Method for preparing magnetic biochar from sludge

A biochar and sludge technology, which is applied in the fields of sludge treatment, pyrolysis sludge treatment, chemical instruments and methods, etc., can solve the problems of poor adsorption performance of biochar, high cost and complicated preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

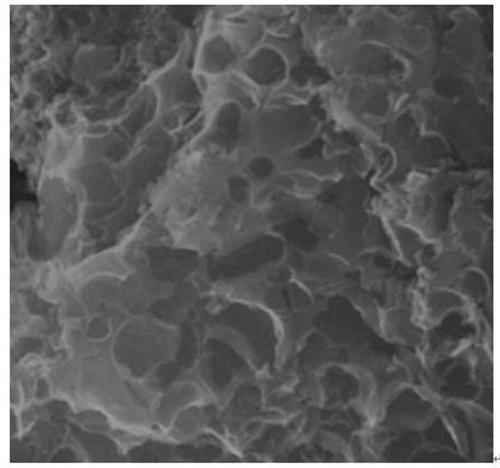

Image

Examples

Embodiment 1

[0033] For pretreatment, add 1.5 L of FeCl with a concentration of 0.015 mol / L to 8.2 kg of sludge 3 solution and 0.6L of KOH solution with a concentration of 0.035mol / L, mix well.

[0034] Drying treatment, after pretreatment, the sludge passes through the mud storage hopper, is transported by the screw feeder, and enters the drying furnace. The drying temperature is controlled at 200°C and the sludge stays for 40 minutes. After drying, the moisture content of the sludge is about 16% for subsequent pyrolysis treatment.

[0035] Pyrolysis treatment, after drying, the sludge enters the pyrolysis furnace, the heating rate of the pyrolysis furnace is 10°C / min, the temperature rises to 800°C, stays in the pyrolysis furnace for 2 hours, and undergoes a series of cracking, dehydrogenation, and reduction reactions.

[0036] In the cooling stage, the product after pyrolysis treatment is cooled, specifically, it can be cooled by spiral water cooling equipment, and cooled to about 50°C...

Embodiment 2

[0038] For pretreatment, add 1.4 L of FeCl with a concentration of 0.018 mol / L to 8.8 kg of sludge 3 solution and 0.6 L of KOH solution with a concentration of 0.055 mol / L, and mix well.

[0039] Drying treatment, after pretreatment, the sludge passes through the mud storage hopper, is conveyed by the screw feeder, and enters the drying furnace. The drying temperature is controlled at 160°C and stays for 40 minutes. After drying, the moisture content of the sludge is about 18% for subsequent pyrolysis treatment.

[0040] Pyrolysis treatment. After drying, the sludge enters the pyrolysis furnace. The heating rate of the pyrolysis furnace is 15°C / min, and the temperature is raised to 850°C. It stays in the pyrolysis furnace for 2 hours and undergoes a series of cracking, dehydrogenation, and reduction reactions.

[0041] In the cooling stage, the product after pyrolysis treatment is cooled, specifically, it can be cooled by spiral water cooling equipment, and cooled to about 50...

Embodiment 3

[0043] For pretreatment, add 1.7 L of FeCl with a concentration of 0.020 mol / L to 9.8 kg of sludge 3 solution and 0.8L of KOH solution with a concentration of 0.060mol / L, mix well.

[0044] Drying treatment, after pretreatment, the sludge passes through the mud storage hopper, is transported by the screw feeder, and enters the drying furnace. The drying temperature is controlled at 200°C and the sludge stays for 40 minutes. After drying, the moisture content of the sludge is about 15% for subsequent pyrolysis treatment.

[0045] Pyrolysis treatment. After drying, the sludge enters the pyrolysis furnace. The heating rate of the pyrolysis furnace is 10°C / min, and the temperature is raised to 660°C. It stays in the pyrolysis furnace for 2 hours and undergoes a series of cracking, dehydrogenation, and reduction reactions.

[0046] In the cooling stage, the product after pyrolysis treatment is cooled, specifically, it can be cooled by spiral water cooling equipment, and cooled to ...

PUM

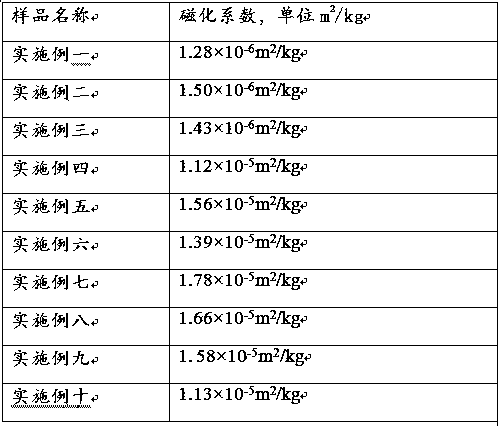

| Property | Measurement | Unit |

|---|---|---|

| magnetic susceptibility | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com