the micropores are connected with the macro pores, so that the conduction of lithium ions can be facilitated; polysulfide negative ions can be excluded under the charge effect of the composite membrane material to a certain extent, so that the shuttle effect is inhibited, the loss of active substances is reduced, and the battery efficiency and stability are improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Lithium-sulfur battery membrane and lithium-sulfur battery with same

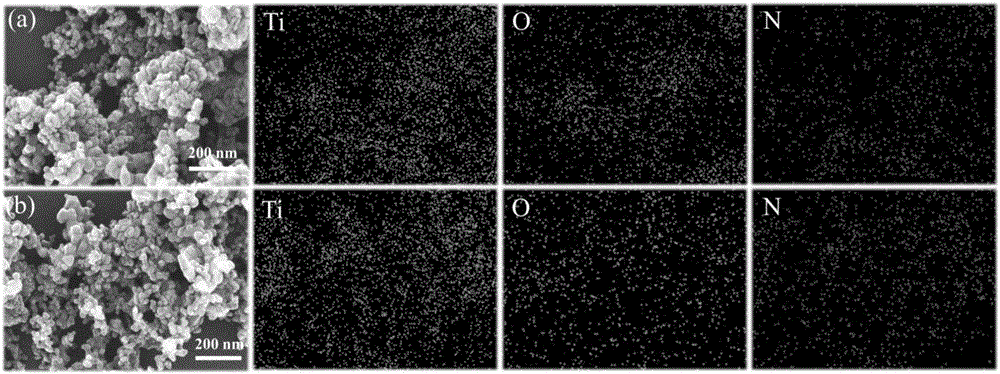

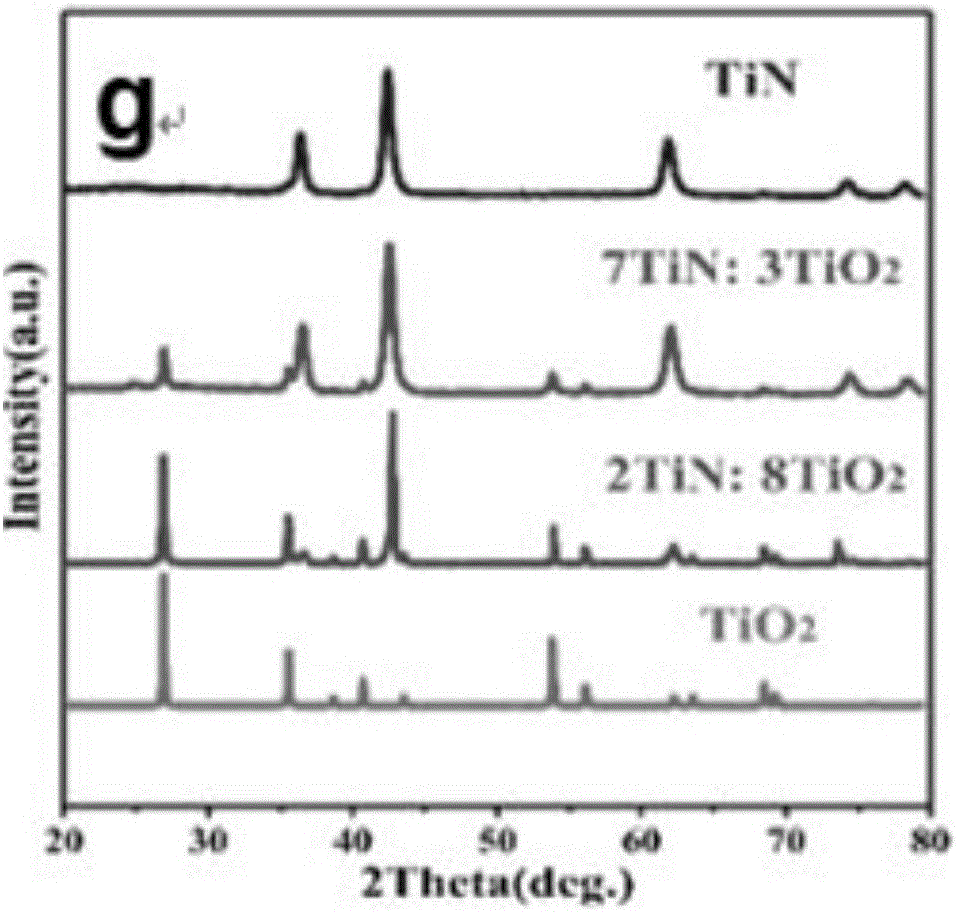

ActiveCN106784554AInhibition of Stability EffectsAvoid stabilityMaterial nanotechnologyLi-accumulatorsHeterojunctionLithium–sulfur battery

The invention belongs to the technical field of lithium-sulfur batteries, and relates to a membrane and for a lithium-sulfur battery. The membrane comprises a membrane body and a covering layer, the covering layer comprises graphene and heterojunction nano materials, the heterojunction nano materials are a symbiotic high adsorption phase-high conductivity phase, the mass ratio of the graphene to the heterojunction nano materials is (3-15):1, and the mass ratio of the high adsorption phase to the high conductivity phase is (1-10): (10-1). Relative to the prior art, according to the membrane, the covering layer is arranged on the membrane, electrochemistry and dynamics performances of the lithium-sulfur battery can be greatly improved, heterojunction nano materials specifically comprise the high adsorption phase and the high conductivity phase, the high adsorption phase has high adsorption action on polysulfide, the high conductivity phase has high conductivity action on the polysulfide, the polysulfide adsorbed by the high adsorption phase can be diffused on the surface of the high conductivity phase, so that transformation of the polysulfide is finished, adsorption and transformation at an interface between the high adsorption phase and the high conductivity phase can be finished, and the 'shuttling effect' of the polysulfide is restrained.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

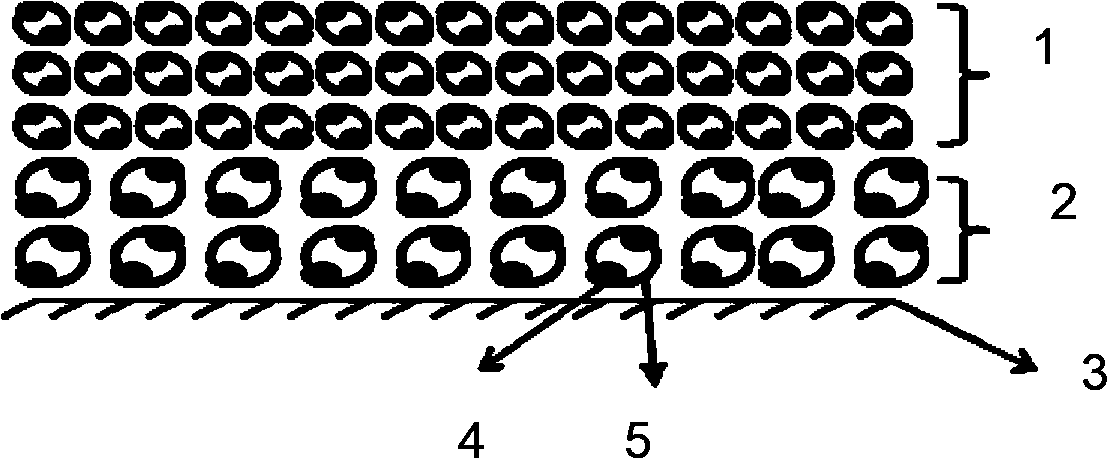

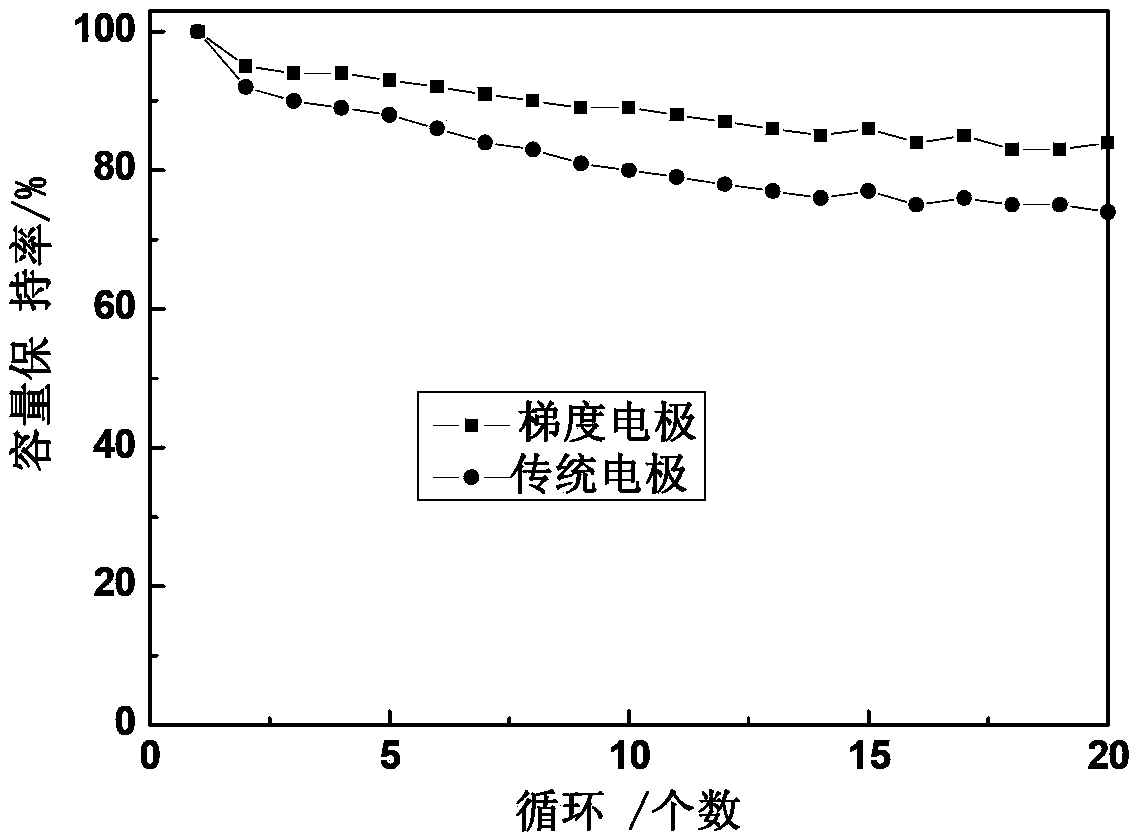

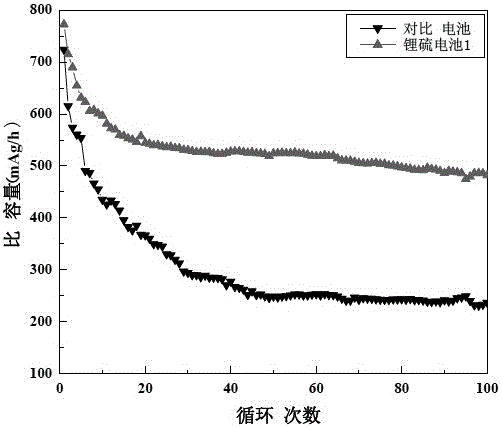

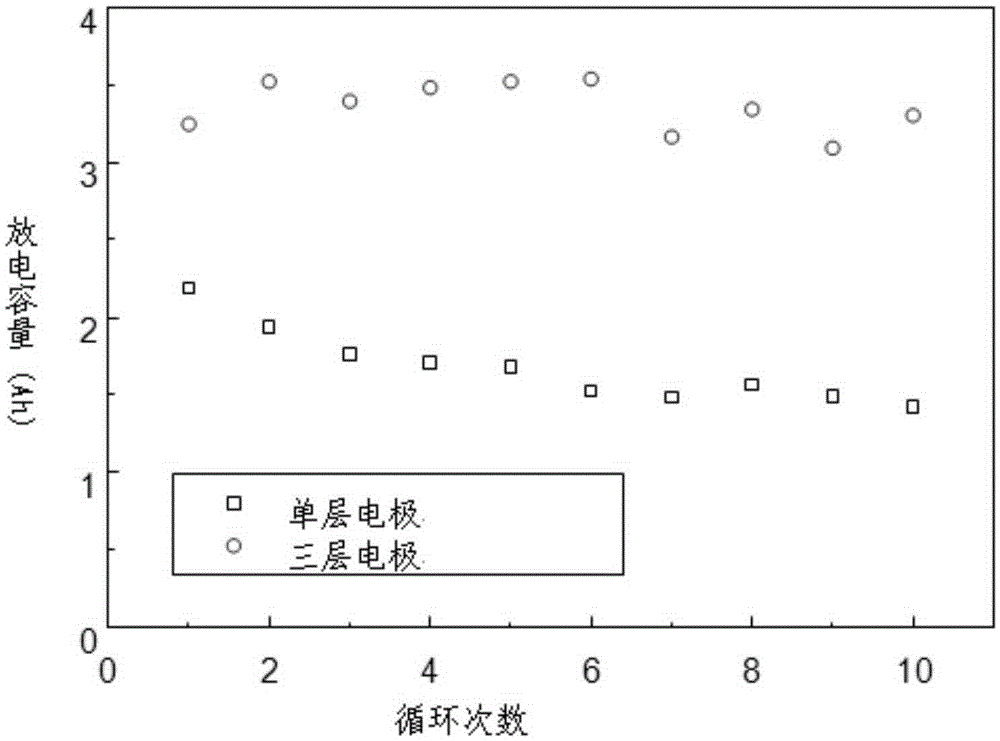

Lithium-sulfur battery positive electrode structure and preparation method thereof

ActiveCN103840125AEasy transferImprove discharge ratePositive electrodesElectrode collector coatingSulfurLithium–sulfur battery

The present invention relates to a lithium-sulfur battery positive electrode structure and a preparation method thereof. According to the lithium-sulfur battery positive electrode structure, a current collector is adopted as a substrate, two carbon-sulfur complex layers with different pore sizes are attached onto the substrate, the structure sequentially comprises the current collector, the large pore size carbon-sulfur complex layer and the small pore size carbon-sulfur complex layer, the thickness of the large pore size carbon-sulfur complex layer is 50-500 mum, the thickness of the small pore size carbon-sulfur complex layer is 10-200 mum, the large pore size carbon material is a carbon material with a pore size of greater than 100 nm and less than 1 mum and a pore volume accounting for 50-90% of the total pore volume, and the small pore size carbon material is a carbon material with a pore size of 0.5-100 nm and a pore volume accounting for more than 50-90% of the total pore volume. With the lithium-sulfur battery positive electrode structure, the mass transfer curvature of the lithium ions in the electrode is effectively increased, the lithium ion transmission path is prolonged, provision of the capacity of the high supporting capacity active substance is easily achieved, and the energy density of the battery is increased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A functional separator for a lithium-sulfur battery, a preparation method thereof and an application thereof in lithium-sulfur battery

ActiveCN109103399AImprove adhesionImprove stabilitySecondary cellsCell component detailsCyclic processAdhesive

The invention relates to a functional separator for a lithium sulfur battery, and a preparation method and application thereof, belonging to the technical field of electrochemistry. The functional separator of the invention is composed of a polymer separator matrix and a functional modification layer applied one side surface of the polymer separator matrix, wherein the functional modification layer comprises a binder, a conductive carbon material and a dendritic branched macromolecule. The adhesive of the invention has good adhesion and high stability. The conductive carbon material has a veryhigh electron conduction rate, can improve the utilization rate of the active substance and greatly reduce the internal impedance of the battery. The dendritic branch macromolecule contains more organic functional groups, the dendritic branched macromolecule has chemisorption to the polysulfide generated in the sulfur positive electrode region during the cycle, and the carbon material has physical adsorption to the dissolve polysulfide, thereby effectively inhibiting the shuttle effect in the lithium-sulfur battery. Therefore, the lithium sulfur battery prepared using the functional separatordescribed in the present invention exhibits excellent cycle performance and rate performance.

Owner:WUHAN UNIV

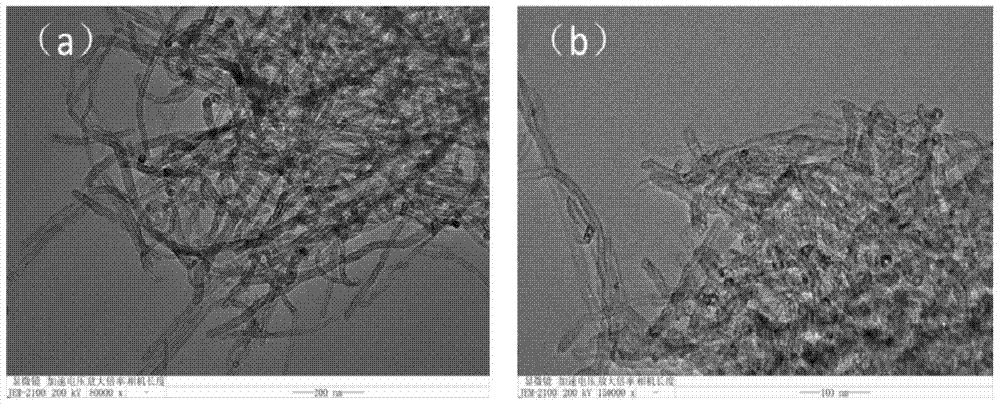

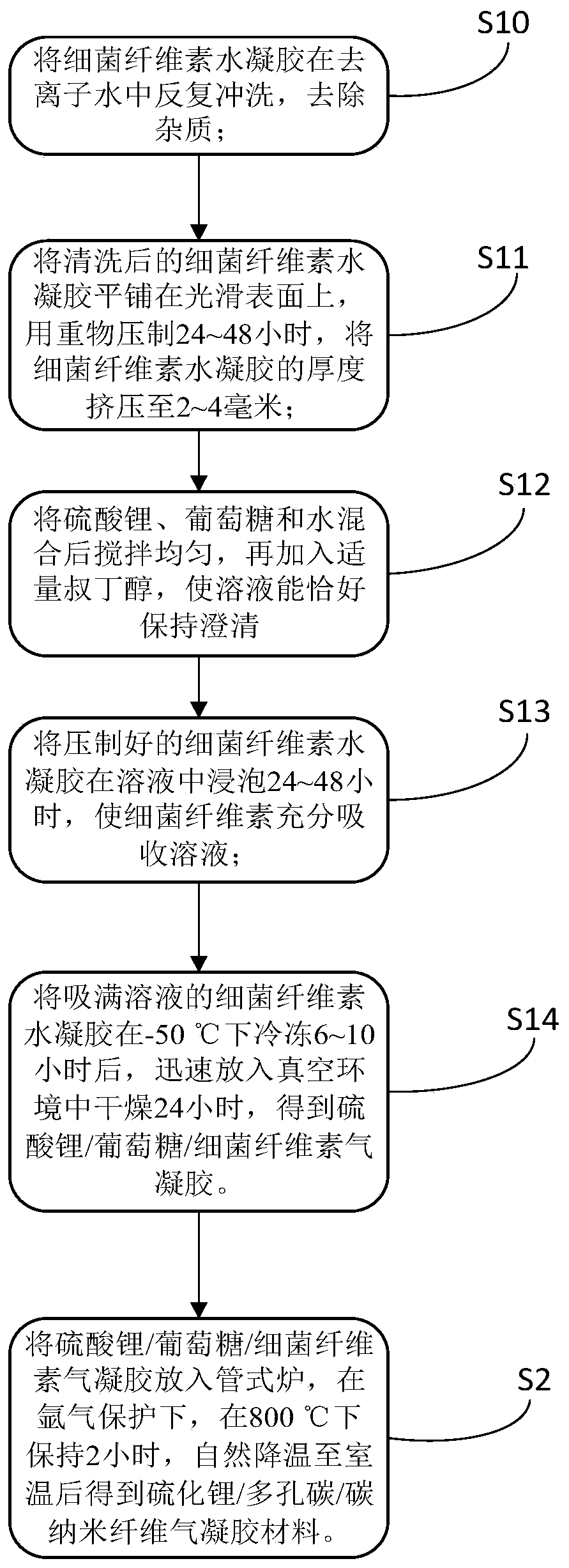

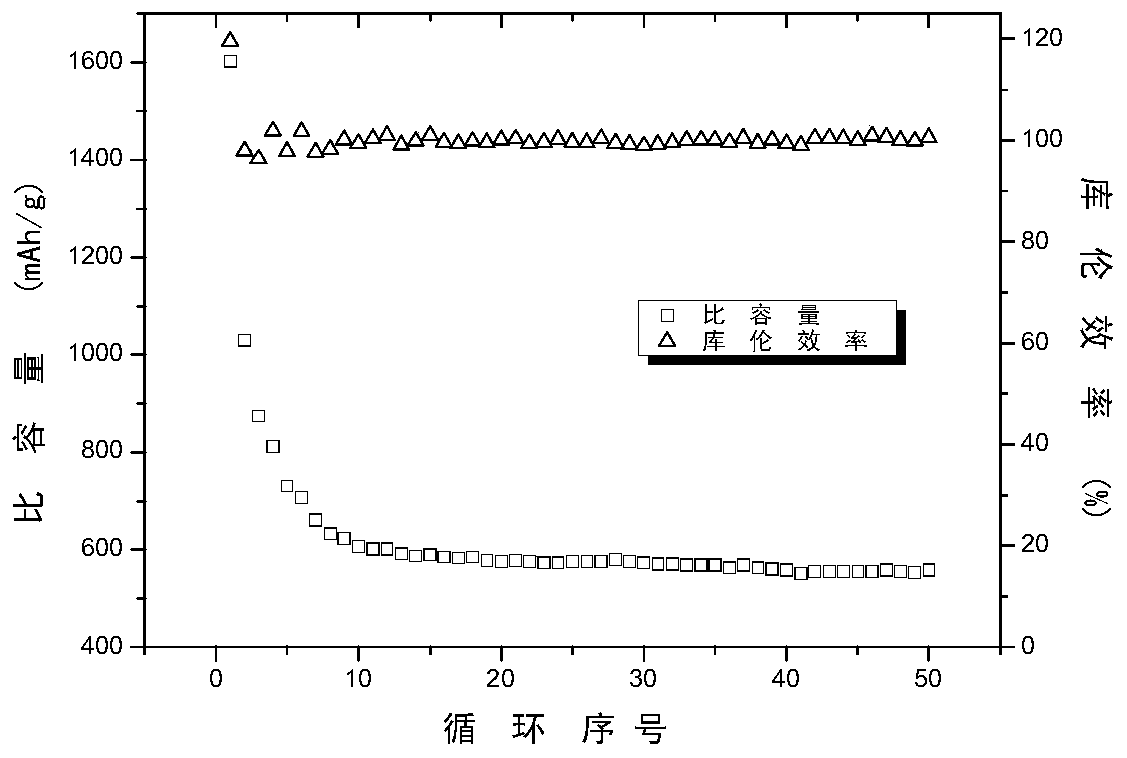

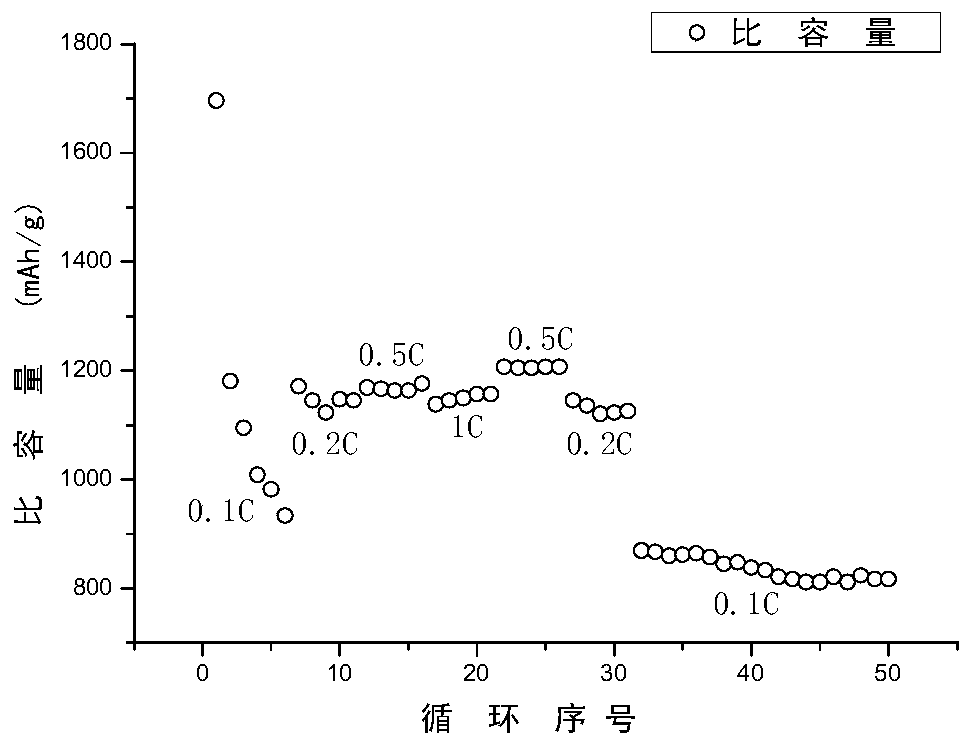

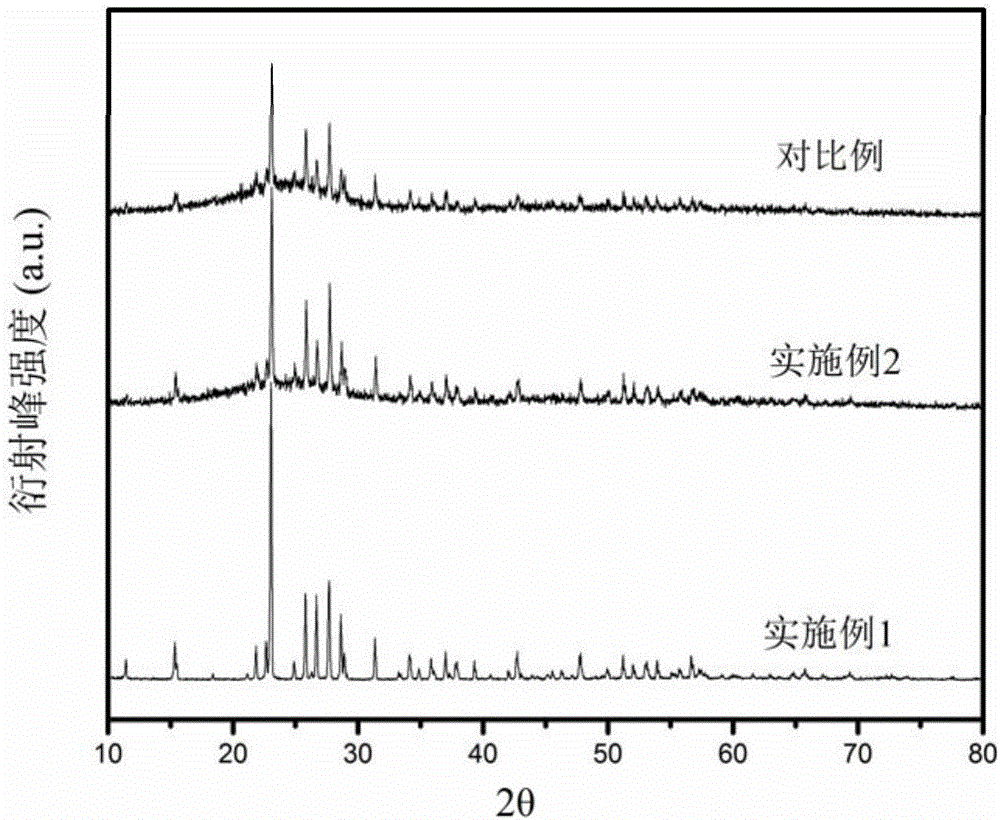

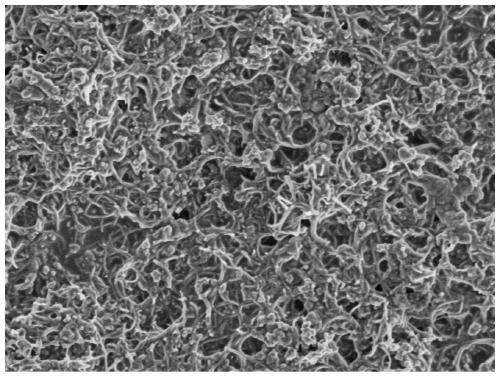

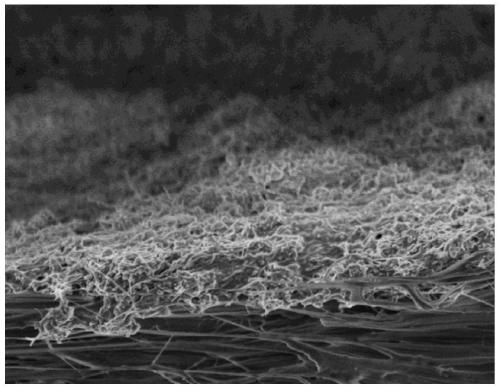

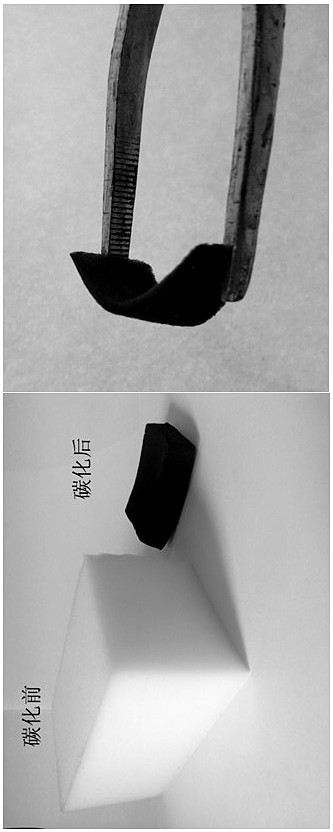

Method for preparing lithium-sulfur battery cathode material by using bacterial cellulose hydrogel

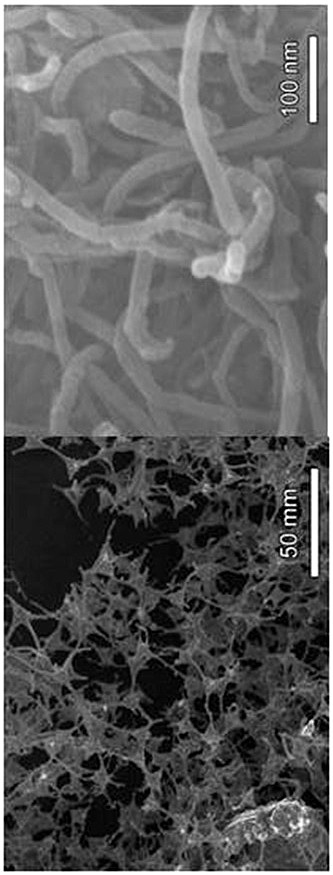

ActiveCN109962222AMitigates low electronic conductivityReduce diffuseCell electrodesPorous carbonCarbon nanofiber

The invention discloses a method for preparing a lithium-sulfur battery cathode material by using bacterial cellulose hydrogel, comprising the following steps of S1, preparing a lithium sulfate / glucose / bacterial cellulose aerogel composite material; and S2, converting the lithium sulfate in the lithium sulfate / glucose / bacterial cellulose aerogel composite material into lithium sulfide, convertingthe glucose into porous carbon, and converting the bacterial cellulose into carbon nanofibers. The method can construct a carbon nanofiber meshed structure, and the lithium sulfide nanoparticles in the structure are coated with the porous carbon, thereby improving the electron transmission efficiency in an electrode, suppressing a shuttling effect, and solving the problem of electrode collapse during lithium-sulfur battery charging and discharging so as to improve the performance of the lithium-sulfur battery.

Owner:HANGZHOU DIANZI UNIV

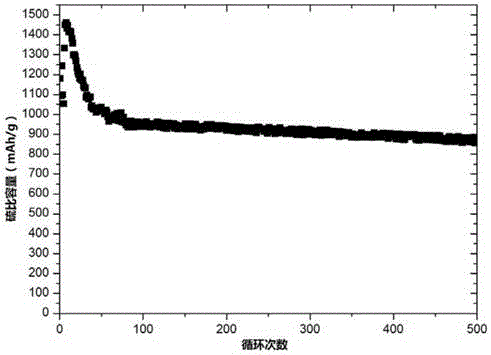

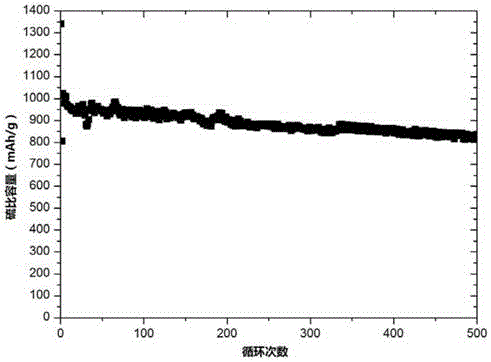

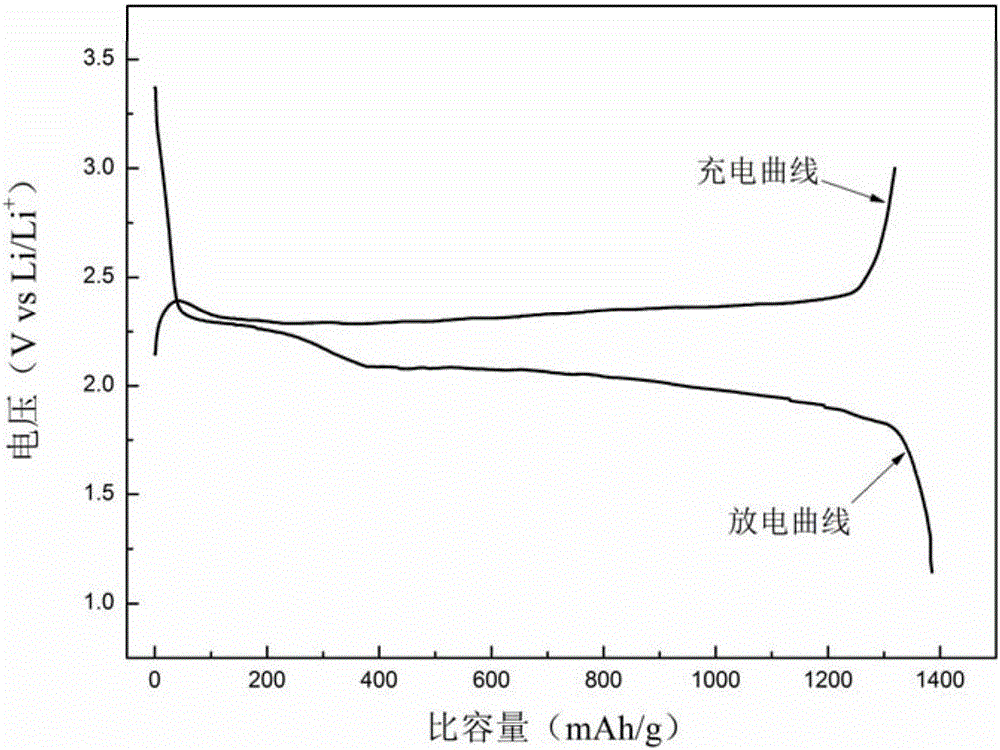

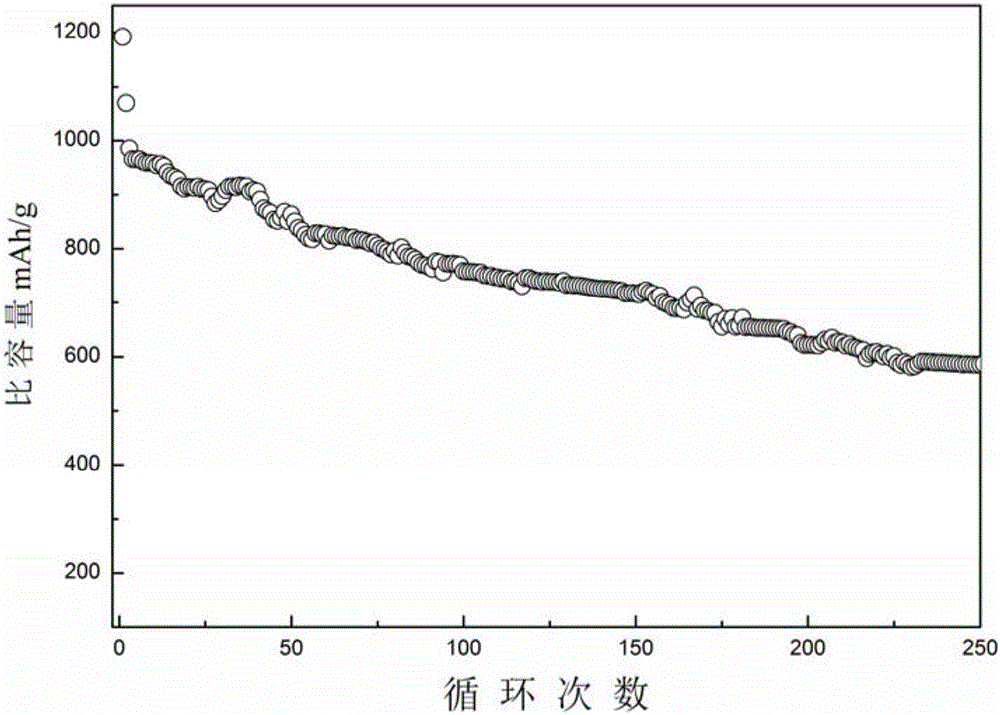

Sulfur-based cathode composite material and preparation method thereof

ActiveCN105958031AReduce the adverse effects of volume effectImprove adsorption capacityCell electrodesSecondary cellsPolypyrroleConductive polymer

The invention discloses a sulfur-based cathode composite material and a preparation method thereof. The sulfur-based cathode composite material is represented as (S-R1 / MCM-41)R2, in which MCM-41 is a molecular sieve and is a cathode material base body; S is elemental sulfur and is an active constituent; R1 is a conducting polymer, is formed through a synthetic reaction of monomers thereof inside pore channels of the molecular sieve, and serves as a conducting agent and a sulfur-fixing agent; and R2 is a conducting substance, and is coated on the surface of composite material S-R1 / MCM-41. The obtained cathode material is charged and discharged under 400 mA.g<-1>, and the first specific discharge capacity is 1390.5 mAh.g<-1> at most; by taking polyaniline as the conducting agent inside the molecular sieve and polypyrrole as the conducting substance, the sulfur-based cathode composite material synthetized by coating outside the material has higher circulation stability performance, the first specific discharge capacity of an assembled battery is 1191.9 mAh.g<-1>, and the capacity retention ratio after 200 times of circulation is 52.17%.

Owner:SOUNDON NEW ENERGY TECH CO LTD

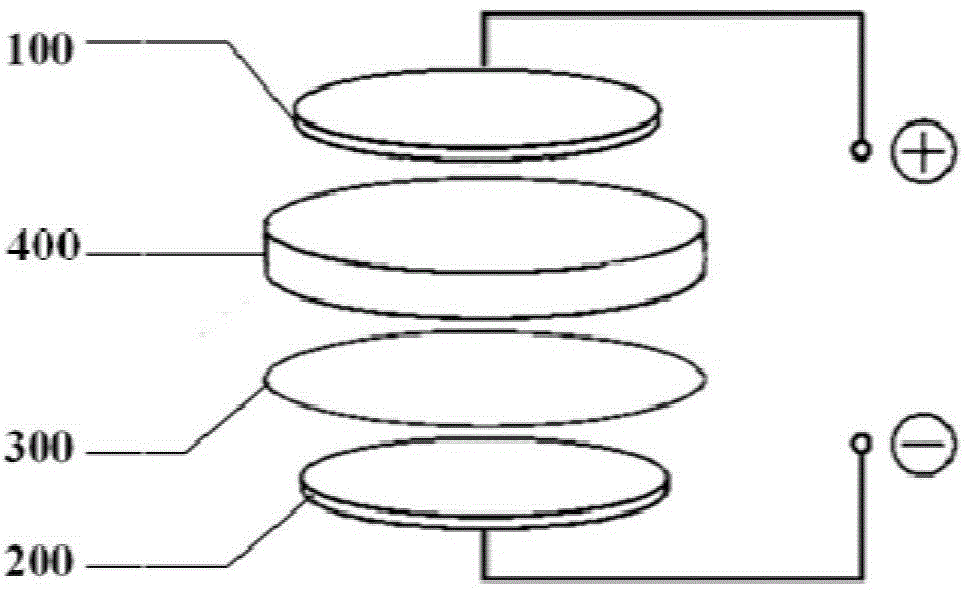

Barrier membrane and preparation method thereof and secondary battery comprising barrier membrane

ActiveCN105789531ASolve the battery capacitySolve efficiency problemsNon-aqueous electrolyte accumulatorsCell component detailsElectrical batterySingle ion

The invention discloses a barrier membrane and a preparation method thereof and a secondary battery comprising the barrier membrane. The barrier membrane comprises one or G layers of single-ion polymer electrolyte membranes, wherein G is greater than or equal to 2; the single-ion polymer electrolyte membranes in the barrier membrane can block electromigration of soluble multi-sulfur anions generated by the secondary battery in the discharge process and block the soluble multi-sulfur anions at one side close to a sulfur positive electrode due to selective through characteristics for cations, so that these multi-sulfur anions are prevented from diffusing to the surface of a negative electrode (for example, a lithium or sodium negative electrode) for reaction; and the problem of reduction of battery capacity and current efficiency of the secondary battery can be solved. In a word, after the barrier membrane is added between the sulfur positive electrode of the secondary battery and a porous membrane, the 'shuttle' effect of polysulfide can be effectively suppressed under the blocking effect of the barrier membrane on the multi-sulfur anions, so that the battery performance of the secondary battery with the sulfur positive electrode can be improved.

Owner:杭州聚力氢能科技有限公司 +1

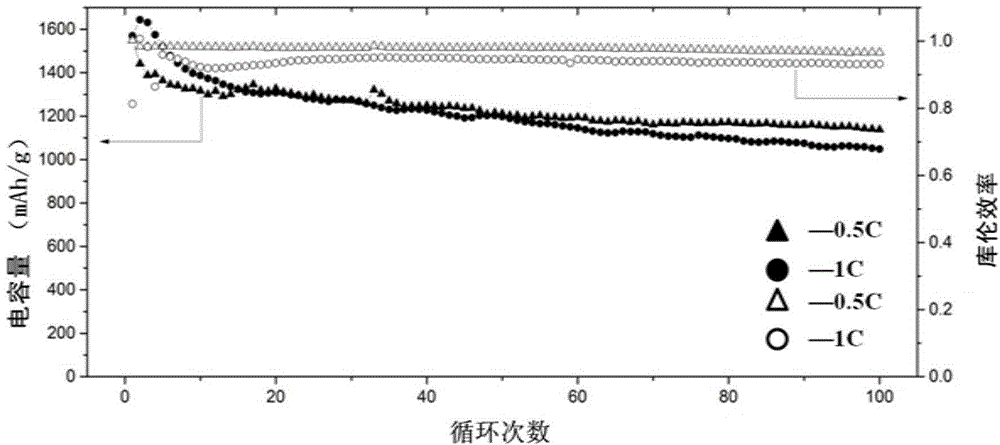

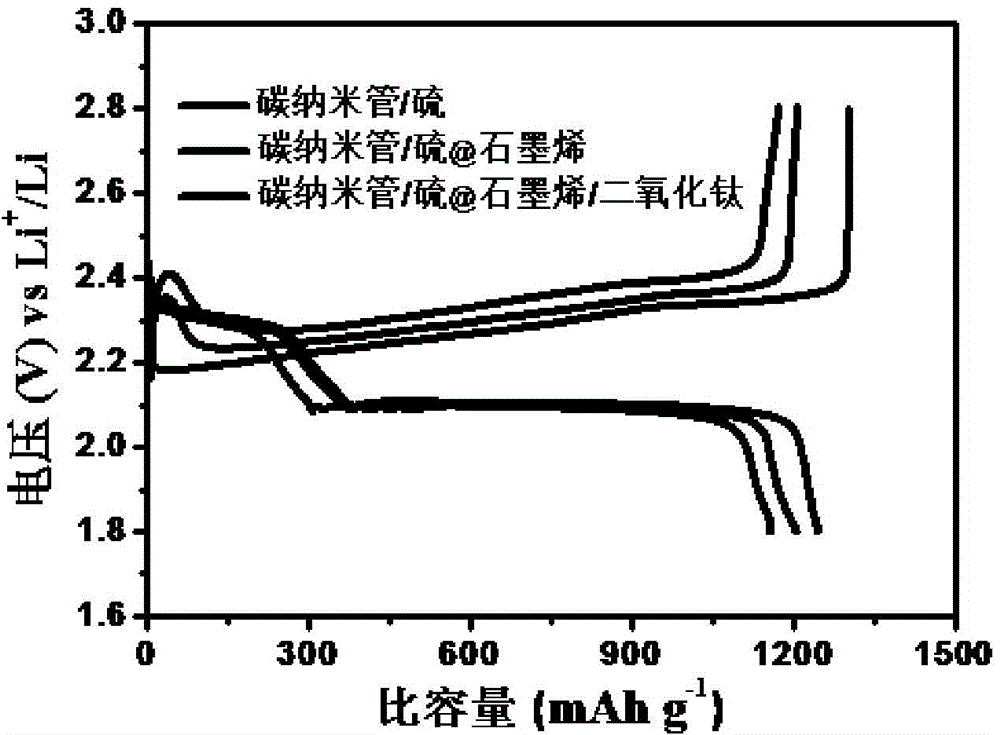

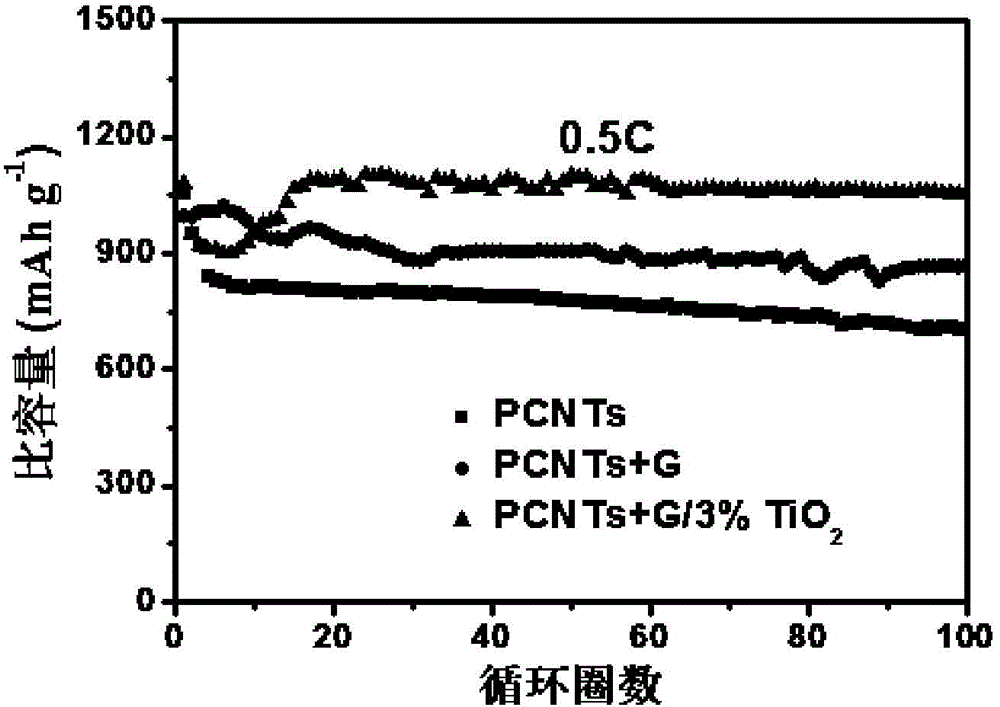

Preparation method of graphene/titanium oxide composite material and application method thereof

ActiveCN104600267AIncrease capacityImprove cycle stabilityCell electrodesSecondary cellsLithiumOrganic solvent

The invention relates to a synthesis and preparation method of a composite material applied to a positive intercalation of a lithium-sulphur battery, and in particular relates to a preparation method and application method of a graphene / titanium oxide composite material. The preparation method comprises the following steps of mixing and dissolving titanium oxide and graphene in an organic solvent to form slurry, and coating the surface of a lithium-sulphur positive material with the slurry. The preparation method is simple to operate and low in cost; furthermore, shuttle effects of polysulfide ions in the lithium-sulphur battery can be effectively inhibited; and the capacity and the cycling performance of the battery are greatly increased.

Owner:WENZHOU UNIVERSITY

Battery anode material and lithium-sulfur battery

PendingCN110289409AImprove cycle stabilityImprove conductivityCell electrodesLi-accumulatorsElectrical batteryLithium sulfur

The invention belongs to the technical field of lithium-sulfur batteries, and particularly relates to a battery positive electrode material and a lithium-sulfur battery. The invention provides the battery positive electrode material. The battery positive electrode material comprises a carbon-based composite material and sulfur filled in the carbon-based composite material, wherein the carbon-based composite material comprises two-dimensional layered graphite carbon nitride and carbon coating the two-dimensional layered graphite carbon nitride; the carbon-based composite material is obtained by carrying out an in-situ pyrolysis reaction on the two-dimensional layered graphite carbon nitride and a carbon-containing organic matter or carrying out chemical vapor deposition on carbon on the surface of the two-dimensional layered graphite carbon nitride. Experimental results show that when the battery positive electrode material is applied to the lithium-sulfur battery, the first specific discharge capacity of the lithium-sulfur battery at 0.1 C can reach 1,166mAh / g, and the lithium-sulfur battery has high specific capacity and good cycle performance.

Owner:GUANGDONG UNIV OF TECH

Lithium-sulfur diaphragm with synergistic effect mechanism, preparation method of lithium-sulfur diaphragm and lithium-sulfur battery

InactiveCN111370626AInhibition of the shuttle effectInhibition formationLi-accumulatorsCell component detailsLithium–sulfur batteryLithium sulfur

The invention discloses a lithium-sulfur diaphragm with a synergistic effect mechanism, a preparation method of the lithium-sulfur diaphragm and a lithium-sulfur battery, and belongs to the technicalfield of battery diaphragms. According to the invention, the porous conductive carbon material is added into the positive electrode side functional layer; a nano oxide material is added into the negative electrode side functional layer; the positive side and the negative side on the two sides of the diaphragm base membrane are coated with the functional layer slurry to prepare the lithium-sulfur diaphragm with a synergistic effect mechanism. The prepared lithium-sulfur diaphragm is applied to the lithium-sulfur battery, so that the shuttle effect caused by lithium polysulfide in the cycle process of the lithium-sulfur battery can be effectively inhibited, the deposition of lithium sulfide on the surface of an electrode can be reduced, lithium dendrites are prevented from piercing a pole piece, and the capacity retention ratio and the cycle effect of the lithium-sulfur battery are improved.

Owner:安徽金力新能源有限公司

Method for preparing lithium sulfur battery anode material

ActiveCN109346691AImprove conductivityHigh mechanical strengthCell electrodesConductive polymer compositeSolvent

The invention relates to a method for preparing a lithium sulfur battery anode material and belongs to the technical field of battery materials. Aiming to solve conventional phenomena of low loading capacities and volume expansion, the invention provides the method for preparing the lithium sulfur battery anode material. The method comprises the following steps: putting an anionic surfactant intoa solvent so as to obtain a micro emulsion, and adding an acid reagent to adjust the pH value till acidity; putting a conductive polymer monomer and a metallic salt into the micro emulsion, adding anoxidant and excessive metal powder to implement a reaction, after the reaction is completed, filtering and collecting a solid mixture, and washing so as to obtain a corresponding conductive metal / conductive polymer composite material; mixing the conductive metal / conductive polymer composite material with single sulfur, and carrying out high-temperature sintering treatment, thereby obtaining a corresponding sulfur anode composite material. By adopting the method, the loading capacity of a metal on a porous conductive polymer can be increased, the framework support capability and the conductivity of the composite material can be increased, and the composite material has high stability and battery circulation performance.

Owner:ZHEJIANG FOREVER NEW ENERGY TECH CO LTD

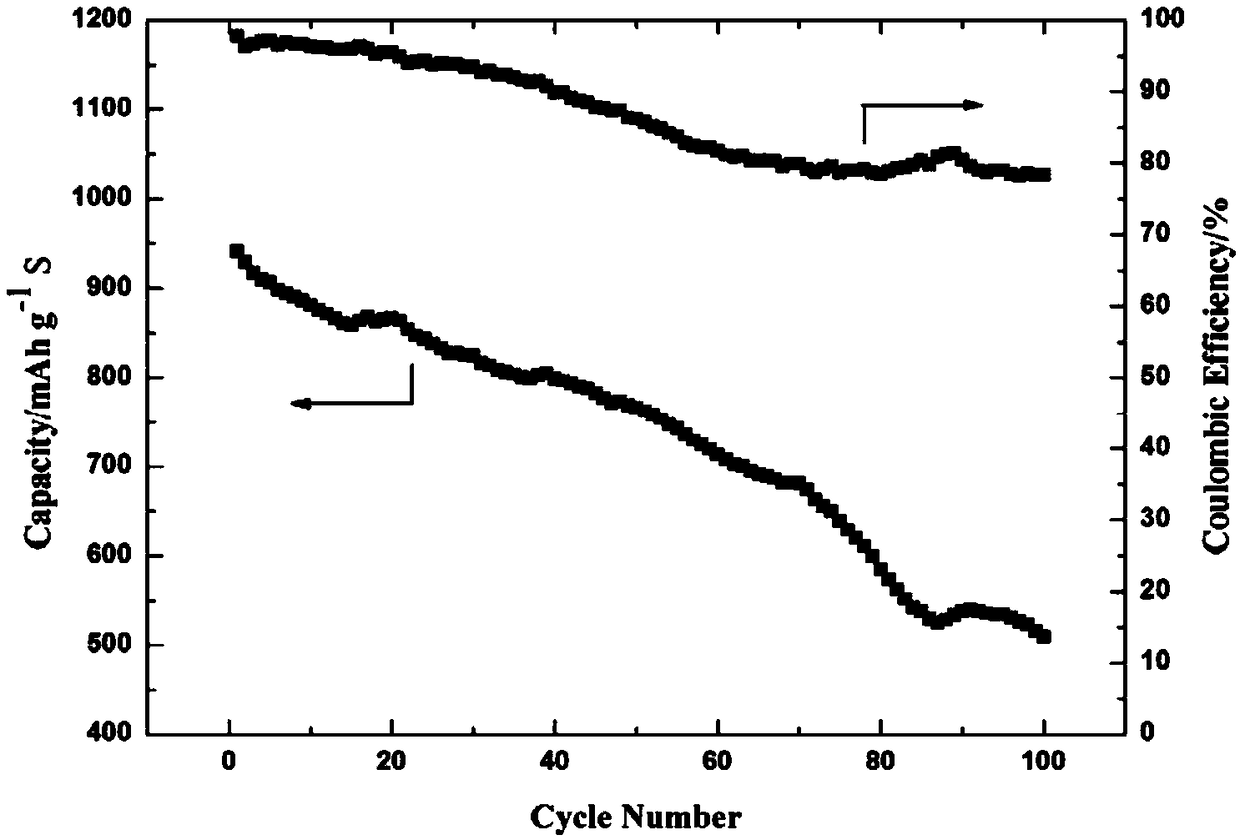

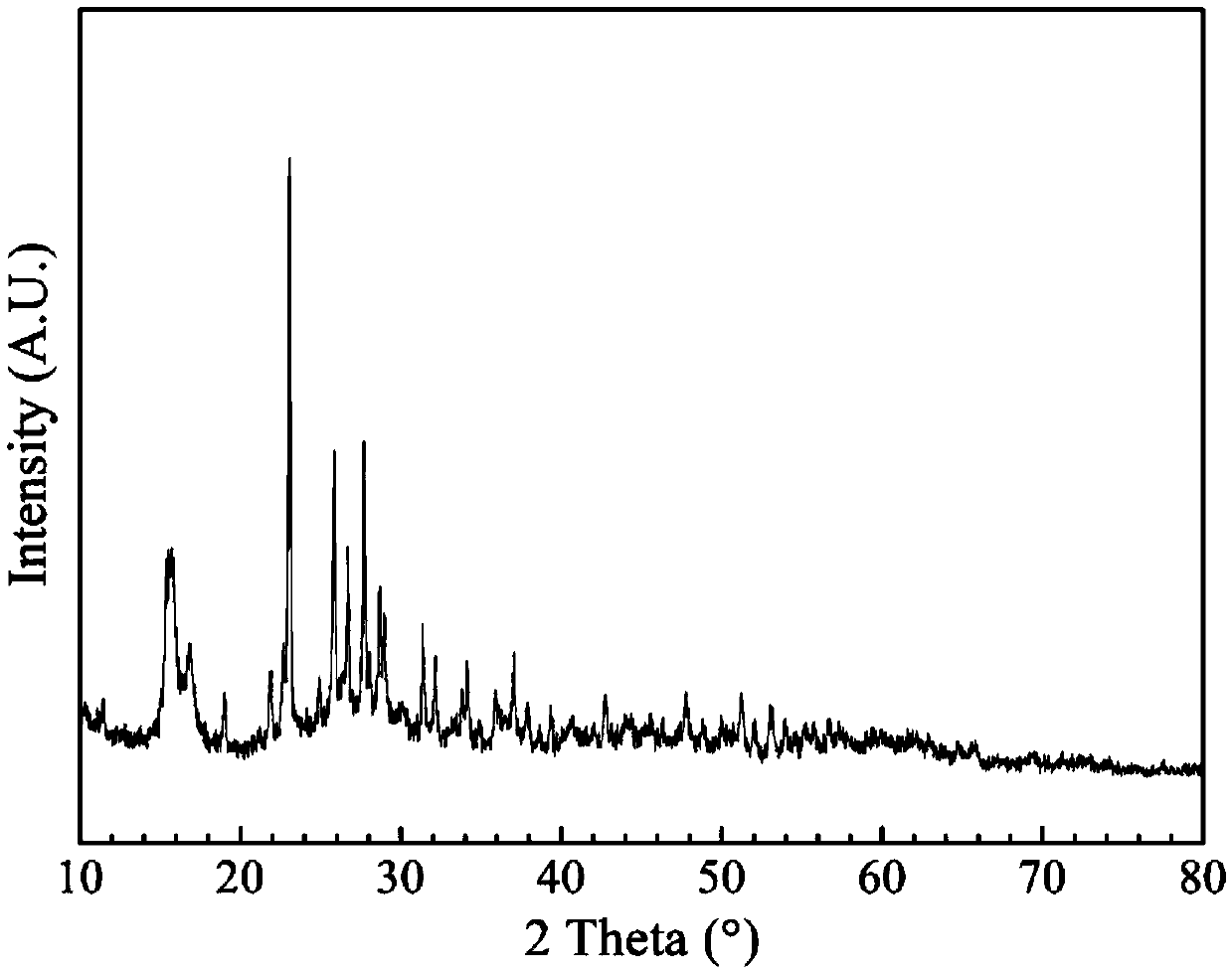

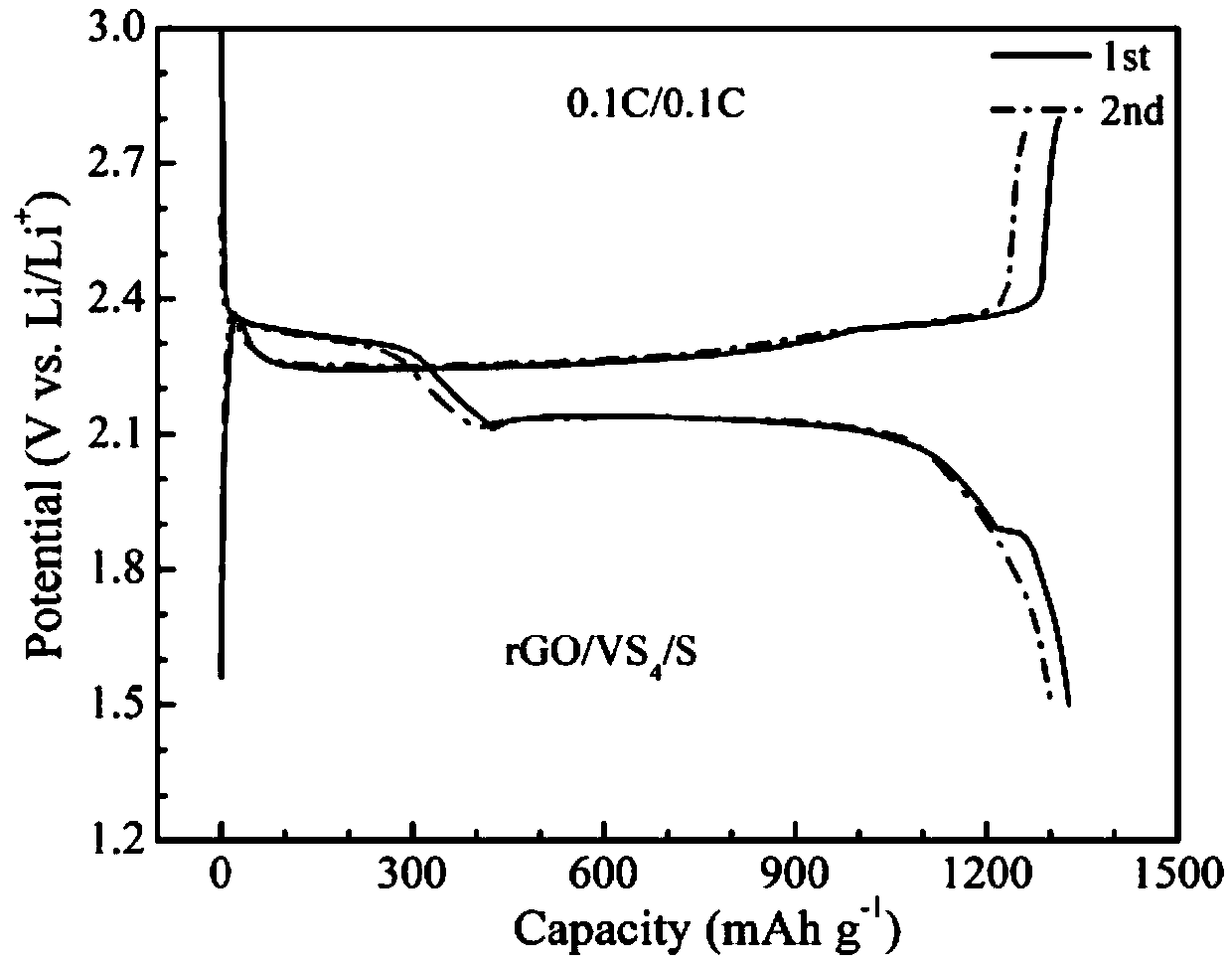

One-step in-situ preparation method of rGO/VS4/S compound as lithium sulfur battery cathode material

ActiveCN109585828AMeet the requirements of electrochemical performanceImprove conductivityCell electrodesLi-accumulatorsHigh rateLithium sulfur

The invention discloses a one-step in-situ preparation method of a rGO / VS4 / S compound as a lithium sulfur battery cathode material. The method comprises firstly adding a stoichiometric vanadium sourceand a sulfur source to a graphene oxide (GO) solution to make a molar ratio S / V of sulfur elements to vanadium elements greater than 10; adding an appropriate amount of oxidant, uniformly stirring the solution, adding the solution to a hydrothermal reaction kettle to perform a hydrothermal reaction at a certain temperature, wherein at this time, the S2- is oxidized by the oxidant into S22-; generating VS4 on the surface of rGO to obtain a rGO / VS4 compound; reacting the remaining S22 with the oxidant to generate an elementary substance S; depositing the elementary substance S on the voids or surface of the rGO / VS4 compound; and finally preparing the rGO / VS4 / S compound. Because both the rGO and the VS4 have high electron conductivity and the electronegativity VS4 can inhibit the shuttle effect of polysulfide ions, the rGO / VS4 / S compound can be used as a high-performance lithium-sulfur battery cathode material which has a high discharge specific capacity, can significantly improve the cycle life and fast discharge capacity of the sulfur cathode material, and accelerates the development of long-life, high-rate lithium-sulfur batteries.

Owner:UNIV OF JINAN

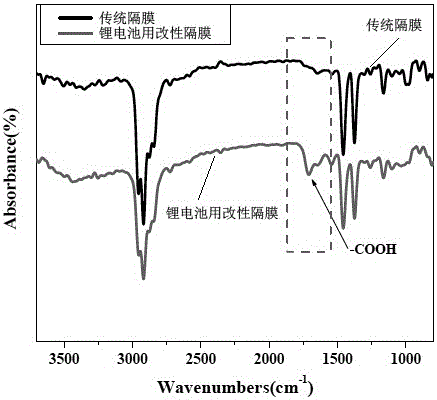

Preparation method for modified diaphragm for lithium battery

ActiveCN106848150AIncrease the number of transfersInhibit the shuttle effectCell component detailsChemistryCyclic process

The invention discloses a preparation method for a modified diaphragm for a lithium battery. The preparation method comprises the following steps of S1: performing corona treating or plasma processing on a battery diaphragm; and S2, adding the battery diaphragm processed in the step S1 into a negative ion type polymer solution to be modified to obtain the modified diaphragm for the lithium battery. The modified diaphragm prepared by the invention can effectively suppress pass of negative ions and improve mobility number of positive ions; and particularly in a lithium-sulfur battery, the modified diaphragm can effectively suppress a "flying shuttle effect" generated by the lithium-sulfur battery in a cyclic process, and can suppress capacity attenuation of the lithium-sulfur battery. The modified diaphragm provided by the invention has the advantages of high ionic selectivity, simple preparation process and low economic cost, so that an effective improvement method for development of a high-performance battery (such as a power lithium battery, a lithium-sulfur battery, a lithium cobalt oxide battery, a lithium manganate battery, a lithium phosphate battery and the like) can be provided.

Owner:SUN YAT SEN UNIV

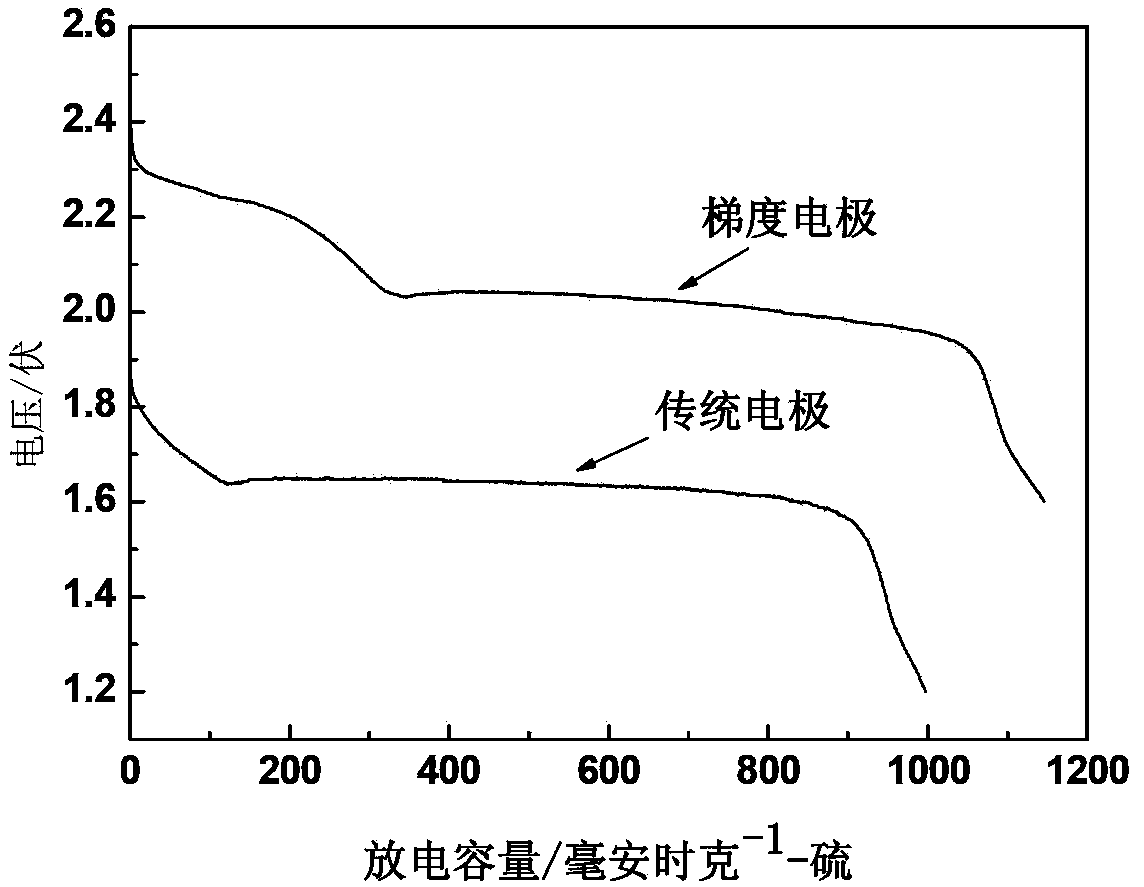

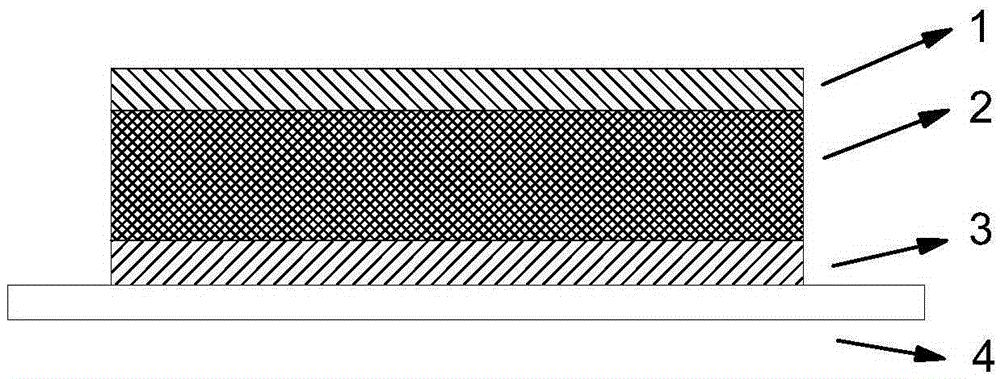

Electrode structure of lithium sulfur battery and processing technology therefor

InactiveCN105374982AImprove solubilityInhibition of the shuttle effectElectrode collector coatingNon-aqueous electrolyte accumulator electrodesCarbon coatingLithium–sulfur battery

The invention discloses an electrode structure of a lithium sulfur battery and a processing technology therefor. The electrode structure comprises a sulfur-containing active substance layer and a current collector; the upper surface of the active substance layer is coated with a first carbon coating layer; the lower surface of the active substance layer is coated with a second carbon coating layer; and the second carbon coating layer is positioned between the active substance layer and the current collector. The electrode structure has the main characteristics that the two sides of the sulfur-containing active substance layer are coated with the carbon coating layers; namely, the surface of the active substance layer, and the space between the active substance layer and the current collector are coated with the carbon coating layers, wherein a carbon material is taken as the main component, and the carbon material with a large specific surface area or low bulk density is preferable; the carbon material with the relatively large specific surface area can absorb polysulfide and restrain a shuttle effect; meanwhile, the carbon material with the low bulk density can form the relatively loosen carbon coating layer so as to store a large amount of electrolyte in the carbon coating layer, and the dissolution of sulfur and the polysulfide is facilitated, a positive electrode reaction is promoted, and the increase of electrolyte viscosity caused by resolution is restrained.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Red phosphorus modified composite separator, preparation method and application thereof

ActiveCN108598343AInhibit the shuttle effectIncrease profitLi-accumulatorsCell component detailsChemistryLithium sulfur

The invention provides a red phosphorus modified composite separator, and belongs to the technical field of lithium sulfur batteries. The red phosphorus modified composite separator comprises a base diaphragm and a mixed coating carried on one side surface of the base diaphragm; the mixed coating comprises nano red phosphorus particles and conductive carbon; the base diaphragm is one of a PP diaphragm and a PE diaphragm; the mixed coating of the nano red phosphorus particles and the conductive carbon has a thickness of 5 to 30 mum; the mass ratio of the nano red phosphorus particles to the conductive carbon in the mixed coating of the nano red phosphorus particles and the conductive carbon is 0.05-1:1; and the nano red phosphorus particles have a particle diameter of 50 to 100 nm. In the red phosphorus modified composite separator, the nano red phosphorus particles can effectively adsorb polysulfide, so that the shuttle flying effect is well suppressed; the conductive carbon is introduced into the composite separator, which can provide a conductive network for nanoparticles of the nano red phosphorus particles; the polysulfide absorbed via the nano red phosphorus particles is used,thereby improving the utilization rate of sulfur; and the ultra-low cost nano red phosphorus particles are used as raw materials for diaphragm modification, thereby facilitating large-scale preparation.

Owner:吉林省东驰新能源科技有限公司

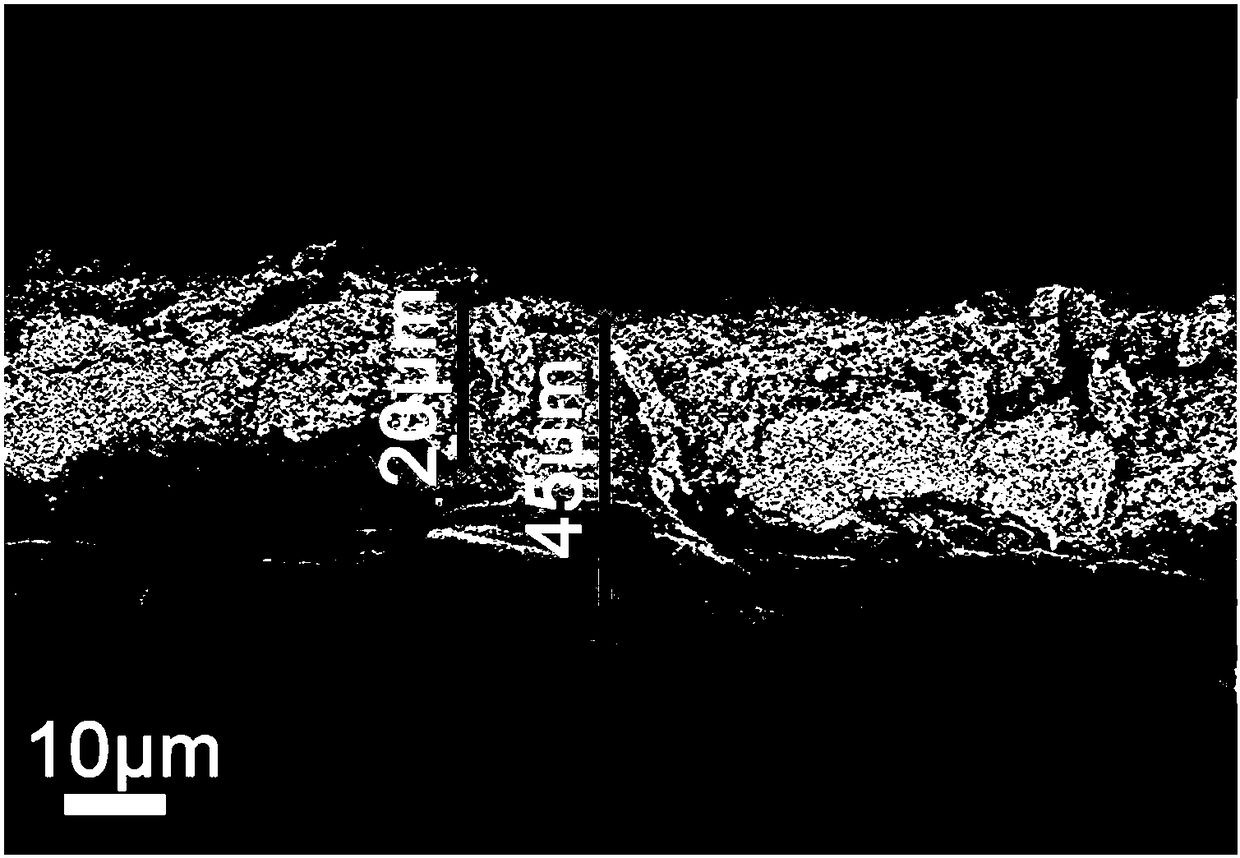

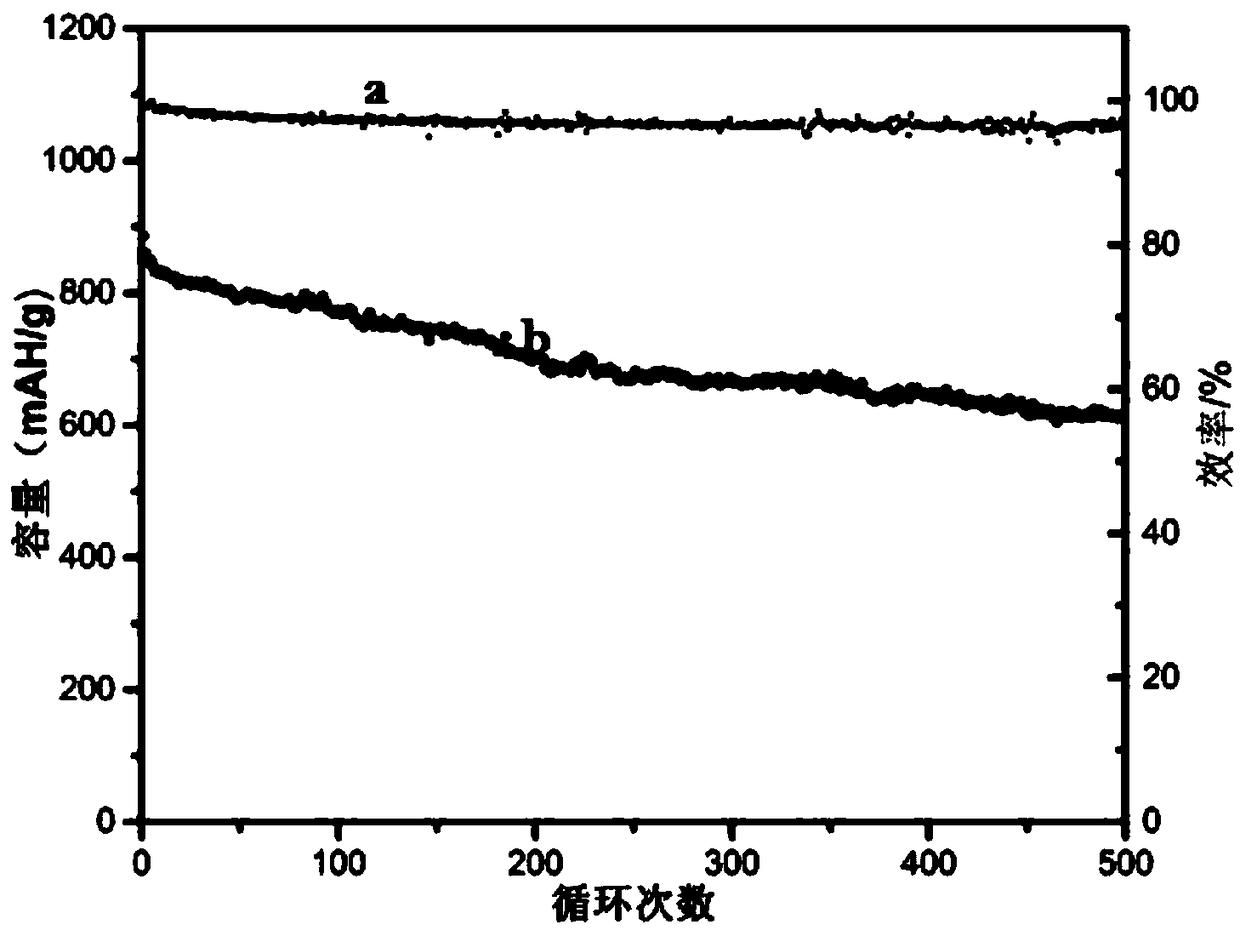

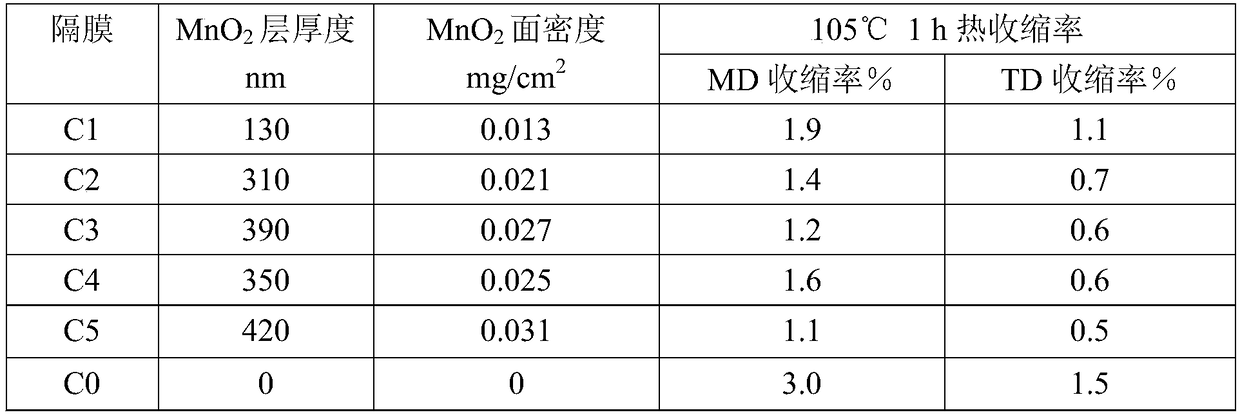

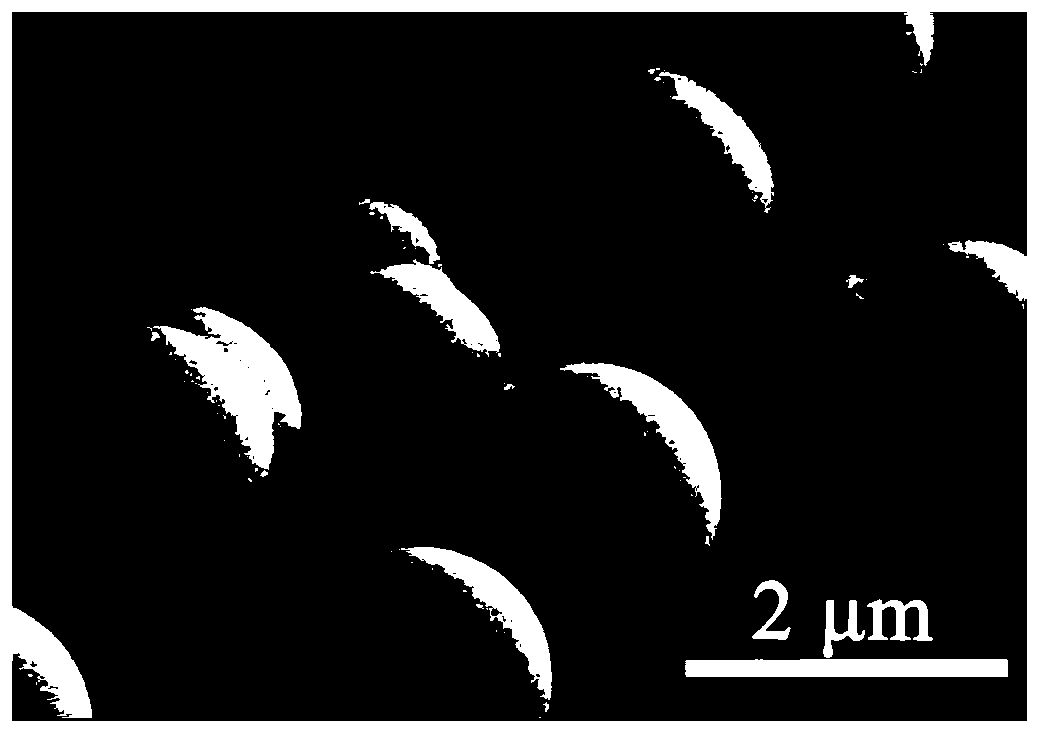

Composite separator, process for preparing the same, and lithium-sulfur battery comprising the same

InactiveCN109037565AInhibit deteriorationDoes not affect energy densityLi-accumulatorsCell component detailsPolyolefinLithium–sulfur battery

The invention relates to a composite separator, a preparation method thereof and a lithium sulfur battery comprising the same. The composite diaphragm comprises a polyolefin-based membrane whose surface is oxidized; And a MnO2 nanoparticle layer disposed on the surface of the polyolefin-based film. When the composite membrane is used for preparing a lithium sulfide battery, the chemical interaction formed by the metal oxygen bond in the MnO2 and the lithium polysulfide can effectively inhibit the diffusion of the lithium polysulfide to the negative electrode, and the cycle life of the lithiumsulfide battery is greatly improved; On the other hand, the mechanical properties of the composite diaphragm have been further improved, especially the thermal shrinkage of the diaphragm is improved obviously, which is helpful to improve the safety of lithium sulfide batteries.

Owner:NINGDE ZHUOGAO NEW MATERIAL TECH CO LTD

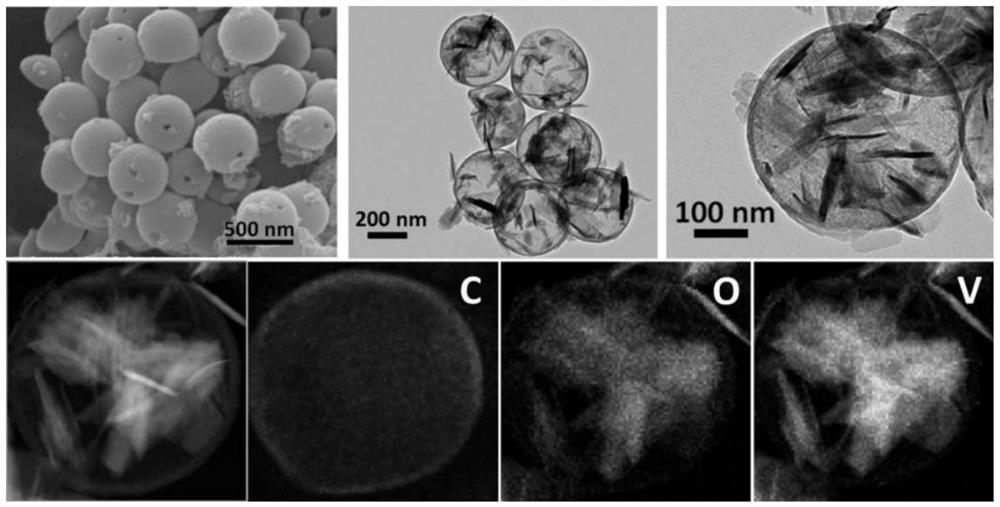

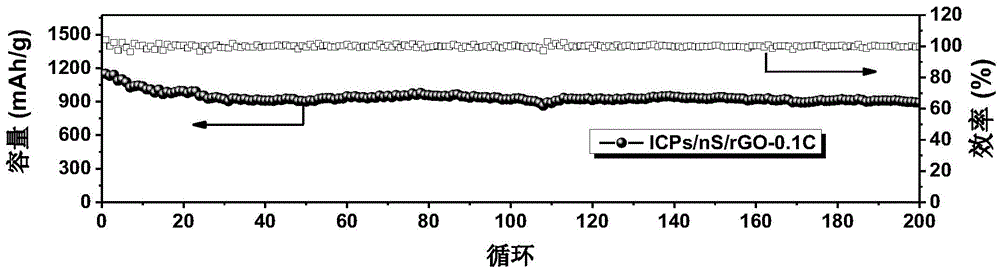

Stannic oxide/carbonized aerogel core-shell structure composite sulfur electrode material, and preparation method and application thereof

ActiveCN109830674AInhibit the "shuttle effect"Improve conductivityCell electrodesLi-accumulatorsMicrosphereSulfur electrode

The invention relates to a stannic oxide / carbonized aerogel core-shell structure composite sulfur electrode material, and a preparation method and application thereof, and belongs to the technical field of lithium-sulfur battery electrode materials. In order to improve the conductivity of a sulfur electrode and solve the poor cycle stability of a lithium-sulfur battery, the electrode material provided by the invention has a shell layer made of stannic oxide and a core layer made of carbonized aerogel microspheres. The monomer sulfur is uniformly dispersed in the carbonized aerogel microsphere,and the mass of sulfur accounts for 60-80% of the total mass of the core-shell structure composite sulfur electrode material. The method improves the conductivity of the sulfur electrode and inhibitsthe volume expansion of sulfur in a reaction process. The stannic oxide shell layer limits the sulfur in the carbonized aerogel core layer to inhibit the leakage of the sulfur, so that the compositesulfur electrode material can maintain good cycle stability during a charge-discharge process. The stannic oxide / carbonized aerogel core-shell structure composite sulfur electrode material provided bythe invention, when applied to the lithium-sulfur battery, can improve the service life and the capacity retention rate of the battery.

Owner:HARBIN UNIV OF SCI & TECH

Nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material, lithium battery diaphragm, preparation method of lithium battery diaphragm, lithium-sulfur battery and electric equipment

ActiveCN111285348AImprove adsorption capacityStop the spreadSecondary cellsCarbon preparation/purificationCarbon compositesElectrical battery

The invention provides a nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material, a lithium battery diaphragm, a preparation method of the lithium batterydiaphragm, a lithium-sulfur battery and electric equipment. A preparation method of the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material comprises the following steps: mixing raw materials including an iron source, a nitrogen-containing organic matter, phytate and an organic solvent, and drying to obtain a precursor; and carrying out heating treatment on the precursor to obtain the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material for the lithium-sulfur battery diaphragm. The preparation method of the lithium battery diaphragm comprises the following steps: mixing raw materials including the nitrogen-phosphorus doped carbon composite iron phosphide three-dimensional rod-like porous material, a binder and a solvent and dispersing to obtain coating slurry; and coating the surface of a diaphragm base material with the coating slurry to obtain the lithium battery diaphragm. According to the nitrogen-phosphorus-doped carbon composite iron phosphide three-dimensional rod-like porous material, the lithium battery diaphragm, the preparation method of the lithium battery diaphragm and thelithium-sulfur battery, the shuttle effect can be effectively solved, and the electrochemical performance of the lithium-sulfur battery is improved.

Owner:湖南桑瑞新材料有限公司

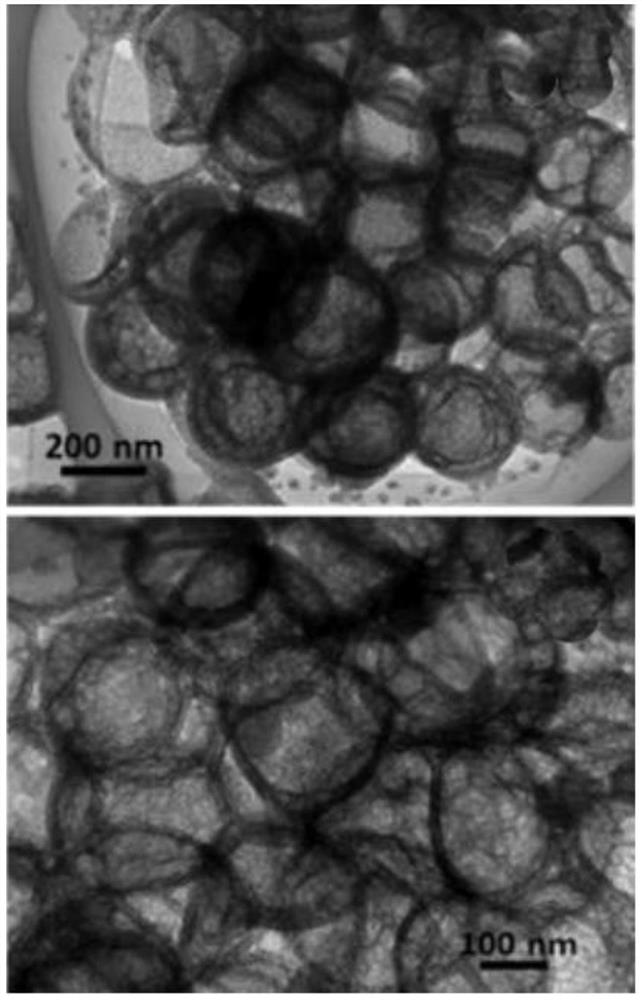

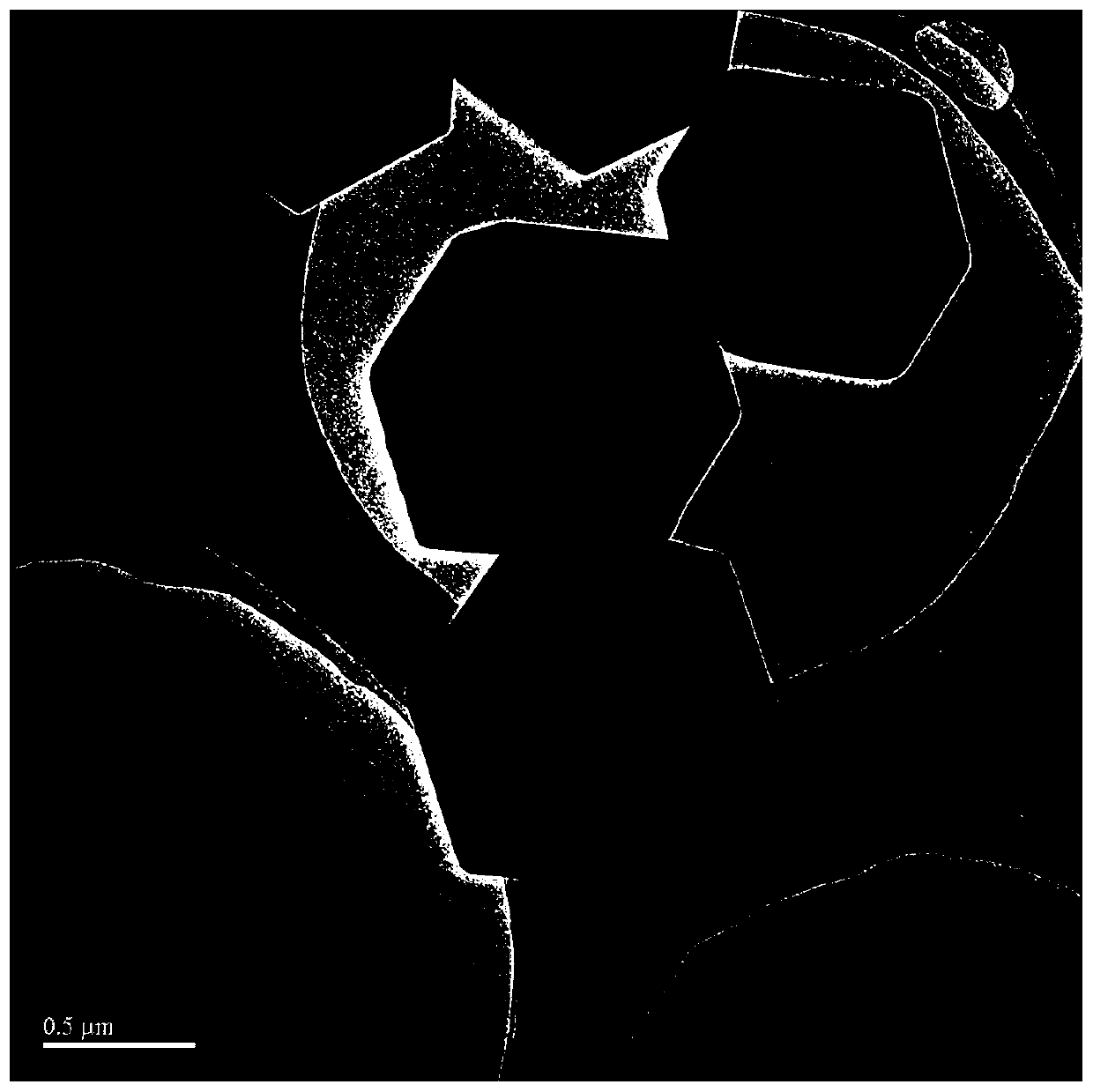

Porous carbon sphere packaged vanadium oxide heterogeneous core-shell sphere structure material and preparation method thereof, lithium-sulfur battery diaphragm and lithium-sulfur battery

ActiveCN113036311AReduce manufacturing costEasy to operateLi-accumulatorsCell component detailsElectrical batteryPorous carbon

The invention belongs to the field of electrochemical materials, and provides a porous carbon sphere packaged vanadium oxide heterogeneous core-shell sphere structure material and a preparation method thereof, a lithium-sulfur battery diaphragm and a lithium-sulfur battery. The preparation method of the porous carbon sphere encapsulated vanadium oxide heterogeneous core-shell sphere structure material comprises the following steps: stirring water, ethanol, ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde, carrying out a stirring reaction to obtain a carbon-coated silicon dioxide core-shell structure, carbonizing the carbon-coated silicon dioxide core-shell structure, adding the carbon-coated silicon dioxide core-shell structure into a sodium hydroxide solution to obtain a hollow porous carbon sphere, mixing ammonium metavanadate, ethanol and nitric acid to obtain a vanadium oxide solution, adding the hollow porous carbon spheres into the vanadium oxide solution, and carrying out ultrasonic treatment and hydrothermal reaction to obtain a product. According to the invention, the amount of a vanadium oxide precursor entering porous carbon spheres is controlled by adjusting ultrasonic time so as to achieve manual control of a nano structure, and the product takes the non-polar carbon spheres as a surface layer so as to achieve an adsorption effect on polysulfide and show high conversion efficiency when sulfur exists in the inner layer.

Owner:TONGJI UNIV

High-sulfur-loading-capacity lithium-sulfur battery positive plate and production method thereof

ActiveCN111446418AUniform depositionGood flexibilityPositive electrodesLi-accumulatorsCarbon compositesLithium–sulfur battery

The invention discloses a high-sulfur-loading-capacity lithium-sulfur battery positive plate and a production method thereof. The positive plate comprises a sulfur-carbon composite material, graphene,a binder (PVDF) and an aluminum foil current collector. The production method comprises the following steps: firstly, adding a proper amount of PVDF glue solution and a graphene conductive slurry into a planetary stirrer, and stirring and dispersing for enough long time; then adding a sulfur-carbon composite material, and stirring and dispersing for enough long time; transferring into a ball mill, carrying out high-temperature ball milling for a long enough time, vacuumizing and filtering to obtain a final positive electrode slurry; and coating an aluminum foil with the slurry by using a transfer coating machine, and drying at a low temperature to obtain a pole piece. The produced positive plate is high in sulfur loading capacity, good in flexibility and outstanding in electrochemical performance, and energy density of a lithium-sulfur battery assembled by adopting the positive plate can reach above 400wh / kg. The production method of the positive plate is simple, and industrial large-scale production can be realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

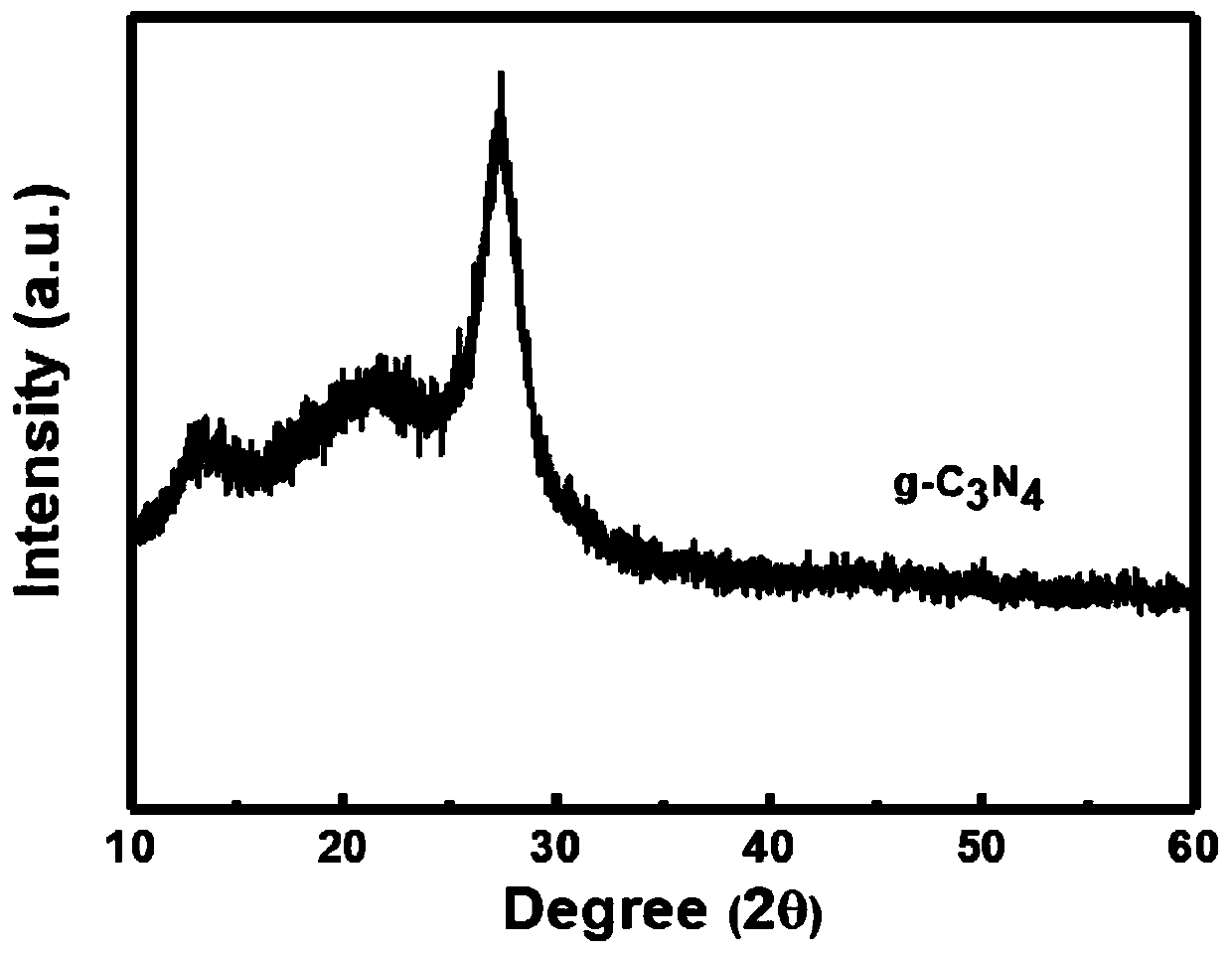

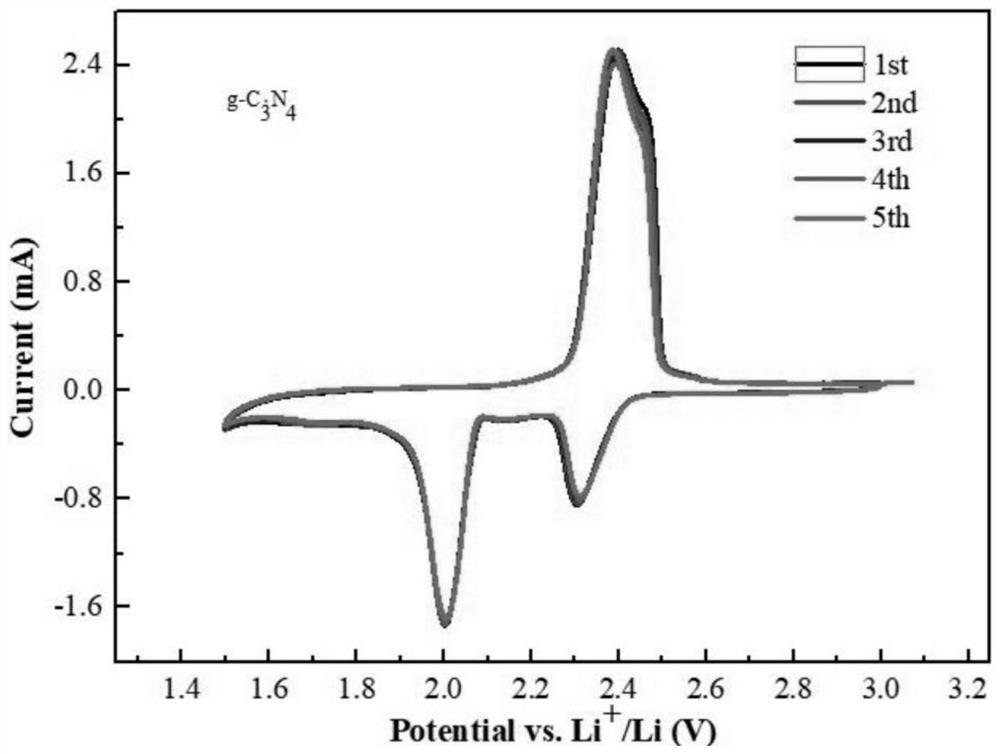

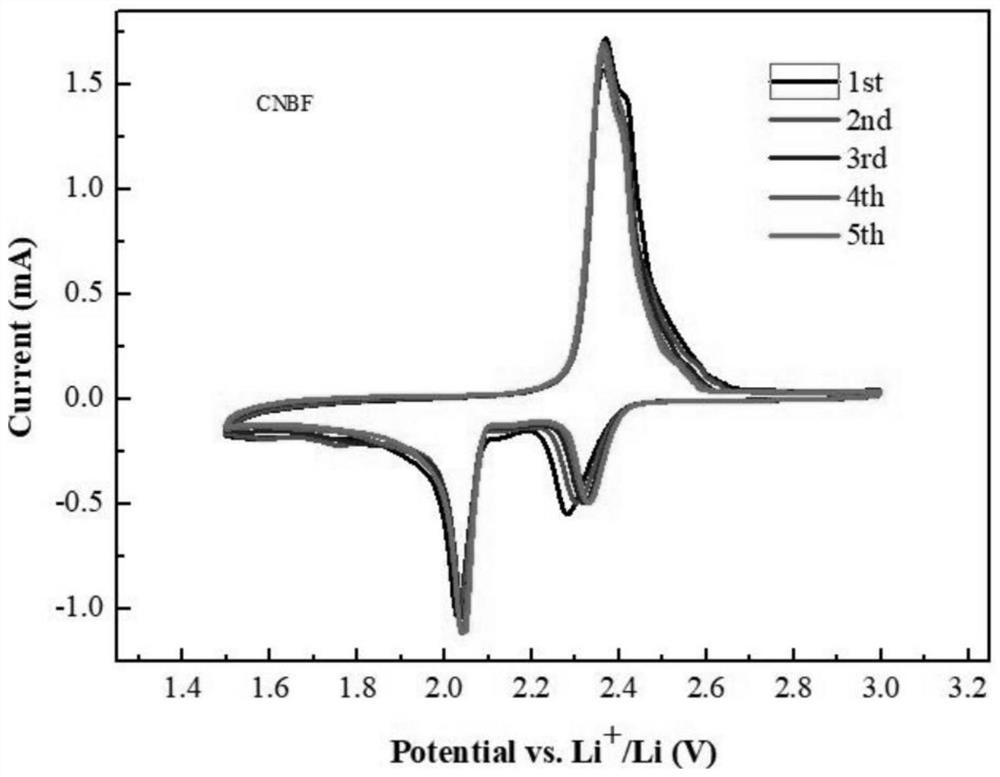

Preparation method of nitrogen-doped, boron-doped or phosphorus-doped graphitized carbon nitride material

InactiveCN111740076AImprove conductivityImprove cycle performancePositive electrodesLi-accumulatorsLithium–sulfur batteryLithium sulfur

The invention discloses a preparation method of a nitrogen-doped, boron-doped or phosphorus-doped graphitized carbon nitride material, and belongs to the technical field of lithium-sulfur batteries. In order to solve the problem that a shuttle effect exists in a lithium-sulfur battery, the method is characterized by fully grinding dicyandiamide and then transferring into a corundum crucible, wherein pores are reserved in the crucible; calcining for 2h at the temperature of 300-400 DEG C, then increasing the temperature to 450-550 DEG C to calcine for 2h so as to obtain the nitrogen-doped graphitized carbon nitride material; uniformly mixing the conductive carbon black and PTFE emulsion, adding deionized water, uniformly mixing, fully grinding for 20 minutes, removing moisture, rolling, punching, drying, and embedding a prepared conductive composite membrane between a sulfur positive electrode and a diaphragm. The preparation method disclosed by the invention is simple and easy to implement, the prepared composite membrane intercalation has good electrical conductivity and does not cause negative effects on the sulfur positive electrode, and the composite membrane intercalation is embedded between the sulfur positive electrode and the diaphragm to block the shuttling effect of polysulfide anions through physical and chemical adsorption, so that the cycle performance of the lithium-sulfur battery is improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

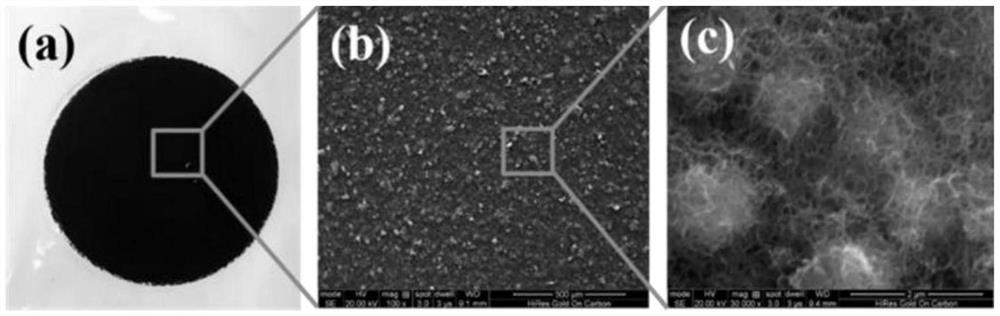

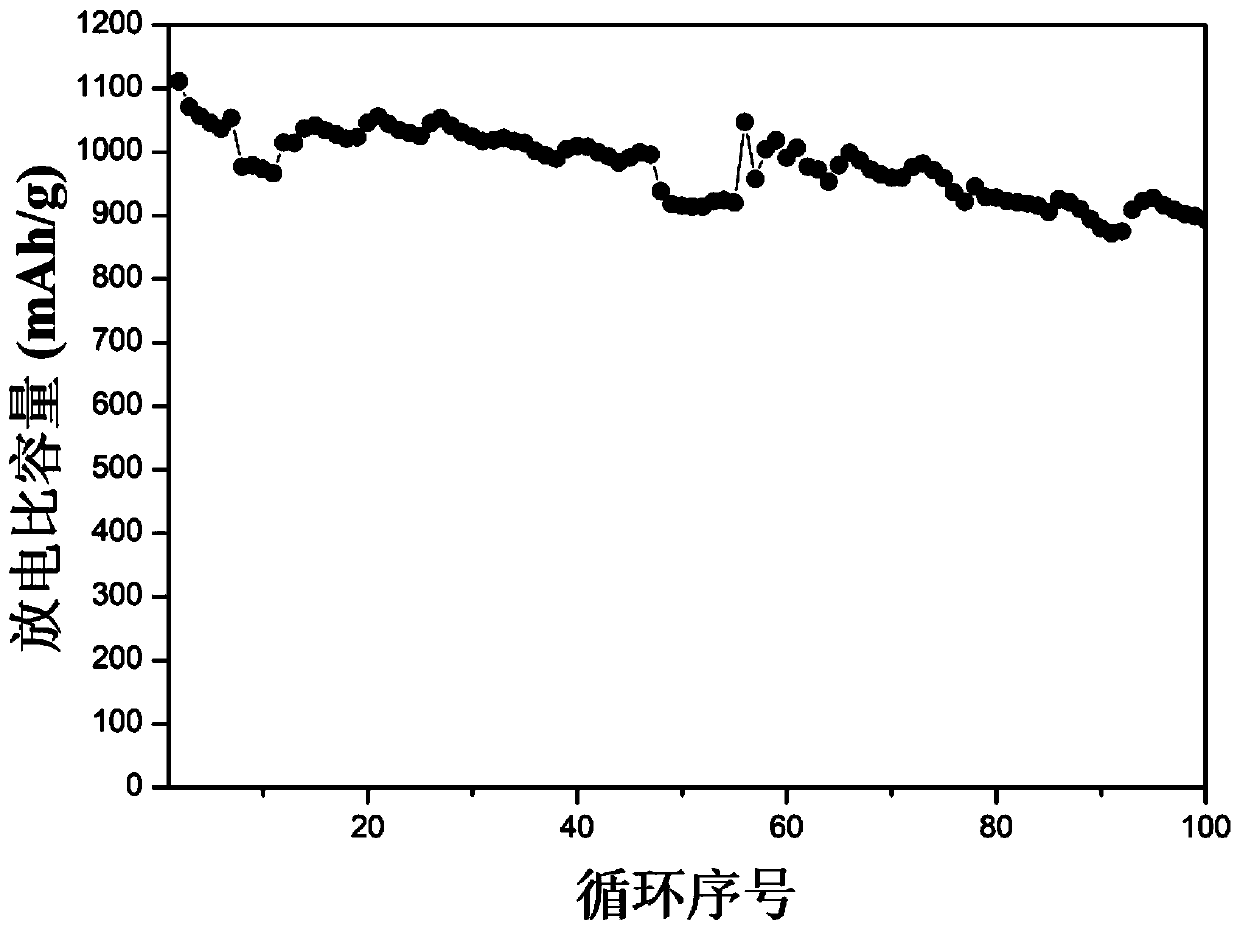

Preparation method of flexible sulfur positive electrode of lithium-sulfur battery

ActiveCN111864190AIncrease profitPromote redox transformationCell electrodesCarbon nanotubesLithium–sulfur batteryPhysical chemistry

The invention discloses a preparation method of a flexible sulfur positive electrode of a lithium-sulfur battery, and belongs to the technical field of lithium-sulfur batteries. The flexible sulfur positive electrode of the lithium-sulfur battery comprises flexible multifunctional carbon foam and a sulfur-containing active substance loaded in the flexible multifunctional carbon foam. The specificpreparation process comprises the steps of preparation of the flexible multifunctional carbon foam, preparation of the flexible sulfur positive electrode of the lithium-sulfur battery and the like. The synthesis method disclosed by the invention is simple and convenient to operate, relatively low in cost and suitable for large-scale production, and has important significance for large-scale production of the lithium-sulfur battery.

Owner:HENAN NORMAL UNIV

Method for preparing lithium-sulfur battery positive electrode material of composite metal organic framework

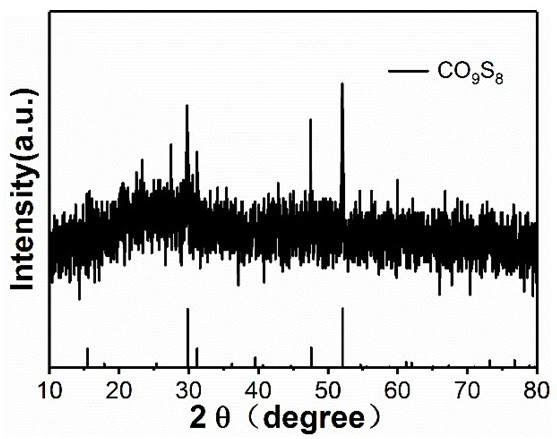

ActiveCN110760072AInhibition of the "shuttle effect"Inhibit the "shuttle effect"Cell electrodesLi-accumulatorsLithium sulfurMaterials science

The invention relates to a method for preparing a lithium-sulfur battery positive electrode material of a composite metal organic framework. The composite material consists of two metal organic frameworks, namely ZIF67 (zeolitic imidazolate framework 67) and ZIF8, and the lithium-sulfur battery positive electrode material is prepared by compounding the two metal organic frameworks with elemental sulfur. The material can be prepared by using a simple and convenient hydrothermal method through synthesis, and is capable of well adsorbing lithium polysulfide, inhibiting the "shuttling effect" of the lithium polysulfide and promoting the redox reaction kinetics of a lithium-sulfur battery in the charge / discharge process, so that the discharge capacity of the battery is increased, and the circulation stability is improved.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

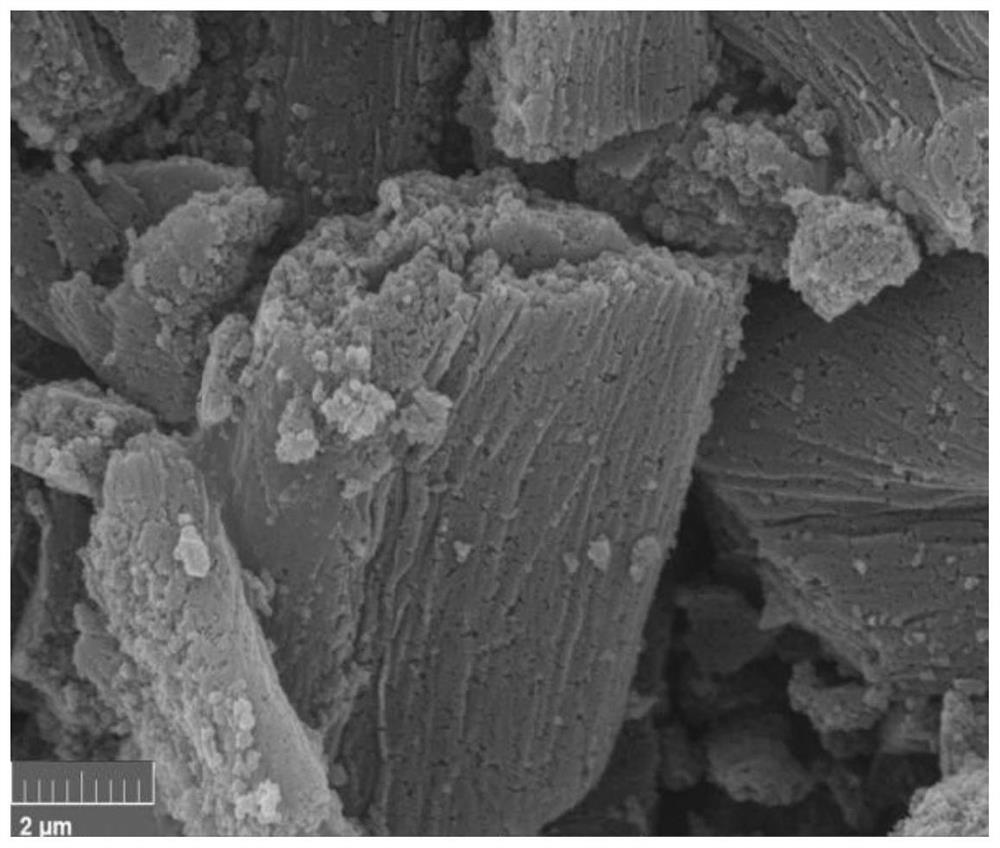

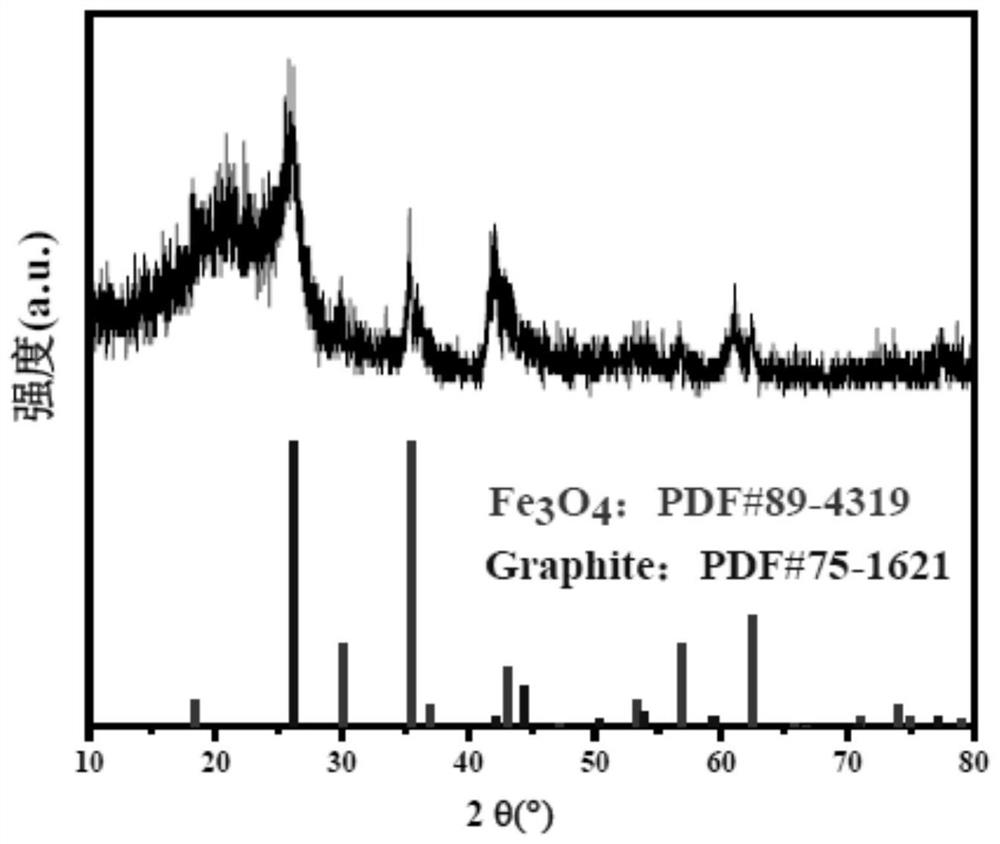

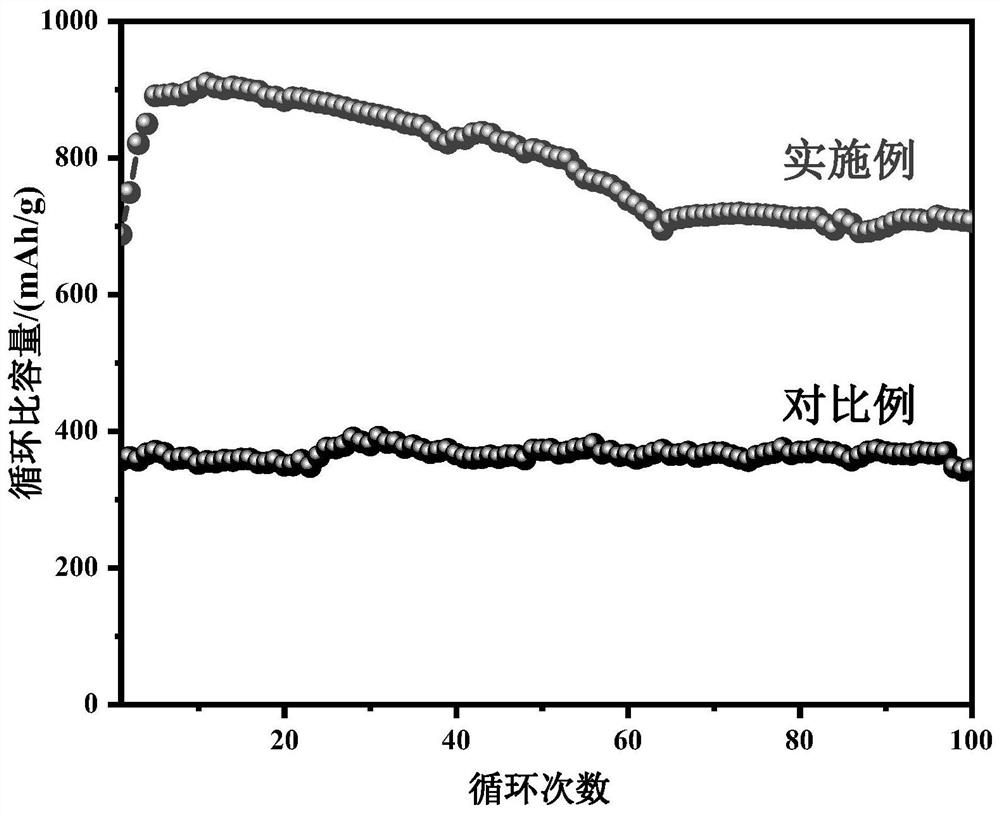

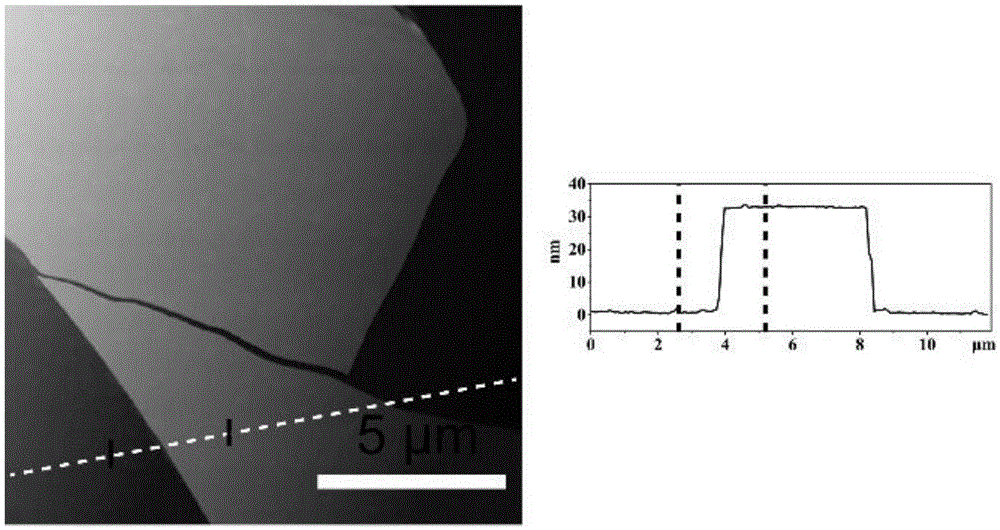

Lithium-sulfur battery iron-based biomass carbon intermediate layer, preparation method thereof and lithium-sulfur battery

PendingCN113421990AImprove electrochemical performanceImprove stabilityElectrode manufacturing processesLi-accumulatorsBiomass carbonLithium–sulfur battery

The invention discloses a lithium-sulfur battery iron-based biomass carbon intermediate layer, a preparation method thereof and a lithium-sulfur battery. The method comprises the following steps: step 1, cleaning and drying biomass to obtain neutral biomass; step 2, adding the neutral biomass in the step 1 into an iron-containing solution, and drying to obtain iron-based biomass; step 3, calcining the iron-based biomass in the step 2 to obtain iron-based biomass carbon; and step 4, tabletting the iron-based biomass carbon in the step 3 to obtain the iron-based biomass carbon intermediate layer. The biomass carbon-based material used in the invention has relatively good conductivity and adsorption performance, the preparation process is relatively simple, the raw material source is wide, and the middle layer prepared from the biomass carbon-based material has a certain adsorption effect on polysulfide generated in a lithium-sulfur battery due to an oxidation-reduction reaction, can inhibit a shuttle effect, and can effectively improve the cycle performance of the battery.

Owner:XIAN UNIV OF TECH

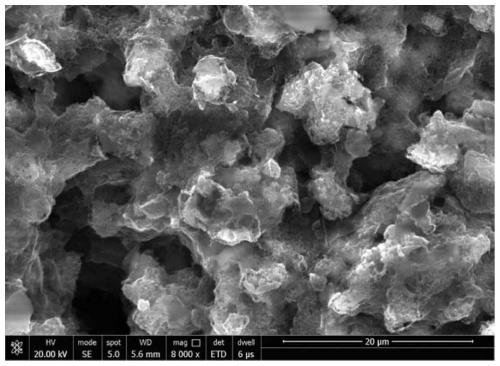

Porous nanocarbon slice

InactiveCN105609323ARich in microporesRich in mesoporesHybrid capacitor electrodesCell electrodesOxygenClean water

The invention relates to a porous nanocarbon slice, and belongs to the technical field of a battery material. The carbon slice has abundant micropores and mesoporous, and adopts a three-dimensional communicating network-shaped structure with the thickness of less than or equal to 50nm; the preparation method comprises the steps of after performing mixed ball milling on a metal simple substance and a carbon source, enabling the metal simple substance and the carbon source to react in an oxygen-free anhydrous vacuum sealing environment at a temperature of 450-600 DEG C for 4-24h; taking the loosening part from the upper layer of the reaction product to be subjected to ball milling, then cleaning the loosening part by diluted hydrochloric acid until no bubbles are generated; then washing by clean water until the pH is neutral; and drying at a temperature of 80-120 DEG C for more than 6h to obtain the porous nanocarbon slice, wherein the metal simple substance is zinc and / or magnesium, and the carbon source is glucose and / or saccharose. The carbon slice can be used as the negative electrode of an ion battery, an electrode material for a supercapacitor, a conductive carbon material for an electrode, and the like, is especially suitable for being used as a framework for a lithium-sulfur battery positive electrode material, and is capable of restraining a shuttle flying effect to realize high conductivity of the positive electrode material and a good current collection effect; and in addition, the preparation method is simple, low in cost, environment-friendly, and the batch production of the porous nanocarbon slice can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

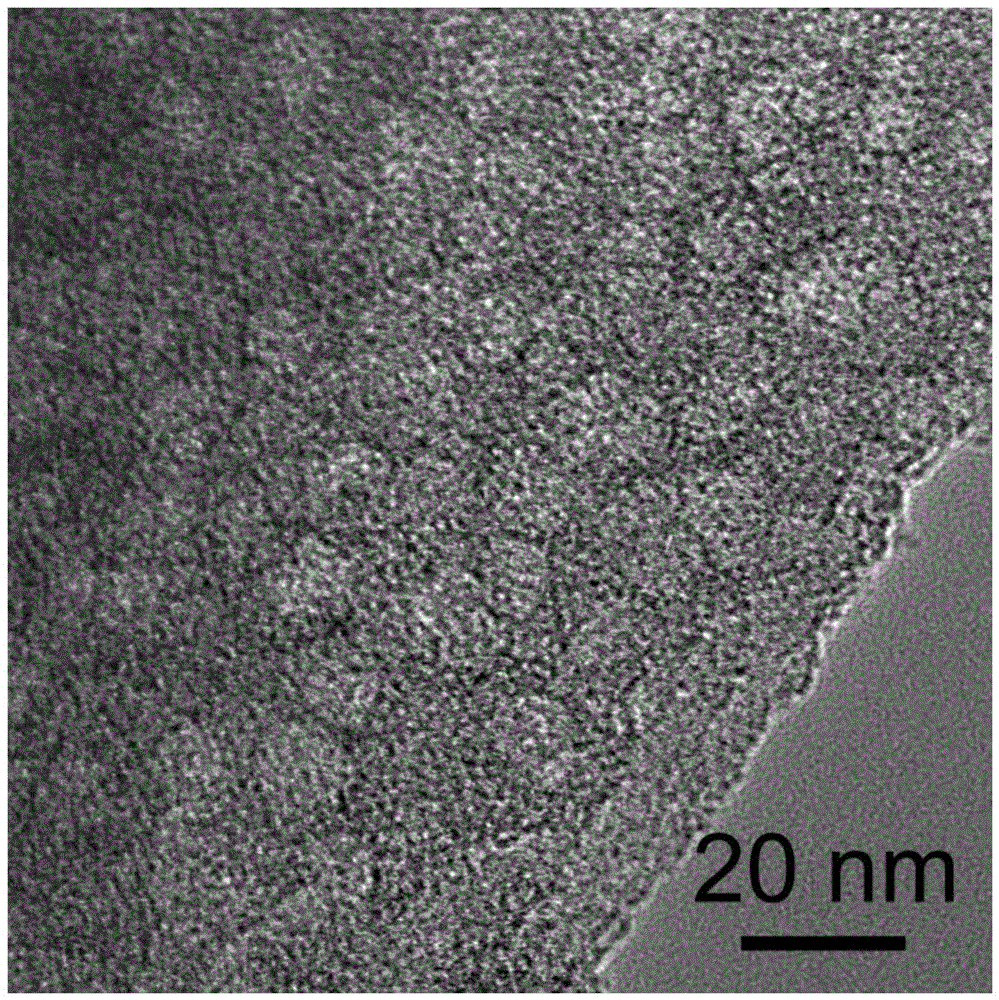

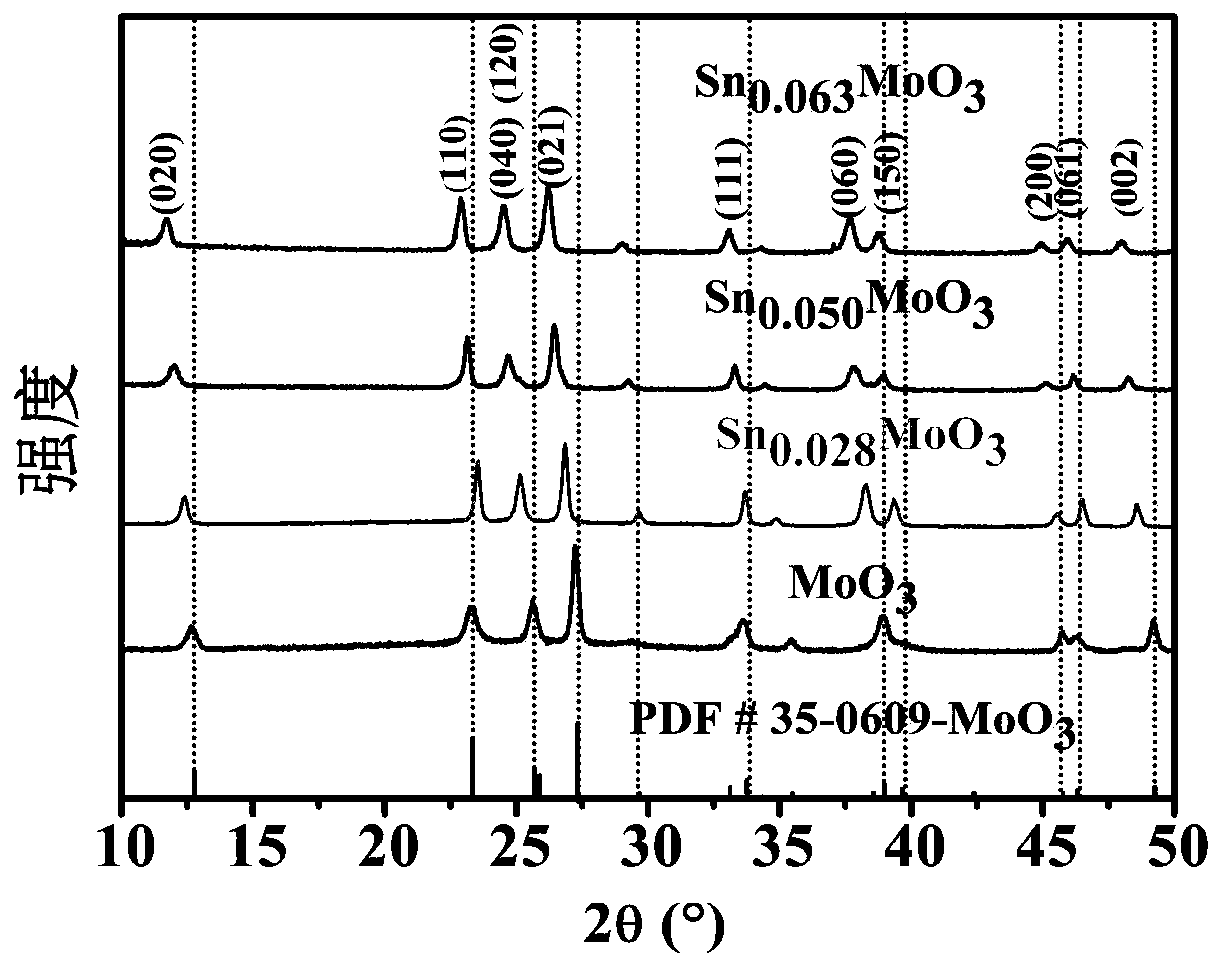

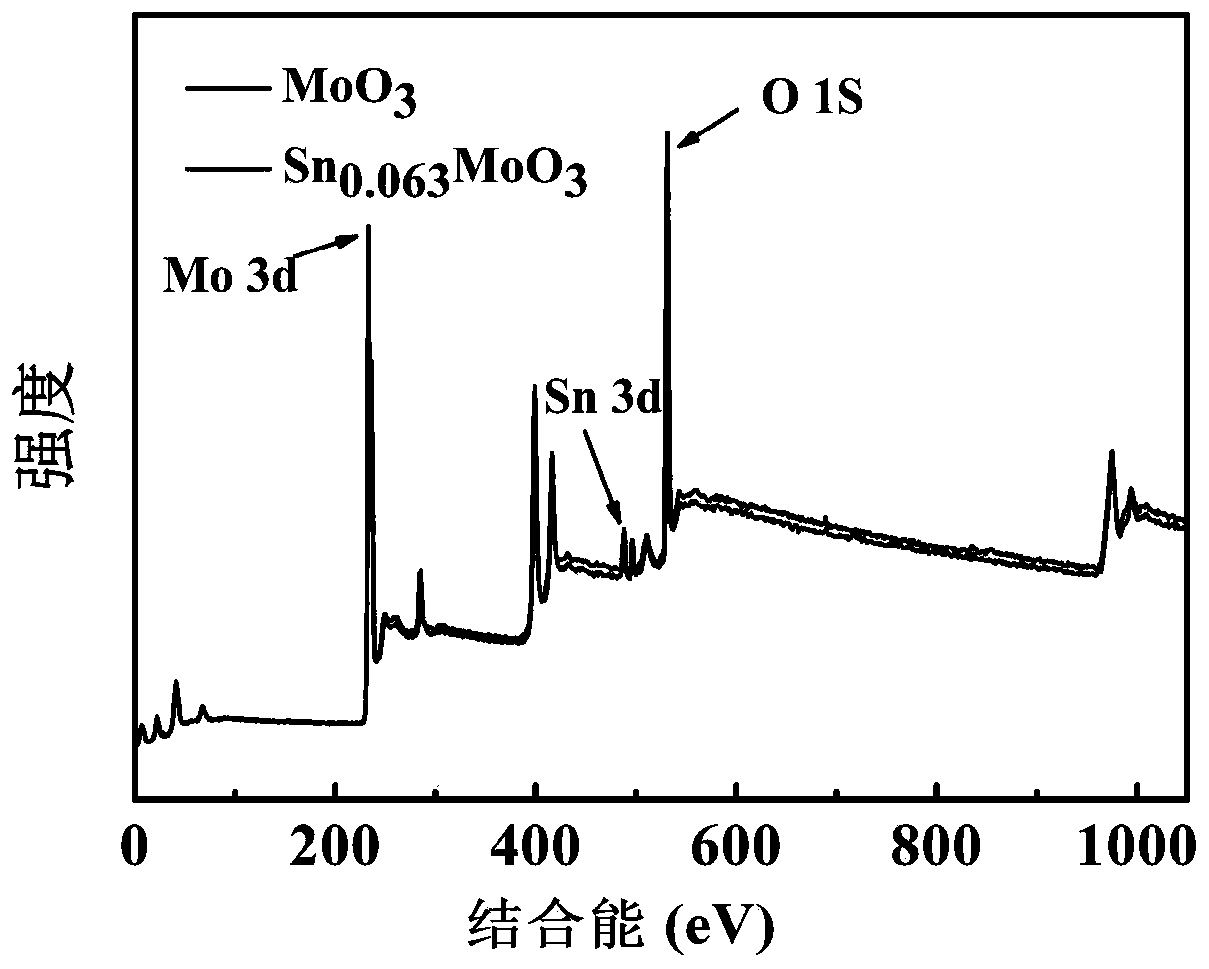

Metal intercalation molybdenum oxide material as well as preparation method and application thereof

ActiveCN109888198AImprove electrochemical performanceImprove discharge capacityCell electrodesLi-accumulatorsLithium sulfurCobalt

The invention relates to a metal intercalation molybdenum oxide material as well as a preparation method and application thereof. The preparation method comprises a step of performing intercalation reaction on molybdenum oxide powder and one of metal salt or metal complex, so that a metal intercalation molybdenum oxide material is obtained, wherein the metal is one or more than one of tin, iron, cobalt, nickel, gold, silver, platinum and palladium, and the metal salt or metal complex is provided in chloride, nitrate and carbonyl complex forms; and a mass ratio of the metal salt or metal complex to molybdenum oxide is 1:(10-100). The prepared material can be used for preparing an electrode material, the electrode material is applicable to organic electrolyte, and the electrode material hasrelatively strong adsorbability and high conductivity on lithium polysulfide, thereby being beneficial to prolonging cycle life of a lithium-sulfur (Li-S) battery and play of rate capability of the lithium sulfur battery. The method provided by the invention is environmentally friendly, simple in process, low in raw material price and simple in preparation flow and is applicable to large-scale preparation of a Li-S battery cathode material.

Owner:北京中瑞泰新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com