Patents

Literature

126results about How to "Improve the effect of current collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium secondary battery

InactiveUS20070054190A1Improve initial performanceImprove adhesionElectrode thermal treatmentFinal product manufactureGraphiteSilicon

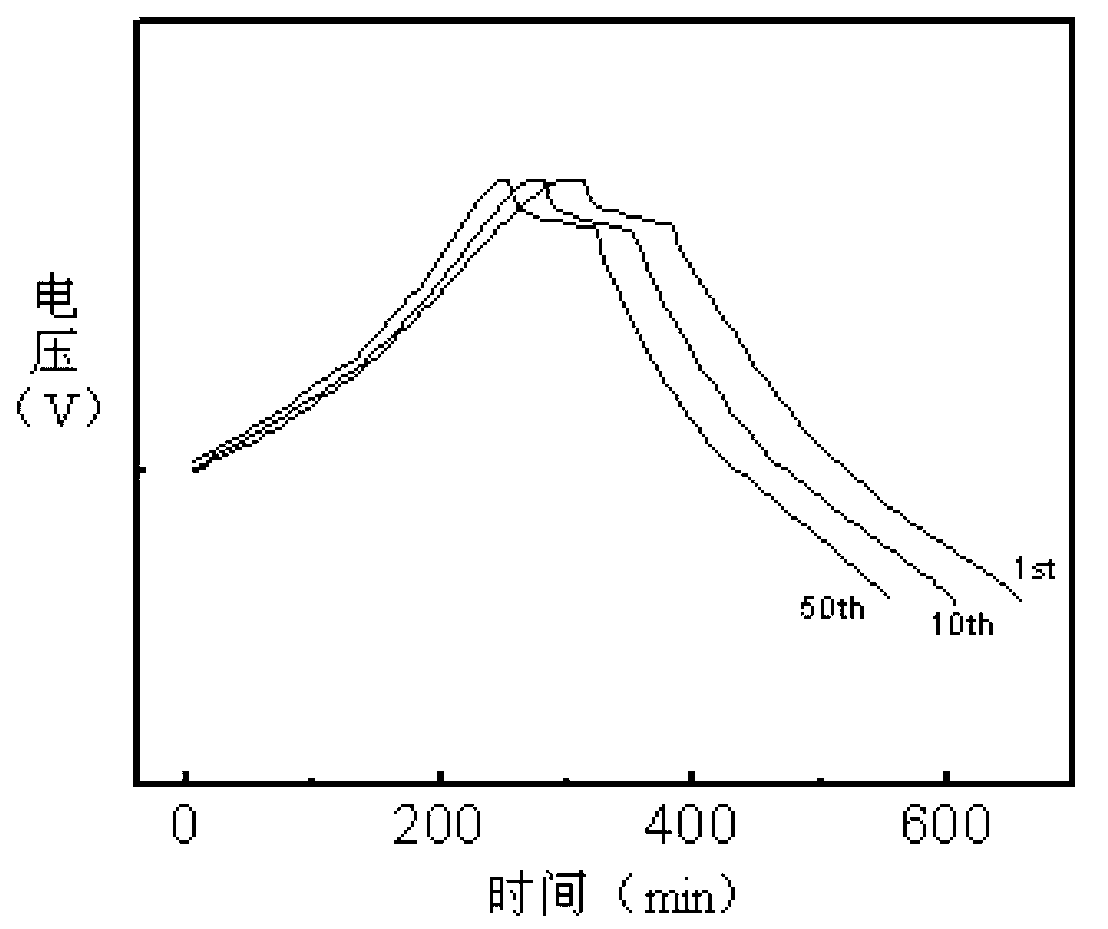

A lithium secondary battery has a positive electrode, a negative electrode, and a non-aqueous electrolyte. The negative electrode has a negative electrode current collector and a negative electrode mixture layer containing a negative electrode conductive agent, a negative electrode binder, and negative electrode active material particles made of a material containing silicon. The negative electrode mixture layer is sintered and disposed on the negative electrode current collector. The negative electrode active material particles have an average particle size of from 5.0-15.0 μm before being charged. The negative electrode conductive agent is made of a graphite material having an average particle size of from 2.5-15.0 μm. The amount of the graphite material added is from 3-20 mass % with respect to the negative electrode active material. The theoretical electrical capacity ratio of the positive electrode to the negative electrode is 1.0 or less.

Owner:SANYO ELECTRIC CO LTD

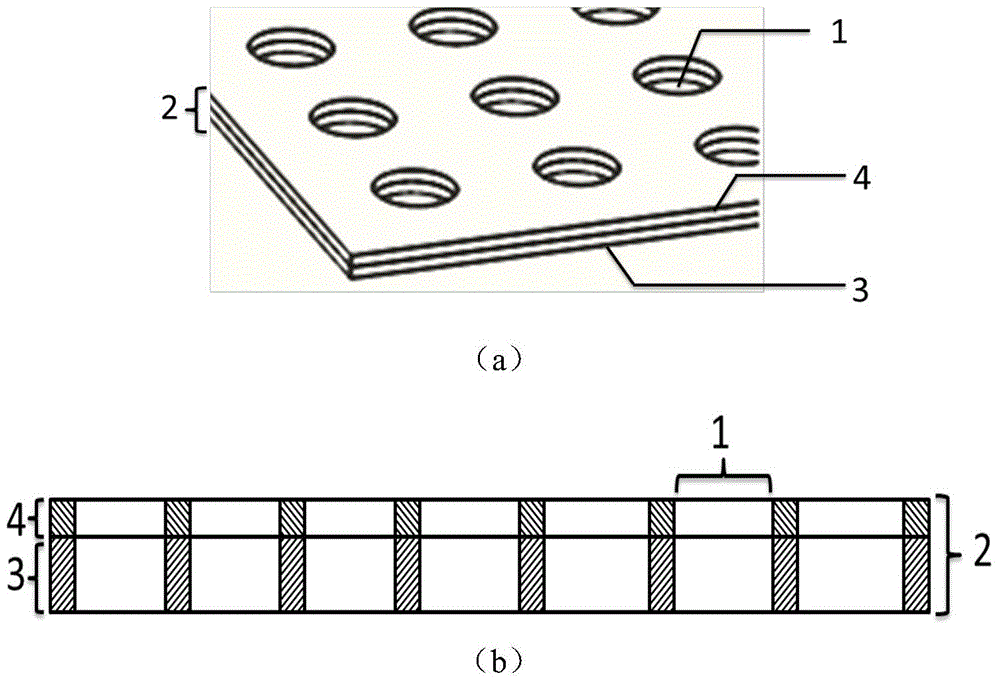

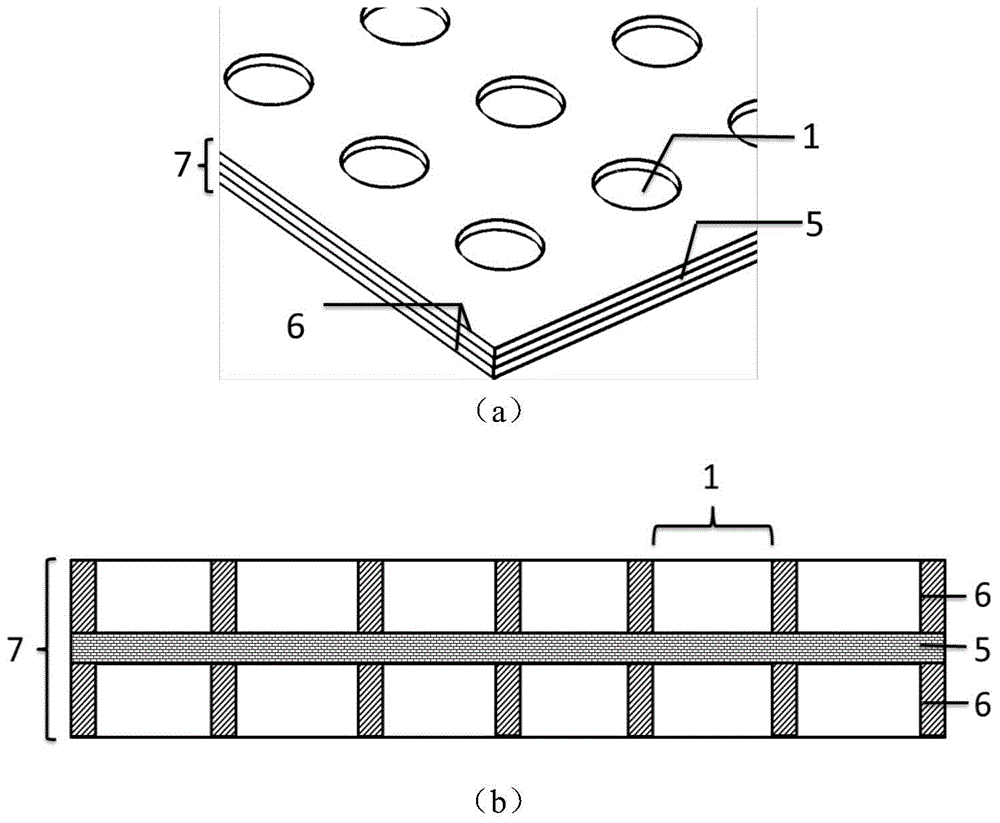

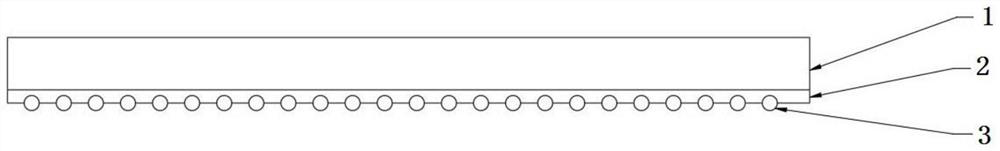

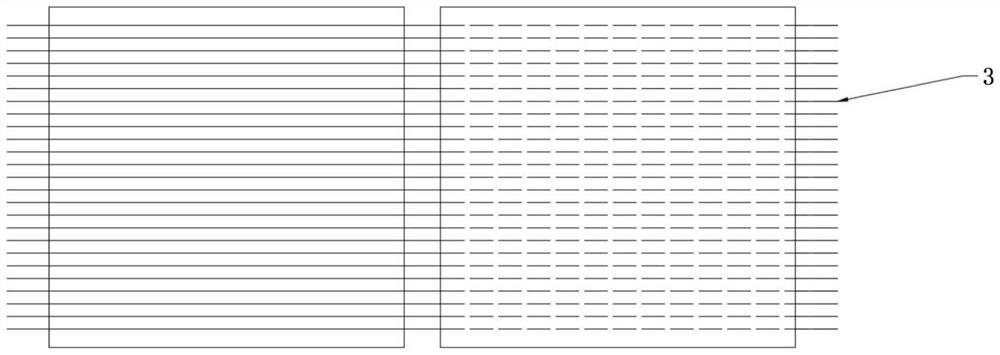

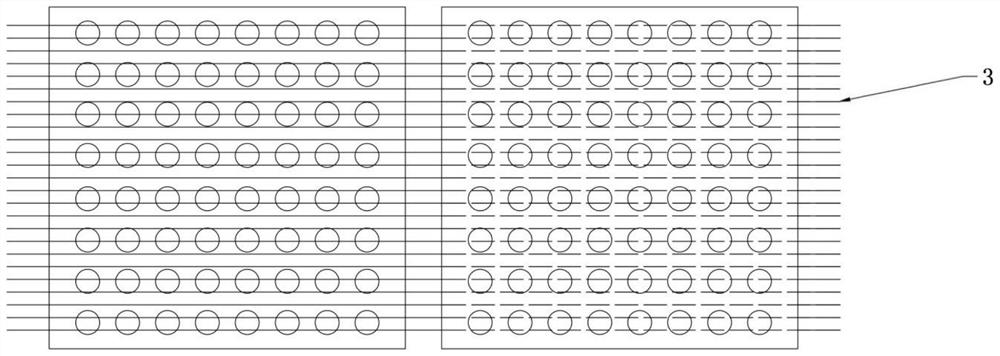

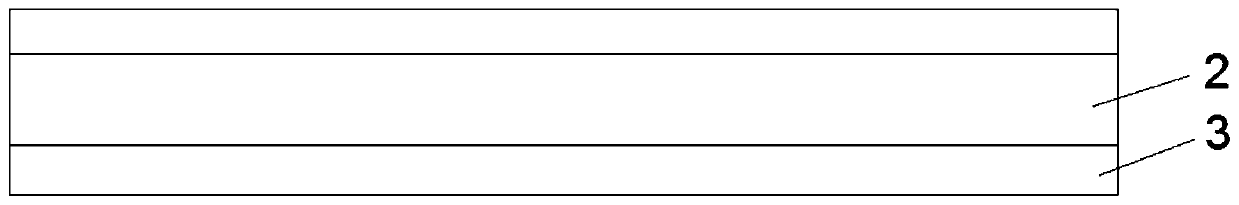

Composite porous current collector, and preparation method and application thereof

The invention provides a composite porous current collector, and a preparation method and an application thereof. The composite porous current collector comprises a porous electron conducting layer with through holes and an electron insulating layer with through holes, wherein the porosity of the through holes of porous electron conducting layer is not less than the porosity of the through holes of the electron insulating layer, a position of the porous electron conducting layer corresponding to the position of the through hole of the electron insulating layer is a through hole, and a position of the porous electron conducting layer corresponding to the position of the non-through hole of the electron insulating layer can be a through hole, and also can be a blind hole or a rough surface. The electron insulating layer is adjacent to an isolation layer, so puncture of precipitated lithium dendrite to a diaphragm is prevented, direct contact of the electron conducting layer is avoided, and the safety of a battery is improved; the above corresponding through hole structure is in favor of transferring lithium ions, so the internal resistance of the battery is reduced; the hole structure of the porous electron conducting layer and the homogeneous rough surface are in favor of full contact of an electrode active substance with the current collector, the current is uniformly distributed, and the current collection effect is improved; and the preparation method adopting airflow punching has the advantages of simplicity, easy implementation, cleanness, energy saving, combination of other various enforcement modes, and convenience for production and application.

Owner:南京竞予能源有限公司

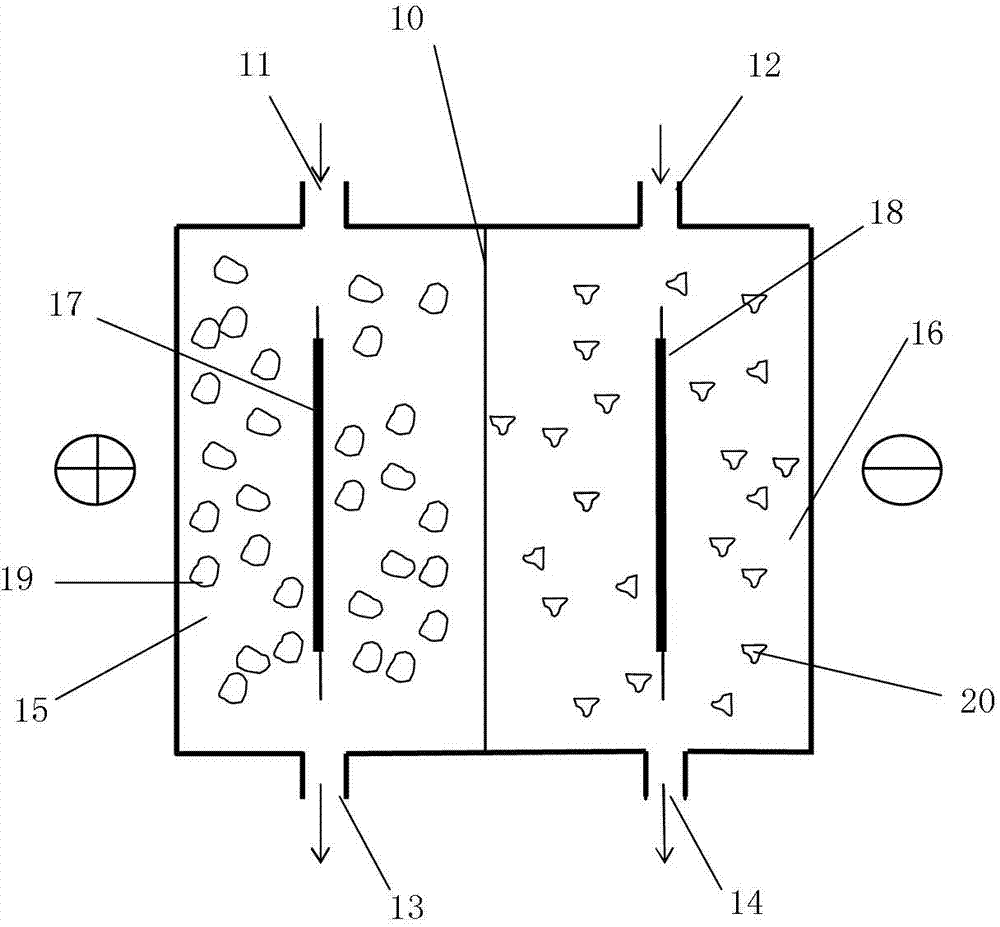

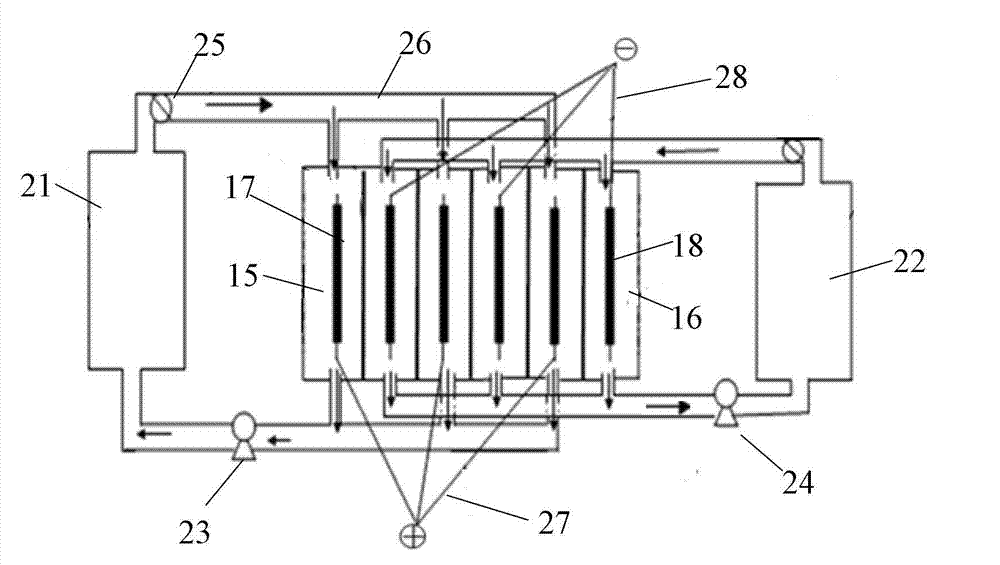

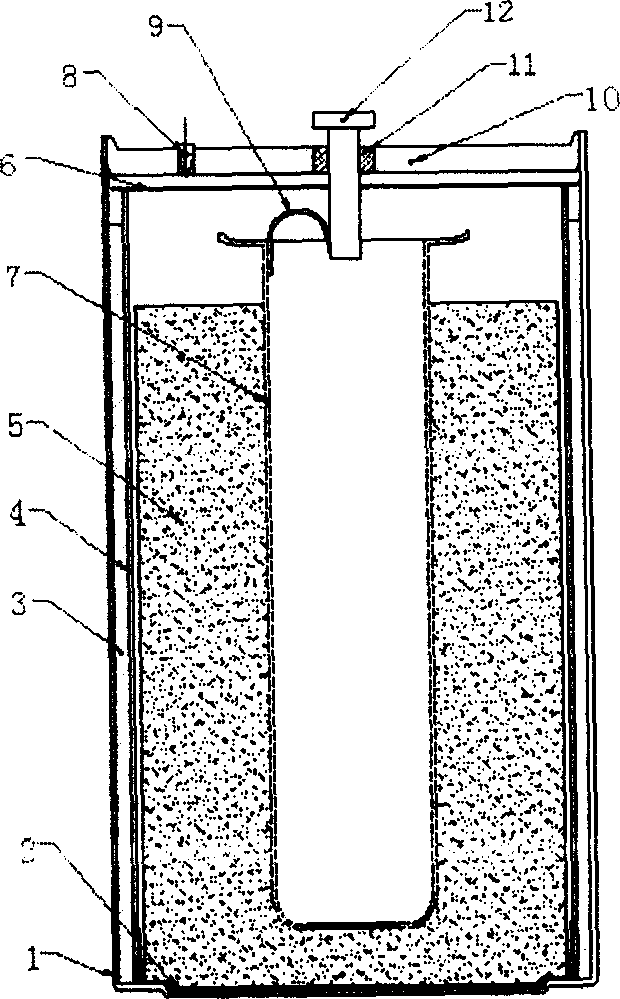

Semi-solid flow cell

ActiveCN103247816AIncrease working current densityGood rate characteristicsFinal product manufactureRegenerative fuel cellsElectrochemical responseElectrical battery

Owner:南京竞予能源有限公司

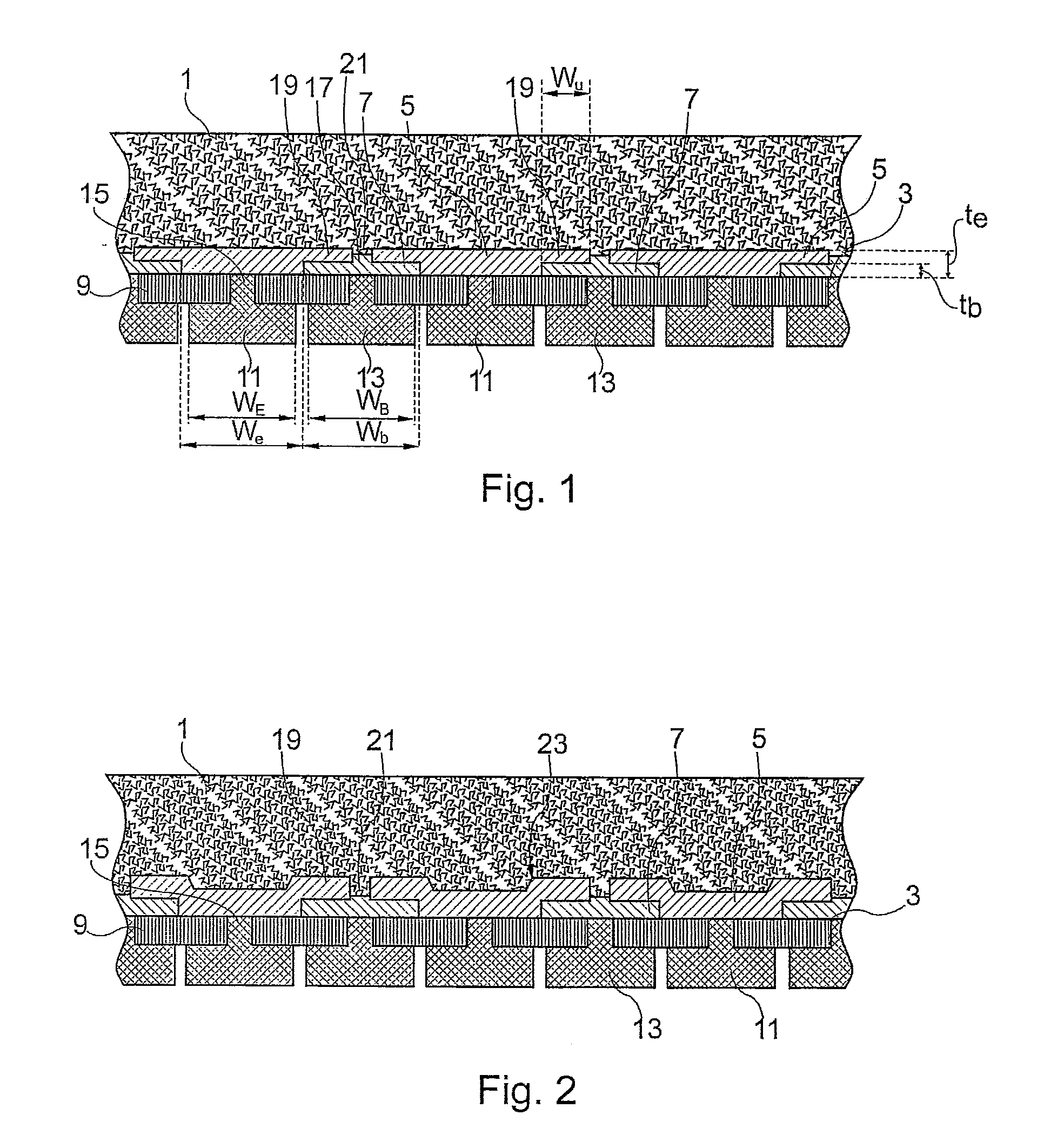

Rear-contact solar cell having extensive rear side emitter regions and method for producing the same

InactiveUS20110023956A1Good propertyShort riskSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSemiconductorSolar cell

The invention relates to a rear-contact solar cell and to a method for producing the same. The rear-contact solar cell comprises a semiconductor substrate on the rear side surface of which emitter regions, contacted by emitter contacts, and base regions, contacted by base contacts, are defined. The emitter regions and the base regions overlap at least in overlap regions, the emitter regions in the overlap regions reaching deeper into the semiconductor substrate than the base regions, when seen from the rear side surface of the solar cell. As a result, a large area percentage of the rear side of the semiconductor substrate can be covered with a charge-collecting emitter, said emitter being at least partially buried in the interior of the semiconductor substrate so that there is no risk of the base contacts provoking a short circuit towards the buried emitter regions.

Owner:INST FUR SOLARENERGIEFORSCHUNG

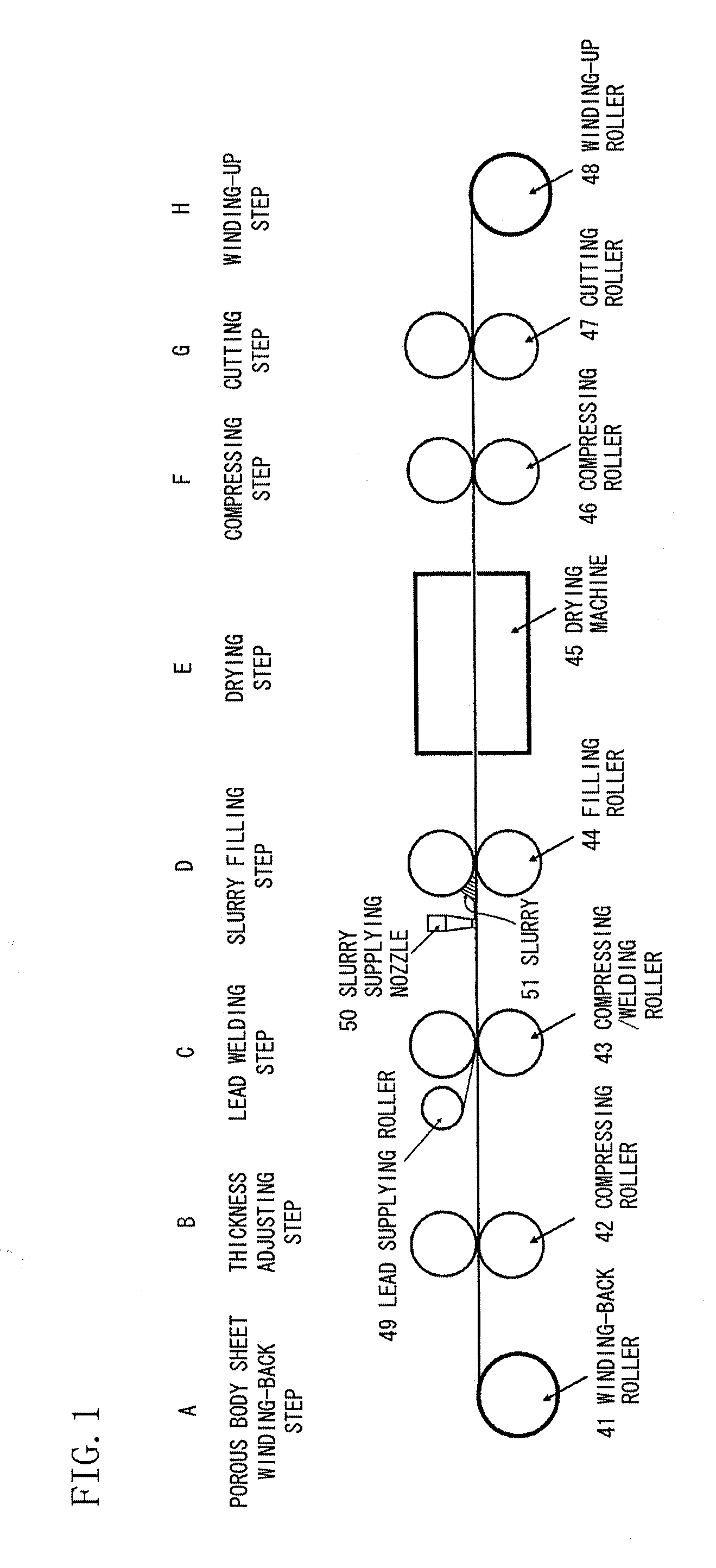

A making method for liquid battery compound conductive plastic current collector body

InactiveCN101150192AImprove conductivityImprove mechanical propertiesElectrode carriers/collectorsCollectors/separatorsFiberConductive materials

This invention provides a preparing method for composite conductive plastic collectors of fluid flow cells, which puts one or several kinds of conductive matrials of conductive filling graphite, carbon black, ethyne black and carbon fiber powder into teflon suspension and mixing them uniformly and drying them then soaking them with IPA and milling them repeatedly under 70-80deg.C to get a diaphragm, which is cut to a necessary size, then single, multiple or conduction net is pressed into mold under 400Kg / cm2 according to the needs and is put into a special clamp and a high temperature oven for sintering, then cooled to get the conductive plastic collector.

Owner:INST OF ELECTRONICS ENG CHINA ACAD OF ENG PHYSICS

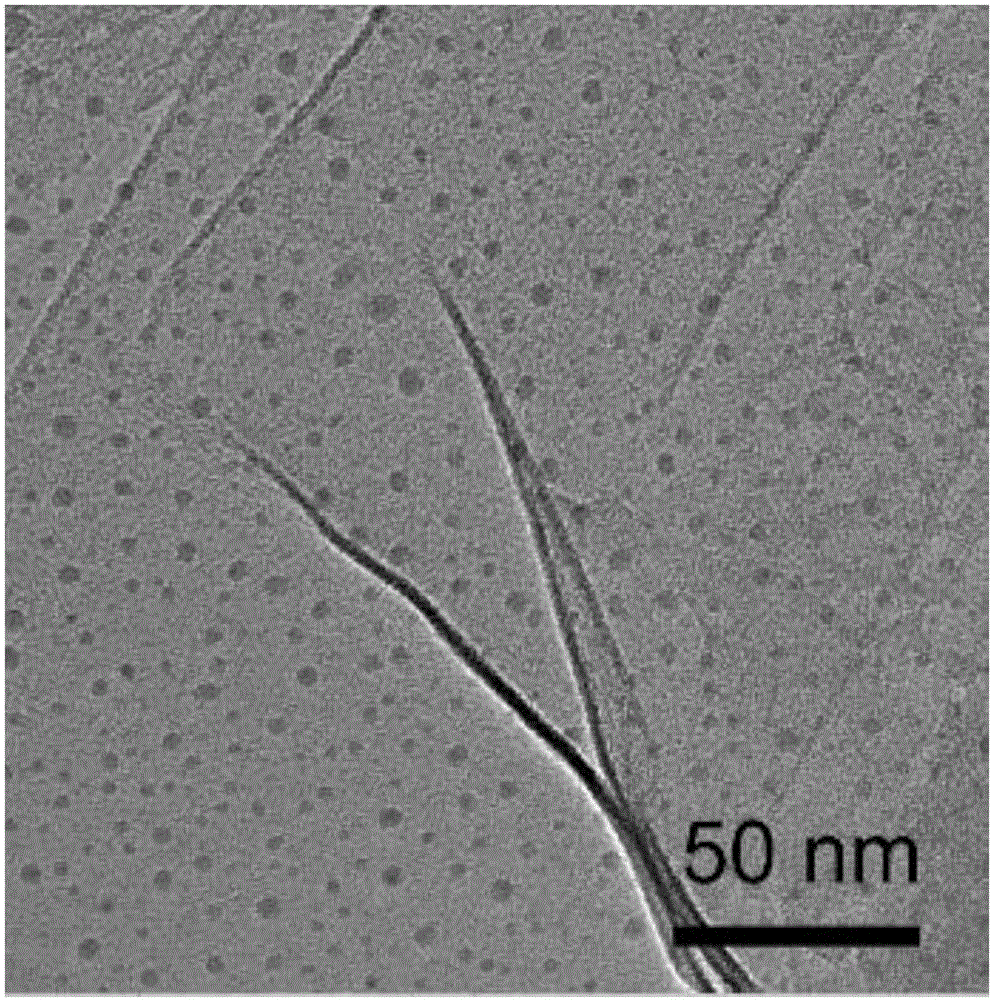

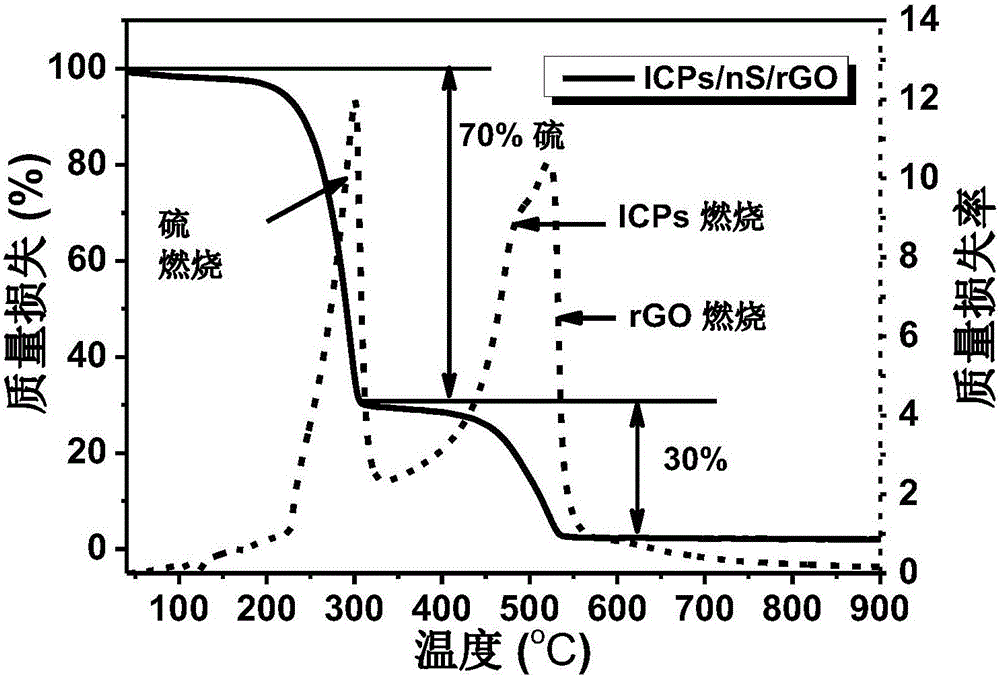

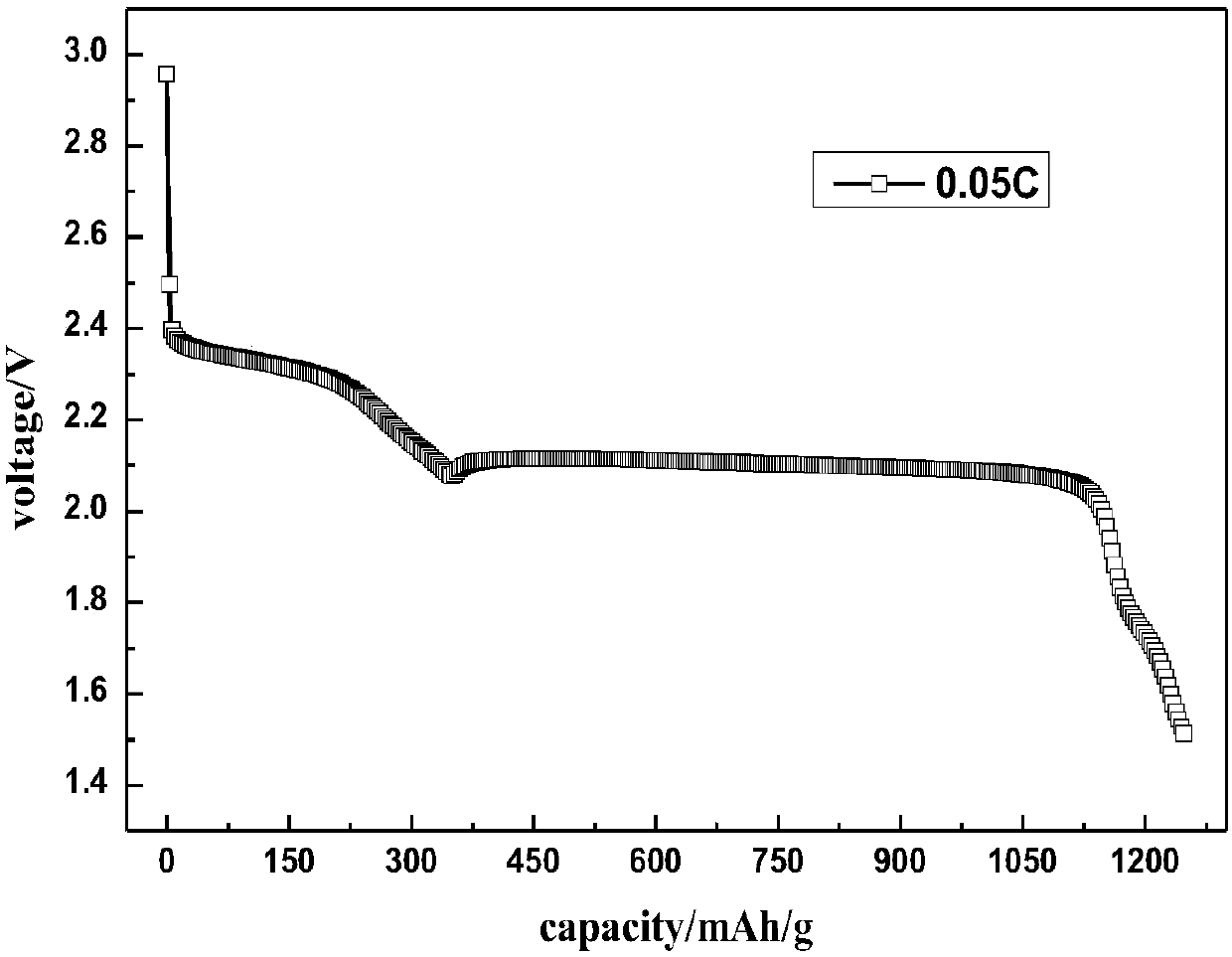

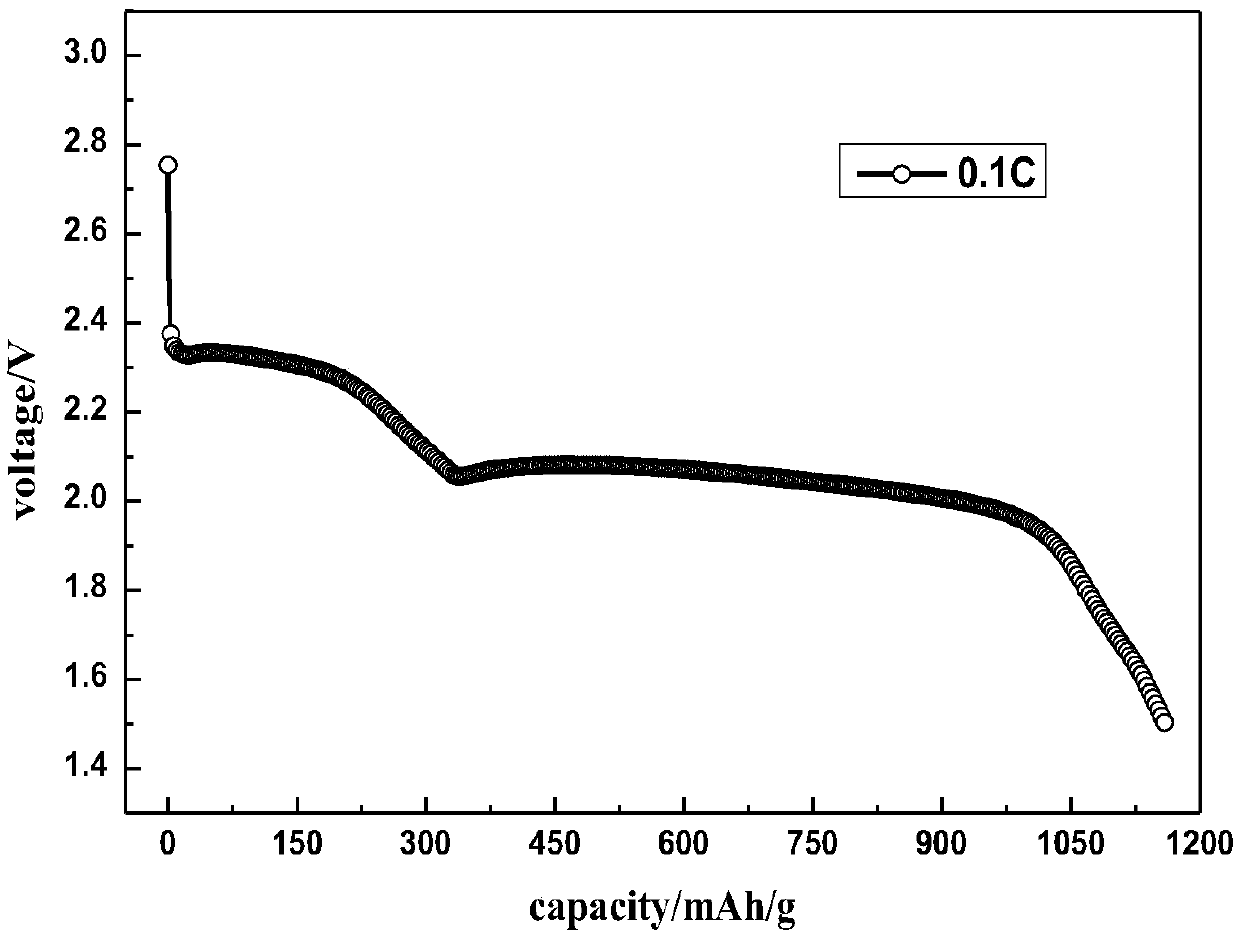

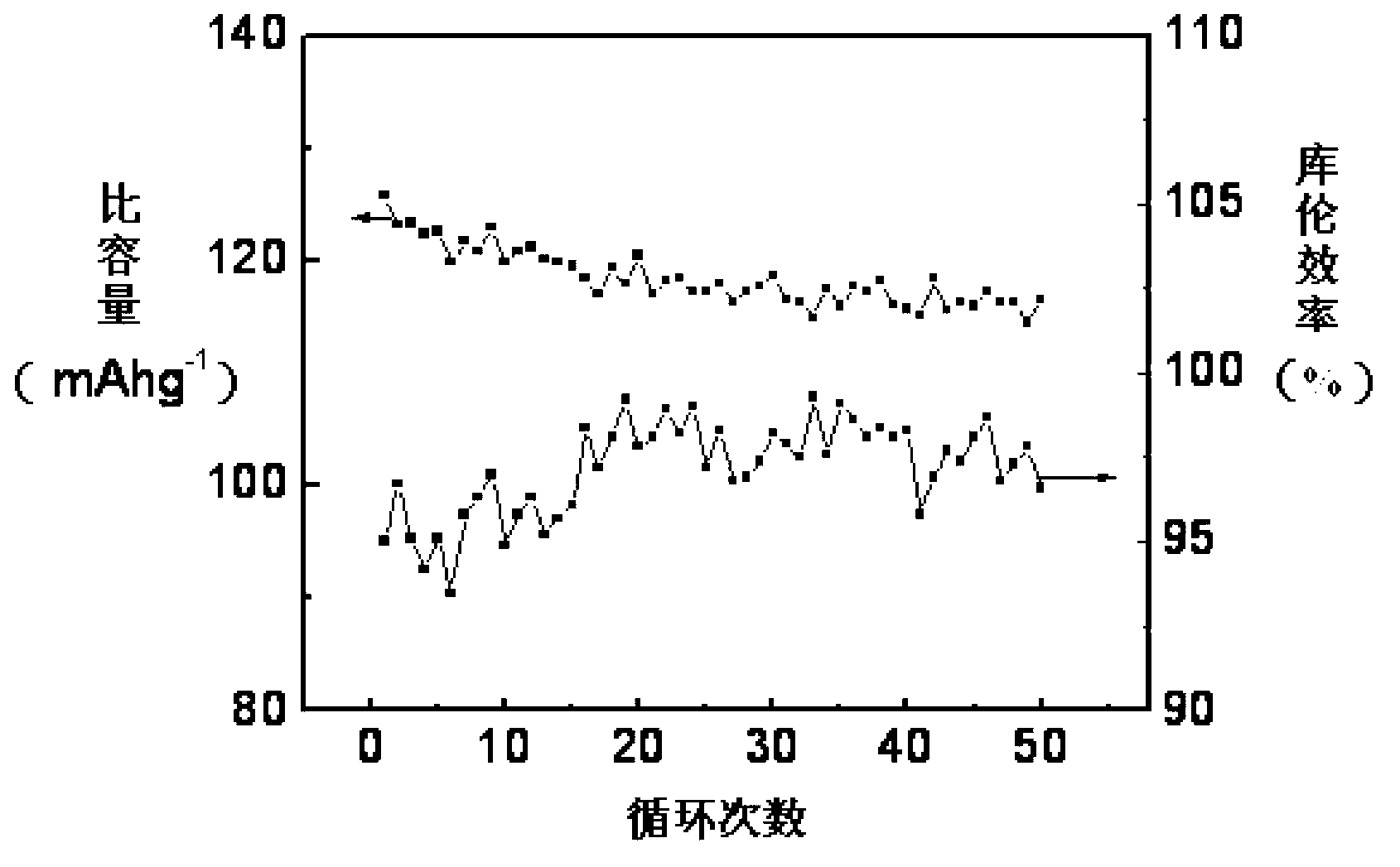

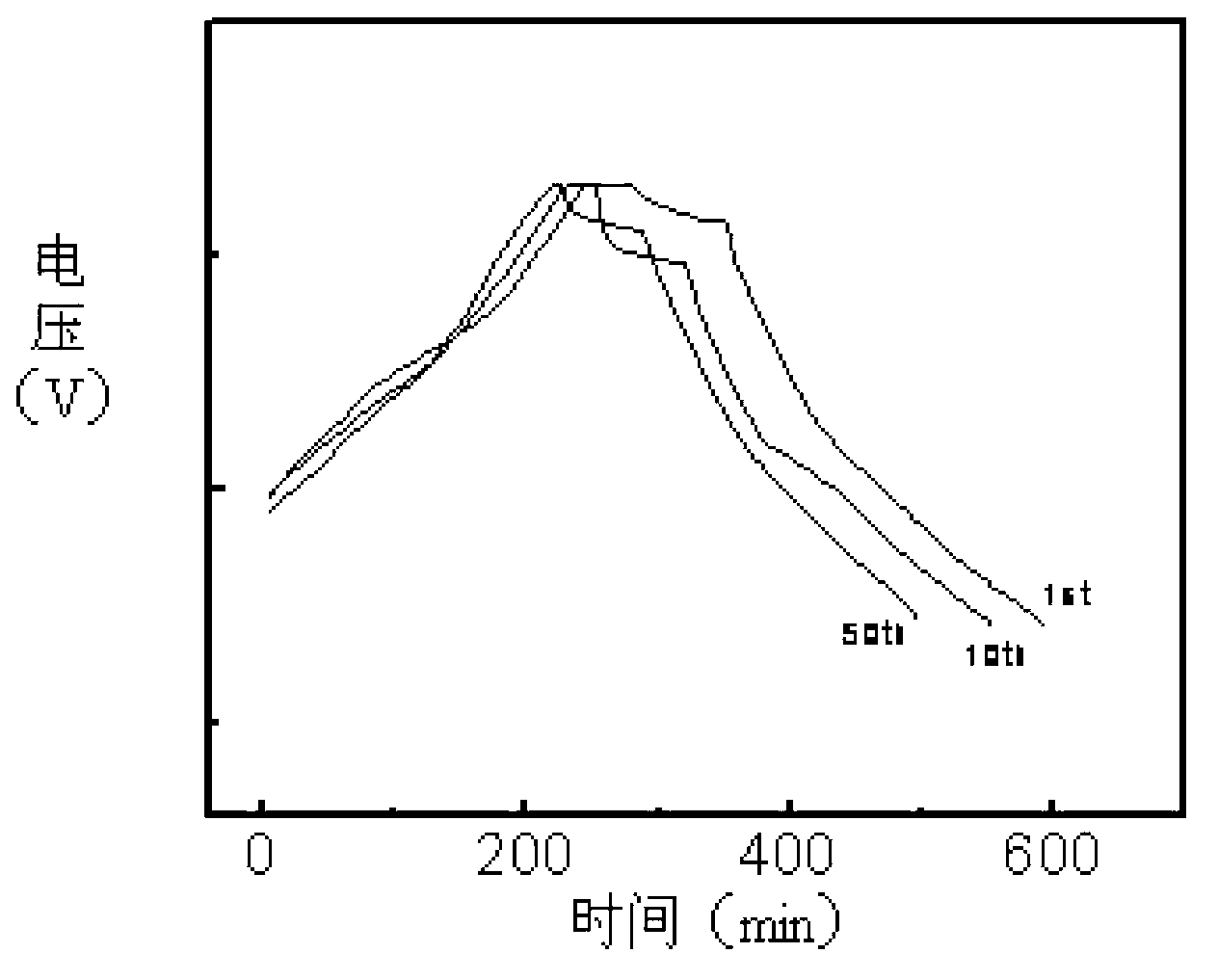

Lithium-sulfur battery positive pole material and preparation method thereof

InactiveCN105826523AImprove conductivityImprove the effect of current collectionMaterial nanotechnologyCell electrodesSingle substanceOxygen

The invention relates to a lithium-sulfur battery positive pole material and a preparation method thereof, and belongs to the technical field of battery materials. The provided positive pole material has abundant micropores and mesopores; porous nano carbon thin sheets with a three-dimensional communicated net structure are taken as the skeleton; nano sulfur dots are filled into the pores of the net structure, and the outer layer of the skeleton is wrapped by reduced oxidized graphene. The preparation method comprises the following steps: mixing porous nano carbon thin sheets with a sulfur single substance, subjecting the mixture to ball milling, carrying out reactions at a temperature of 180 to 200 DEG C in an enclosed environment in the absence of oxygen and water under the protection of inert gas to obtain a porous nano carbon thin sheet / nano sulfur compound; dissolving the compound into an ethanol solution, dispersing the compound by ultrasonic waves, adding oxidized graphene, adjusting the pH to 10.1 by ammonia water, carrying out ultrasonic dispersion, carrying out hydrothermal reactions at a temperature of 80 to 100 DEG C, filtering, washing the reaction product until the reaction product becomes neutral, and drying to obtain the positive pole material. The positive material has the advantages of high specific capacity and stable electrochemical circulation performance, moreover, the preparation method is simple, the price is low, and the positive material is environment-friendly and can be easily produced in batches.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

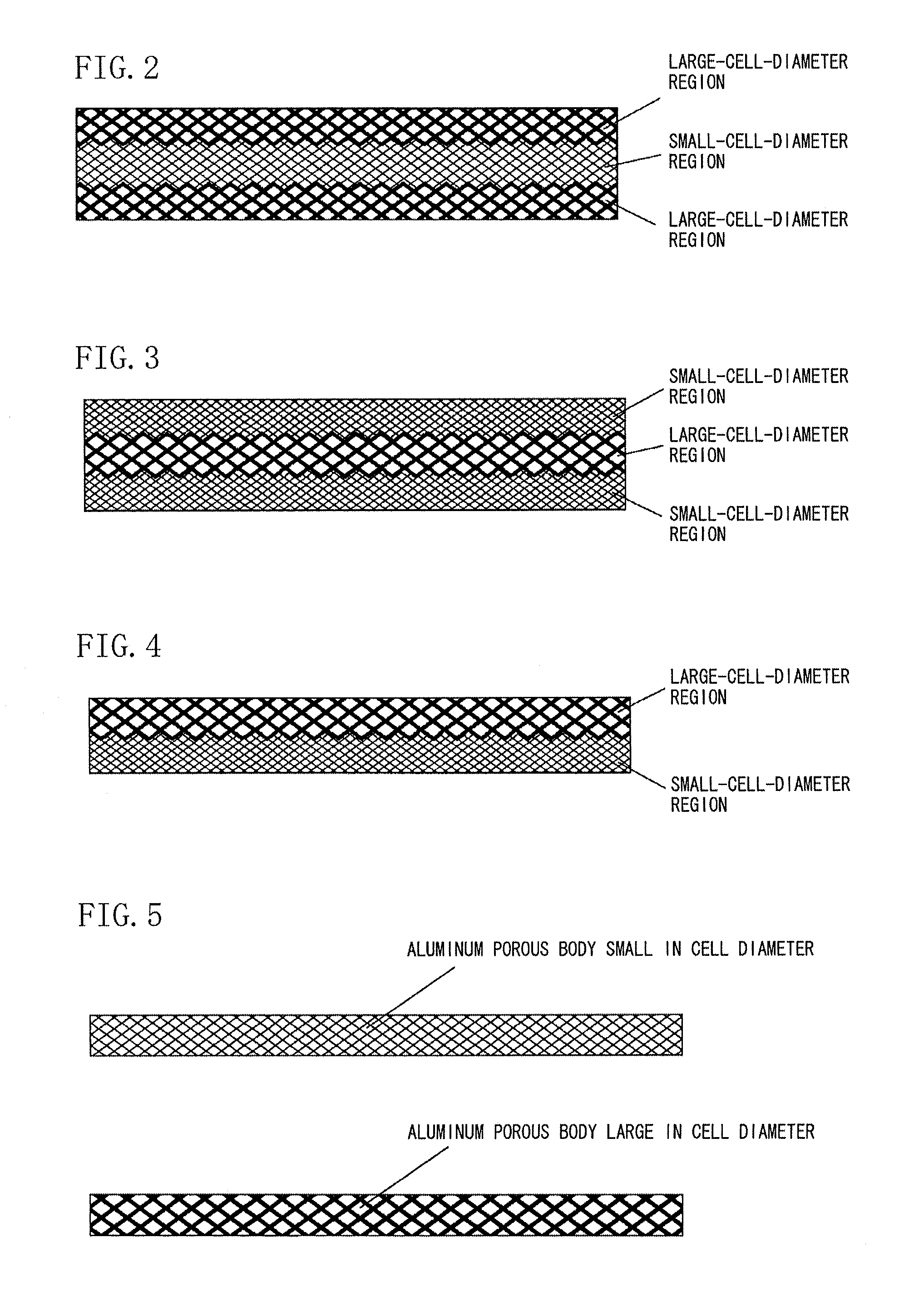

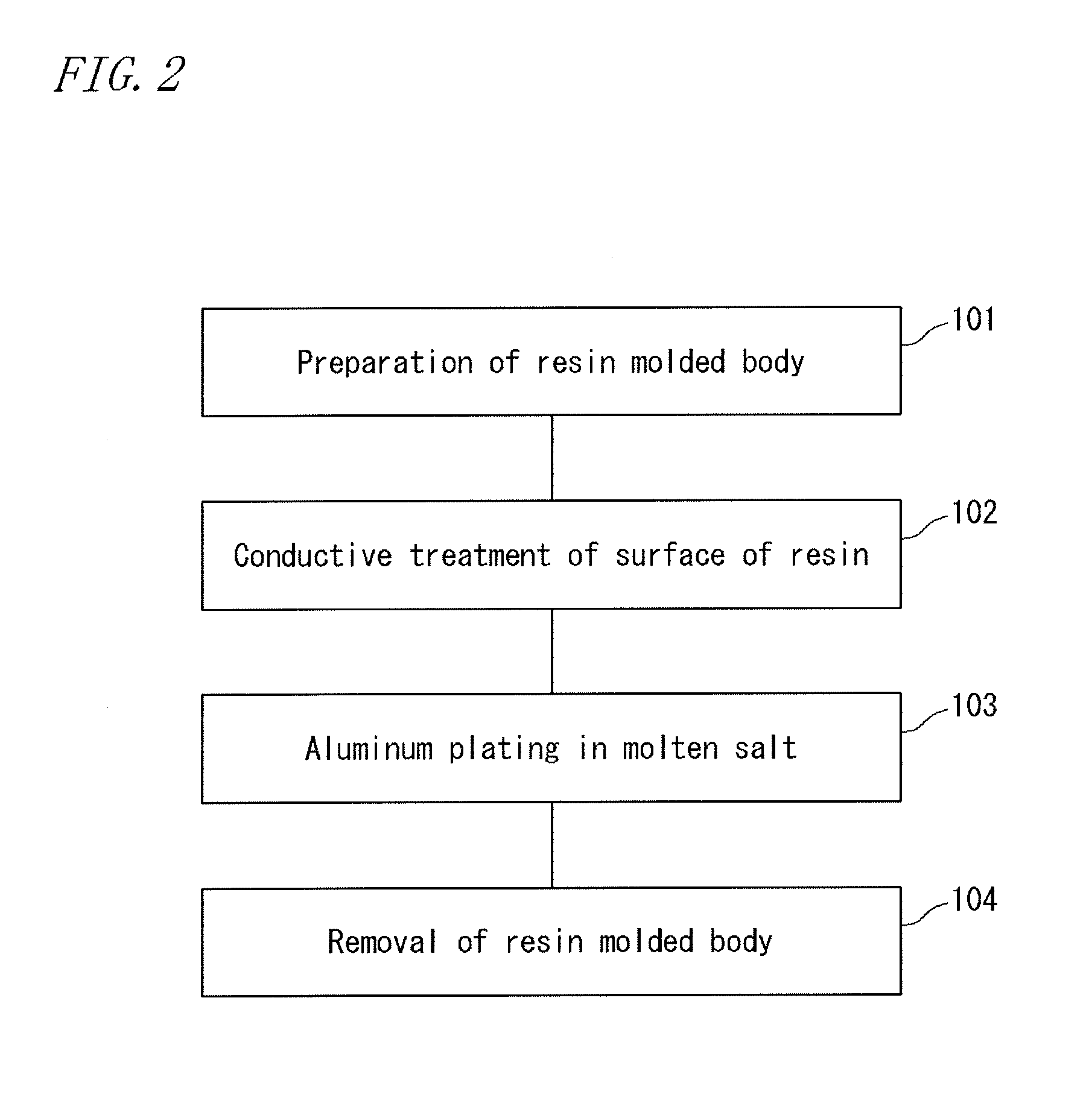

Three-dimensional net-like aluminum porous body, electrode using the aluminum porous body, nonaqueous electrolyte battery using the electrode, and nonaqueous electrolyte capacitor using the electrode

ActiveUS20120115035A1Reduce industrial costsImprove the effect of current collectionHybrid capacitor electrolytesLiquid electrolytic capacitorsCapacitorMaterials science

Provided are a three-dimensional net-like aluminum porous body in which the diameter of cells in the porous body is uneven in the thickness direction of the porous body; a current collector and an electrode each using the aluminum porous body; and methods for producing these members. The porous body is a three-dimensional net-like aluminum porous body in a sheet form, for a current collector, in which the diameter of cells in the porous body is uneven in the thickness direction of the porous body. When a cross section in the thickness direction of the three-dimensional net-like aluminum porous body is divided into three regions of a region 1, a region 2 and a region 3 in this order, the average cell diameter of the regions 1 and 3 is preferably different from the cell diameter of the region 2.

Owner:SUMITOMO ELECTRIC IND LTD +1

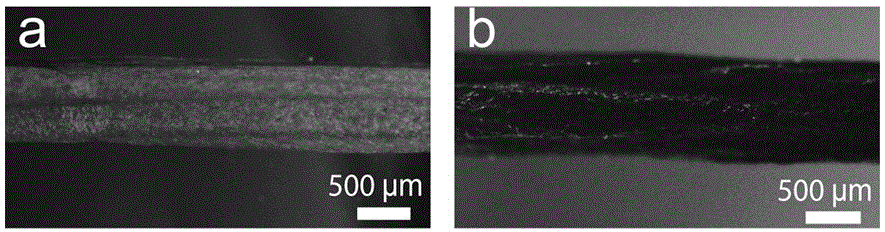

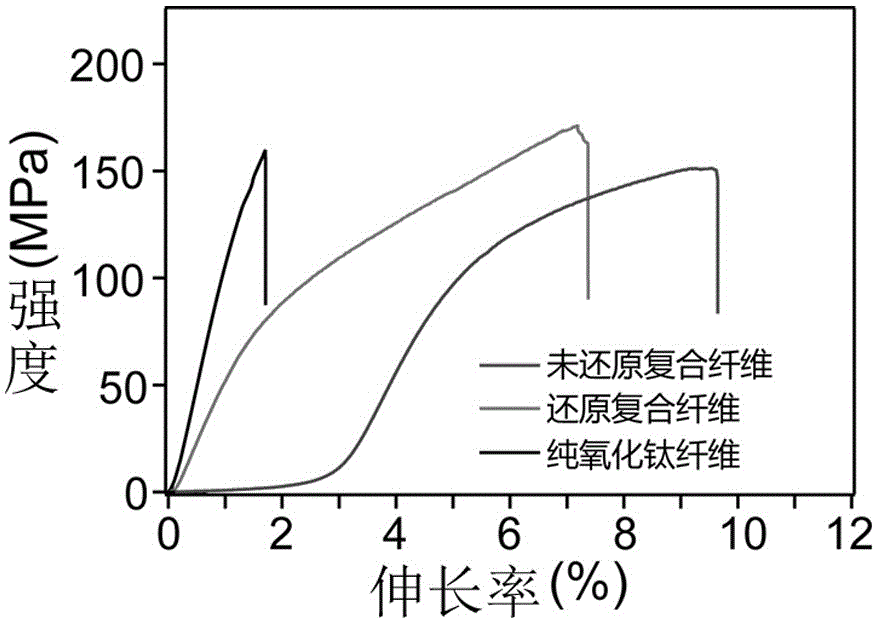

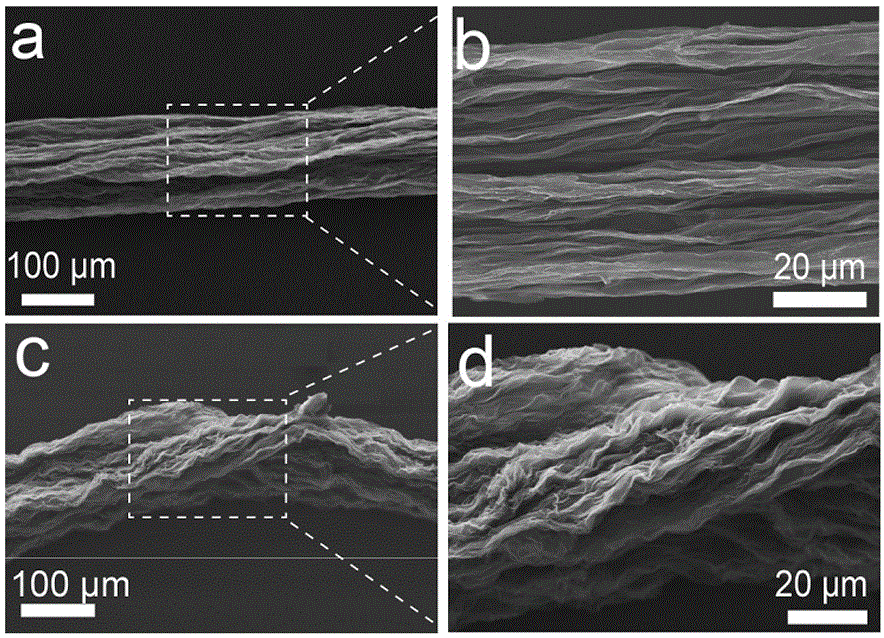

Flexible cell based on metallic oxide/graphene composite macroscopic fibers and preparation method

ActiveCN107180947AGood mechanical propertiesExcellent electrochemical performanceFinal product manufactureCell electrodesCvd grapheneHydroiodic acid

The invention relates to a flexible cell based on metallic oxide / graphene composite macroscopic fibers and a preparation method. The preparation method comprises the following steps: after mixing an anionic metal oxide aqueous solution with graphene oxide to obtain a spinning solution, adding the spinning solution in wet spinning equipment to obtain nascent fibers; repeatedly washing the obtained nascent fibers with deionized water, and drying the nascent fibers to obtain metallic oxide and graphene oxide composite fibers; reducing the metallic oxide and graphene oxide composite fibers with hydroiodic acid, and then washing and drying the metallic oxide and graphene oxide composite fibers to obtain the metallic oxide and graphene composite fibers; placing the composite fibers, lithium lines and lithium manganate loaded carbon cloth fibers in a shrinkable tube in parallel; and adding diaphragms and electrolyte so that half cells and total cells can be assembled respectively. The preparation process is simple and controllable, and large-scale production is facilitated. The metallic oxide and graphene composite fibers which are prepared by the preparation method for the first time have unlimited prospects in the field of energy storage of flexible cells.

Owner:SUZHOU UNIV

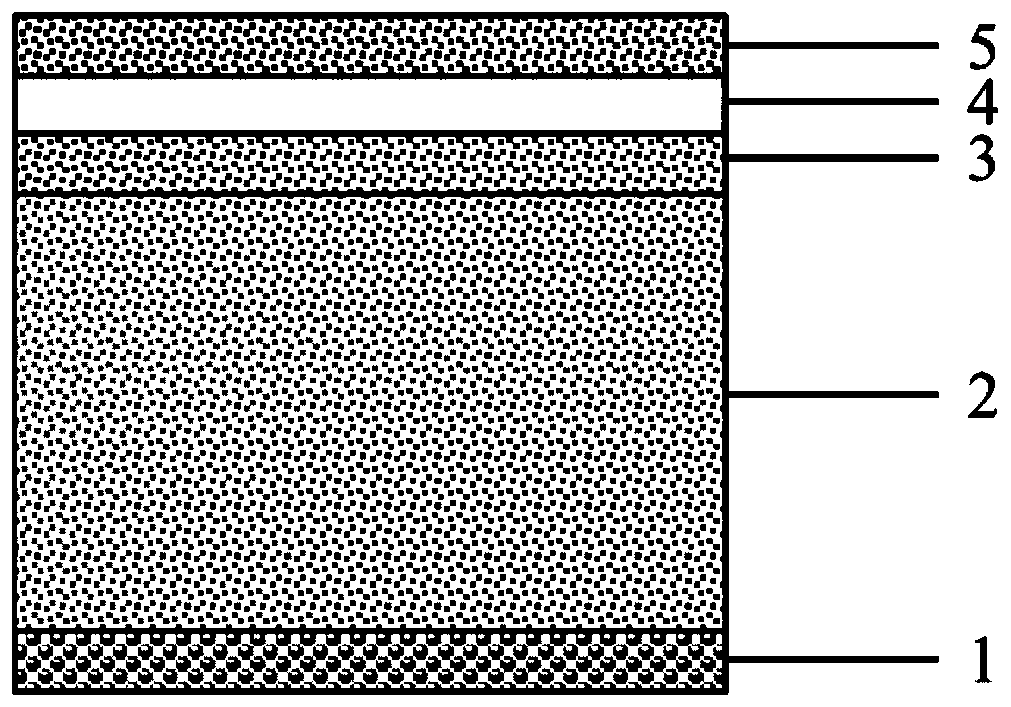

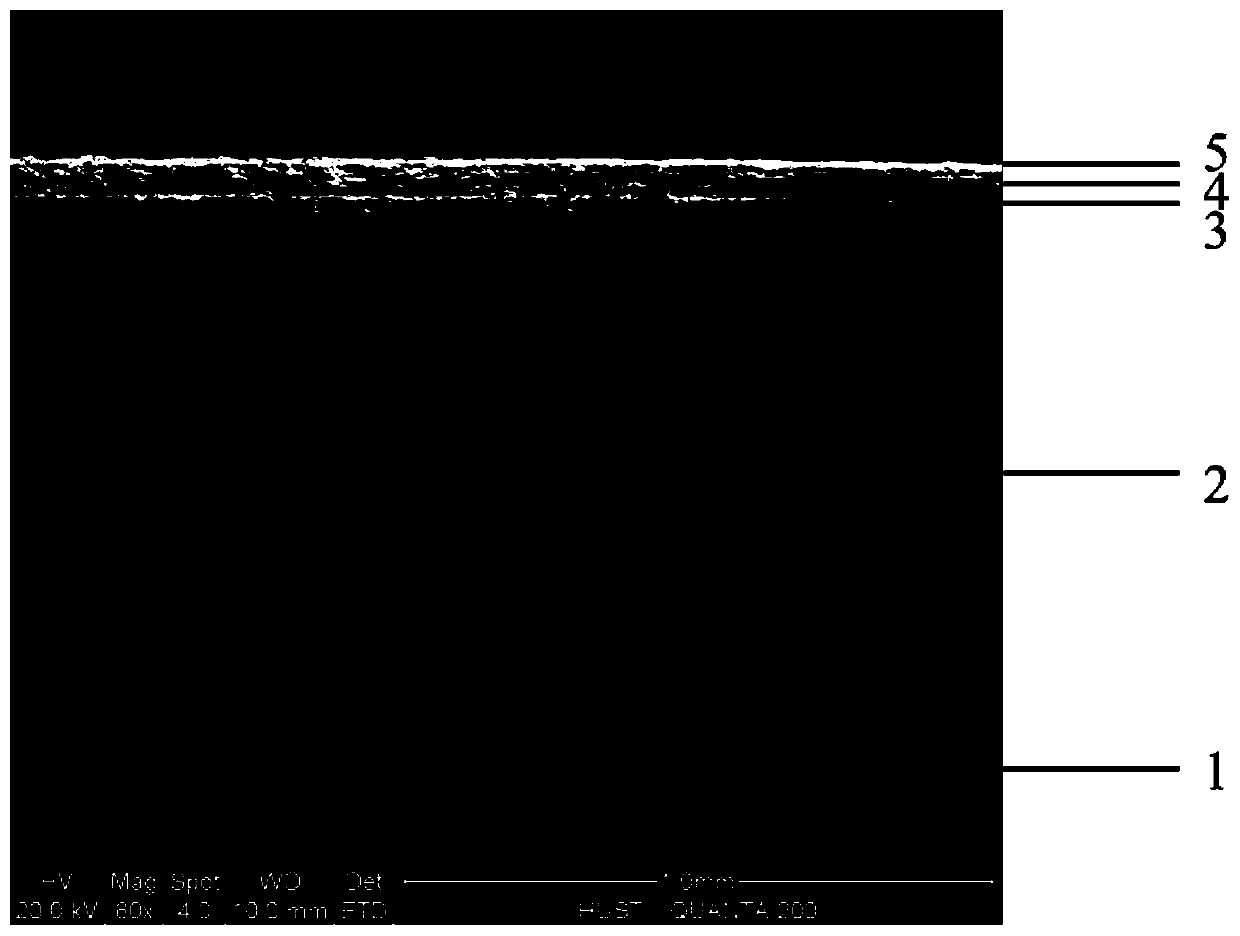

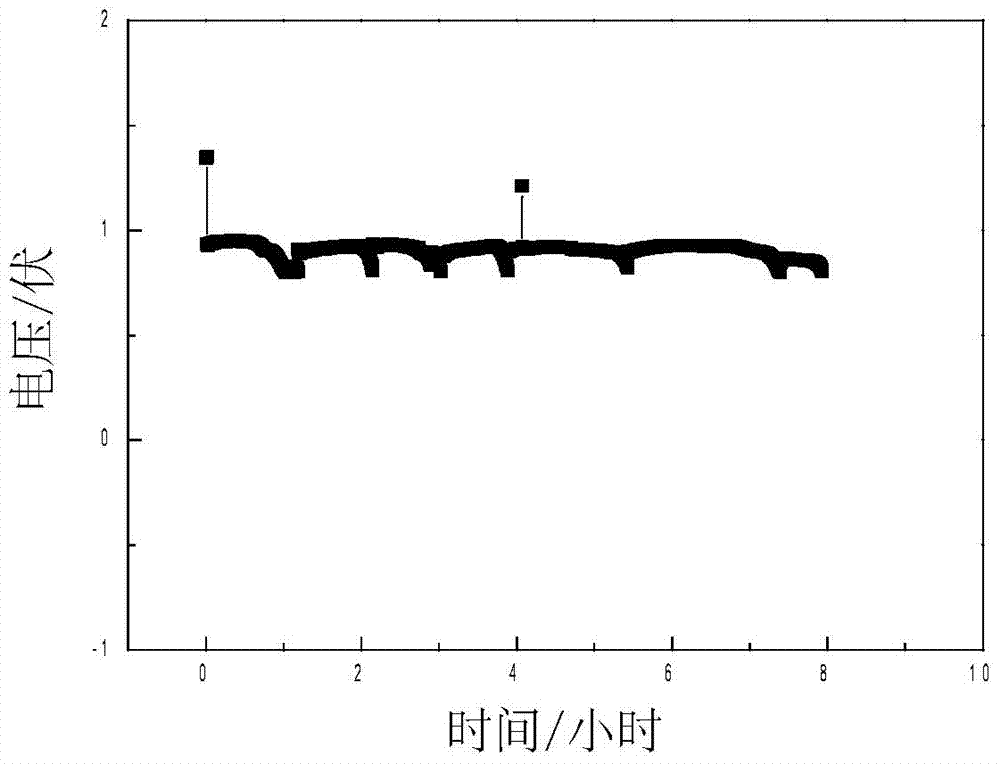

Anti-carbon metal-supported solid oxide fuel cell and preparation method thereof

ActiveCN109904497ALow cost of preparation processBroad application prospectsFinal product manufactureCell electrodesIonOxide

The invention belongs to the technical field of solid oxide fuel cells, and discloses an anti-carbon metal-supported solid oxide fuel cell and a preparation method thereof. The anti-carbon metal-supported solid oxide fuel cell comprises a porous catalytic reforming layer, a porous metal supporting layer, a porous anode functional layer, a dense electrolyte layer and a porous cathode layer which are sequentially and tightly combined; wherein the porous catalytic reforming layer comprises a Ni-M alloy and an oxygen storage-water absorbing oxide; the porous metal supporting layer comprises a Ni-Malloy and MgO; and the porous anode functional layer comprises a Ni-M alloy and a fluorite structural oxide or comprises a Ni-M alloy and a (ionic conductive) perovskite structural oxide. The invention further discloses the preparation method of the corresponding cell. When hydrocarbons are used as fuel, the anti-carbon metal-supported solid oxide fuel cell can operate steadily in a long term inthe hydrocarbon fuel, and the fuel cell has low preparation process cost, is suitable for large-area single cells and scale production and manufacturing, and has broad application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

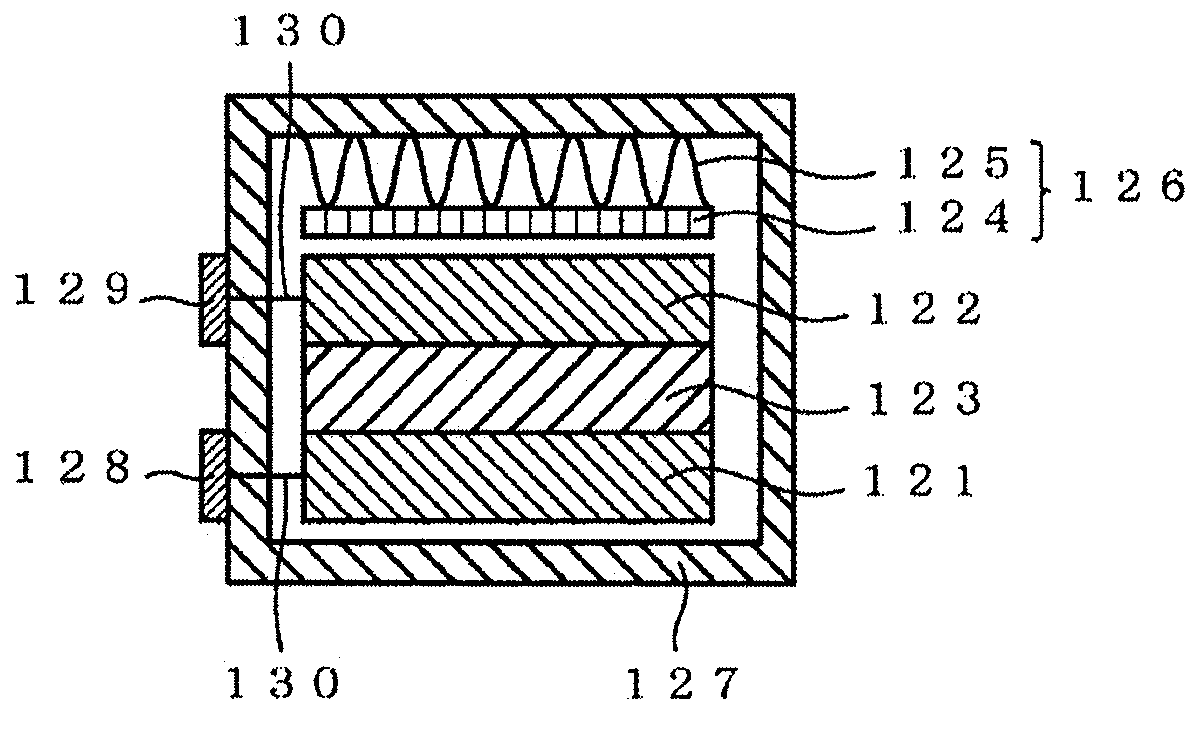

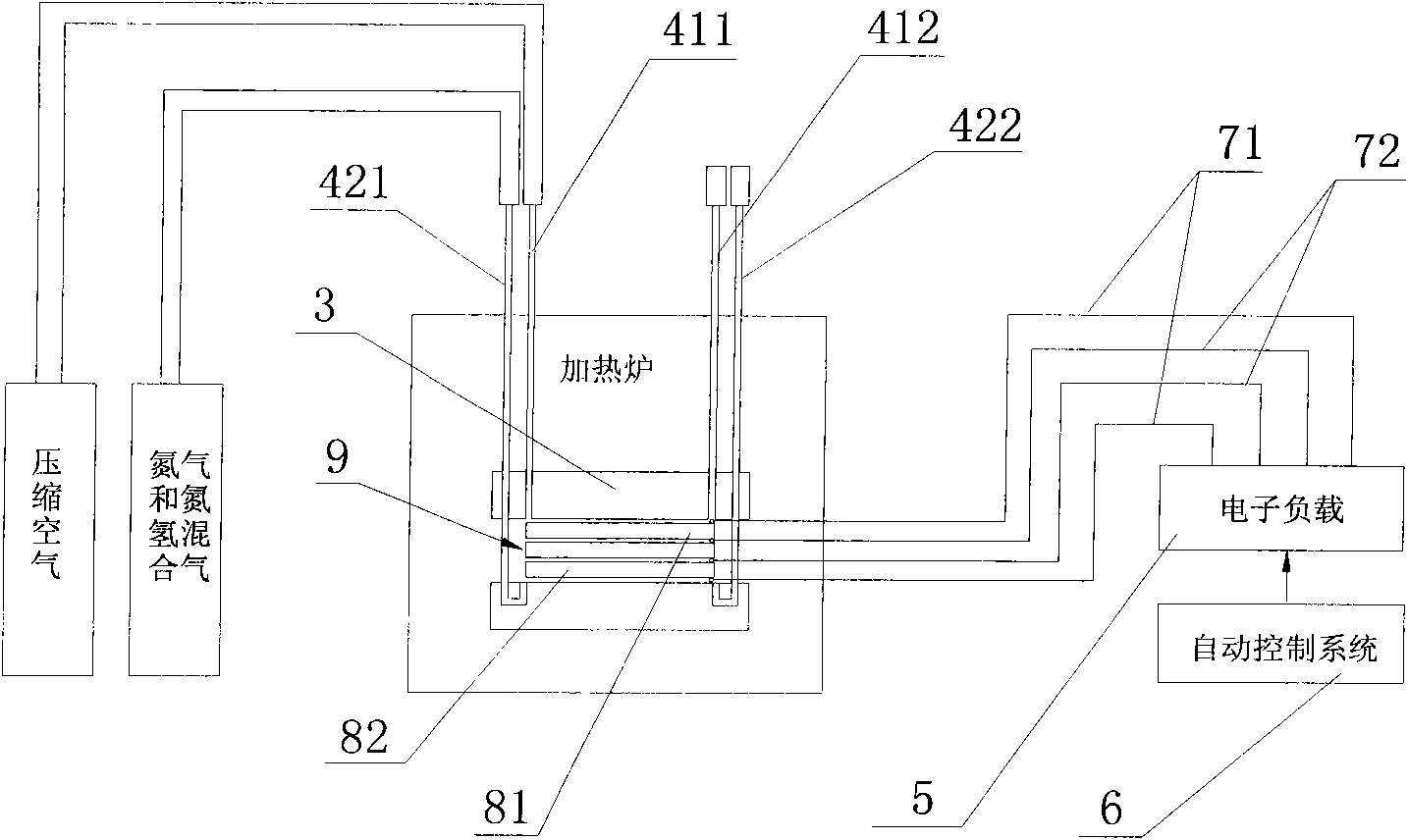

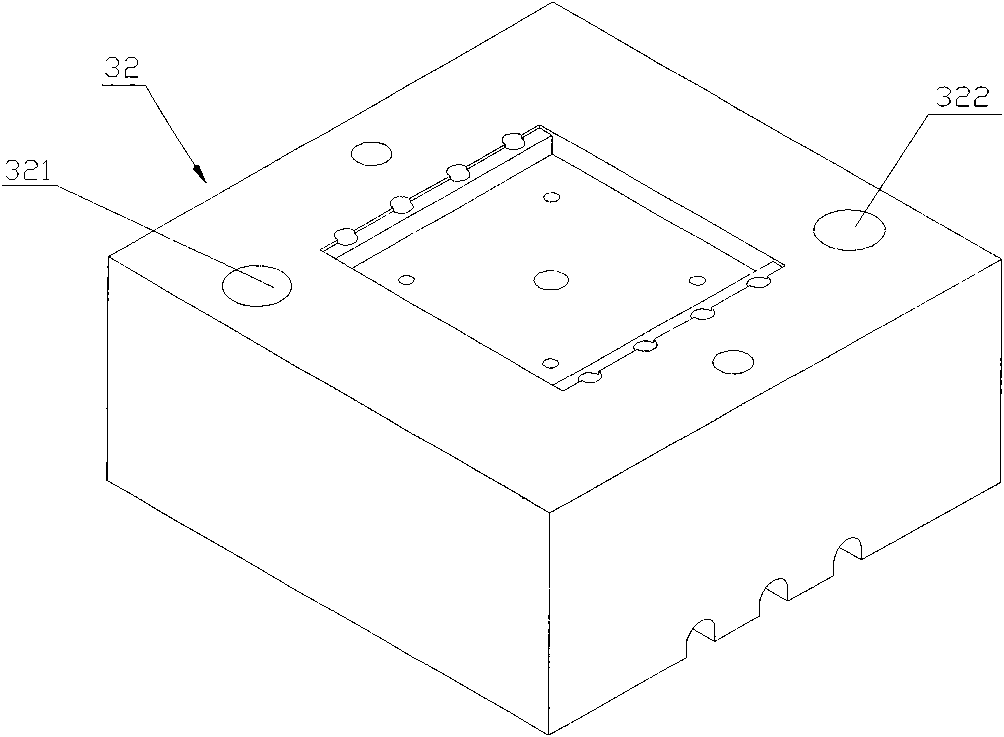

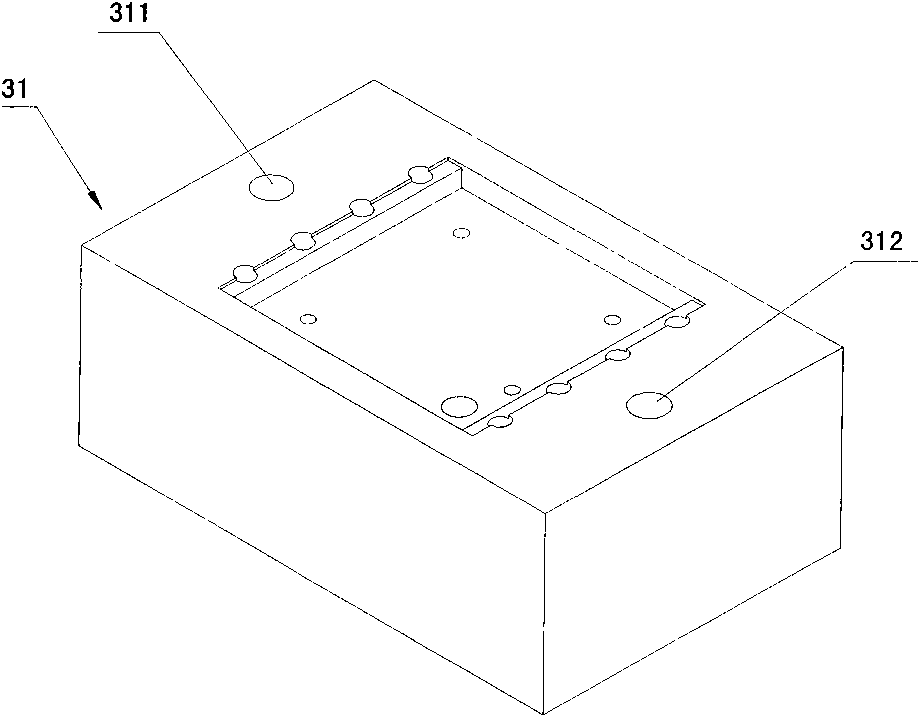

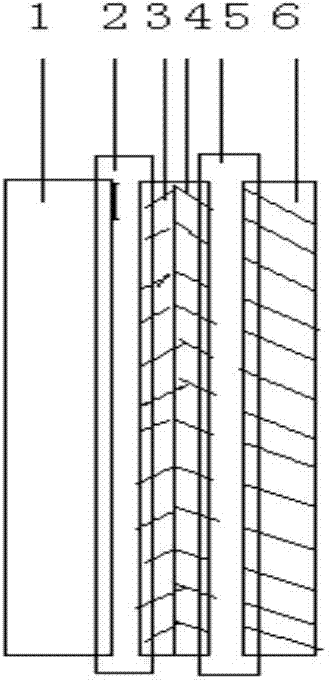

System and method for testing performance of large-area flat-plate SOFC single battery

ActiveCN101614792AConducive to DC discharge testIntegrity guaranteedElectrical testingFluid-tightness measurement using electric meansTest performanceDirect-current discharge

The invention discloses a system and a method for testing an SOFC single battery. The test system comprises an electronic load, a test room, and a single battery sealing member, a Pt sheet and a Ni sheet current collection layer which are arranged in the test room, wherein the Pt sheet and the Ni sheet current collection layer are connected with the electronic load respectively through a first high-temperature resistant conducting wire, the single battery sealing member is connected with the electronic load through a second high-temperature resistant conducting wire, the test room is connected with ventilating pipes of a cathode inlet, a cathode outlet, an anode inlet and an anode outlet, an anode air flow channel of the single battery sealing member adopts a foam nickel air flow channel, and a cathode air flow channel adopts a platinum gauze wrapped LSM air flow channel. The system is characterized in that the platinum gauze wrapped LSM air flow channel is used as the cathode air flow channel of the single battery, the foam nickel air flow channel is used as the cathode air flow channel, and simultaneously a thick silver wire is used as a current lead wire, thus the system reduces the high-temperature contact resistance and the conducting wire resistance, is advantageous for performing direct current discharge test on the single battery, and reduces the voltage obtained in the discharge process of the single battery to less than 0.5 V.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

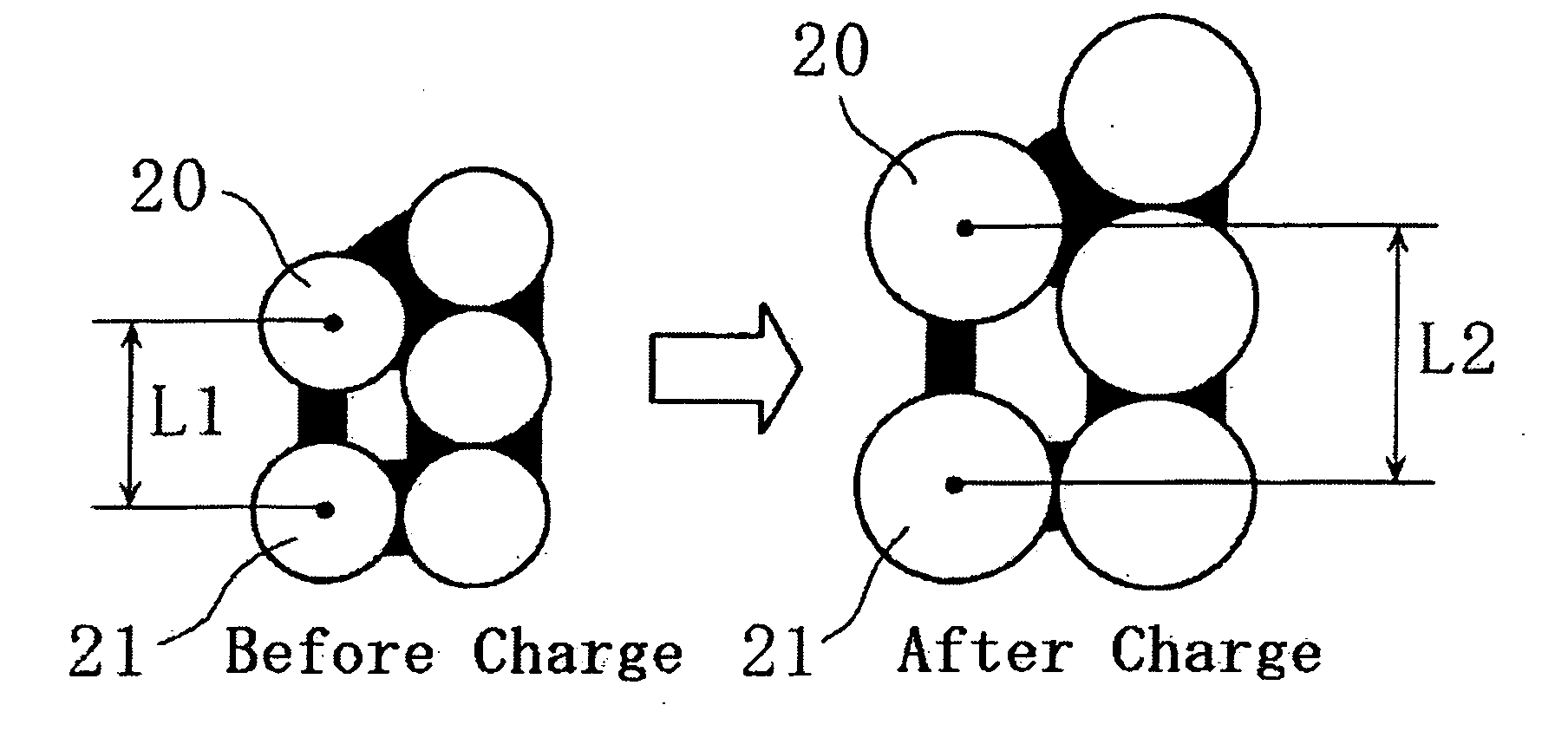

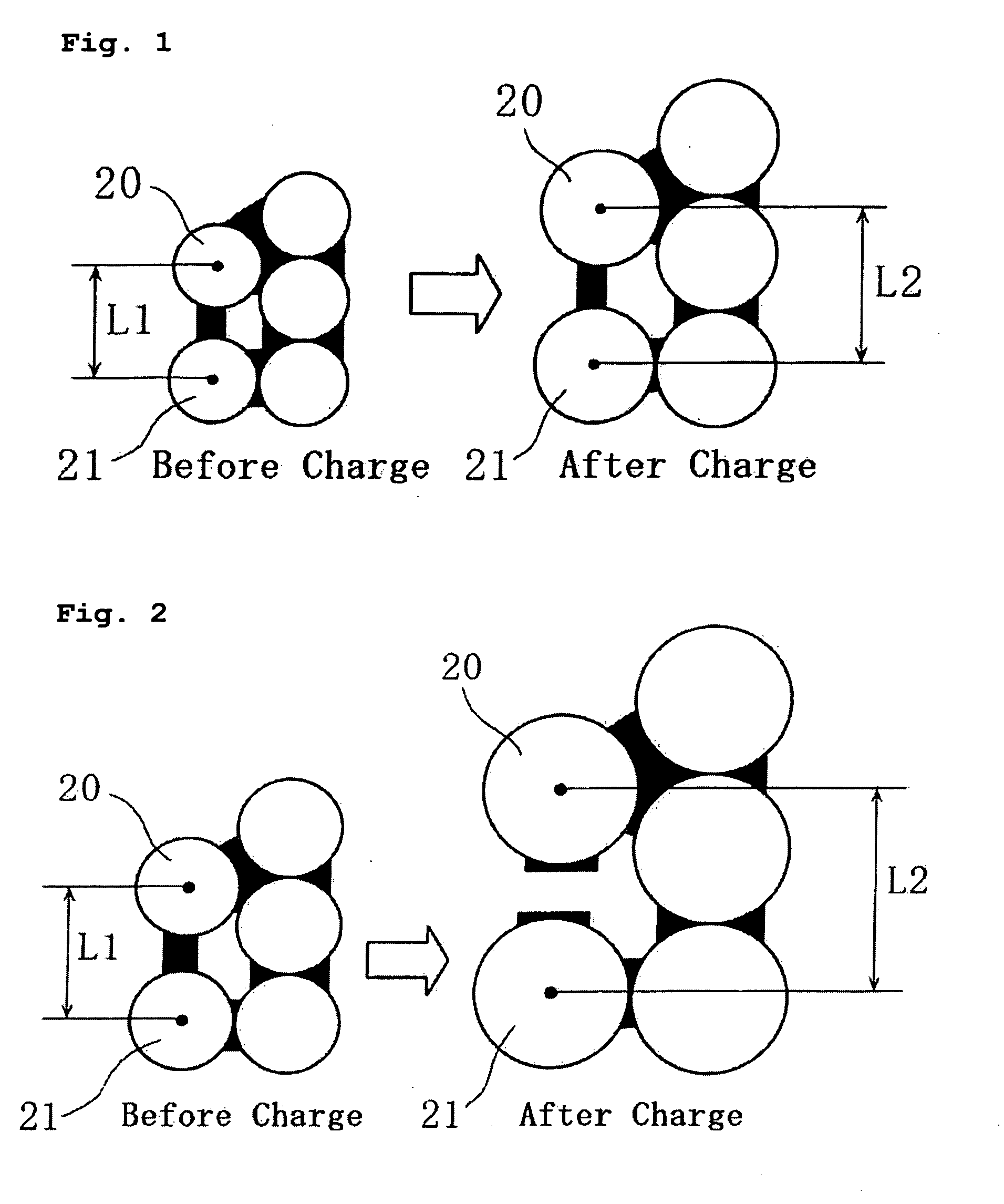

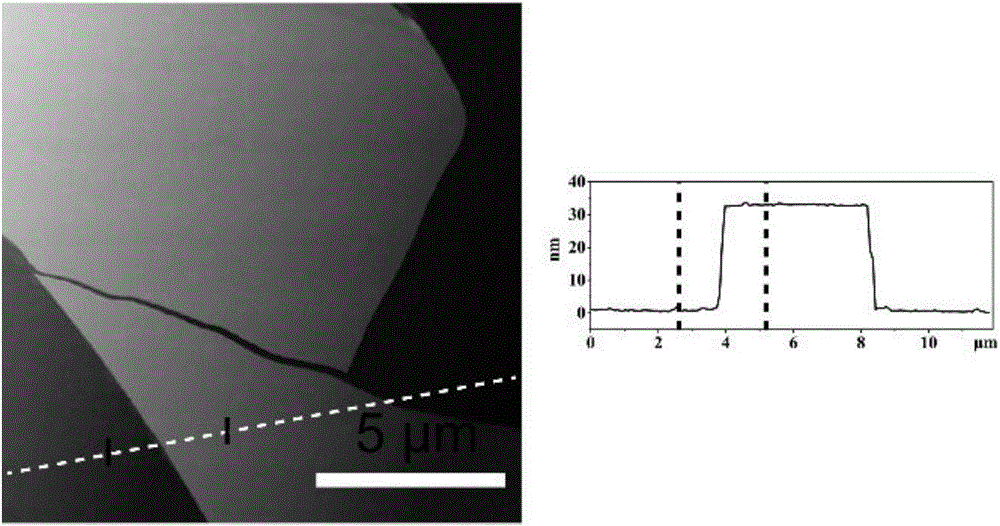

Negative electrode for lithium secondary batteries and lithium secondary battery

InactiveUS20100330424A1Alleviate stressPrevent peelingElectrode carriers/collectorsActive material electrodesCurrent collectorMaterials science

A negative electrode (2) for a lithium secondary battery having a negative electrode current collector (21) having an arithmetical mean surface roughness Ra of 0.01 μm or greater and a negative electrode active material layer (22) formed on the negative electrode current collector (21). The negative electrode active material layer (22) contains a negative electrode active material (22a) including a material capable of alloying with lithium. A conductive layer (23) including a material not intercalating or deintercalating lithium is formed on the negative electrode active material layer.

Owner:SANYO ELECTRIC CO LTD

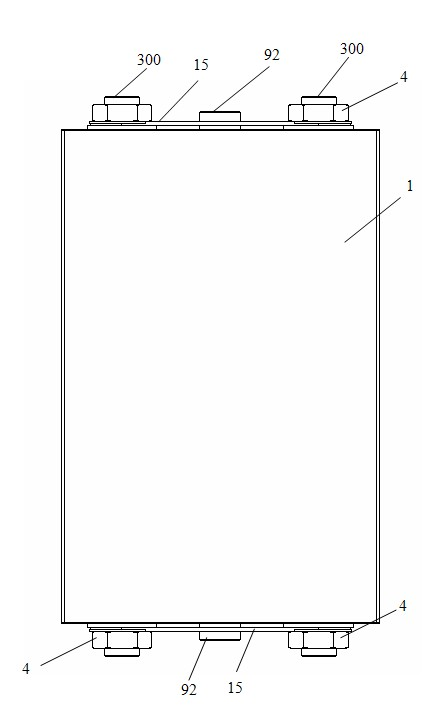

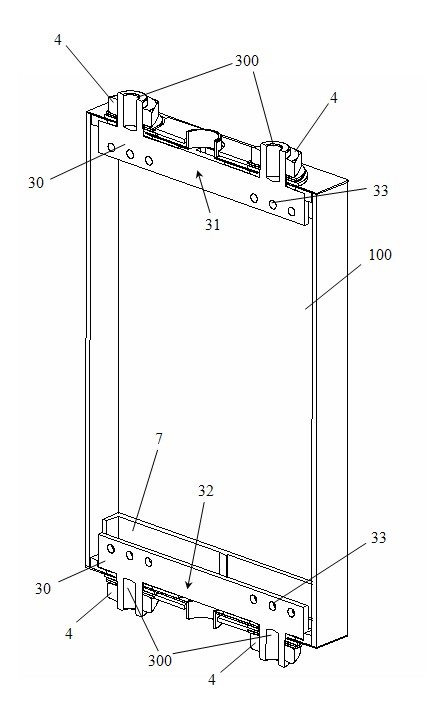

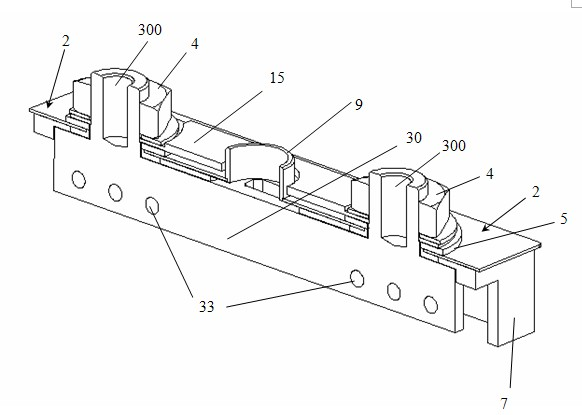

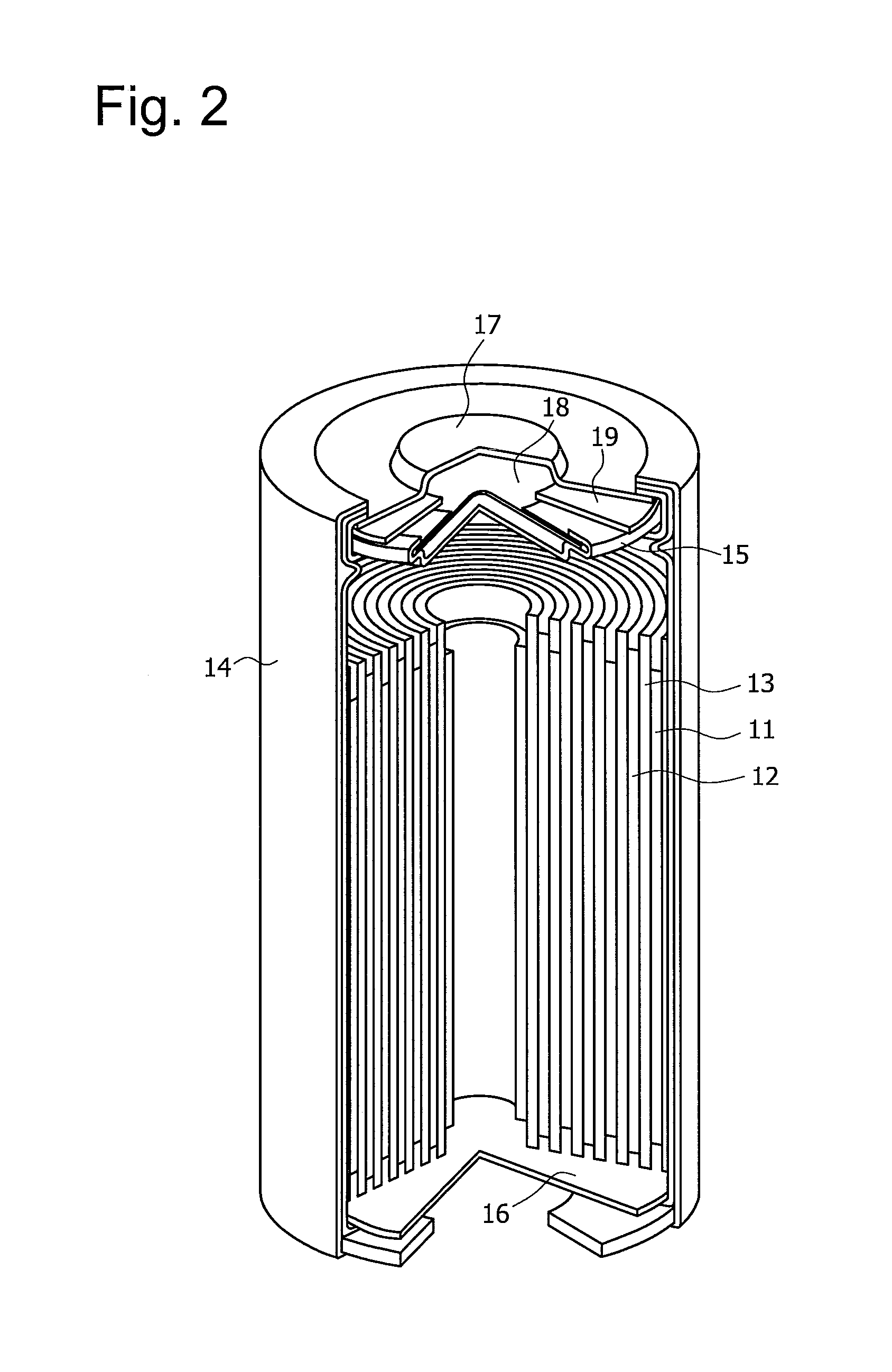

Lithium ion power battery with bidirectional current collectors

InactiveCN102013513AIncrease energy densityImprove rate discharge performanceElectrode carriers/collectorsSecondary cellsLithiumPower battery

The invention discloses a lithium ion power battery with bidirectional current collectors, which comprises a battery case (1). A battery core electrode group (100) is arranged in the battery case (1). An anode current collector (31) and a cathode current collector (32) are fixedly arranged at the upper and lower ends of the battery core electrode group (100) respectively. Cylindrical terminal posts (300) are arranged at the left and right ends of each of the anode current collector (31) and the cathode current collector (32) respectively. Battery covers (2) are arranged on the outer surfaces of the anode current collector (31) and the cathode current collector (32). The lithium ion power battery with the bidirectional current collectors adopts bidirectionally led-out external current collector structures, realizes a shortest current path and uniform current density, has increased energy density, improved rate discharge performance and relatively better current collection effect, and can be widely applied in the field of traffic and transportation.

Owner:TIANJIN LISHEN BATTERY

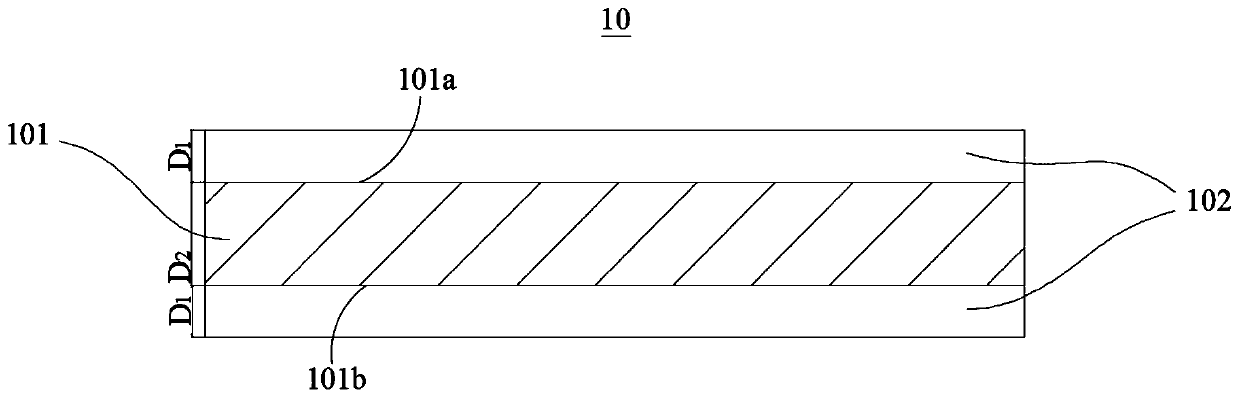

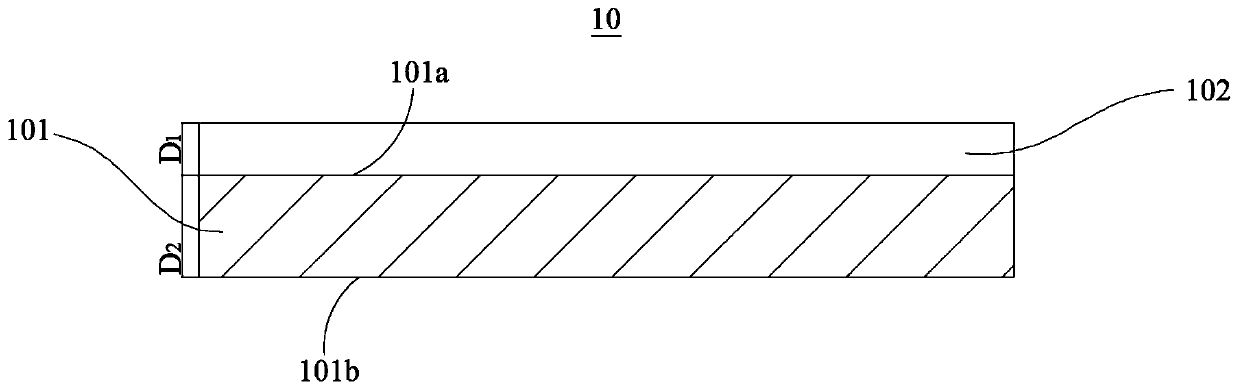

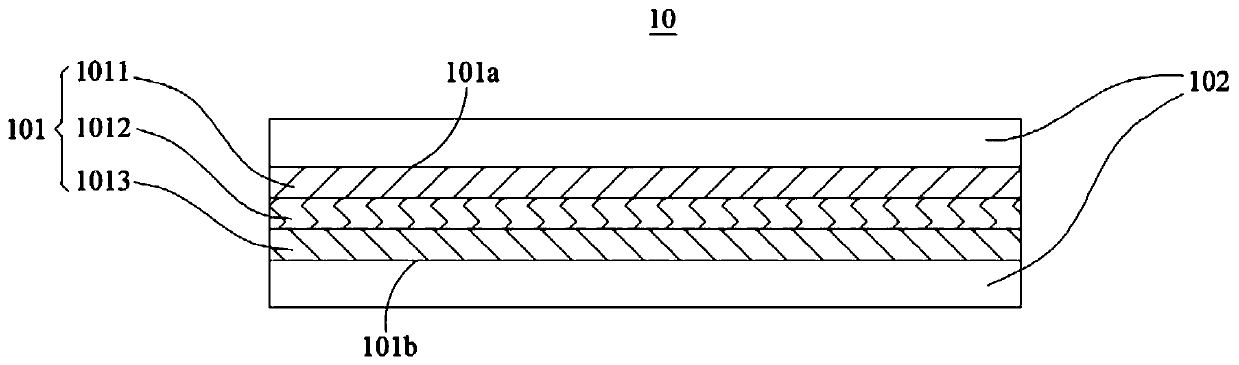

Negative current collector, negative pole piece and electrochemical device

ActiveCN110943224AIncreased gravimetric energy densityImprove conductivityFinal product manufactureElectrode carriers/collectorsElectrical resistance and conductanceEngineering

The invention discloses a negative current collector, a negative pole piece and an electrochemical device. The negative current collector comprises a support layer and a conductive layer arranged on at least one of two opposite surfaces in the thickness direction of the support layer, wherein the density of the support layer is smaller than that of the conductive layer; the thickness D1 of the conducting layer is larger than or equal to 300 nm and smaller than or equal to 2 micrometers, and preferably, D1 is larger than or equal to 500 nm and smaller than or equal to 1.5 micrometers. When thetensile strain of the negative current collector is 1.5%, the square resistance growth rate T of the conductive layer is less than or equal to 5%. The negative electrode current collector provided bythe invention can simultaneously consider low weight and good conductivity and current collection performance, so that the electrochemical device can simultaneously consider relatively high weight energy density and good comprehensive electrochemical performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Three-dimensional network aluminum porous body for current collector, electrode using the aluminum porous body, and nonaqueous electrolyte battery, nonaqueous electrolytic solution capacitor and lithium-ion capacitor each using the electrode

InactiveUS20120315540A1Improve the effect of current collectionReduce usageHybrid capacitor electrodesFinal product manufactureIn planeElectric resistivity

It is an object of the present invention to provide an aluminum porous body for a current collector in which electric resistivity is reduced to enhance current collecting performance, and an electrode, a nonaqueous electrolyte battery, a capacitor and a lithium-ion capacitor each using the aluminum porous body for a current collector. Such a sheet-shaped three-dimensional network aluminum porous body of the present invention is a three-dimensional network aluminum porous body for a current collector including an electric resistivity in an in-plane direction and in a thickness direction of 0.5 mΩcm or less. An electrode can be configured by using the three-dimensional network aluminum porous body for a current collector, and further a nonaqueous electrolyte battery, a capacitor and a lithium-ion capacitor can be configured by using the electrode.

Owner:SUMITOMO ELECTRIC IND LTD +1

Method for preparing anode of high-power nickel-hydrogen battery

InactiveCN102263255ALower internal resistanceShorten the activation periodAlkaline accumulator electrodesPowder mixtureNickel substrate

The invention discloses a method for preparing the anode of a high-power nickel-hydrogen battery. The method comprises the following steps: a) weighing a fixed quantity of an active substance; b) adding a defined amount of nanometer-scale conductive agent to the active substance, mixing and stirring the nanometer-scale conductive agent and the active substance to form a powder mixture; c) placing the powder mixture into an ultrasonic dispersion machine for ultrasonic vibration so that the nanometer-scale conductive agent is uniformly absorbed on the surface of the active substance; d) filling the powder mixture onto a foam nickel substrate in a physical filling manner; and e) spot-welding current collectors on the foam nickel substrate to finally obtain the anode. The nanometer-scale conductive agent is added to anode material, thereby reducing the internal resistance of the battery, efficiently promoting the conducting efficiency of an anode, promoting the high-power discharging property of the battery, shortening the activating period of the battery and improving the consistency of the battery.

Owner:QUANZHOU JINTION ELECTRONICS

Cathode carrier of lithium thionyl chlorine cell

InactiveCN1649194AImprove conductivityChange the mechanical structureElectrode carriers/collectorsLithiumAdhesive

This invention relates to a Li sub-battery cathode carrier. Composition and content of the slurry include 3-9 acetylene black, 0.2-1.5 Cu-electrolyte powder and 20-120 adhesives. The prepared-slurry is pressed to format or stacked on an under-pan to be caked and foamed for at least 15h under 180deg.C-200deg.C to increase its mechanical structure performance of the cathode carrier.

Owner:武汉孚特电子科技有限公司

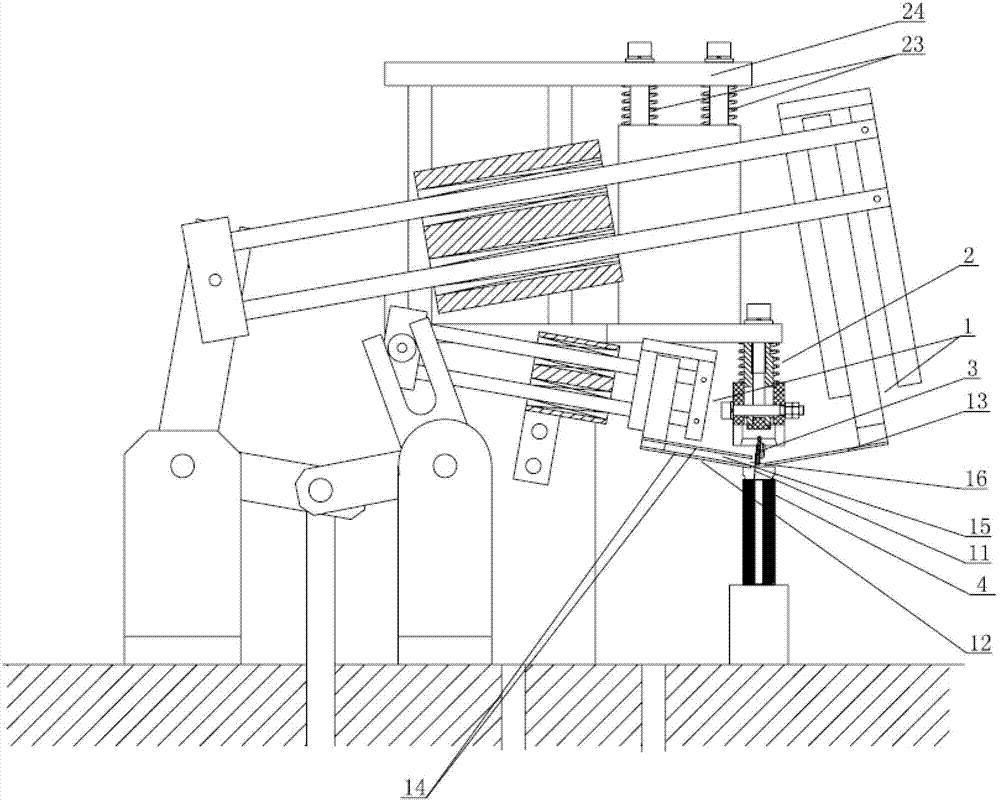

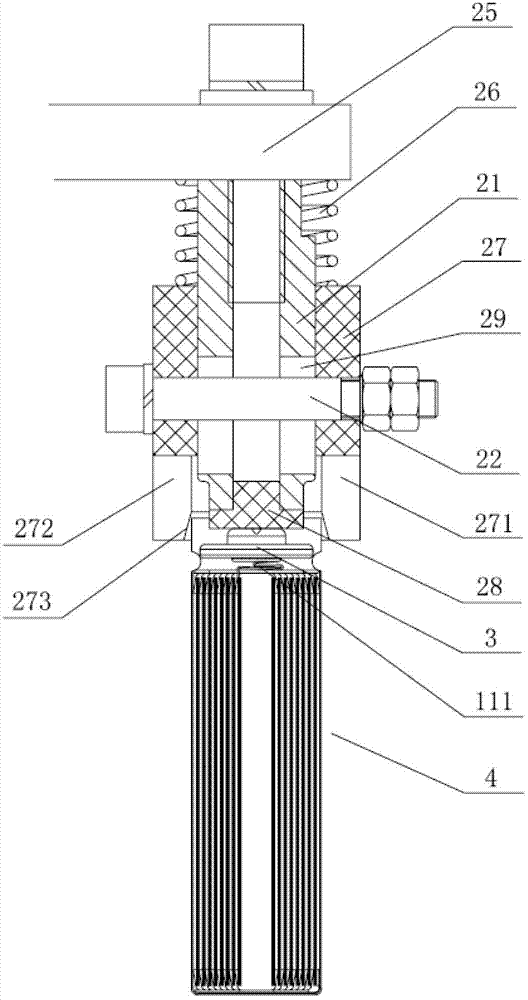

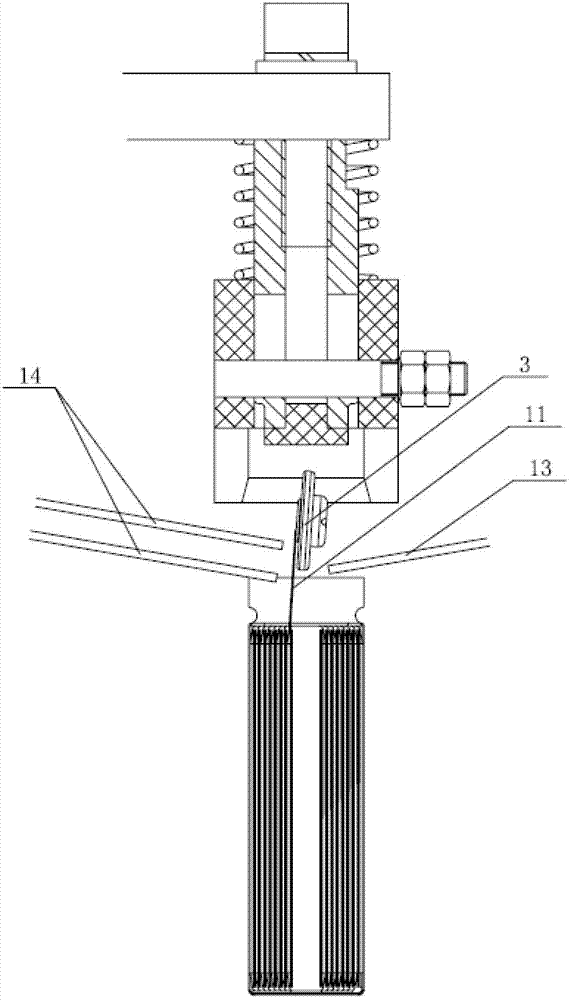

Anode lug bending and sealing body press-in device for cylindrical lithium battery

ActiveCN103050735AGuaranteed discharge capacityImprove sealingFinal product manufactureCell component detailsEngineeringControllability

The invention discloses an anode lug bending and sealing body press-in device for a cylindrical lithium battery, which is characterized by comprising an anode lug bending mechanism and a press-in mechanism, wherein the press-in mechanism is positioned right above a sealing port to be pressed in; the anode lug bending mechanism comprises a limiting assembly and an ejecting and pressing rod; the limiting assembly is positioned at one side of an anode lug; the ejecting and pressing rod is positioned at the other side of the anode lug; the limiting assembly is provided with a space for accommodating the bent anode lug; the space is provided with an opening which is towards the anode lug; and in the bending process, the anode lug is ejected and pressed by the ejecting and pressing rod to generate bending deformation and the bent anode lug enters the space from the opening. The anode lug bending and sealing body press-in device for the cylindrical lithium battery has the advantages that the device has good controllability; after the anode lug is bent and the sealing body is pressed into a steel shell of the battery, the anode lug is generally of an S shape; the battery leakage phenomenon caused by the case the anode lug is clamped between the steel shell of the battery and a sealing ring is avoided; the anode lug has a good current collecting effect; discharge capacity of the lithium battery can be effectively ensured; and the produced lithium battery has good sealing performance.

Owner:ZHONGYIN NINGBO BATTERY CO LTD

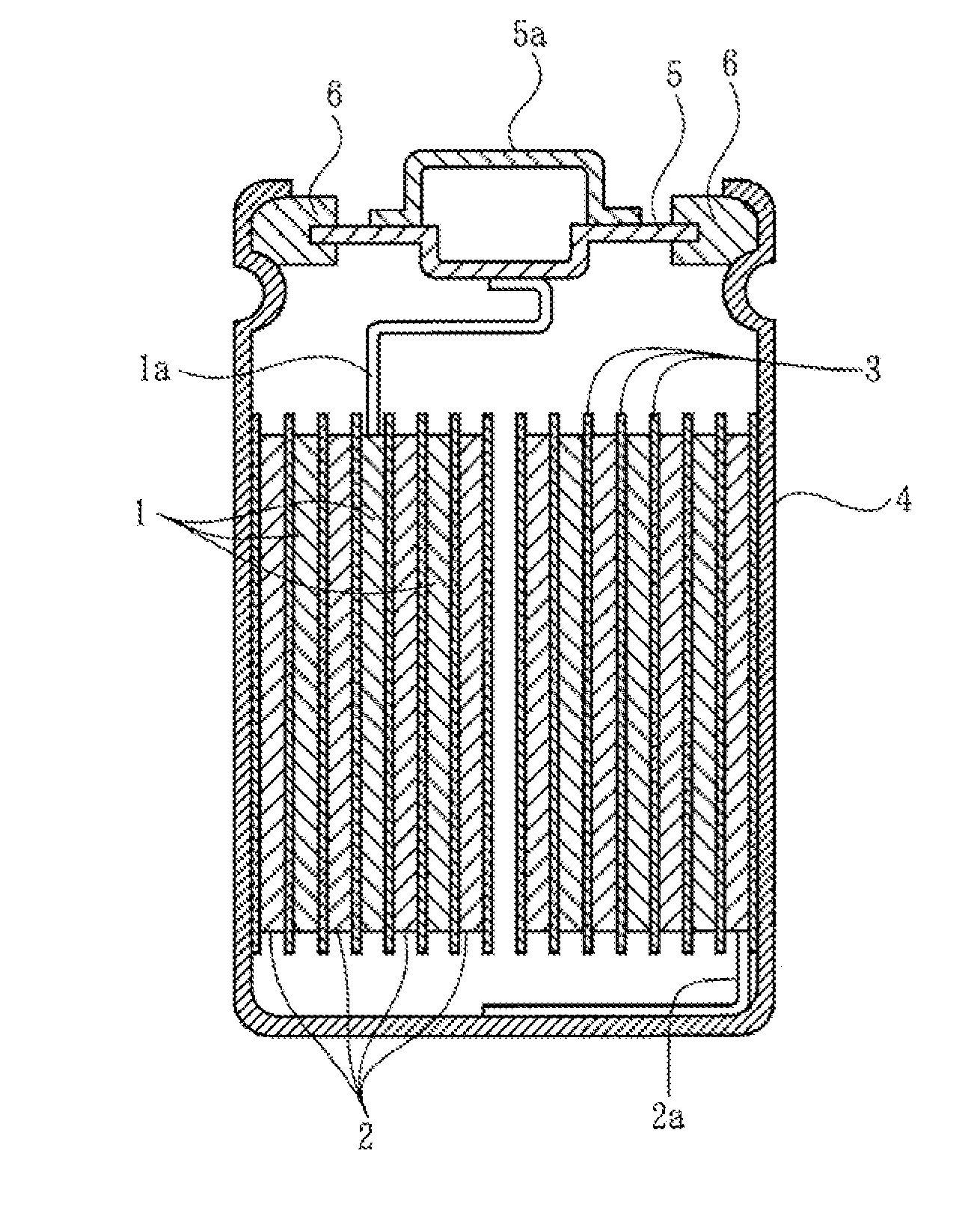

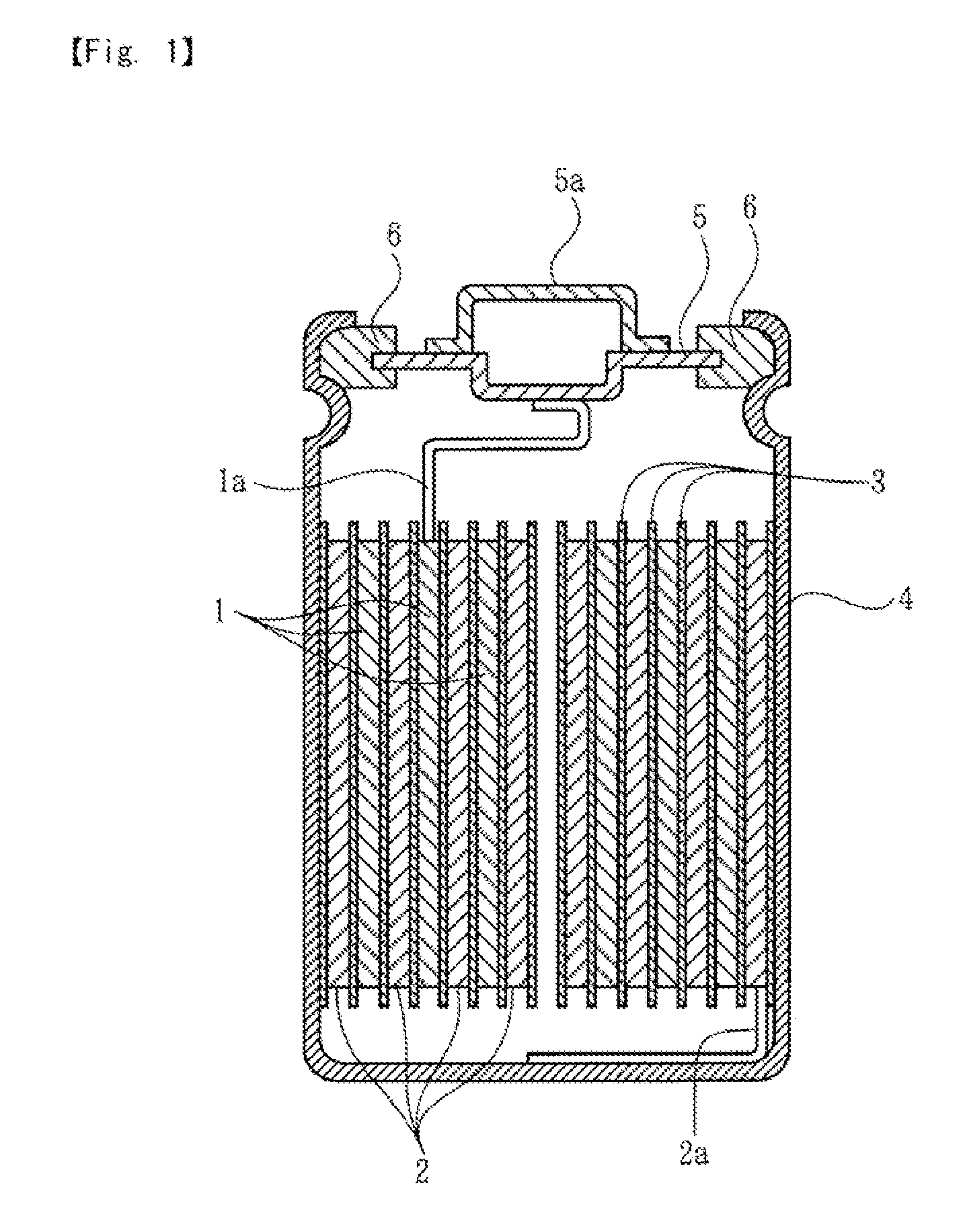

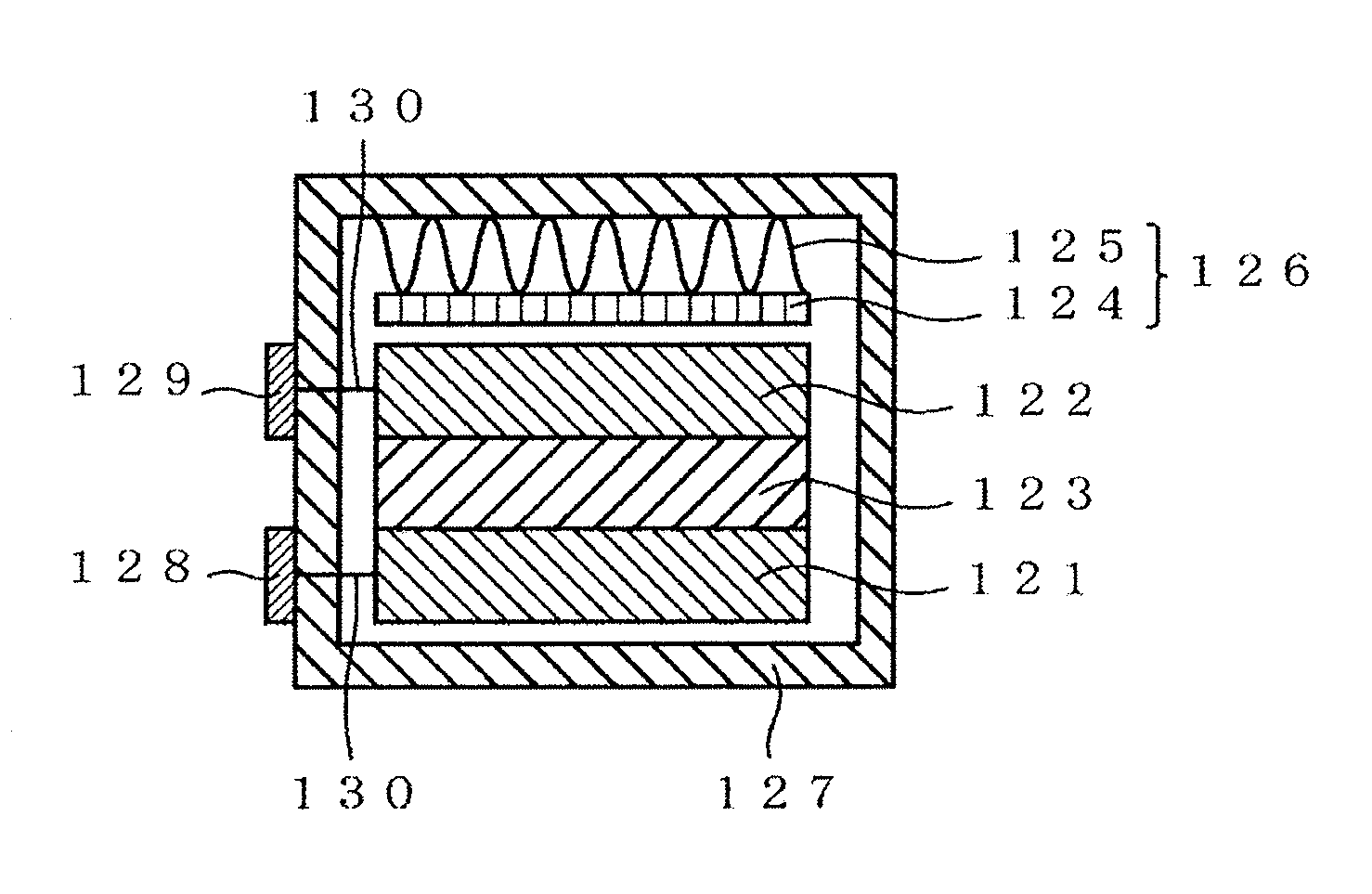

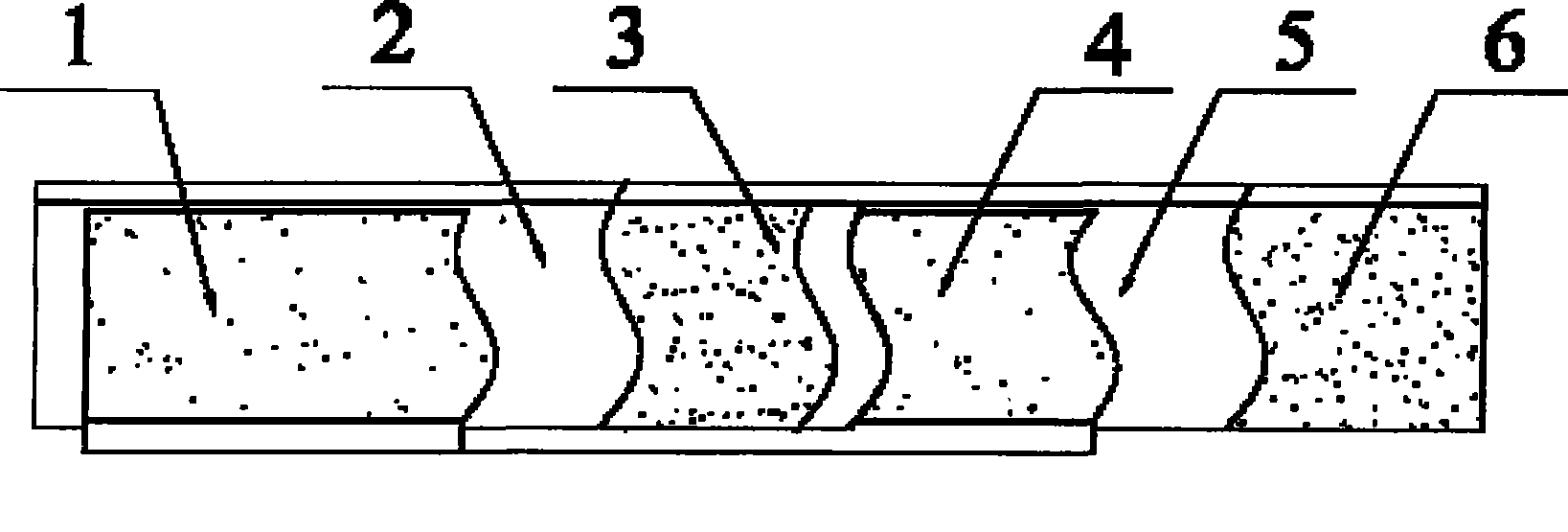

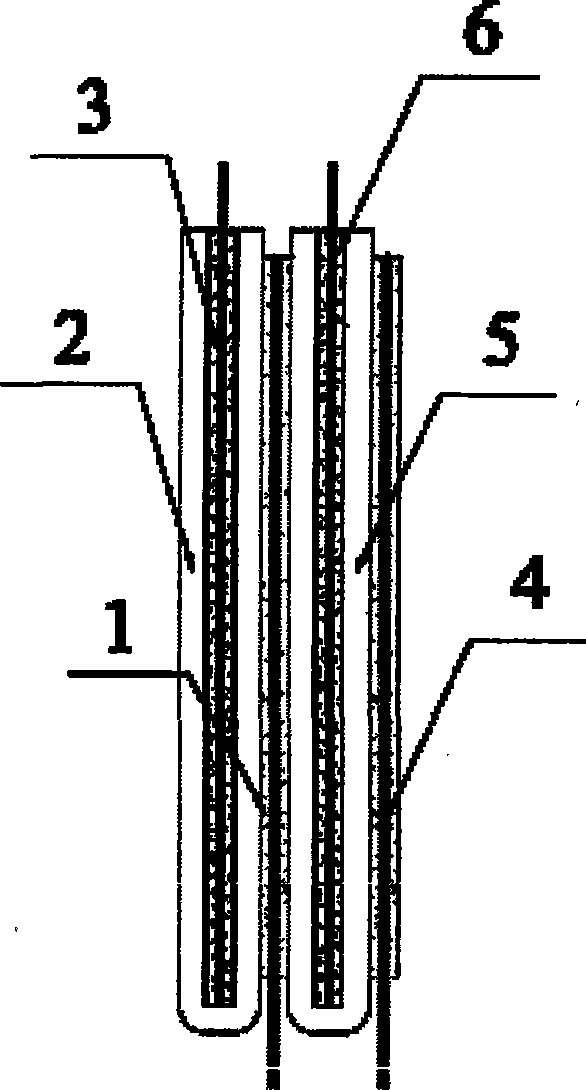

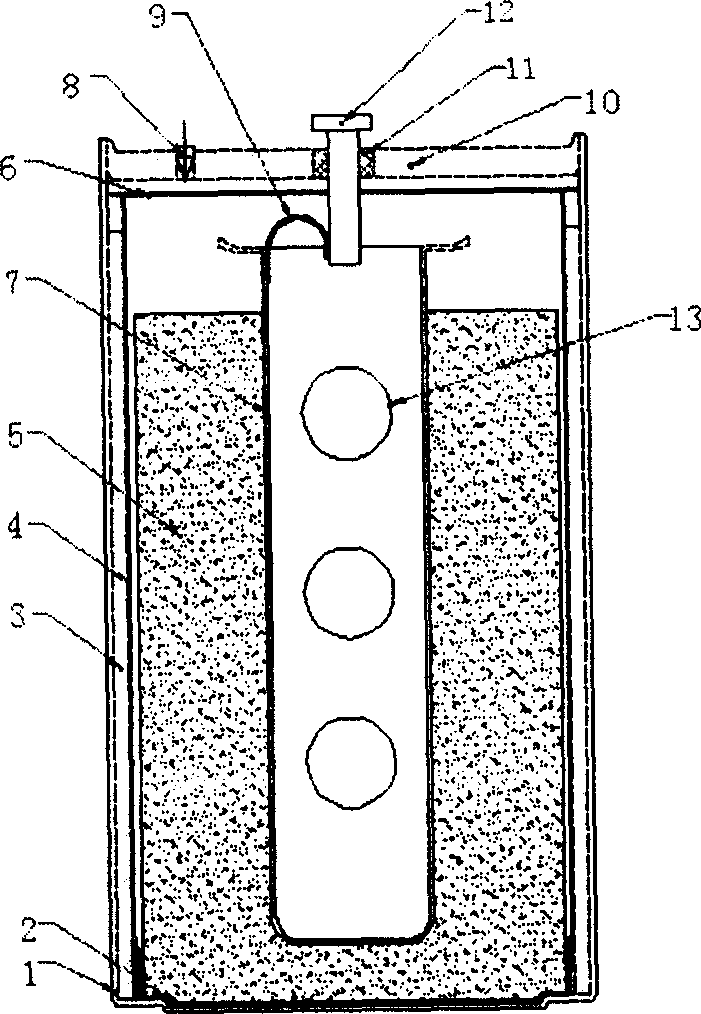

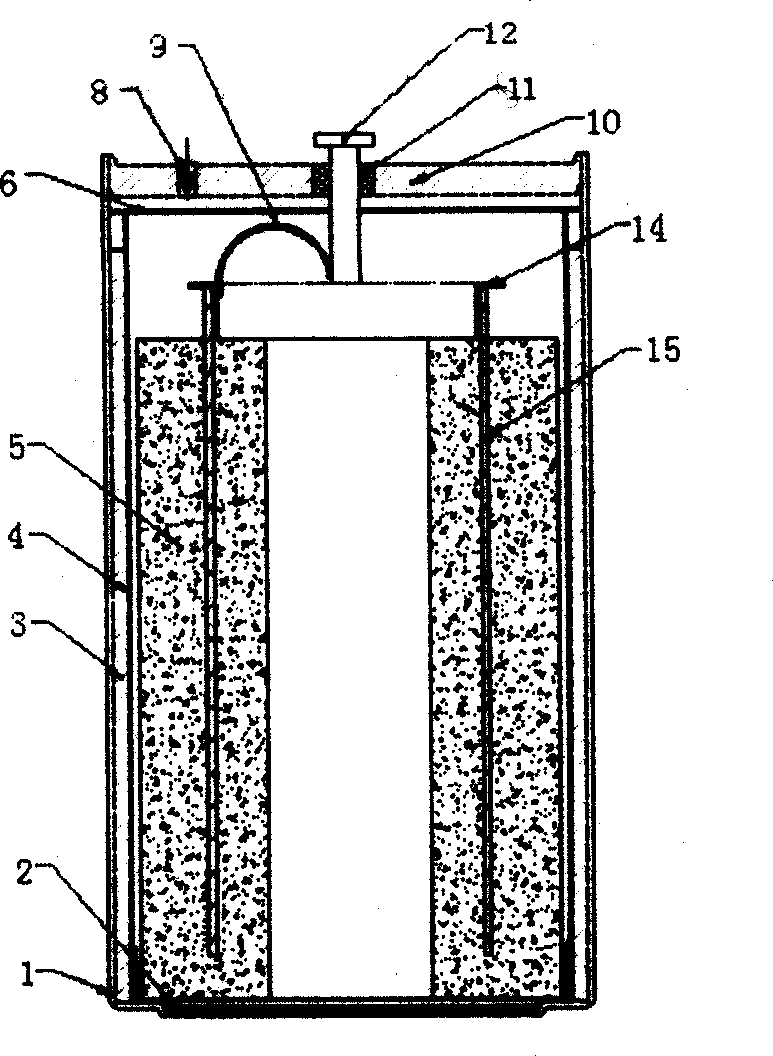

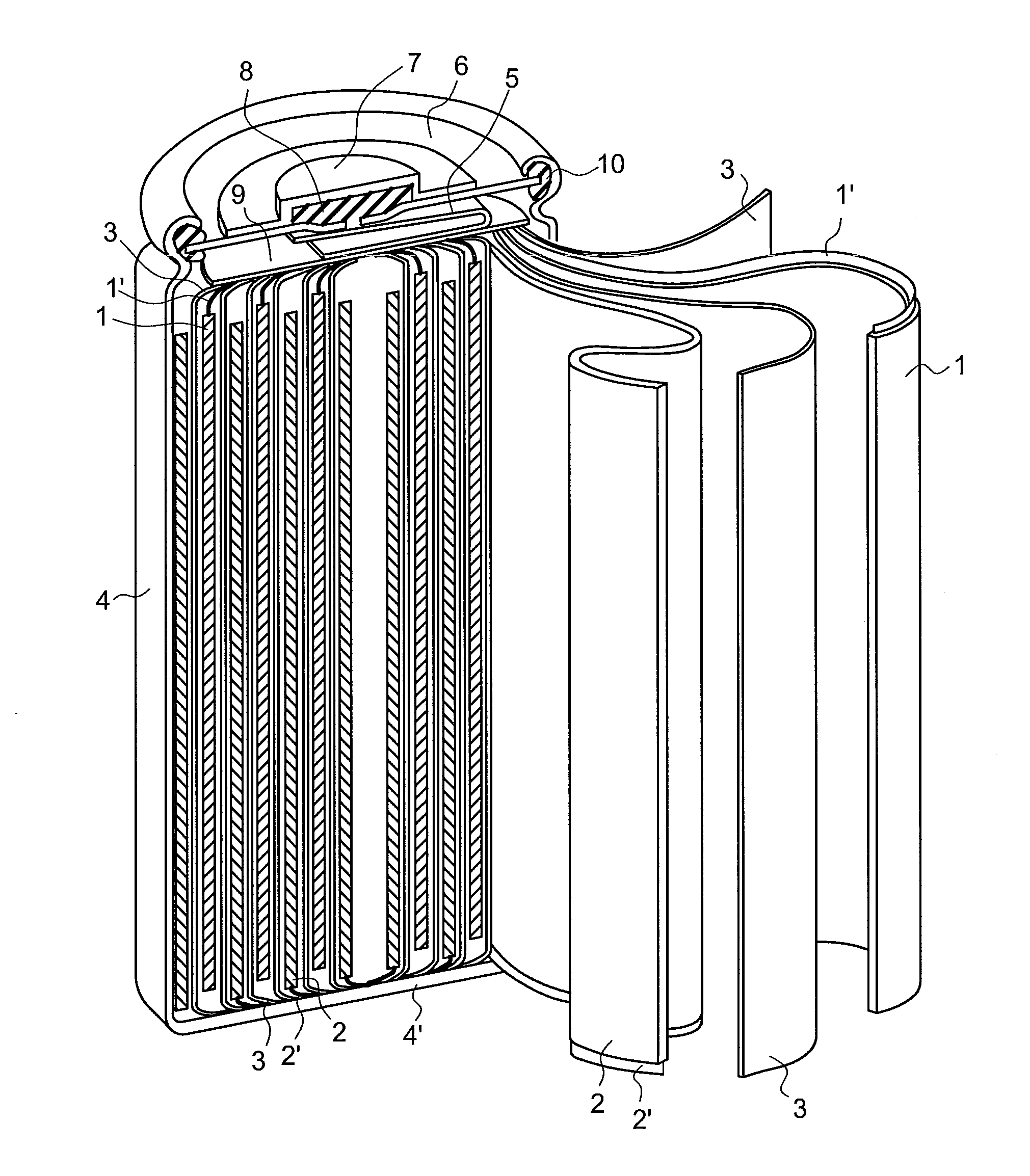

New-type Ni-MH power battery

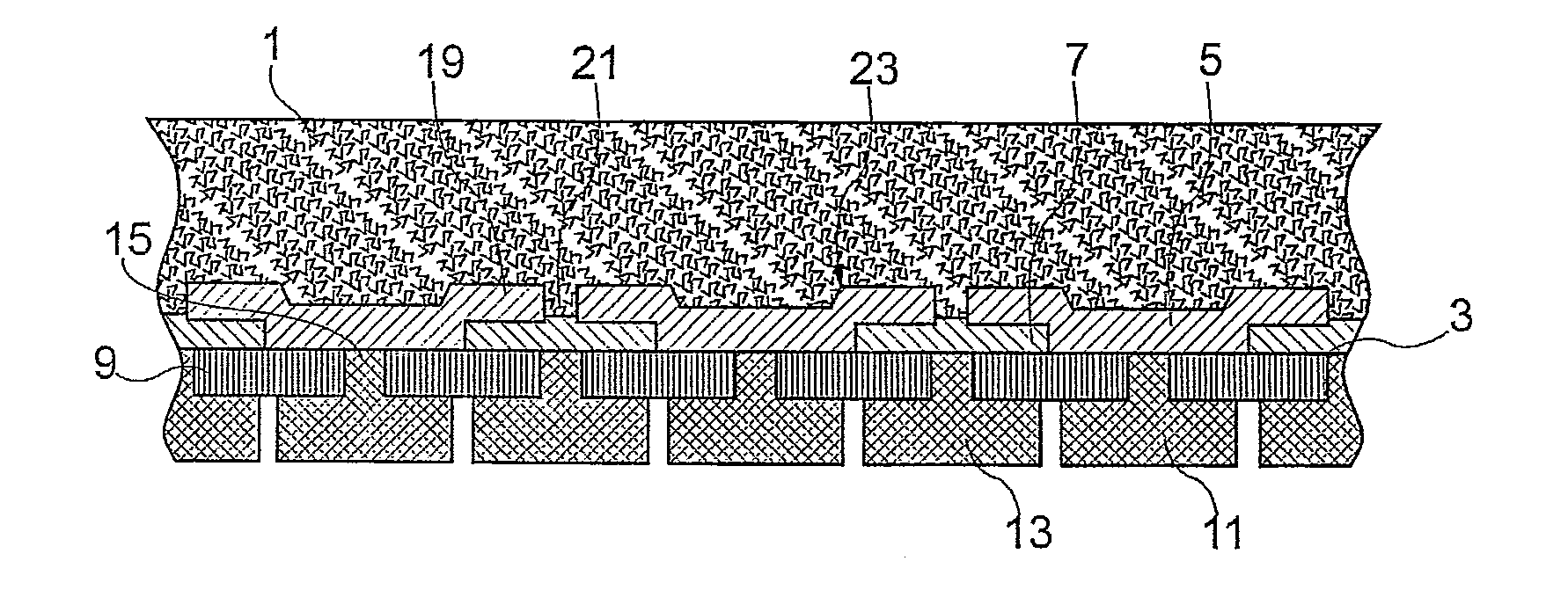

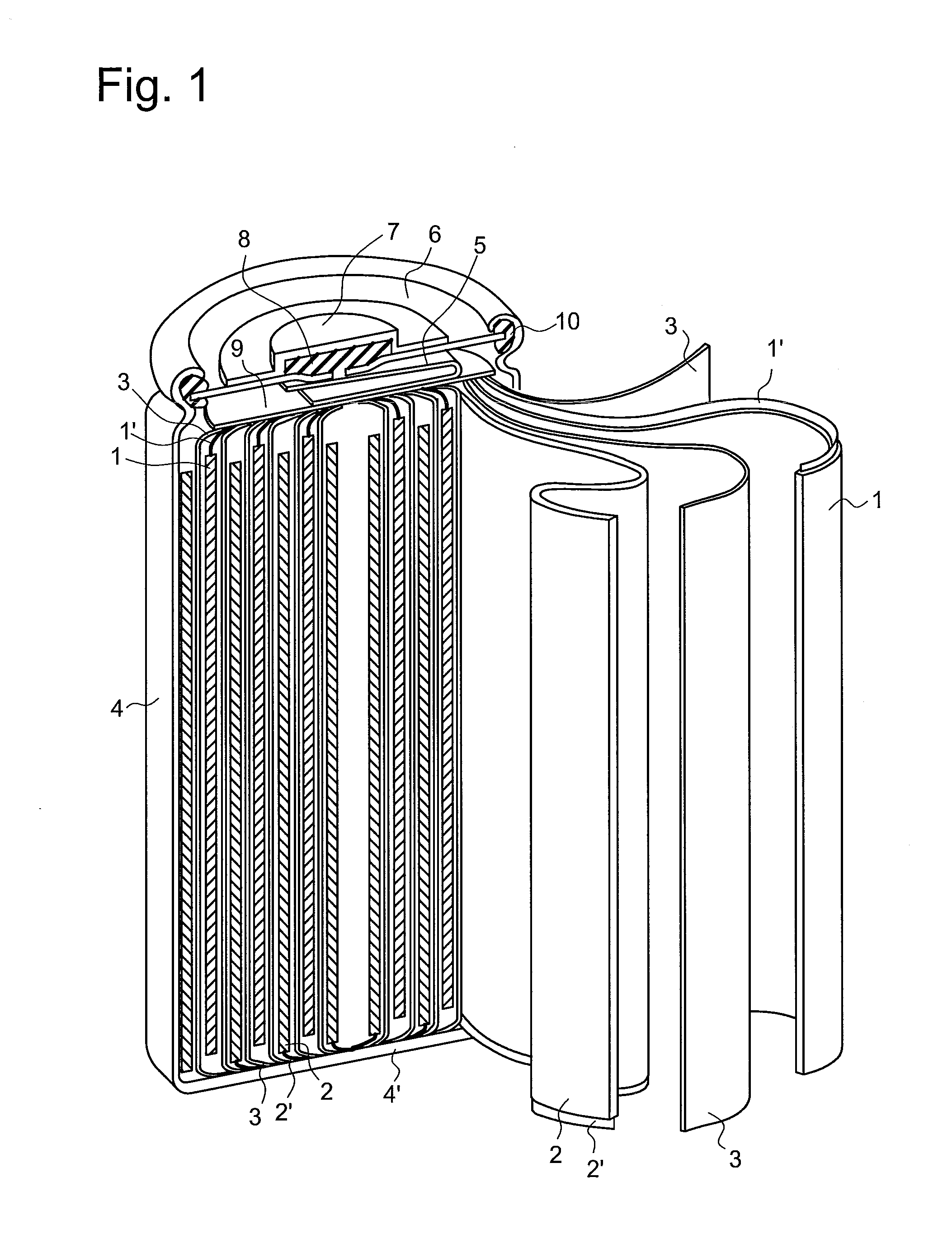

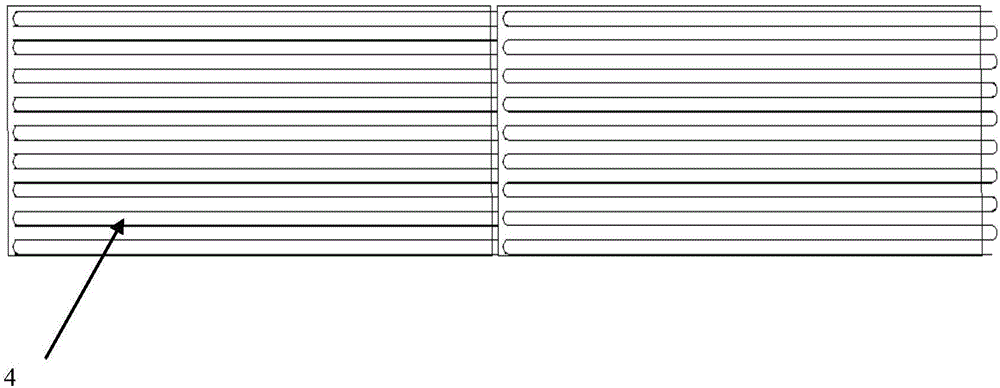

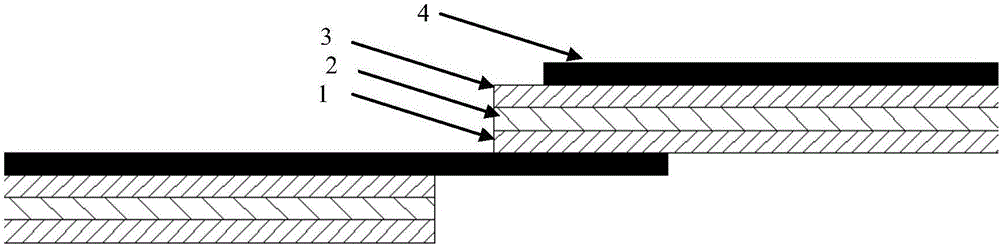

InactiveUS20060154142A1Improve the effect of current collectionSimple processFinal product manufactureElectrode carriers/collectorsPower batteryElectrical conductor

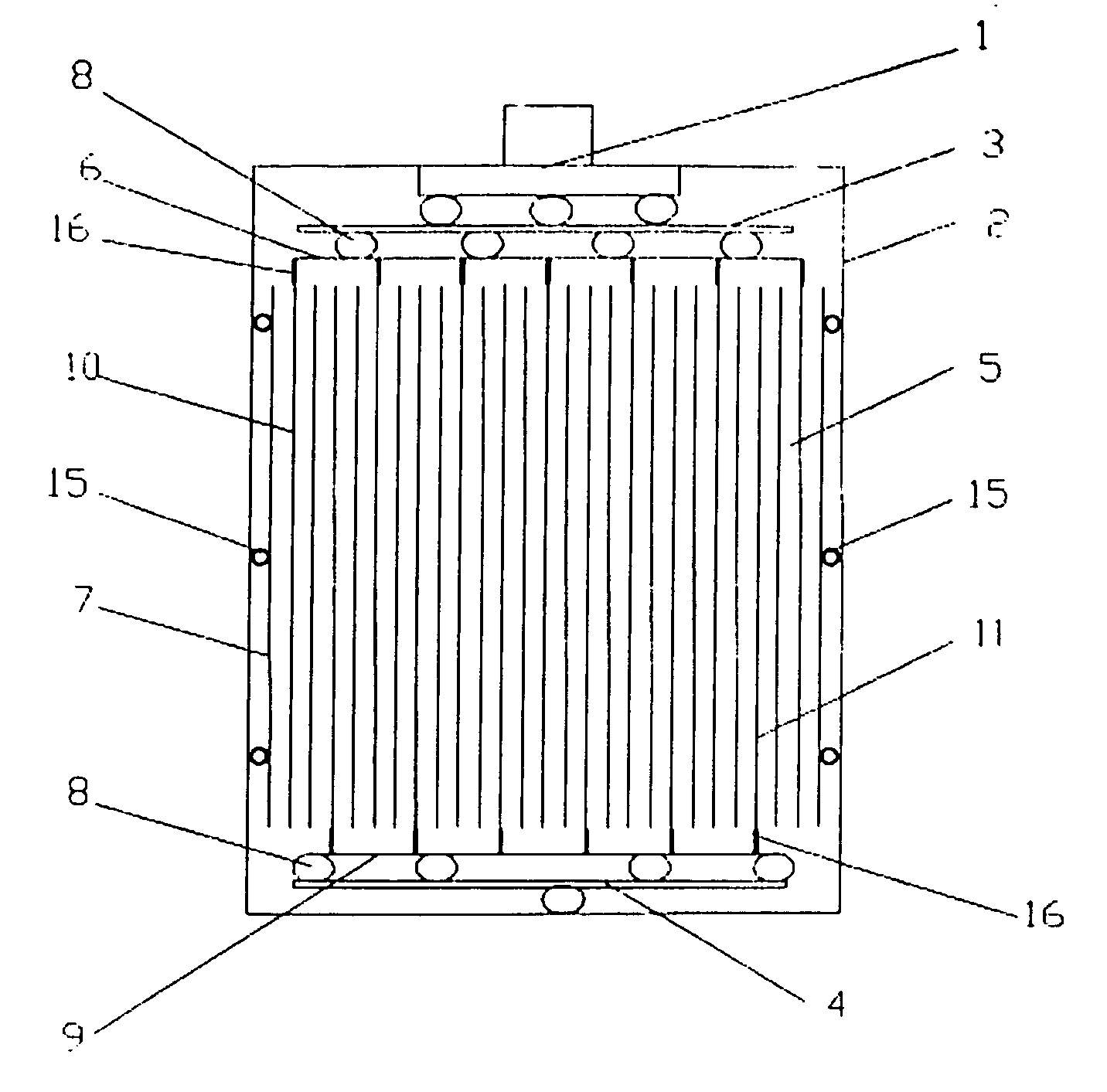

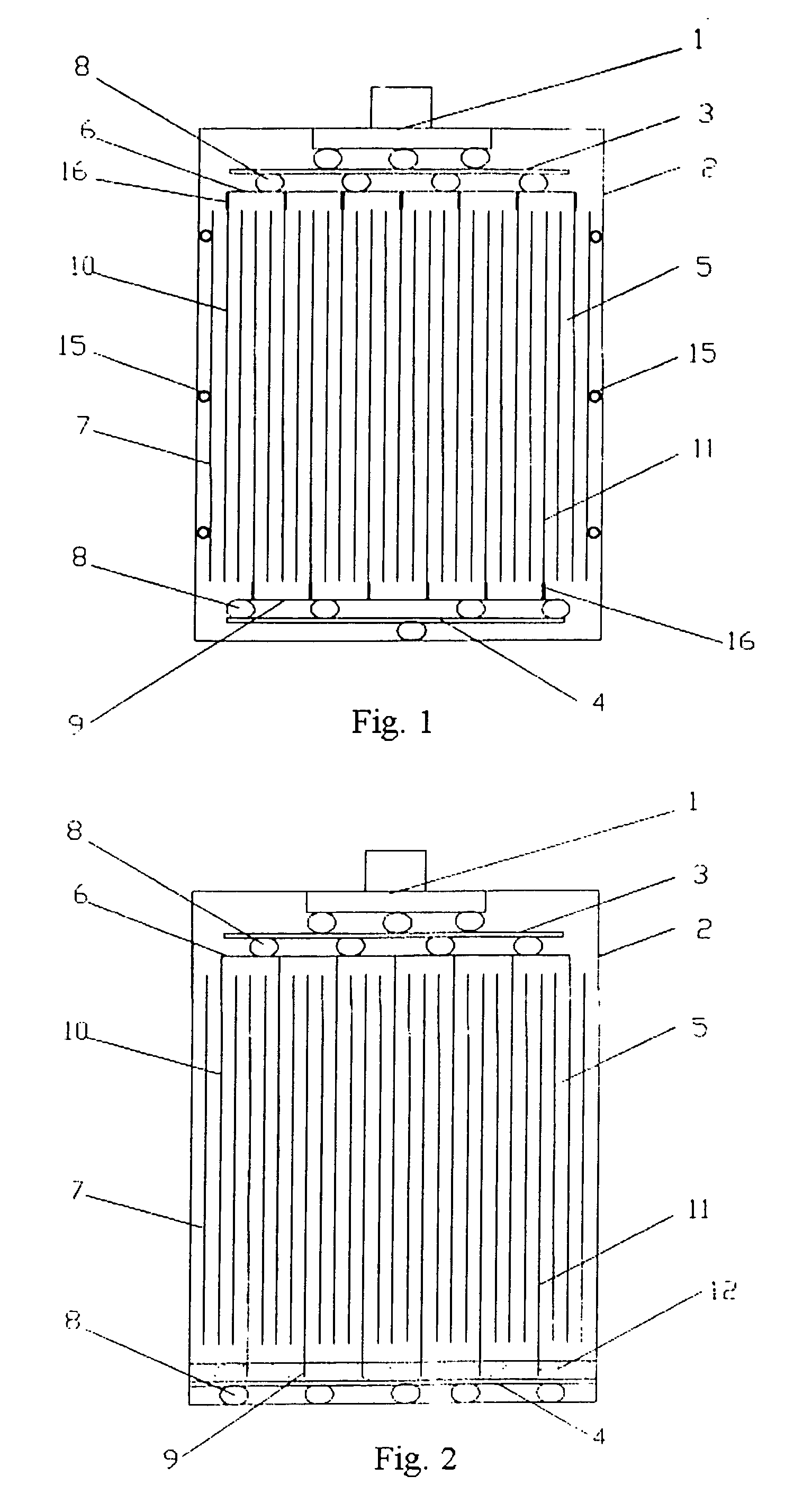

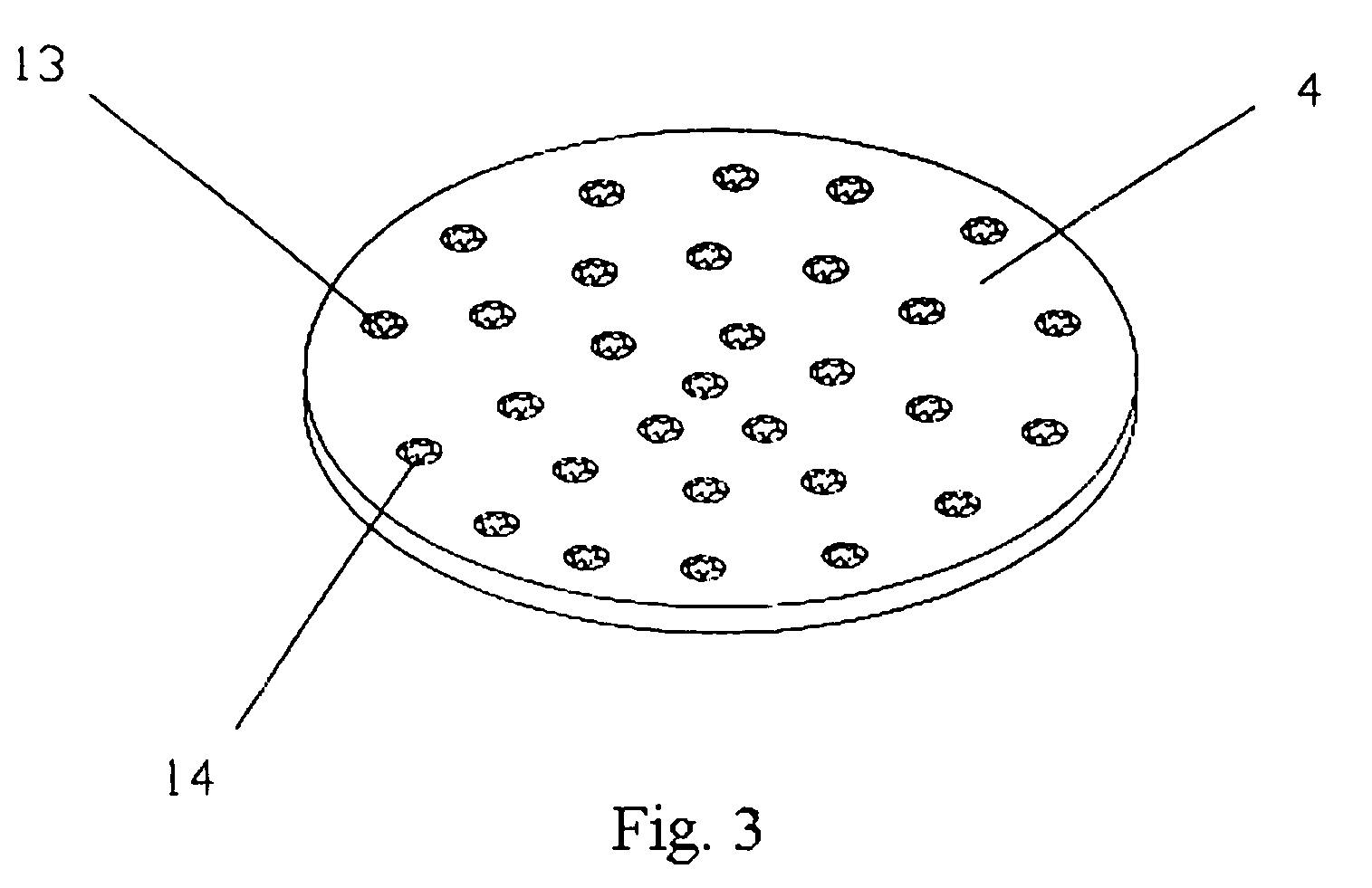

The present invention provides a new-type Ni-MH power battery, which includes a battery vent cap 1, a metal can 2, a positive electrode current collector 3 and a negative electrode current collector 4 inside the can 2, and an electrode assembly 5 generally formed by winding a positive electrode plate 10, a separator 7, and a negative electrode plate 11 having a copper mesh as a substrate. The upper and lower surface of the positive electrode current collector 3 are connected to the lower surface of the battery vent cap 1 and a positive electrode 6 of the electrode assembly 5 via welding spots 8 respectively. The lower surface of the negative electrode current collector 4 is connected to the inner surface of the can 2 via multiple welding spots 8. The upper surface of the negative electrode current collector 4 contacts a negative electrode 9 of the electrode assembly via a layer of metal foam conductor 12, in which the negative electrode 9 is embedded in the metal foam conductor 12. The invention is beneficial to high-current discharge, and has favorable current collecting effect, low cost, large capacity, high power / volume ratio, high energy / volume ratio, and outstanding comprehensive battery performance.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Lithium battery negative electrode current collecting method

InactiveCN109546068AGood current collection effectReduce the proportionFinal product manufactureLi-accumulatorsElectrical batteryEnergy density

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Novel winding type lithium ionic cell and manufacturing method thereof

InactiveCN101499541AIncrease the number ofLarge capacityFinal product manufactureSecondary cellsPower performanceMetal foil

Owner:TIANJIN LISHEN BATTERY

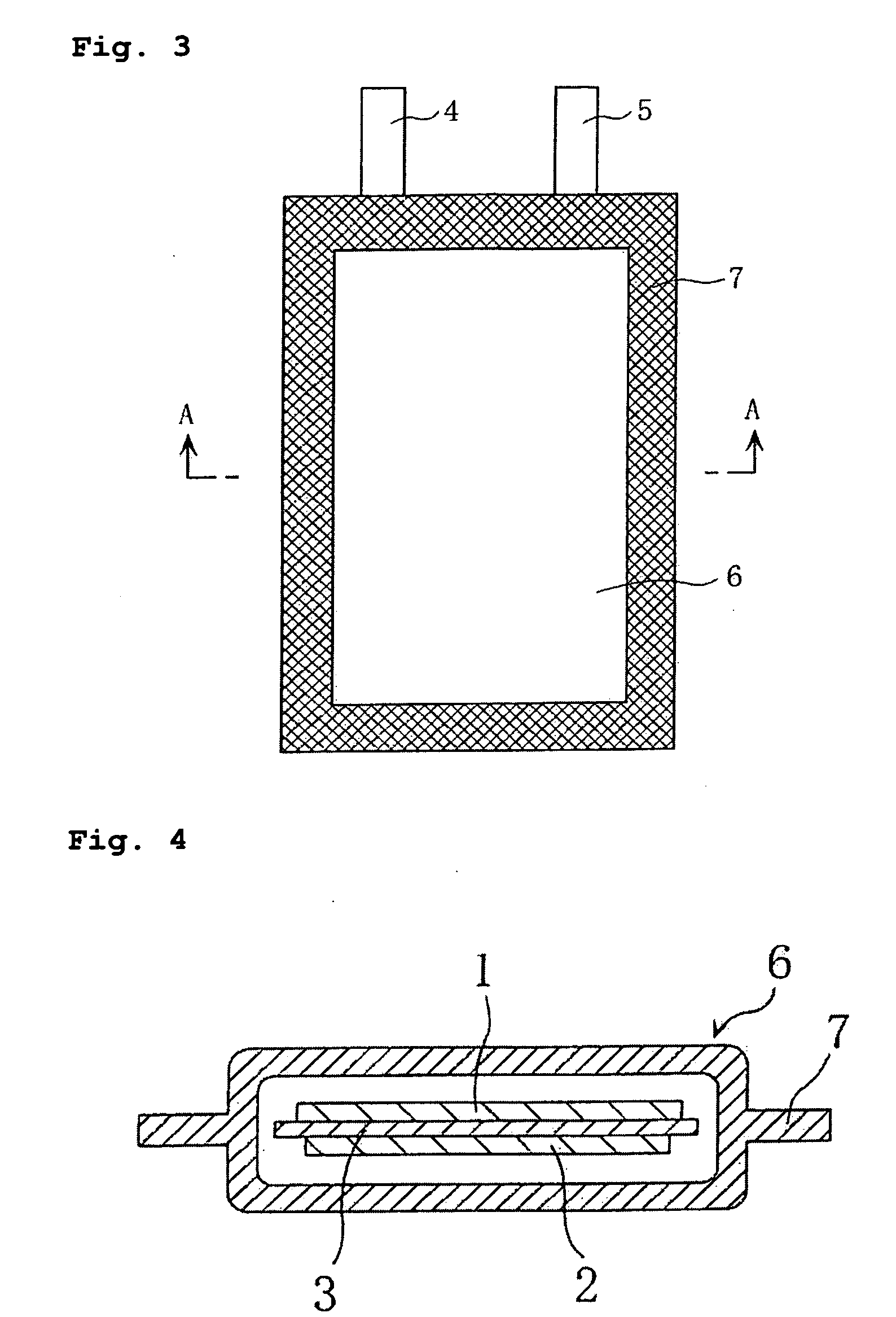

Negative electrode and lithium ion secondary battery

InactiveUS20090311601A1High quality current collecting performanceReduce deformationNon-aqueous electrolyte accumulatorsElectrode carriers/collectorsLithiumEngineering

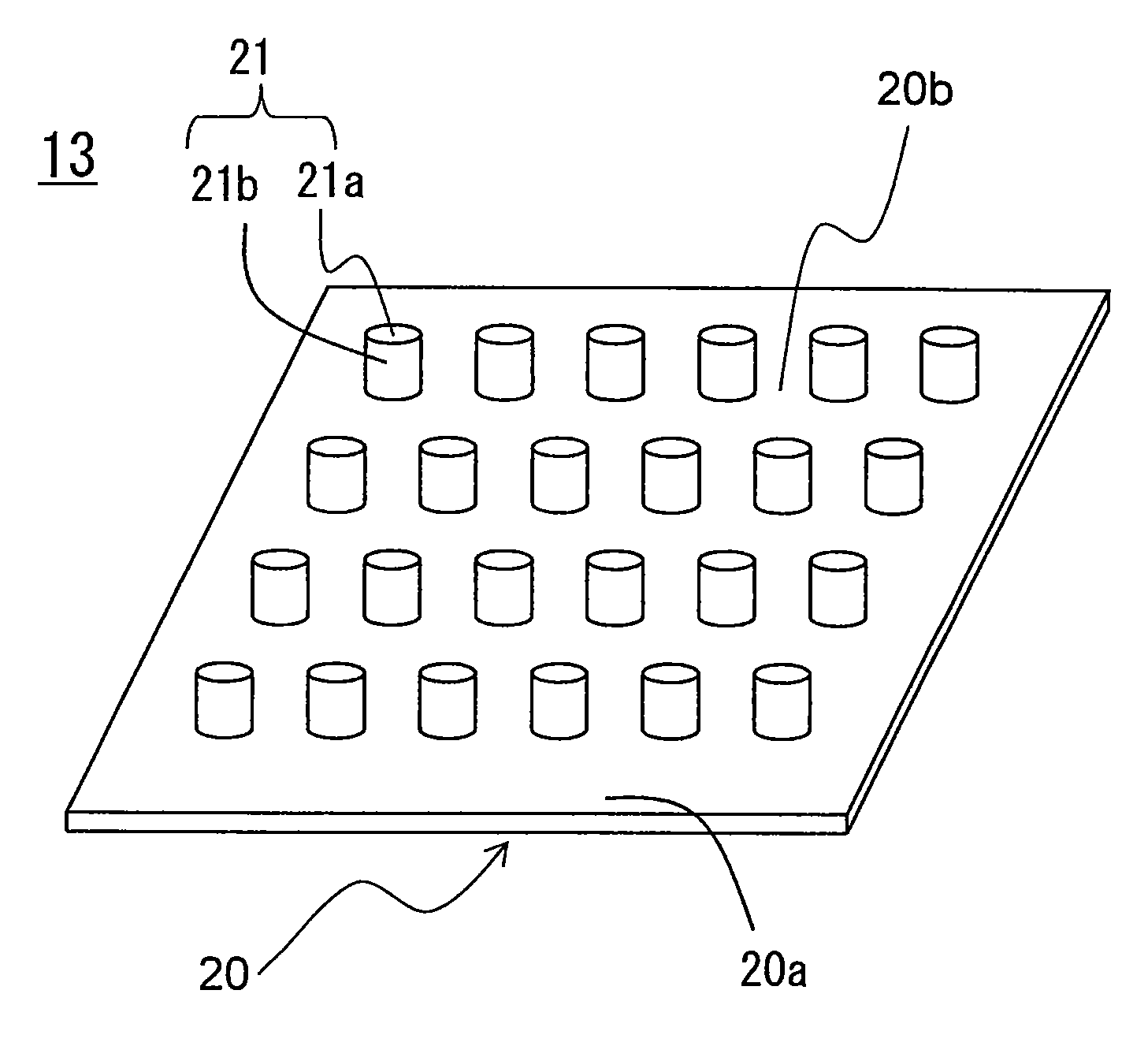

In the negative electrode of the present invention, the negative electrode current collector includes a substrate and a plurality of protrusions, and the protrusions are formed on the surface of the substrate. The negative electrode active material layer includes a columnar active material layer and a stacked active material layer containing an alloy-based negative electrode active material. The columnar active material layer includes one or more columns that extend outwardly from the surface of the protrusions. The stacked active material layer is formed by stacking a thin film in a zigzag manner on the substrate surface between the protrusions. By using this negative electrode, negative electrode deformation, and separation of the negative electrode active material layer from the negative electrode current collector are suppressed, and a lithium ion secondary battery that has excellent charge and discharge cycle performance and output performance can be obtained.

Owner:PANASONIC CORP

Synthetic method of electrode material polyaniline

The invention provides a synthetic method of electrode material polyaniline. The synthetic method comprises the following steps of: (a) dissolving aniline into a perchloric acid solution, and reacting at below 10 DEG C in the presence of ferric sulfate or manganese dioxide, thereby obtaining reaction liquid; and (b) dropping a perchloric acid solution with dissolved ammonium persulfate in batches in the reaction liquid obtained from the step (a), and reacting continuously at below 10 DEG C, thereby obtaining the electrode material polyaniline. According to the invention, ferric sulfate or manganese dioxide as well as ammonium persulfate are taken as oxidizing agents for complex use; perchloric acid is taken as a reaction medium, and the reaction temperature is controlled to be below 10 DEG C; the synthetic technology enables the productivity and capacity of polyaniline during the whole synthetic process to be much high, solves the problems of low productivity and poor capacity of a traditional method, and is suitable for industrial production; and further, according to the invention, activated carbon with excellent conductivity and adsorption is added during the synthetic process, so that a traditional chemical oxidation method is changed into an electrochemical oxidation method, and meanwhile, the utilization ratio of the electrode material is improved.

Owner:WEICHAI POWER CO LTD

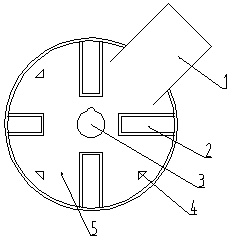

End surface welding current collector of lithium battery

InactiveCN103730624ALower ohmic resistanceImprove performanceCell component detailsPower batteryManufacturing technology

The invention belongs to the technical field of electric power storage equipment, and discloses a component structure of a lithium battery, in particular to an end surface welding current collector of a lithium battery. The current collector comprises a current conduction disc, wherein a center hole is formed in the current conduction disc; more than three welding grooves distributed at equal intervals are radially formed in the surface of the current conduction disc and equally divide the surface of the current conduction disc into more than three quadrants; a conductive pole tab is arranged in one quadrant and integrally connected with the current conduction disc; and liquid guide holes are formed in the rest quadrants. The end surface welding current collector has the advantages that the brand-new end surface welding current collector of the lithium battery is simple in manufacturing technology, has a good current collecting effect during use, greatly reduces ohmic resistance of the battery, greatly improves performances of the lithium battery, and contributes to automatic production of assembly of the high-power and ultrahigh-volume cylindrical lithium power battery at the same time.

Owner:周培荣

Composite film for interconnection of main-grid-free heterojunction solar cell modules, and preparation method thereof

ActiveCN112786727AThe production process is simpleHigh photoelectric conversion powerFinal product manufacturePhotovoltaic energy generationHeterojunctionComposite film

The invention discloses a composite film for interconnection of main-grid-free heterojunction solar cell modules. The composite film comprises composite film bodies and copper wires, each composite film body comprises a base material layer and an adhesive film layer, the adhesive film layer is arranged on the base material layer, and the copper wires are embedded in the adhesive film layer in parallel along the adhesive film layer. A preparation method of the composite film comprises the following steps: arranging and straightening the copper wires, putting a whole piece of one composite film body or cutting the whole piece of the composite film body into a slice film, putting the slice film on a pressing tool heating platform with the adhesive surface facing upwards, pressing the composite film body or the slice film with half of the copper wires, placing another whole piece of the composite film body or cutting the other whole piece of composite film body into a slice film with the adhesive surface facing downwards on the other half of the copper wire, closing the pressing tool, adjusting the pressing pressure and the pressing time, pressing the copper wires and the composite film bodies together to manufacture the required composite film, taking out the composite film, and cooling the composite film. The composite film is simple in manufacturing process, low in cost, diversified in structure and better in use effect, and the production efficiency can be improved.

Owner:无锡市联鹏新能源装备有限公司

Lithium battery

ActiveCN1556554APrevent uncontrollable changesImprove performanceElectrode carriers/collectorsActive material electrodesEngineeringControllability

The invention relates to a lithium battery, which is made up of a shell, a bottom film, metal lithium negative electrode, side film, a positive electrode cover, a upper cover film, flow gathering barrel, sealed pin, connecting nickel band, top cover, a glass insulator, a positive end. the character lies in: one end of the flow gathering pin or the gathering pole is connected to a metal flow gathering ring, forms the multiple flow gathering body to replace the flow gathering barrel, the pin or the pole are inserted into the positive electrode cover. The uncontrollable change of positive electrode size and shape can be avoided when inserting the flow gathering barrel into the positive electrode cover, the uniformity and controllability of the battery can be improved, and the performance is improved.

Owner:EVE ENERGY CO LTD

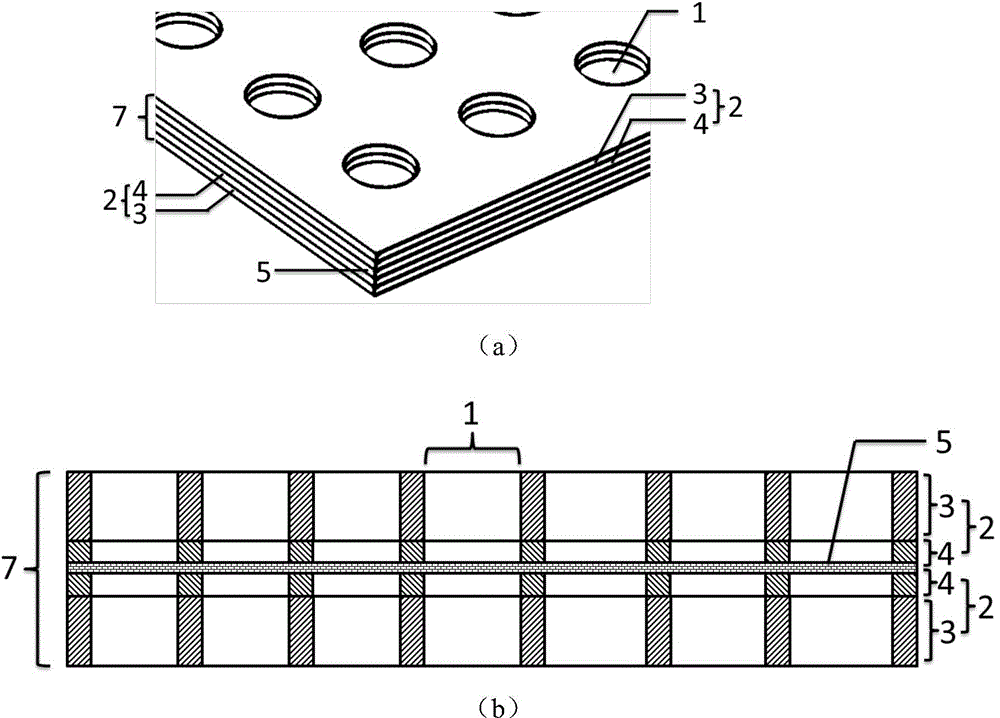

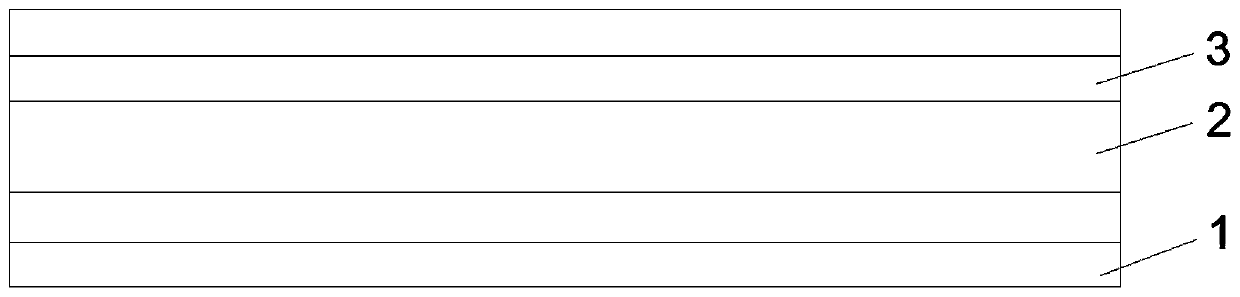

Current collector and lithium ion battery containing current collector

ActiveCN111276701AImprove conductivityImprove the effect of current collectionElectrode carriers/collectorsSecondary cellsElectrolysisMetallic materials

The invention discloses a current collector and a lithium ion battery containing the current collector. The current collector comprises a conductive layer, an insulating layer and a reinforcing layer,wherein the number of the conducting layers is two, an insulating layer is arranged between the two conducting layers, and a reinforcing layer used for reinforcing conductivity is further arranged between the conducting layers and the insulating layer. The conductive layer, the enhancement layer and the insulating layer are compounded by adopting vacuum electroplating or electrolytic electroplating; the conductive layer is made of a metal material, wherein the thickness of the conductive layer is 0.1-1 [mu]m; the insulating layer is made of an organic polymer insulating material, wherein thethickness of the insulating layer is 2-8 microns; the enhancement layer is made of at least one of a carbon-based conductive material and a nano conductive ceramic material, wherein the thickness of the enhancement layer is 0.1-1 micron. The insulating layer is arranged between the two conductive layers, and the reinforcing layer is arranged between the conductive layers and the insulating layer,so the weight of the current collector is reduced, the conductivity of the current collector is ensured, the toughness of the current collector can be improved, and the consistency and safety of products are improved.

Owner:荆门市诺维英新材料科技有限公司

Air cathode for zinc air cell

ActiveCN104716331AImprove discharge performanceFacilitated DiffusionFuel and primary cellsCell electrodesAir cellEngineering

An air cathode for a zinc air cell comprises a first electrode and a second electrode which are sequentially superposed in a layered manner; the first electrode comprises a hydrophobic breathable layer, a first current collector and a first catalytic layer; and the second electrode comprises a second current collector and a second catalytic layer. Compared with cathodes in the prior art, the air cathode for the zinc air cell, adopting the double current collector layer structure has the advantages of substantial improvement of the current collection effect, facilitation of formation of a certain aperture structure, increase of the area of a three-phase interface, convenient oxygen diffusion, and improvement of the discharge performance of the air electrode.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

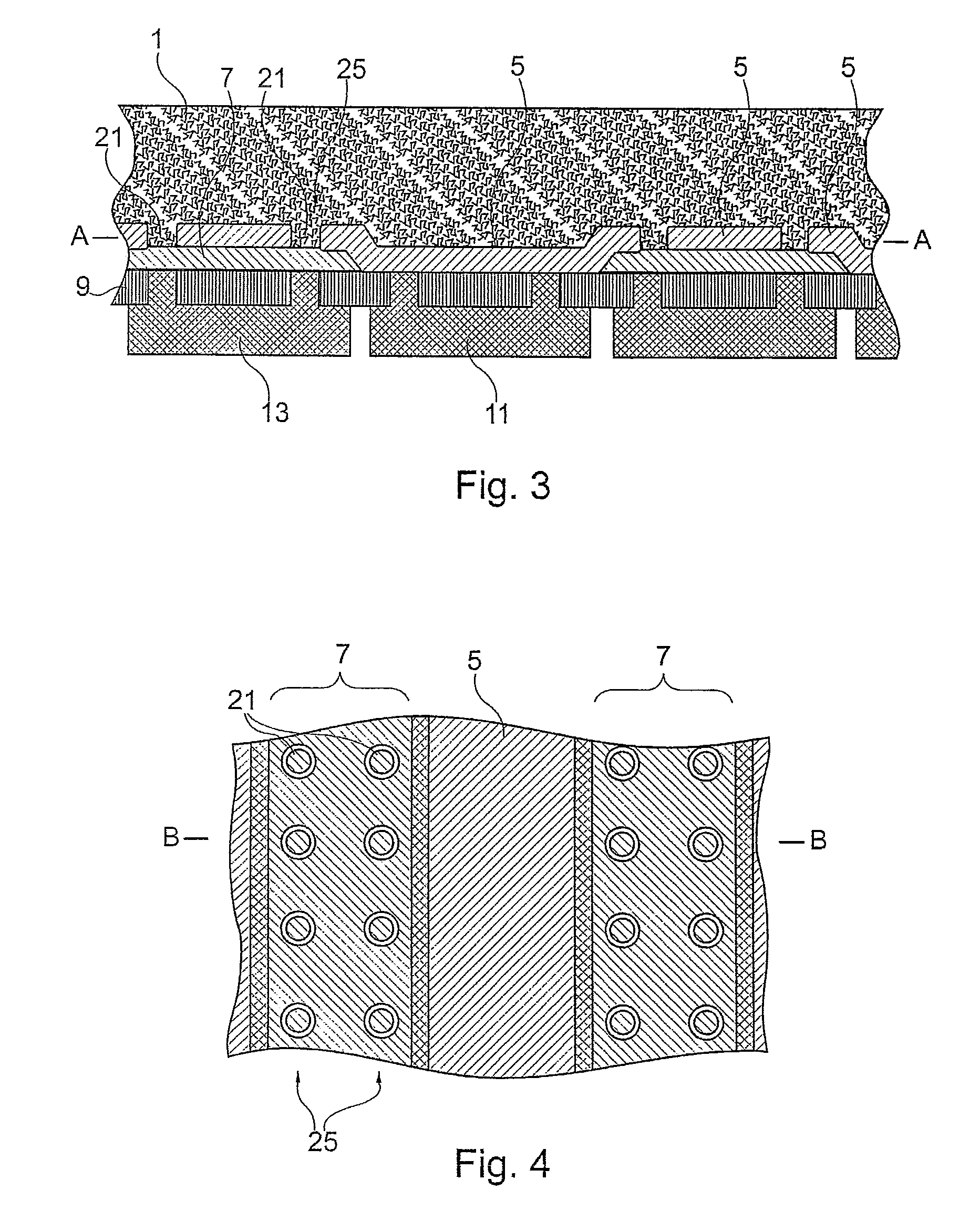

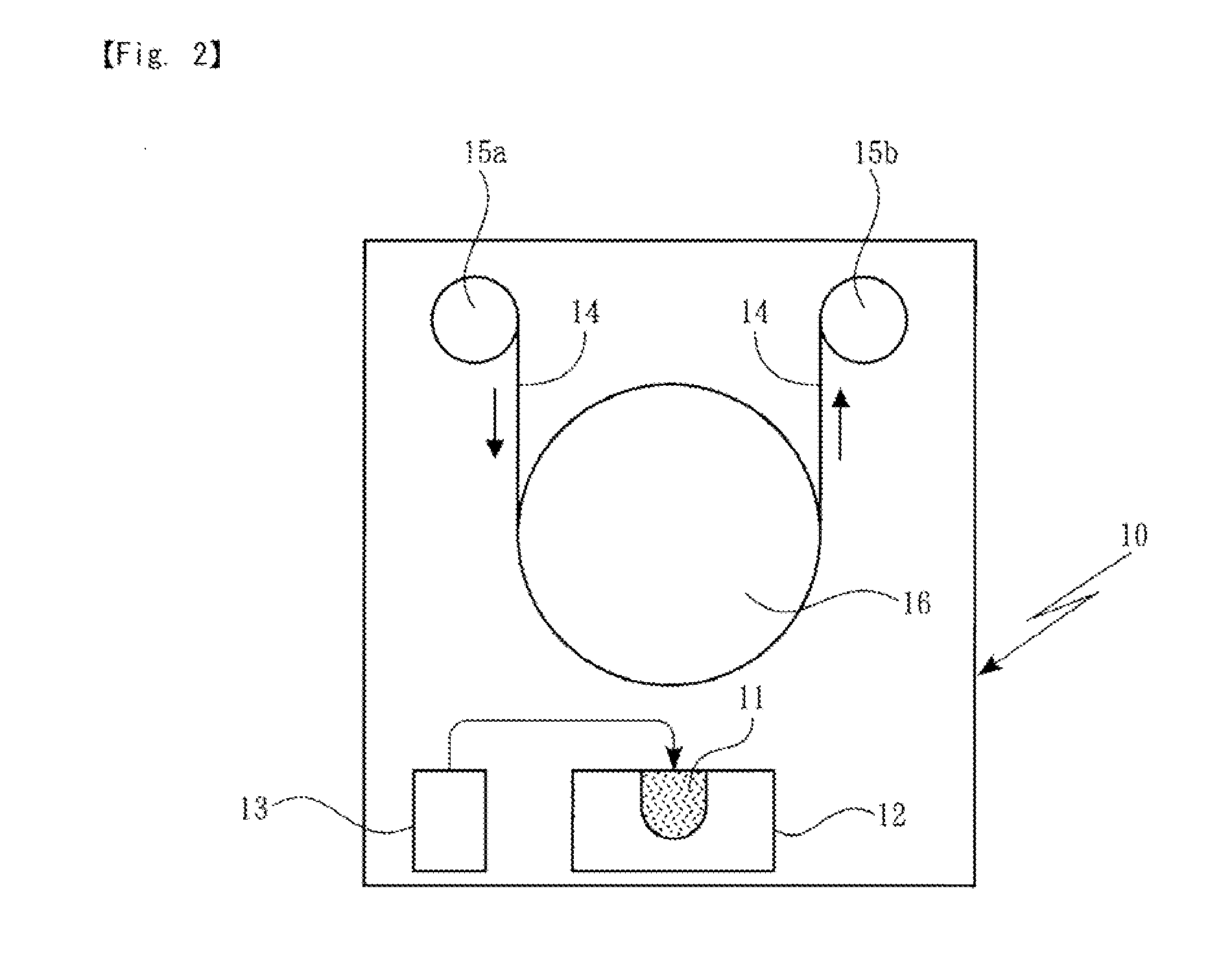

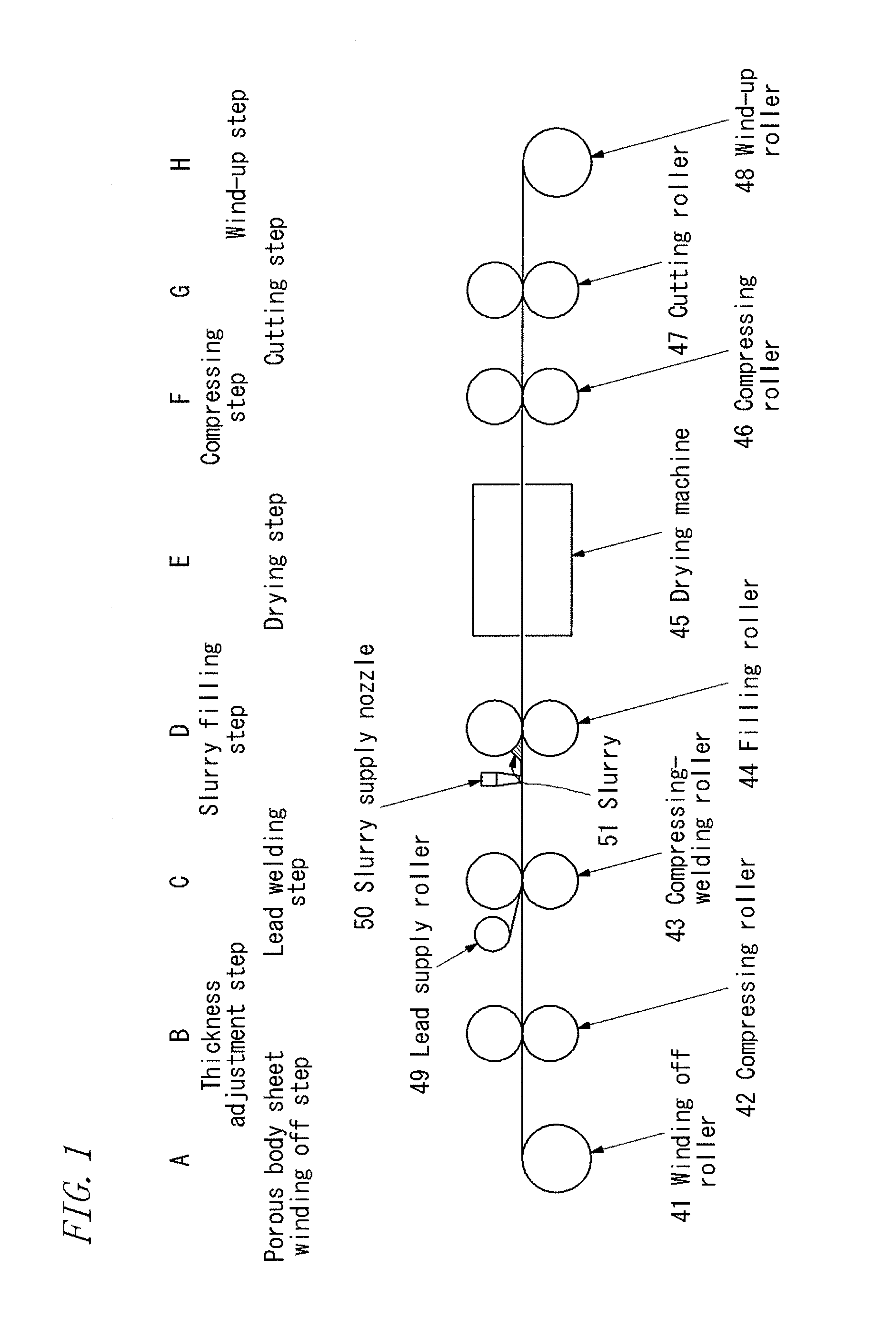

Method for Manufacturing Metal-Made Three-Dimensional Substrate for Electrodes, Metal-Made Three-Dimensional Substrate for Electrodes and Electrochemical Applied Products Using the Same

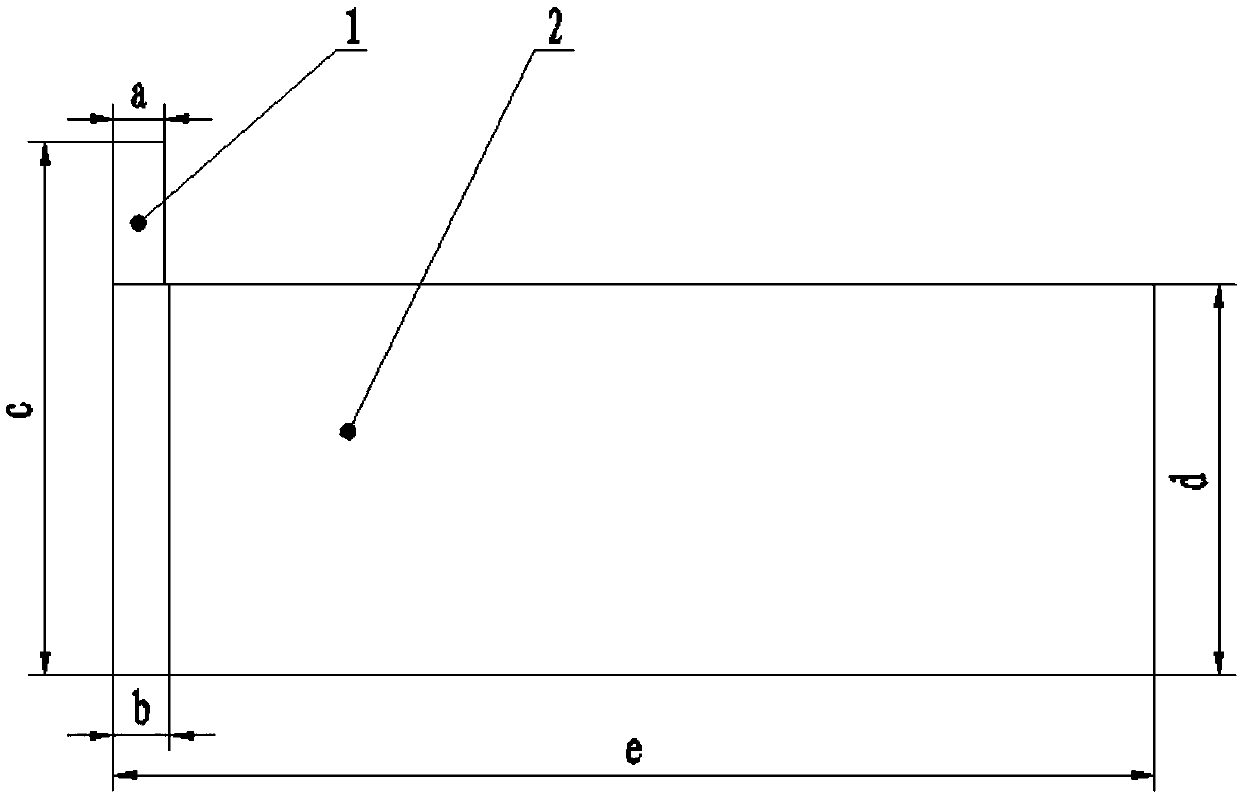

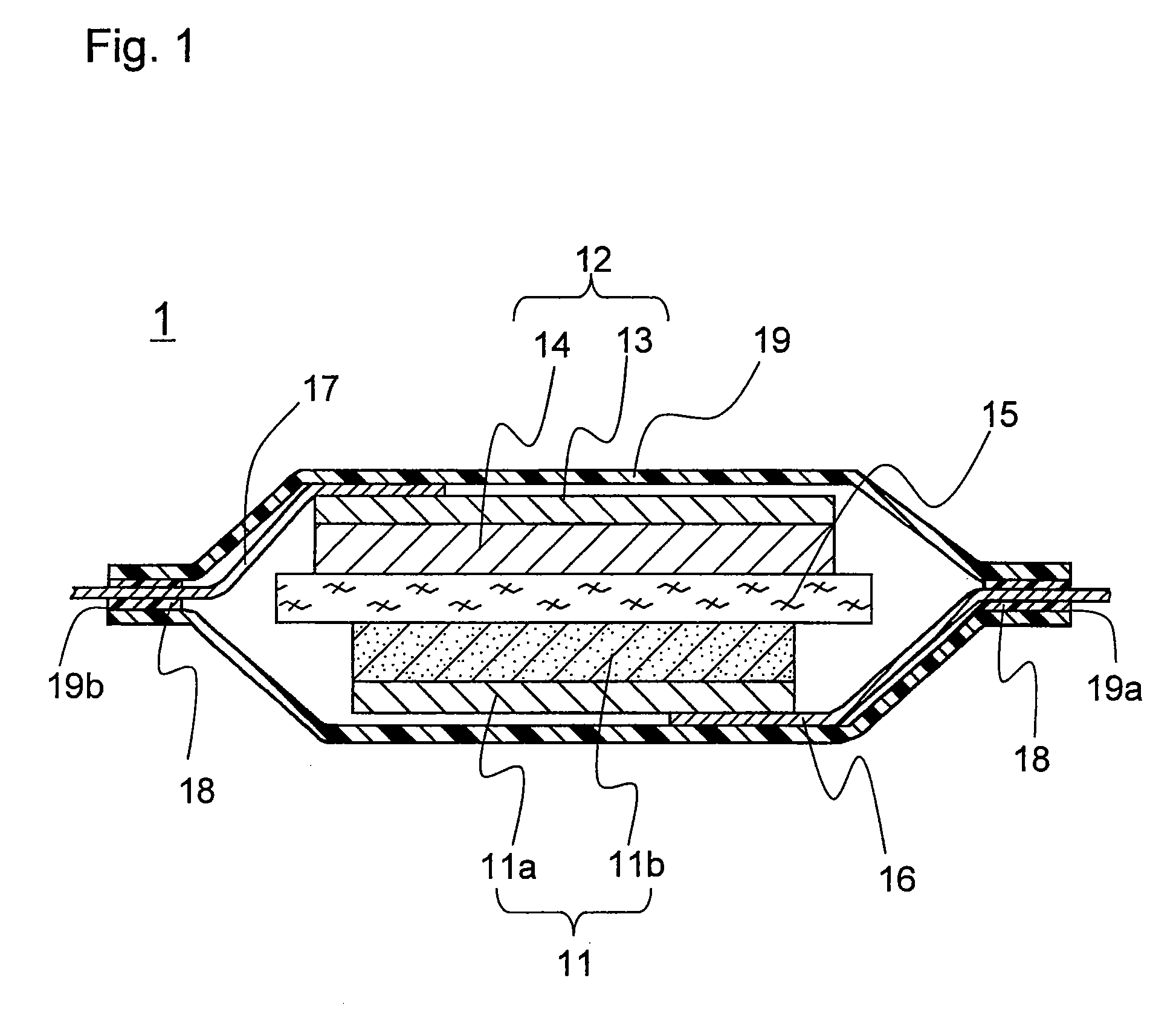

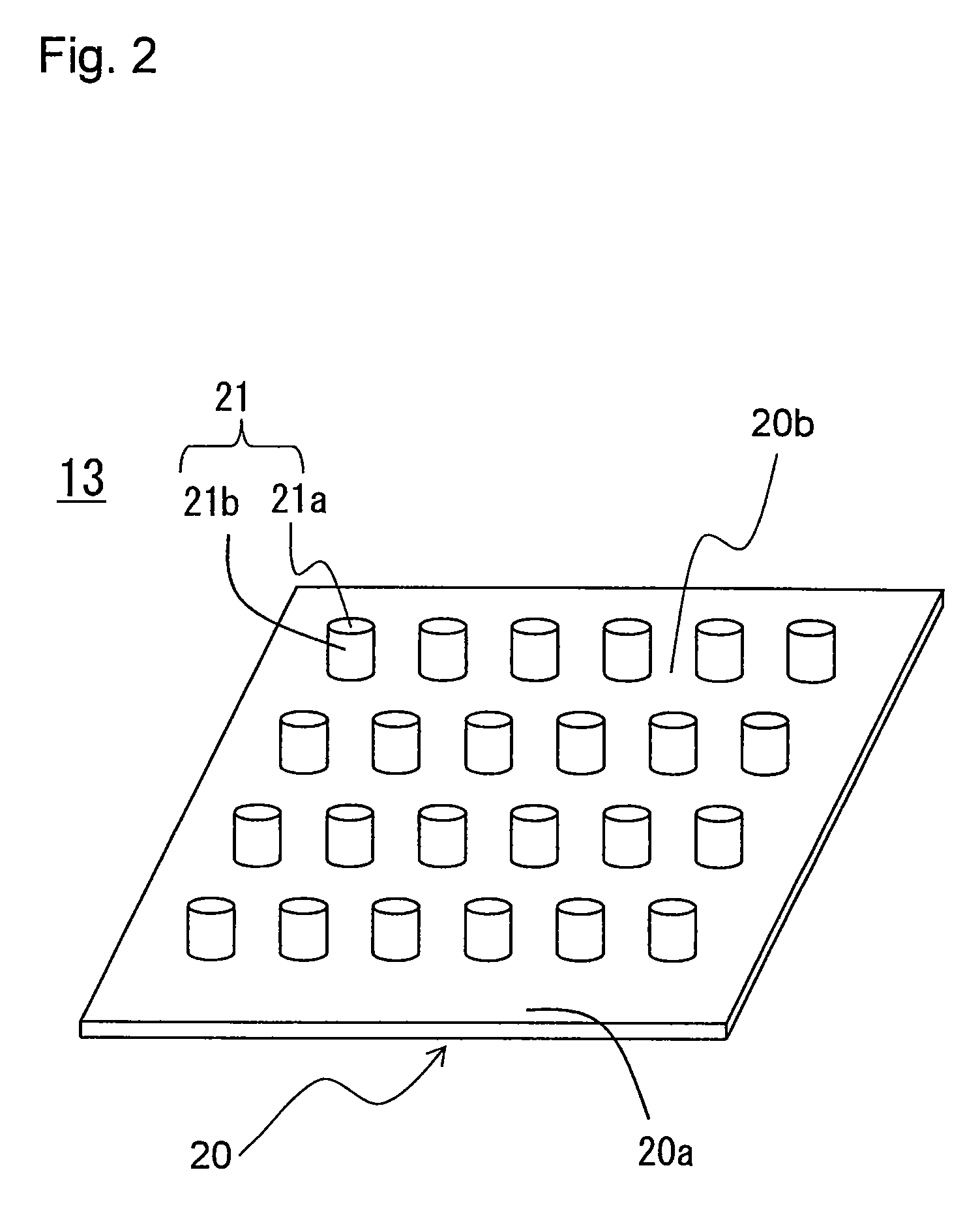

ActiveUS20120100432A1Improve the effect of current collectionImprove rate discharge performanceFinal product manufactureElectrode carriers/collectorsGrid patternMetal foil

In a method for manufacturing a metal-made three-dimensional substrate, a metal foil is passed between a pair of rollers 21 and 22 . Each surface S of a pair of the rollers 21 and 22 is provided with protrusion portions 23 arranged in a grid pattern, and the protrusion portions 23 are arranged so that protrusions 23 of the one roller 22 are oriented toward the center 27 of a virtual quadrangle having four adjacent protrusion portions 23a to 23d of the other roller 21 as the apices.

Owner:JAPAN CAPACITOR IND

Foam nickel, and method for fabricating the foam nickel, and battery of using the foam nickel

InactiveCN1797826ALower internal resistanceIncrease roughnessElectrode carriers/collectorsInternal resistanceCopper

The foam nickel possesses mesh structure in multiple layers formed from multilaminar mesh ribs. The mesh rib also contains metal copper in granular. The method for preparing foam nickel includes step of making foam of polyurethane conducting, step of electrodeposit, and heat treatment step. In step of electrodeposit, copper powder in added to electrodeposit tank liquor. Surface of the foam nickel possesses higher roughness to enhance effect of flow concentration of polar plates, as well as to raise utilization ratio of active material in battery. Battery made from the disclosed foam nickel possesses longer service life, high capacitance, and lower internal resistance.

Owner:BYD CO LTD

Flexible film photovoltaic solar cell component and manufacturing method thereof

InactiveCN106784082AClose contactReliable contactPhotovoltaic energy generationSemiconductor devicesSemiconductor materialsOhmic contact

The invention provides a film photovoltaic solar cell component and a manufacturing method thereof. A flexible solar cell comprises at least two flexible photovoltaic solar cell units. Each of the flexible photovoltaic solar cell units comprises a flexible battery substrate, a semiconductor material layer and a light receiving layer which are orderly stacked. The light receiving layer is provided with a conductive bus bar. The series connection mode of the two adjacent flexible photovoltaic solar cell units is that ohmic connection is formed between the conductive bus bar of one flexible photovoltaic solar cell conductive bus bar and the substrate of the other flexible photovoltaic solar cell to realize series connection. The invention also discloses a manufacturing method of an interconnected type flexible solar cell. The process operation is simple, ohmic contact is easy to form, and the safety performance is good.

Owner:BEIJING SIFANG CRENERGEY OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com