Imbibition agent applied to low-permeability reservoir imbibition oil recovery and preparation method thereof

An imbibant and low-permeability technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increasing oil production costs, achieve the effects of small particle size, high surface hydroxyl content, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Modified nano-SiO 2 preparation:

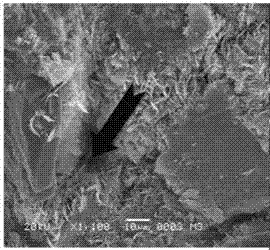

[0025] (1) Selected nano-SiO 2 The basic parameters are shown in Table 1; after infrared spectrum analysis, nano-SiO 2 There are a large number of hydroxyl groups and unsaturated residual bonds on the surface, which deviates from the stable silicon-oxygen structure; the nano-SiO2 is measured by the Omnisorp100CX specific surface and porosity analyzer 2 Its surface contains many nanoscale micropores with a porosity of 0.611ml / g. Weigh 15g nano-SiO 2 Place in a constant temperature box and dry at 101°C to remove adsorbed water.

[0026] Table 1 Nano-SiO used 2 Basic parameters

[0027]

[0028] (2) The dried nano-SiO 2 Disperse in 300ml of absolute ethanol, stir at a high speed of 4000r / min for 1h, and make an emulsion with a concentration of 5%;

[0029] (3) According to nano-SiO 2 Add the modifier dichlorodimethylsilane at a feed ratio of 1% to 7% by mass, and azeotropically reflux at a temperature of 80°C for 3 hours;

...

Embodiment 2

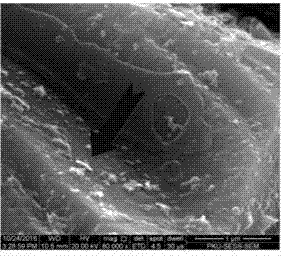

[0054] (1) The basic parameters of the selected nano-silica are shown in Table 6. According to infrared spectrum analysis, there are a large number of hydroxyl groups and unsaturated residual bonds on the surface of nano-silica, which deviates from the stable silicon-oxygen structure; Omnisorp100CX specific surface and pores The surface of the nano-silica contains many nano-scale micropores as measured by the rate analyzer, and its porosity reaches 0.611ml / g. Weigh 15g of nano silicon dioxide and place it in a constant temperature box to dry at 101°C to remove the adsorbed water.

[0055] Table 6 Nano-SiO used 2 Basic parameters

[0056]

[0057] (2) According to the feed ratio of 5% mass fraction of absolute ethanol, the dried nano-SiO 2 Disperse in 300ml of absolute ethanol, stir at a high speed of 4000r / min for 1h, and make an emulsion with a concentration of 5%;

[0058] (3) According to nano-SiO 2 Add the modifier dichlorodimethylsilane at a feed ratio of 1% to 7% ...

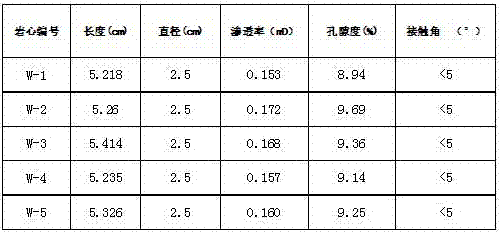

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com