Porous carbon sphere packaged vanadium oxide heterogeneous core-shell sphere structure material and preparation method thereof, lithium-sulfur battery diaphragm and lithium-sulfur battery

A technology of core-shell structure and vanadium oxide, which is applied in the field of electrochemical materials, can solve the problems of increased electrolyte consumption, low conductivity, and reduced rate performance, etc., and achieves the effects of easy industrial scale-up production, low preparation cost, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

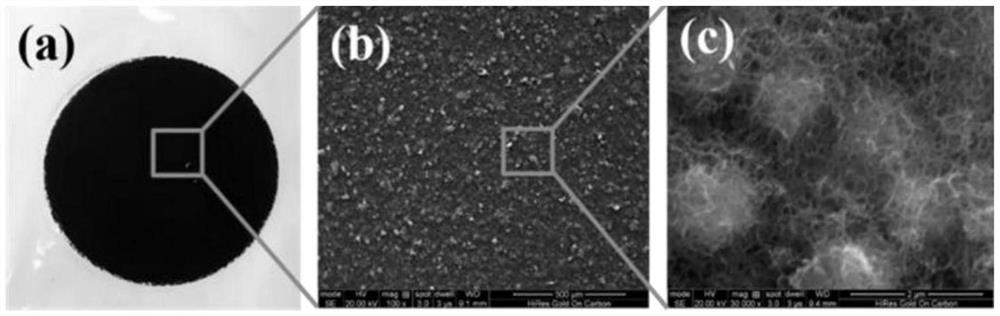

[0040] The preparation method of lithium-sulfur battery separator is as follows:

[0041] In step S1, the porous carbon sphere material is uniformly dispersed in the ethanol solution to obtain a pre-coating solution.

[0042] In step S2, the pre-coating solution is evenly coated on the surface of the separator body, and vacuum-dried at 30° C. to obtain a lithium-sulfur battery separator.

[0043] Among them, the diaphragm body is a polypropylene diaphragm, and the polypropylene diaphragm is a commercial diaphragm Clegard2400.

[0044] The preparation method of lithium-sulfur battery is as follows:

[0045] With metal lithium as the counter electrode, sulfur as the working electrode, and 1M LiPF6 dissolved in a mixed solution of ethylene carbonate (EC) and ethyl methyl carbonate (EMC) (volume ratio 1:1) as the electrolyte, the lithium-sulfur battery The diaphragm acts as a diaphragm. The battery was assembled in a glove box filled with argon, and after the battery was assemb...

Embodiment 1

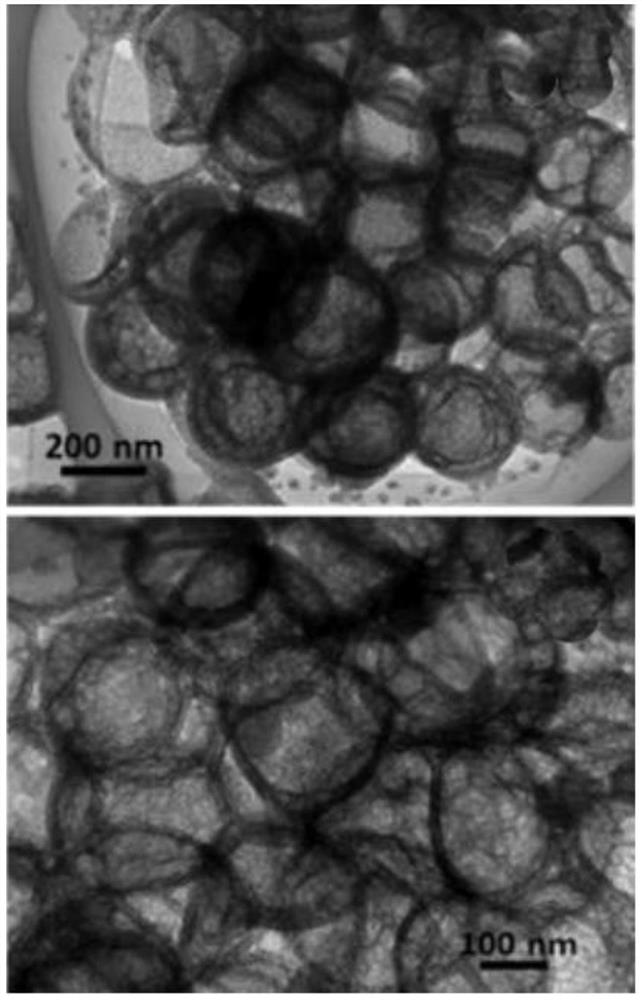

[0047] This example describes in detail the porous carbon sphere-encapsulated vanadium oxide heterogeneous core-shell sphere structure material, lithium-sulfur battery separator, lithium-sulfur battery and the preparation method.

[0048] The preparation method of the porous carbon sphere-encapsulated vanadium oxide heterogeneous core-shell sphere structure material (hereinafter referred to as the porous carbon sphere material) of this embodiment is as follows:

[0049] Step 1: Mix 70mL of ethanol, 10mL of water and 3mL of ammonia water, then add 3.46mL of tetraethyl orthosilicate into the reaction system, stir magnetically for 15 minutes, then add 0.4g of resorcinol and 0.56mL aqueous formaldehyde solution, stirring continuously for 24h.

[0050] Step 2: After the stirring in step 1, the precipitate was collected by centrifugation, washed with deionized water and ethanol, and dried in vacuum at 60° C. for 12 hours to obtain a carbon-coated silica core-shell structure.

[005...

Embodiment 2

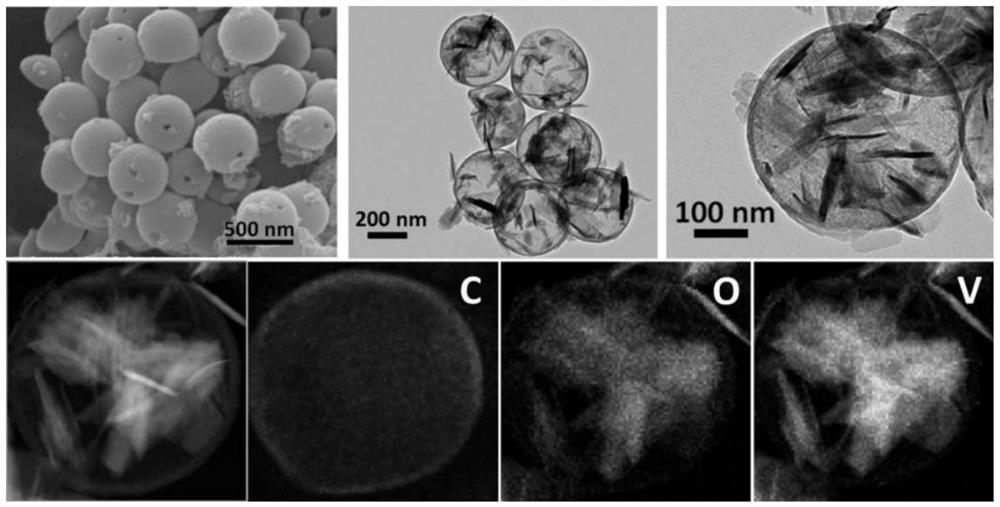

[0072] This example describes in detail the porous carbon sphere-encapsulated vanadium oxide heterogeneous core-shell sphere structure material and its preparation method.

[0073] The preparation method of the porous carbon sphere-encapsulated vanadium oxide heterogeneous core-shell sphere structure material (hereinafter referred to as the porous carbon sphere material) of this embodiment is as follows:

[0074] Step 1: Mix 70mL of ethanol, 10mL of water and 3mL of ammonia water, then add 3.46mL of tetraethyl orthosilicate into the reaction system, stir magnetically for 15 minutes, then add 0.4g of resorcinol and 0.56mL aqueous formaldehyde solution, stirring continuously for 24h.

[0075] Step 2: After the stirring in step 1, the precipitate was collected by centrifugation, washed with deionized water and ethanol, and dried in vacuum at 60° C. for 12 hours to obtain a carbon-coated silica core-shell structure.

[0076] Step 3, place the carbon-coated core-shell structure ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com