Porous nanocarbon slice

A nano-carbon and flake technology, which is applied in the direction of carbon-silicon compound conductors, electrical components, battery electrodes, etc., can solve the problems of cumbersome process and unfavorable large-scale preparation, and achieve low cost, good conductivity and current collection effect, and suppress flying The effect of the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1.15g zinc and 3.9g sucrose are mixed ball milled, the ball-to-material ratio is 10:1, the rotating speed is 300rpm, ball milled for 6h, the resulting mixture is sealed in a stainless steel autoclave in a glove box full of inert gas, and then the autoclave is pumped Vacuum to below 0.1MPa; heat the autoclave to 550°C with an electric furnace, react for 8 hours and then cool it down to room temperature naturally to obtain the reaction product. Take the loose part of the upper layer of the reaction product and ball mill it at a speed of 300rpm for 6 hours. First wash with dilute hydrochloric acid with a concentration of 0.1M until no bubbles are generated, then wash with deionized water until the pH is neutral, and dry at 100° C. for 10 h to obtain porous nano-carbon flakes.

[0033] The porous nano-carbon flakes prepared in the present embodiment are tested, and the results are as follows:

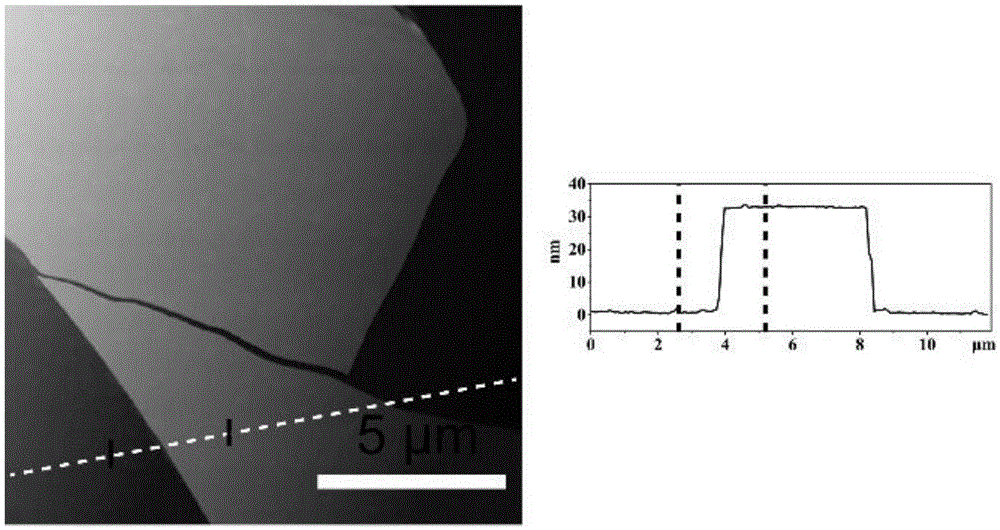

[0034] (1) Atomic force microscope test:

[0035] Test results such as figure ...

Embodiment 2

[0039] (1) 1.15g magnesium and 3.9g sucrose are mixed and ball-milled, the ball-to-material ratio is 10:1, and the rotating speed is 300rpm, ball milled for 6h, and the resulting mixture is sealed in a stainless steel autoclave in a glove box full of an inert gas, and the described The autoclave was evacuated to below 0.1MPa; the autoclave was heated to 550°C with an electric furnace, and after 8 hours of reaction, it was naturally cooled to room temperature to obtain the reaction product, and the loose part of the upper layer of the reaction product was ball milled at 300rpm for 6 hours. After ball milling, the obtained The material was first washed with dilute hydrochloric acid with a concentration of 0.1M until no bubbles were generated, then washed with deionized water until the pH was neutral, and dried at 100°C for 10 hours to obtain porous nanocarbon flakes.

[0040] The porous nano-carbon flakes prepared in the present embodiment are tested, and the results are as follo...

Embodiment 3

[0046] (1) 1.15g zinc and 3.9g glucose are mixed ball milled, the ball-to-material ratio is 10:1, the rotating speed is 300rpm, ball milled for 6h, the resulting mixture is sealed in a stainless steel autoclave in a glove box full of inert gas, and then the The autoclave was evacuated to below 0.1MPa; the autoclave was heated to 550°C with an electric furnace, and after 8 hours of reaction, it was naturally cooled to room temperature to obtain the reaction product, and the loose part of the upper layer of the reaction product was ball milled at a speed of 300rpm for 6 hours. The obtained material was first washed with dilute hydrochloric acid with a concentration of 0.1M until no bubbles were generated, then washed with deionized water until the pH was neutral, and dried at 100°C for 10 hours to obtain porous nanocarbon flakes.

[0047] The porous nano-carbon flakes prepared in the present embodiment are tested, and the results are as follows:

[0048] (1) Atomic force microsc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com