Method for preparing lithium-sulfur battery cathode material by using bacterial cellulose hydrogel

A technology of bacterial cellulose and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of battery cycle capacity attenuation, active material loss, electrode structure collapse, etc., to reduce low electronic conductivity and simplify battery installation Process, effect of increasing content and loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0034] Bacterial cellulose is a porous network nano-scale biopolymer synthesized by microbial fermentation. It has a fine network structure, high mechanical strength, high water absorption and water retention, good biocompatibility and biological Degradability and many other unique properties, it is widely used in textiles, medical materials, food and other fields. Since the bacterial cellulose has a nanoscale porous network structure, the present invention adopts it to construct a carbon nanometer three-dimensional network structure of the positive electrode material of the lithium-sulfur battery, and the structure can overcome the defects of the prior art.

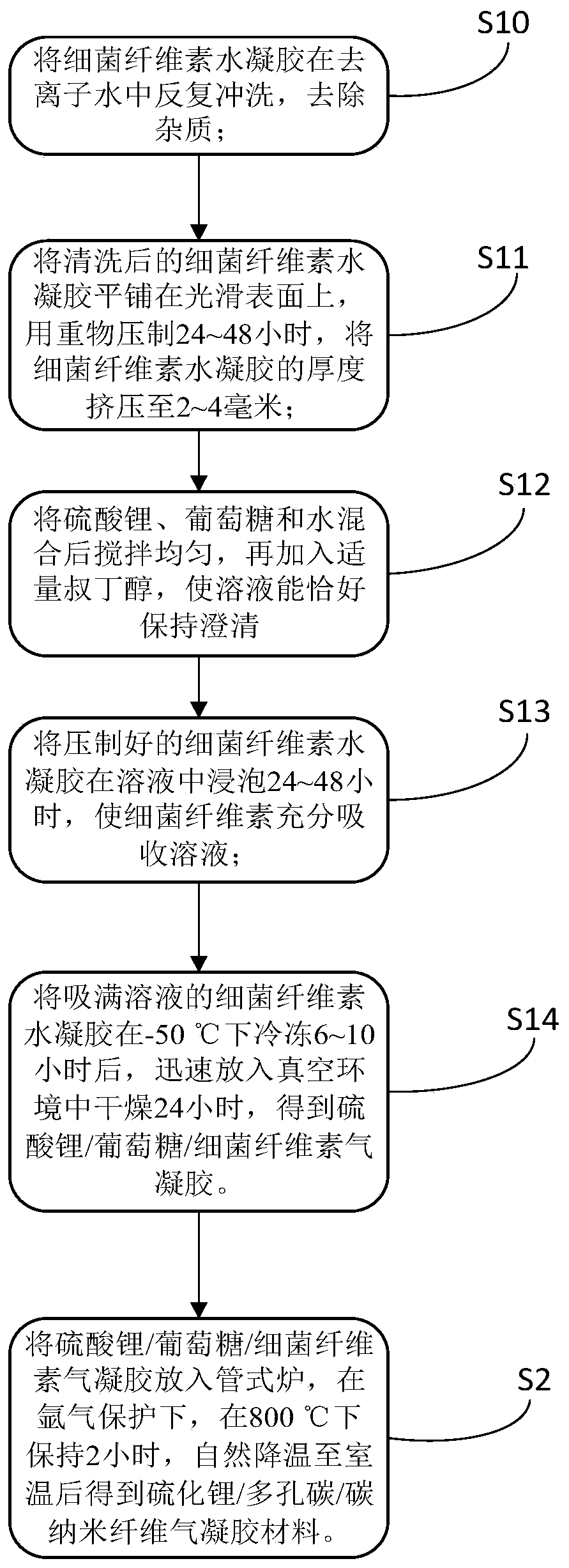

[0035] The invention provides a method for preparing lithium-sulfur battery cathode materials by using bacterial cellulose hydrogel, comprising the following steps:

[0036] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com