Diaphragm of lithium-sulfur battery

A lithium-sulfur battery and diaphragm technology, applied in the field of composite membranes for lithium-sulfur batteries, can solve the problems of low conductivity and strength of the gel electrolyte diaphragm, reduced electrolyte conductivity, loss of positive active materials, etc., and achieve the suppression of the "shuttle" effect , Improve battery efficiency and stability, and high storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 0.25 g of sulfonated polyether ether ketone, 0.5 g of polyvinylidene fluoride, and 0.1 g of lithium chloride in 6 ml of N,N-dimethylformamide, and cast the resulting solution at 30°C after defoaming Scratch coating on the platform, the thickness of the liquid film is 500 microns; after 30 minutes, transfer the liquid film together with the bottom plate to soak in a water bath at room temperature for 30 minutes to complete the phase transition, then separate the film from the bottom plate, soak and rinse with deionized water repeatedly , to completely remove the solvent inside the membrane; then treat it with a lithium hydroxide aqueous solution with a concentration of 0.5M (25°C, 12 hours) to make the lithium sulfonate in the membrane form; wash it repeatedly with deionized water and place it at 70°C Vacuum dry for 24 hours.

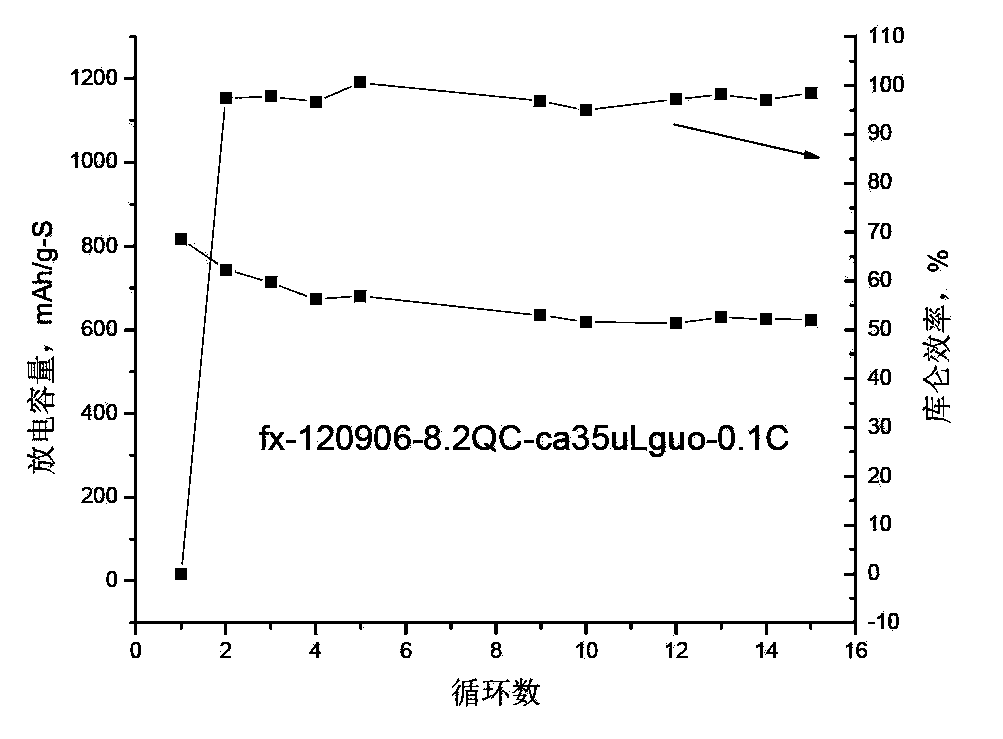

[0026] The lithium-sulfur button battery was assembled using the composite film obtained above, and its positive electrode was a carbon-...

Embodiment 2

[0029] Dissolve 0.4 g of sulfonated polyether ether ketone, 0.6 g of polyvinylidene fluoride, and 0.2 g of lithium chloride in 8 ml of N,N-dimethylformamide, and cast the resulting solution at 40°C after defoaming Scrape coating on the platform, the thickness of the liquid film is 280 microns; after 20 minutes, transfer the liquid film together with the bottom plate to soak in a water bath at room temperature for 30 minutes to complete the phase transition, then separate the film from the bottom plate, soak and rinse with deionized water repeatedly , to completely remove the solvent inside the membrane; then treat it with a lithium hydroxide aqueous solution with a concentration of 0.5M (25°C, 12 hours) to make the lithium sulfonate in the membrane form; wash it repeatedly with deionized water and place it at 70°C Vacuum dry for 24 hours.

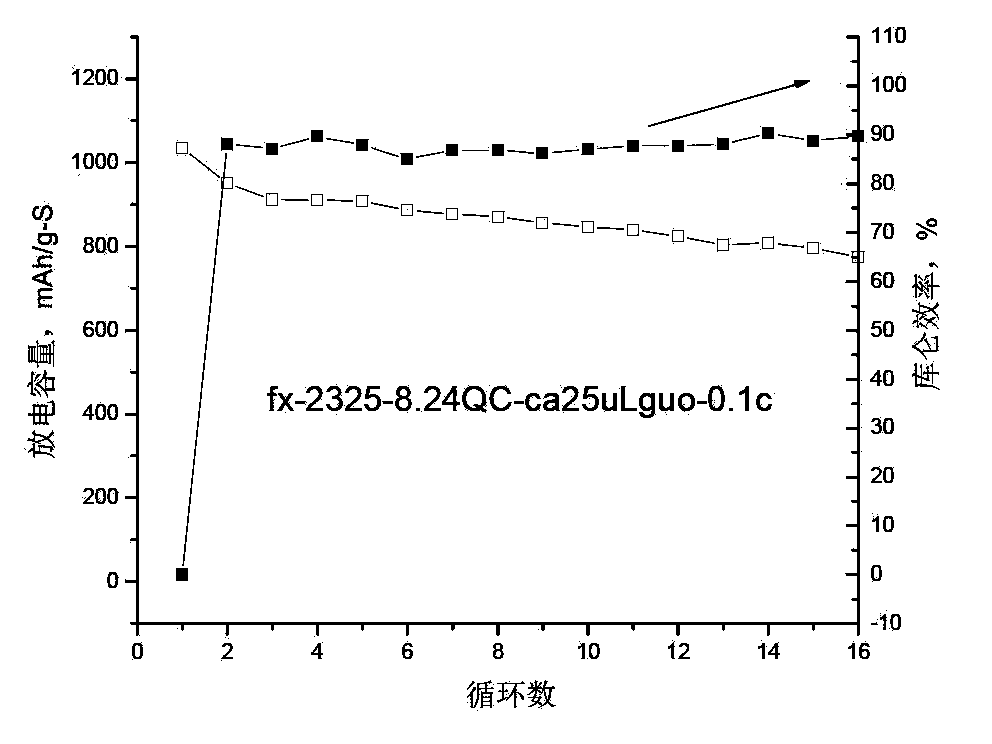

[0030] The lithium-sulfur button battery was assembled using the composite film obtained above, and its positive electrode was a carbon-su...

Embodiment 3

[0032]Add 0.504 grams of polyvinylidene fluoride to 12 milliliters of Nafion's N,N-dimethylformamide solution, then add 0.2 grams of lithium chloride, dissolve completely after stirring, and place it on a casting film platform at 60 ° C after standing for defoaming Cast film with a liquid film thickness of 280 microns; after 100 minutes, transfer the liquid film together with the bottom plate into a water bath at room temperature for 30 minutes to complete the phase transition, then separate the film from the bottom plate, soak and rinse with deionized water repeatedly, and Thoroughly remove the solvent inside the membrane; then treat it with a lithium hydroxide aqueous solution with a concentration of 0.5M (25°C, 12 hours) to form the lithium sulfonate in the membrane; wash it repeatedly with deionized water and dry it in vacuum at 70°C 24 hours.

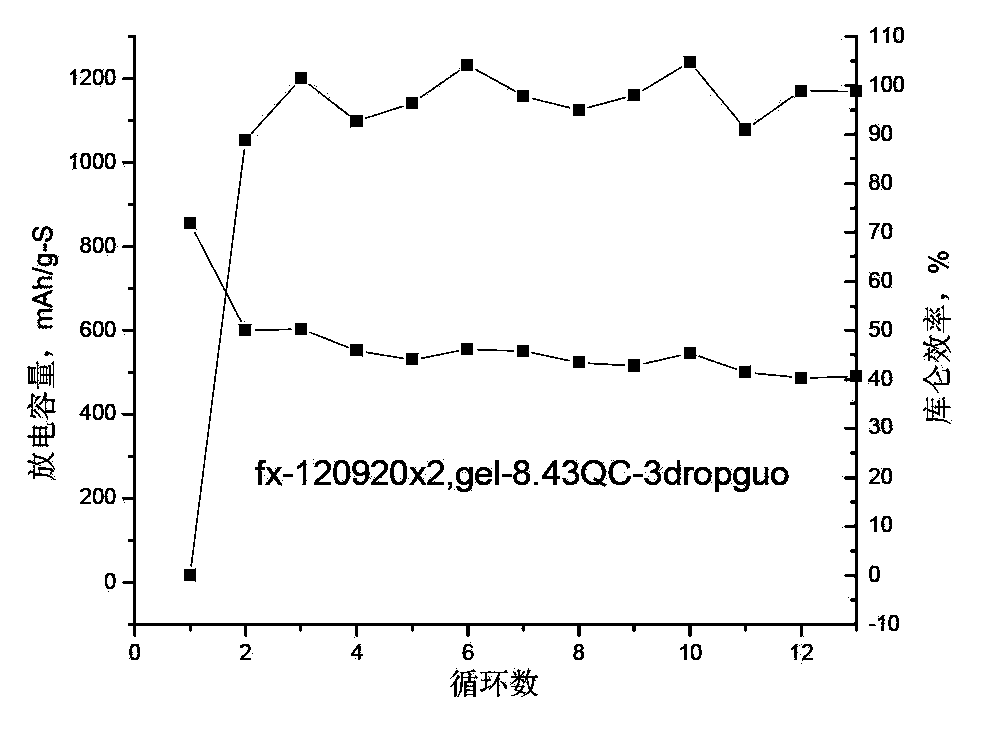

[0033] The lithium-sulfur button battery was assembled using the composite film obtained above, and its positive electrode was a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com