Battery anode material and lithium-sulfur battery

A battery positive electrode, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of fast capacity decay, low rate performance of lithium-sulfur batteries, etc., to improve conductivity and reaction kinetics performance, and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

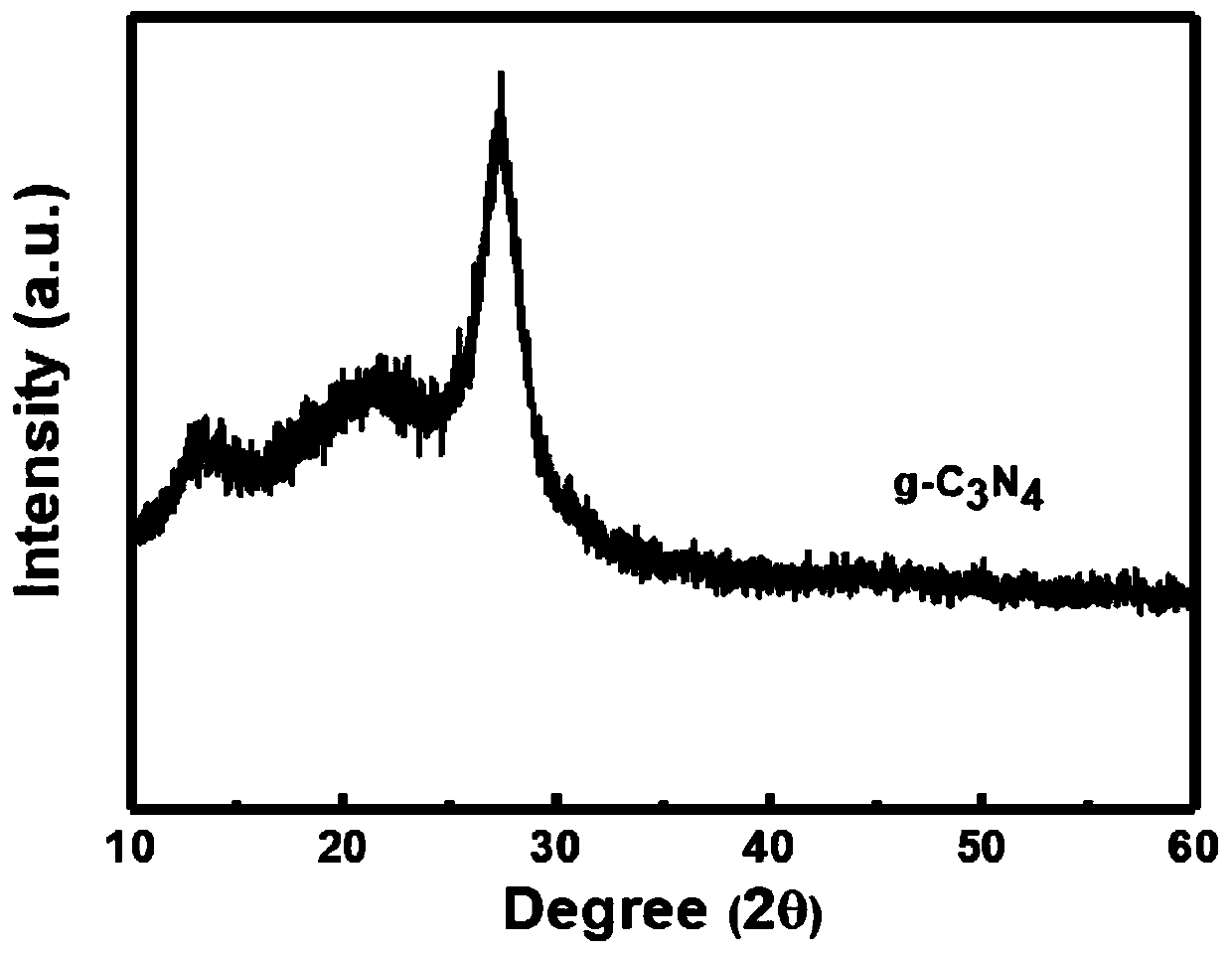

[0084] Weigh 20g of urea into a crucible with a lid, place it in a muffle furnace and raise the temperature to 500°C at 2.5°C / min, carry out a thermal polymerization reaction for 4 hours, and obtain light yellow block g-C after natural cooling 3 N 4 . block g-C 3 N 4 After grinding and crushing, it is dispersed in absolute ethanol by ultrasonic stirring, the temperature is set to room temperature, and the ultrasonic time is set to 60 minutes, then centrifuged or filtered, and vacuum-dried for 12 hours after cleaning to obtain a two-dimensional layered graphitic carbon nitride, a two-dimensional layer The specific surface area of graphitic carbon nitride is 64m 2 / g, for pictures of two-dimensional layered graphitic carbon nitride, please refer to figure 1 . see image 3 , is the XRD pattern of the two-dimensional layered graphitic carbon nitride prepared in Example 1 of the present invention, image 3 Among them, there are two peaks at 13.1° and 27.4°, which belong to...

Embodiment 2

[0089] Weigh 20g of melamine into a crucible with a lid, place it in a muffle furnace and raise the temperature to 550°C at 2.5°C / min, carry out a thermal polymerization reaction for 4 hours, and obtain light yellow block g-C after natural cooling 3 N 4 . block g-C 3 N 4 After grinding and crushing, it is dispersed in absolute ethanol by ultrasonic stirring, the temperature is set to room temperature, and the ultrasonic time is set to 60 minutes, then centrifuged or filtered, and vacuum-dried for 12 hours after cleaning to obtain a two-dimensional layered graphitic carbon nitride, a two-dimensional layer The specific surface area of graphitic carbon nitride is 65m 2 / g. see Figure 4 , is the Raman diagram of the two-dimensional layered graphitic carbon nitride prepared in Example 2 of the present invention, Figure 4 Medium, g-C 3 N 4 No obvious Raman signal was detected on the composite material, but two clear Raman shift peaks were detected on the composite materi...

Embodiment 3

[0094] Weigh 20g of urea into a crucible with a lid, place it in a muffle furnace and raise the temperature to 550°C at 2.5°C / min, carry out a thermal polymerization reaction for 6h, and obtain light yellow block g-C after natural cooling 3 N 4 . block g-C 3 N 4 After grinding and crushing, it is dispersed in absolute ethanol by ultrasonic stirring, the temperature is set to room temperature, and the ultrasonic time is set to 60 minutes, then centrifuged or filtered, and vacuum-dried for 12 hours after cleaning to obtain a two-dimensional layered graphitic carbon nitride, a two-dimensional layer The specific surface area of graphitic carbon nitride is 63m 2 / g.

[0095] Weigh 5g of two-dimensional layered graphite carbon nitride and 5g of starch, mix and grind for 30min, take it out and put it into a quartz boat with a quartz glass cover and place it in a tube furnace. The heating rate of min was raised to 700°C for 3 h in situ pyrolysis reaction, and after natural cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com